Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Assembly & Repair interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Assembly & Repair Interview

Q 1. Describe your experience with different types of assembly techniques.

My experience encompasses a wide range of assembly techniques, from basic mechanical fastening to more complex processes involving intricate electronics and hydraulic systems. I’m proficient in various methods, including:

- Bolting and Screw Fastening: This includes selecting appropriate fasteners based on material strength, torque requirements, and vibration resistance. For example, I’ve worked extensively on engine assemblies where precise torque control is crucial to prevent damage.

- Welding: I’m skilled in various welding techniques like MIG, TIG, and spot welding, understanding the importance of choosing the right technique for different materials and applications. I once repaired a critical component on a manufacturing line using TIG welding, ensuring the weld was both strong and aesthetically pleasing.

- Press-fitting and Interference Fits: This requires precision and understanding of material properties to avoid damage during assembly. I’ve successfully assembled numerous hydraulic components using press-fitting, guaranteeing a leak-proof seal.

- Adhesive Bonding: I have experience using various adhesives, including epoxies and cyanoacrylates, for bonding different materials. Careful surface preparation and the selection of appropriate adhesives are key to long-lasting bonds, a principle I’ve applied in numerous electronic assembly projects.

- Soldering and Circuit Board Assembly: My skills extend to surface mount and through-hole soldering techniques for delicate electronic components. In one instance, I repaired a complex circuit board failure by meticulously identifying the faulty components and resoldering the connections.

Understanding the strengths and limitations of each technique is crucial for selecting the most appropriate method for a given task, ensuring both durability and efficiency.

Q 2. What are the common tools and equipment used in assembly and repair?

The tools and equipment I use vary depending on the project, but some common items include:

- Hand Tools: Screwdrivers (various types and sizes), wrenches, pliers, hammers, sockets, Allen keys.

- Power Tools: Drills, impact wrenches, grinders, saws (e.g., reciprocating saws, circular saws), and specialized tools like rivet guns.

- Measuring and Inspection Tools: Calipers, micrometers, rulers, levels, and dial indicators for precise measurements and quality checks.

- Specialized Tools: Depending on the task, this might include torque wrenches, crimpers, soldering irons, welding equipment (MIG, TIG, etc.), and specialized jigs and fixtures.

- Test Equipment: Multimeters, oscilloscopes, and other diagnostic tools for electrical systems. Pressure gauges for hydraulic systems are also critical.

- Safety Equipment: Safety glasses, gloves, ear protection, and appropriate clothing are essential for every task.

Proper tool selection and maintenance are critical for efficient and safe work practices. For example, using a worn-out screwdriver can strip screws, leading to additional work and potential damage.

Q 3. Explain your troubleshooting process when encountering a faulty assembly.

My troubleshooting process is systematic and follows these steps:

- Identify the Symptoms: Thoroughly examine the faulty assembly to determine the exact nature of the problem. What is malfunctioning? What are the visible signs of failure?

- Gather Information: Collect any relevant information, such as technical drawings, schematics, maintenance logs, or previous repair records. This helps understand the assembly’s design and history.

- Visual Inspection: Carefully examine all components for any visible signs of damage, such as cracks, breaks, loose connections, or corrosion.

- Testing and Measurement: Use appropriate testing equipment (multimeters, pressure gauges, etc.) to check the functionality of individual components and verify that they are operating within their specifications.

- Component Isolation: Isolate potential problem areas by systematically testing each component or subsystem until the faulty part is identified. This may involve removing and testing components individually.

- Repair or Replacement: Once the faulty component is identified, repair it if possible, or replace it with a new, identical part. Ensure the replacement part is of the same quality and specifications as the original.

- Verification: After repair or replacement, thoroughly test the entire assembly to ensure that the problem is resolved and the assembly is functioning correctly.

For example, if a motor is not turning, I’d check the power supply, the motor windings, the wiring connections, and ultimately, the motor itself, using systematic elimination.

Q 4. How do you ensure quality control during the assembly process?

Quality control is an integral part of my assembly process. I utilize several techniques to ensure high-quality results:

- Visual Inspection: A thorough visual check at each stage of the assembly process to identify any defects or inconsistencies.

- Dimensional Checks: Using measuring tools (calipers, micrometers) to ensure that all components are within the specified tolerances. For example, checking the diameter of a shaft before installing it in a bearing.

- Functional Testing: Testing the assembled unit to confirm that it meets all operational requirements. This could involve running the motor, testing the hydraulic pressure, or checking the electrical functionality.

- Torque Control: Using a torque wrench to tighten fasteners to the specified values. This prevents damage to components and ensures proper assembly.

- Documentation: Maintaining detailed records of the assembly process, including any deviations from the standard procedure or any encountered issues.

- Use of Jigs and Fixtures: These tools ensure consistent assembly, reduce the risk of human error, and improve overall quality.

Adherence to these steps minimizes errors and enhances the reliability of the final product. I often use checklists to ensure every step is followed.

Q 5. Describe your experience with reading and interpreting technical drawings and schematics.

I have extensive experience reading and interpreting technical drawings and schematics. This includes understanding various types of drawings such as:

- Orthographic Projections: Interpreting multiple views (front, top, side) to visualize the three-dimensional shape and dimensions of a component.

- Isometric Drawings: Understanding three-dimensional views to visualize the assembly and spatial relationships between components.

- Schematic Diagrams: Interpreting circuit diagrams, hydraulic schematics, and pneumatic schematics to understand the flow of signals, fluids, or air through a system.

- Exploded Views: Using exploded views to understand the assembly sequence and the relationships between various parts.

- Bill of Materials (BOM): Using the BOM to identify and locate all necessary components for the assembly.

I’m proficient in using various software packages for viewing and annotating technical drawings. My ability to interpret drawings accurately ensures I assemble components correctly and efficiently. I remember a time where understanding an intricate exploded view was crucial to repair a specialized machinery part successfully.

Q 6. What are your preferred methods for documenting assembly and repair procedures?

My preferred methods for documenting assembly and repair procedures prioritize clarity and accuracy to ensure repeatability and troubleshooting ease. I utilize:

- Detailed Written Procedures: Creating step-by-step instructions with clear images or diagrams illustrating each step. This includes specifying tools, parts, and any critical measurements or tolerances.

- Digital Photography and Video Recording: Documenting the assembly process with photos and videos. This is especially helpful for complex assemblies or repairs, allowing for visual reference.

- Spreadsheets and Databases: Using spreadsheets to track part numbers, quantities, and serial numbers of components. Databases can assist in managing repair history and part usage.

- Annotated Drawings: Marking up original drawings with notes, modifications, or details specific to a particular assembly or repair.

Comprehensive documentation not only facilitates efficient repair but also aids in continuous improvement by highlighting common issues or areas for optimization. A well-maintained log ensures consistency and efficiency, both for individual tasks and the larger project.

Q 7. How do you handle working under pressure and meeting tight deadlines?

Working under pressure and meeting tight deadlines is a regular part of my role. My approach involves:

- Prioritization: I identify critical tasks and focus on those first to ensure timely completion of the most important aspects of the project. This often includes breaking down complex tasks into smaller, manageable steps.

- Time Management: Using time management techniques like creating detailed schedules and sticking to them. Regular progress checks and adjusting the schedule as needed help keep projects on track.

- Effective Communication: Maintaining open communication with supervisors and team members to ensure everyone is informed of progress, potential roadblocks, or required support. Proactive communication helps address challenges early.

- Stress Management: I utilize stress-management techniques to ensure that I maintain focus and productivity even under pressure. This may include taking short breaks and prioritizing personal well-being.

I recall a project with a very tight deadline where prioritizing tasks and effective communication with the team allowed us to successfully complete the project without compromising quality. A calm and organized approach is paramount under pressure.

Q 8. Describe a time you had to repair a complex piece of equipment. What was the challenge, and how did you overcome it?

One of the most challenging repairs I undertook involved a high-precision CNC milling machine that had suddenly stopped functioning mid-operation. The initial diagnosis pointed to a potential issue within the servo-motor control system, a complex network of electronics and feedback loops crucial for precise movement. The challenge wasn’t simply identifying the faulty component; it was pinpointing the exact cause of failure within this intricate system. The machine’s error logs were cryptic, offering only partial clues.

My approach involved a systematic troubleshooting process. First, I meticulously examined the error logs and cross-referenced them with the machine’s wiring diagrams and schematics. This revealed a potential voltage fluctuation affecting the servo-motor driver. I then used a multimeter to test all voltage levels and current flows throughout the circuit, comparing my readings against the manufacturer’s specifications. This painstaking process eventually pinpointed a faulty capacitor within the driver module – a small component, but one causing significant disruption.

Replacing the capacitor was relatively straightforward, but verifying the repair required careful calibration and testing. I used the machine’s built-in diagnostics to run a series of test cuts, meticulously measuring the precision and consistency. After several iterations of adjustment and fine-tuning, I restored the machine to its original operational parameters, ensuring the precision required for its intended tasks. The experience underscored the importance of systematic troubleshooting, careful attention to detail, and the need for a strong foundation in electronics alongside mechanical expertise.

Q 9. What safety precautions do you follow when performing assembly and repair tasks?

Safety is paramount in assembly and repair. My approach always follows a layered safety protocol. This begins with a thorough risk assessment of the job, identifying potential hazards like electrical shock, sharp edges, moving parts, and hazardous materials. Appropriate Personal Protective Equipment (PPE) is essential – this includes safety glasses, gloves, hearing protection, and, where necessary, respirators. I always ensure the work area is clean, organized, and well-lit to minimize tripping hazards or accidental contact with tools or equipment.

Before beginning any task involving power tools, I always check their cords and connections for any damage. I ensure the tools are properly grounded and that I have a clear understanding of their operation and safety features. Similarly, when handling hazardous materials such as solvents or lubricants, I carefully review the Material Safety Data Sheets (MSDS) and follow all recommended safety precautions.

Lockout/Tagout procedures are strictly followed when working on machinery or equipment that could cause injury or damage if unexpectedly energized. Proper lifting techniques are utilized to prevent back injuries, and any heavy components are handled using appropriate lifting aids. Ultimately, my approach prioritizes proactive risk management and adherence to strict safety protocols, establishing a culture of safety consciousness.

Q 10. How familiar are you with different types of fasteners and their applications?

I have extensive experience with a wide variety of fasteners, from simple screws and bolts to more specialized options like rivets, clamps, and threaded inserts. My understanding extends beyond simply knowing their names; I understand their applications, strengths, and limitations, enabling me to choose the optimal fastener for a given task. For example:

- Screws: I’m familiar with different screw types, including machine screws, wood screws, self-tapping screws, and sheet metal screws, and understand the implications of different head styles (Phillips, flathead, hex) and thread pitches.

- Bolts: I understand the differences between various bolt types such as carriage bolts, eye bolts, and hex bolts and can select the appropriate grade and material based on the application’s load requirements.

- Rivets: I know how to select and install solid and blind rivets for joining materials where welding or bolting isn’t feasible.

- Specialized Fasteners: I’m also experienced with specialized fasteners like keyways, set screws, and various types of locking devices used to prevent loosening under vibration or stress.

My knowledge enables me to select fasteners that are not only secure but also appropriate for the material being fastened and the operating environment. This ensures structural integrity and prevents premature failure.

Q 11. Explain your experience with using hand tools and power tools.

I’m highly proficient in using both hand tools and power tools, understanding the proper techniques and safety procedures for each. My experience with hand tools encompasses a comprehensive range, including screwdrivers, wrenches, pliers, hammers, saws, files, and measuring instruments such as calipers and micrometers. I understand the importance of selecting the right tool for the job, employing proper techniques to maximize efficiency and minimize risk of damage or injury.

My power tool experience includes drills, grinders, saws (reciprocating, circular, band), routers, and sanders. I am familiar with the various safety features of these tools, including safety switches, guards, and dust collection systems, and utilize them consistently to ensure a safe working environment. Furthermore, I’m experienced in maintaining and repairing power tools, ensuring they’re in optimal working condition and adhering to regular maintenance schedules to prevent accidents and ensure precision.

I am adept at selecting the appropriate tools and techniques for specific tasks, combining the precision of hand tools with the efficiency of power tools to accomplish complex repairs efficiently and safely. For example, I might use a hand-held file for detailed finishing work after rough cutting with a power saw.

Q 12. How do you identify and address potential hazards in a work environment?

Identifying and addressing potential hazards in a work environment is a crucial part of my routine. It starts with a visual inspection of the workspace, identifying potential hazards like loose wires, spills, obstructions, and poorly maintained equipment. I then assess the specific tasks involved, anticipating any potential risks associated with the tools, materials, and processes being used.

This assessment might involve checking for proper grounding of equipment, verifying the integrity of safety devices (e.g., emergency stop buttons, safety guards), and inspecting tools for damage or wear. I also consider ergonomic factors, ensuring workstations are properly configured to minimize the risk of musculoskeletal injuries. If any hazards are identified, I take immediate action to mitigate them, which may involve implementing corrective measures, providing appropriate PPE, or even halting work until the hazard is eliminated.

Beyond immediate risk identification, I advocate for proactive hazard prevention. This might involve suggesting improvements to workspace layout, recommending better storage solutions for materials, or providing training to colleagues on safe work practices. In essence, my approach combines proactive hazard identification with reactive mitigation, prioritizing both immediate safety and the establishment of a consistently safe work environment.

Q 13. Describe your experience with soldering and/or welding techniques.

I possess practical experience in both soldering and welding, with a strong understanding of the techniques, materials, and safety precautions involved. My soldering skills encompass various techniques, including through-hole soldering, surface mount soldering, and specialized soldering for delicate electronic components. I’m familiar with different types of solder, fluxes, and soldering irons, and can select the appropriate combination for specific materials and applications. For example, I would use a lower wattage iron and lead-free solder for delicate electronics and a higher-wattage iron with a different flux for heavier-gauge wires.

My welding experience is primarily focused on arc welding (MIG and TIG), although I have some exposure to other methods like stick welding. I understand the importance of proper joint preparation, electrode selection, and welding parameters to achieve strong, clean welds. Safety is paramount when welding – proper ventilation, eye protection, and fire precautions are always observed. The specific technique used depends heavily on the materials being joined and the desired quality of the weld. For example, TIG welding is better suited for precision work on thin materials, while MIG welding is more efficient for thicker materials.

My experience in both soldering and welding is invaluable for repairing and assembling a wide range of equipment, from electronics to mechanical systems, ensuring structural integrity and electrical functionality.

Q 14. How do you stay current with the latest advancements in assembly and repair technologies?

Staying current with the latest advancements in assembly and repair technologies is crucial for maintaining a high level of expertise. I actively participate in professional development activities, attending workshops, conferences, and webinars focused on new tools, techniques, and industry best practices. This includes staying abreast of developments in materials science, robotics in assembly, and the increasing use of sophisticated diagnostic tools.

I also regularly review industry publications, journals, and online resources, subscribing to relevant newsletters and following leading experts and manufacturers in the field. This constant learning helps me stay informed about new equipment, materials, and software solutions that enhance efficiency, precision, and safety in assembly and repair operations. The ever-evolving nature of technology requires continuous learning, and I actively seek opportunities to expand my knowledge and skillset.

Furthermore, I actively engage with online communities and forums to exchange information with other professionals, participating in discussions about troubleshooting techniques and sharing experiences with challenging repairs. This collaborative approach offers valuable insights and keeps me connected to the latest trends and best practices in the industry.

Q 15. What is your experience with preventative maintenance?

Preventative maintenance is the key to keeping equipment running smoothly and avoiding costly breakdowns. It’s all about proactively identifying and addressing potential problems before they become major issues. Think of it like regular check-ups at the doctor – much better to catch something small before it turns into a serious illness!

My experience includes developing and implementing preventative maintenance schedules for a variety of machinery, ranging from complex automated assembly lines to simpler hand tools. This involves meticulously reviewing equipment manuals, identifying critical components prone to wear and tear, and scheduling regular inspections, lubrication, and part replacements. For example, in my previous role, I implemented a preventative maintenance program for our CNC milling machines, which reduced downtime by 25% in the first year by ensuring regular lubrication and timely replacement of cutting tools.

- Developing schedules: Creating tailored schedules based on manufacturer recommendations and operational usage.

- Inspection and testing: Conducting thorough inspections, performing functional tests, and documenting findings.

- Parts management: Ensuring the timely procurement and availability of necessary replacement parts.

- Record keeping: Maintaining detailed records of all maintenance activities for tracking and analysis.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle difficult or demanding customers?

Handling demanding customers requires a combination of empathy, strong communication, and problem-solving skills. It’s about understanding their perspective while calmly and efficiently addressing their concerns. I believe in active listening; letting the customer fully explain their issue before offering solutions. I always strive to maintain a professional demeanor, even in stressful situations.

For instance, I once dealt with a customer whose machine had unexpectedly malfunctioned during a critical production run. Instead of getting defensive, I actively listened to their frustration, reassured them that we would work towards a solution, and immediately dispatched a technician to diagnose and resolve the problem. This prompt and empathetic response ultimately salvaged the situation and preserved the customer relationship. Transparency is key; I keep customers informed every step of the way, managing their expectations and providing realistic timelines for resolution.

- Active Listening: Truly understanding the customer’s perspective.

- Empathy: Showing understanding and concern for their situation.

- Clear Communication: Explaining technical issues in a clear, concise manner.

- Problem-Solving: Taking ownership and finding practical solutions.

Q 17. Describe your experience with using Computerized Maintenance Management Systems (CMMS).

Computerized Maintenance Management Systems (CMMS) are invaluable tools for streamlining maintenance operations. They provide a centralized platform for scheduling, tracking, and managing all aspects of maintenance, from preventative maintenance tasks to repair work orders. My experience includes using CMMS software to manage work orders, track inventory, analyze maintenance data, and generate reports.

In my previous role, we used a CMMS to track all maintenance activities for over 500 pieces of equipment. This allowed us to effectively manage preventative maintenance schedules, reducing downtime and improving overall equipment effectiveness (OEE). The software’s reporting features were also invaluable in identifying trends and improving maintenance strategies. For example, the CMMS highlighted a recurring issue with a specific component on one type of machine, leading to a proactive investigation and ultimately a design improvement to prevent future failures.

- Work Order Management: Creating, assigning, and tracking work orders.

- Inventory Management: Tracking spare parts and equipment.

- Preventative Maintenance Scheduling: Scheduling and managing PM tasks.

- Reporting and Analysis: Generating reports to identify trends and improve efficiency.

Q 18. How do you manage multiple tasks and prioritize your workload effectively?

Effective task management is crucial in assembly and repair, where multiple projects often compete for attention. I utilize a combination of prioritization techniques and organizational tools to manage my workload. I start by identifying tasks with the tightest deadlines and highest impact. Then, I break down larger tasks into smaller, more manageable steps.

I often use a Kanban board – either physical or digital – to visualize my workflow. This helps me track progress, identify bottlenecks, and adjust my priorities as needed. I also utilize time-blocking techniques, scheduling specific time slots for focused work on particular tasks. This minimizes interruptions and enhances productivity. This structured approach ensures that even under pressure, urgent issues are handled promptly, and long-term projects stay on track.

- Prioritization: Identifying tasks based on urgency and importance (Eisenhower Matrix).

- Task Breakdown: Dividing larger tasks into smaller, manageable steps.

- Time Blocking: Scheduling dedicated time for specific tasks.

- Kanban Boards: Visualizing workflow and tracking progress.

Q 19. What is your experience with different types of adhesives and their applications?

Adhesives are a critical component in many assembly and repair processes, and my experience encompasses a wide range of types and applications. I’m familiar with various adhesive chemistries, including epoxies, cyanoacrylates (super glues), silicones, and urethanes. The choice of adhesive depends heavily on the materials being bonded, the environmental conditions, and the required strength and durability of the bond.

For example, I’ve used epoxy adhesives for structural bonding applications where high strength and temperature resistance are crucial. Cyanoacrylates are excellent for quick, temporary fixes, while silicones are often used for sealing and weatherproofing. Understanding the limitations of each type is essential. Improper adhesive selection can lead to bond failure and compromise the integrity of the repaired item. I always carefully consider the surface preparation required for optimal adhesion, as this is just as critical as selecting the correct adhesive type.

- Epoxy: High strength, excellent for structural bonding.

- Cyanoacrylate: Fast-curing, suitable for quick repairs.

- Silicone: Flexible, often used for sealing and weatherproofing.

- Urethane: Durable, good for high-stress applications.

Q 20. Describe your experience with calibration and testing equipment.

Calibration and testing equipment are essential for ensuring the accuracy and reliability of repairs and assemblies. My experience includes using a wide variety of calibration and testing equipment, from simple hand tools like micrometers and calipers to sophisticated electronic test equipment. Understanding how to operate, maintain, and interpret the data from these instruments is critical.

I’m proficient in using equipment such as multimeters for electrical testing, pressure gauges for pneumatic systems, and torque wrenches for ensuring proper fastener tightening. Regular calibration is critical; for instance, a poorly calibrated torque wrench can lead to stripped threads or fastener failure. I follow strict calibration procedures, meticulously documenting all readings and ensuring traceability. This rigorous approach guarantees the quality and safety of my work.

- Multimeters: Measuring voltage, current, and resistance.

- Pressure Gauges: Measuring pressure in pneumatic and hydraulic systems.

- Torque Wrenches: Ensuring proper fastener tightening.

- Micrometers & Calipers: Precision measurements of dimensions.

Q 21. Explain your understanding of ISO 9001 or other relevant quality standards.

ISO 9001 is an internationally recognized quality management standard that outlines requirements for a quality management system (QMS). A strong QMS ensures that an organization consistently meets customer and regulatory requirements. My understanding of ISO 9001 encompasses its key principles, including customer focus, process approach, leadership, engagement of people, improvement, and evidence-based decision making.

In practice, this translates to a meticulous approach to documentation, traceability, and continuous improvement. This includes maintaining detailed records of all processes, ensuring that work is performed according to established procedures, and regularly reviewing performance data to identify areas for improvement. Adherence to ISO 9001 standards ensures high quality work, reduces errors, and enhances customer satisfaction. It’s not just about meeting a standard; it’s about building a culture of quality throughout the entire organization.

- Customer Focus: Understanding and meeting customer requirements.

- Process Approach: Defining and managing processes to achieve objectives.

- Continuous Improvement: Regularly seeking opportunities to enhance processes.

- Evidence-Based Decision Making: Using data to inform decisions.

Q 22. How do you ensure the accuracy and precision of your work?

Accuracy and precision are paramount in assembly and repair. I ensure this through a multi-pronged approach focusing on meticulous planning, precise execution, and rigorous verification. It’s like building a complex LEGO castle – you need detailed instructions (plans), steady hands (execution), and careful checks (verification) to ensure it stands tall and strong.

Planning: Before starting any task, I thoroughly review blueprints, schematics, and work orders. I identify critical dimensions and tolerances, understanding the implications of even minor deviations. This prevents costly errors and rework down the line.

Precise Execution: I utilize appropriate tools and techniques for each step of the process. This includes selecting the right size drill bits, using calibrated measuring instruments, and following established assembly procedures. For instance, when installing a bearing, ensuring proper alignment and torque is crucial to prevent premature wear.

Rigorous Verification: Regular checks throughout the assembly process are essential. I use calibrated measuring instruments like micrometers and calipers to verify dimensions and ensure components meet specifications. Post-assembly, functional testing confirms proper operation. If there’s a discrepancy, I meticulously trace the root cause and implement corrective actions. This systematic approach avoids overlooking potential issues.

Q 23. What is your experience working with different materials (e.g., metals, plastics, composites)?

My experience spans a broad range of materials, including metals (steel, aluminum, titanium), plastics (ABS, polycarbonate, nylon), and composites (fiber-reinforced polymers). Each material demands a unique approach to handling and assembly. Think of it like cooking – you wouldn’t use the same technique to bake a cake as you would to grill a steak.

Metals: Working with metals often involves techniques like machining, welding, and brazing. I’m experienced in selecting the appropriate fasteners and considering factors such as material strength, corrosion resistance, and thermal expansion.

Plastics: Plastics require careful handling to avoid damage during assembly. Understanding the material’s properties—its flexibility, thermal sensitivity, and susceptibility to solvents—is crucial. Improper handling can lead to cracking or warping.

Composites: Composites are challenging because of their layered structure and the need for precise bonding. Understanding the curing process, adhesive selection, and the proper clamping techniques is essential to achieve a strong and durable bond.

My diverse experience allows me to adapt to various material requirements, ensuring efficient and reliable assemblies.

Q 24. Describe your experience with using measuring instruments (e.g., calipers, micrometers).

Proficiency with measuring instruments is fundamental. I’m comfortable using calipers, micrometers, dial indicators, and other precision measuring tools. Accuracy is not just about reading the instrument; it’s about understanding its limitations and employing proper measuring techniques.

Calipers: I use calipers for quick measurements of external and internal dimensions, depths, and step measurements. I understand how to zero the calipers properly and to avoid parallax error (reading the measurement from an angle).

Micrometers: Micrometers offer higher precision than calipers, and I use them for extremely accurate measurements, typically within micrometer tolerances. I understand how to adjust the thimble and ratchet correctly to avoid damage to the instrument and the workpiece.

Dial Indicators: Dial indicators are useful for checking alignment, runout, and other dimensional variations. I understand the significance of the dial’s graduations and how to interpret the readings.

Regular calibration and maintenance of these instruments are crucial to maintaining accuracy. I always ensure that my instruments are properly calibrated before performing any measurements, using certified standards whenever possible. It’s like regularly tuning a musical instrument to ensure it’s playing in tune.

Q 25. How do you handle situations where you need to work collaboratively with a team?

Collaboration is key in assembly and repair. I thrive in team environments, contributing my skills while actively listening to and respecting the input of my colleagues. I’ve been part of several teams where effective communication and problem-solving were vital for project success.

Clear Communication: I actively participate in team meetings, providing updates on my progress and seeking clarification when needed. This proactive approach prevents misunderstandings and keeps the project on track.

Shared Responsibility: I believe in a collaborative spirit, where each member contributes their expertise and takes ownership of their tasks. I’m always willing to help team members if they encounter challenges, as I know we achieve more collectively than individually.

Conflict Resolution: In any team, disagreements can arise. I prioritize open and constructive communication to resolve conflicts and find mutually acceptable solutions. The focus is always on the project’s success.

For example, on a recent project assembling a complex robotic arm, I worked closely with the electrical engineers to ensure proper integration of the mechanical and electrical components. This collaboration resulted in a seamless and successful integration.

Q 26. What is your understanding of lean manufacturing principles?

Lean manufacturing principles focus on maximizing customer value while minimizing waste. In assembly and repair, this translates to optimizing processes, reducing unnecessary steps, and improving efficiency. Think of it as streamlining a kitchen – removing clutter, improving workflow, and making the process smoother and faster.

Waste Reduction: Identifying and eliminating waste (e.g., excess inventory, unnecessary movement, defects) is critical. This includes optimizing storage, implementing efficient material handling, and implementing quality control measures to minimize rework.

Process Improvement: Lean methodologies, like 5S (Sort, Set in Order, Shine, Standardize, Sustain) and Kaizen (continuous improvement), help streamline processes and improve workflow. This could involve rearranging workspaces, improving tool organization, or simplifying assembly steps.

Just-in-Time Inventory: Maintaining optimal inventory levels helps to minimize storage costs and reduce waste from obsolete parts. It’s about having the right parts at the right time in the right quantity.

By applying lean principles, we can reduce costs, improve quality, and increase productivity in the assembly and repair process.

Q 27. Describe your experience with troubleshooting electrical and/or mechanical systems.

Troubleshooting electrical and mechanical systems requires a systematic approach, combining analytical skills and practical experience. I start by identifying the symptoms, then use a combination of diagnostic tools and techniques to pinpoint the root cause.

Electrical Systems: When troubleshooting electrical systems, I use multimeters, oscilloscopes, and other diagnostic tools to measure voltage, current, and resistance. I understand schematics and circuit diagrams, enabling me to trace signals and identify faulty components. Understanding electrical safety protocols is paramount.

Mechanical Systems: Troubleshooting mechanical systems often involves visual inspection, functional testing, and the use of specialized tools to measure parameters such as pressure, temperature, and vibration. Experience with different mechanical components (e.g., bearings, gears, hydraulics) is essential.

Systematic Approach: I typically follow a structured approach to troubleshooting, involving: (1) identifying the problem, (2) formulating hypotheses, (3) testing hypotheses, (4) implementing corrective actions, and (5) verifying the solution. This prevents wasted time and effort. It’s similar to solving a puzzle – you need to identify the pieces, test how they fit, and build the solution logically.

A recent example involved troubleshooting a malfunctioning conveyor system. Through careful observation and measurements, I identified a worn-out bearing as the cause of the problem, which was quickly replaced, restoring the system’s functionality.

Q 28. How do you document your work and ensure traceability?

Accurate documentation and traceability are crucial for accountability and future reference. My documentation practices ensure that all work is meticulously recorded, enabling easy tracking and reproducibility. Think of it like a detailed recipe – if you follow it precisely, you’ll get the same result each time.

Work Orders & Logs: I diligently complete work orders, documenting the tasks performed, parts used, and any deviations from the original plan. This log acts as an audit trail and allows anyone to quickly trace the history of a repair.

Visual Documentation: Photographs and videos are invaluable for documenting complex repairs or assemblies. They provide clear visual records of the work performed and help to identify potential issues that might not be apparent in text alone.

Digital Systems: I utilize Computerized Maintenance Management Systems (CMMS) when available to track parts, labor, and repair history electronically, enhancing traceability and facilitating data analysis. This ensures efficient inventory management and improved maintenance planning.

This robust documentation system is not only essential for ensuring quality but also for facilitating training, improving processes, and identifying recurring issues, enhancing efficiency and reducing downtime.

Key Topics to Learn for Assembly & Repair Interview

- Blueprint Reading and Interpretation: Understanding technical drawings, schematics, and diagrams to accurately assemble and repair components.

- Hand Tool Proficiency: Demonstrating expertise in using various hand tools (screwdrivers, wrenches, pliers, etc.) safely and effectively.

- Power Tool Operation and Safety: Safe and proficient operation of power tools like drills, saws, and grinders, adhering to all safety regulations.

- Troubleshooting and Diagnostics: Identifying and resolving mechanical issues, using logical problem-solving skills to diagnose malfunctions.

- Quality Control and Inspection: Understanding quality standards and performing thorough inspections to ensure assembled products meet specifications.

- Assembly Processes and Techniques: Knowledge of various assembly methods (e.g., fastening, joining, bonding) and choosing the appropriate technique for different materials.

- Repair Methods and Techniques: Familiarity with various repair techniques (e.g., welding, soldering, patching) and selecting the optimal approach for specific repairs.

- Material Science Basics: Understanding the properties of common materials used in assembly and repair (metals, plastics, composites) and their interaction.

- Safety Procedures and Regulations: Adherence to workplace safety regulations, including proper use of personal protective equipment (PPE).

- Maintenance and Preventative Maintenance: Understanding basic preventative maintenance procedures to extend the life of equipment and minimize downtime.

Next Steps

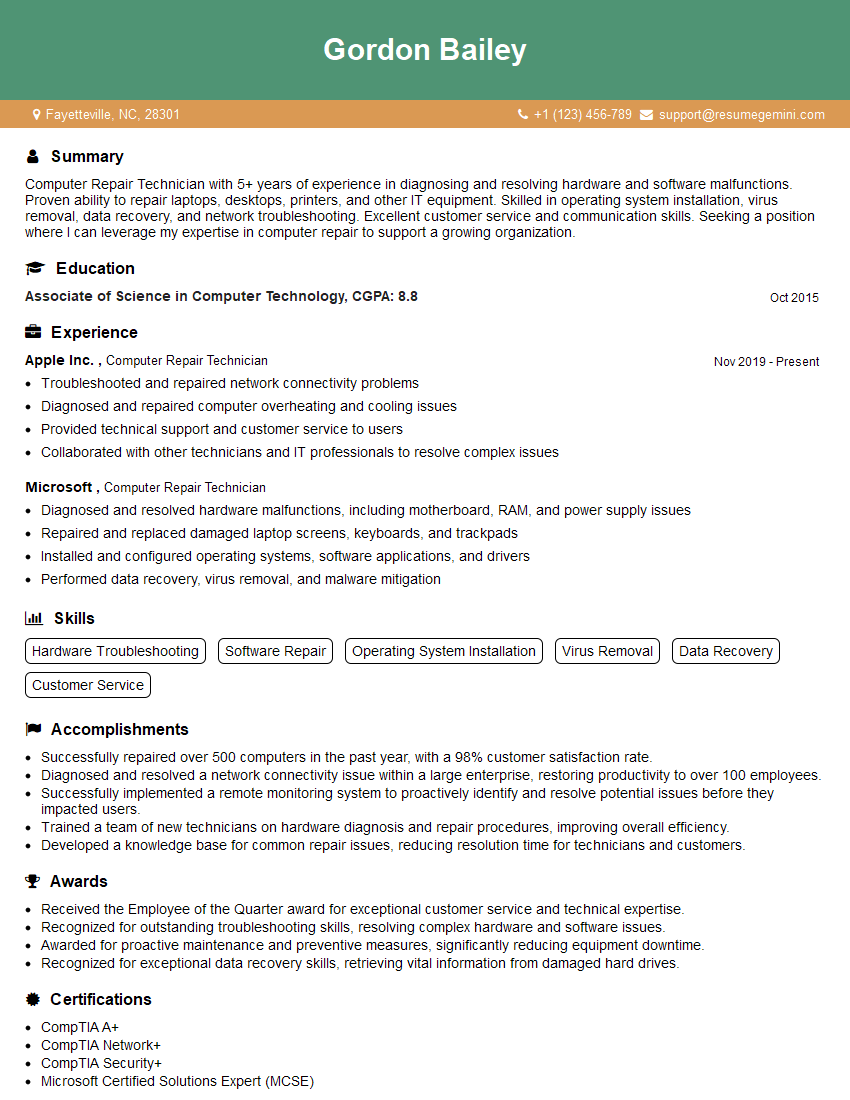

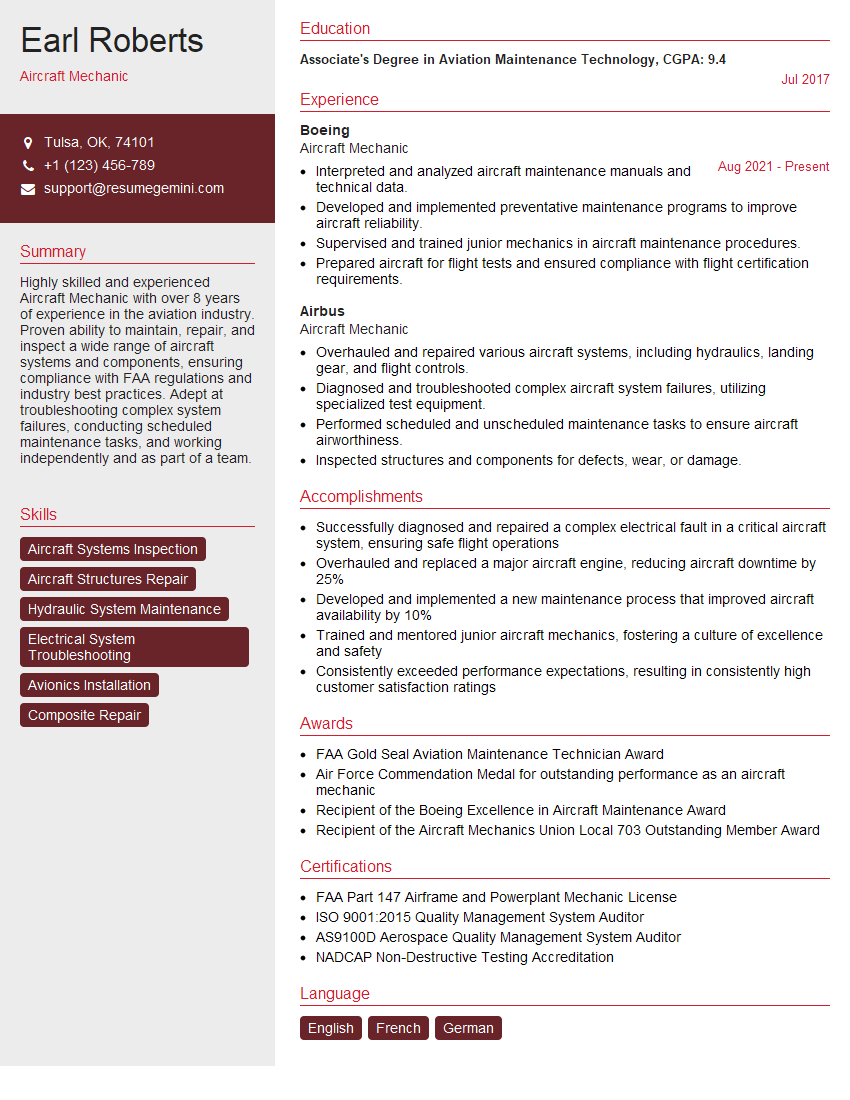

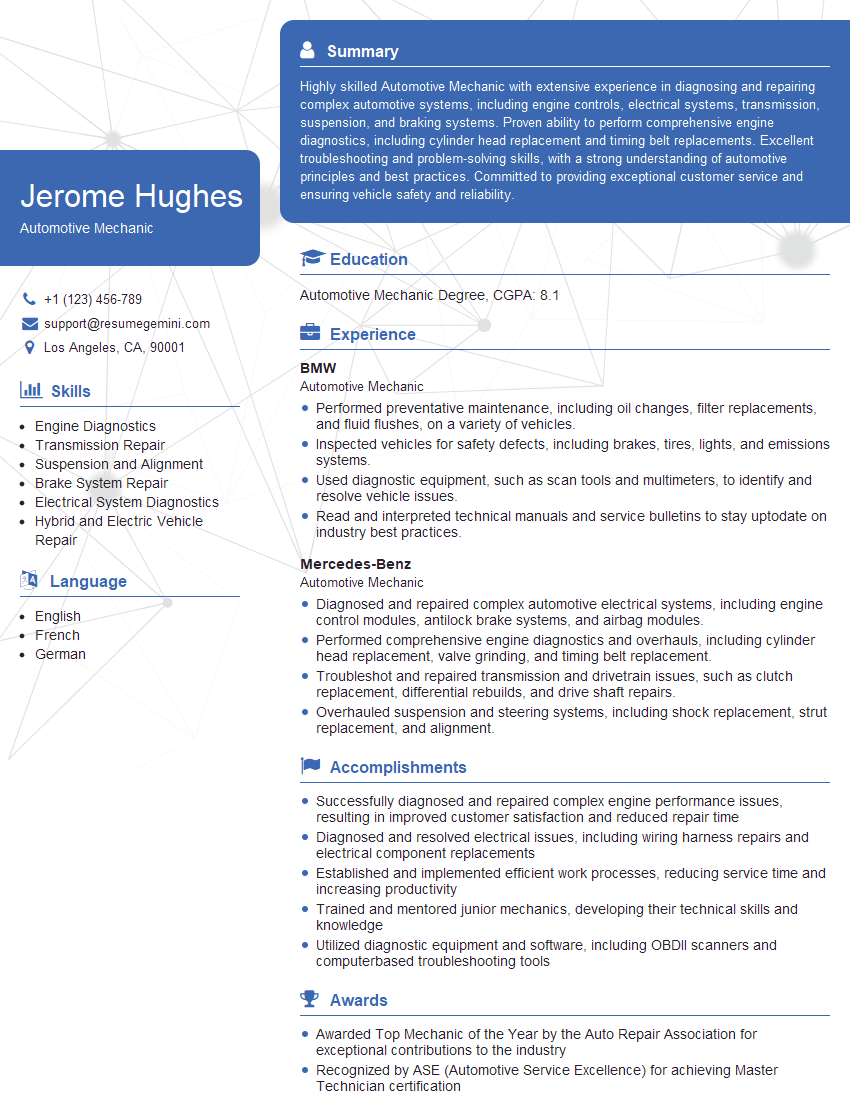

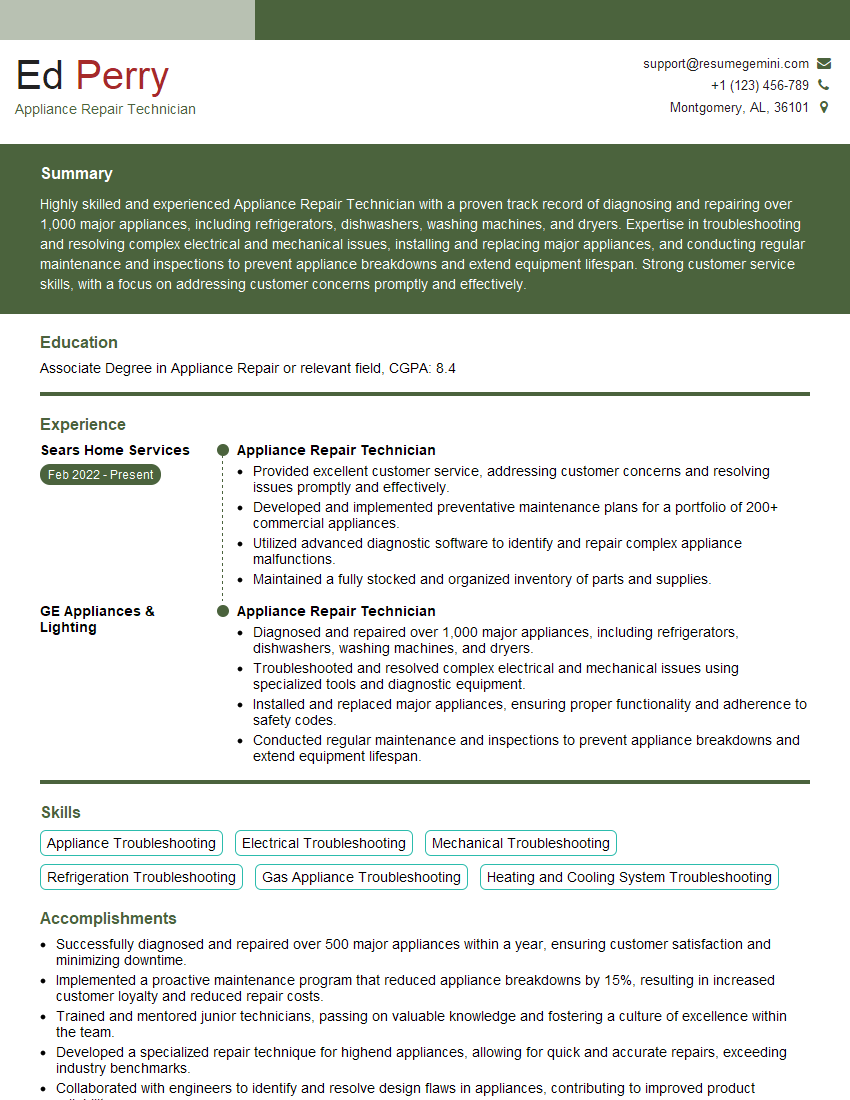

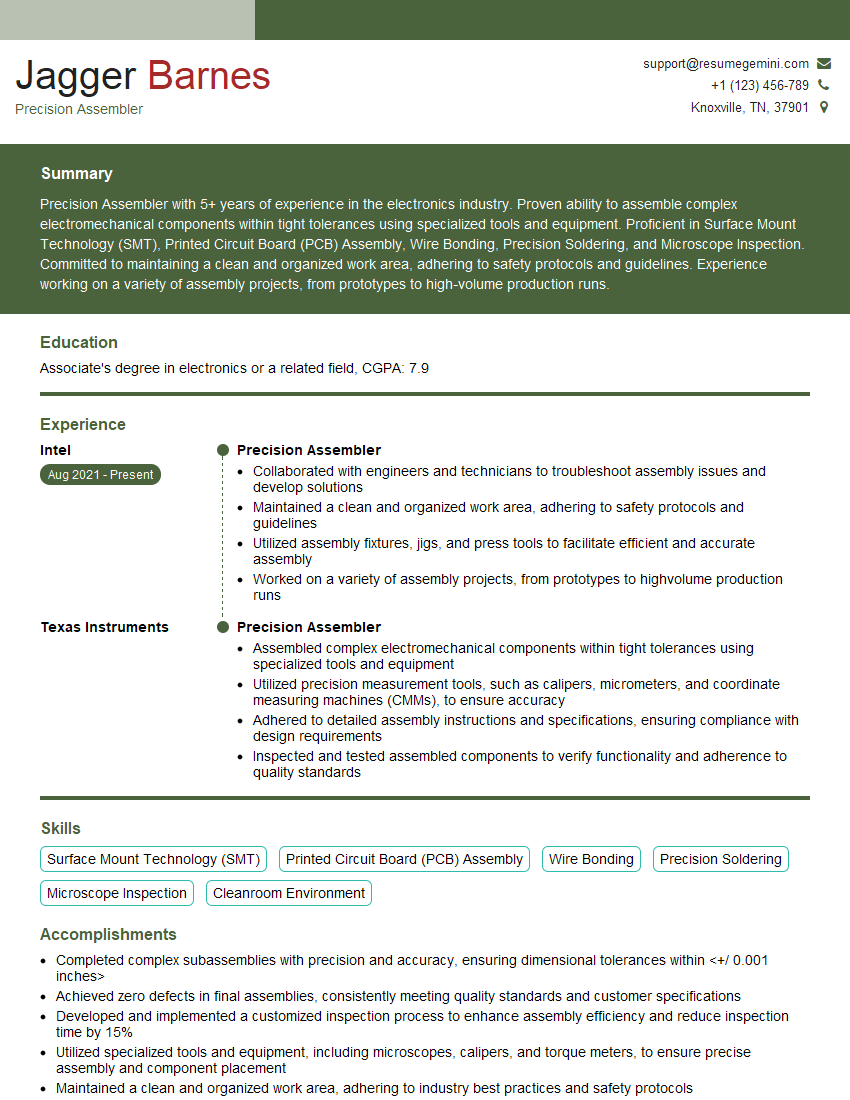

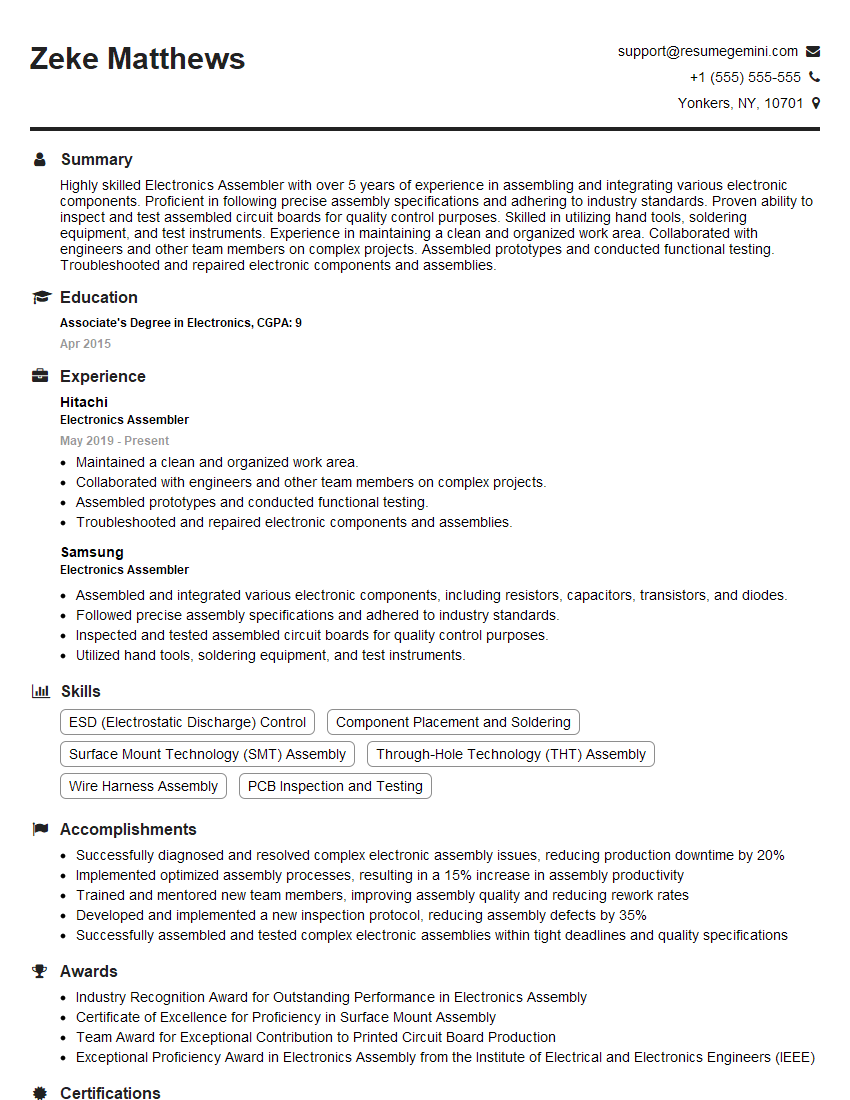

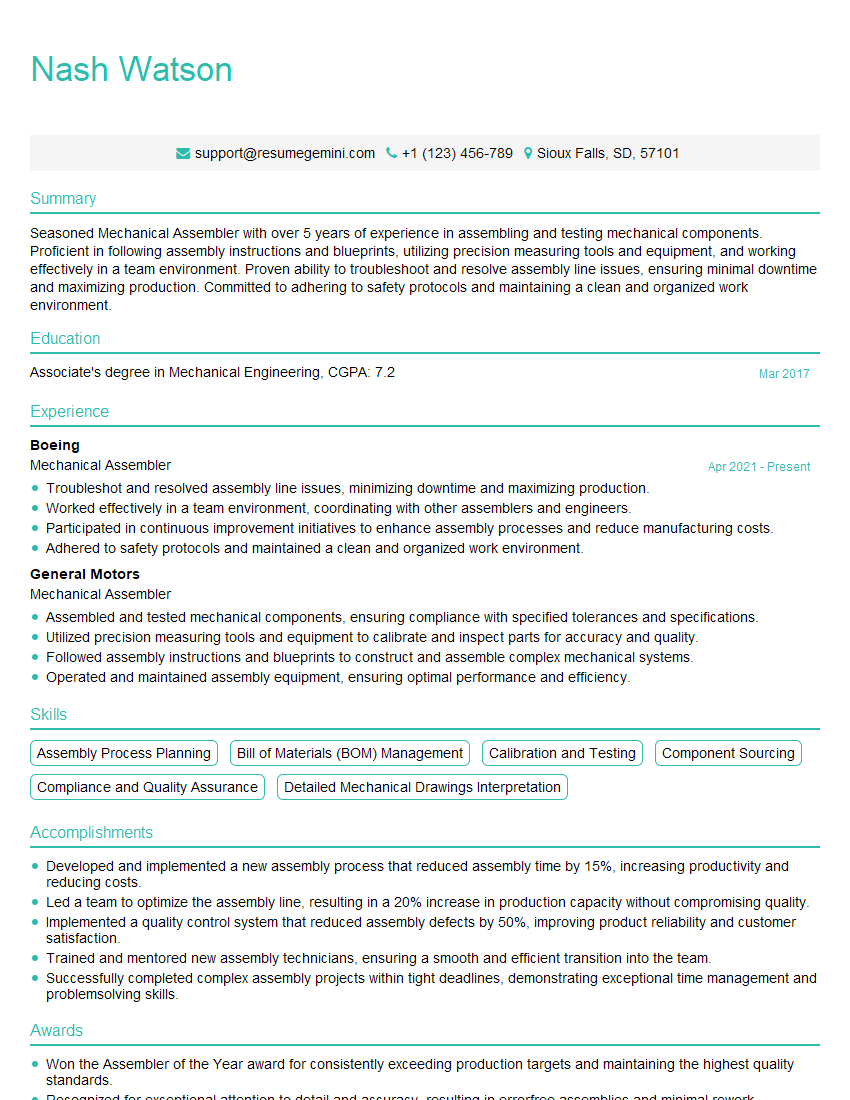

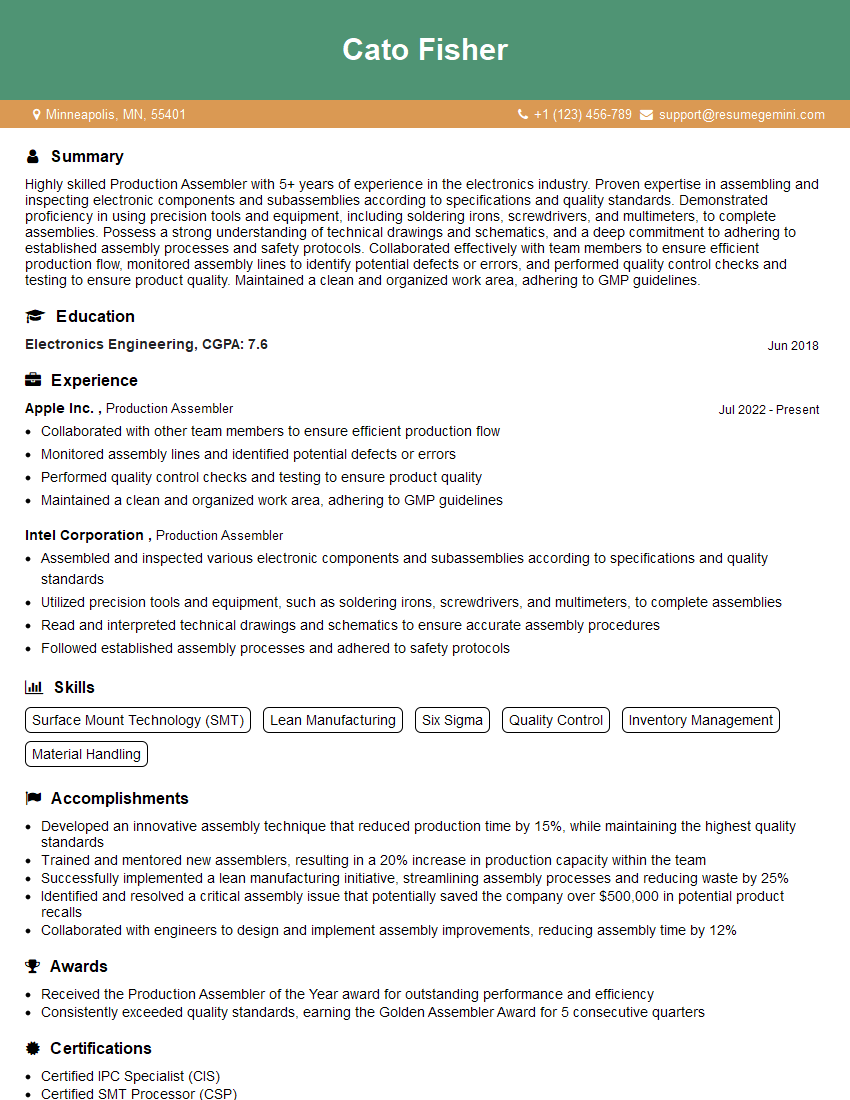

Mastering Assembly & Repair opens doors to diverse and rewarding career paths, offering opportunities for advancement and specialization. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume increases your chances of getting noticed by Applicant Tracking Systems, which screen many applications. To build a compelling and effective resume, leverage the power of ResumeGemini. ResumeGemini provides a user-friendly platform to craft a professional document that highlights your qualifications. Examples of resumes tailored to the Assembly & Repair field are available within ResumeGemini to guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good