Are you ready to stand out in your next interview? Understanding and preparing for Advanced Knowledge of Pipeline Operations interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Advanced Knowledge of Pipeline Operations Interview

Q 1. Explain the difference between a pigging operation and a hydrostatic test.

Pigging and hydrostatic testing are both crucial pipeline maintenance procedures, but they serve distinct purposes. Pigging involves sending a specialized cleaning tool, called a pig, through the pipeline to remove debris, liquids, or other materials. Think of it like a giant plumber’s snake, cleaning the inside of the pipe. This ensures efficient product flow and prevents contamination. There are various types of pigs, including cleaning pigs, gauging pigs, and batching pigs, each designed for a specific task.

In contrast, a hydrostatic test is a pressure test used to verify the pipeline’s integrity. Water is pumped into the pipeline under pressure, and the pressure is monitored for leaks or pressure drops. It’s like a rigorous stress test for the pipe, ensuring its ability to withstand the pressure of its operating environment. This test is critical before commissioning a new pipeline or after significant repairs.

The key difference is that pigging focuses on cleaning and maintaining the pipeline’s operational efficiency, while a hydrostatic test assesses its structural integrity and safety.

Q 2. Describe the various methods used for pipeline leak detection.

Pipeline leak detection employs a variety of methods, each with strengths and weaknesses. These methods can be broadly categorized as:

- Pressure Monitoring: This is a fundamental method. Sensors continuously monitor pressure along the pipeline. A sudden or gradual pressure drop can indicate a leak. This is often the first line of defense.

- Acoustic Leak Detection: Specialized sensors listen for the high-frequency sounds generated by escaping fluids. Sophisticated algorithms analyze these sounds to pinpoint leak locations.

- Flow Metering: Comparing the flow rate at different points along the pipeline can reveal discrepancies indicative of leaks. Any reduction without an expected cause raises suspicion.

- Inline Inspection (ILI): Smart pigs equipped with sensors are run through the pipeline to detect internal flaws, including corrosion and cracks, that might lead to future leaks. This is a more proactive and comprehensive method.

- Aerial Surveys: Using aerial imagery, such as infrared or satellite photography, to detect anomalies on the ground surface above the pipeline, potentially indicating leaks. Changes in vegetation or soil moisture can be telling clues.

- Distributed Acoustic Sensing (DAS): This emerging technology uses fiber optic cables along the pipeline as sensors to detect leaks and other events with high spatial resolution.

The best approach often combines multiple methods for a comprehensive and reliable leak detection system.

Q 3. What are the common causes of pipeline corrosion and how are they mitigated?

Pipeline corrosion is a significant concern, leading to leaks, failures, and environmental damage. Common causes include:

- Soil Chemistry: The soil surrounding the pipeline can be highly corrosive, particularly if it’s acidic or contains corrosive chemicals.

- Electrochemical Corrosion: This occurs when there’s a difference in electrical potential between different parts of the pipeline, often due to dissimilar metals or variations in the soil’s properties. This electrochemical process causes the metal to dissolve.

- Microbiologically Influenced Corrosion (MIC): Certain microorganisms in the soil can accelerate corrosion by creating conditions that favor it.

- Stray Currents: External electrical currents can interfere with the pipeline’s electrical potential and cause localized corrosion.

Corrosion mitigation strategies include:

- Coating: Applying protective coatings to the pipeline’s exterior acts as a barrier against corrosive elements.

- Cathodic Protection: This involves electrically protecting the pipeline by supplying electrons to counteract the corrosion process. This is commonly achieved using sacrificial anodes or impressed current cathodic protection.

- Corrosion Inhibitors: Chemicals can be added to the pipeline’s contents to inhibit corrosion.

- Regular Inspections and Monitoring: Using tools like ILI to identify corrosion before it becomes a significant problem.

A combination of these methods is often used to effectively manage corrosion risk.

Q 4. Explain the principles of pipeline hydraulics and their impact on operations.

Pipeline hydraulics describes the flow of fluids within pipelines. Understanding these principles is critical for efficient and safe operations. Key concepts include:

- Pressure Drop: Fluid pressure decreases as it flows through the pipeline due to friction with the pipe walls and internal resistance. This pressure drop influences the flow rate and pump requirements.

- Flow Rate: The volume of fluid flowing through the pipeline per unit time. Factors like pipeline diameter, pressure, and fluid viscosity affect flow rate.

- Fluid Viscosity: The resistance of a fluid to flow. Higher viscosity means more pressure is needed to maintain the same flow rate.

- Head Loss: The loss of pressure head due to friction and other factors along the pipeline. Accurate head loss calculations are essential for pipeline design and operation.

In practice, understanding pipeline hydraulics is crucial for:

- Sizing pipelines: Selecting appropriate pipeline diameter and material based on desired flow rate and pressure requirements.

- Pump selection: Determining the capacity and pressure requirements for pumps based on pipeline parameters.

- Troubleshooting operational issues: Identifying problems with flow rate or pressure and diagnosing potential causes.

- Predictive modeling: Simulating pipeline performance under different conditions to optimize operations.

Ignoring these principles can lead to inefficient operation, excessive energy consumption, and potential pipeline failures.

Q 5. Describe different pipeline integrity management (PIM) programs.

Pipeline Integrity Management (PIM) programs are comprehensive strategies to ensure the safe and reliable operation of pipelines. They typically encompass several key elements:

- Risk Assessment: Identifying potential hazards and assessing their likelihood and consequences. This helps to prioritize mitigation efforts.

- In-Line Inspection (ILI): Regular internal inspection using smart pigs to detect defects like corrosion, cracks, and dents.

- External Corrosion Assessment: Regular inspection of the pipeline’s exterior to identify signs of external corrosion.

- Data Management: Collecting, analyzing, and storing data from inspections and other monitoring activities to track pipeline condition over time.

- Repair and Replacement: Addressing identified defects through repair or pipeline replacement as needed.

- Emergency Response Planning: Developing plans for handling leaks, failures, and other emergencies.

- Compliance and Regulatory Oversight: Ensuring adherence to all relevant regulations and industry best practices.

Different companies and regulatory agencies may have variations in their specific PIM programs, but these elements generally constitute a robust framework for safe pipeline operation. Some organizations might also incorporate advanced analytics and predictive modelling into their PIM programs to improve their efficiency and effectiveness.

Q 6. How do you assess the risk associated with a pipeline failure?

Assessing the risk associated with pipeline failure involves a systematic approach. It generally incorporates the following steps:

- Hazard Identification: Identify all potential hazards that could lead to pipeline failure, such as corrosion, ground movement, third-party damage, and material defects.

- Consequence Analysis: Determine the potential consequences of a failure, including environmental damage, property damage, injuries, and fatalities. This may involve simulations or modeling to estimate the extent of the impact.

- Probability Assessment: Estimate the probability of each hazard occurring. This often involves analyzing historical data, inspection reports, and relevant statistics.

- Risk Calculation: Combine the probability and consequence assessments to calculate the overall risk for each hazard. A common method is to multiply the probability of occurrence by the consequence severity. This results in a risk score or level.

- Risk Ranking and Prioritization: Rank identified hazards based on their risk scores. This determines which hazards require the most urgent attention and mitigation efforts.

- Risk Mitigation: Develop and implement strategies to reduce the likelihood or severity of the identified hazards. These strategies can include pipeline maintenance, repair, replacement, and improved operating procedures.

This risk assessment process allows operators to prioritize resources, proactively mitigate risks, and optimize the overall safety and reliability of their pipeline systems.

Q 7. What are the key regulatory requirements for pipeline operations in your region?

The specific regulatory requirements for pipeline operations vary significantly by region. However, common themes include:

- Pipeline Design and Construction Standards: Regulations specify design criteria, materials, and construction methods to ensure pipeline safety and durability.

- Testing and Inspection Requirements: Regular testing, such as hydrostatic testing and in-line inspection, are mandated to identify and address defects. These requirements usually depend on the age, type, and location of the pipeline.

- Operational Procedures: Strict operational procedures are required to control pipeline operation, including pressure management, monitoring, and emergency response protocols.

- Safety Management Systems (SMS): Many jurisdictions require companies to implement formal SMS to effectively manage safety risks and ensure compliance.

- Emergency Response Planning: Companies must have detailed emergency response plans to handle leaks, spills, and other incidents.

- Personnel Training and Qualification: Operators must ensure their personnel are adequately trained and qualified to carry out their duties safely and effectively.

- Reporting and Record-Keeping: Detailed record keeping is often required for inspections, maintenance, repairs, and incidents.

It is crucial to consult the specific regulations and guidance documents in your particular operating area to ensure full compliance and safe operations. Failure to comply can result in significant penalties and legal repercussions.

Q 8. Explain the role of SCADA systems in pipeline monitoring and control.

SCADA, or Supervisory Control and Data Acquisition, systems are the nervous system of any modern pipeline operation. They act as a central hub, collecting real-time data from various points along the pipeline and providing operators with the ability to monitor and control the flow of materials.

Think of it like this: imagine a vast network of sensors scattered along hundreds of miles of pipeline. These sensors constantly monitor pressure, flow rate, temperature, and other critical parameters. SCADA systems gather this data, process it, and display it on a user-friendly interface, often a series of graphical displays showing the pipeline’s overall status. This allows operators to identify potential problems—like leaks or blockages—quickly and proactively.

Beyond monitoring, SCADA systems also provide control functionalities. Operators can remotely adjust valves, pumps, and compressors to manage flow rates, pressure, and other parameters, ensuring optimal pipeline performance and safety. For instance, if pressure in a section rises above a predefined threshold, the SCADA system might automatically close a valve to prevent a potentially dangerous situation. This automated response is crucial for preventing major incidents and optimizing efficiency.

Modern SCADA systems often incorporate advanced analytics and machine learning algorithms to predict potential issues before they occur, allowing for preventative maintenance and further enhancing safety and reliability. They’re truly indispensable for efficient and safe pipeline management.

Q 9. Describe your experience with pipeline maintenance and repair procedures.

My experience in pipeline maintenance and repair spans over a decade, encompassing both preventative and corrective maintenance strategies. Preventative maintenance involves regular inspections, cleaning, and minor repairs to prevent major issues. For example, we conduct regular in-line inspections (ILI) using smart pigs to detect internal corrosion or defects, allowing for timely repairs before they become significant problems. We also perform regular above-ground inspections checking for signs of external corrosion, damage, or right-of-way encroachment.

Corrective maintenance involves addressing issues as they arise. This can range from simple repairs like replacing a section of damaged pipe to more complex projects involving excavation and replacement of larger sections. I’ve overseen repairs resulting from third-party damage, natural disasters, and equipment failures. A specific instance involved a pipeline experiencing a significant leak due to soil erosion. My team utilized specialized excavation equipment, quickly isolated the affected section, and completed a repair while minimizing environmental impact and production downtime. Safety protocols are strictly followed throughout the entire process, and post-repair integrity tests are always implemented.

We use a variety of techniques depending on the nature of the damage, ranging from welding and patching to full pipe replacement. Detailed documentation and reporting are crucial, ensuring compliance with regulations and building a comprehensive history of the pipeline’s maintenance.

Q 10. How do you manage pipeline emergencies and incidents?

Managing pipeline emergencies requires a swift, coordinated response. Our emergency response plan is crucial, which includes clear communication protocols and pre-defined roles and responsibilities. When an incident occurs, the first step is to secure the area and ensure the safety of personnel and the public. This involves isolating the affected section of the pipeline, using emergency shut-off valves and implementing traffic control measures. We then assess the situation using SCADA data and on-site inspections to determine the extent of the damage and the cause of the incident.

Next, we engage appropriate emergency services, regulatory agencies, and environmental protection specialists, as needed. Communication is key; regular updates are provided to stakeholders. Once the immediate threat is mitigated, we initiate repair procedures, closely following established safety protocols and industry best practices. A thorough investigation is carried out to determine the root cause of the incident and to implement corrective actions to prevent recurrence. Post-incident analysis and reporting are crucial for continuous improvement and for complying with regulatory requirements. For instance, in one incident involving a third-party damage, our rapid response and effective communication ensured minimal environmental impact and rapid restoration of service.

Q 11. What are the different types of pipeline materials and their applications?

Pipelines utilize a variety of materials, each suited to specific applications and conditions. The choice of material depends on factors like the transported fluid, the operating pressure, the soil conditions, and environmental considerations.

- Steel: The most common material, offering high strength and durability. Different grades of steel are used depending on the application, with higher-strength steels used for high-pressure pipelines.

- High-Density Polyethylene (HDPE): A widely used plastic material for lower-pressure applications, particularly for distribution pipelines. It offers excellent corrosion resistance and flexibility, making it ideal for challenging terrain.

- Ductile Iron: A cast iron alloy with increased ductility and strength, often used for water pipelines and in situations where corrosion resistance is crucial.

- Concrete: Used for pipelines transporting non-corrosive materials, often in conjunction with steel reinforcement for strength. It’s commonly used in large-diameter pipelines.

The selection process involves detailed analysis of the project specifics, considering factors like cost, lifespan, and environmental impact. Each material has its own set of advantages and limitations; choosing the correct material is critical for pipeline safety and longevity.

Q 12. Explain the process of pipeline construction and commissioning.

Pipeline construction and commissioning is a multi-stage process requiring meticulous planning and execution. It starts with detailed design, route selection, and environmental impact assessments. The route is carefully planned to minimize environmental disruption and to consider factors like soil conditions and accessibility. Then comes the procurement of materials, including pipes, fittings, valves, and other necessary equipment.

Construction involves the actual laying of the pipeline, which can be done via various methods such as trenching, directional drilling, or other specialized techniques depending on the terrain and environmental factors. Welding and inspection of the pipe joints are crucial steps to ensure integrity. Once the pipeline is laid, it undergoes hydro-testing to verify its ability to withstand operating pressures and to detect any leaks. This is followed by commissioning, involving various tests to verify that the pipeline meets the design specifications and is safe for operation.

Commissioning involves bringing the pipeline into service. This includes cleaning, drying, and purging of the pipeline, filling it with the transported material, and carefully ramping up to full operational pressure. Continuous monitoring and data collection during commissioning are essential for ensuring the pipeline’s integrity and optimal performance.

Q 13. How do you ensure the safety of personnel working on pipeline projects?

Pipeline safety is paramount. A robust safety program is essential and begins with rigorous training for all personnel. This includes safety awareness, hazard identification, and emergency response procedures. We use a permit-to-work system for all tasks, ensuring that every activity is properly planned and executed safely. Regular safety meetings and toolbox talks are conducted to reinforce safe work practices and address any concerns.

Personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and high-visibility clothing is mandatory. We maintain a strong emphasis on hazard communication and provide clear instructions and signage to identify hazards. Our sites use regular inspections to check for potential hazards and to ensure compliance with safety regulations. Emergency response drills are conducted regularly to ensure effective response in case of incidents. Moreover, a well-defined reporting system ensures that all incidents, near-misses, and safety concerns are promptly investigated and addressed.

Proactive risk management and continuous improvement are key to maintaining a safe work environment. We regularly review our safety protocols and make adjustments as needed to incorporate lessons learned and to stay abreast of industry best practices. The ultimate goal is to create a culture of safety where everyone feels responsible for their safety and the safety of their colleagues.

Q 14. Describe your experience with pipeline design software and tools.

My experience encompasses a range of pipeline design software and tools, including AutoCAD, Bentley OpenRoads, and specialized pipeline simulation software. AutoCAD is extensively used for 2D and 3D modeling of pipeline layouts and facilities. Bentley OpenRoads assists with route optimization and detailed design, considering factors like terrain, soil conditions, and environmental constraints. Pipeline simulation software allows us to model the hydraulics and thermodynamics of the pipeline, predicting flow rates, pressures, and temperature profiles under various operating conditions.

This software is crucial for optimizing pipeline design, ensuring that it meets the required capacity and safety standards. It also facilitates stress analysis, determining the pipeline’s ability to withstand various loads and pressures. The use of simulation software aids in optimizing the operational efficiency of the pipeline. Furthermore, these tools help in generating detailed construction drawings and specifications for contractors. My proficiency in these tools allows me to effectively design, analyze, and optimize pipeline systems while adhering to industry standards and regulatory requirements. I’m also familiar with data management tools which help in effectively managing the massive datasets involved in pipeline projects.

Q 15. What are the environmental considerations associated with pipeline operations?

Environmental considerations in pipeline operations are paramount, impacting everything from initial planning to decommissioning. They center around minimizing the risk of spills and leaks, which can contaminate soil and water sources, harming ecosystems and human health. We must consider the potential for greenhouse gas emissions from leaks of transported gases, as well as the impact of pipeline construction on natural habitats. This often involves thorough environmental impact assessments (EIAs) before any project commences, aiming to identify and mitigate potential risks. For example, pipelines are often routed to avoid sensitive ecological areas, and emergency response plans are crucial for swift containment and cleanup in the unlikely event of an incident. Furthermore, we must also adhere to strict regulations regarding wastewater discharge and noise pollution from compressor stations and other facilities.

Specific considerations include: Selecting appropriate pipeline materials and coatings to minimize corrosion; Implementing advanced leak detection systems; Utilizing effective erosion and sediment control measures during construction; And adhering to stringent environmental permits and regulations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you utilize data analytics to improve pipeline performance?

Data analytics plays a crucial role in optimizing pipeline performance. We use advanced algorithms to analyze vast amounts of data from various sources, including sensors monitoring pressure, flow rate, temperature, and even vibrations within the pipeline. This data helps us identify potential problems before they escalate into major incidents. For instance, a slight increase in pipeline pressure over a period of time might indicate a developing blockage, allowing for preventative maintenance before a complete shutdown is required. Furthermore, we can analyze historical data to predict future maintenance needs and optimize operational efficiency. Predictive modeling, using machine learning techniques, can accurately forecast potential failures and plan accordingly.

Examples of data analytics applications include:

- Predictive Maintenance: Forecasting equipment failures and scheduling maintenance to prevent downtime.

- Leak Detection: Identifying anomalies in flow rates and pressures that might indicate a leak.

- Optimization of Operational Parameters: Fine-tuning parameters such as flow rate and pressure to maximize efficiency and minimize energy consumption.

- Improved Safety: Identifying high-risk areas and implementing safety measures to reduce the likelihood of incidents.

Q 17. Explain the importance of pipeline inspection and maintenance schedules.

Regular inspection and maintenance are critical for pipeline safety and longevity. Think of it like a health checkup for your body; neglecting regular checkups can lead to serious problems later on. Schedules are based on various factors, including pipeline material, age, operating conditions, and regulatory requirements. These schedules typically include both internal and external inspections, using various techniques like in-line inspection tools (ILIs) for internal assessments and aerial surveys or ground patrols for external ones. We often use risk-based inspection methods, prioritizing areas with higher risk of failure. For example, pipelines in corrosive environments or with a history of incidents might require more frequent inspections. Maintenance tasks range from simple repairs to major overhauls and replacements, with the aim of preventing leaks, corrosion, and other damage.

The consequences of neglecting maintenance can be disastrous, leading to environmental damage, economic losses, and even fatalities. Therefore, a well-defined and meticulously followed inspection and maintenance schedule is non-negotiable for safe and efficient pipeline operations.

Q 18. Describe your experience with different pipeline flow regimes.

Pipeline flow regimes describe the way fluids move through the pipeline. Understanding these regimes is crucial for optimizing pipeline design and operation. Different fluids exhibit different flow behaviors depending on factors such as velocity, viscosity, and pipe diameter. Common flow regimes include laminar flow, where the fluid moves in smooth layers, and turbulent flow, characterized by chaotic mixing. In pipelines, we often encounter transitional flow regimes, somewhere between laminar and turbulent. Each regime impacts pressure drop, heat transfer, and the potential for erosion and corrosion.

My experience includes working with pipelines carrying various fluids, from light crude oil exhibiting mostly turbulent flow, to highly viscous heavy crude exhibiting more laminar behavior. Understanding the specific flow regime enables optimized pump selection and pressure management strategies. For example, in turbulent flow, higher energy losses need to be considered compared to laminar flow. Specialized modeling software and experimental data are crucial tools in assessing and managing flow regimes in different pipeline scenarios.

Q 19. How do you handle pipeline pressure fluctuations?

Pipeline pressure fluctuations can result from a variety of factors, including changes in flow rate, variations in elevation, and equipment malfunctions. Managing these fluctuations is vital for maintaining pipeline integrity and safety. We utilize sophisticated control systems, often incorporating pressure sensors and control valves, to automatically adjust flow rates and maintain pressure within safe operating limits. If the pressure drops too low, the flow might become sluggish, leading to inefficiencies or even blockages. Conversely, excessively high pressure can damage the pipeline itself. Pressure surge mitigation equipment, such as surge tanks and pressure relief valves, is often included in pipeline designs to handle sudden pressure spikes.

Furthermore, we use advanced modeling and simulation techniques to predict pressure fluctuations and optimize operational strategies. This predictive approach allows us to proactively adjust operations to prevent or mitigate pressure variations and ensure the safe and efficient operation of the pipeline system.

Q 20. Explain the role of pipeline valves in system operation and safety.

Pipeline valves are essential components for system operation and safety, acting as on/off switches and flow regulators. They allow for isolation of sections of the pipeline during maintenance, emergencies, or planned shutdowns. Different types of valves, including gate valves, globe valves, ball valves, and check valves, each serve specific functions. Gate valves, for example, are primarily used for on/off operation, while globe valves provide more precise flow control. Check valves prevent backflow, crucial in maintaining the integrity and direction of fluid flow. The selection of valves depends heavily on the type of fluid, pressure, and specific operational requirements.

Safety is paramount: Valves play a crucial role in emergency shutdown procedures, allowing for rapid isolation of sections of the pipeline in case of leaks or other incidents. Regular inspections and maintenance of valves are absolutely critical for their reliable operation, as a malfunctioning valve could lead to serious consequences.

Q 21. What are the different types of pipeline pigging tools and their applications?

Pipeline pigging involves sending specialized tools, called pigs, through the pipeline to perform various tasks. These tools are crucial for pipeline maintenance and operation. Different types of pigs are used for different purposes:

- Cleaning Pigs: These remove debris, liquids, and other contaminants from the pipeline, improving flow efficiency and preventing corrosion.

- Inspection Pigs: These are equipped with sensors to detect internal pipeline defects, such as corrosion, dents, and cracks. Data is collected during their passage, providing valuable insights into the pipeline’s condition.

- Batching Pigs: These separate different fluids within the pipeline, preventing mixing and maintaining product quality. This is particularly important in multi-product pipelines.

- Smart Pigs: These are advanced inspection pigs with sophisticated sensors capable of gathering detailed data about pipeline integrity and condition.

Selecting the correct pig type is critical for the specific application. The size and design of the pig must be compatible with the pipeline’s diameter and operating conditions. The use of pigging tools ensures the pipeline remains efficient and safe, minimizing the risk of blockages and extending its lifespan.

Q 22. How do you ensure compliance with pipeline safety regulations?

Ensuring pipeline safety compliance is paramount. It’s a multi-faceted process involving meticulous adherence to regulations set by bodies like PHMSA (Pipeline and Hazardous Materials Safety Administration) in the US, or equivalent agencies internationally. This starts with a thorough understanding of the applicable regulations, which vary depending on the pipeline’s size, material, and the substance transported.

We achieve this through a robust program encompassing:

- Regular Inspections: Internal and external inspections using various techniques like in-line inspection (ILI) tools, smart pigs, and aerial surveys to detect anomalies like corrosion, cracks, or dents.

- Preventive Maintenance: Scheduled maintenance includes cleaning, coating repairs, and cathodic protection system checks to prevent degradation. For example, we might schedule a complete system overhaul every five years depending on the age and condition of the pipeline.

- Emergency Response Planning: This involves detailed procedures for handling leaks, spills, and other emergencies, including communication protocols, emergency shutdown procedures, and environmental remediation strategies.

- Record Keeping and Reporting: Meticulous records are kept of all inspections, maintenance, and incidents. These records are crucial for audits and demonstrating compliance. We utilize specialized software to maintain accurate and easily accessible records.

- Employee Training: Regular training for all personnel involved in pipeline operations is critical. This training covers safety regulations, emergency response procedures, and the proper use of equipment. We conduct annual training programs updated with the latest regulations and best practices.

Non-compliance can lead to significant penalties, environmental damage, and reputational harm; therefore, maintaining a proactive and rigorous safety program is essential.

Q 23. Describe your experience with pipeline integrity assessment techniques.

Pipeline integrity assessment is a crucial aspect of safe pipeline operations. My experience encompasses a range of techniques, including:

- In-line Inspection (ILI): ILI uses intelligent pigs equipped with various sensors to inspect the pipeline’s internal condition, identifying corrosion, cracks, dents, and other defects. I’ve worked extensively interpreting ILI data, using specialized software to pinpoint the location and severity of defects. A recent project involved analyzing ILI data that identified a significant area of corrosion in a high-pressure gas line; the area was immediately addressed preventing a potential catastrophe.

- External Corrosion Direct Assessment (ECDA): This technique uses non-destructive methods like magnetic flux leakage (MFL) to assess the extent of external corrosion on the pipeline. I’ve managed projects employing ECDA and have experience correlating results with other data sources to prioritize repair efforts.

- Pressure Testing: Hydraulic testing involves pressurizing the pipeline beyond operating pressure to identify leaks or weaknesses. I’ve overseen numerous pressure tests, ensuring strict adherence to safety protocols and proper data recording.

- Leak Detection Systems: These systems continuously monitor pipeline pressure and flow rates, alerting operators to potential leaks. I’ve been involved in designing, implementing, and interpreting data from these systems, ensuring early detection and response to potential incidents.

The choice of techniques depends on factors such as pipeline age, material, operating conditions, and regulatory requirements. Data analysis and risk assessment are crucial for prioritizing repairs and ensuring the pipeline’s long-term integrity.

Q 24. How do you manage pipeline right-of-way issues?

Managing pipeline right-of-way (ROW) issues requires a proactive and multi-faceted approach. This involves:

- Landowner Relations: Building and maintaining positive relationships with landowners along the pipeline ROW is crucial. This includes regular communication, addressing concerns promptly, and complying with agreements. I’ve managed several challenging negotiations, always striving for mutually beneficial outcomes.

- Environmental Compliance: Ensuring compliance with all environmental regulations related to the ROW is essential. This includes minimizing environmental impact, obtaining necessary permits, and adhering to reclamation plans after construction or repairs. I have successfully implemented environmentally-friendly practices in ROW management, reducing our carbon footprint and ensuring compliance.

- ROW Maintenance: Regular maintenance, including vegetation control, erosion prevention, and security measures, is crucial to protect the pipeline and minimize disturbances to landowners. We follow a meticulous ROW management plan, updated annually and reviewed by all stakeholders.

- Legal Compliance: Ensuring that all activities within the ROW comply with relevant legal and regulatory frameworks is paramount. This includes understanding property rights, easement agreements, and any relevant environmental laws. I collaborate with legal counsel to maintain compliance.

Conflicts can arise, such as disputes over land access or environmental concerns. Effective communication, negotiation, and adherence to established procedures are crucial in resolving such conflicts fairly and efficiently.

Q 25. What is your experience with pipeline modeling and simulation?

Pipeline modeling and simulation are essential for optimizing pipeline design, operation, and safety. My experience includes using specialized software such as OLGA, PIPESIM, and others to:

- Design Optimization: Simulating different pipeline configurations, materials, and operating parameters to optimize design for efficiency, safety, and cost-effectiveness. For instance, I used simulation to optimize the design of a new pipeline, resulting in a 15% reduction in material costs.

- Transient Analysis: Simulating transient events such as pressure surges, liquid slugs, and compressor trips to identify potential problems and develop mitigation strategies. This allows for preventive measures and safety protocols to be implemented.

- Steady-State Analysis: Modeling the steady-state behavior of the pipeline to optimize flow rates, pressures, and energy consumption. For example, I modeled a pipeline system to optimize flow and minimize pressure drops to improve efficiency.

- Risk Assessment: Using simulation to assess the risks associated with various scenarios, such as equipment failures or external threats. This data is then used to implement appropriate safety procedures.

These simulations provide valuable insights, allowing us to make informed decisions about pipeline operation and maintenance, ultimately improving safety and reliability.

Q 26. Describe different types of pipeline failures and their causes.

Pipeline failures can have catastrophic consequences. They can be broadly categorized as follows:

- Corrosion: This is a major cause of pipeline failures, often resulting from electrochemical reactions between the pipeline material and the surrounding environment. Internal corrosion from the transported substance or external corrosion from soil conditions can lead to leaks or ruptures. This often requires cathodic protection.

- Stress Corrosion Cracking (SCC): This occurs when the pipeline material is subjected to stress in a corrosive environment, leading to cracking and potential failure. This is particularly concerning in high-pressure pipelines.

- Fatigue Failures: Repeated stress cycles over time, such as pressure fluctuations or vibrations, can lead to fatigue cracking and failure.

- Mechanical Damage: External forces, such as digging activities or ground movement, can cause dents, cracks, and ruptures in the pipeline. Proper ROW management can mitigate these issues.

- Manufacturing Defects: Imperfections during pipeline manufacturing can create weaknesses that lead to failure. Rigorous quality control during the manufacturing process is essential to prevent such failures.

Understanding the causes of failures is crucial for implementing effective prevention and mitigation strategies. Root cause analysis is critical after any failure to prevent recurrence.

Q 27. How do you interpret pipeline data to identify potential problems?

Interpreting pipeline data is essential for identifying potential problems. This involves analyzing various data streams from different sources, including:

- SCADA (Supervisory Control and Data Acquisition) Systems: These systems provide real-time data on pressure, flow rate, temperature, and other parameters. Anomalies in these parameters, such as sudden pressure drops or increases, can indicate leaks or other problems.

- In-line Inspection (ILI) Data: ILI data provides detailed information on the internal condition of the pipeline, allowing for the identification of corrosion, cracks, and other defects. We use sophisticated software to analyze this data and prioritize areas requiring repair.

- Leak Detection Systems: These systems continuously monitor pipeline pressure and flow rates, providing early warnings of potential leaks.

- External Corrosion Direct Assessment (ECDA) Data: ECDA data helps assess external corrosion on the pipeline.

Data analysis often involves statistical methods, trend analysis, and anomaly detection. Advanced machine learning techniques can be employed to identify patterns and predict potential failures before they occur. Combining data from multiple sources allows a more holistic view of the pipeline’s health, facilitating more effective preventative maintenance and risk mitigation.

Q 28. Explain your understanding of pipeline cathodic protection.

Cathodic protection (CP) is a crucial technique for preventing corrosion in pipelines. It involves applying a negative electrical potential to the pipeline, making it the cathode in an electrochemical cell. This inhibits the electrochemical reactions that cause corrosion.

There are two main types of CP:

- Sacrificial Anodes: These are made of a more active metal than the pipeline material (e.g., zinc or magnesium). They corrode preferentially, protecting the pipeline. They need periodic replacement.

- Impressed Current Cathodic Protection (ICCP): This system uses an external power source to drive current through the pipeline, protecting it from corrosion. This offers more control over the protection potential but requires more sophisticated monitoring and maintenance.

Effective CP requires careful design, installation, and monitoring. Regular inspections and testing are crucial to ensure that the CP system is functioning correctly and providing adequate protection. We continuously monitor CP systems using specialized equipment and software to check potential levels and identify any issues before they escalate. Poorly maintained or designed CP systems are one of the main causes of failure in older pipelines. CP is a vital part of our pipeline integrity management program.

Key Topics to Learn for Advanced Knowledge of Pipeline Operations Interview

- Pipeline Integrity Management: Understanding risk assessment methodologies, inline inspection techniques (e.g., ILI, MFL), and strategies for mitigating pipeline threats like corrosion and third-party damage. Consider practical application of these techniques in a real-world scenario.

- Pipeline Hydraulics and Flow Assurance: Mastering concepts like pressure drop calculations, multiphase flow dynamics, and strategies for optimizing pipeline throughput and efficiency. Think about how you’d troubleshoot a pressure drop issue in a specific pipeline segment.

- Pipeline Control Systems and SCADA: Gain a thorough understanding of supervisory control and data acquisition (SCADA) systems, pipeline automation technologies, and emergency shutdown procedures. Be prepared to discuss practical experiences with SCADA systems and troubleshooting.

- Pipeline Safety and Regulations: Demonstrate comprehensive knowledge of relevant safety regulations (e.g., PHMSA), emergency response protocols, and best practices for preventing incidents and minimizing environmental impact. Consider examples of how regulations impact daily operations.

- Pipeline Construction and Maintenance: Familiarize yourself with various pipeline construction techniques, materials selection criteria, and routine maintenance procedures. Discuss the practical implications of different construction methods.

- Advanced Pipeline Modeling and Simulation: Explore the use of specialized software and analytical tools for pipeline modeling, performance prediction, and optimization. Be ready to discuss the strengths and limitations of different modeling approaches.

- Data Analytics in Pipeline Operations: Understand how data analytics are used to improve pipeline efficiency, safety, and maintenance. Discuss practical applications and potential challenges.

Next Steps

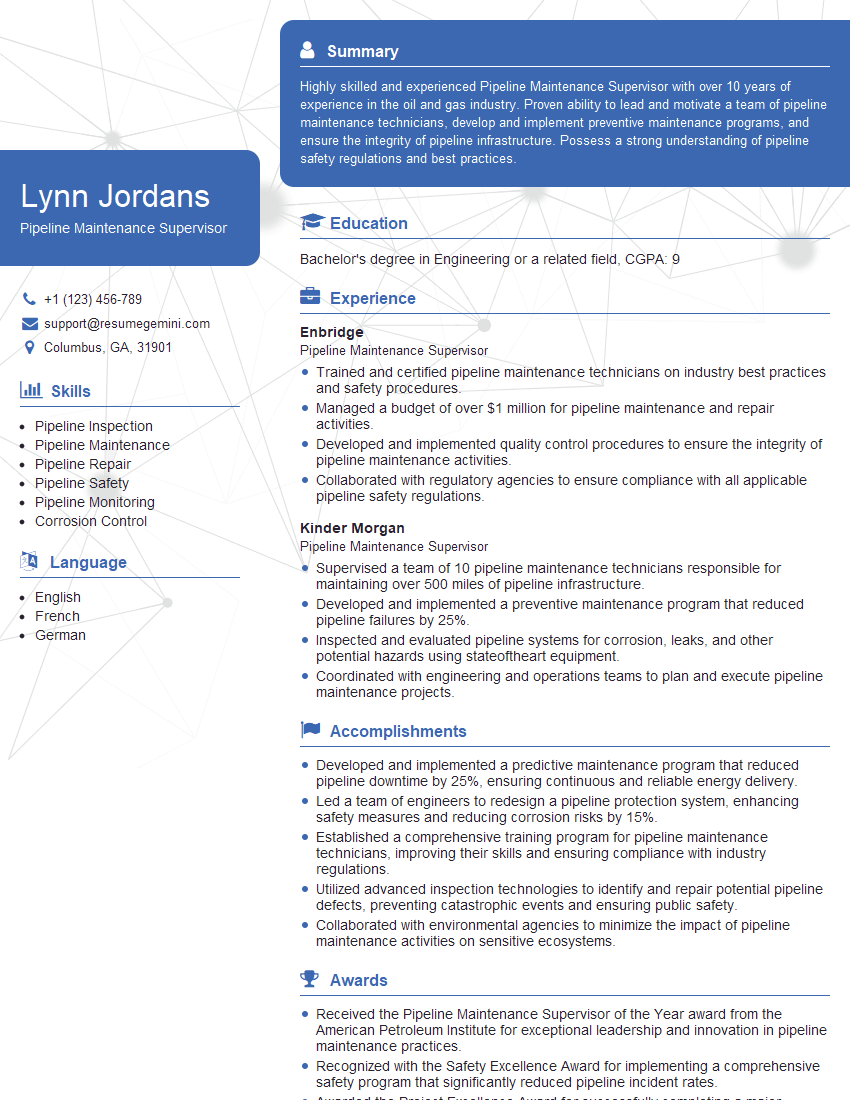

Mastering Advanced Knowledge of Pipeline Operations is crucial for career advancement in this dynamic industry. Demonstrating a strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To further strengthen your application, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the energy sector. Examples of resumes tailored to Advanced Knowledge of Pipeline Operations are available to provide inspiration and guidance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).