Cracking a skill-specific interview, like one for Machine Tool Design, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Machine Tool Design Interview

Q 1. Explain the difference between subtractive and additive manufacturing in machine tool design.

Subtractive and additive manufacturing represent fundamentally different approaches to creating parts. Think of sculpting versus 3D printing.

Subtractive manufacturing, the core of traditional machine tool design, involves removing material from a larger block (like carving a statue). This is how CNC milling and turning machines work. They start with a workpiece and use cutting tools to shape it to the desired form. Examples include milling a metal block into a complex part or turning a cylindrical piece of metal into a precision shaft.

Additive manufacturing, or 3D printing, builds up a part layer by layer from a digital design. Material, such as plastic, metal powder, or resin, is added incrementally until the final shape is created. While not directly a ‘machine tool’ in the traditional sense, additive processes are increasingly integrated into the design process for tooling and even the creation of some machine components. For example, creating complex molds for casting using 3D printing.

The key difference lies in material removal versus material addition, impacting design freedom, material usage, lead times, and cost.

Q 2. Describe the process of designing a CNC milling fixture.

Designing a CNC milling fixture is crucial for holding a workpiece securely and accurately during machining. It’s like creating a custom cradle for your work, ensuring precision and safety.

The process involves several key steps:

- Part Analysis: Thoroughly examine the workpiece geometry, identifying clamping points and areas needing support to prevent deflection or vibration during cutting.

- Fixture Design: Sketch the fixture, considering the number and location of clamps, the material, and how it will interface with the CNC machine’s table. Software like SolidWorks or Autodesk Inventor is often used to create a 3D model.

- Material Selection: Choose a material that’s rigid, durable, and machinable (often steel or cast iron) and resistant to deflection under machining loads.

- Clamp Design: Design appropriate clamps that securely hold the workpiece without causing damage. Consider quick-change mechanisms for efficient setup.

- Locating Features: Incorporate features such as pins, bushings, or V-blocks to accurately position the workpiece on the fixture. These features will repeatably position the part ensuring consistent machining.

- Simulation and Analysis: Use Finite Element Analysis (FEA) to simulate the fixture’s performance under machining loads, ensuring it can withstand forces and prevent deflection.

- Manufacturing: The fixture is then manufactured, potentially through CNC machining itself. Quality control is essential at each stage.

A well-designed fixture ensures accuracy, repeatability, and operator safety, significantly impacting the quality and efficiency of the CNC milling process.

Q 3. What are the key considerations when selecting a material for a machine tool component?

Material selection for machine tool components is critical as it directly impacts performance, longevity, and cost. Think of building a house – you wouldn’t use cardboard for the foundation.

Key considerations include:

- Strength and Rigidity: The material must withstand the forces and vibrations generated during operation, preventing deformation and ensuring accuracy.

- Wear Resistance: Components subject to friction or abrasion, such as ways and slides, need high wear resistance to minimize wear and maintain accuracy.

- Hardness: Hardness is important for resisting scratching, scoring, and deformation. However, excessively hard materials might be brittle.

- Machinability: The material should be relatively easy to machine to reduce production costs and time.

- Thermal Stability: The material should maintain its properties over a wide range of temperatures, preventing expansion or contraction that might affect accuracy.

- Corrosion Resistance: In environments with moisture or chemicals, corrosion resistance is vital to extend the lifespan of the components.

- Cost: Material cost significantly impacts the overall machine cost.

Often, a balance between these properties is required. For instance, high-speed steel (HSS) is excellent for cutting tools due to its hardness and wear resistance, but it’s relatively expensive and harder to machine than mild steel, which is suitable for less demanding parts.

Q 4. How do you ensure the rigidity and stability of a machine tool design?

Rigidity and stability are paramount in machine tool design; they directly impact the accuracy and repeatability of the machining process. Imagine trying to draw a straight line on a wobbly table – it’s impossible!

Strategies to ensure rigidity and stability include:

- Robust Structural Design: Use FEA to optimize the design, minimizing deflections under load. This might involve adding ribs, stiffeners, or changing the cross-sectional shape of components.

- High-Strength Materials: Choose materials with high yield strength and stiffness, such as cast iron or steel alloys.

- Optimized Geometry: Design components with minimal overhangs and maximize moment of inertia to resist bending and twisting. This might involve using box-section beams instead of I-beams or round bars.

- Proper Support Structures: Ensure adequate support for all moving parts, minimizing deflection and vibrations. This often involves strategically placed bearings and guides.

- Vibration Damping: Incorporate vibration damping materials or structures to minimize vibrations caused by the cutting process.

- Precise Assembly: Accurate assembly of components is vital to ensure proper alignment and minimize play or looseness. Shimming may be necessary.

By meticulously addressing these aspects, machine tool designers guarantee the precision needed for consistent and accurate machining.

Q 5. What are the different types of CNC machining centers and their applications?

CNC machining centers come in various types, each optimized for specific applications.

Some common types include:

- 3-Axis Machining Centers: These offer three axes of movement (X, Y, Z) suitable for simple milling and drilling operations. They’re versatile and commonly used in a wide variety of applications.

- 4-Axis Machining Centers: These add a rotary axis (A or B) to allow for machining of complex shapes and surfaces, such as curved parts or molds.

- 5-Axis Machining Centers: These add another rotary axis (C) for complete 5-axis machining, allowing for complex 3D surface machining with increased flexibility. Often used for aerospace parts or complex molds.

- Horizontal Machining Centers (HMCs): The spindle is horizontally oriented, enabling the machining of large, heavy parts. Often used in heavy industries.

- Vertical Machining Centers (VMCs): The spindle is vertically oriented, generally better suited for smaller and lighter workpieces, offering better accessibility.

- Turning Centers: These are primarily designed for turning operations such as creating shafts, cylinders, or other rotational parts. They may include milling capabilities.

The choice of machining center depends on the complexity of the parts being machined, the required accuracy, and production volume. Selecting the wrong type can lead to increased costs, longer processing times, and even inability to complete the tasks.

Q 6. Explain the concept of tolerance stack-up analysis in machine tool design.

Tolerance stack-up analysis is a critical aspect of machine tool design. It’s about understanding how individual tolerances of components accumulate to impact the overall accuracy of the machine. Imagine building a tower with slightly inaccurate bricks – the error will compound as the tower gets taller.

In machine tools, each component has manufacturing tolerances (the acceptable range of variation in dimensions). These tolerances propagate through the system. For example, the tolerance on the bearing, the spindle, and the ways will all affect the final positioning accuracy of the cutting tool. Tolerance stack-up analysis helps determine if the combined effect of individual component tolerances meets the overall machine’s accuracy specifications.

Methods for performing this analysis include:

- Worst-case analysis: This conservative approach adds the maximum possible deviations of all tolerances to determine the worst-case scenario.

- Root-sum-square (RSS) analysis (statistical analysis): This method considers the statistical distribution of tolerances, assuming variations are randomly distributed. It provides a more realistic estimate than worst-case analysis.

- Monte Carlo simulation: This sophisticated technique simulates many variations of component tolerances and provides a probability distribution of the overall tolerance. It’s excellent for more complex systems.

By performing tolerance stack-up analysis early in the design phase, designers can identify potential problems and make informed decisions to optimize component tolerances and ensure the machine meets its accuracy requirements.

Q 7. How do you design for manufacturability in machine tool design?

Designing for manufacturability (DFM) is a crucial aspect of machine tool design. It ensures the machine can be efficiently and cost-effectively produced. It’s like planning a construction project carefully – the more planning, the less chance of issues during the build.

Key aspects of DFM in machine tool design:

- Standard Components: Utilizing off-the-shelf components whenever possible reduces lead times, costs, and potential compatibility issues.

- Modular Design: Breaking the machine into modular subassemblies simplifies manufacturing, assembly, and maintenance. It allows for easier troubleshooting and replacement of faulty modules.

- Simplified Geometry: Avoid complex geometries that increase machining time and cost. Simpler shapes are easier and faster to machine.

- Accessibility for Machining: Design components with easily accessible surfaces for machining, avoiding blind holes or difficult-to-reach areas.

- Material Selection for Machinability: Choose materials that are readily available and easily machined, balancing cost with performance.

- Ease of Assembly: Design the machine for easy assembly, minimizing the number of parts and fasteners. This could involve using techniques like press fits or snap fits.

- Tolerances and Fits: Specify realistic tolerances that allow for efficient manufacturing without compromising accuracy. Use appropriate fit types for different components.

By incorporating DFM principles from the outset, designers can significantly reduce manufacturing costs, shorten lead times, and improve the overall quality and reliability of the machine tool.

Q 8. What are common failure modes in machine tool components and how to mitigate them?

Machine tool components experience various failure modes, often stemming from fatigue, wear, or improper operation. Let’s explore some common issues and mitigation strategies.

Spindle failures: Bearing wear, imbalance, and lubrication issues are common culprits. Mitigation involves using high-quality bearings, precise balancing during assembly, and implementing a robust lubrication system with regular maintenance.

Guideway wear: Linear guides and ways are subjected to continuous friction. Improper lubrication, contamination (chips, coolant), and excessive loads lead to wear. Regular cleaning, proper lubrication, and the use of hardened guideways or protective coatings are key solutions. Consider using linear motors for higher speed and accuracy applications where wear is a major concern.

Gearbox failures: Gear teeth wear, lubrication failure, and misalignment can cause gearbox problems. Proper gear selection (considering material, module, and pressure angle), regular lubrication checks, and alignment procedures are crucial. Consider using advanced gear materials like hardened steel or ceramic for improved durability in high-load applications.

Structural failures: Excessive vibrations, overloading, and poor structural design can lead to frame distortion or cracking. Finite element analysis (FEA) during the design stage allows for optimization of structural integrity. Robust design principles, material selection (e.g., high-strength cast iron or steel), and proper vibration damping mechanisms are important preventative measures.

In short, proactive maintenance, robust design incorporating FEA, high-quality components, and the implementation of effective monitoring systems are essential for preventing common failure modes.

Q 9. Describe different types of cutting tools and their applications.

Cutting tools are categorized based on their geometry, material, and application. Understanding the tool’s capabilities is critical for efficient machining.

Single-point cutting tools: These tools, like lathe tools and milling cutters, remove material using a single cutting edge. Their geometry (rake angle, clearance angle, etc.) is tailored to the specific material being machined and the desired surface finish. Examples include high-speed steel (HSS) tools, carbide tools, and ceramic tools, each offering varying degrees of hardness, wear resistance, and cutting speeds.

Multi-point cutting tools: These, like drills, reamers, and taps, have multiple cutting edges. Drills create holes, reamers enlarge and precisely finish existing holes, and taps create internal threads. These tools are designed for specific operations and material types.

Abrasive cutting tools: Grinding wheels, honing stones, and lapping plates use abrasive materials to remove material. They offer high material removal rates but generate heat, which necessitates appropriate coolant selection and careful operation.

Choosing the correct cutting tool depends on factors such as the workpiece material, the desired surface finish, the required accuracy, and the machining operation. A wrong choice can result in tool breakage, poor surface quality, or even damage to the machine tool itself.

Q 10. Explain the importance of thermal management in machine tool design.

Thermal management in machine tool design is paramount as excessive heat affects accuracy, precision, and component lifespan. Heat is generated from friction during cutting, motor operation, and other processes.

Heat dissipation: Effective cooling systems (e.g., coolant circulation, air cooling) are crucial to remove heat from the cutting zone, spindle bearings, and motors. Proper design of coolant channels and heat sinks helps to maintain optimal operating temperatures.

Material selection: Components exposed to high temperatures require materials with good thermal conductivity and resistance to thermal stresses. For example, using specialized bearing materials in high-speed spindles enhances performance and longevity.

Thermal modeling: Computational Fluid Dynamics (CFD) and FEA simulations are used to predict temperature distributions and identify potential thermal hotspots during the design stage, enabling preventative measures.

Ignoring thermal management can lead to thermal distortion, reduced accuracy, premature component failure, and decreased machining efficiency. A well-designed thermal management system is crucial for ensuring the machine’s precision and extended operational life.

Q 11. How do you ensure the accuracy and precision of a machine tool?

Ensuring the accuracy and precision of a machine tool involves meticulous design, manufacturing, and maintenance practices.

Geometric accuracy: Precise machining of the machine tool’s structural components, accurate assembly, and the use of high-precision linear guides and bearings are essential. Regular calibration and alignment procedures are needed to maintain accuracy over time.

Precision components: High-quality spindles, ball screws, and linear guides are necessary for accurate motion control. The selection of appropriate tolerances and surface finishes for critical components plays a significant role.

Control system: Advanced numerical control (NC) systems with feedback mechanisms (e.g., encoders, linear scales) monitor and adjust machine movements, enhancing precision. Regular calibration of the control system is vital.

Environmental control: Temperature variations and vibrations can affect accuracy. Proper environmental control (e.g., temperature-controlled environment, vibration isolation) minimizes these impacts.

Regular maintenance, including periodic inspection, lubrication, and calibration, is essential for preserving the accuracy and precision of the machine tool. This proactive approach ensures long-term reliable operation.

Q 12. What are the safety considerations when designing machine tools?

Safety is paramount in machine tool design. Designers must incorporate various safety features to protect operators and minimize risks.

Emergency stops: Easily accessible and reliable emergency stop buttons are mandatory. Multiple emergency stop circuits ensure redundancy.

Guards and enclosures: Moving parts must be shielded to prevent accidental contact. Enclosures protect operators from flying chips and coolant spray.

Interlocks: Interlocking mechanisms prevent access to hazardous areas while the machine is operating. These mechanisms ensure that the machine cannot operate if safety measures are not in place.

Risk assessments: Thorough risk assessments should be carried out during the design phase to identify and mitigate potential hazards. This involves considering all possible scenarios and designing safety systems accordingly.

Ergonomics: Ergonomic design principles ensure that the machine is comfortable and safe to operate. Operator fatigue can lead to mistakes, and proper design can significantly mitigate this risk.

Compliance with relevant safety standards and regulations is crucial in machine tool design. Continuous improvement in safety design is needed to maintain a safe working environment for operators.

Q 13. Describe your experience with CAD/CAM software (e.g., SolidWorks, AutoCAD, NX).

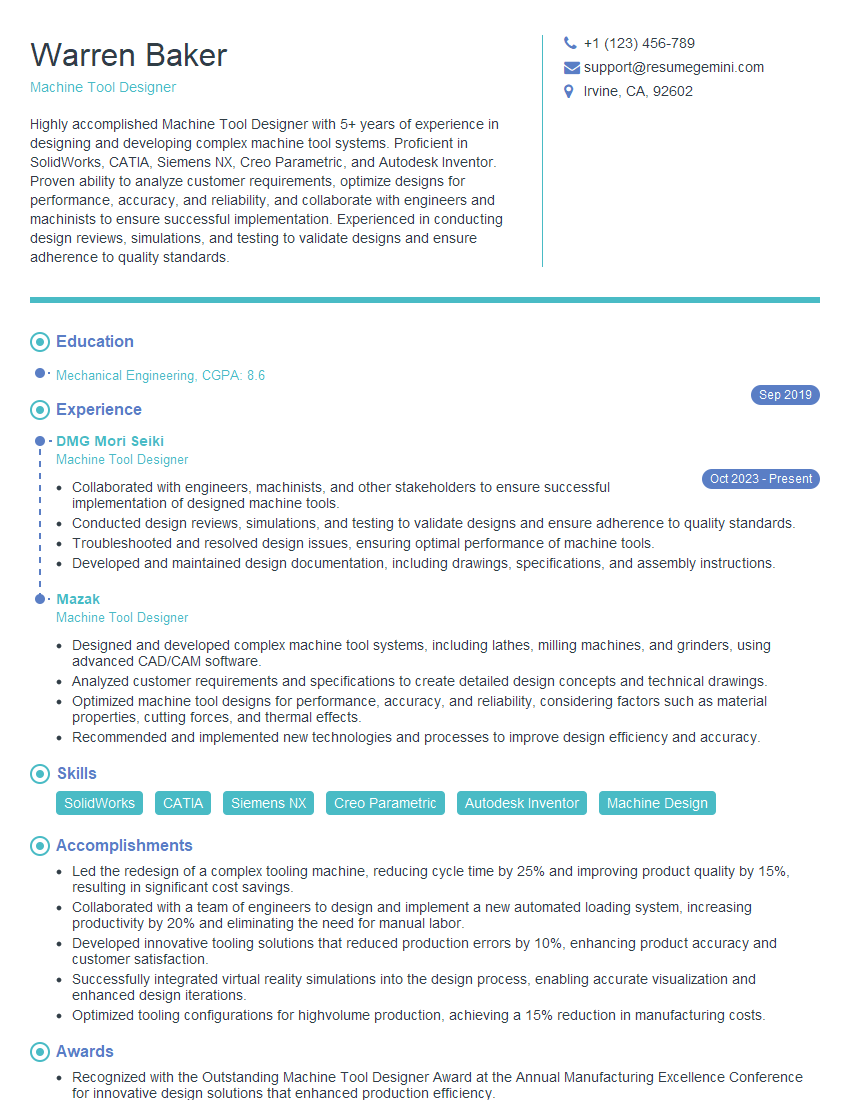

I have extensive experience using several CAD/CAM software packages, including SolidWorks, AutoCAD, and NX. My expertise spans from 2D drafting to advanced 3D modeling, FEA, and CAM programming.

SolidWorks: I’ve used SolidWorks extensively for 3D modeling of machine tool components, assemblies, and complete machines. I’m proficient in creating detailed drawings, performing simulations (FEA), and generating manufacturing documentation.

AutoCAD: AutoCAD remains essential for creating precise 2D drawings and detailed shop documentation. I leverage AutoCAD’s capabilities for creating accurate schematics, layouts, and technical illustrations.

NX: My experience with NX includes advanced surface modeling, creating complex geometries, and generating CNC toolpaths. I have effectively utilized NX’s integrated CAM capabilities for optimizing machining processes.

I regularly use these software packages to design, analyze, and document machine tools. My skills enable me to seamlessly transition between these platforms, leveraging the strengths of each for specific design tasks.

Q 14. How do you handle design changes and revisions in a project?

Handling design changes and revisions efficiently is crucial in any project. My approach involves a structured process to ensure seamless integration of updates.

Version control: I utilize version control systems (e.g., PDM systems) to track changes, allowing easy rollback if needed. This maintains a clear history of design iterations.

Change management process: A formalized change request process is crucial. Each change is documented, reviewed, and approved before implementation. This ensures that all stakeholders are aware of the modifications and their implications.

Impact analysis: Before implementing a change, I assess its impact on other components, assemblies, and the overall system. This preventative measure avoids cascading effects that lead to further revisions.

Communication: Clear and frequent communication with all stakeholders (engineers, manufacturing, clients) is essential to ensure everyone understands the design changes and their implications.

My experience shows that a well-defined process for managing design changes ensures that revisions are implemented efficiently and that the integrity of the design remains intact throughout the project lifecycle.

Q 15. Explain your process for validating a machine tool design.

Validating a machine tool design is a crucial step ensuring its functionality, safety, and efficiency. It’s not a single test, but a multi-stage process encompassing various analyses and practical tests. Think of it like building a bridge – you wouldn’t just throw some materials together; you’d meticulously check the structural integrity at each stage.

Design Reviews: We start with thorough design reviews involving the entire engineering team. This allows for early detection of potential issues and ensures everyone understands the design specifications and complies with safety regulations.

Finite Element Analysis (FEA): FEA simulates the machine’s behavior under various loads and conditions. This helps us optimize the design for stiffness, strength, and prevent failures. For example, we might simulate high-speed cutting operations to analyze stress concentrations in critical components like the spindle and toolholder.

Prototyping and Testing: A physical prototype is built and rigorously tested. This includes static load tests to check strength, dynamic tests to evaluate vibration and stability during operation, and thermal tests to ensure proper temperature control within specified ranges. We also conduct cutting tests using various materials to validate performance and accuracy.

Control System Validation: The machine’s control system is also tested extensively. This involves testing the accuracy of motion control, the response to various commands, and the safety features. We perform simulations and real-world testing to ensure smooth operation.

Field Testing: Before final release, the machine is typically deployed in a real-world production environment for further testing. This helps us identify any unexpected issues that might not have been discovered during earlier stages. This feedback is crucial for continuous improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you incorporate ergonomics into your machine tool designs?

Ergonomics in machine tool design focuses on creating a safe and comfortable working environment for the operator. Ignoring ergonomics can lead to operator fatigue, injuries, and reduced productivity. We approach it systematically, considering factors such as reach, posture, vibration, noise, and visual demands.

Control Panel Placement: The control panel is strategically located to minimize operator reach and awkward postures. The buttons and displays are sized and placed for easy access and visibility.

Operator Access and Safety: We design the machine with easy access to all maintenance points, minimizing the need for awkward positions or dangerous maneuvers during maintenance and repair. Safety features, such as emergency stops and safety guards, are integrated into the design.

Vibration Reduction: Vibration dampening measures are included in the design to reduce fatigue and discomfort for the operator. This might involve using vibration-isolating mounts or implementing structural modifications to reduce resonant frequencies.

Noise Reduction: Enclosures and sound-dampening materials are used to minimize noise pollution, creating a more comfortable working environment.

Illumination: Adequate lighting is essential for reducing eye strain and improving visibility. Work areas are well-illuminated, and glare is minimized.

Q 17. Describe your experience with different types of machine tool control systems.

My experience spans various machine tool control systems, from traditional PLC-based systems to advanced CNC systems incorporating modern technologies like adaptive control and predictive maintenance. Each system presents unique strengths and challenges.

PLC-Based Systems: These are reliable and robust, particularly well-suited for simpler machines. They offer ease of programming and maintenance but might lack the flexibility and precision of modern CNC systems.

CNC Systems (Computer Numerical Control): I’ve worked extensively with CNC systems from various manufacturers, including Fanuc, Siemens, and Heidenhain. These provide precise control over machine movements and offer features like tool path optimization and advanced machining strategies.

Adaptive Control Systems: These systems adapt machining parameters in real-time based on the measured cutting forces and material properties, resulting in improved surface finish, reduced tool wear, and higher machining efficiency. I have experience integrating adaptive control algorithms into CNC systems.

Direct Numerical Control (DNC): I have experience implementing DNC systems for networked machine control, where multiple machines can be controlled from a central computer. This significantly improves production efficiency and data management.

Selecting the appropriate control system depends on the specific application and requirements. For a high-precision, high-speed machining center, a sophisticated CNC system with adaptive control would be preferred, while a simpler PLC-based system might suffice for a less demanding application.

Q 18. What are the benefits and limitations of different machine tool configurations?

Machine tool configurations vary significantly, each offering unique advantages and limitations. The optimal configuration depends heavily on the intended application.

Vertical Machining Centers (VMCs): These are versatile and suitable for a wide range of applications. They offer good accessibility for tooling and workpieces but can be limited in terms of the maximum workpiece size.

Horizontal Machining Centers (HMCs): HMCs are ideal for high-volume production of large, heavy parts. They often feature automatic tool changers and pallet systems for increased efficiency, but they have less accessibility than VMCs.

Lathes: Used for rotating parts, lathes offer high precision and efficiency for cylindrical machining. They can be either engine lathes or CNC lathes, with the latter offering greater flexibility and control.

Grinding Machines: Used for precision surface finishing, grinding machines are essential for producing highly accurate and smooth surfaces. They are categorized based on various factors like the type of grinding wheel, the method of material removal, and the workpiece configuration.

For instance, a VMC is suitable for creating complex parts requiring multiple operations, while a lathe is best for cylindrical parts. Choosing the right configuration significantly impacts productivity, accuracy, and overall cost-effectiveness.

Q 19. How do you select appropriate bearings and lubrication systems for machine tools?

Bearing and lubrication system selection are crucial for machine tool performance, reliability, and longevity. Factors like speed, load, environment, and required precision heavily influence the choices.

Bearing Selection: The type of bearing (ball, roller, hydrostatic, hydrodynamic) depends on the application. High-speed spindles typically use precision ball bearings, while heavy-duty applications might require roller bearings. Hydrostatic or hydrodynamic bearings are often preferred for applications requiring extremely high precision and low friction.

Lubrication System: Lubrication systems must ensure continuous and adequate lubrication to minimize friction, wear, and heat generation. Options include grease lubrication (simpler, less precise), oil mist lubrication (for high-speed applications), and centralized lubrication systems (for complex machines with numerous bearings).

Material Compatibility: Bearing materials and lubricants must be compatible with each other and the operating environment to prevent corrosion and other forms of degradation.

Environmental Considerations: If the machine will operate in extreme temperatures or harsh environments, special considerations are needed for both bearing and lubrication system selection.

A poorly selected bearing or lubrication system can lead to premature failure, reduced accuracy, increased maintenance costs, and even catastrophic breakdowns. Therefore, a detailed analysis of the operating conditions and requirements is essential.

Q 20. Describe your experience with finite element analysis (FEA) in machine tool design.

FEA is an indispensable tool in modern machine tool design. It allows for the virtual simulation of stresses, strains, and deformations under various operating conditions, significantly reducing the need for extensive and costly physical prototyping. I’ve used FEA extensively for:

Structural Analysis: Analyzing the strength and stiffness of machine components to ensure they can withstand the anticipated loads and vibrations. This helps optimize designs for weight reduction without compromising structural integrity.

Modal Analysis: Identifying natural frequencies and mode shapes to avoid resonance and minimize vibrations during operation. This is crucial for ensuring machine stability and precision.

Thermal Analysis: Simulating heat generation and dissipation to predict temperature distributions and ensure the machine remains within acceptable operating temperatures. This helps prevent thermal-induced deformation and improve machining accuracy.

Fatigue Analysis: Predicting the lifespan of machine components under cyclic loading to prevent fatigue failures. This allows for designing components with increased lifespan and improved reliability.

Software packages like ANSYS and Abaqus are frequently used. A successful FEA analysis requires accurate modeling of the machine, appropriate material properties, and well-defined boundary conditions.

Q 21. How do you perform vibration analysis in machine tool design?

Vibration analysis is critical in machine tool design to ensure smooth, precise, and reliable operation. Excessive vibrations lead to reduced accuracy, surface finish problems, premature tool wear, and even machine damage. My approach involves several steps:

Modal Analysis (FEA): As mentioned before, FEA is used to identify the natural frequencies and mode shapes of the machine structure. This helps determine potential resonance frequencies that could be excited by operating conditions.

Experimental Modal Analysis: This involves exciting the machine structure with an external force (e.g., an impact hammer) and measuring the resulting vibrations using accelerometers. This provides experimental validation of the FEA results.

Operational Deflection Shape (ODS) Analysis: This involves measuring vibrations while the machine is running under normal operating conditions. It helps identify vibration sources and their impact on machine performance.

Vibration Damping Techniques: Based on the analysis results, vibration damping techniques are implemented. These can include modifications to the machine structure, the use of vibration dampers, or adjustments to operating parameters.

Effective vibration analysis requires a combination of FEA, experimental measurements, and an understanding of the machine’s dynamic behavior. The goal is to minimize vibrations to within acceptable levels for the specific application.

Q 22. How do you select appropriate actuators and motors for machine tools?

Selecting actuators and motors for machine tools is a critical design decision impacting performance, accuracy, and cost. The process involves careful consideration of several factors, beginning with the specific application requirements.

- Required Force/Torque: This is determined by the cutting forces, workpiece size, and desired feed rates. For example, a heavy-duty milling machine requires significantly more torque than a precision engraving machine. We calculate this based on material properties, cutting parameters and tooling geometry.

- Speed and Acceleration: The required speed and acceleration profiles dictate the type of motor and the need for any gearing systems. High-speed applications necessitate motors with high rotational speeds and potentially specialized control systems.

- Accuracy and Resolution: Precision machining demands high-resolution actuators and control systems. Servo motors, offering excellent precision and responsiveness, are often preferred in such cases. Stepper motors may suffice for less demanding applications.

- Environment: Factors like temperature, humidity, and potential for contamination impact motor and actuator selection. For example, a machine operating in a harsh environment may require a more robust and sealed motor.

- Cost and Maintenance: The cost of the actuator, motor, and associated control systems should be balanced against the overall machine cost and maintenance requirements. Hydraulic systems can provide high force but require more complex maintenance compared to electric solutions.

For instance, in designing a high-speed CNC router, we might choose high-performance servo motors with ball screw actuators for precise and rapid movement of the cutting head. In contrast, a simpler lathe might use a less expensive AC motor with a lead screw drive.

Q 23. Describe your experience with designing for different materials (e.g., aluminum, steel, composites).

Material selection significantly influences machine tool design, affecting performance, cost, and durability. My experience encompasses working with a range of materials, each presenting unique challenges and opportunities.

- Steel: A common choice for its high strength and stiffness, steel is ideal for machine tool structures requiring high rigidity and resistance to deformation under load. However, its high weight can affect machine dynamics, and careful consideration of vibration damping might be necessary.

- Aluminum: Lighter than steel, aluminum is preferred where reduced weight and inertia are crucial, improving machine responsiveness. However, aluminum’s lower stiffness requires careful design to minimize vibrations and ensure sufficient rigidity. We often use aluminum alloys with enhanced mechanical properties.

- Composites: Materials such as carbon fiber reinforced polymers (CFRP) offer high strength-to-weight ratios and can be tailored to specific applications. Their use is expanding in high-speed and lightweight machine tools. However, their processing and manufacturing require specialized expertise, and fatigue considerations become very important in long-term operation.

In a recent project involving a high-speed milling machine, we used a hybrid approach. The main structure was fabricated from a high-strength steel casting for rigidity, while lightweight aluminum components were employed for moving parts to minimize inertia and improve responsiveness. This optimized the machine’s performance and reduced energy consumption.

Q 24. How do you address issues with machine tool noise and vibration?

Noise and vibration are critical concerns in machine tool design, impacting both operator comfort and machine accuracy. Mitigation strategies involve a multi-faceted approach:

- Structural Design: Rigidity is key to minimizing vibrations. Finite Element Analysis (FEA) is crucial in identifying areas of potential resonance and optimizing structural design. We frequently use Finite Element Modelling (FEM) to optimise the rigidity and dampen the resonance frequency of the machine structure.

- Damping: Adding damping materials to the machine structure (e.g., vibration dampers, constrained layer damping) reduces vibration amplitude. This could involve using viscoelastic materials strategically within the machine’s frame or implementing vibration isolators at the base.

- Acoustic Enclosure: Enclosing noisy components reduces noise pollution. Sound-absorbing materials inside the enclosure further reduce the noise level.

- Motor and Actuator Selection: Choosing low-noise motors and actuators reduces the source of vibrations.

- Optimized Cutting Parameters: Properly selecting cutting parameters (speed, feed rate, depth of cut) minimizes vibrations generated during machining.

For example, in designing a precision grinding machine, we used a combination of high-stiffness castings, constrained layer damping on the table, and acoustic enclosure to achieve low noise and vibration levels, enhancing both the accuracy of the machine and the operator’s workspace.

Q 25. Explain your experience with machine tool testing and commissioning.

Machine tool testing and commissioning is a systematic process to verify design specifications and ensure proper functionality. It involves several stages:

- Functional Testing: Individual components and sub-assemblies are tested to verify their functionality according to design specifications. For example, we would test the accuracy of the axis movements, the responsiveness of the control system, and the performance of the spindle.

- Integration Testing: Once components are assembled, integrated tests verify their interaction and overall system performance. This involves evaluating the overall accuracy of the machine and verifying the interoperability of the subsystems.

- Performance Testing: Performance tests assess the machine’s capabilities under real-world operating conditions. This includes assessing machining accuracy, surface finish, and overall productivity.

- Acceptance Testing: This final stage verifies that the machine meets the customer’s requirements and specifications. Acceptance tests involve the customer directly validating the machine’s capabilities.

For example, in testing a CNC lathe, we’d perform rigorous accuracy tests using precision gauge blocks and verify the surface finish of test parts through microscopy. We’d also perform load tests to confirm the machine can withstand the specified cutting forces.

Q 26. How do you ensure the maintainability and serviceability of a machine tool design?

Ensuring maintainability and serviceability is crucial for minimizing downtime and maximizing the machine’s lifespan. This is achieved through:

- Modular Design: Designing the machine with easily replaceable modules simplifies maintenance and repairs. This would mean designing sub-assemblies that can be easily removed and replaced.

- Accessibility: Components should be easily accessible for inspection, maintenance, and repair. We plan for sufficient space around critical components for easy access and service.

- Standardized Components: Using standard components simplifies parts procurement and replacement.

- Clear Documentation: Comprehensive documentation, including assembly drawings, wiring diagrams, and maintenance manuals, are essential.

- Diagnostics: Incorporating diagnostics features allows for quick fault detection and troubleshooting.

For instance, in designing a milling machine, we ensured easy access to the spindle for bearing replacement by designing the machine head as a removable module. We also used readily available components for the hydraulic system.

Q 27. Describe your understanding of different machine tool standards and regulations.

Understanding machine tool standards and regulations is critical for ensuring safety, performance, and compliance. Key standards include:

- ISO Standards: Various ISO standards cover aspects such as machine safety (ISO 13849), numerical control systems (ISO 13849), and geometric product specifications (GPS).

- CE Marking (Europe): Compliance with the Machinery Directive ensures the machine meets safety and health requirements.

- NFPA (North America): National Fire Protection Association standards address electrical safety and fire prevention.

- Local Regulations: Local regulations might impose specific requirements related to environmental protection, noise emissions, and other aspects.

Adherence to these standards is not merely a regulatory requirement; it also impacts the machine’s reliability and safety, crucial for user acceptance and minimizing liability. For each project, we thoroughly review the relevant standards applicable to the target market to guarantee compliance.

Q 28. What is your approach to resolving design conflicts and managing trade-offs?

Design conflicts and trade-offs are inherent in engineering. My approach involves a structured process:

- Clearly Defined Requirements: A thorough understanding of all requirements (performance, cost, safety, etc.) is paramount. This often involves thorough consultations with clients to understand their exact needs.

- Prioritization: Prioritizing requirements based on their criticality helps navigate trade-offs. For example, accuracy might be prioritized over cost in a precision machine.

- Trade-off Analysis: Systematically evaluating the implications of different design choices helps identify the optimal balance. We often use Decision Matrices to analyse the various trade-offs and weigh different design solutions against one another.

- Iterative Design: Iterative design allows for refinements and adjustments based on analysis and testing. This iterative process refines design choices and allows for changes based on real-world test results.

- Collaboration: Open communication and collaboration among the design team are crucial for resolving conflicts.

For example, in designing a high-speed milling machine, we faced a conflict between cost and performance. Through trade-off analysis, we optimized the design by using a more cost-effective motor while employing advanced control algorithms to achieve the required performance.

Key Topics to Learn for Machine Tool Design Interview

- Kinematics and Dynamics of Machine Tools: Understanding the motion and forces involved in machining processes, including analysis of mechanisms, vibrations, and accuracy.

- Design for Manufacturing (DFM): Applying DFM principles to optimize the design for efficient and cost-effective manufacturing, considering material selection, tolerances, and assembly processes.

- Material Science and Selection: Knowing the properties of various materials used in machine tool construction and their suitability for different applications, considering wear resistance, strength, and machinability.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): Proficiency in using CAD/CAM software for designing and simulating machine tools and machining processes. Practical experience with specific software packages is highly valuable.

- Control Systems and Automation: Understanding the principles of numerical control (NC) and computer numerical control (CNC) systems, including programming, troubleshooting, and automation strategies. This includes familiarity with PLC programming and industrial control networks.

- Machine Tool Structures and Components: Detailed knowledge of different machine tool structures (e.g., bed, column, spindle) and components (e.g., bearings, spindles, feed mechanisms), and their design considerations for rigidity, accuracy, and thermal stability.

- Geometric Dimensioning and Tolerancing (GD&T): Applying GD&T principles to ensure precise manufacturing and assembly of machine tool components.

- Finite Element Analysis (FEA): Using FEA for stress analysis, vibration analysis, and thermal analysis of machine tool components and structures.

- Troubleshooting and Maintenance: Demonstrating practical understanding of diagnosing and resolving common machine tool problems, including preventative maintenance strategies.

- Safety and Ergonomics: Incorporating safety considerations and ergonomic principles into machine tool designs to ensure operator safety and efficiency.

Next Steps

Mastering Machine Tool Design opens doors to exciting career opportunities in manufacturing, automation, and research. A strong understanding of these principles is highly sought after by leading companies. To maximize your chances of landing your dream role, a well-crafted, ATS-friendly resume is crucial. ResumeGemini is a trusted resource for building professional resumes that get noticed. Use ResumeGemini to create a compelling resume that showcases your skills and experience effectively. Examples of resumes tailored to Machine Tool Design are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good