Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Odor Detection and Control interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Odor Detection and Control Interview

Q 1. Describe the different methods used for odor detection.

Odor detection methods range from simple, human-based assessments to sophisticated instrumental techniques. The choice depends on factors like the complexity of the odor, required sensitivity, and available resources.

- Human Olfactory Detection: This is the simplest method, relying on trained panelists to assess odor intensity and character. It’s subjective but provides a holistic perception of the overall odor profile. We often use standardized odor intensity scales and descriptive sensory analysis.

- Electronic Noses: These instruments use arrays of sensors to detect and discriminate between different volatile organic compounds (VOCs) responsible for odors. They offer objective measurements and are useful for continuous monitoring. Imagine them like a sophisticated artificial nose, able to differentiate between the smell of coffee and burnt toast.

- Gas Chromatography-Mass Spectrometry (GC-MS): This is a powerful analytical technique that allows for the identification and quantification of individual VOCs in an odor sample. It provides detailed chemical information, which is crucial for precise odor source identification and control strategies.

- Portable Odor Detectors: These compact devices measure total volatile organic compounds (TVOCs) or specific gases and provide on-site, rapid odor assessment. They are especially useful for initial screening or emergency response.

Q 2. Explain the principles of gas chromatography-mass spectrometry (GC-MS) in odor analysis.

Gas Chromatography-Mass Spectrometry (GC-MS) separates and identifies volatile organic compounds (VOCs) in a sample. Think of it as a two-step process: separation and identification.

First, Gas Chromatography (GC) separates the VOCs based on their different boiling points and interactions with a stationary phase inside a column. Imagine a race where different molecules, based on their size and properties, move through the column at varying speeds.

Next, the separated VOCs are detected by the Mass Spectrometer (MS). The MS ionizes the molecules and separates the ions based on their mass-to-charge ratio. This creates a unique fingerprint or mass spectrum for each VOC, allowing for its identification by comparing the spectrum to a database.

For example, in a landfill odor analysis, GC-MS might reveal the presence of methane, hydrogen sulfide, and various sulfur-containing compounds, pinpointing the contributing factors to the unpleasant smell.

Q 3. How do you identify the source of an odor in a complex environment?

Identifying the source of an odor in a complex environment requires a systematic approach. This often involves a combination of techniques:

- Odor Mapping: Using odor detection equipment or trained personnel, create an odor map by systematically sampling the air at different locations. This helps pinpoint the area of highest concentration.

- Process Evaluation: Review industrial processes, waste management practices, and storage areas to identify potential odor sources. Investigate activities that might generate VOCs.

- Wind Direction and Dispersion Modeling: Consider prevailing wind direction to determine the likely path of the odor plume. Models can help trace the odor back to its source.

- Chemical Analysis: Collect air samples from the suspected source area and analyze them using techniques like GC-MS to identify the specific VOCs contributing to the odor. This allows us to directly link the detected chemicals to the specific processes.

- On-site observation and investigation: Conduct a visual inspection of the area to identify potential leaks, spills, or equipment malfunctions that might be releasing odorous compounds.

For example, if we find high concentrations of sulfur compounds near a wastewater treatment plant, we can investigate the aeration process or sludge management as potential sources.

Q 4. What are the common odor-causing compounds in industrial settings?

Industrial settings often generate a variety of odor-causing compounds, depending on the industry. Here are some common examples:

- Hydrogen sulfide (H2S): A rotten egg smell, common in wastewater treatment, oil refineries, and pulp and paper mills.

- Mercaptans (thiols): Have strong, unpleasant odors, often added to natural gas as an odorant. They can also be byproducts of industrial processes.

- Amines: Produce fishy or ammonia-like odors, found in some food processing, chemical, and pharmaceutical industries.

- Volatile organic compounds (VOCs): A broad category encompassing numerous compounds with diverse odors, including solvents, aldehydes, ketones, and esters. These can be released from paints, coatings, and many manufacturing processes.

- Ammonia (NH3): A pungent odor found in agricultural settings, waste treatment, and some chemical production facilities.

Q 5. Describe your experience with odor control technologies, such as biofiltration or activated carbon adsorption.

I have extensive experience with various odor control technologies. Biofiltration and activated carbon adsorption are two prominent examples.

Biofiltration uses microorganisms to break down odorous compounds. Air containing the odor is passed through a bed of compost or other suitable media, where microorganisms metabolize the VOCs. It’s an environmentally friendly option, especially effective for removing a wide range of biodegradable odors. For example, we successfully implemented biofiltration at a rendering plant, significantly reducing the odor impact on the surrounding community.

Activated carbon adsorption involves passing the odorous air through a bed of activated carbon, a highly porous material with a large surface area. The VOCs adsorb onto the surface of the carbon, effectively removing them from the air stream. This is particularly useful for removing specific odorous compounds or when high efficiency is required, even for non-biodegradable compounds. We’ve used this extensively for controlling solvent emissions in a paint manufacturing facility.

Q 6. Explain the difference between odor masking and odor elimination.

Odor masking and odor elimination are fundamentally different strategies.

Odor masking involves adding a fragrance to cover up the unpleasant odor, essentially creating a more pleasant olfactory experience. It does not actually remove the odor-causing compounds, simply hides them. Think of it as putting perfume on top of a bad smell; it covers it but the bad smell is still there. It’s a temporary solution and often less environmentally friendly.

Odor elimination focuses on removing or destroying the odor-causing compounds, addressing the root cause of the odor. Techniques like biofiltration and activated carbon adsorption are examples of odor elimination. This approach provides a more permanent and sustainable solution.

Q 7. How do you determine the appropriate odor control strategy for a given situation?

Selecting the appropriate odor control strategy depends on several factors:

- Type and concentration of odor-causing compounds: This dictates the suitability of different technologies. Biofiltration is best for biodegradable compounds, while activated carbon is suitable for a wider range.

- Airflow rate and volume: The scale of the problem impacts the size and capacity of the odor control system required.

- Regulatory requirements: Environmental regulations may dictate specific control measures to meet emission standards.

- Cost-effectiveness: Different technologies have varying costs associated with installation, operation, and maintenance.

- Environmental impact: Choosing environmentally friendly solutions is crucial. Biofiltration is generally a preferred option in this regard.

A thorough odor assessment and impact study are necessary to determine the best approach, often involving a combination of strategies tailored to the specific needs.

For instance, for a small-scale odor problem in a restaurant, a simple, locally installed activated carbon filter might suffice. But for a large industrial complex, a more complex multi-stage system involving biofiltration and additional treatment might be required.

Q 8. What are the relevant regulations and standards concerning odor emissions?

Regulations and standards concerning odor emissions vary significantly depending on location (national, regional, or local) and the type of emission source. Generally, these regulations aim to protect public health and welfare by limiting the concentration and frequency of offensive odors. Key aspects often covered include:

- Emission limits: Many jurisdictions set limits on the concentration of odorous compounds released into the air, often expressed as odor units per cubic meter (ouE/m³).

- Odor impact assessments: Regulations frequently require impact assessments to evaluate the potential effects of new or modified facilities on nearby communities.

- Best available techniques (BAT): Regulations often encourage or mandate the adoption of the most effective odor control technologies available.

- Monitoring and reporting: Facilities emitting odors may be required to regularly monitor emissions and report results to regulatory authorities.

- Enforcement and penalties: Non-compliance with odor regulations can lead to warnings, fines, or even legal action.

Examples of relevant regulations include the EPA’s guidance in the US, similar national-level legislation in European countries, and specific local ordinances focused on industries such as waste management or agriculture. It’s crucial to be aware of the applicable regulations for a given project or location.

Q 9. How do you measure and quantify odor intensity?

Odor intensity measurement relies on sensory evaluation, often using olfactometry. This involves trained panelists who assess the intensity of a diluted odor sample. The quantification is typically expressed in odor units (ouE/m³), representing the dilution factor required to bring the odor to the detection threshold of the average person. There are two main methods:

- Dynamic olfactometry: The odorant is progressively diluted with clean air until the panelist can no longer detect the odor. The dilution factor is then used to calculate the odor concentration.

- Static olfactometry: Panelists smell a series of samples with varying dilutions and rate the odor intensity. Statistical analysis determines the concentration corresponding to a specific intensity level.

Instrumentation plays a supporting role, ensuring accurate dilution and delivery of odor samples. The process requires careful control of environmental factors (temperature, humidity) and rigorous training of panelists to ensure consistent and reliable results. For example, a waste water treatment plant might use dynamic olfactometry to quantify the odor released from its aeration tanks, allowing them to track effectiveness of odor control measures.

Q 10. Explain the concept of odor threshold and its importance in odor control.

The odor threshold is the lowest concentration of an odorant that can be detected by the average person under specified conditions. It’s a critical parameter in odor control because it defines the point at which an odor becomes perceptible. Knowing the odor threshold for a specific compound is crucial for setting emission limits and designing effective control strategies.

For example, if the odor threshold for hydrogen sulfide (a common odor in wastewater treatment) is 0.0005 ppm, then any concentration below this will likely be undetectable. However, even at concentrations below the threshold, some people might still perceive the odor due to individual sensitivity variations. Understanding the odor threshold helps in setting realistic objectives for odor control – complete elimination may not always be feasible or necessary, but reducing the concentration below the threshold ensures minimal public impact.

Q 11. Describe your experience with odor impact assessments.

My experience with odor impact assessments involves a systematic approach encompassing several steps:

- Odor source identification and characterization: Determining the specific sources of odors, their types and strengths.

- Meteorological data analysis: Assessing wind speed, direction, and atmospheric stability to predict odor plume dispersion.

- Odor dispersion modeling: Using specialized software to predict odor concentrations at various locations downwind of the source.

- Sensory evaluation: Conducting field measurements using olfactometry to validate model predictions and assess the actual odor impact on the surrounding area.

- Data interpretation and reporting: Analyzing the data to determine the extent and potential impact of the odor emissions.

I’ve worked on numerous projects, from industrial facilities to agricultural operations, helping clients assess their potential odor impact on the community and develop mitigation plans to meet regulatory requirements and maintain positive relationships with neighbours. One memorable project involved a rendering plant, where we used a combination of modeling and field measurements to identify optimal locations for odor control equipment to minimize the impact on a nearby residential area. This involved considering factors like prevailing winds and topography.

Q 12. What are the health effects associated with exposure to specific odors?

The health effects of odor exposure vary widely depending on the specific odorant, concentration, and duration of exposure. Some odors can cause:

- Respiratory irritation: Many volatile organic compounds (VOCs), such as formaldehyde or ammonia, can irritate the airways, leading to coughing, wheezing, or shortness of breath.

- Headaches and nausea: High concentrations of certain odorous compounds can cause headaches, nausea, dizziness, or even vomiting.

- Central nervous system effects: Some odors can affect the central nervous system, leading to drowsiness, confusion, or other neurological symptoms.

- Allergic reactions: Certain odors can trigger allergic reactions in sensitive individuals, leading to skin rashes, respiratory problems, or other allergic symptoms.

- Long-term health impacts: Exposure to some odorous pollutants over a long period may increase the risk of developing chronic respiratory diseases or other health problems. For example, chronic exposure to high concentrations of certain VOCs has been linked to increased cancer risks.

It’s vital to note that the intensity and duration of exposure play a crucial role in determining the severity of health effects. A brief exposure to a low concentration of an odorant is unlikely to cause significant harm, while prolonged exposure to a high concentration can lead to serious health problems. Accurate odor measurements and effective control strategies are thus essential to minimize potential health risks.

Q 13. How do you develop and implement an odor control plan?

Developing and implementing an odor control plan involves a structured, multi-step process:

- Odor source identification and quantification: Pinpoint the sources and determine the intensity and types of odorous emissions.

- Control strategy selection: Choose appropriate control technologies based on the nature of the odor, emission characteristics, and cost-effectiveness.

- Design and engineering: Design the selected control systems, considering factors such as airflow, retention time, and process parameters.

- Implementation and commissioning: Install and test the chosen equipment, ensuring proper functionality and compliance with regulations.

- Monitoring and evaluation: Regularly monitor odor emissions, assess the effectiveness of the control measures, and make adjustments as needed.

- Documentation and reporting: Maintain comprehensive records of the odor control program, including monitoring data, maintenance logs, and regulatory compliance documentation.

The chosen strategy often involves a combination of techniques such as biofiltration (using microorganisms to degrade odorous compounds), activated carbon adsorption (adsorbing odorous molecules onto activated carbon), thermal oxidation (burning odorous compounds at high temperatures), or masking agents (disguising odors using fragrance). The most effective plan is site-specific and requires a comprehensive understanding of the odor sources and environmental conditions.

Q 14. What are the different types of odor sensors and their applications?

Various odor sensors are available, each with specific applications and limitations:

- Electronic noses (e-noses): These systems use arrays of different sensors to create a ‘fingerprint’ of an odor, enabling the identification and quantification of complex odor mixtures. E-noses are useful for monitoring diverse odor sources but may lack the specificity of targeted sensors.

- Gas chromatography-mass spectrometry (GC-MS): GC-MS provides highly specific identification and quantification of individual volatile organic compounds. While powerful, it’s a laboratory-based technique and may not be suitable for real-time monitoring.

- Metal oxide semiconductor (MOS) sensors: These sensors detect changes in electrical conductivity caused by the presence of specific gases. They are relatively inexpensive and compact, suitable for continuous monitoring but their sensitivity and selectivity can vary.

- Photoionization detectors (PIDs): PIDs detect and measure volatile organic compounds by ionizing them using ultraviolet light. They’re useful for monitoring a wide range of VOCs but may not be sensitive to all odor-causing compounds.

- Infrared (IR) sensors: These sensors detect specific molecules based on their characteristic infrared absorption spectra. They offer high specificity but are often less sensitive than other types of sensors.

Choosing the right sensor depends on several factors, such as the specific odorants of concern, required sensitivity, cost, and the need for real-time monitoring. For example, an e-nose might be used for continuous odor monitoring at a landfill, while GC-MS could be employed for detailed analysis of odor samples in a laboratory setting.

Q 15. Explain the process of calibrating and maintaining odor detection equipment.

Calibrating and maintaining odor detection equipment is crucial for accurate and reliable measurements. It’s like regularly servicing your car – neglecting it leads to inaccurate readings and potential problems. The process typically involves several steps:

Pre-calibration checks: This involves visually inspecting the equipment for any damage or signs of malfunction. For example, checking for leaks in gas chromatograph systems or ensuring the sensor is clean and free from obstructions.

Calibration using standard gases: We use known concentrations of odoriferous compounds (e.g., hydrogen sulfide, methyl mercaptan, etc.) to calibrate the equipment. This establishes a baseline for accurate measurements. Different techniques exist depending on the type of instrument, such as dynamic dilution olfactometry (DDO) or electronic nose calibration using reference gases. For example, with a gas chromatograph-mass spectrometer (GC-MS), we would run known standards through the system and adjust the instrument’s parameters until the measured concentration matches the known concentration.

Regular maintenance: This includes tasks like replacing filters, cleaning sensors (with appropriate cleaning agents specific to the sensor type), and performing system diagnostics to check for errors or anomalies. Frequency depends on usage, but it could range from weekly to monthly checks, alongside annual servicing by qualified technicians. Maintaining proper record-keeping is essential for compliance and traceability.

Post-calibration verification: After calibration and maintenance, we perform another check using standard gases to verify that the equipment is functioning correctly within acceptable tolerances. This ensures accuracy and prevents erroneous data.

Failure to properly calibrate and maintain equipment can lead to inaccurate odor assessments, potentially resulting in ineffective odor control strategies and non-compliance with environmental regulations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle complaints related to odor emissions?

Handling odor complaints requires a systematic and professional approach. I begin by acknowledging the complaint and assuring the complainant that their concern is being taken seriously. Then, a multi-step process unfolds:

Investigate and Document: I gather information about the complaint, including location, time, frequency, intensity of the odor (using descriptors if possible), and any potential sources. I also take note of weather conditions, as these significantly influence odor dispersion.

On-site Assessment: I conduct a site visit to assess the situation firsthand, using odor detection equipment (like portable gas detectors or olfactometers) to measure odor concentrations. I also observe the source(s) of odor and potential pathways of dispersion. Photography and video documentation are vital.

Data Analysis: The collected data is analyzed to identify the source of the odor and its strength. This might involve analyzing wind patterns, topographical features and comparing them to emission sources.

Implement Corrective Actions: Based on the investigation, I recommend and implement appropriate corrective actions. This could include adjustments to processes, equipment upgrades, or implementation of odor control technologies like biofilters, scrubbers, or thermal oxidizers.

Follow-up and Reporting: I follow up with the complainant to inform them of the actions taken and any progress made. A written report summarizing the investigation, findings, and corrective actions is also prepared and submitted.

Maintaining open communication with complainants is essential throughout this process to foster trust and ensure resolution.

Q 17. Describe your experience with data analysis and interpretation in odor control projects.

Data analysis is the backbone of effective odor control projects. It’s not just about numbers; it’s about translating data into actionable insights. My experience involves:

Statistical Analysis: I use statistical software (like R or SPSS) to analyze odor concentration data, identifying trends and patterns. This helps determine the effectiveness of implemented control measures and the impact of variables such as wind speed and direction.

Spatial Analysis: GIS (Geographic Information Systems) software is utilized to map odor plumes and identify high-concentration areas, helping pinpoint the sources and predict dispersion patterns. For example, I might use dispersion modeling software to predict the impact of different control measures.

Data Visualization: Presenting complex data in a clear and understandable manner is crucial. I use graphs, charts, and maps to effectively communicate findings to both technical and non-technical audiences. For instance, a heat map displaying odor concentration levels can be readily understood by both engineers and community members.

Correlation Analysis: Identifying correlations between odor concentration and various factors (e.g., production levels, weather parameters) helps establish cause-and-effect relationships and optimize control strategies. For example, if odor concentration correlates strongly with wind speed, we might prioritize measures to mitigate odor during high-wind periods.

Essentially, my goal is to convert raw data into a compelling narrative that guides informed decision-making and effective odor control.

Q 18. How do you present technical information to both technical and non-technical audiences?

Communicating technical information effectively is paramount. My approach involves tailoring the message to the audience:

Technical Audiences: When communicating with engineers or scientists, I use precise terminology, detailed data, and sophisticated analyses to support my recommendations. I might present complex graphs and statistical analyses, focusing on technical details.

Non-technical Audiences: For the public or regulatory agencies, I use clear, concise language, avoiding jargon. Visual aids like infographics, simple charts, and analogies play a crucial role. For example, I might use an analogy to describe the odor concentration, such as comparing it to the strength of a perfume.

Regardless of the audience, I always ensure the information is accurate, objective, and presented in a manner that encourages understanding and collaboration.

Q 19. What are some common challenges in odor control projects?

Odor control projects present unique challenges. Some common ones include:

Identifying Odor Sources: Pinpointing the exact source of an odor can be difficult, especially when multiple sources exist or when the odor is diffuse. Complex industrial processes often involve multiple potential emission points, making source identification challenging.

Meteorological Conditions: Wind speed, direction, temperature, and humidity significantly influence odor dispersion, making prediction and control challenging. An odor that’s barely noticeable on one day could be widespread under different weather conditions.

Odor Perception: Odor perception is subjective and varies between individuals. What one person considers an acceptable level of odor, another might find intolerable. This subjective nature requires careful consideration of community sensitivities.

Regulatory Compliance: Meeting odor emission standards requires a thorough understanding of applicable regulations and implementation of effective monitoring programs.

Cost-Effectiveness: Balancing the cost of implementing odor control measures with the benefits achieved is crucial. A cost-effective solution doesn’t always mean the cheapest option, but rather the most efficient solution in terms of cost per unit of odor reduction.

Addressing these challenges requires a multidisciplinary approach, utilizing expertise in engineering, chemistry, meteorology, and community relations.

Q 20. How do you ensure compliance with environmental regulations related to odor?

Ensuring compliance with environmental regulations related to odor is a critical aspect of any project. This involves:

Understanding Regulations: Thoroughly understanding all applicable local, state, and federal regulations is paramount. Regulations vary significantly based on location and the type of industry. For example, a food processing plant will have different odor emission standards compared to a wastewater treatment plant.

Permitting: Obtaining necessary permits for odor emissions is critical before commencing any operations. This involves submitting comprehensive plans that detail odor control measures and monitoring protocols.

Monitoring and Reporting: Regularly monitoring odor emissions using approved methods and equipment is required. This data is then compiled into reports that are submitted to regulatory agencies according to their specified schedules. Failure to meet reporting requirements can result in penalties.

Record Keeping: Maintaining comprehensive and accurate records of all odor-related activities, including monitoring data, maintenance logs, and corrective actions, is essential for demonstrating compliance and potentially mitigating liability in case of non-compliance issues.

Contingency Planning: Developing a plan to address potential exceedances of odor emission limits is crucial. This includes a detailed procedure outlining how to identify and respond to violations, including implementing corrective actions and reporting them to regulatory bodies.

Proactive compliance is the best approach to avoid penalties and maintain a positive relationship with regulatory agencies.

Q 21. Describe your experience with odor control in different industries (e.g., food processing, wastewater treatment).

My experience in odor control spans various industries, each with its unique challenges and solutions:

Food Processing: In food processing, odor control is vital for maintaining product quality and preventing nuisance odors for nearby communities. Common sources include rendering plants, dairies, and composting facilities. Control measures often involve scrubbing systems, biofilters, and improved ventilation.

Wastewater Treatment: Wastewater treatment plants are significant sources of odor due to the decomposition of organic matter. Techniques used include activated carbon adsorption, biofiltration, and chemical treatment to reduce the levels of odoriferous compounds like hydrogen sulfide and mercaptans.

Agriculture: Livestock operations, particularly large-scale farms, can generate significant odor issues. Solutions often focus on improved manure management practices, anaerobic digestion, and odor masking agents.

Landfills: Landfills generate a variety of odoriferous gases due to the decomposition of waste. Control strategies include gas collection systems, flaring, and bioreactors.

My approach involves understanding the specific odor sources and characteristics within each industry to tailor effective and efficient control strategies. This often involves a combination of engineering controls, operational adjustments, and the selection of appropriate treatment technologies.

Q 22. What are the limitations of different odor control technologies?

Odor control technologies, while effective, have inherent limitations. The best technology depends heavily on the specific odor source and its characteristics (e.g., concentration, chemical composition, airflow patterns).

Biofiltration: While environmentally friendly, biofilters are susceptible to overloading if the odor concentration exceeds the capacity of the microbial population. They also require careful monitoring and maintenance to ensure optimal performance and can be less effective for highly volatile or toxic compounds.

Scrubbers (chemical or physical): These can be expensive to operate and maintain, especially those using specialized chemicals. They can also generate secondary waste products that need further treatment. Effectiveness varies greatly depending on the odor’s chemical properties; some compounds are simply not easily absorbed or neutralized.

Thermal Oxidation: This is highly effective but energy-intensive, making it costly. It’s also not suitable for all odorants, as some may degrade into even more problematic byproducts.

Activated Carbon Adsorption: While efficient for many odors, activated carbon eventually becomes saturated and requires replacement or regeneration, adding to ongoing costs. The choice of carbon type is crucial and depends heavily on the specific odor compounds.

Masking agents: These only cover up the odor, not eliminate the source; they can also have their own unwanted side effects (like creating headaches in some individuals) and can’t be used in all situations (e.g., near food processing facilities).

Q 23. How do you prioritize odor control projects based on risk and impact?

Prioritizing odor control projects involves a systematic risk assessment considering both the impact and likelihood of the problem. I use a matrix approach.

Impact: This considers the severity of the odor (intensity, offensiveness, duration), its potential impact on public health (respiratory irritation, nausea), environmental effects (harm to wildlife), and economic consequences (e.g., property devaluation, business disruption, legal action).

Likelihood: This evaluates the probability of the odor event occurring, considering factors like the source’s reliability, frequency of operation, prevailing weather conditions, and the effectiveness of existing controls.

The combination of impact and likelihood creates four quadrants: High Impact/High Likelihood (immediate action), High Impact/Low Likelihood (plan for mitigation), Low Impact/High Likelihood (monitor and consider less intensive controls), and Low Impact/Low Likelihood (lowest priority). This allows me to effectively allocate resources and focus on projects with the greatest potential risk and impact.

Q 24. Describe your experience with using modeling software to predict odor dispersion.

I have extensive experience using AERMOD, CALPUFF, and other atmospheric dispersion modeling software to predict odor plume behavior. These models use meteorological data (wind speed, direction, atmospheric stability), emission rates, and terrain information to simulate odor concentrations downwind from a source.

For example, I recently used AERMOD to model the odor dispersion from a rendering plant. The model predicted the odor plume’s extent and concentration, helping us identify areas most likely to be affected. This information was crucial in designing an effective odor control strategy, including the optimal placement of control technologies such as biofilters and scrubbers, and helped to secure the necessary permits. The results were validated through field measurements.

The software allows for ‘what-if’ scenarios. For example, we can simulate the effect of different mitigation strategies (e.g., increasing the height of a stack, using a different scrubber technology) to optimize the design and minimize odor impacts.

Q 25. What are your strategies for troubleshooting odor control systems?

Troubleshooting odor control systems requires a systematic approach. I typically follow these steps:

Identify the problem: This involves characterizing the odor (intensity, type, frequency) and identifying areas of impact. Is the odor stronger in certain areas or at specific times? This often necessitates on-site odor investigations utilizing gas chromatography–mass spectrometry (GC-MS) for odor identification.

Inspect the system: Examine all components of the odor control system (e.g., pumps, filters, scrubbers) for malfunctions, blockages, or signs of degradation. Check for proper airflow and pressure differentials.

Review operational data: Analyze operational logs to identify any unusual trends or events that may have contributed to the problem. This includes reviewing maintenance logs and emission rates.

Test the system: Perform performance tests to assess the efficiency of the odor control system. This may involve measuring odor concentrations upstream and downstream of the control equipment.

Implement corrective actions: Based on the troubleshooting analysis, implement necessary repairs, replacements, or process modifications. This may involve cleaning or replacing filters, recalibrating equipment, or adjusting operating parameters.

Monitor and evaluate: After implementing corrective actions, monitor the system’s performance to ensure the odor problem is resolved. Regular monitoring is key to prevent future issues.

Q 26. How do you stay up-to-date with the latest advancements in odor detection and control?

Staying current in this dynamic field requires a multifaceted approach. I actively engage in:

Professional organizations: Membership in organizations like the Air & Waste Management Association (AWMA) provides access to publications, conferences, and networking opportunities with other professionals.

Industry publications and journals: I regularly read journals such as Atmospheric Environment and Journal of the Air & Waste Management Association to learn about new technologies and research findings.

Conferences and workshops: Attending conferences allows for direct interaction with leading researchers and engineers and exposure to the latest advancements.

Online resources and databases: Utilizing online databases and resources to stay updated on regulatory changes and emerging technologies.

Continuing education: Participating in professional development courses and workshops to enhance my expertise.

Q 27. Describe a time you had to solve a challenging odor problem. What was your approach and outcome?

I once faced a particularly challenging odor problem at a large composting facility. Complaints from nearby residents about offensive odors were frequent and intense. Initial investigations revealed high levels of volatile organic compounds (VOCs).

My approach involved a multi-pronged strategy. First, we conducted a comprehensive odor assessment including field measurements, dispersion modeling, and detailed characterization of the odorants using GC-MS. This detailed analysis helped us to understand the dominant odor contributors and their sources. Then, we implemented a series of control measures including optimization of the composting process (adjusting moisture content and aeration rates), installing a biofilter of significantly increased capacity, and optimizing the existing ventilation system to control odor emissions.

We also implemented a robust monitoring program to assess the effectiveness of our control measures. The outcome was a significant reduction in odor complaints. Regular monitoring allowed us to continuously adjust our approach, ensuring sustained odor control and improved community relations.

Q 28. How do you integrate odor control considerations into overall facility design or operation?

Integrating odor control into facility design and operation is crucial for long-term success and compliance. This should be considered from the initial planning stages.

Source control: Design processes to minimize odor generation (e.g., enclosed systems, efficient wastewater treatment). Process modifications should be prioritized over end-of-pipe solutions.

Ventilation and airflow management: Properly designed ventilation systems are essential to capture and transport odors to control equipment. This includes calculating air exchange rates and modeling airflow patterns.

Odor control technology selection: The type and capacity of odor control technology (e.g., biofilter, scrubber, thermal oxidizer) should be carefully selected based on the specific odor characteristics and volume of emissions.

Monitoring and maintenance: A robust monitoring program is essential to ensure continued effectiveness. This also includes scheduled maintenance of the odor control equipment.

Emergency response planning: Develop procedures to handle unexpected odor events.

By integrating odor control considerations from the outset, we can avoid costly retrofits, minimize environmental impact, and ensure the facility’s long-term sustainability and community acceptance.

Key Topics to Learn for Odor Detection and Control Interview

- Odor Sources and Characterization: Understanding the chemical composition of different odors and their sources (industrial, agricultural, environmental). This includes learning about various analytical techniques used for odor identification.

- Odor Detection Technologies: Familiarize yourself with different methods for odor detection, including gas chromatography-mass spectrometry (GC-MS), electronic noses, and sensory panels. Understand their strengths, weaknesses, and applications.

- Odor Control Strategies: Explore various odor control techniques, such as absorption, adsorption, biofiltration, thermal oxidation, and masking agents. Be prepared to discuss the effectiveness and limitations of each method.

- Regulatory Compliance and Standards: Understand relevant environmental regulations and industry standards related to odor emissions and control. This includes knowledge of permit applications and compliance monitoring.

- Risk Assessment and Management: Learn how to assess the risks associated with odor emissions and develop effective management strategies to minimize their impact on the environment and human health.

- Practical Application Case Studies: Research real-world examples of odor control projects in different industries (e.g., wastewater treatment, food processing, agriculture). Analyze the challenges faced and the solutions implemented.

- Problem-Solving and Troubleshooting: Be ready to discuss your approach to diagnosing and resolving odor-related problems in various settings. This includes data analysis, critical thinking, and decision-making skills.

- Emerging Technologies: Stay updated on the latest advancements in odor detection and control technologies. This demonstrates your commitment to professional development and staying ahead of the curve.

Next Steps

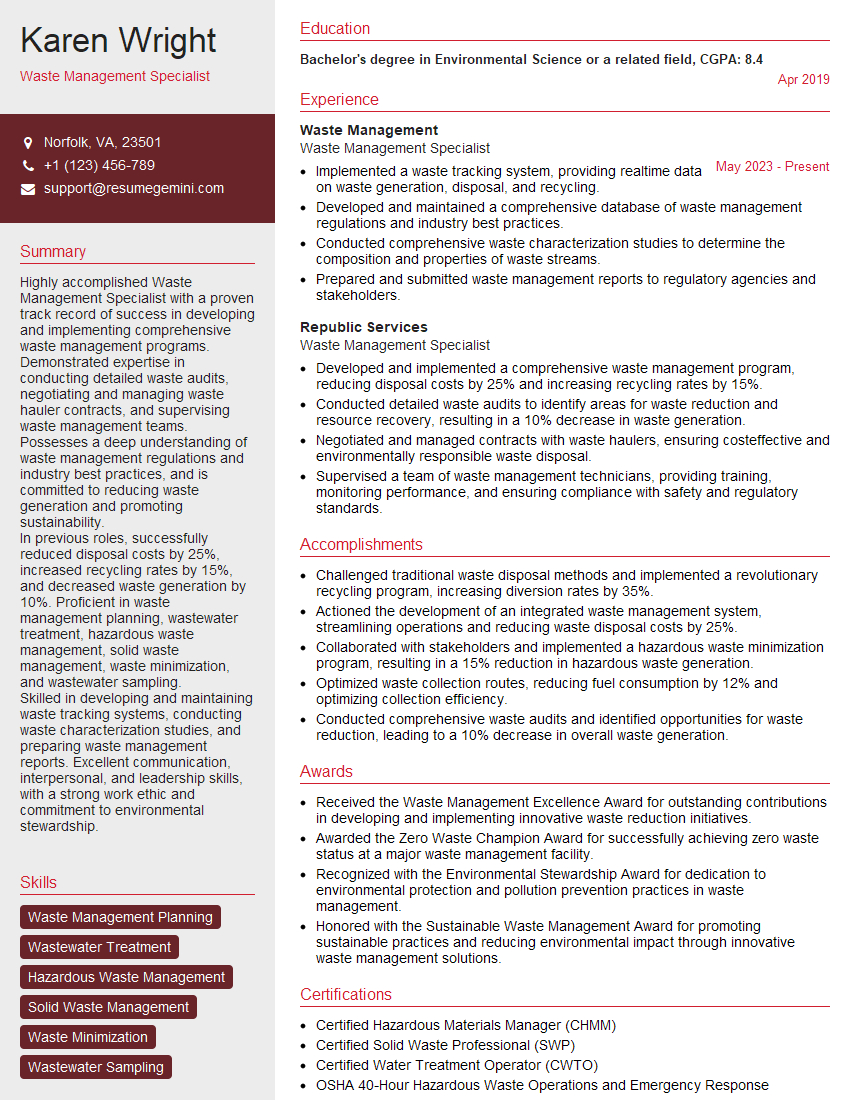

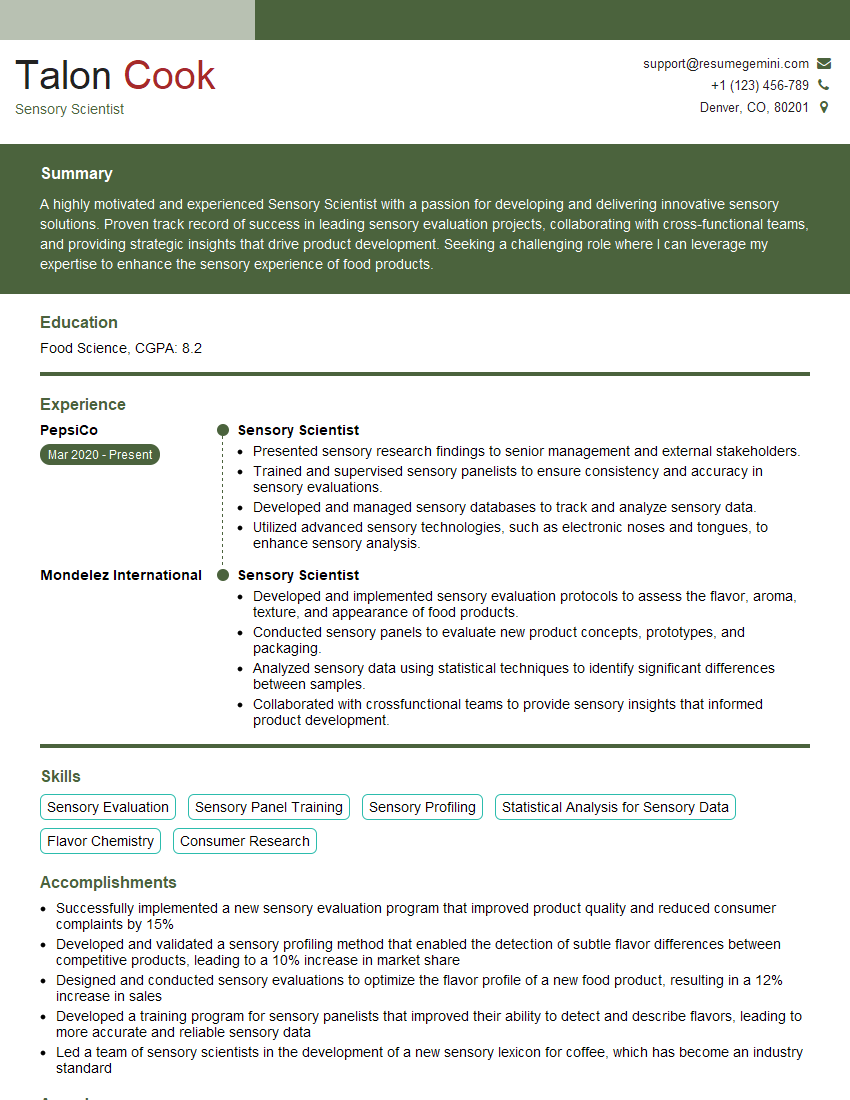

Mastering Odor Detection and Control opens doors to a rewarding career with significant growth potential in various sectors. A strong understanding of these concepts is crucial for securing your dream role. To maximize your chances, creating an ATS-friendly resume is essential. This ensures your application gets noticed by recruiters and hiring managers. We strongly encourage you to use ResumeGemini, a trusted resource for building professional resumes that stand out. ResumeGemini offers valuable tools and examples tailored to the Odor Detection and Control field, helping you present your skills and experience effectively. Examples of resumes specifically crafted for this field are available.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good