Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Kinematics and Dynamics interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Kinematics and Dynamics Interview

Q 1. Explain the difference between kinematics and dynamics.

Kinematics and dynamics are both branches of mechanics that describe the motion of objects, but they focus on different aspects. Kinematics is concerned with the geometry of motion – describing how things move without considering the forces causing that motion. Think of it as a purely geometrical description of position, velocity, and acceleration over time. Dynamics, on the other hand, takes into account the forces and moments that cause changes in motion. It’s about understanding why things move the way they do. A simple analogy: kinematics describes the *what* and *how* of motion (e.g., a car travels 60 mph for 2 hours), while dynamics explains the *why* (e.g., the car’s engine provides the force to overcome friction and maintain that speed).

For example, in kinematics you might describe the path of a projectile launched at a certain angle and velocity. In dynamics, you’d also consider the gravitational force acting on the projectile and how it affects its trajectory and speed.

Q 2. What are degrees of freedom in a kinematic system?

Degrees of freedom (DOF) in a kinematic system represent the number of independent parameters needed to fully define its configuration. Essentially, it’s the number of ways a system can move independently. Imagine a robot arm with three joints – each joint can rotate independently. This means the robot arm has three degrees of freedom. A rigid body moving freely in 3D space has six DOF: three for translation along the x, y, and z axes, and three for rotation about these axes. Constraints like joints or fixed points reduce the degrees of freedom. For instance, a car driving on a straight road has only one DOF (forward/backward movement), even though its wheels have individual rotations. The constraints of the road and the car’s structure limit its overall movement.

Q 3. Describe different types of kinematic pairs.

Kinematic pairs are connections between two rigid bodies that constrain their relative motion. They are classified based on the type of contact and the number of degrees of freedom allowed. Some common types include:

- Lower Pairs: Surface contact between links. Examples include:

- Revolute Pair (R): Allows only rotational motion about a single axis (e.g., a hinge).

- Prismatic Pair (P): Allows only translational motion along a single axis (e.g., a slider).

- Cylindrical Pair (C): Allows both rotation and translation along a single axis (e.g., a piston in a cylinder).

- Spherical Pair (S): Allows rotation about three axes intersecting at a point (e.g., a ball-and-socket joint).

- Higher Pairs: Point or line contact between links. Examples include:

- Cam-Follower Pair: One link (cam) has a curved surface that guides the motion of another link (follower).

- Gear Pair: Two links with teeth that mesh to transmit rotation.

Understanding kinematic pairs is crucial in mechanism design, robotics, and machine design to determine the possible movements and constraints of a system.

Q 4. Explain the concept of Jacobian matrix in robotics.

The Jacobian matrix in robotics relates the velocities of the joints to the velocities of the end-effector (the robot’s hand or tool). It’s a crucial tool for controlling and planning robot movements. The matrix elements are partial derivatives of the end-effector’s position and orientation with respect to the joint angles. Specifically, it maps joint velocities (angular velocities for revolute joints and linear velocities for prismatic joints) to the linear and angular velocities of the end-effector in Cartesian space. This is extremely useful for things like:

- Inverse Kinematics: Finding the joint angles needed to achieve a desired end-effector pose.

- Trajectory Planning: Generating smooth and collision-free paths for the robot.

- Singularity Analysis: Identifying configurations where the robot loses degrees of freedom.

For example, if you know the desired velocity of the end-effector, you can use the Jacobian matrix to calculate the required joint velocities. The Jacobian is not constant, as it changes with the robot’s configuration. This necessitates continuous recalculation for accurate control.

Q 5. How do you determine the velocity and acceleration of a point on a rotating body?

To determine the velocity and acceleration of a point on a rotating body, you need to consider both the body’s angular velocity and the point’s position relative to the body’s center of rotation. Let’s assume a body rotates with angular velocity ω (omega) about an axis. A point P on the body has position vector r relative to the center of rotation.

- Velocity: The velocity

vof pointPis given by the cross product:v = ω × r. This means the velocity is perpendicular to both the angular velocity vector and the position vector. - Acceleration: The acceleration

aof pointPhas two components: - Tangential Acceleration:

at = α × r, whereα(alpha) is the angular acceleration. This acceleration is due to the change in angular velocity. - Centripetal Acceleration:

ac = -ω × (ω × r). This acceleration is always directed towards the center of rotation and keeps the point moving in a circular path. It is also called radial acceleration.

a = at + ac.Remember that all these vectors are expressed in the same coordinate system. These equations form the foundation for analyzing motion in rotating machines, robotic manipulators, and many other mechanical systems.

Q 6. What are Euler angles and how are they used?

Euler angles are a set of three angles used to represent the orientation of a rigid body in three-dimensional space. They describe the rotation of a body by sequentially rotating it about three axes. The order of rotations matters, leading to different conventions (e.g., XYZ, ZYX). The most common convention is the ZYX Euler angles which often represent yaw, pitch and roll respectively.

- Yaw (ψ): Rotation around the Z-axis.

- Pitch (θ): Rotation around the Y-axis (after the yaw rotation).

- Roll (φ): Rotation around the X-axis (after the yaw and pitch rotations).

Euler angles are used extensively in various applications, including:

- Robotics: To represent the orientation of a robot’s end-effector or the orientation of a link in a robot arm.

- Aircraft Navigation: To describe the orientation of an aircraft.

- Computer Graphics: To define the rotation of objects in 3D scenes.

However, it’s important to note that Euler angles suffer from gimbal lock – a singularity where one degree of freedom is lost, resulting in an inability to represent certain orientations. This limitation is why other methods like quaternions are sometimes preferred for representing orientations.

Q 7. Explain the concept of inertia and its importance in dynamics.

Inertia is a fundamental property of matter that describes its resistance to changes in motion. A larger inertia means a greater resistance to both starting motion (from rest) and stopping motion (from movement). In dynamics, inertia is quantified by the moment of inertia (for rotational motion) and mass (for linear motion).

The moment of inertia depends not only on the mass of an object but also on how that mass is distributed relative to the axis of rotation. A mass concentrated farther from the axis of rotation has a larger moment of inertia, making it harder to rotate. Think about spinning a figure skater: they pull their arms in to decrease their moment of inertia and increase their rotation speed. This illustrates the inverse relationship between moment of inertia and rotational speed for a constant angular momentum.

Inertia is crucial in dynamics because it determines how forces and torques affect the motion of an object. Newton’s second law (F=ma) is a direct expression of this: the acceleration (change in motion) is proportional to the force, and inversely proportional to the mass (inertia). Similarly, for rotational motion, the angular acceleration is proportional to the torque and inversely proportional to the moment of inertia.

In engineering design, understanding inertia is essential for designing stable and efficient systems. For example, in vehicle design, minimizing the moment of inertia of rotating parts such as wheels and engine components contributes to better performance, reduced energy consumption and improved maneuverability.

Q 8. Define Newton’s laws of motion and their application in dynamics.

Newton’s three laws of motion are fundamental to classical mechanics and form the bedrock of dynamics. They describe the relationship between a body and the forces acting upon it, and its subsequent motion.

Newton’s First Law (Inertia): A body at rest remains at rest, and a body in motion remains in motion with a constant velocity unless acted upon by an external net force. Think of a hockey puck gliding on frictionless ice – it continues at a constant velocity until it hits something.

Newton’s Second Law (F=ma): The acceleration of an object is directly proportional to the net force acting on it and inversely proportional to its mass. The equation

F = maquantifies this relationship. For example, a heavier car requires a larger force to accelerate at the same rate as a lighter car.Newton’s Third Law (Action-Reaction): For every action, there is an equal and opposite reaction. When you jump, you push down on the Earth, and the Earth pushes back on you with an equal force, propelling you upwards. This applies to all interacting bodies.

Application in Dynamics: Newton’s laws are directly used to analyze the motion of objects. By identifying all forces acting on a body (gravity, friction, applied forces, etc.), we can use Newton’s second law to determine its acceleration and subsequently its velocity and position as functions of time. This forms the basis for solving many dynamics problems, from simple projectile motion to complex multi-body systems.

Q 9. What is a Lagrangian and how is it used in dynamics?

The Lagrangian (L) is a function that encapsulates the dynamics of a system. It’s defined as the difference between the system’s kinetic energy (T) and its potential energy (V): L = T - V. This seemingly simple function holds immense power.

How it’s used: Instead of directly using Newton’s laws, which often involve dealing with multiple forces and constraints, the Lagrangian formulation employs the principle of least action. This principle states that the system will evolve in a way that minimizes the action integral (the integral of the Lagrangian over time). This leads to the Euler-Lagrange equations:

d/dt(∂L/∂ẋ) - ∂L/∂x = 0

where x represents the generalized coordinates of the system and ẋ represents their time derivatives. Solving these equations provides the equations of motion for the system. This approach is particularly useful for systems with constraints or those involving multiple degrees of freedom, making it a powerful tool in advanced dynamics.

Example: A simple pendulum. The Lagrangian can be easily formulated, and the Euler-Lagrange equation will yield the differential equation describing the pendulum’s oscillatory motion.

Q 10. What is a Hamiltonian and how is it used in dynamics?

The Hamiltonian (H) is another powerful function in classical mechanics, representing the total energy of a system. It’s defined as the sum of the system’s kinetic and potential energies expressed in terms of generalized coordinates (q) and their conjugate momenta (p):

H = T + V = H(q, p)

How it’s used: The Hamiltonian formulation utilizes Hamilton’s equations of motion, which are first-order differential equations:

dq/dt = ∂H/∂p

dp/dt = -∂H/∂q

These equations provide an alternative, yet equivalent, way to describe the system’s dynamics. The Hamiltonian approach is especially beneficial when dealing with systems exhibiting conserved quantities, such as energy or momentum. It’s also fundamental to the transition to quantum mechanics.

Example: A particle moving in a central potential. The Hamiltonian allows for a straightforward analysis of the system’s conserved angular momentum.

Q 11. Explain the concept of impulse and momentum.

Impulse: Impulse is a measure of the change in momentum of an object. It’s defined as the product of the force acting on an object and the time interval over which the force acts. Mathematically:

Impulse = ∫F dt

Impulse is a vector quantity having the same direction as the average force. A large impulse implies a significant change in momentum.

Momentum: Momentum is a measure of an object’s mass in motion. It’s the product of an object’s mass (m) and its velocity (v):

Momentum (p) = mv

Momentum is also a vector quantity having the same direction as the velocity.

Relationship: The impulse-momentum theorem states that the change in momentum of an object is equal to the impulse acting on it:

Δp = ∫F dt

This theorem is useful for analyzing collisions, where forces are often large and act over short time intervals. For example, it can predict the final velocity of a ball after it’s hit by a bat.

Q 12. What is the principle of work and energy?

The principle of work and energy states that the work done on an object is equal to the change in its kinetic energy. Work is the energy transferred to or from an object via the application of force along a displacement. Mathematically:

Work (W) = ∫F · ds

where F is the force and ds is an infinitesimal displacement vector. The dot product accounts for only the component of force parallel to the displacement doing work. The principle can be expressed as:

W = ΔKE = KEfinal - KEinitial

This principle is incredibly useful for analyzing the motion of objects when forces are not constant or when the path of motion is complex. It sidesteps the need to directly solve for acceleration.

Example: A roller coaster. The work done by gravity as the coaster descends converts potential energy to kinetic energy, increasing its speed.

Q 13. Explain the concept of conservation of energy.

The principle of conservation of energy states that the total energy of an isolated system remains constant over time. Energy cannot be created or destroyed, only transformed from one form to another. This is a fundamental principle in physics and applies to both mechanical energy (kinetic and potential) and other forms of energy (thermal, electrical, etc.).

Example: A ball thrown vertically upwards. As the ball rises, its kinetic energy decreases, while its potential energy increases. At the peak of its trajectory, kinetic energy is zero, and all the initial energy is potential. As it falls, the process reverses. Ignoring air resistance, the total mechanical energy (kinetic + potential) remains constant throughout the motion.

Application: The principle of conservation of energy is a powerful tool for solving problems in dynamics. In systems where non-conservative forces (like friction) are negligible, it greatly simplifies the analysis by providing a direct relationship between initial and final energy states.

Q 14. How do you analyze the motion of a rigid body in 2D and 3D?

Analyzing the motion of a rigid body involves considering both its translational and rotational motion. The approach differs slightly between 2D and 3D cases.

2D Rigid Body Motion: In 2D, a rigid body has three degrees of freedom: two for translation (x and y coordinates of the center of mass) and one for rotation (angle θ). Newton’s second law is applied separately for translation and rotation:

Translation:

ΣF = maGwhereaGis the acceleration of the center of mass.Rotation:

ΣMG = IGαwhereΣMGis the net moment about the center of mass,IGis the moment of inertia about the center of mass, and α is the angular acceleration.

3D Rigid Body Motion: In 3D, a rigid body has six degrees of freedom: three for translation (x, y, z coordinates of the center of mass) and three for rotation (about x, y, and z axes). The equations of motion become more complex. Newton’s second law for translation is the same, but for rotation, we use:

ΣM = Iω̇ + ω × Iω

where ΣM is the net moment vector, I is the inertia tensor (a 3×3 matrix), ω is the angular velocity vector, and ω̇ is the angular acceleration vector. The term ω × Iω represents the gyroscopic effect due to the rotation of the body.

Solving the Equations: The equations of motion (either 2D or 3D) are usually differential equations that need to be solved to determine the motion of the rigid body as a function of time. This can be done analytically or numerically depending on the complexity of the system.

Q 15. Describe different types of forces (e.g., conservative, non-conservative).

Forces are interactions that can change an object’s motion. They’re categorized based on whether the work they do depends on the path taken.

- Conservative Forces: These forces do work independent of the path taken. The total work done in a closed loop is zero. Gravity is a classic example. No matter how you lift a book to a shelf, the work done by gravity is the same. Another example is the elastic force of a spring.

- Non-conservative Forces: These forces do work dependent on the path. The work done in a closed loop is not zero. Friction is a prime example. Pushing a box across a rough floor in a square path versus a straight path requires different amounts of work. Air resistance and viscous drag are other examples.

Understanding this distinction is crucial in energy conservation calculations. Conservative forces allow us to define potential energy, simplifying many problems.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of friction and its effect on motion.

Friction is a force that opposes motion between two surfaces in contact. It arises from microscopic irregularities interacting at the interface. There are two main types:

- Static Friction: This prevents motion from starting. It’s the force you need to overcome to get an object moving. The maximum static friction is proportional to the normal force (force pressing the surfaces together) and a coefficient of static friction (µs), which is material-dependent.

- Kinetic Friction: This opposes motion once it has begun. It’s usually slightly less than maximum static friction and is also proportional to the normal force and a coefficient of kinetic friction (µk).

Friction’s effect on motion is always to reduce velocity. Think about sliding a hockey puck across ice—friction slows it down until it stops. In engineering, managing friction is vital. We use lubricants to reduce it in engines and machines, while we sometimes rely on friction in brakes and clutches.

Q 17. What is a damped harmonic oscillator?

A damped harmonic oscillator is a system that exhibits oscillatory motion (like a simple pendulum or a mass on a spring) but with energy dissipation. This energy loss, usually due to friction or resistance, causes the oscillations to gradually decrease in amplitude over time until they eventually stop. Imagine pushing a child on a swing. Eventually, the swing stops due to air resistance and friction in the swing’s hinges – that’s damping.

The equation of motion often involves a damping term proportional to velocity. A common example is:

m(d²x/dt²) + c(dx/dt) + kx = 0where ‘m’ is mass, ‘c’ is the damping coefficient, ‘k’ is the spring constant, and ‘x’ is displacement. The nature of the damping (underdamped, critically damped, or overdamped) influences how quickly the oscillations decay.

Q 18. Explain the concept of resonance.

Resonance occurs when a system is driven by an external force at its natural frequency (or a frequency close to it). This leads to a dramatic increase in the amplitude of oscillations. Imagine pushing a child on a swing. If you push at the right time (the swing’s natural frequency), the swing goes higher and higher with each push. If you push at the wrong time, it will barely move.

In engineering, understanding resonance is crucial. For example, bridge designs must avoid resonance with wind or traffic vibrations to prevent catastrophic failure. Conversely, resonance is utilized in musical instruments to create sound at specific frequencies.

Q 19. What are the different types of vibrations?

Vibrations are classified in several ways:

- Free Vibrations: These occur when a system is displaced from its equilibrium position and then allowed to oscillate without any external force. The frequency is determined by the system’s inherent properties (mass and stiffness).

- Forced Vibrations: These are caused by an external force acting on the system. The frequency is determined by the external force.

- Damped Vibrations: These are oscillations with energy dissipation, as explained with the damped harmonic oscillator. The amplitude decays over time.

- Undamped Vibrations: These are ideal oscillations with no energy loss. The amplitude remains constant.

- Linear Vibrations: The system’s response is proportional to the applied force. The governing equations are linear.

- Nonlinear Vibrations: The system’s response is not proportional to the applied force. The governing equations are nonlinear and more complex to analyze.

Q 20. How do you analyze vibration using modal analysis?

Modal analysis is a powerful technique used to understand the vibrational behavior of complex structures. It involves determining the system’s natural frequencies (modal frequencies) and corresponding mode shapes (modal shapes). These represent the system’s characteristic ways of vibrating.

The process typically involves:

- Modeling: Creating a mathematical model of the structure (using finite element analysis, for example).

- Eigenvalue Problem: Solving an eigenvalue problem to find the natural frequencies and mode shapes. Each mode shape represents a distinct pattern of deformation at a specific frequency.

- Interpretation: Analyzing the results to identify potential resonance issues and optimize the design to avoid them.

This analysis is essential in designing aircraft, bridges, buildings, and machinery, ensuring they can withstand dynamic loads without experiencing excessive vibrations or resonance failures.

Q 21. Describe different methods for solving equations of motion.

Several methods exist for solving equations of motion, depending on the system’s complexity and the desired level of accuracy:

- Analytical Methods: These involve solving the equations directly using mathematical techniques. This works best for simple systems with linear equations. Examples include direct integration, Laplace transforms, and solving characteristic equations.

- Numerical Methods: These are used for complex systems where analytical solutions are not feasible. They involve approximating the solution using computational techniques. Common methods include the Euler method, Runge-Kutta methods, and finite element analysis. Software packages like MATLAB and ANSYS are commonly employed.

- Experimental Methods: These involve measuring the system’s response directly through experiments. This is often combined with analytical or numerical methods for validation and refinement.

The choice of method depends on the specific problem and the desired level of accuracy and detail. Often, a combination of methods is used for a complete understanding.

Q 22. Explain the concept of kinematic synthesis.

Kinematic synthesis is the process of designing mechanisms to achieve a specific set of motion requirements. Instead of analyzing the motion of an existing mechanism, we’re designing it from the ground up. Think of it like reverse engineering, but for movement. We start with the desired output motion – perhaps a robotic arm needing to reach certain points in space – and work backward to determine the necessary links, joints, and their dimensions.

This involves various techniques, including graphical methods (like the graphical synthesis of four-bar linkages), analytical methods (using equations to define the desired motion), and optimization techniques (using software to find the optimal design parameters). For example, designing a robotic gripper to pick and place objects requires careful kinematic synthesis to ensure the gripper can reach all necessary points with the correct orientation and avoid collisions.

- Graphical Synthesis: Useful for simpler mechanisms, involving geometrical constructions to find link lengths and angles.

- Analytical Synthesis: Employs mathematical equations, often more precise for complex mechanisms, but requires a strong mathematical foundation.

- Computer-Aided Synthesis: Utilizes software to optimize designs, considering factors like workspace, transmission angles, and singularity avoidance.

Q 23. Explain the concept of dynamic balancing.

Dynamic balancing is the process of distributing mass within a rotating system to minimize vibration and ensure smooth operation. Unbalanced rotating components generate centrifugal forces that vary with rotation, leading to vibrations that can damage the system and surrounding structures, and produce unwanted noise. Think of an unbalanced washing machine – it’ll shake violently!

Dynamic balancing involves determining the magnitude and location of the imbalance and then adding or removing mass to counteract it. This is typically done in two planes (for most rotating components) because a single imbalance can manifest as two imbalances in different planes. Static balancing addresses only one plane.

The process often utilizes specialized balancing machines that measure the vibration levels and provide the necessary corrections. This is critical in high-speed applications like turbines, engines, and rotating machinery in general, ensuring longevity and safe operation.

Q 24. How do you model a system using Simulink or similar software?

Modeling a system in Simulink (or similar software like MATLAB/Simscape) involves representing the system’s components and their interactions using blocks and connections. The process typically involves these steps:

- System Definition: Clearly define the system’s boundaries and components, including inputs, outputs, and internal variables.

- Block Diagram Creation: Choose appropriate blocks representing the system’s components (e.g., transfer functions, integrators, differentiators, sensors, actuators). Connect these blocks according to the system’s structure and interactions.

- Parameter Assignment: Assign numerical values to the parameters of the blocks (e.g., mass, spring constant, gain). These parameters can be determined from physical measurements or theoretical calculations.

- Simulation and Analysis: Run the simulation to observe the system’s behavior under different conditions. Analyze the results to evaluate the model’s accuracy and identify areas for improvement.

- Model Validation: Compare the simulation results to experimental data (if available) to verify the model’s validity. This may involve iterative refinement of the model.

For example, to model a simple mass-spring-damper system, you’d use integrator blocks for velocity and position, gain blocks for the spring constant and damping coefficient, and a summing block to combine forces. You would then use a scope block to visualize the results.

% Example MATLAB code (not a complete Simulink model): m = 1; % mass k = 10; % spring constant b = 2; % damping coefficient % Transfer function representation: sys = tf([1],[m, b, k]); step(sys); % Simulate step responseQ 25. Describe your experience with finite element analysis (FEA) in dynamic systems.

My experience with FEA in dynamic systems involves using it to analyze the dynamic response of structures and components under various loading conditions. I’ve used FEA software (like ANSYS or Abaqus) to model systems experiencing vibration, impact, or other dynamic loads, predicting their displacements, stresses, and natural frequencies.

For example, I used FEA to analyze the vibrational modes of a turbine blade. The model accurately predicted its natural frequencies, which were then used to avoid resonance and potential failures during operation. In another project, FEA helped analyze the impact forces on a vehicle chassis during a collision, contributing to the design of a safer vehicle. The ability to visualize stress distributions and deformations within the model is incredibly valuable for design optimization and failure prevention.

FEA is particularly helpful in predicting dynamic behavior where analytical solutions are either too complex or impossible to obtain. It allows the exploration of various design parameters and identification of potential weaknesses before physical prototyping.

Q 26. How would you approach troubleshooting a system with unexpected dynamic behavior?

Troubleshooting a system with unexpected dynamic behavior is a systematic process. I would approach it with this structured method:

- Data Acquisition: First, I’d gather as much data as possible. This includes sensor readings (accelerometers, strain gauges, etc.), operational parameters, and any relevant logs or records. Visual inspection of the system’s physical condition is also important.

- Model Comparison: If a model of the system exists (e.g., in Simulink), I’d compare its predicted behavior to the observed behavior. This comparison can highlight discrepancies and point to potential sources of error in the model or the physical system.

- System Identification: If a model doesn’t exist, I’d use system identification techniques to create one from the gathered data. This involves fitting a mathematical model to the experimental data.

- Fault Isolation: Based on the analysis of the data and model comparison, I’d isolate potential sources of the unexpected behavior. This might involve checking individual components, connections, and control algorithms.

- Testing and Verification: I’d test the proposed solutions and verify their effectiveness by observing changes in the system’s dynamic behavior. This might involve replacing faulty components, adjusting control parameters, or modifying the physical system.

A crucial aspect is careful documentation at each stage to ensure traceability and to facilitate future troubleshooting efforts. The iterative nature of this process often necessitates returning to earlier steps to refine the diagnosis.

Q 27. Explain your experience with different types of sensors used in dynamic measurements.

My experience with sensors used in dynamic measurements includes a wide range of technologies, each with its own strengths and weaknesses:

- Accelerometers: Measure acceleration, widely used for vibration analysis and shock detection. Piezoelectric accelerometers are common for their high frequency response.

- Strain Gauges: Measure strain (deformation) on a structure, providing information about stress and deflection. They’re often bonded to the surface of a component.

- Load Cells: Measure force or weight, applicable in applications where dynamic forces are present, like impact testing.

- Gyroscopes: Measure angular velocity, essential for applications involving rotation and orientation, like robotics and aerospace.

- Optical Sensors: Including high-speed cameras and laser Doppler vibrometers, enabling non-contact measurements of displacement and velocity, especially useful for delicate systems or high-temperature environments.

Selecting the appropriate sensor depends heavily on the specific application, considering factors such as frequency range, sensitivity, measurement accuracy, environmental conditions, and cost.

Q 28. Describe a challenging kinematics or dynamics problem you’ve solved.

One challenging problem involved optimizing the design of a complex robotic manipulator with seven degrees of freedom (7-DOF). The challenge was not only to achieve the desired workspace but also to minimize the manipulator’s inertia and maximize its speed and agility. Simple kinematic analysis wasn’t sufficient due to the complexity of the system and the need to avoid singularities (configurations where the manipulator loses its degrees of freedom).

My approach involved a combination of analytical methods, numerical optimization techniques, and FEA. I used Denavit-Hartenberg parameters to model the manipulator’s kinematics, developed a dynamic model using Lagrangian mechanics, and then used optimization algorithms to find optimal link lengths and joint placements that minimized inertia while maintaining a desirable workspace. FEA was used to verify the structural integrity of the design under dynamic loading conditions.

This project involved significant iterative refinement, balancing competing design goals, and requiring in-depth understanding of both kinematics and dynamics. The successful outcome resulted in a more efficient and agile robot design.

Key Topics to Learn for Kinematics and Dynamics Interview

- Kinematics:

- Position, velocity, and acceleration: Understanding their relationships and representations (graphical, analytical).

- Motion in one, two, and three dimensions: Analyzing projectile motion, relative motion, and curvilinear motion.

- Rotational kinematics: Angular displacement, velocity, and acceleration; relating linear and angular motion.

- Practical Application: Analyzing the trajectory of a rocket, designing robotic arm movements, or understanding the motion of a planetary system.

- Dynamics:

- Newton’s Laws of Motion: Applying these fundamental laws to solve a variety of dynamic problems.

- Work, energy, and power: Understanding the concepts of kinetic and potential energy, conservation of energy, and power calculations.

- Momentum and impulse: Analyzing collisions and impacts using the concepts of linear and angular momentum.

- Rotational dynamics: Torque, moment of inertia, angular momentum, and rotational kinetic energy; applying these concepts to rotating systems.

- Practical Application: Designing a suspension system for a vehicle, analyzing the forces on a bridge, or optimizing the efficiency of a machine.

- Problem-Solving Strategies:

- Free-body diagrams: Creating and interpreting free-body diagrams to analyze forces acting on objects.

- Coordinate systems: Selecting appropriate coordinate systems for problem-solving.

- Conservation laws: Applying conservation of energy and momentum to simplify complex problems.

Next Steps

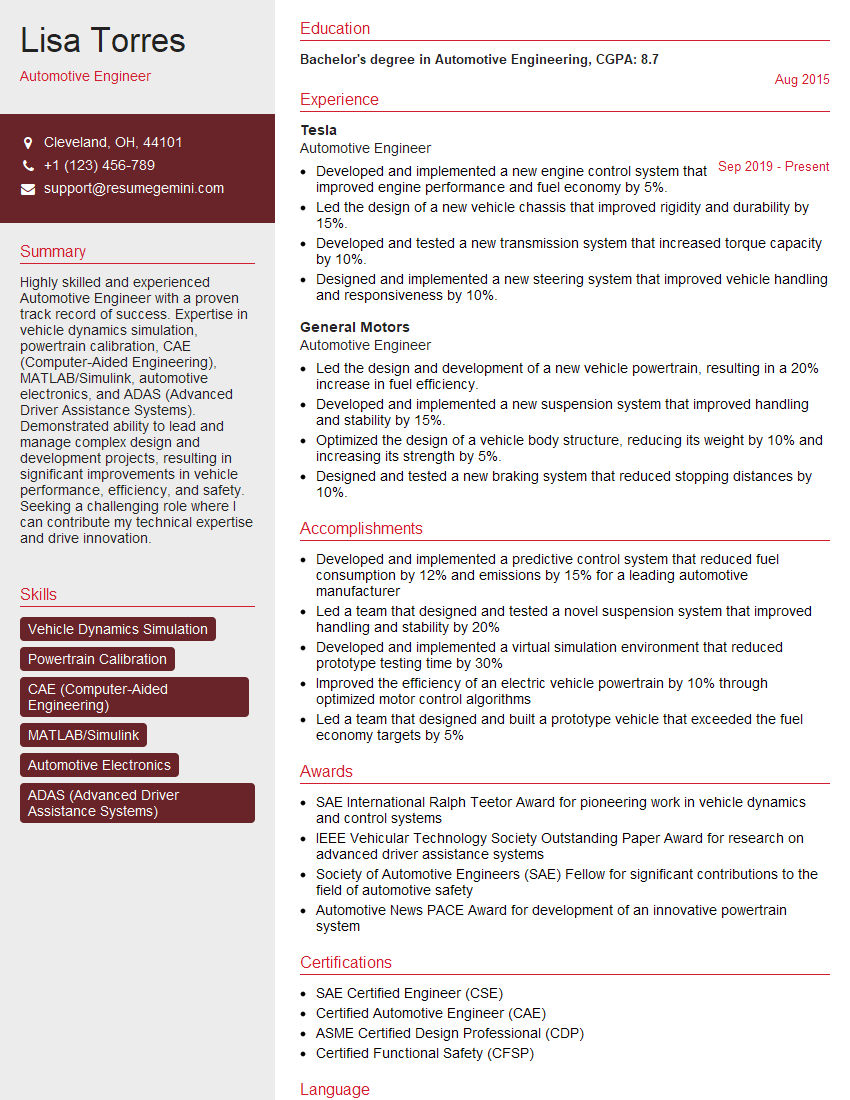

Mastering Kinematics and Dynamics is crucial for a successful career in engineering, physics, and related fields. A strong understanding of these principles opens doors to exciting opportunities and allows you to contribute meaningfully to innovative projects. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to Kinematics and Dynamics to help you showcase your expertise. Invest the time to craft a compelling resume – it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good