Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Metal Screen Printing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Metal Screen Printing Interview

Q 1. Describe the process of emulsion coating a screen for metal screen printing.

Emulsion coating is the crucial first step in preparing a screen for metal screen printing. It involves applying a photosensitive emulsion to the screen’s mesh, creating a light-sensitive layer that will define the image to be printed. Think of it like creating a photographic negative on the screen itself.

The process typically involves:

- Screen Preparation: The screen (usually made of stainless steel or aluminum) is thoroughly cleaned to remove any debris or oils that could interfere with emulsion adhesion. This might involve washing with a degreaser and rinsing with water.

- Emulsion Mixing: The photosensitive emulsion, usually a diazo-type or a newer polymer-based emulsion, is carefully mixed according to the manufacturer’s instructions. Proper mixing is crucial for a uniform coating and consistent results.

- Coating: The emulsion is applied evenly to both sides of the screen using a scoop coater, a trough and squeegee, or a specialized coating machine. The goal is a consistent, thin layer without any drips or runs. Too thick, and it’s prone to cracking; too thin, and the image might be weak.

- Drying: The coated screen is then allowed to dry completely in a dark, dust-free environment. This typically takes several hours, depending on the emulsion type and environmental conditions. Premature drying or exposure to light will ruin the emulsion.

- Exposure and Washout: Once dry, the screen is exposed to UV light through a film positive containing the desired image. The exposed areas harden, while the unexposed areas remain soluble. The unexposed emulsion is then washed away, leaving behind the hardened image on the screen, ready for printing.

For example, if you are printing a detailed logo onto a stainless steel coffee mug, a high-quality emulsion and careful coating are vital to reproduce the fine details accurately.

Q 2. Explain the difference between plastisol and water-based inks in metal screen printing.

Plastisol and water-based inks are the two primary ink types used in metal screen printing, each with distinct advantages and disadvantages. The choice depends heavily on the application and desired properties of the final print.

- Plastisol inks are solvent-based and are known for their vibrant, opaque colors, excellent durability, and great flexibility. They’re ideal for applications requiring long-lasting prints on items subject to wear and tear, like metal signs or appliances. However, they require higher curing temperatures (typically in a conveyor oven) and can have some environmental concerns due to their solvent content. They provide a thicker, more textured print.

- Water-based inks are environmentally friendly, often requiring lower curing temperatures, and generally have less odor. They are better suited for printing on smaller scale or indoors where solvent fumes are a concern. However, they tend to be less opaque, requiring more layers to achieve full color saturation, and their durability might be slightly lower than plastisol for very abrasive applications. They also typically yield a softer, less textured feel.

Imagine printing a company logo on a large metal sign for outdoor use versus printing a design on a smaller, indoor metal art piece. The durable plastisol would be ideal for the outdoor sign, while the eco-friendly water-based ink might be better suited for the art piece, especially if there are odor or safety concerns.

Q 3. What are the common mesh counts used in metal screen printing and when would you choose each?

Mesh count refers to the number of threads per linear inch (TPI) in the screen. Higher mesh counts mean finer mesh openings, allowing for more precise detail and finer lines. Lower mesh counts provide larger openings, ideal for printing bolder designs or using thicker inks. The selection depends largely on the design’s complexity and ink viscosity.

- Low mesh counts (e.g., 43-61 TPI): Used for printing large, bold designs or when using very thick inks. The larger openings allow for good ink flow and less clogging but sacrifice detail resolution.

- Medium mesh counts (e.g., 86-110 TPI): A good balance between detail and ink flow. Suitable for a wide range of designs and ink types. This is often the preferred mesh for general metal screen printing.

- High mesh counts (e.g., 156-230 TPI and above): Ideal for fine detail work, such as very small text or intricate designs. Higher mesh counts require lower viscosity inks and more careful printing techniques.

For example, if you’re printing a simple, large logo on a metal toolbox, a lower mesh count would suffice. But for printing a highly detailed image on a metal sign, you would choose a much higher mesh count to reproduce the image fidelity.

Q 4. How do you ensure proper registration in multi-color metal screen printing?

Accurate registration is essential in multi-color metal screen printing, ensuring that each color aligns precisely with the others to produce a sharp, well-defined final image. Improper registration leads to blurry or misaligned prints, ruining the overall aesthetic and potentially the value of the product.

Achieving proper registration requires meticulous attention to detail and may involve several steps:

- Accurate Film Positives: Precisely created film positives are crucial. These films dictate the location of each color on the screen, and any inaccuracies at this stage will propagate through the entire printing process. Often, specialized software is used to ensure perfect alignment.

- Screen Clamping and Alignment System: The screen clamping mechanism on the printing press needs to be robust and precise, ensuring the screen stays perfectly aligned during the printing process. This system may be manual or automated, depending on the equipment’s complexity.

- Registration Marks: Registration marks are printed or incorporated into the film positives, acting as guides for aligning each color. These marks allow the printer to easily align subsequent screens and ensure that the colors register accurately.

- Careful Printing Technique: The printer needs to exercise care and precision during the printing process. Any slight misalignment during the printing of a color can affect the registration of subsequent colors. This is where experience and precision techniques like using alignment pins come into play.

- Test Prints: Before commencing full-scale production, test prints are essential to verify the registration. These tests help identify any problems and fine-tune the alignment before the entire batch is printed.

Failure to achieve good registration can lead to a print where, for example, a company’s logo colors appear to be misaligned or blurred.

Q 5. What are the challenges of printing on different metal substrates (e.g., aluminum, stainless steel)?

Printing on different metal substrates presents unique challenges due to variations in surface properties like smoothness, porosity, and reactivity to inks. Aluminum and stainless steel, while both metals, have distinct characteristics.

- Surface Preparation: Aluminum often requires a thorough cleaning and degreasing, potentially including a pretreatment like chromating to improve ink adhesion. Stainless steel, being less reactive, may require less aggressive cleaning but may benefit from a surface treatment to improve the adhesion of certain inks. The surface must be free of oils, dirt, and any imperfections.

- Ink Adhesion: Certain inks may adhere better to one metal than another. Some formulations might require specific additives or primers to ensure adequate adhesion. The selection of the right ink is critical to successful printing, considering substrate properties, ink type, and desired longevity of the print.

- Substrate Distortion: During the curing process, particularly with high-temperature plastisol inks, some substrates can distort. Aluminum, being softer than stainless steel, is slightly more prone to this issue. Special attention might be needed to control the curing temperature and time to prevent warping or other distortions.

- Ink Bleeding and Feathering: Certain inks might bleed into or feather on different metal surfaces due to their porosity or surface chemistry. Careful ink selection and appropriate screen mesh count can mitigate these problems.

For instance, if you’re printing on a highly polished stainless steel surface, the ink might not adhere as well as it would to an anodized aluminum surface which has a higher surface energy. Using the proper pre-treatment and ink is essential for a durable, high-quality print.

Q 6. Explain the process of reclaiming a screen after use.

Screen reclaiming is the process of removing the old ink and emulsion from a screen, preparing it for reuse. This is a critical step in saving money and resources. Efficient reclaiming methods minimize waste and extend the life of your screens.

The process typically involves:

- Initial Cleaning: Remove excess ink from the screen using a solvent or water-based cleaner appropriate for the ink used. For plastisol ink, a specialized plastisol remover is often used. This step can involve wiping, scrubbing, or pressure washing.

- Emulsion Removal: After the ink is removed, the emulsion is removed using an emulsion remover and gentle scrubbing. This step needs to be carefully done to avoid damaging the mesh.

- Final Cleaning: Thoroughly clean the screen using soap and water to remove any remaining residue. For stubborn stains or build-up, ultrasonic cleaning is an effective method.

- Drying: Allow the screen to air dry completely before storing. Store the screen properly, typically in a protective sleeve to prevent damage to the mesh.

Proper screen reclaiming techniques significantly reduce waste and prolong the life of your screens, lowering the overall cost of your print production.

Q 7. How do you troubleshoot issues like pinholes, screen clogging, or ink bleed?

Troubleshooting common metal screen printing issues requires a systematic approach and careful observation. Understanding the cause is crucial for finding the right solution.

- Pinholes: These small holes in the print result from imperfections in the screen coating or exposure process. Solutions include using a higher-quality emulsion, ensuring proper emulsion coating techniques, and correcting exposure times to achieve the right emulsion thickness and hardening.

- Screen Clogging: This often occurs when the ink is too thick or the mesh count is too high for the ink viscosity. Solutions include using a thinner ink, using a lower mesh count screen, or modifying the ink with additives to improve its flow. Ensure the squeegee is also of appropriate hardness and the print pressure is optimal.

- Ink Bleed: Ink bleeding happens when ink spreads beyond the intended print area, often due to the ink being too thin or the mesh being too loose. This can be solved by using a thicker ink or choosing a higher mesh count, or by optimizing the print pressure to minimize ink spreading.

Careful observation of the problem – looking at the location, patterns, and extent of the defect – is always the first step toward effective troubleshooting. Remember, meticulous process control is essential to minimizing defects and achieving consistently high-quality prints.

Q 8. What safety precautions are necessary when working with screen printing inks and chemicals?

Safety is paramount in metal screen printing. We’re dealing with potentially hazardous materials, so a comprehensive approach is crucial. This starts with proper Personal Protective Equipment (PPE), including gloves (nitrile is a good choice for most inks), eye protection (safety glasses at minimum, a face shield for potentially splashing inks), and respiratory protection (depending on the ink and ventilation, a respirator might be needed). The workspace should be well-ventilated to minimize inhalation of ink fumes and solvents.

Secondly, we must handle chemicals according to their Safety Data Sheets (SDS). These sheets provide crucial information on handling, storage, first aid, and disposal. Always store chemicals properly, away from incompatible materials, and in clearly labeled containers. Regularly clean up spills immediately and correctly dispose of waste materials according to local regulations.

Furthermore, fire safety is critical. Many screen printing inks are flammable, and solvents are highly flammable. Keep flammable materials away from ignition sources and have fire extinguishers readily available. Regular safety training and adherence to established safety protocols are non-negotiable.

- Always wear appropriate PPE.

- Consult and follow the SDS for all chemicals.

- Maintain a clean and well-ventilated workspace.

- Handle flammable materials with extreme care.

Q 9. What are the different types of squeegees and their applications in metal screen printing?

Squeegees are the heart of the screen printing process, and choosing the right one significantly impacts print quality. The key factors are blade material, durometer (hardness), and angle.

Blade Material: Common materials include urethane, rubber, and silicone. Urethane is versatile, offering good durability and ink release. Rubber is softer, ideal for delicate prints or thicker inks. Silicone is extremely durable and heat-resistant, perfect for high-volume printing and plastisol inks.

Durometer: This refers to the squeegee’s hardness, measured on the Shore A scale. A harder squeegee (higher Shore A value, e.g., 70A) is better for crisp, fine details and less flexible substrates. Softer squeegees (lower Shore A value, e.g., 60A) are preferred for thicker inks, textured surfaces, and more forgiving printing.

Angle: The angle of the squeegee during printing is crucial for even ink distribution. A steeper angle creates less pressure, suitable for delicate prints. A shallower angle applies more pressure, useful for thicker inks or less porous substrates. The choice depends on ink viscosity, mesh count, and the substrate. For metal printing, we often use harder squeegees (70A-80A) with urethane or silicone blades, adjusted to a controlled angle to achieve the desired thickness and detail on the metal surface.

Q 10. How do you determine the proper ink viscosity for optimal printing results?

Ink viscosity is paramount for consistent and high-quality prints. Too thick, and the ink won’t flow smoothly, leading to uneven coverage and clogging. Too thin, and the ink may bleed, resulting in blurry images and poor definition. We determine the proper viscosity through several methods.

Visual Inspection: A simple yet effective way is to observe the ink’s flow. It should be smooth and consistent, without being overly runny or thick.

Viscosity Cup: A more precise method involves using a viscosity cup (like a Zahn cup or Ford cup). The time it takes for the ink to flow through the cup’s orifice indicates its viscosity. This method provides a numerical value for consistency.

Rheometer: For even greater precision, we utilize a rheometer. It measures viscosity under various shear rates, providing a detailed profile of the ink’s flow behavior. This is particularly useful when dealing with complex inks or demanding printing situations.

Ultimately, the ‘correct’ viscosity is determined empirically; we often fine-tune it through trial and error, adjusting using thinners or retarders as needed to achieve the optimal print result for the specific ink, substrate (metal), and screen mesh.

Q 11. Describe your experience with different types of drying ovens/systems.

My experience encompasses various drying oven/systems, each with its strengths and weaknesses.

Convection Ovens: These are common and relatively inexpensive. They use fans to circulate hot air, providing even drying. However, drying times can be longer compared to other methods.

Infrared (IR) Ovens: These use infrared radiation to heat the ink directly, resulting in faster drying times. This is particularly advantageous for high-volume production. However, uneven heating can be a concern if not properly calibrated.

UV Curing Systems: UV curing uses ultraviolet light to instantly cure certain inks, eliminating the need for lengthy drying times. This significantly increases production speed, but the initial investment cost is higher. Furthermore, safety precautions for UV exposure must be carefully observed.

Hybrid Systems: Some facilities combine different drying methods, leveraging their respective advantages. For example, using IR for initial drying and then convection for final curing, optimizing both speed and evenness. The choice of drying system depends heavily on factors like production volume, ink type, budget, and environmental considerations.

Q 12. Explain the importance of proper pre-press preparation for metal screen printing.

Proper pre-press preparation is crucial for high-quality metal screen printing. It lays the groundwork for a successful print run and minimizes potential problems down the line.

Film Preparation: High-resolution artwork is essential. We use high-quality films with sharp, clean lines and accurate color separations for optimal results.

Screen Preparation: Choosing the right mesh count is critical. Finer meshes (high thread count) allow for intricate detail, while coarser meshes (low thread count) handle thicker inks and larger areas. We carefully stretch and adhere the mesh to the frame, ensuring minimal tension inconsistencies. The screen is then coated with emulsion, exposed to UV light to create the stencil, and washed to reveal the design.

Substrate Preparation: Metal surfaces need to be cleaned meticulously before printing to ensure good ink adhesion. Cleaning methods include degreasing, and sometimes etching or surface treatments to improve adhesion.

Test Prints: Before proceeding with full-scale production, we conduct test prints to verify ink viscosity, pressure, squeegee angle, and overall print quality. This allows adjustments to be made to optimize the process and avoid wasted materials. This meticulous preparation ensures that the final print accurately reflects the design and is of high quality.

Q 13. How do you maintain and clean screen printing equipment?

Regular maintenance and cleaning are vital for the longevity and performance of screen printing equipment.

Screens: After each use, screens are thoroughly cleaned to remove residual ink using appropriate solvents, followed by a rinse with water. This prevents ink build-up and maintains the integrity of the stencil. Proper screen storage is also important to prevent damage.

Squeegees: Squeegees should be cleaned after every use to remove dried ink. A simple wipe with a solvent is usually sufficient, and more thorough cleaning might involve a dedicated squeegee cleaner. Proper storage can extend their life.

Press: The printing press should be regularly inspected for wear and tear. Moving parts require lubrication as needed. The press should be cleaned after every use to remove any residual ink or debris.

Drying Ovens: Drying ovens need regular cleaning to remove any dust or debris buildup that can impact heating efficiency. The air filters may need to be replaced or cleaned periodically.

Preventive Maintenance: A scheduled preventive maintenance program should be in place to address potential issues before they become major problems. This ensures the smooth and efficient operation of all equipment.

Q 14. What are the different types of curing methods used in metal screen printing?

Metal screen printing uses various curing methods depending on the ink type and desired properties.

Convection Curing: This uses heated air to dry the ink, suitable for many types of screen printing inks. It’s a relatively low-cost option but can be slower than other methods.

Infrared (IR) Curing: IR radiation provides rapid curing by directly heating the ink, suitable for high-volume applications.

Ultraviolet (UV) Curing: UV light instantly cures specialized UV-curable inks, ideal for rapid production. However, this requires specialized inks and equipment.

Thermal Curing: This involves baking the printed metal substrate in a controlled oven at a specific temperature to cure the ink. This method is often used for inks that require a higher curing temperature to achieve full hardness and durability. The curing method selection depends on the ink properties, the metal substrate used, the required durability, and production speed considerations.

Q 15. How do you inspect printed metal parts for defects?

Inspecting printed metal parts for defects in screen printing requires a meticulous approach, combining visual inspection with specialized tools. Initially, a thorough visual check under good lighting is crucial to identify obvious flaws. This includes looking for:

- Missing or incomplete prints: Areas where the ink didn’t transfer properly.

- Smears or smudges: Ink that has bled beyond the intended design area.

- Pin holes or voids: Tiny holes or gaps in the ink layer.

- Scratches or damage: Physical imperfections on the metal surface itself, possibly incurred during the printing process.

- Color inconsistencies: Variations in shade or tone across the printed area.

Beyond visual inspection, I often use magnification tools like jeweler’s loupes or microscopes to pinpoint microscopic defects. For larger runs, automated inspection systems can be employed, using digital imaging to detect subtle variations in print quality. Documenting defects with clear photographic evidence is also vital for quality control and troubleshooting.

For example, on a recent project printing intricate logos onto stainless steel panels, I discovered a recurring pinhole issue. By carefully examining the screen mesh under magnification, we identified a slight tear causing the defect, allowing for prompt screen replacement and a solution to the problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with color matching in metal screen printing.

Color matching in metal screen printing is a critical aspect, requiring a strong understanding of ink properties and color theory. It’s not simply about mixing colors; it’s about understanding how the metal substrate interacts with the ink, creating a unique reflective quality that differs from printing on paper or fabric. I utilize several key techniques:

- Color charts and spectrophotometers: These tools provide precise color measurements to ensure consistency. We use spectrophotometers to get exact numerical values, allowing for repeatable color matching across batches.

- Ink layering and underbases: Often, achieving a desired color requires layering different inks to build depth and accuracy. For example, a metallic gold often necessitates a metallic silver underbase to achieve the right vibrancy.

- Substrate testing: The metal’s surface finish (polished, brushed, etc.) significantly affects color perception. We always conduct test prints on the exact substrate that will be used for the final production run.

- Collaboration with ink suppliers: I work closely with ink manufacturers to custom-blend colors and understand the limitations of specific inks on metal surfaces.

A memorable challenge involved matching a specific Pantone color on anodized aluminum. Through careful layering of clear coats and base inks, and several test prints, we successfully reproduced the client’s desired shade, demonstrating the importance of iterative testing and a collaborative approach.

Q 17. How do you handle waste materials and chemicals in accordance with environmental regulations?

Environmental responsibility is paramount in screen printing. I adhere strictly to all local and national regulations concerning waste management and chemical disposal. Our practices include:

- Waste segregation: We carefully separate waste streams into categories like spent inks, solvents, cleaning materials, and general waste. This ensures proper and efficient recycling or disposal.

- Hazardous waste disposal: Spent inks and solvents are handled by licensed hazardous waste contractors, ensuring compliance with regulations and preventing environmental contamination.

- Solvent recovery systems: Where feasible, we utilize solvent recovery systems to minimize waste and reduce costs. This involves capturing and filtering solvents for reuse, reducing the amount sent for disposal.

- Water-based inks: Whenever possible, we opt for water-based inks which reduce the reliance on harsh chemicals, minimizing environmental impact.

- Proper ventilation and equipment maintenance: Our facility maintains appropriate ventilation to minimize airborne emissions, and we perform regular maintenance on equipment to prevent leaks or spills.

We maintain detailed records of all waste disposal activities, complying with all reporting requirements. This commitment to environmental stewardship is not just a legal requirement but a core part of our operation’s philosophy.

Q 18. What experience do you have with different types of screen printing presses?

My experience encompasses a range of screen printing presses, each suited for different production volumes and applications. I’ve worked extensively with:

- Manual presses: These are ideal for smaller runs and prototyping, offering great control over the printing process but requiring more manual labor.

- Semi-automatic presses: These offer a balance between manual control and automation, improving efficiency for medium-sized runs.

- Fully automatic presses: These are suited for high-volume production, offering speed and consistency but requiring higher initial investment.

- Carousel presses: These are particularly useful for printing on cylindrical or curved metal surfaces, a common need in many applications.

For example, when producing small batches of custom-designed metal plates, a manual press provided the necessary precision and flexibility. Conversely, for a large-scale project printing identical designs on hundreds of aluminum housings, a fully automated press proved indispensable for maximizing output and maintaining consistent quality.

Q 19. Describe your experience with digital screen printing techniques.

My experience with digital screen printing techniques is focused on the use of Direct-to-Screen (DTS) imaging systems. This technology allows for precise and efficient screen creation, eliminating the need for traditional hand-scooping or photographic methods. DTS systems provide several advantages:

- High resolution and detail: The ability to produce screens with incredibly fine details, ideal for complex designs.

- Reduced setup time: Eliminates the lengthy process of preparing and exposing screens manually.

- Improved consistency: Consistent results from print to print, minimizing variations caused by manual processes.

- Cost-effectiveness for short runs: Eliminates the need for high initial investment in film positives, making it cost-effective for smaller print jobs.

We use a DTS system regularly for producing screens with detailed artwork, and it has significantly improved our turnaround time while maintaining high print quality. This is particularly advantageous when dealing with short-run, high-complexity designs.

Q 20. How do you ensure consistency in color and print quality throughout a large production run?

Maintaining consistent color and print quality throughout a large production run necessitates a comprehensive approach. Key strategies include:

- Precise ink mixing and management: Using calibrated measuring instruments and dedicated mixing stations, ensuring each batch of ink is identical to the previous one.

- Regular press maintenance: Routine inspections and calibrations of the printing press itself are crucial to maintain consistent pressure, squeegee speed, and ink flow.

- Substrate uniformity: Ensuring the metal substrates themselves are consistent in terms of surface finish and material properties across the whole batch prevents variations in ink absorption.

- Environmental control: Maintaining a stable temperature and humidity level in the printing environment reduces variations in ink viscosity and drying time, contributing to consistent print quality.

- Periodic quality checks: Throughout the production run, we conduct regular quality checks using samples to monitor for any deviations from the established standards. Early detection allows for prompt corrective actions.

For a large order of signage for a national retailer, meticulous adherence to these steps was crucial. By implementing regular quality checks and meticulously monitoring ink consistency, we ensured that all the signage maintained consistent color and print quality throughout the large production run without any significant issues.

Q 21. What is your experience with different types of screen printing frames?

My experience encompasses various types of screen printing frames, each with its own strengths and weaknesses. The selection depends on the nature of the job and the desired print quality:

- Aluminum frames: Lightweight, durable, and commonly used for their versatility across different mesh types and printing techniques.

- Wooden frames: Traditional, but less durable than aluminum. They are often used for smaller runs or specific applications.

- Stainless steel frames: Highly durable and resistant to chemicals, suitable for aggressive cleaning agents and long-term use, although more expensive.

- Different mesh counts: The mesh count (threads per inch) determines the fineness of the detail and the ink deposit. A finer mesh (higher count) produces sharper details but requires more precise ink control. A coarser mesh (lower count) is better suited for bold designs or less detailed images.

In practice, I often choose aluminum frames for their balance of durability, cost-effectiveness, and ease of handling. However, for projects requiring extremely high durability or exposure to harsh chemicals, stainless steel frames become the preferred choice. Selecting the appropriate mesh count is equally critical, ensuring we use the optimal mesh for the specific design’s complexity.

Q 22. What are the advantages and disadvantages of using different types of inks?

Choosing the right ink is crucial in metal screen printing. Different inks offer varying advantages and disadvantages depending on the substrate, desired finish, and application.

- UV-curable inks: These offer excellent durability, vibrant colors, and fast curing times. However, they require specialized UV curing equipment and can be more expensive.

- Water-based inks: Environmentally friendly and less expensive, these inks are suitable for applications where durability is less critical. However, they might have lower scratch resistance compared to UV-curable inks.

- Plastisol inks: Known for their excellent opacity and flexibility, plastisol inks are ideal for printing on complex shapes. However, they require higher curing temperatures and can be less vibrant than UV-curable inks. They also have a slightly raised feel after curing.

- Ceramic inks: These inks offer exceptional high-temperature resistance and are ideal for applications where the printed metal will be exposed to heat. However, the curing process requires specialized high-temperature kilns, making this option more time-consuming and expensive.

For example, if I’m printing a decorative design on a stainless steel appliance panel, I’d likely choose a UV-curable ink for its durability and vibrant color reproduction. But for a simple, functional marking on a low-temperature part, a water-based ink might be sufficient.

Q 23. How do you address customer concerns or complaints about print quality?

Addressing customer concerns about print quality involves a systematic approach. First, I carefully examine the printed piece alongside the original artwork to identify the exact nature of the issue. This might involve things like color inconsistencies, registration problems (misalignment of colors), or defects in the print itself.

Once the problem is pinpointed, I investigate potential causes. This could include issues with ink viscosity, screen mesh count, squeegee pressure, or even the substrate preparation. I might use a microscope to examine the print for tiny imperfections.

Following this, I discuss my findings with the customer, explaining the potential causes and suggesting solutions. This may involve re-printing the job using adjusted parameters, offering a partial refund, or discussing modifications to the design to improve printability. Open communication and transparency are key to resolving the issue satisfactorily.

For instance, if a customer complains about faded colors, I’ll investigate whether the ink was properly cured, if the mesh was too fine resulting in less ink deposit, or if the substrate wasn’t adequately prepared. I document every step of my investigation and resolution to avoid similar problems in future jobs.

Q 24. Describe your experience with different types of metal substrates and their printing requirements.

My experience encompasses various metal substrates, each requiring specific printing considerations.

- Aluminum: This is a common substrate, generally easy to print on, but requires proper surface preparation to ensure good ink adhesion. Different aluminum alloys may require different pretreatments.

- Stainless Steel: More challenging than aluminum due to its smooth, non-porous surface. Pre-treatment is critical; often involving degreasing and a chemical etching process to improve ink adhesion.

- Copper: Requires careful handling to avoid oxidation and tarnishing. Special inks might be necessary to ensure durability and prevent discoloration.

- Steel: Similar to stainless steel, often requiring pre-treatment for optimal adhesion. The type of steel (mild steel, galvanized steel, etc.) influences the pre-treatment method.

For example, when printing on stainless steel, I might employ a process involving degreasing, etching, and a primer coat before applying the ink to ensure the print withstands the harsh conditions the metal will likely face.

Q 25. How do you manage your time and prioritize tasks in a fast-paced screen printing environment?

In a fast-paced screen printing environment, efficient time management is essential. I employ a combination of techniques to prioritize tasks and meet deadlines. I begin by meticulously reviewing job orders to understand the specific requirements and deadlines of each project. I then prioritize jobs based on urgency and complexity.

I utilize project management tools to schedule tasks, track progress, and identify potential bottlenecks. Breaking down larger projects into smaller, more manageable tasks is also key. This approach allows for better focus and avoids being overwhelmed. I also prioritize tasks that require the most setup time early to ensure timely completion. Additionally, efficient communication and collaboration with the team are vital for preventing delays.

Imagine a scenario where we have three urgent jobs – one small, one large, and one complex – all with tight deadlines. I’d start with the preparation for the complex job, alongside a parallel start on the small one. The larger job would follow once the preparations were complete for the complex job. This allows for simultaneous work, maximizing efficiency without sacrificing quality.

Q 26. Explain your troubleshooting process when encountering unexpected printing problems.

My troubleshooting process is systematic and thorough. When encountering printing problems, I follow these steps:

- Identify the problem: Carefully examine the printed output, noting the specific defect, its location, and the affected area. Is it a color issue, registration problem, or a defect in the print itself?

- Analyze potential causes: Consider factors such as ink viscosity, screen mesh, squeegee pressure, substrate preparation, curing process, and the condition of printing equipment.

- Test potential solutions: Systematically address each potential cause through testing. For instance, if the ink seems too thick, I’ll thin it appropriately and test again. If registration is off, I’ll adjust the screen alignment and retest. I keep detailed records of each test and its outcome.

- Implement the solution: Once the root cause is identified and a solution is proven effective, I implement the fix across the rest of the production run.

- Document the issue and solution: Thorough documentation is vital to prevent the same problem from recurring.

For example, if I’m seeing pinholes in the print, I’ll check the mesh for damage, the ink for proper viscosity, and the squeegee pressure for consistency. The solution might be replacing a damaged screen or making adjustments to the print process.

Q 27. Describe your experience with quality control procedures and documentation.

Quality control is paramount in metal screen printing. My experience involves implementing and maintaining robust quality control procedures and documentation throughout the entire process. This begins with inspecting the incoming materials such as inks, substrates, and screens to ensure they meet required specifications. I use standardized checklists for this inspection.

During production, I regularly monitor the printing process, inspecting samples for defects such as pinholes, registration errors, and color inconsistencies. These inspections are documented with detailed notes and photographic evidence. Following the printing, a final inspection takes place before packaging, ensuring the finished product meets customer specifications.

All quality control data is meticulously documented, including inspection reports, test results, and any corrective actions taken. This documentation is crucial for traceability, problem-solving, and continuous improvement. It also helps in meeting industry standards and customer requirements.

I’ve worked in environments employing statistical process control (SPC) to track key parameters and identify trends, enabling proactive adjustments to minimize defects. This data-driven approach significantly enhances quality and efficiency.

Q 28. How do you stay updated on new technologies and trends in metal screen printing?

Staying updated on new technologies and trends in metal screen printing is crucial for maintaining a competitive edge. I regularly attend industry trade shows and conferences to learn about the latest advancements in inks, equipment, and techniques. I also actively participate in online forums and communities dedicated to screen printing, engaging with other professionals and sharing knowledge.

Subscribing to industry publications and journals keeps me informed about emerging technologies and best practices. I also actively seek out training opportunities to enhance my skills and broaden my knowledge. Furthermore, I regularly research and evaluate new equipment and software solutions to assess their potential benefits for improving efficiency and quality. Continuous learning is a vital aspect of my professional development in this field.

For example, recently I’ve been exploring the use of digital screen printing technology which allows for precise, variable-data printing on metal substrates, offering increased efficiency and customization options. I would evaluate its potential benefits and cost implications in relation to traditional screen printing for future projects.

Key Topics to Learn for Metal Screen Printing Interview

- Screen Preparation: Understanding mesh selection, emulsion coating techniques, and proper stencil creation for various metal substrates (aluminum, stainless steel, etc.). This includes knowing the differences in mesh counts and their impact on print quality.

- Ink Selection and Application: Familiarity with different ink types (e.g., UV-curable, ceramic, plastisol) and their suitability for various metals and applications. Understanding viscosity control and proper squeegee pressure for optimal print results. Practical application involves knowing how to troubleshoot ink issues like clogging or uneven printing.

- Metal Substrate Preparation: Knowing the importance of surface cleaning and pretreatment methods for different metals to ensure proper ink adhesion. This includes understanding the impact of surface imperfections on the final print.

- Drying and Curing Processes: Understanding the specific drying and curing requirements for different inks on metal substrates. This includes knowledge of UV curing systems, convection ovens, and other relevant technologies. Troubleshooting issues with incomplete curing is crucial.

- Troubleshooting and Quality Control: Identifying and resolving common printing defects (e.g., pinholes, smearing, registration issues). Implementing quality control measures to ensure consistent print quality and minimizing waste.

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety regulations and procedures related to ink handling, equipment operation, and waste disposal in a metal screen printing environment.

- Automation and Technologies: Familiarity with automated screen printing equipment and technologies, such as automatic screen changers and conveyor systems, is beneficial for demonstrating advanced knowledge.

Next Steps

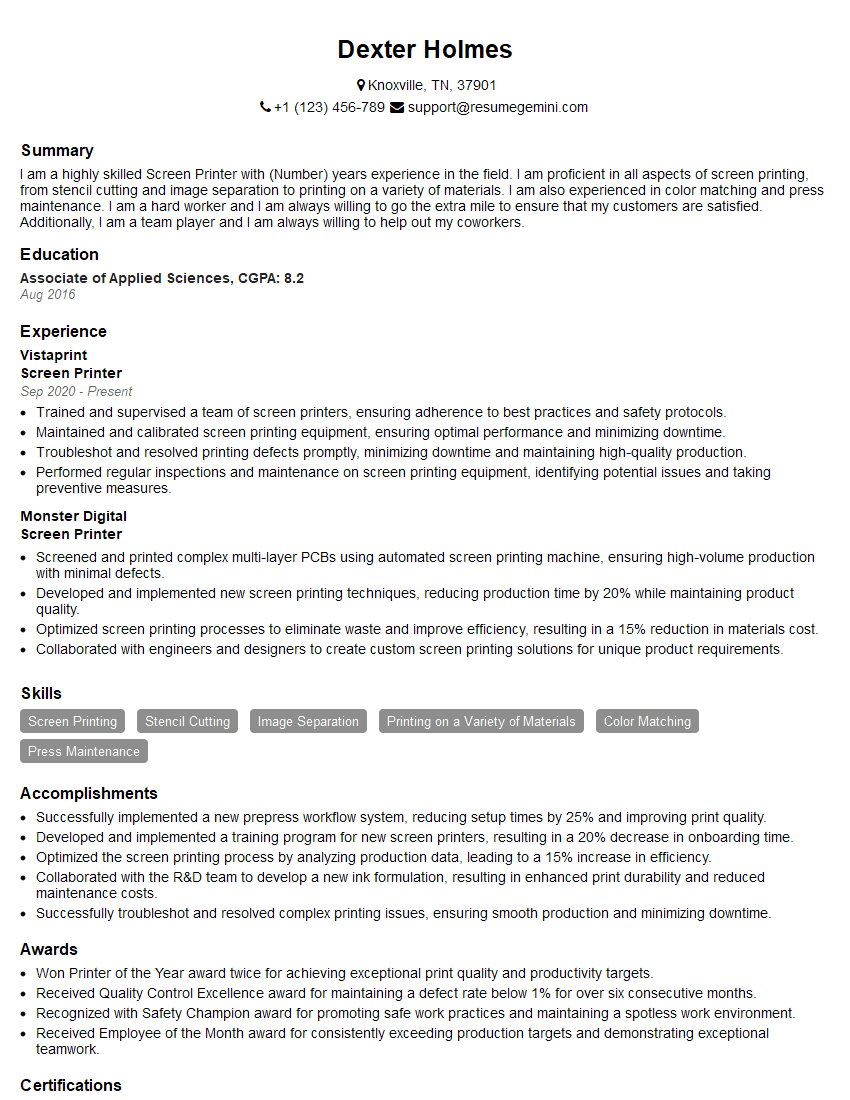

Mastering metal screen printing opens doors to exciting career opportunities in diverse industries, offering excellent growth potential. A strong resume is your key to unlocking these opportunities. An ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting your application noticed. To create a compelling and effective resume that showcases your skills and experience, we highly recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and valuable resources to build a professional resume. Examples of resumes tailored specifically to the Metal Screen Printing industry are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good