Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Maintenance Planning & Scheduling interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Maintenance Planning & Scheduling Interview

Q 1. Explain your experience with CMMS software (e.g., SAP PM, Maximo).

My experience with CMMS software spans several years and includes extensive use of both SAP PM and IBM Maximo. I’m proficient in all aspects, from data entry and work order management to reporting and analysis. With SAP PM, I’ve successfully implemented and optimized maintenance plans for complex machinery in a manufacturing environment, leading to significant reductions in downtime. This included configuring equipment hierarchies, defining maintenance plans with various strategies (e.g., preventive, predictive, corrective), and managing the entire lifecycle of work orders. In Maximo, my focus was on leveraging its mobile capabilities to improve technician efficiency and real-time data tracking. I developed custom reports to monitor key performance indicators (KPIs) and proactively identify potential maintenance issues. For example, I created a report that highlighted equipment with a high number of recurring failures, which allowed for a focused effort on preventive measures to improve reliability.

My expertise extends beyond just using the software; I understand the underlying principles of maintenance management and how to configure the system to best support the organization’s specific needs. I’m confident in my ability to customize and extend CMMS functionalities to meet the challenges of any organization.

Q 2. Describe your process for developing a preventive maintenance schedule.

Developing a preventive maintenance (PM) schedule involves a systematic approach. First, I conduct a thorough assessment of the equipment, considering its criticality, failure modes, and potential consequences of failure. This often involves reviewing historical maintenance data, manufacturer recommendations, and industry best practices. Think of it like planning a car’s maintenance – you wouldn’t just change the oil randomly; you’d follow a schedule based on mileage and the manufacturer’s recommendations.

Next, I define the specific PM tasks for each piece of equipment. These tasks should address the most likely failure modes identified during the assessment. Each task will have an assigned frequency (e.g., daily, weekly, monthly, annually) and the necessary resources (parts, tools, labor). For example, a pump might have a PM schedule that includes daily lubrication checks, weekly vibration analysis, and annual overhaul.

Finally, the PM schedule is integrated into the CMMS system, where work orders are automatically generated based on the defined frequencies. Regular review and adjustments are crucial; the schedule is not static. It should be adapted based on actual equipment performance and emerging trends, such as changes in operational conditions or identification of new failure modes through data analysis. This iterative process ensures the schedule remains effective and cost-efficient.

Q 3. How do you prioritize work orders in a high-pressure environment?

Prioritizing work orders in a high-pressure environment requires a structured approach. I use a multi-criteria prioritization system that considers several factors, including the severity of the problem, the criticality of the equipment, and the potential impact on production or operations. Think of it like a hospital emergency room – patients are triaged based on the urgency of their condition.

I employ a matrix or scoring system, assigning weights to each factor. For example, a critical piece of equipment experiencing a complete shutdown receives a higher priority than a minor issue with non-critical equipment. The system is implemented within the CMMS and can even incorporate automated prioritization rules based on pre-defined criteria. This allows for a transparent and objective assessment, minimizing potential biases. Regular communication is also crucial; keeping stakeholders informed of the prioritization process and rationale helps manage expectations and maintain trust.

In addition to severity and criticality, I might also consider factors like safety risks, environmental impact, and the cost of downtime. By integrating these factors, a comprehensive and effective prioritization system is achieved.

Q 4. What metrics do you use to measure the effectiveness of your maintenance planning?

Measuring the effectiveness of maintenance planning requires a set of key performance indicators (KPIs). These metrics provide insights into the efficiency and effectiveness of our maintenance strategies. Some critical KPIs I use include:

- Mean Time Between Failures (MTBF): This measures the average time between equipment failures. A higher MTBF indicates improved equipment reliability.

- Mean Time To Repair (MTTR): This measures the average time taken to repair failed equipment. A lower MTTR indicates improved maintenance efficiency.

- Maintenance Cost per Unit of Production: This tracks the maintenance cost relative to the output, providing a cost-effectiveness measure.

- Equipment Uptime: This represents the percentage of time equipment is operational. Higher uptime is the ultimate goal.

- Preventive Maintenance Compliance Rate: This measures the percentage of scheduled PM tasks completed on time.

- Backlog of Work Orders: Tracks the number of outstanding work orders, providing insights into maintenance workload.

By regularly tracking and analyzing these KPIs, we can identify areas for improvement, optimize our maintenance strategies, and demonstrate the value of our maintenance planning efforts.

Q 5. Explain your understanding of Reliability Centered Maintenance (RCM).

Reliability Centered Maintenance (RCM) is a systematic process for determining the optimal maintenance strategy for each piece of equipment. It focuses on understanding the functions of the equipment and the potential consequences of failure. Instead of relying on arbitrary schedules, RCM uses a structured approach to determine what needs to be done, how often, and why.

The RCM process typically involves identifying all potential failure modes, assessing their consequences, and determining appropriate preventative actions. This might include preventive maintenance tasks, design modifications, operator training, or even choosing to accept the risk of failure if the consequences are minimal. Imagine a simple lightbulb – RCM might determine that replacing it when it burns out is a more cost-effective strategy than frequent preventive checks.

RCM is a proactive and data-driven approach that shifts the focus from reactive maintenance (fixing things after they break) to a more effective and cost-efficient strategy that improves overall equipment reliability and reduces downtime.

Q 6. How do you handle unexpected equipment failures and emergency repairs?

Handling unexpected equipment failures and emergency repairs requires a rapid and coordinated response. Our first step is to assess the severity of the failure and its impact on operations. This often involves engaging skilled technicians and engineers to quickly diagnose the problem.

Next, we utilize the CMMS to generate a prioritized work order for the emergency repair. The system facilitates communication and coordination among the maintenance team, management, and other stakeholders. Critical spare parts are identified and procurement is expedited. The repair work is closely monitored to ensure it’s completed efficiently and effectively, with safety remaining a top priority. Following the repair, a root cause analysis is conducted to prevent similar failures in the future; this might involve modifying the PM schedule or addressing underlying design flaws.

In some cases, we might utilize external resources for emergency repairs, especially for specialized equipment or if internal resources are unavailable. Post-incident reviews are then conducted to improve our response procedures.

Q 7. Describe your experience with predictive maintenance techniques.

My experience with predictive maintenance (PdM) techniques includes the use of various technologies and data analysis to anticipate potential equipment failures before they occur. This approach contrasts with preventive maintenance, which is based on time-based intervals. PdM allows for more targeted and cost-effective interventions.

Specific techniques I’ve used include vibration analysis (using accelerometers to detect abnormalities in equipment operation), oil analysis (checking lubricant samples for signs of wear or contamination), thermography (infrared imaging to detect overheating components), and motor current signature analysis (monitoring electrical current to detect developing faults in motors). The data collected is then analyzed to identify trends and predict potential failures. These predictions allow for proactive maintenance tasks to be scheduled, minimizing downtime and avoiding costly repairs. For instance, detecting an anomaly in vibration analysis of a pump might allow us to schedule maintenance before it leads to a complete failure, saving substantial production time.

In addition to these technologies, I utilize data analytics to identify patterns and correlations that could predict failures. This involves integrating data from various sources, such as CMMS, process control systems, and sensor data, into a comprehensive predictive model.

Q 8. How do you ensure accurate and up-to-date inventory of spare parts?

Maintaining an accurate and up-to-date spare parts inventory is crucial for minimizing downtime and optimizing maintenance costs. It’s like running a well-stocked grocery store – you need the right items, in the right quantity, at the right time. My approach involves a multi-pronged strategy:

- Implementing a robust CMMS (Computerized Maintenance Management System): A CMMS is the backbone of inventory management. It allows for real-time tracking of parts, including quantities on hand, minimum stock levels, and lead times for reordering. We use the system to generate automated alerts when stock levels fall below predefined thresholds.

- Regular Physical Inventory Counts: While the CMMS provides a digital record, regular physical verification is essential. We conduct cyclical counts, focusing on high-value or critical parts, to reconcile physical stock with the system data and identify any discrepancies. This helps catch errors early and prevent stockouts.

- ABC Analysis: We categorize parts based on their criticality and usage (A – high value/frequent use, B – medium, C – low). This allows us to focus our inventory control efforts on the most important parts (A items), ensuring we have sufficient stock on hand while implementing stricter control for less critical parts (C items).

- Vendor Managed Inventory (VMI): For frequently used parts, we work closely with suppliers using VMI. They are responsible for monitoring stock levels and replenishing inventory automatically, reducing our workload and ensuring timely delivery.

- Barcode/RFID Tracking: Utilizing barcode or RFID technology further enhances accuracy and efficiency in tracking parts throughout the entire lifecycle, from receipt to usage.

For example, in a previous role, we implemented a CMMS and ABC analysis, resulting in a 15% reduction in inventory holding costs and a 10% decrease in downtime due to spare parts shortages.

Q 9. How do you manage and resolve conflicts between maintenance and production schedules?

Balancing maintenance and production schedules is a delicate act, akin to juggling multiple balls. Conflicts are inevitable, but effective management is key to minimizing disruption. My approach centers around:

- Collaborative Planning: I foster open communication between maintenance and production teams. We jointly review planned maintenance activities well in advance, considering production schedules, deadlines, and potential impacts. This collaborative approach prevents surprises and allows for proactive adjustments.

- Prioritization and Scheduling Techniques: We use critical path analysis and prioritization matrices to determine the most critical maintenance tasks and schedule them accordingly, minimizing disruptions to production. Techniques like Critical Path Method (CPM) or Program Evaluation and Review Technique (PERT) can be employed to identify and address potential bottlenecks.

- Utilizing a CMMS: A robust CMMS is essential for visualizing both maintenance and production schedules simultaneously, identifying potential conflicts early on. The system facilitates real-time updates and allows for efficient rescheduling when necessary.

- Negotiation and Compromise: Sometimes, unavoidable conflicts arise. In such cases, open communication, negotiation, and compromise are key. We may need to adjust production schedules slightly or perform maintenance during less critical production periods to minimize downtime.

- Contingency Planning: We always develop contingency plans to address unexpected equipment failures or prolonged maintenance activities. This ensures minimal disruption to production even in unforeseen circumstances.

For instance, in a previous project, we implemented a collaborative planning process, which reduced production downtime due to maintenance conflicts by 20%.

Q 10. What is your experience with developing and managing maintenance budgets?

Developing and managing maintenance budgets requires meticulous planning, forecasting, and control. It’s like managing a household budget—you need to allocate funds effectively while staying within financial constraints. My experience includes:

- Budget Forecasting: I begin by forecasting maintenance costs based on historical data, equipment condition assessments, and planned maintenance activities. This involves analyzing factors like labor costs, spare parts, and contract services.

- Cost Estimation: Accurate cost estimation is critical. We use various methods, including parametric estimating and bottom-up estimating, to determine the cost of individual maintenance tasks and projects.

- Budget Allocation: Once the total budget is determined, we allocate funds to various maintenance activities based on priorities and risk assessments. This could involve prioritizing preventative maintenance over corrective maintenance.

- Budget Tracking and Control: Regular monitoring of actual vs. budgeted costs is essential to identify any deviations and implement corrective actions. This involves reviewing reports, analyzing variances, and taking proactive measures to stay within budget.

- Performance Reporting: I regularly report on maintenance budget performance to stakeholders, highlighting successes, challenges, and areas for improvement. This involves providing clear and concise reports with relevant data and visuals.

In a past role, I successfully managed a $2 million maintenance budget, resulting in a 5% reduction in overall maintenance costs while improving equipment reliability.

Q 11. Describe your process for optimizing maintenance resources.

Optimizing maintenance resources—both human and material—is crucial for maximizing efficiency and minimizing costs. Think of it as optimizing a team’s performance on a sports field—you need the right players in the right positions.

- Workforce Planning: We analyze workload, skill requirements, and availability to ensure we have the right number of technicians with the appropriate skills. This might include cross-training technicians or outsourcing specialized work.

- Preventative Maintenance Optimization: Implementing a well-defined preventative maintenance schedule is key. We optimize schedules by focusing on critical equipment and employing predictive maintenance techniques like vibration analysis to identify potential failures before they occur.

- Inventory Optimization (as described in answer 1): Efficient inventory management minimizes storage costs and reduces downtime due to part shortages.

- Resource Allocation: We use techniques like linear programming or simulation modeling to optimize the allocation of maintenance resources to different tasks, maximizing efficiency and minimizing conflicts.

- Technology Adoption: Implementing CMMS software, mobile devices, and other technologies improves communication, streamlines tasks, and enhances overall resource utilization.

For example, by implementing predictive maintenance, we reduced unplanned downtime by 30% in a manufacturing plant.

Q 12. How do you communicate effectively with maintenance technicians and other stakeholders?

Effective communication is the cornerstone of successful maintenance management. It’s like the conductor of an orchestra—you need to ensure everyone is playing in harmony.

- Regular Meetings: We conduct regular meetings with maintenance technicians to discuss work schedules, challenges, and opportunities for improvement. These meetings foster open communication and allow for immediate feedback.

- Clear Communication Channels: We establish clear communication channels (email, instant messaging, etc.) to facilitate quick and efficient information exchange.

- Use of CMMS: The CMMS serves as a central hub for communication, allowing technicians to access work orders, update progress, and report issues.

- Feedback Mechanisms: We actively solicit feedback from technicians regarding work processes, safety procedures, and training needs. This feedback is crucial for continuous improvement.

- Training and Development: We invest in training and development to enhance technical skills and communication abilities among maintenance personnel.

In a previous role, we implemented a daily huddle system with maintenance technicians, which improved communication, reduced errors, and increased overall team morale.

Q 13. Explain your experience with root cause analysis.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems, preventing their recurrence. It’s like detective work—you need to uncover the root of the problem, not just treat the symptoms.

- 5 Whys Technique: We frequently use the 5 Whys technique, repeatedly asking “why” to peel back layers of explanation and arrive at the root cause. For example: Why did the machine fail? Because the bearing seized. Why did the bearing seize? Because of insufficient lubrication. Why was there insufficient lubrication? Because the lubrication system was faulty, etc.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps to systematically brainstorm potential causes grouped by categories (materials, methods, manpower, machinery, environment, measurement). It helps to visualize potential root causes and identify interdependencies.

- Fault Tree Analysis (FTA): FTA uses a top-down approach to systematically break down a failure into its contributing factors. This is especially useful for complex systems.

- Data Analysis: We often use data analysis to identify trends and patterns that might contribute to recurring problems. This includes reviewing maintenance logs, equipment performance data, and other relevant information.

For example, using RCA after a major equipment failure, we identified a faulty component in the supply chain that was causing repeated failures, saving significant cost and preventing further breakdowns.

Q 14. How do you measure and improve maintenance technician productivity?

Measuring and improving maintenance technician productivity is crucial for maximizing efficiency and cost-effectiveness. It’s like measuring the effectiveness of a sales team – you need key metrics to assess performance and make improvements.

- Key Performance Indicators (KPIs): We define and track KPIs such as mean time to repair (MTTR), mean time between failures (MTBF), equipment availability, and backlog of maintenance tasks. These provide quantifiable measures of productivity.

- Work Order Completion Rates: Monitoring the timely completion of work orders indicates efficiency and effective resource allocation. Delays or backlog indicate areas requiring attention.

- First-Time Fix Rate: This metric measures the percentage of repairs completed successfully on the first attempt, minimizing repeated visits and improving overall efficiency.

- Employee Feedback and Training: Regularly gathering feedback from technicians and providing targeted training enhances skills and improves productivity. This includes both technical skills training and training on work management techniques.

- Process Improvement Initiatives: Analyzing work processes and identifying bottlenecks allows for streamlining and optimization, enhancing overall productivity.

In a past role, by implementing a comprehensive KPI tracking system and focused training programs, we increased technician productivity by 15% within six months.

Q 15. What is your experience with implementing a new CMMS system?

Implementing a new CMMS (Computerized Maintenance Management System) is a significant undertaking requiring careful planning and execution. It’s not just about software; it’s about transforming how an organization manages its maintenance processes. My experience includes leading the full lifecycle, from initial needs assessment and vendor selection to system configuration, data migration, user training, and ongoing optimization.

For instance, in a previous role, we replaced a legacy system with a cloud-based CMMS. The process involved:

- Needs Assessment: We identified key pain points in the existing system, such as inefficient work order management and inadequate reporting capabilities. This informed our requirements for the new system.

- Vendor Selection: We evaluated multiple vendors based on features, scalability, cost, and user-friendliness. We even conducted pilot tests with a subset of users to get their feedback.

- System Configuration: We customized the CMMS to match our specific workflows and reporting needs. This involved configuring equipment hierarchies, maintenance schedules, and user roles and permissions.

- Data Migration: We meticulously migrated historical maintenance data to ensure continuity. This required careful data cleansing and validation to avoid errors.

- User Training: We provided comprehensive training to all maintenance personnel to ensure effective adoption of the new system.

- Post-Implementation Support: We established a process for ongoing support, monitoring system performance, and making necessary adjustments.

The result was a significant improvement in maintenance efficiency, reduced downtime, and improved data-driven decision-making.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle changes in production schedules and their impact on maintenance?

Changes in production schedules directly impact maintenance planning. A reactive approach is inefficient and can lead to increased downtime and costs. My approach is proactive and involves close collaboration with production planning teams.

For example, if a production line needs to run overtime to meet a customer deadline, I would:

- Review the maintenance schedule: Identify any planned maintenance tasks that conflict with the extended production hours.

- Prioritize tasks: Assess the criticality of the maintenance tasks and reschedule non-critical tasks to minimize disruption.

- Communicate with production: Clearly communicate any potential maintenance windows to production to avoid conflicts and ensure smooth operations.

- Utilize CMMS functionalities: Leverage the CMMS’s scheduling and notification features to manage changes efficiently and keep all stakeholders informed.

- Consider alternative approaches: If rescheduling isn’t possible, explore alternatives like reduced-scope maintenance or compressed maintenance schedules.

This proactive approach ensures that maintenance needs are met without compromising production targets.

Q 17. Describe your experience with key performance indicators (KPIs) in maintenance.

Key Performance Indicators (KPIs) are crucial for measuring maintenance effectiveness and identifying areas for improvement. My experience includes defining, tracking, and analyzing various KPIs, including:

- Mean Time To Repair (MTTR): Measures the average time it takes to repair a piece of equipment after a failure.

- Mean Time Between Failures (MTBF): Measures the average time between equipment failures.

- Overall Equipment Effectiveness (OEE): Measures the overall efficiency of equipment, considering availability, performance, and quality.

- Maintenance Backlog: Tracks the number of outstanding maintenance tasks.

- Maintenance Cost per Unit Produced: Measures the cost of maintenance relative to production output.

I use data visualization tools and dashboards to present KPI data in a clear and concise manner. This allows for easy identification of trends and potential issues. For instance, a consistently high MTTR might indicate a need for improved spare parts management or technician training. Regular KPI review allows for data-driven decision making and continuous improvement.

Q 18. How do you identify and address potential maintenance bottlenecks?

Identifying and addressing maintenance bottlenecks requires a systematic approach. I typically use a combination of methods, including:

- Data Analysis: Analyze historical maintenance data to identify recurring issues, long repair times, or frequent equipment failures. This often reveals patterns that point to bottlenecks.

- Visual Management: Utilize visual aids such as Kanban boards or workflow diagrams to visualize the maintenance process and identify choke points.

- 5 Whys Analysis: Use the 5 Whys technique to drill down to the root cause of recurring problems. For example, consistently long repair times may be due to a lack of spare parts, inadequate technician training, or poorly defined maintenance procedures.

- Root Cause Analysis (RCA): Conduct more in-depth root cause analysis to thoroughly understand the underlying reasons for bottlenecks.

- Process Improvement Techniques: Implement process improvement techniques such as Lean or Six Sigma to optimize maintenance workflows and eliminate waste.

By addressing these bottlenecks, we can significantly improve maintenance efficiency and reduce downtime.

Q 19. What is your experience with developing and implementing maintenance procedures?

Developing and implementing effective maintenance procedures is essential for ensuring consistent and safe maintenance practices. This involves a structured approach that considers:

- Task Breakdown: Breaking down complex maintenance tasks into smaller, manageable steps. This ensures clarity and consistency.

- Safety Considerations: Incorporating safety precautions and procedures into each step of the maintenance task. This is crucial for minimizing risks.

- Tools and Equipment: Specifying the necessary tools, equipment, and materials for each task. This ensures that technicians have everything they need.

- Standard Operating Procedures (SOPs): Developing detailed SOPs that clearly outline each step of the process. This ensures consistency across all technicians.

- Training and Documentation: Providing adequate training to technicians on the new procedures and maintaining up-to-date documentation.

- Regular Review and Updates: Regularly reviewing and updating procedures based on feedback from technicians and lessons learned.

Well-defined procedures reduce errors, improve efficiency, and ensure compliance with safety regulations. For instance, a clear procedure for changing a critical component can significantly reduce downtime and the risk of accidents.

Q 20. How do you ensure compliance with safety regulations and standards in maintenance?

Ensuring compliance with safety regulations and standards is paramount in maintenance. This involves a multi-faceted approach that includes:

- Regular Safety Audits: Conducting regular safety audits to identify potential hazards and ensure compliance with relevant regulations.

- Lockout/Tagout Procedures: Implementing strict lockout/tagout procedures to prevent accidental energization of equipment during maintenance.

- Personal Protective Equipment (PPE): Ensuring that technicians have access to and use appropriate PPE, such as safety glasses, gloves, and hearing protection.

- Safety Training: Providing comprehensive safety training to all maintenance personnel, covering topics such as hazard identification, risk assessment, and safe work practices.

- Incident Reporting and Investigation: Establishing a system for reporting and investigating safety incidents to identify root causes and prevent recurrence.

- Compliance Documentation: Maintaining detailed records of safety inspections, training, and incident investigations.

Compliance not only protects personnel but also mitigates risks associated with legal liabilities and operational disruptions. A strong safety culture is vital, fostering an environment where safety is prioritized above all else.

Q 21. Describe your experience with different types of maintenance strategies (preventative, predictive, corrective).

Different maintenance strategies serve different purposes. My experience encompasses the effective application of corrective, preventive, and predictive maintenance:

- Corrective Maintenance: This is reactive maintenance performed after equipment failure. While essential, it’s often costly and disruptive. It’s crucial to analyze corrective maintenance data to identify trends and potential areas for preventive maintenance.

- Preventive Maintenance: This is proactive maintenance performed at scheduled intervals to prevent equipment failures. It typically involves inspections, lubrication, and parts replacements. A well-defined preventive maintenance schedule minimizes unplanned downtime and extends equipment life. However, over-maintenance can also be wasteful, so optimization is key.

- Predictive Maintenance: This is proactive maintenance based on real-time monitoring of equipment condition. It leverages technologies like vibration analysis, oil analysis, and thermal imaging to predict potential failures before they occur. This is the most advanced approach, minimizing downtime and optimizing maintenance resource allocation. It requires investment in monitoring equipment and expertise in data interpretation.

The optimal maintenance strategy often involves a combination of all three approaches, creating a balanced approach that addresses both immediate needs and long-term reliability. For example, a company might use preventive maintenance for routine tasks, corrective maintenance for unexpected failures, and predictive maintenance for critical equipment.

Q 22. How do you use data analytics to improve maintenance planning and scheduling?

Data analytics is crucial for optimizing maintenance planning and scheduling. We can leverage data to move away from reactive, break-fix maintenance towards proactive, predictive strategies. This involves collecting and analyzing data from various sources, such as equipment sensors, work orders, and historical maintenance records.

- Predictive Maintenance: By analyzing sensor data (vibration, temperature, pressure), we can identify patterns that indicate impending equipment failure. This allows us to schedule maintenance before a breakdown occurs, minimizing downtime and maximizing equipment lifespan. For example, analyzing vibration data from a pump might reveal increasing amplitude, predicting bearing failure within the next week. This allows us to schedule preventative maintenance to replace the bearing.

- Optimizing Maintenance Schedules: Analyzing historical data on equipment failures and maintenance activities helps us to refine maintenance schedules. We can identify recurring issues, understand failure rates, and optimize the frequency and type of maintenance needed. For instance, if we see a pattern of failures in a specific component every six months, we can adjust our schedule to include its preventative maintenance at that interval.

- Resource Allocation: Data analytics helps to optimize resource allocation. By analyzing historical data on maintenance tasks, labor hours, and material costs, we can predict resource needs more accurately. This ensures that we have the right people and materials available when and where they are needed, minimizing delays and costs.

- Performance Monitoring: Tracking key performance indicators (KPIs) such as Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), and Overall Equipment Effectiveness (OEE) provides insights into the effectiveness of our maintenance strategies and helps identify areas for improvement. This continuous monitoring and analysis allows for data-driven decision-making.

In essence, using data analytics transforms maintenance from a reactive cost center to a proactive, value-adding function.

Q 23. How do you manage and track maintenance costs?

Managing and tracking maintenance costs requires a robust system for capturing, categorizing, and analyzing expenditure data. This involves several key steps:

- Detailed Cost Tracking: Each work order should meticulously document all associated costs, including labor (direct and indirect), materials, contracted services, and disposal fees. We use a computerized maintenance management system (CMMS) for this purpose, enabling automated tracking and reporting.

- Cost Categorization: Costs are categorized into relevant buckets (e.g., preventive maintenance, corrective maintenance, inspections) to allow for detailed analysis and comparison of expenditure across different maintenance activities. This provides valuable insights into cost drivers.

- Budgeting and Forecasting: Based on historical data and predicted future needs, we develop budgets and forecasts for maintenance costs. This facilitates better resource allocation and helps prevent cost overruns. We regularly compare actual costs against the budget to identify variances and take corrective actions.

- Performance Analysis: We analyze maintenance costs in relation to KPIs such as MTBF and MTTR. This helps identify areas where cost reduction strategies can be implemented without compromising equipment reliability. For example, if we find that a certain type of corrective maintenance is exceptionally expensive, we might investigate preventative maintenance options.

- Regular Reporting: We generate regular reports on maintenance costs, presenting them in clear and concise formats to stakeholders. These reports facilitate informed decision-making and accountability.

By implementing these measures, we ensure transparent, efficient, and data-driven management of maintenance costs.

Q 24. Explain your experience with spare parts management.

Effective spare parts management is essential for minimizing downtime and ensuring operational efficiency. My experience involves implementing and managing a comprehensive spare parts inventory control system which includes:

- Inventory Optimization: Using ABC analysis (classifying parts based on their value and usage), we optimize inventory levels. High-value, critical parts are closely monitored and strategically stocked, while low-value, less critical parts are managed with less stringent controls. This prevents excessive capital tied up in inventory.

- Demand Forecasting: We utilize historical data and predictive analytics to forecast spare parts demand. This helps optimize procurement processes and avoid stockouts or excess inventory.

- Vendor Management: We develop and maintain strong relationships with key suppliers to ensure timely delivery and competitive pricing. This involves negotiating favorable contracts and establishing clear communication channels.

- Warehouse Management: Implementing a well-organized warehouse system, utilizing appropriate storage methods and tracking systems (barcodes, RFID), is essential for efficient inventory management. This ensures easy location and retrieval of parts when needed.

- Regular Inventory Audits: Conducting regular physical inventories and reconciling them with our inventory management system is crucial to maintain accuracy and prevent discrepancies. We address any issues promptly.

A well-managed spare parts system ensures that the right parts are available at the right time, minimizing downtime and maintenance costs.

Q 25. How do you use work order management systems to improve efficiency?

Work order management systems (WOMS) are pivotal for streamlining maintenance operations. My experience with WOMS focuses on leveraging these systems to increase efficiency by:

- Centralized Work Order Management: A WOMS centralizes all maintenance requests, providing a single point of access for scheduling, tracking, and reporting. This eliminates confusion and improves communication.

- Automated Scheduling: The system can automate scheduling of routine maintenance tasks, optimizing resource allocation and minimizing downtime. For example, we can schedule preventative maintenance tasks based on equipment runtime or calendar intervals.

- Real-time Tracking: WOMS provide real-time visibility into the status of each work order, allowing us to monitor progress, identify delays, and take corrective action. This enhances accountability and improves response times.

- Improved Communication: The system facilitates communication among maintenance personnel, management, and other departments. This ensures everyone is informed about the status of maintenance activities.

- Data-driven Insights: WOMS generate valuable data on maintenance activities, providing insights into maintenance costs, equipment reliability, and technician performance. This data can be used to improve maintenance strategies and optimize resource allocation.

By fully utilizing the features of a WOMS, we can significantly enhance the efficiency and effectiveness of our maintenance operations.

Q 26. What is your experience with leading and motivating a maintenance team?

Leading and motivating a maintenance team requires a combination of strong leadership skills, effective communication, and a focus on team development. My approach involves:

- Clear Communication: Establishing clear expectations, providing regular feedback, and fostering open communication are crucial for building a strong team. I prioritize regular team meetings and one-on-one discussions to address concerns and celebrate successes.

- Empowerment and Trust: I empower my team members by giving them autonomy and responsibility. This builds trust and motivates them to take ownership of their work. I also encourage continuous improvement and development.

- Training and Development: Investing in the training and development of my team members is essential for maintaining a skilled and motivated workforce. This might involve providing opportunities for advanced training, attending conferences, or mentoring junior technicians.

- Recognition and Rewards: Recognizing and rewarding good work is crucial for boosting morale and motivation. I actively acknowledge individual and team achievements to reinforce positive behaviors.

- Conflict Resolution: Addressing conflicts promptly and fairly is essential for maintaining a positive work environment. I strive to create a culture of respect and collaboration where team members feel comfortable raising concerns.

My goal is to create a high-performing maintenance team that is both efficient and engaged.

Q 27. Describe a situation where you had to make a difficult decision regarding maintenance priorities. What was the outcome?

In a previous role, we faced a critical situation where two critical pieces of equipment simultaneously required major maintenance. One was essential for a high-value production line, while the other supported a less critical but still important process. Both needed immediate attention, and we lacked the resources to address both simultaneously. The decision was complex because delaying either repair would result in significant financial losses.

My approach was to:

- Assess the Risks: We carefully analyzed the potential consequences of delaying each repair, considering the impact on production, revenue, and safety.

- Prioritize Based on Impact: We prioritized the equipment crucial for the high-value production line, as the potential financial loss from downtime was significantly higher.

- Develop a Mitigation Plan: For the less critical equipment, we developed a temporary mitigation plan to minimize disruption until its repair could be completed.

- Communicate Clearly: We communicated our decision and the mitigation plan transparently to all stakeholders, managing expectations effectively.

Outcome: While delaying the repair of the less critical equipment caused some minor disruption, the timely repair of the high-value line equipment prevented significant financial losses. The temporary mitigation plan worked well, and overall, the impact was minimized. The experience highlighted the importance of a robust risk assessment process and effective prioritization in managing complex maintenance challenges.

Q 28. How do you ensure the accuracy of maintenance data and records?

Ensuring the accuracy of maintenance data and records is paramount for effective maintenance planning and decision-making. This involves several key steps:

- Data Input Validation: We implement data input validation rules within our CMMS to prevent errors during data entry. For example, we might use drop-down menus for selecting equipment types or parts, preventing typos and inconsistencies.

- Regular Data Audits: We conduct regular audits of maintenance data to identify and correct errors or inconsistencies. This might involve comparing data from the CMMS with physical inspections or other sources.

- Standardized Data Formats: Using standardized data formats and naming conventions ensures consistency and simplifies data analysis. This prevents ambiguity and facilitates easier data integration with other systems.

- Data Reconciliation: We reconcile data from different sources (e.g., work orders, sensor data, inventory records) to ensure consistency and accuracy. Discrepancies are investigated and resolved promptly.

- Training and Procedures: Providing adequate training to maintenance personnel on data entry procedures and emphasizing the importance of accurate data recording is crucial. Clear documented procedures ensure consistency.

By implementing these measures, we ensure the integrity of our maintenance data, leading to more accurate reporting, better decision-making, and improved maintenance outcomes.

Key Topics to Learn for Maintenance Planning & Scheduling Interview

- Preventive Maintenance Strategies: Understanding different types of preventive maintenance (PM) programs, their implementation, and how to optimize their effectiveness based on equipment criticality and failure modes.

- CMMS Software Proficiency: Demonstrating experience with Computerized Maintenance Management Systems (CMMS) – from data entry and work order management to reporting and analysis. Highlight your ability to utilize data for improved decision-making.

- Scheduling Techniques: Familiarity with various scheduling methodologies, such as priority scheduling, critical path method (CPM), and others. Be prepared to discuss the pros and cons of different approaches and how to adapt them to specific situations.

- Spare Parts Management: Explain your understanding of inventory control, optimal stock levels, and the impact of effective spare parts management on minimizing downtime.

- Root Cause Analysis (RCA): Showcase your ability to investigate equipment failures, identify root causes, and implement corrective actions to prevent recurrence. Mention specific RCA methodologies you’ve used (e.g., 5 Whys, Fishbone diagrams).

- Budgeting and Resource Allocation: Demonstrate understanding of how to develop and manage maintenance budgets, allocate resources effectively, and justify maintenance expenditures.

- Performance Metrics and KPIs: Discuss key performance indicators (KPIs) used to measure the effectiveness of maintenance planning and scheduling, such as MTTR (Mean Time To Repair), MTBF (Mean Time Between Failures), and overall equipment effectiveness (OEE).

- Teamwork and Communication: Highlight your experience collaborating with maintenance technicians, operations personnel, and management to ensure effective communication and coordination.

- Risk Assessment and Mitigation: Discuss your approach to identifying potential maintenance-related risks, assessing their impact, and implementing strategies to mitigate those risks.

- Continuous Improvement: Showcase your commitment to continuous improvement by discussing how you’ve identified areas for improvement within a maintenance program and implemented changes to optimize efficiency and reduce costs.

Next Steps

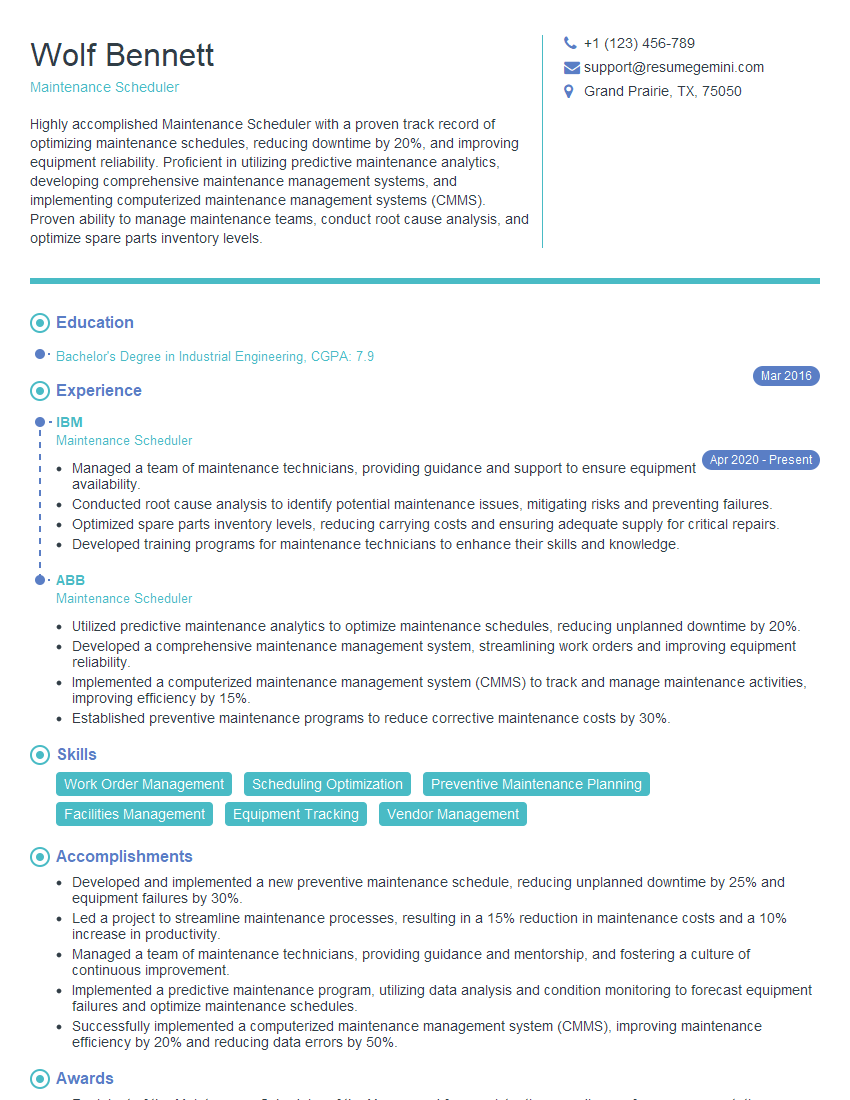

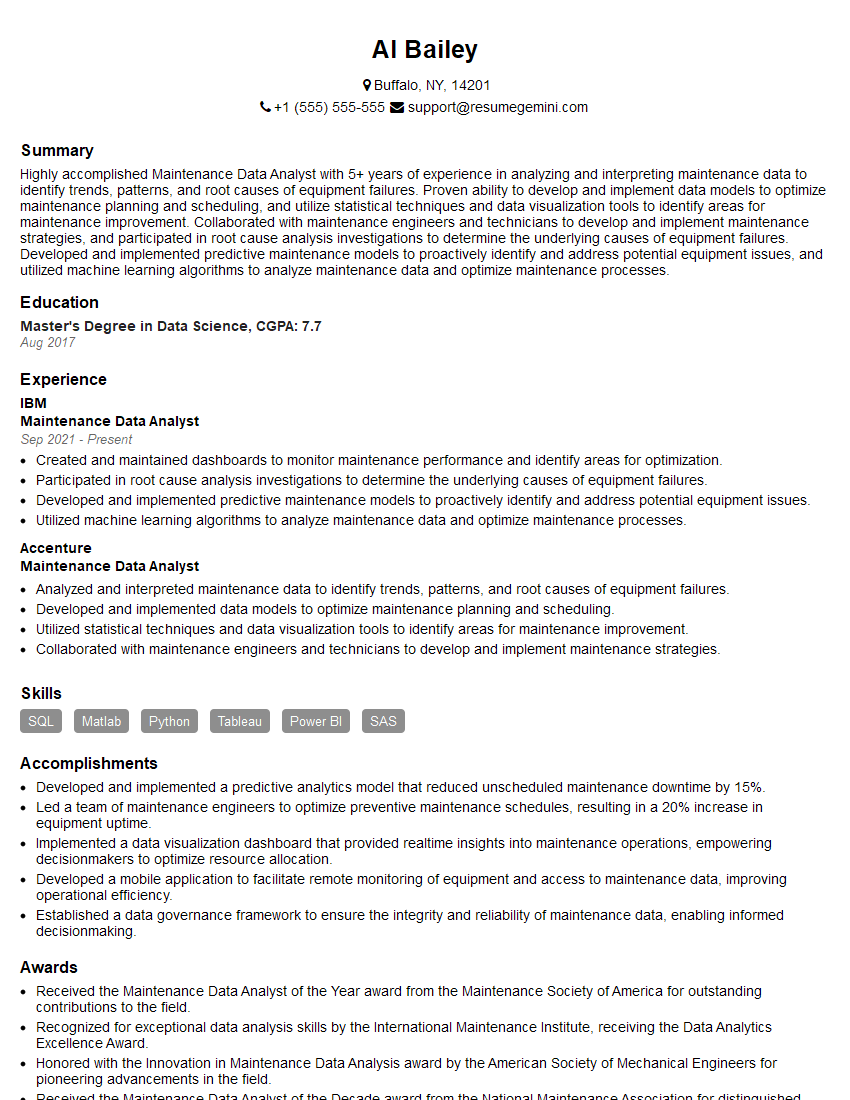

Mastering Maintenance Planning & Scheduling is crucial for career advancement in many industries. It demonstrates your ability to optimize efficiency, reduce downtime, and contribute significantly to the bottom line. Building a strong, ATS-friendly resume is key to showcasing your skills and experience to potential employers. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that highlights your expertise. We provide examples of resumes tailored to Maintenance Planning & Scheduling to help you get started. Take the next step toward your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good