The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Screen Printing Setup and Registration interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Screen Printing Setup and Registration Interview

Q 1. Explain the process of setting up a screen printing press for a new job.

Setting up a screen printing press for a new job is a methodical process that ensures efficient and high-quality printing. It starts with careful planning and preparation, moving through a series of crucial steps to minimize errors and maximize productivity.

- Artwork Preparation: First, we ensure the artwork is properly formatted and sized for the desired print area. This often involves separating colors into individual screens, if necessary.

- Screen Preparation: Next, we prepare the screens themselves. This includes making sure they are properly stretched, coated (with emulsion), and exposed with the correct artwork. We check for any pinholes or defects.

- Press Setup: We then align the screens on the press, ensuring they are perfectly registered with each other. This involves using registration marks on the artwork and precise adjustments on the press itself. We also check screen tension to maintain optimal print quality. Incorrect tension leads to distortions or uneven printing.

- Ink Preparation: The correct ink for the job is mixed to the desired viscosity, and the squeegee is selected based on the ink and mesh count of the screen.

- Test Print: Before full-scale printing, we always conduct a test print to check for registration, ink consistency, and overall print quality. This allows for adjustments before significant material is wasted.

- Production Run: Once everything is satisfactory, we proceed with the production run, closely monitoring the print quality throughout.

Imagine it like building a precise machine. Each component (screen, ink, press) needs to fit perfectly for the machine to function as intended.

Q 2. Describe how you achieve accurate screen registration.

Achieving accurate screen registration is crucial for producing professional-looking prints. It’s all about precisely aligning multiple screens to print different colors or elements in their correct positions. We utilize several methods:

- Accurate Artwork Setup: The artwork itself needs registration marks—small, precisely placed marks that we can use for alignment on the screens.

- Micron Adjustment System: Most modern presses have micron-adjustment systems allowing for incredibly fine-tuned positioning of each screen. We meticulously align the screens using these adjustments, referencing the registration marks on the artwork.

- Pallet Registration: This system involves using a precise pallet for placing the substrate (shirt, poster etc.). This ensures that the substrate stays in precisely the same location for each color print.

- Combination of methods: Frequently, a combination of pallet registration, micron adjustment, and visual inspection guarantees precise alignment.

- Test Prints and Adjustments: Frequent test prints are vital; we adjust registration as needed. Even minor misalignment becomes obvious in a test print.

Think of it like a complex puzzle where each piece (color) needs to fit perfectly with the others. The precision is key.

Q 3. What are the common causes of misregistration in screen printing?

Misregistration, the bane of screen printers, stems from various sources. Identifying the root cause is critical for correction.

- Inaccurate Screen Alignment: Poor setup, including improper use of registration marks or insufficient micron adjustments, is a major culprit.

- Substrate Movement: The garment or substrate may shift during the printing process. This is especially common on manual presses or with unstable substrate.

- Screen Tension Issues: Uneven screen tension can distort the print and cause misregistration.

- Press Issues: Mechanical problems within the press itself, such as loose screws or worn parts, can lead to inconsistent results.

- Improper Pallet Registration: Inaccurate pallet systems can result in the substrate shifting each print run.

- Human Error: Let’s face it; human error is a factor in many misregistrations—poor attention to detail in the setup process.

Debugging misregistration is like detective work. We systematically eliminate potential causes until we pinpoint the problem.

Q 4. How do you troubleshoot a screen that is producing blurry prints?

Blurry prints indicate a problem with the printing process itself. Several factors can contribute.

- Squeegee Pressure & Speed: Too much pressure, too little pressure, or an incorrect squeegee speed can lead to uneven ink deposit, causing blurring.

- Screen Mesh Count: Using an inappropriate mesh count for the design can result in blurred prints. A finer mesh is generally required for fine detail.

- Ink Viscosity: Ink that is too thick or too thin will not transfer properly, leading to blurred edges.

- Off-Contact Issues: If the screen is too close to or too far from the substrate, the ink won’t transfer cleanly resulting in blurring.

- Emulsion Problems: A poorly prepared screen, with a worn emulsion, may cause the ink to bleed, leading to blurred lines.

- Flood Stroke Technique: The flood stroke, critical for ink consistency, needs to be executed properly to avoid variations that lead to blurry prints.

We troubleshoot blurry prints by systematically checking each of these elements, adjusting as necessary. Testing is paramount throughout the process.

Q 5. What are the different types of screen printing inks and when would you use each?

Screen printing inks come in many varieties, each suited to specific applications.

- Plastisol Inks: The workhorse of the industry, known for their vibrant colors, durability, and excellent opacity. Ideal for textiles, particularly cotton, and offer a broad range of finishes.

- Water-Based Inks: Environmentally friendly, these inks are softer than plastisol, offering a more vintage or hand-printed look. They are ideal for sensitive substrates and environmentally conscious customers.

- Discharge Inks: These inks remove the color from the fabric, leaving a lighter or white print on darker garments. Used to create lighter designs on dark-colored fabrics.

- UV-Curable Inks: Cure instantly upon exposure to ultraviolet light. They are extremely durable and work well on various surfaces.

Choosing the correct ink is like choosing the right paint for a house. The wrong choice leads to sub-par results. The substrate material, desired effect, and environmental considerations all determine ink selection.

Q 6. Explain the importance of proper screen tension in screen printing.

Proper screen tension is essential for consistent print quality. The tension holds the mesh taut, preventing sagging or stretching that can distort the print and result in inconsistent ink lay-down.

- Consistent Ink Deposit: Proper tension ensures that the ink is transferred evenly, preventing areas of heavy or light ink.

- Sharp Images: Tight tension enhances the sharpness of the print, ensuring crisp details are achieved.

- Reduced Ink Bleeding: It helps prevent ink from bleeding into areas outside the designed print areas.

- Preventing Screen Damage: Proper tension extends screen life, minimizing the risk of tearing or stretching during the printing process.

Think of a drumhead on a drum; insufficient tension yields a muted, inconsistent sound; conversely, too much tension can break the drumhead. Screen tension is analogous to maintaining the correct tension for consistent, high-quality prints.

Q 7. How do you clean and maintain your screen printing equipment?

Cleaning and maintaining screen printing equipment is critical for longevity and efficient operation.

- Daily Cleaning: After each printing job, remove excess ink from screens, squeegees, and the press bed. This prevents ink build-up and improves print quality in the long term.

- Screen Cleaning: Screens need thorough cleaning with appropriate screen cleaning solutions to remove all ink residue, ensuring proper emulsion integrity for future use.

- Press Maintenance: Regular lubrication of moving parts on the press, like the shuttle or adjustments, is essential. Inspect for any damage and address any mechanical issues promptly.

- Squeegee Maintenance: Clean and store squeegees correctly. Damaged or worn squeegees lead to poor print quality.

- Storage: Proper storage of all equipment, including screens (in a dark, cool environment to protect the emulsion), helps maintain the quality and prolongs the lifespan.

Regular cleaning and maintenance are like a car’s service. Ignoring it results in breakdowns and costly repairs. Consistent attention to detail is key.

Q 8. What safety precautions do you take when working with screen printing inks and chemicals?

Safety is paramount in screen printing. Working with inks and chemicals requires a proactive approach. This begins with understanding the Safety Data Sheets (SDS) for every product used. These sheets detail hazards, safe handling procedures, and emergency response information.

- Personal Protective Equipment (PPE): I always wear gloves (nitrile are my preference for their chemical resistance), eye protection (safety glasses at minimum, a face shield for more extensive work), and a respirator, especially when working with plastisols or other potentially harmful inks or solvents. Long sleeves and closed-toe shoes are also standard practice.

- Ventilation: A well-ventilated workspace is crucial. This might involve using exhaust fans, working outdoors, or utilizing a dedicated screen printing booth with proper extraction. Poor ventilation can lead to inhalation of harmful fumes.

- Proper Waste Disposal: Ink and chemical waste must be disposed of according to local regulations. Never pour them down the drain. We use designated containers and follow our facility’s hazardous waste protocols.

- Emergency Preparedness: Knowing the location of safety showers and eyewash stations is essential. Our team conducts regular safety training to reinforce best practices and emergency procedures. For example, I always make sure to have a spill kit readily available.

Think of it like this: treating every material with respect and employing best practices isn’t just about following rules; it’s about protecting yourself and your coworkers.

Q 9. How do you determine the correct exposure time for a screen?

Determining the correct exposure time is critical for a successful screen print. Too little exposure, and the emulsion won’t fully harden, leading to image degradation during washing. Too much, and the emulsion may become brittle, potentially cracking and causing print defects. The ideal exposure time depends on several factors:

- Emulsion Type: Different emulsions have varying sensitivities to light. A high-sensitivity emulsion requires less exposure time compared to a low-sensitivity one.

- Screen Mesh: Finer mesh screens require less exposure time than coarser ones because less light passes through the screen.

- Light Source: The intensity and type of exposure unit (UV or other) significantly impact exposure time. Older units may require longer exposures.

- Film Quality: A high-contrast film will yield better results and potentially allow for shorter exposure times compared to a film with low contrast.

We use a test strip method to determine optimal exposure. We expose multiple sections of a test screen to varying times (e.g., 15, 30, 45, 60 seconds) using the same film. After washing out, we inspect each section. The ideal exposure time will reveal a well-defined image, completely hardened without overexposure.

It’s an iterative process; we fine-tune the exposure time until we achieve consistent and sharp results.

Q 10. What are the different methods for reclaiming screens?

Screen reclamation is essential for cost-effectiveness and environmental responsibility. There are several methods:

- Chemical Reclamation: This involves using emulsion removers to dissolve the emulsion. It’s effective but requires careful handling due to the chemicals involved. Proper ventilation and PPE are crucial. We typically choose this method for highly detailed screens or those with difficult-to-remove emulsions.

- Pressure Washing: This method uses high-pressure water to strip away the emulsion. It’s quicker than chemical reclamation, but may require more effort, especially for stubborn emulsions. This works best for less detailed screens.

- Enzyme Cleaners: These are environmentally friendly and effective, especially on water-based emulsions. They’re biodegradable and often require less rinsing.

The choice of method depends on factors like the type of emulsion used, the complexity of the design, and environmental concerns. Often, a combination of methods (e.g., pressure washing followed by an enzyme cleaner) delivers the best results.

Q 11. Describe your experience with different types of screen printing presses (e.g., manual, automatic).

My experience encompasses both manual and automatic presses. Manual presses, like a Vastex, offer great control and are ideal for small runs and intricate designs. I’ve worked extensively on these, developing a keen sense of pressure and registration. It’s a more physical process requiring precise hand movements and a steady hand.

Automatic presses, such as those by M&R or Anatol, are much faster and better suited for large-scale production. They require a different skill set – understanding the press’s mechanics, settings, and troubleshooting capabilities. While they reduce physical strain, setting up the pallets, registering the screens, and maintaining the automated system require precision and technical know-how.

My experience covers a range of press types – from simple, single-station manual presses to multi-station carousel presses, allowing me to adapt efficiently to various production requirements.

Q 12. How do you manage ink consistency during a long print run?

Maintaining consistent ink viscosity throughout a long print run is vital for achieving uniform color and print quality. Several strategies help achieve this:

- Proper Ink Mixing: Begin with thoroughly mixed ink. Use a mixer (preferably a power mixer for large batches) to ensure homogeneity before starting the print run.

- Ink Temperature: Ink viscosity changes with temperature. In colder environments, inks can thicken, while excessive heat can thin them. Maintaining a consistent ink temperature is critical, especially for plastisol inks. We often use heated ink reservoirs to manage this.

- Regular Ink Stirring: Even with thorough initial mixing, pigment can settle over time. Regular stirring throughout the print run keeps the ink consistency uniform.

- Ink Additives: Some additives can help control viscosity. Consult with your ink supplier about appropriate additives for your specific ink type. This requires careful consideration to avoid compromising print quality.

- Scheduled Cleaning and Maintenance: Regular cleaning of the screen, squeegee, and press components can prevent build-up of dried ink that would impact ink flow.

Think of it like baking a cake: the correct ingredient proportions and baking temperature ensure a consistent outcome. Similarly, meticulous ink management is key to a successful, high-quality screen print run.

Q 13. What are some common issues with screen mesh and how do you address them?

Screen mesh issues can significantly impact print quality and efficiency. Common problems include:

- Mesh Stretching or Distortion: Improper stretching during screen preparation can result in mesh irregularities that affect registration and print quality. This usually stems from insufficient tension or uneven stretching. I carefully check and adjust tension using a tensionometer during screen prep to prevent this.

- Mesh Tears or Holes: These can occur due to mishandling, incorrect cleaning procedures, or even the natural wear and tear of repeated use. Minor tears can sometimes be repaired, but severely damaged screens often need replacement. Care is important to avoid damage during usage and cleaning.

- Mesh Clogging: This commonly happens with thick or improperly mixed inks. Using a higher-mesh screen than necessary or improper cleaning techniques can also contribute to this. Thorough cleaning and the use of suitable cleaning agents are crucial to avoid clogging.

Addressing these issues involves preventative measures (like proper screen preparation and careful handling) and corrective actions (replacing damaged screens, using appropriate cleaning methods, etc.). Consistent inspection and maintenance are key to minimizing mesh-related problems.

Q 14. Explain the concept of halftone printing in screen printing.

Halftone printing in screen printing simulates continuous tone images using dots of varying sizes and densities. Unlike traditional printing, where the image is made of solid color areas, screen printing (and especially plastisol) is primarily a process of laying down solid dots of ink. To reproduce a photograph or continuous tone image, we use halftone screens that break the image into a grid of dots.

The size of the dots determines the tonal value—smaller dots create lighter areas, and larger dots create darker areas. This is achieved using a halftone screen in the film that is used to expose the screen. The image is broken into many small dots that create a continuous tone illusion from a distance.

For example, a dark area in a photograph would be represented by a high concentration of large dots, while a light area would have smaller, less dense dots. This process allows us to reproduce the continuous tones of photos and detailed artwork. Selecting the appropriate halftone screen ruling (lines per inch) is crucial to achieve the desired resolution and print quality.

Q 15. How do you prepare artwork for screen printing?

Preparing artwork for screen printing involves ensuring it’s optimized for the process. This goes beyond simply having a visually appealing design; it’s about creating a file that’s technically sound for accurate reproduction. Think of it like baking a cake – you need the right ingredients and instructions for a successful outcome.

- Resolution: Artwork needs a high resolution, typically 300 DPI (dots per inch) or higher, to avoid pixelation or blurry prints. Lower resolution will result in a grainy, unprofessional look.

- Color Mode: Convert your artwork to CMYK (Cyan, Magenta, Yellow, Key/Black) mode. Screen printing uses inks based on this color model, unlike the RGB (Red, Green, Blue) used on screens. Using RGB can lead to significant color shifts.

- File Format: Vector-based formats like AI (Adobe Illustrator) or EPS (Encapsulated PostScript) are preferred. These maintain crisp lines and details regardless of scaling. Raster images (JPEG, PNG) can work, but only if the resolution is extremely high.

- Bleeds: Add bleeds to your artwork – extra space around the design that gets trimmed after printing. This prevents white borders from appearing on the final product, ensuring a clean edge. A typical bleed is 1/8th inch.

- Spot Colors: If you’re using specific pantone colors, ensure they’re accurately identified and separated. This guarantees color consistency across different print runs.

For example, I once worked on a project with a client who submitted low-resolution JPEGs. The resulting prints were noticeably pixelated. By guiding them towards providing high-resolution vector files, we achieved a dramatically improved final product.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle color separations for multi-color prints?

Color separation is crucial for multi-color prints. It’s the process of dividing a full-color design into individual color channels (typically CMYK) which are then printed one at a time, each on a separate screen. Imagine it like layering different colored cellophane sheets to create a composite image.

Software like Adobe Illustrator or Photoshop is used to separate the artwork. Each color channel needs to be meticulously created, ensuring accurate registration marks (small guide marks on the artwork) are included. These marks are essential for aligning the screens during the printing process.

Accurate color separation requires a keen eye for detail. Slight misalignments in the separations can result in muddy colors or halos around the design elements. In my experience, I’ve found that meticulously checking and double-checking each separated color ensures a smooth process. I often use a digital proof to visualize the final result before proceeding to screen making.

Q 17. Describe your experience with different types of screen printing substrates.

My experience encompasses a wide variety of screen printing substrates, each presenting unique challenges and opportunities. Choosing the right substrate is crucial for achieving the desired print quality and durability.

- Cotton T-shirts: This is a classic substrate that’s relatively easy to print on, but the fabric’s absorbency can affect ink penetration and drying time.

- Polyester Fabrics: These require specialized plastisol inks to ensure proper adhesion and prevent cracking. The smoother surface often results in sharper prints.

- Paper: Different paper types (card stock, fine art paper, etc.) require specific inks and techniques. The weight and texture impact the final print’s appearance.

- Canvas: Printing on canvas can create stunning art prints, but requires specialized techniques to avoid ink bleeding or cracking due to the porous nature of the fabric.

- Mugs: This calls for specialized inks that are heat-cured after printing. Ensuring proper curing is crucial for both print longevity and safety.

I once had a job involving a complex design printed on a blend of cotton and polyester. Understanding the properties of each fiber type allowed me to choose the correct ink and printing technique to achieve a high-quality print that didn’t crack or peel.

Q 18. How do you address issues with ink bleeding or spreading?

Ink bleeding or spreading is a common problem, often caused by factors like the ink’s viscosity, mesh count of the screen, print pressure, or substrate type. Addressing this involves a multifaceted approach.

- Ink Viscosity: Correcting ink viscosity is crucial. Too thick, and it won’t spread evenly. Too thin, and it will bleed.

- Mesh Count: Higher mesh counts (more threads per inch) are better for fine detail and reduce bleeding. Lower mesh counts work well for bold designs and opaque ink coverage.

- Print Pressure: Excessive pressure can force ink under the stencil, leading to bleeding. Consistent pressure is key.

- Substrate Preparation: A pre-treatment of the substrate can sometimes be necessary to improve ink adhesion and reduce bleeding.

- Ink Additives: Retarders can help slow down the drying time, which can prevent bleeding on absorbent substrates.

I recall a project where ink was bleeding on a specific type of paper. By adjusting the ink viscosity with a retarder and slightly reducing the print pressure, we solved the issue.

Q 19. How do you ensure consistent ink coverage throughout a print run?

Consistent ink coverage is paramount for achieving professional-looking prints. It ensures each item is identical in color saturation and clarity.

- Consistent Ink Supply: Maintaining a consistent flow of ink to the screen is crucial. Regularly check the ink tray and add ink as needed to avoid variation.

- Screen Tension: A properly tensioned screen minimizes inconsistencies. A loose screen will lead to uneven ink deposit.

- Squeegee Technique: Using a consistent squeegee angle, pressure, and speed is fundamental for even ink distribution across the print area.

- Regular Screen Cleaning: Clean the screens thoroughly between colors and after each print run to prevent ink build-up and inconsistencies.

- Substrate Alignment: Precisely aligning the substrate each time ensures consistent placement of the design and maintains print uniformity.

Maintaining a consistent workflow and regularly checking the print quality are key practices I employ to guarantee consistent ink coverage throughout a print run.

Q 20. What is your experience with different types of squeegees and their application?

Squeegees are the workhorses of screen printing, and selecting the right one is key. The material, durometer (hardness), and shape all impact the print result.

- Rubber Squeegees: These are the most common type. Different durometers (measured on the Shore A scale) offer varied flexibility. A harder squeegee (higher Shore A) is better for less absorbent substrates and sharp designs. A softer squeegee (lower Shore A) is preferable for highly absorbent fabrics and softer prints.

- Polyurethane Squeegees: These are more durable and resistant to abrasion than rubber, offering a longer lifespan. They’re also known for their consistency in ink transfer.

- Shape: Squeegees come in various shapes, including straight and curved. The choice often depends on the design and substrate. A curved squeegee is often preferred for curved surfaces like mugs.

My experience has shown that understanding the relationship between squeegee properties and the printing substrate and design is vital for optimizing ink transfer and print quality. I’ve found that polyurethane squeegees are particularly beneficial when printing on difficult surfaces.

Q 21. How do you calculate the number of screens needed for a multi-color print job?

The number of screens needed for a multi-color print job is directly related to the number of colors in the design. Each color requires its own screen. It’s a simple but crucial calculation.

For example, a design with four colors (CMYK) requires four screens. A design with a specific pantone color in addition to CMYK requires five screens. If a color is used multiple times, it still only requires one screen.

Spot colors are often incorporated. These are pre-mixed inks that provide very specific shades and are crucial for accurate brand representation. Each unique spot color adds one screen to the total count.

Therefore, the number of screens directly correlates to the number of distinct colors or spot colors. This is why careful planning during the design phase can significantly impact the efficiency and cost of the printing process.

Q 22. How do you troubleshoot a screen that is producing pinholes or other defects?

Pinhole defects in screen printing are frustrating, but usually solvable. They appear as tiny holes in the stencil, allowing ink to bleed through unwanted areas. The first step is to identify the *cause*. This could be anything from insufficient emulsion coating (too thin), improper emulsion exposure (under-exposed), damage to the screen mesh during the stretching or cleaning process, or even dust particles trapped during the coating or drying phase.

My troubleshooting process starts with a careful visual inspection of the screen under bright light. I look for inconsistencies in the emulsion coating, checking for thin spots or areas that look patchy. Next, I examine the mesh itself for any tears or damage. If the pinholes are clustered in one area, it often points to a localized problem like a snag in the mesh. If the pinholes seem random, the culprit is likely a problem with the emulsion coating or exposure process.

- Insufficient Emulsion: Remedy: Apply a thicker, more even coat of emulsion next time.

- Under-Exposure: Remedy: Increase the exposure time in the exposure unit, ensuring proper contact between the screen and the film positive.

- Mesh Damage: Remedy: Unfortunately, this usually requires replacing the screen. Prevention involves careful handling.

- Dust/Debris: Remedy: Maintain a clean work environment and use a lint-free cloth to clean the screen before coating.

Sometimes, even with meticulous care, a few pinholes might slip through. For minor issues, a small touch-up with emulsion can be effective; however, for significant problems, remaking the screen is the best approach. It’s all about prevention and careful attention to detail.

Q 23. Explain the difference between plastisol and water-based inks.

Plastisol and water-based inks are the two dominant types in screen printing, but they have very different properties. Think of it like this: plastisol is like a thick, durable paint, while water-based ink is more like a vibrant, thin watercolor.

- Plastisol: PVC-based, requires a curing process (high heat) to bond to the garment. It’s known for its vibrant, opaque colors, excellent durability, and wide range of effects (glitter, puff, etc.). However, it’s less environmentally friendly and can have a strong odor during the curing process. Cleanup usually involves solvents.

- Water-based: Generally, less durable than plastisol, but it’s more environmentally friendly and has a softer hand-feel on garments. It cures at lower temperatures, reducing energy consumption and eliminating harsh solvents. Cleanup is easier, using just water. The colors tend to be slightly less vibrant and opaque compared to plastisol, but advances in water-based inks have significantly improved their performance.

The choice depends heavily on the project requirements. For apparel with high durability needs, like t-shirts for construction workers, plastisol is king. For eco-conscious projects or garments with a softer feel, water-based inks are preferred. I’ve successfully used both types extensively, always tailoring the ink selection to the client’s needs and the garment type.

Q 24. What is your experience with using a vacuum exposure unit?

Vacuum exposure units are essential for creating high-quality screen prints. They ensure consistent and even exposure of the emulsion to UV light, preventing under-exposed or over-exposed areas that can lead to print defects. My experience with vacuum exposure units includes both manual and automated models.

With a manual unit, the process involves carefully aligning the film positive on the screen, creating a vacuum seal to ensure perfect contact, and then exposing the screen to UV light for a predetermined time. I understand the importance of precise exposure times and the effect of different bulb types and strengths.

Automated units offer greater efficiency and consistency but often require specialized training and maintenance. I’m also familiar with troubleshooting common problems with vacuum units, such as leaks in the vacuum system or malfunctioning timers. A crucial aspect is understanding the relationship between the vacuum pressure, exposure time and the type of emulsion used. I carefully adjust these parameters based on the screen mesh count and the emulsion’s sensitivity to UV light.

Accurate exposure is critical. Under-exposure results in weak stencils and print defects, while over-exposure can harden the emulsion, making it difficult to wash out. My experience enables me to consistently achieve perfect exposure, leading to sharp, clean prints.

Q 25. How do you manage waste and disposal of screen printing materials responsibly?

Responsible waste management is paramount in screen printing. We operate under strict guidelines to minimize our environmental impact. This starts with proper segregation of waste materials.

- Ink Waste: Used inks, especially plastisol, are treated as hazardous waste and disposed of through licensed hazardous waste disposal companies. We minimize ink waste by accurately measuring ink quantities and employing techniques such as color matching software to reduce waste from trial prints.

- Emulsion Waste: Spent emulsion is collected and disposed of according to local regulations. Often this involves drying and then sending it to a hazardous waste facility.

- Solvent Waste: Any solvents used for cleaning are collected in designated containers and handled by specialist waste management companies. We’re moving toward water-based inks to minimize solvent use.

- Screen Recycling: We recycle unusable screens, separating the metal mesh from the frames for proper disposal.

We maintain detailed records of all waste disposal activities to ensure compliance and transparency. Sustainability is not just a trend—it’s a crucial part of our operational ethos.

Q 26. What is your experience with digital screen printing?

Digital screen printing, using direct-to-screen (DTS) printers, represents a significant advancement in the industry. Unlike traditional methods which involve film positives, DTS printers directly expose the screen using digital imaging technology. My experience includes working with several DTS systems, ranging from small-format printers ideal for short runs and prototypes to larger industrial models for high-volume production.

The benefits are numerous: increased speed and efficiency, reduced setup time, elimination of film positives, and enhanced design possibilities. I’m proficient in operating and maintaining these printers, understanding the software needed to create and manage print files, and adjusting settings to optimize image quality and resolution. For example, I’ve used DTS for creating highly detailed, photographic images on apparel, something that would be significantly more challenging with traditional methods. However, I’m also aware of the limitations, such as the higher initial investment cost and the need for specific skills to operate and maintain this equipment.

Q 27. Describe your proficiency with different types of screen printing emulsion.

My proficiency spans several types of screen printing emulsion, each with its unique properties suited for different applications. This includes diazo emulsion, photopolymer emulsion, and capillary film.

- Diazo Emulsion: A classic, relatively inexpensive option, sensitive to UV light. I’m skilled in its handling, mixing ratios (with diazo sensitizer), and exposure techniques to achieve optimal stencil durability and detail.

- Photopolymer Emulsion: A higher-quality, more light-sensitive emulsion offering finer detail and better stencil durability. My experience encompasses various photopolymer types, understanding their sensitivity and optimizing exposure times accordingly. It’s the emulsion of choice when high-quality, fine-detail printing is required.

- Capillary Film: A pre-sensitized film that is easily applied to the screen. This is especially valuable when speed is important or for simpler designs. I’m adept at working with various types of capillary film, aware of their limitations (typically not as durable as liquid emulsions).

My choice of emulsion always depends on the print design, the desired quality, the mesh count of the screen, and the nature of the job (large-scale production versus a short run).

Q 28. How do you maintain accurate color consistency across multiple prints?

Maintaining consistent color accuracy across multiple prints is essential for professional screen printing. Inconsistency can lead to customer dissatisfaction and wasted materials. My approach is multi-faceted.

- Color Management System (CMS): I utilize a robust CMS, ensuring color profiles are accurately calibrated for all devices involved in the process, from the design software to the printers. This creates a consistent color representation throughout.

- Ink Mixing and Consistency: For multi-color prints, accurate and consistent ink mixing is crucial. I follow precise formulas and use calibrated measuring tools to guarantee uniformity.

- Print Test and Adjustment: Before starting a large production run, I always conduct thorough test prints. These are carefully evaluated to ensure that the color matches the client’s specifications. Adjustments are made to the ink mixtures, screen mesh tension, or printing pressure as needed.

- Environmental Factors: I’m mindful that environmental factors such as humidity and temperature can subtly affect ink drying and color appearance. We maintain consistent environmental conditions in the print shop to minimize variability.

- Regular Calibration: Screens, printers, and other equipment are regularly calibrated to prevent gradual color drift and ensure optimal performance.

Maintaining color consistency requires attention to detail at every stage, from design to final print. My experience and methodical approach ensure that every print accurately reflects the intended color, fostering customer confidence.

Key Topics to Learn for Screen Printing Setup and Registration Interview

- Screen Preparation: Understanding different screen mesh counts, emulsion application techniques, and proper exposure methods for optimal print results. This includes troubleshooting issues like pinholes and uneven coating.

- Registration Techniques: Mastering precise alignment of screens using different registration methods (e.g., micro-registration, tape registration) to ensure accurate multi-color printing. Be prepared to discuss the challenges of maintaining registration across multiple prints.

- Press Setup and Operation: Familiarity with various screen printing presses (manual, automatic), including ink setup, squeegee pressure and angle adjustments, and proper off-contact settings to optimize print quality and efficiency. Troubleshooting press malfunctions is key.

- Ink Selection and Mixing: Understanding different ink types (plastisol, water-based, discharge), their properties, and appropriate mixing techniques for achieving desired color and viscosity. Be ready to discuss ink limitations and solutions for specific applications.

- Troubleshooting and Problem-Solving: This includes addressing common issues like screen clogging, misregistration, poor ink adhesion, and print defects. Highlighting your methodical approach to diagnosing and resolving these problems will impress interviewers.

- Safety Procedures: Demonstrate knowledge of safe handling of chemicals, proper equipment operation, and adherence to workplace safety regulations.

- Quality Control: Explain your understanding of quality control measures to maintain consistent print quality and identify defects. Discuss your experience with print inspection and rework.

Next Steps

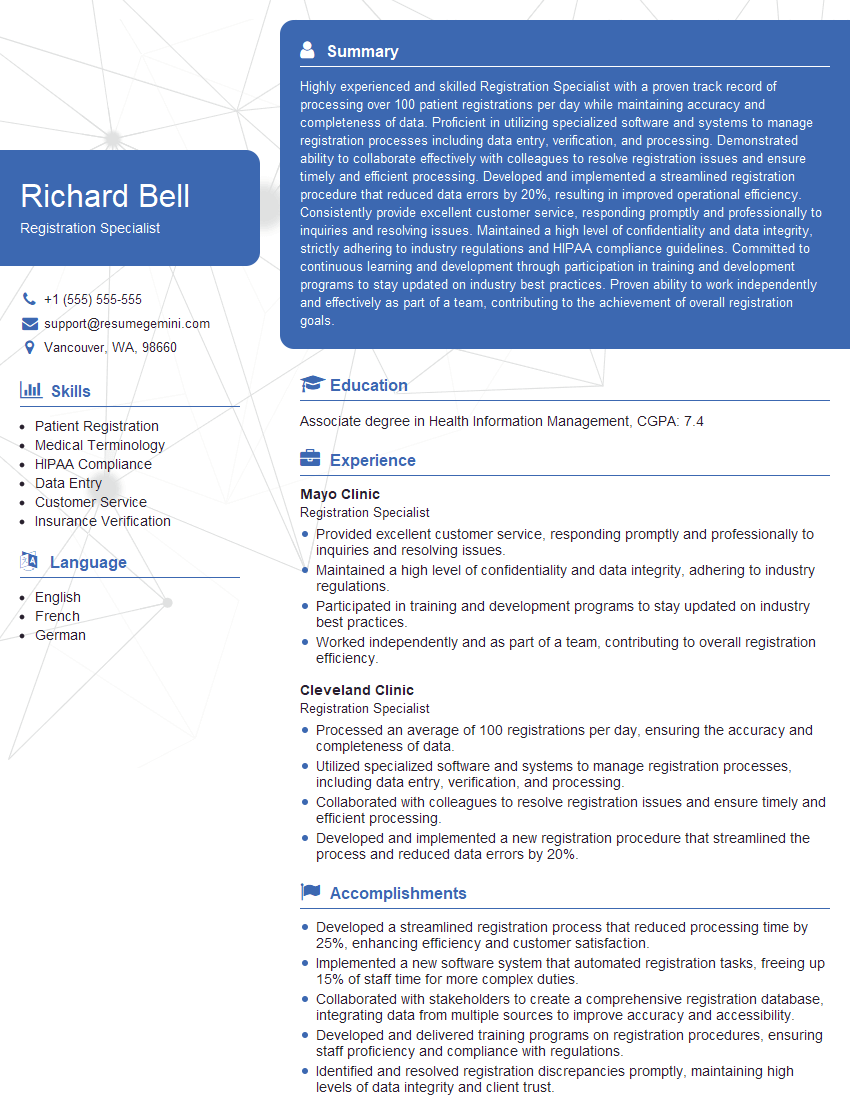

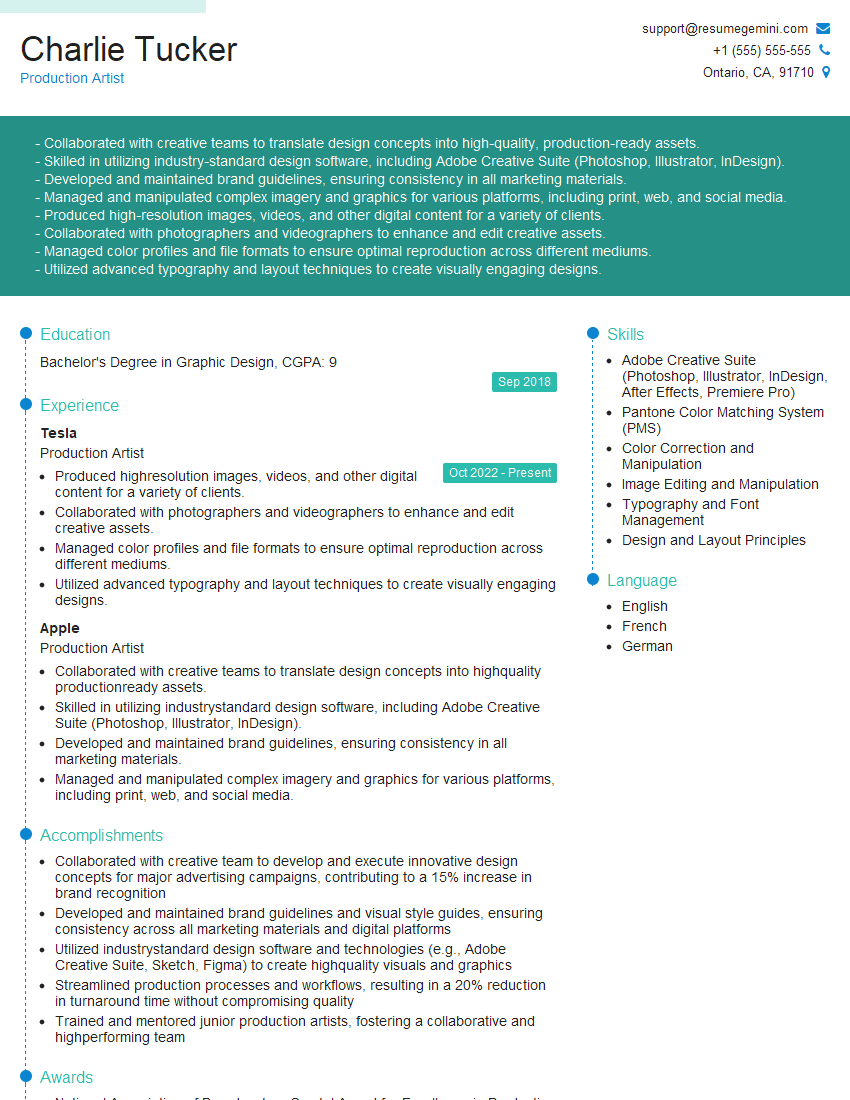

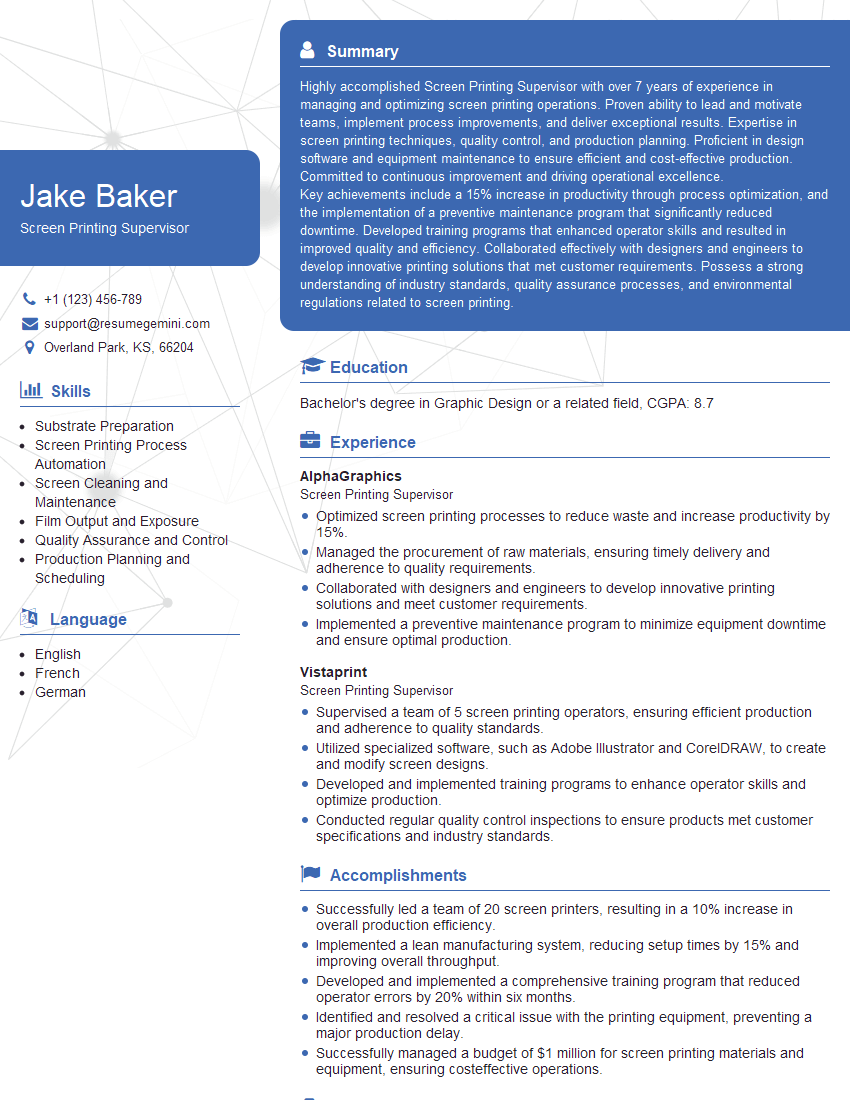

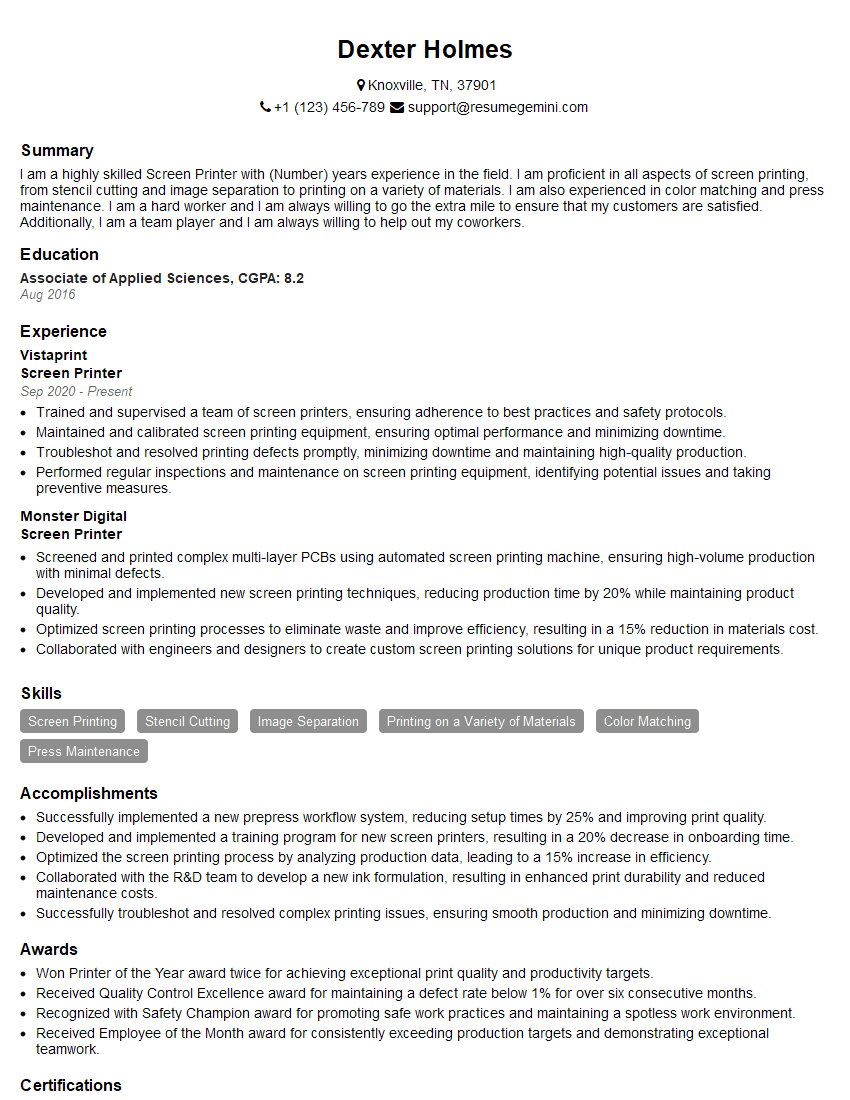

Mastering Screen Printing Setup and Registration is crucial for career advancement in the graphic arts industry, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to ensure it gets noticed by potential employers. ResumeGemini is a valuable tool for creating a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Screen Printing Setup and Registration are available through ResumeGemini, helping you present yourself effectively to prospective employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good