Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Plate Mounting and Registration interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Plate Mounting and Registration Interview

Q 1. Explain the process of plate mounting on a Heidelberg press.

Plate mounting on a Heidelberg press involves precisely attaching a printing plate to a plate cylinder. Think of it like carefully placing a sticker onto a perfectly round, rotating surface. The process ensures the plate is securely held and correctly aligned for printing. It typically involves these steps:

- Plate Preparation: The plate is inspected for any damage or imperfections. Any burrs or debris are carefully removed.

- Plate Positioning: The plate is positioned on the plate cylinder using registration marks (small, precise marks on the plate and cylinder). These marks are crucial for accurate alignment.

- Securing the Plate: The plate is secured to the cylinder using a mounting tape or other clamping mechanism. This step requires careful attention to ensure even pressure and avoid wrinkles or air bubbles.

- Verification: After mounting, a visual check and often a test print is conducted to confirm proper registration and secure attachment.

Improper mounting can lead to misregistration, causing blurry or misaligned prints, and potentially damaging the press. Heidelberg presses offer sophisticated clamping systems to simplify and improve the accuracy of this crucial step.

Q 2. Describe different types of printing plates used in offset printing.

Offset printing uses various plate types, each with its advantages and disadvantages:

- Metal Plates: Traditionally made from aluminum, these are durable and provide high print quality. They’re frequently used for long print runs.

- Polymer Plates: These flexible plates are made from photopolymer material. They offer a cost-effective solution, particularly for shorter runs and faster turnaround times. They’re also easier to handle and less prone to damage.

- Surface Plates: These plates have a special coating that allows for quicker processing and higher print speeds. Their lifespan might be shorter compared to traditional metal plates.

- Waterless Plates: These plates eliminate the need for dampening solution, offering environmental advantages and often improved ink transfer.

The choice of plate type depends on factors such as print volume, budget, desired print quality, and environmental considerations. For example, a large-scale commercial printer might prefer metal plates for longevity, while a small print shop might opt for more cost-effective polymer plates.

Q 3. How do you ensure proper plate registration during the mounting process?

Ensuring proper plate registration is paramount for accurate printing. It’s a multi-step process that begins even before the plate reaches the press:

- Accurate Pre-Press Workflow: Precise imposition and platemaking are crucial. Any errors here will carry through to the press.

- Using Registration Marks: These marks (usually crosshairs or other geometric shapes) are essential for aligning the plate with the cylinder. They guide the mounting process.

- Precise Mounting Techniques: Careful adherence to the manufacturer’s instructions for plate mounting is crucial. Even pressure and absence of wrinkles is essential.

- Verification Tools: Micrometers, gauges, and test prints are used to verify registration before the run starts. This avoids costly errors later.

- Heidelberg specific features: Heidelberg presses often have automated registration systems that further ensure accuracy and assist in minimizing human error.

Think of it like aligning puzzle pieces: if even one piece is slightly off, the entire picture is distorted. Precise registration ensures crisp and accurately positioned images and text on the printed material.

Q 4. What are the common causes of poor plate registration and how do you troubleshoot them?

Poor plate registration can stem from various sources:

- Incorrect Plate Mounting: Uneven pressure, wrinkles, or air bubbles under the plate can cause misalignment.

- Damaged or Worn Plates: Scratches or damage to the plate surface can affect registration.

- Improper Cylinder Adjustment: Incorrect settings on the press itself can contribute to misalignment.

- Inaccurate Imposition: Errors in the pre-press stage, like incorrect imposition of the images onto the plates, can cause misregistration.

- Wear and tear of mechanical components on the press: Over time, the mechanical components of the press might wear down, resulting in poor alignment.

Troubleshooting involves systematically checking each of these areas. Start with a visual inspection of the plate and its mounting, then move to checking the press settings and finally review the pre-press steps. A test print is crucial at each stage to verify the correction.

Q 5. Explain the importance of proper plate cleaning and storage.

Proper plate cleaning and storage are vital for extending the life of plates and maintaining print quality. Dirty plates can lead to poor ink transfer and misregistration. Proper storage prevents damage and degradation.

- Cleaning: Plates should be cleaned thoroughly after each use with appropriate cleaning solutions to remove ink and debris. The choice of cleaner depends on the plate type.

- Storage: Plates should be stored in a clean, dry, and dark environment to protect them from damage, dust, and UV light. Avoid storing plates in direct sunlight or extreme temperatures.

- Protective Sleeves: Storing plates in protective sleeves further minimizes the risk of scratching and contamination.

Imagine leaving your expensive camera lens exposed to dust and dirt – it would quickly become unusable. Similarly, neglecting plate cleaning and storage leads to premature plate wear and compromises print quality.

Q 6. What safety precautions do you follow when handling printing plates?

Safety is paramount when handling printing plates:

- Wear Appropriate PPE: Gloves should always be worn to protect hands from chemicals and sharp edges. Eye protection is also recommended, especially when cleaning plates.

- Proper Handling: Plates should be handled carefully to avoid scratches or bending. Avoid dropping or mishandling them.

- Safe Disposal: Used plates and cleaning solutions should be disposed of according to local regulations and environmental guidelines.

- Chemical Safety: Always follow the safety data sheets (SDS) for any chemicals used in plate cleaning and preparation.

Neglecting safety precautions can lead to injuries, environmental damage, and costly mistakes. Always prioritize safety in every step of the process.

Q 7. How do you identify and correct misregistration during a printing run?

Identifying and correcting misregistration during a printing run requires a methodical approach:

- Visual Inspection: Carefully examine the printed sheets for misalignment of images or text.

- Measuring Misregistration: Use a measuring tool to quantify the amount of misregistration.

- Press Adjustments: Minor adjustments to the press’s registration controls can often correct small misalignments. Heidelberg presses provide precise controls for such adjustments.

- Plate Re-Mounting: If the misregistration is significant, the plate may need to be re-mounted, ensuring proper alignment with the registration marks.

- Re-imposition and new plate creation: In case of major issues, a review of the pre-press process and even the creation of a new plate might be necessary.

Misregistration can be a costly problem, so prompt identification and correction is vital. A systematic approach, combined with the ability to use the press controls and to diagnose the issue will minimize production downtime and waste.

Q 8. Describe your experience with different plate mounting techniques (e.g., manual, automated).

Plate mounting, the process of securely attaching a printing plate to a printing cylinder, can be done manually or automatically. Manual mounting, while requiring more skill and time, allows for greater control and is often used for smaller print runs or specialized plates. This involves carefully positioning the plate on the cylinder using tools like a mounting tape and ensuring perfect alignment. Automated plate mounting, common in high-volume printing, uses sophisticated machinery to precisely and quickly attach plates, minimizing human error and significantly increasing efficiency. I’ve extensive experience with both methods. For example, in a previous role, I regularly handled manual mounting for intricate, high-value projects demanding meticulous attention to detail. In contrast, at another company, I oversaw the operation and maintenance of an automated plate mounting system, ensuring optimal throughput and minimizing downtime.

The choice depends heavily on factors such as print volume, plate type, budget, and the overall workflow. For short runs with specific needs, manual mounting offers flexibility. For large print runs demanding speed and consistency, automated systems are essential.

Q 9. What are the key differences between film and digital platemaking?

The key difference between film and digital platemaking lies in the imaging process. Film-based platemaking uses photosensitive plates exposed to film negatives generated from digital artwork. This involves chemical processing and requires a darkroom. Digital platemaking, on the other hand, directly images the plate from digital files using a computer-to-plate (CTP) system. This eliminates the need for film, reducing processing time, chemical waste, and overall cost.

- Film: More labor-intensive, higher chemical consumption, requires darkroom facilities, potentially lower resolution.

- Digital: More efficient, environmentally friendly, higher potential resolution, faster turnaround.

I’ve witnessed firsthand the transition from film to digital in the industry. The move to digital resulted in a noticeable improvement in efficiency, improved image quality, and reduced environmental impact at my previous workplace. It was a considerable investment, but the long-term benefits greatly outweighed the initial costs.

Q 10. How do you assess the quality of a mounted plate?

Assessing the quality of a mounted plate involves several crucial checks. Firstly, I visually inspect the plate for any physical damage, such as scratches, blemishes, or inconsistencies in the image area. Secondly, I verify the plate’s registration, ensuring precise alignment with the other color plates. This is often done using a registration target or a specialized measuring tool. Thirdly, I check the plate’s mounting for secure adhesion to the cylinder, ensuring there are no gaps or loose areas which could cause printing issues. Finally, a test print is crucial to confirm image quality, sharpness, and color accuracy. Any defects detected at this stage necessitate immediate corrective action.

For instance, if I notice a slight misregistration during visual inspection, I might need to re-mount the plate or adjust the cylinder settings. If a test print reveals a blurry image, this could point to problems with the plate itself or with the printing press settings.

Q 11. Explain the concept of color registration and its importance in printing.

Color registration refers to the precise alignment of multiple color plates (cyan, magenta, yellow, and black – CMYK) during printing to create a sharp and accurate image. Imagine each color plate as a transparent sheet with a part of the final image printed on it. Perfect registration ensures that these ‘sheets’ perfectly overlay each other, producing a crisp, well-defined image. Imperfect registration leads to blurry images, misaligned colors, and significant aesthetic flaws. Think of it like building a Lego castle – each brick needs to be perfectly aligned to build the structure correctly; otherwise, the entire castle would look messy and distorted. In printing, inaccurate registration renders the final product unacceptable.

The importance of color registration is paramount to achieving high-quality prints and meeting client expectations. Poor registration reflects poorly on print quality and can result in reprints or rejected jobs. For example, a misregistered print job may require reprinting, leading to increased costs and delays.

Q 12. What tools and equipment are commonly used in plate mounting and registration?

The tools and equipment used in plate mounting and registration vary depending on the scale of the operation and the level of automation. Common tools include:

- Plate Mounting Tape: Used to securely adhere the plate to the cylinder.

- Mounting tools: Spatulas, rollers, and positioning tools to aid in precise plate placement.

- Registration Targets: Printed guides used to check the alignment of plates.

- Measuring Devices: Micrometers and gauges used to ensure precise alignment.

- Automated Plate Mounting Systems: Sophisticated machines that automate the entire mounting process.

- Plate Processors (for film-based systems): Machines for developing and processing photosensitive plates.

- CTP (Computer-to-plate) system (for digital systems): System that directly creates plates from digital files.

In my experience, having the right tools at hand is crucial for efficiency and accuracy. Investing in high-quality tools not only improves the precision of the process but also reduces the risk of errors.

Q 13. How do you handle damaged or defective plates?

Handling damaged or defective plates requires careful assessment and action. Firstly, I would thoroughly inspect the plate to identify the type and extent of the damage. Scratches or minor blemishes might be acceptable depending on their location and size; however, significant damage rendering the image unusable necessitates discarding the plate. Defective plates, exhibiting imaging errors or inconsistent color density, are usually replaced. Depending on the severity and cause, the defective plate may need further investigation to prevent future recurrences. This might involve checking the plate-making process, the CTP system settings, or even the press conditions.

For example, a scratch on a plate could be tolerated if it’s in a non-image area, but a scratch through important text would necessitate replacement. Similarly, a plate with a consistent color cast points towards problems in plate exposure or processing.

Q 14. How do you maintain accurate color consistency throughout a print job?

Maintaining accurate color consistency throughout a print job involves several strategies. Firstly, a calibrated color management system is critical, encompassing everything from the design software to the CTP system and the printing press. This ensures that the colors are accurately represented throughout the entire workflow. Secondly, regular color checks are important during the printing process to verify consistency. This includes printing color bars and comparing them to the original artwork and standards. Thirdly, using color standards and proofing materials that are consistently calibrated helps to validate the print against accurate expectations. Lastly, maintaining the printing press and its components is crucial, including regular cleaning and calibration of the ink delivery system. Any deviation should trigger immediate corrective action.

Without consistent color management, you risk producing batches of prints with different color profiles, potentially leading to rejects and costly reprints. A rigorous and proactive color management approach throughout the entire printing process is absolutely vital for a successful outcome.

Q 15. Describe your experience with different types of printing presses.

My experience spans various printing presses, including sheetfed offset, web offset, and digital printing systems. Sheetfed offset presses, like Heidelberg and Komori, are my primary focus, involving meticulous plate mounting and registration for high-quality, short-to-medium run jobs. I’m also familiar with the challenges of web offset presses, where maintaining accurate registration across a continuous web of paper is crucial for high-speed production. Finally, my work with digital presses, like Xerox and HP Indigo, has provided valuable insight into the differences in plate-less workflows and the importance of precise color calibration for accurate registration in this fast-paced environment. Each press type presents unique challenges; for example, sheetfed requires precise plate mounting to avoid slippage, while web offset demands consistent tension control to prevent registration issues. I adapt my techniques based on the specific capabilities and limitations of each machine.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with pre-flighting files and checking for potential registration issues?

Preflighting is an essential part of my workflow. I use software like PitStop Pro and Acrobat to meticulously check PDF files for potential registration issues before they even reach the press. This includes verifying that color separations are accurately aligned, checking for bleed issues that could cause misregistration, and scrutinizing image resolution and file sizes to ensure optimal print quality. I look for things like incorrect crop marks, missing or misplaced bleeds, and inconsistent color profiles. For instance, I once caught a file with a slight offset in the crop marks, which if not corrected, would have resulted in a significant misregistration on the printed product. Catching such errors pre-flight saves time, reduces waste, and prevents costly reprints.

Q 17. What is the role of the imposition process in achieving accurate registration?

Imposition is the critical process of arranging pages on a printing sheet to optimize the use of paper and ensure accurate registration. For example, in a four-color job, the imposition software positions the plates (Cyan, Magenta, Yellow, Black) to ensure perfect alignment during printing. Without proper imposition, even with perfect plate mounting, the colors won’t align correctly. Accurate imposition uses specific software and involves considering factors like sheet size, number of pages, and the printing press’s capabilities. This can involve techniques like ‘gang printing’ for multiple jobs and different imposition schemes depending on the sheet size and number of pages.

Q 18. How do you use a densitometer or other quality control instruments in registration verification?

A densitometer is a vital tool for verifying registration. I use it to measure the density of each color at specific points across the printed sheet, ensuring consistent color values throughout the job. Differences in density between colors, especially at the edges of the print, can indicate registration issues. Beyond the densitometer, I also utilize a magnifying glass for close visual inspection, looking for discrepancies in color alignment. If color registration is consistently off by a small amount, adjustments to the press itself may be necessary to realign the print heads or cylinders. These visual and instrumental checks provide objective data to confirm registration accuracy.

Q 19. What are the common causes of ghosting or slurring in print, and how can plate mounting/registration affect it?

Ghosting, or slurring, appears as a faint, blurry image of the previous print on the next sheet. This is often caused by issues such as incorrect ink-water balance, improper press dampening, or insufficient drying time. Plate mounting and registration, while not the direct cause, can exacerbate ghosting. If plates are improperly mounted, slight misalignment can create overlapping images leading to a more noticeable ghosting effect. Furthermore, improper registration can emphasize any existing ghosting from other factors because the misaligned colors will further blur the overall image. Addressing the root cause (ink-water balance, etc.) is crucial, but proper plate mounting and registration help minimize the visibility of these issues.

Q 20. How do you deal with issues of dot gain or dot loss affecting registration?

Dot gain (enlarged dots) and dot loss (reduced dots) are common printing problems that affect registration. Dot gain can cause colors to appear darker and muddy, especially if not consistent across colors. This can make misregistration more noticeable, particularly where different colors meet. Dot loss, on the other hand, can lead to pale or faded colors, creating different color overlaps than intended. To mitigate these, I work closely with pre-press to adjust the dot gain compensation in the printing profile. Careful monitoring of ink-water balance and paper characteristics are critical for minimizing dot gain or loss which directly impacts registration accuracy.

Q 21. How would you address a situation where plates are repeatedly misregistering?

Repeated misregistration points to a systematic problem, not just a random error. My troubleshooting approach is systematic:

- Check Plate Mounting: Verify that plates are securely mounted, free of debris, and properly aligned on the cylinders. Improper clamping or dirty plates are common culprits.

- Inspect Press Condition: Examine the press for any mechanical issues, like worn rollers, misaligned cylinders, or faulty registration mechanisms.

- Review Imposition: Double-check the imposition settings to ensure correct page arrangement. Errors here can cause consistent misregistration.

- Analyze Print Data: Evaluate the print file for any inherent registration problems, and examine the press output for patterns in the misregistration. This might indicate an issue with a specific cylinder.

- Consult with Press Operators: Gather feedback from experienced press operators to identify potential issues overlooked.

Q 22. Describe your experience with different types of plate materials (e.g., aluminum, polyester).

My experience encompasses a wide range of plate materials, each with its own advantages and disadvantages. Aluminum plates, for instance, are a workhorse in the industry, offering excellent durability and print quality. However, their production can be less environmentally friendly. I’ve extensively worked with different aluminum alloys, each subtly affecting printing characteristics such as ink holdout and plate longevity. Polyester plates, on the other hand, are known for being lighter and more environmentally conscious due to their recyclable nature. They often offer superior flexibility, making them ideal for certain printing processes, such as flexography. However, their durability can sometimes be less than that of aluminum, requiring more careful handling. I’ve also had experience with some newer materials exploring bio-degradable options, showcasing my commitment to sustainable practices within the industry. Ultimately, the choice of plate material is highly dependent on the specific printing application, budget, and environmental considerations.

Q 23. Explain the importance of maintaining a clean and organized plate mounting area.

Maintaining a clean and organized plate mounting area is paramount for several reasons. Firstly, it prevents contamination. Dust, debris, or even stray ink can affect the accuracy of registration and the quality of the final print. Think of it like a surgeon’s operating room – the slightest contamination can ruin the whole procedure. Secondly, a clean environment improves efficiency. A clutter-free space allows for smoother workflows, faster turnaround times, and reduced chances of errors. Finally, it ensures the safety of operators by minimizing the risk of slips, trips, and falls, and reduces the potential for injury from improperly stored or handled materials.

In practice, this means implementing strict cleaning protocols, utilizing designated storage areas for plates, tools, and chemicals, and adhering to a structured organization system that minimizes waste and ensures smooth transitions between tasks.

Q 24. How familiar are you with different platemaking technologies (CTP, etc.)?

I’m highly familiar with various platemaking technologies, most prominently Computer-to-Plate (CTP) systems. I have extensive experience with different CTP technologies, including thermal, violet, and UV laser systems. Each technology has its strengths and weaknesses. For example, thermal CTP is relatively low cost and easy to maintain, while violet and UV offer higher resolution and wider color gamut capabilities. My experience includes troubleshooting these systems, optimizing imaging parameters to improve dot gain, and working to minimize platemaking costs. I understand the process from prepress to plate output, including the role of RIP software in ensuring accurate color reproduction and registration. My knowledge extends to evaluating and comparing different CTP systems based on factors like speed, resolution, and cost-effectiveness for a particular print shop’s needs.

Q 25. Describe your experience with color management systems in relation to plate mounting.

Color management is intrinsically linked to plate mounting and registration. Inaccurate color management can lead to mismatches between proofs, plates, and the final printed product. My experience includes working with industry-standard color management systems such as G7, ensuring color consistency across different printing presses and substrates. This involves careful calibration of the CTP system, accurate profile creation for each plate material and printing press, and meticulous monitoring of color throughout the production process. Any deviation from the target color profile is identified and corrected to ensure accurate color reproduction and brand consistency. I utilize spectrophotometers and color measurement software to ensure consistent and accurate color from start to finish. The goal is always to achieve a visual match to the approved proof.

Q 26. How do you handle the challenge of maintaining registration across different substrates?

Maintaining registration across different substrates is a significant challenge because different materials have varying degrees of expansion and contraction due to changes in humidity and temperature. My approach involves a multi-faceted strategy. First, meticulous pre-press preparation is essential. This includes using high-resolution images and precise platemaking techniques to create accurate plates. Second, I use precision mounting equipment that allows for very fine adjustments to ensure accurate plate placement on the printing press. Third, I regularly check registration during the printing process, employing sophisticated registration controls on the press and making necessary adjustments in real-time. Finally, I utilize specific substrate-dependent settings within the press to compensate for any material-specific expansion or contraction. This might involve modifying the blanket pressure or gripper settings to accommodate subtle material differences. Continuous monitoring and feedback loops throughout the process are essential to maintaining accurate registration.

Q 27. What are some best practices for optimizing plate life and minimizing waste?

Optimizing plate life and minimizing waste are crucial for both economic and environmental reasons. Best practices include proper plate storage in a controlled environment to prevent damage or degradation. This includes managing humidity and temperature to minimize expansion and contraction. Using appropriate cleaning solutions and processes is also key. Aggressive cleaning can damage the plate surface, reducing its lifespan, while insufficient cleaning can lead to contamination and print defects. Furthermore, optimizing the exposure parameters during platemaking minimizes waste by ensuring efficient image transfer onto the plate. Proper press setup and operation are equally important in maximizing the plate’s lifespan. Finally, a robust system of plate inventory management, tracking plate usage and disposal, is crucial for minimizing waste and maximizing efficiency.

Q 28. How do you document and track plate mounting and registration procedures?

Documentation and tracking of plate mounting and registration procedures are essential for quality control, troubleshooting, and continuous improvement. We employ a comprehensive system involving both digital and physical records. Digital records include detailed job tickets with all relevant information like plate material, CTP settings, press settings, and quality control checks. We utilize a digital asset management system to store and access all relevant documents. Physical records, such as signed-off quality control reports, provide an auditable trail of the entire process. This ensures transparency and accountability, making it easy to track down issues if needed and allowing us to continually refine our processes based on data analysis. We also utilize barcode or RFID systems for tracking plates throughout their lifespan.

Key Topics to Learn for Plate Mounting and Registration Interview

- Understanding Plate Types and their Properties: Explore the differences between various plate types (e.g., flexo, offset, letterpress) and their impact on mounting and registration accuracy. Consider factors like thickness, material, and surface characteristics.

- Plate Mounting Techniques: Master different plate mounting methods, including adhesive application, proper pressure, and techniques for avoiding air bubbles or misalignment. Be prepared to discuss the advantages and disadvantages of various techniques.

- Registration Principles: Demonstrate a thorough understanding of color registration, including the concept of register marks, and the importance of precise alignment for accurate print reproduction. Discuss common registration issues and their solutions.

- Troubleshooting and Problem-Solving: Be ready to discuss common problems encountered during plate mounting and registration, such as improper plate adhesion, misregistration, and image distortion. Explain your approach to diagnosing and resolving these issues.

- Quality Control and Inspection: Describe the quality control measures you would implement to ensure accurate plate mounting and registration. Explain how you would identify and correct defects.

- Safety Procedures and Best Practices: Highlight your awareness of safety protocols related to handling plates, adhesives, and equipment used in the process. Discuss environmentally friendly practices.

- Equipment Knowledge: Familiarize yourself with the types of equipment used in plate mounting and registration. Be able to discuss their operation, maintenance, and troubleshooting.

- Impact of Prepress Procedures: Understand how prepress processes, such as proofing and imposition, affect the accuracy of plate mounting and registration.

Next Steps

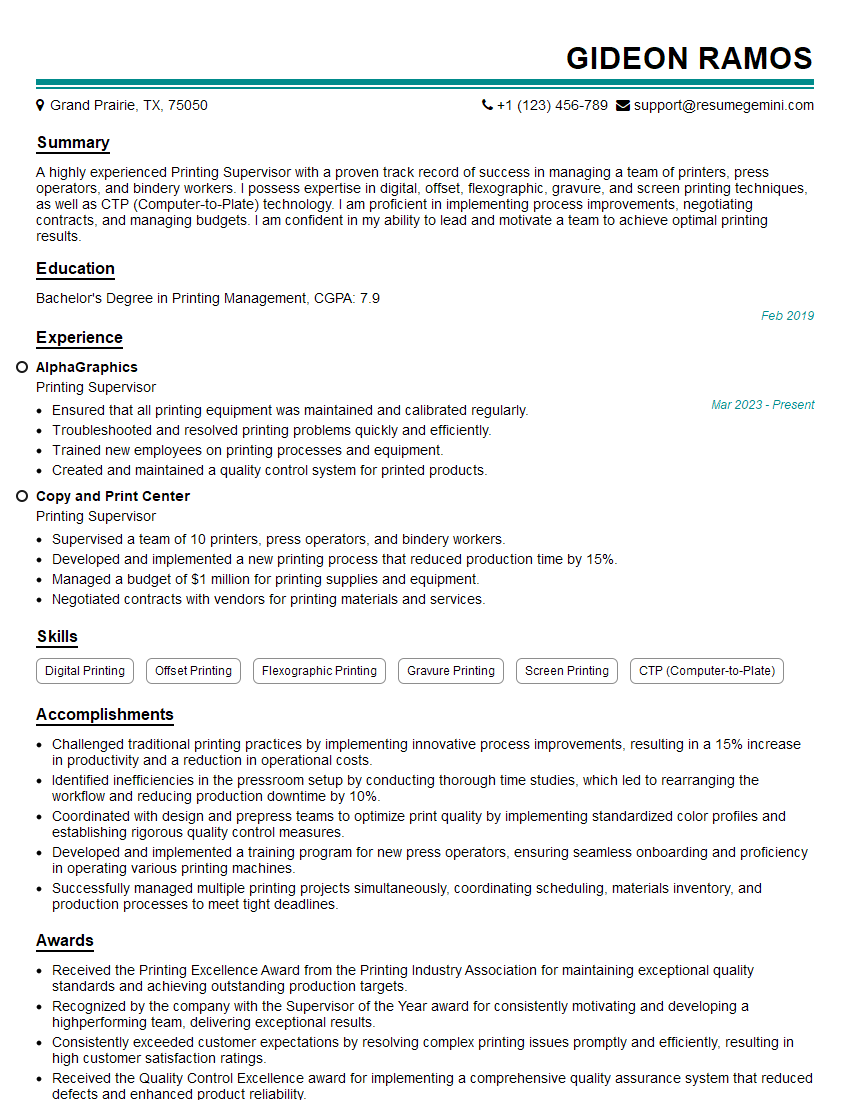

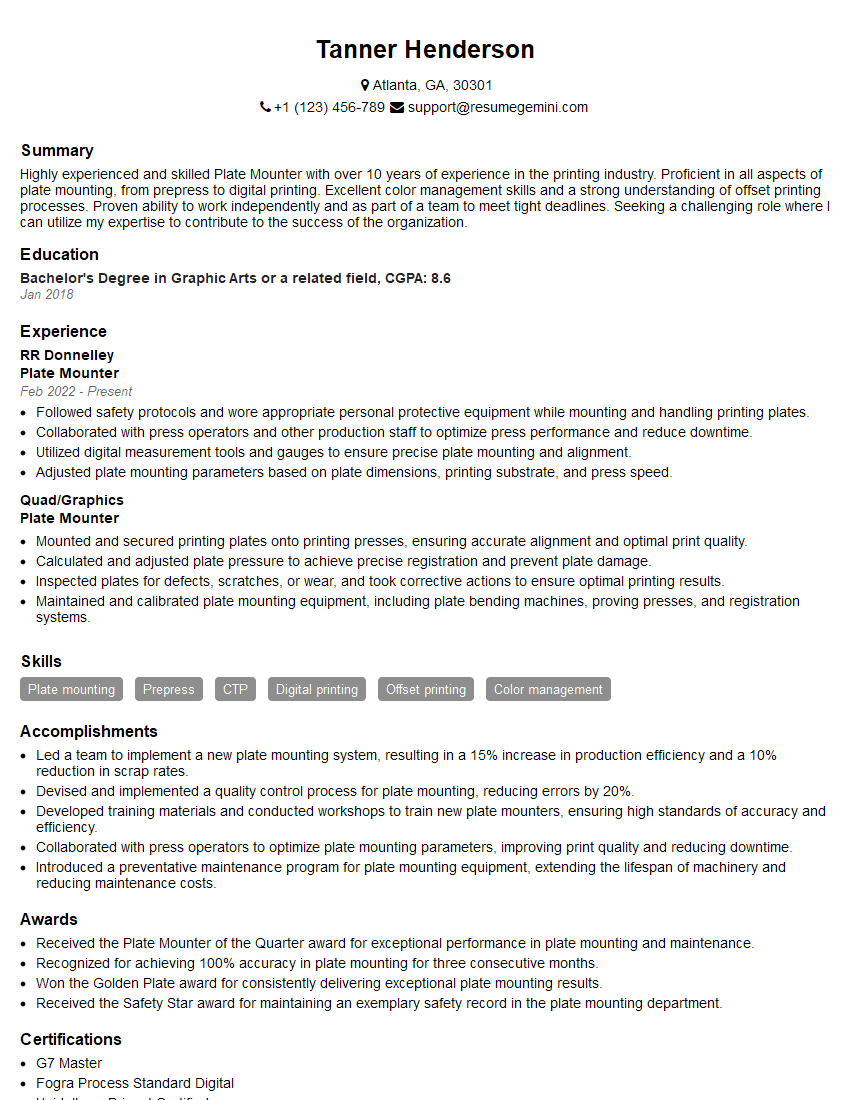

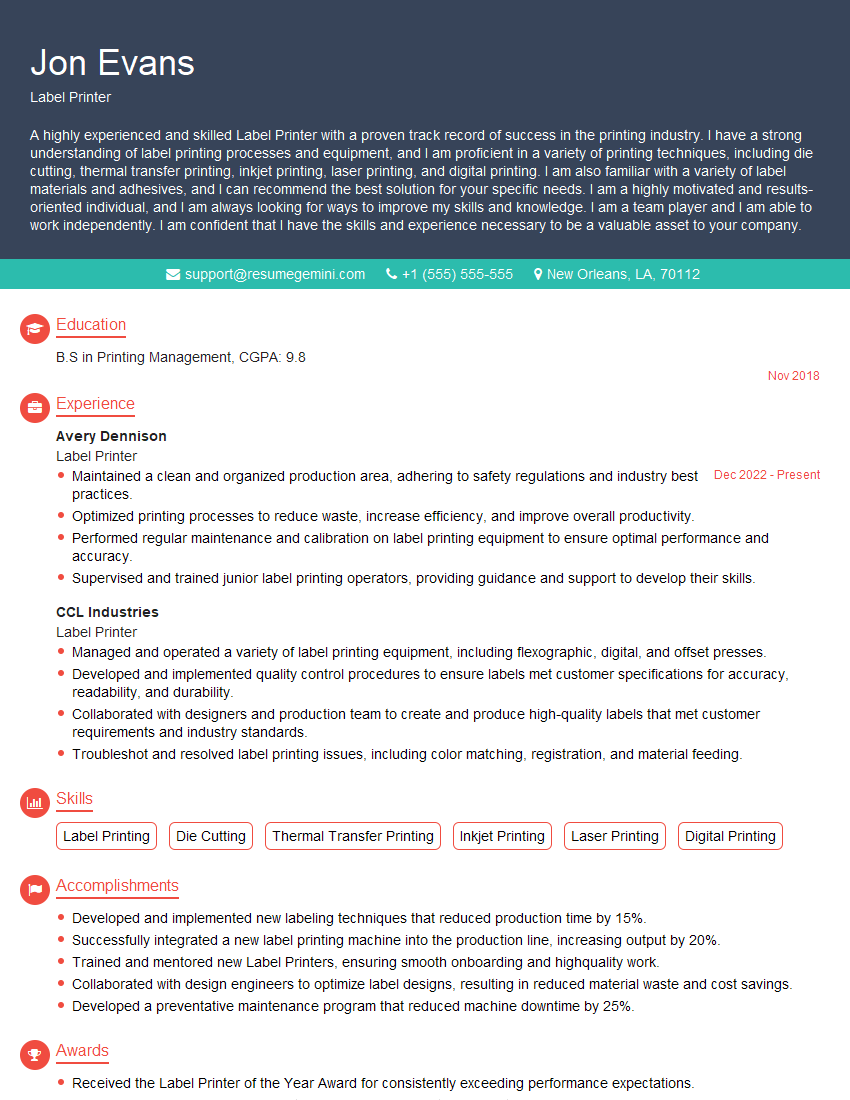

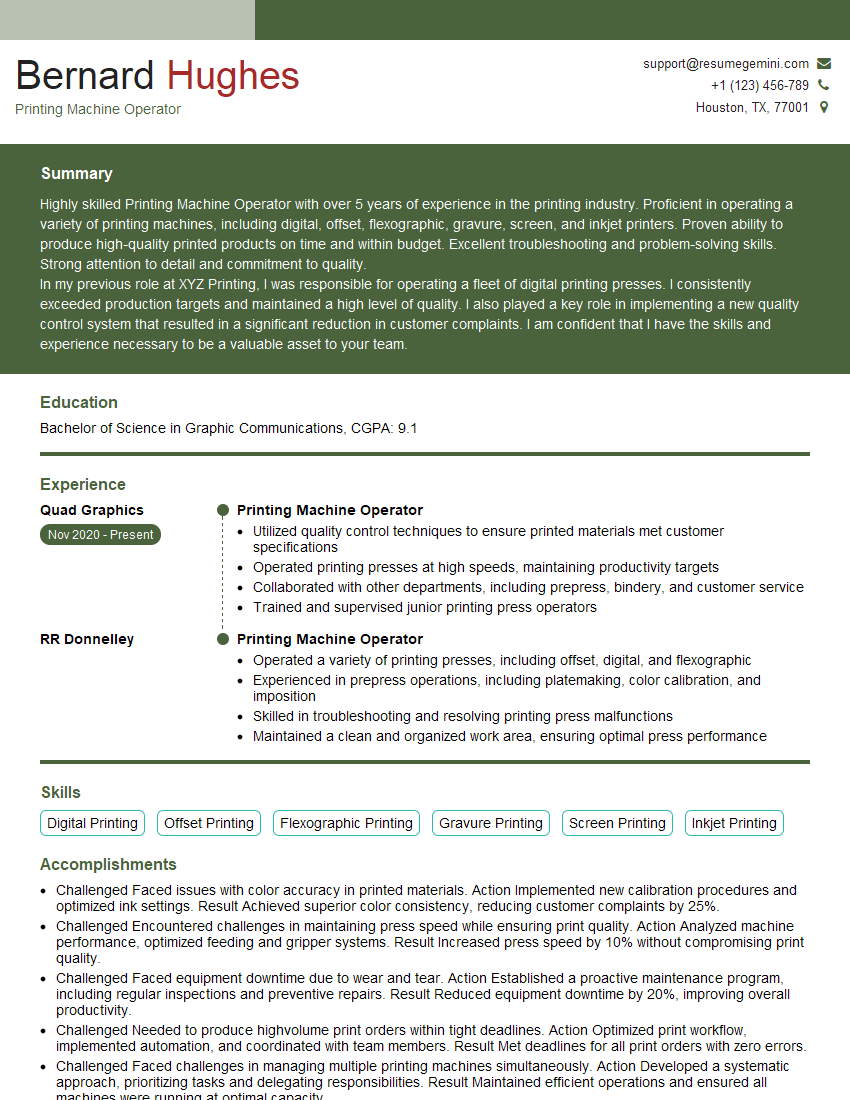

Mastering Plate Mounting and Registration is crucial for career advancement in the printing industry, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. To significantly increase your chances of getting noticed by Applicant Tracking Systems (ATS), it’s vital to have an ATS-friendly resume. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume tailored to highlight your skills and experience in Plate Mounting and Registration. We provide examples of resumes specifically designed for this field to help you get started. Invest the time to build a compelling resume – it’s an investment in your future.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good