Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Screen Printing on Paper interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Screen Printing on Paper Interview

Q 1. Explain the screen printing process on paper, step-by-step.

Screen printing on paper involves transferring ink through a mesh stencil onto the paper substrate. It’s a surprisingly versatile process, allowing for vibrant, detailed designs. Here’s a step-by-step breakdown:

- Design Preparation: Your artwork needs to be a positive image – the areas you want printed are solid, and the areas you don’t want printed are transparent. This is typically prepared digitally and then output to a film positive.

- Screen Preparation: A screen is coated with a photosensitive emulsion. This emulsion is light-sensitive, allowing us to create the stencil by exposing the screen to UV light through the film positive.

- Exposure: The screen, coated in emulsion and layered with the film positive, is exposed to a strong UV light source. The exposed areas harden, while the unexposed areas remain soft and can be washed away.

- Washing Out: The screen is washed under running water to remove the unexposed emulsion, revealing the stencil. This stencil is the mesh areas that will allow ink to pass through.

- Screen Setup: The screen is secured in a screen printing frame, and the paper is positioned on a flat surface under the screen.

- Inking: Ink is applied to the top of the screen using a squeegee. The ink’s viscosity is crucial; too thick, and it won’t flow; too thin, and it may bleed.

- Printing: With a firm, even stroke, the squeegee pushes the ink across the screen. The ink passes through the open stencil areas and onto the paper.

- Drying: The printed paper is allowed to dry completely to prevent smudging. This can be air drying or expedited with a heat source depending on the ink.

- Post-Printing Cleanup: The screen is carefully cleaned with a screen cleaning solvent to remove any remaining ink and prepare it for the next print run.

Each step requires precision and attention to detail to achieve high-quality prints.

Q 2. What types of inks are best suited for screen printing on paper?

Ink selection is crucial for successful screen printing on paper. The best inks are those designed specifically for paper, balancing vibrancy with the paper’s absorbency and preventing bleed-through. Here are some top choices:

- Water-based inks: These are environmentally friendly, relatively easy to clean, and offer a good range of colors. However, they can be less vibrant than plastisol inks.

- Plastisol inks: Known for their brilliant, opaque colors and excellent durability, plastisol inks are popular but require a heat-setting process to cure. This is a critical step to prevent the inks from being smudged.

- Discharge inks: These are used on pre-printed or dyed fabrics, but adaptable for paper, essentially bleaching the existing color and replacing it with a new one.

The choice depends on the desired outcome – for instance, water-based inks are suitable for smaller projects, while plastisol inks are preferable for projects needing exceptional durability and vibrancy.

Q 3. How do you choose the appropriate mesh count for screen printing on paper?

Mesh count refers to the number of threads per inch (TPI) in the screen. Choosing the right mesh count impacts ink deposit and detail resolution. A higher mesh count (e.g., 156 TPI) results in finer detail and a thinner ink deposit, which is best for intricate designs and fine lines. Conversely, a lower mesh count (e.g., 43 TPI) allows for thicker ink deposits suitable for bold graphics or high-coverage areas.

For screen printing on paper, a mid-range mesh count like 110-156 TPI is often a good starting point. If you’re working with very detailed artwork, you might opt for the higher end of this range. Thicker paper might tolerate a lower mesh count better, while thinner paper requires higher to prevent bleed-through.

I always test a few different mesh counts with a sample piece of the paper I’ll be printing on to determine the best option for a given project.

Q 4. Describe your experience with emulsion coating and exposure techniques.

Emulsion coating is the process of applying a light-sensitive coating to the screen. This creates the stencil. I typically use a scoop coater for even application, ensuring a consistent coating thickness is maintained. Over-coating leads to pinholes, while under-coating can result in improper exposure.

Exposure is the process of hardening the emulsion through UV light. A precise exposure time is crucial; underexposure leads to incomplete hardening and stencil weakness, causing ink bleed. Overexposure results in a very hard stencil which may be harder to clean.

I’ve worked with both direct and indirect exposure methods. Direct exposure (film in direct contact with the screen) yields sharper detail. Indirect exposure (film separated from the screen by a vacuum frame) can be beneficial for screens with complex designs, but this requires careful setup to prevent distortion.

In my experience, consistent emulsion thickness, accurate exposure times, and a high-quality vacuum frame (for indirect exposure) significantly impact the print quality.

Q 5. How do you troubleshoot a clogged screen during the printing process?

A clogged screen is a common frustration. The first step is identifying the cause. It’s usually either dried ink, thickened ink, or emulsion residue in the stencil area.

- Identify the Clog: Examine the screen closely to pinpoint the location and type of clog.

- Cleaning Methods:

- For dried ink: Use a screen cleaning solvent and a soft brush to gently loosen and remove the dried ink. A high-pressure water jet can be helpful for stubborn clogs, but be cautious to prevent damaging the stencil.

- For thickened ink: A screen degreaser may be needed to break down the ink’s viscosity before cleaning. A special ink-thinning agent can also help.

- For emulsion residue: This usually happens after the washout stage and is best prevented by thorough initial washing. Gentle rinsing can help remove any residual emulsion.

- Prevention: Proper ink mixing, storage, and screen cleaning are vital in preventing clogs. Use a suitable solvent and clean your screen thoroughly after each print run. Avoid letting ink dry on the screen.

Remember to always test your cleaning solution on a small, inconspicuous area of the screen first to ensure it doesn’t damage the stencil.

Q 6. What are the common issues encountered when screen printing on different paper weights?

Paper weight significantly affects the screen printing process. Thicker papers (e.g., cardstock) provide a more robust surface that prevents ink from penetrating through to the back. However, they might require more pressure during printing to get a good ink deposit. Thinner papers, like standard printer paper, are more prone to ink bleed-through and distortion. They may need a higher mesh count to prevent this. In addition, the paper may even buckle and warp under the pressure of the squeegee, requiring a printing technique to mitigate.

For thinner papers, I usually use a lower printing pressure and possibly a thinner ink consistency to avoid damage. A soft backing board can help prevent the paper from buckling. With heavier papers, increased pressure is needed to ensure sharp, crisp prints but care must be taken to prevent damaging the paper.

Testing different printing pressures and ink viscosities is key to achieving optimal results with varying paper weights.

Q 7. Explain the importance of proper registration in screen printing on paper.

Proper registration is essential for multi-color screen printing. Registration refers to the precise alignment of subsequent print layers. Without accurate registration, colors will misalign, resulting in blurred images or overlapping colors. For example, if you are printing a design with separate layers for red, yellow, and blue, each layer must be accurately placed to create the correct color blend, if needed.

I use registration marks on my artwork and screens to align each print run accurately. These marks are small reference points that help guide the precise placement of the screen. Using a registration system – which can be as simple as accurately placing guide pins on the printing surface – is essential for multi-color prints to line up. Precision is key, and practice refines this technique. Misaligned prints are frustrating and waste materials, emphasizing the importance of attention to detail.

Q 8. How do you achieve accurate color matching in screen printing?

Accurate color matching in screen printing is crucial for achieving the desired visual outcome. It’s a multi-step process that begins even before the printing process itself.

First, we use a color management system (CMS). This involves using calibrated monitors and profiling our inks. This ensures that the colors we see on screen closely match the printed results. We often use Pantone Matching System (PMS) colors for consistency across different print jobs, allowing us to specify exact color values that remain constant.

Secondly, test prints are essential. We perform multiple test prints, adjusting ink concentrations and screen mesh counts to fine-tune the color matching. This iterative process is critical, as factors like paper absorption and ink layering can influence the final color.

Thirdly, experience plays a huge role. Years of experience allow me to anticipate subtle variations in color based on the paper type and ink interactions. I can often make adjustments during the printing process to correct minor discrepancies. For example, I might need to adjust the ink viscosity or squeegee pressure depending on the specific paper.

Q 9. Describe your experience with different screen printing techniques (e.g., flood coating, off-contact printing).

My experience encompasses a range of screen printing techniques, each with its own strengths and weaknesses. Flood coating, for instance, is a technique where a thin layer of ink is spread evenly across the screen before printing. This ensures uniform ink distribution and prevents pinholes, resulting in a more consistent print quality, especially useful on absorbent papers.

Off-contact printing involves adjusting the distance between the screen and the paper during printing. This fine-tuning is vital for controlling the amount of ink deposited and achieving sharp, well-defined images. A slightly larger off-contact distance can produce crisper prints, while a smaller distance can result in a more saturated and bolder print. Choosing the right technique greatly depends on the desired print outcome and the paper being used.

I’ve also worked with techniques like multiple-color registrations, which involve aligning multiple screens to achieve detailed multi-color prints. This method demands extreme precision and meticulous attention to detail to avoid misalignments.

Q 10. How do you maintain and clean your screen printing equipment?

Maintaining and cleaning screen printing equipment is essential for ensuring long-term performance and print quality. This process involves regular cleaning of screens, squeegees, and the printing surface.

After each printing session, I meticulously clean the screens using a screen cleaning solution and a soft brush or sponge to remove any residual ink. Careful cleaning prevents clogging and ensures the longevity of the screens. Squeegees also require cleaning, ideally with a dedicated squeegee cleaner to maintain their sharpness and efficiency.

The printing surface, whether a table or a press, needs regular cleaning to remove excess ink and debris. Any build-up can negatively impact print quality and lead to damage. Regular lubrication of moving parts on automated equipment is also crucial for smooth operation and prevents wear and tear.

Proper storage of screens is also crucial. Screens should be stored flat to prevent warping and damage. They also need to be kept clean and away from dust.

Q 11. What safety precautions do you follow while screen printing?

Safety is paramount in screen printing. We always work in a well-ventilated area to minimize exposure to ink fumes, which can be harmful. This is particularly important when working with solvent-based inks.

We wear appropriate personal protective equipment (PPE), including gloves to protect our hands from ink and cleaning solutions, and eye protection to safeguard our eyes from ink splashes. Proper ventilation is always the primary safety concern. Long sleeves and closed-toe shoes are also a must.

Furthermore, we handle chemicals responsibly, following the manufacturer’s guidelines for storage and disposal. This includes using proper disposal containers and appropriately labeling all materials.

Finally, we always follow safe lifting procedures for heavy equipment and materials, to prevent strain and injuries.

Q 12. How do you handle different paper types and their specific printing requirements?

Different paper types demand specific adjustments in the screen printing process. For instance, highly absorbent papers like watercolor paper may require a thicker ink layer to prevent the ink from being absorbed too quickly, resulting in a less vibrant print. On the other hand, coated papers might require less ink and a lighter touch to avoid smearing.

The mesh count of the screen also needs to be adjusted depending on the paper. Finer mesh counts are suitable for finer details on smooth papers, while coarser mesh counts are better for textured papers.

I have extensive experience working with various paper types, including cardstock, specialty papers and fine art papers, and adjust my techniques accordingly. For instance, I have discovered that pre-treating certain papers with a sizing agent can improve the print quality and color vibrancy. This is especially useful for papers that are unusually absorbent.

Q 13. Describe your experience with image preparation and film creation for screen printing.

Image preparation and film creation are critical steps in screen printing. This process involves converting digital artwork into a format that can be used to create a screen stencil.

My process starts with ensuring the artwork is high-resolution and in a suitable format. I typically use Adobe Photoshop and Illustrator to prepare the artwork, ensuring proper color separation for multi-color prints. Each color needs its own film positive, and precise alignment is key.

Next, the artwork is outputted onto film using a high-resolution film output device. This process requires careful attention to detail, as any flaws in the film will be reflected in the final print. I meticulously check the film positives for any errors before using them to create the screens. We usually make use of a high-quality film positive for professional results.

The film is then used to expose the emulsion-coated screens. This process creates a stencil that allows ink to pass through only the areas where the image is to be printed.

Q 14. What software are you proficient in for designing screen-printed artwork?

I am proficient in several software packages commonly used for designing screen-printed artwork. Adobe Photoshop is my primary tool for image manipulation, color correction, and detailed artwork creation. Adobe Illustrator is essential for vector-based designs, ensuring crisp lines and scalability.

I also have experience using CorelDRAW, another popular vector graphics editor, offering similar functionalities to Illustrator. My familiarity with these programs extends to preparing files for output to film, ensuring the correct resolution and color settings for optimal screen printing results.

Q 15. Explain your experience with halftones and their application in screen printing.

Halftones are crucial in screen printing for reproducing images with continuous tones, like photographs, on a medium that inherently only allows for solid colors. Instead of printing millions of subtle variations in ink density, we use dots of varying sizes to create the illusion of gradation. Think of it like looking at a newspaper image up close – you see individual dots, but from a distance, it looks like a smooth image. In screen printing, we achieve this by using a digital halftone screen, which breaks the image down into a matrix of dots. The size of these dots correlates to the tone – larger dots represent darker areas, smaller dots represent lighter areas.

My experience involves creating these halftone screens in software like Photoshop and Illustrator, specifically using the ‘convert to halftone’ function with different line screens (the number of dots per inch) depending on the paper quality and desired resolution. A finer line screen (e.g., 150 lpi) provides a smoother image but requires more precise screen printing, while a coarser screen (e.g., 60 lpi) is more forgiving but has a more noticeable dot pattern. The choice depends on the desired aesthetic and print limitations.

For instance, when printing a fine art reproduction on high-quality archival paper, I’d opt for a higher line screen to capture subtle details and tonal variations. But for a simple poster on standard paper, a coarser screen would be perfectly acceptable and quicker to produce.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the appropriate amount of ink needed for a specific print run?

Calculating ink usage for a screen printing job requires a systematic approach. It’s not just about the number of prints; it involves the design complexity, ink coverage, and paper type. There’s no single formula, but a practical method involves combining estimations and past experience.

First, I estimate the ink coverage per print. This is subjective but becomes easier with experience. A design with large solid areas will consume more ink than a design with fine lines and details. For example, a poster with extensive black coverage will obviously use more black ink than one featuring delicate grayscale washes. I’d often make test prints to fine-tune ink quantities before the main run.

Next, I calculate the total ink required. Let’s say a design uses 2ml of ink per print and I need 100 prints. That’s 200ml total. However, it’s crucial to account for waste. I typically add an extra 10-20%, depending on the complexity of the print and my experience with the specific ink. In this case, adding 20% would mean needing 240ml of ink (200ml + 40ml).

Finally, I factor in the ink’s viscosity and the printing method. A higher viscosity (thicker ink) might require more squeegee pressure, which could slightly alter consumption rates. This is why consistent ink viscosity management is vital, which I’ll discuss later.

Q 17. What are the different types of screens used in screen printing and their applications?

Screen printing utilizes various screens, each with specific properties suited for particular applications. The main difference lies in the mesh count (threads per inch) and the material.

- Mesh Count: Higher mesh counts (e.g., 190-300) produce finer details, allowing for more precise halftone reproduction and sharp lines. They’re ideal for high-resolution images and delicate artwork, but require more careful printing technique. Lower mesh counts (e.g., 43-60) are best suited for large, solid areas and bold designs, offering greater ink deposit and are less prone to clogging.

- Materials: Common materials include nylon, polyester, and stainless steel. Nylon is versatile and cost-effective but less durable. Polyester is stronger and more resistant to chemicals, making it suitable for long print runs. Stainless steel meshes are very durable, offering the highest resistance and best for industrial applications but are more expensive.

For instance, when printing detailed botanical illustrations on fine paper, I’d choose a high-mesh count polyester screen. If producing large-scale posters with bold graphics, a lower mesh count nylon screen would suffice. The choice is dictated by the design, print quality requirements, and budget.

Q 18. How do you address issues like pinholes or cracks in the screen mesh?

Pinholes and cracks in the screen mesh are common issues that significantly impact print quality, leading to unwanted ink bleed or incomplete prints. Addressing them effectively is crucial.

Pinholes are small holes that allow ink to pass through unintentionally. My approach is to use a screen filler or sealant. This involves carefully applying a specialized solution to the pinhole(s) using a small brush or needle, allowing it to dry completely before cleaning the screen and proceeding with printing. For larger pinholes, I might need to repair the mesh using a specialized patching material.

Cracks are more severe and usually indicate screen damage. Minor cracks can sometimes be repaired using screen filler, but extensive damage often necessitates replacing the screen. Preventative measures like careful handling and proper screen tensioning are vital to avoid cracks in the first place.

The repair method and material selection depend on the severity of the damage and the screen material. Preventive maintenance, such as proper cleaning and storage, is always a more efficient and cost-effective approach.

Q 19. Describe your experience with color separation techniques for screen printing.

Color separation is the process of dividing a full-color image into individual color channels (typically CMYK – Cyan, Magenta, Yellow, and Key/Black) for separate screen printing. This is essential because each color requires a unique screen. I have extensive experience using both traditional methods and digital techniques.

Traditionally, color separation involved using photographic techniques to create individual film positives for each color. Today, however, digital methods are prevalent. I utilize software like Adobe Photoshop and Illustrator. I start by creating a high-resolution digital file of the artwork. Then I convert the image into CMYK mode and separate the color channels. Each channel is then processed into a halftone screen, optimized for screen printing based on dot size and angle to minimize moiré patterns (unwanted interference patterns).

One real-world example: While producing a limited-edition print of a vibrant landscape, I had to meticulously separate the colors to achieve the rich tones of the sunset and the intricate detailing of the vegetation. Accurate separation is crucial to avoid color muddying or color shifts in the final print.

Q 20. How do you manage ink viscosity to ensure consistent print quality?

Ink viscosity, or thickness, is paramount for consistent print quality. Too thick, and the ink won’t flow smoothly; too thin, and it will bleed and lack opacity. I manage viscosity in several ways.

First, I ensure the ink is mixed thoroughly according to the manufacturer’s instructions. Some inks require the addition of a retarder (to slow down drying time) or a reducer (to thin the ink). The addition of these needs to be very carefully calibrated. I carefully measure the amounts to maintain uniformity throughout the print run.

Next, I use a viscosity gauge to consistently monitor the ink’s thickness. This involves taking samples and testing them throughout the printing process. If the viscosity changes, I can adjust it using retarders or reducers as needed. This allows me to maintain precise control over ink flow and ensures the consistency of the prints.

Finally, I consider environmental factors like temperature and humidity, as they affect ink viscosity. In hot and dry conditions, inks tend to thicken and dry more quickly, whereas the opposite is true in humid environments. Adjusting ink consistency according to the conditions keeps the ink flowing correctly throughout the entire print run.

Q 21. What are your preferred methods for drying screen-printed paper?

Drying screen-printed paper depends on the ink type, paper stock, and the desired speed of the drying process. I employ various methods depending on the circumstances.

- Air Drying: This is the simplest method, ideal for small print runs or when using inks that dry relatively quickly. I’d lay the printed paper flat in a clean, dust-free area, ensuring adequate air circulation to prevent smudging. This method can be slow, but it’s gentle and avoids damaging the prints. It’s my go-to method for archival-quality prints using water-based inks.

- Forced Air Drying: This is faster and uses fans to circulate air across the prints, speeding up the evaporation process. This is useful for larger print runs and when time is a constraint. I’d be careful to regulate the fan speed and distance to prevent the paper from being damaged by excessive airflow.

- Heat Drying: For quicker drying, especially with plastisol inks, I use a heat press or convection oven set to an appropriate temperature to accelerate the curing process. This method is excellent for large print runs but requires careful monitoring to avoid damaging the paper or the ink.

The optimal drying method depends on the situation. For example, a small, delicate print run using water-based inks would benefit from air drying, whereas a large-scale project with plastisol inks would best utilize heat drying for efficiency.

Q 22. How do you ensure accurate and consistent print registration across multiple colors?

Achieving accurate and consistent print registration across multiple colors in screen printing on paper is crucial for high-quality results. It’s like creating a perfectly aligned multi-layered cake – each layer needs to be in precisely the right place. We accomplish this through meticulous planning and execution.

Precise Screen Alignment: Before printing, we use registration marks (tiny marks printed on the paper or screen) to align each screen perfectly with the previous one. This ensures that subsequent colors print exactly where they should, creating sharp, well-defined images.

Micrometer Adjustments: Our presses often incorporate micrometer adjustments, allowing for incredibly fine-tuned positioning of screens. This allows for precise adjustments even with minor shifts or variations in paper thickness.

Multiple Passes and Test Prints: We always perform test prints before the full run to verify alignment and make any necessary corrections. This iterative process guarantees accurate registration throughout the job. Think of it like a dress rehearsal before a big performance – better to catch mistakes early!

Proper Screen Tension: Ensuring screens are taut minimizes stretching and misalignment during the printing process. A loose screen can easily shift, compromising registration.

Q 23. Explain your experience with different drying methods and their effect on paper.

Drying methods significantly impact the final product quality and the paper itself. Different papers have different sensitivities to heat and moisture. I’ve worked with several drying techniques, each with its own strengths and weaknesses.

Air Drying: This is the simplest method, using ambient air to evaporate the ink. It’s gentle on the paper but slow and susceptible to uneven drying, potentially leading to smudging or sticking.

Convection Drying: Utilizing fans to circulate warm air accelerates the drying process, improving efficiency compared to air drying. It’s a good balance of speed and gentleness.

Infrared (IR) Drying: IR lamps generate heat that penetrates the paper and ink, leading to rapid drying. It’s highly effective but requires careful monitoring to prevent scorching or warping of the paper, especially with delicate stock.

UV Drying: This method is primarily used with UV-curable inks. UV light instantly cures the ink, making it incredibly fast and providing a durable finish. However, specialized inks and equipment are needed.

The choice of drying method depends on the type of paper, ink, and the desired speed of production. For instance, delicate watercolor paper would require a gentle air or convection drying, while thicker cardstock can tolerate faster methods like IR or UV drying.

Q 24. How do you handle different types of paper finishes and their impact on printing?

Paper finishes significantly impact the screen printing process. The surface texture, absorbency, and coating affect ink adhesion, drying time, and the overall print quality. We carefully consider these factors for each project.

Coated Papers: These offer a smooth printing surface, resulting in sharp, crisp prints. However, they may require specialized inks to ensure proper adhesion.

Uncoated Papers: These have a more textured surface, leading to a more rustic or vintage look. However, the ink may absorb unevenly, affecting color consistency. Often, a higher ink density is needed.

Textured Papers: These add visual interest but can be challenging to print on consistently due to the uneven surface. Careful screen tension and ink viscosity adjustment are crucial.

We test various inks and techniques to achieve optimal results for each paper type. It’s like choosing the right paint for a specific surface – a glossy paint might not adhere well to a rough texture, and vice-versa.

Q 25. Describe a time you had to troubleshoot a printing problem. What was the problem, and how did you solve it?

One time, we experienced significant ink bleeding on a large print run of posters using a high-absorbency paper. The problem was that the ink was too thin, and the paper was absorbing it too rapidly before it could properly set, leading to blurry, undefined images.

To solve this, we implemented a multi-step approach:

Ink Viscosity Adjustment: We first adjusted the ink viscosity by adding a retarder. This slowed down the drying process, giving the ink more time to settle on the paper.

Test Prints: We conducted several test prints with different ink viscosity levels to determine the optimal consistency.

Paper Pre-Treatment: We considered pre-treating the paper with a sizing agent to reduce its absorbency. However, in this case, we found the ink viscosity adjustment was sufficient.

Drying Method Optimization: We switched to a slower drying method, using convection drying instead of IR to prevent rapid absorption.

By systematically addressing each potential issue, we successfully resolved the ink bleeding problem and completed the print run to the client’s satisfaction. This situation highlighted the importance of thorough testing and adaptability in problem-solving.

Q 26. What are the advantages and disadvantages of screen printing on paper compared to other printing methods?

Screen printing on paper offers unique advantages and disadvantages compared to other printing methods such as offset or digital printing.

Advantages:

- Vibrant Colors: Screen printing can produce incredibly rich and vibrant colors.

- Unique Textures: It allows for the creation of textured prints using specialized inks or techniques.

- Cost-Effective for Small Runs: It can be more economical than offset printing for smaller quantities.

- Versatile Substrate Options: It can print on a variety of paper types and weights.

Disadvantages:

- Slower Production Speed: Screen printing is generally slower than digital or offset printing for large runs.

- Higher Setup Costs: Creating screens is time-consuming and requires specialized equipment.

- Less Detail than Offset: Screen printing may not be suitable for producing intricate designs with fine details.

- Ink Limitations: The range of available inks is often narrower compared to other methods.

Q 27. How do you maintain print quality consistency throughout a large print run?

Maintaining consistent print quality throughout a large run requires meticulous attention to detail and several key strategies. It’s like baking a large batch of cookies – you need to maintain the same recipe and baking conditions to ensure consistent results.

Consistent Ink Mixing: Precisely measuring and mixing inks is critical. Using calibrated scales and adhering to specific formulas helps maintain color consistency.

Regular Screen Cleaning: Cleaning screens regularly prevents ink buildup and ensures consistent ink deposit across the print run.

Monitoring Ink Viscosity: Regularly checking and adjusting ink viscosity helps maintain print quality and prevents issues such as clogging or bleeding.

Paper Consistency: Using paper from the same batch helps minimize variations in absorbency and texture, leading to consistent results.

Regular Press Maintenance: Maintaining the printing press ensures consistent pressure and alignment throughout the run.

Periodic Quality Checks: Regularly inspecting printed sheets throughout the run and comparing them to the original artwork helps detect any deviations early.

Q 28. What are your strategies for minimizing waste during the screen printing process on paper?

Minimizing waste in screen printing on paper is crucial for both environmental and economic reasons. We employ several strategies to reduce waste.

Accurate Job Estimation: Careful planning and accurate estimation of material needs helps minimize overproduction and wasted paper.

Efficient Screen Creation: Creating screens with precision helps avoid wasted screens due to misalignment or errors.

Careful Ink Management: Using the correct amount of ink and minimizing spillage prevents ink waste.

Test Prints and Adjustments: Performing test prints allows for adjustments before the full run, minimizing wasted materials due to errors.

Recycling: We recycle wasted paper and inks whenever possible, adhering to responsible environmental practices.

Optimized Workflow: Streamlining the printing process minimizes downtime and wasted time, reducing material consumption.

Implementing these strategies minimizes waste, saves money, and reduces our environmental impact.

Key Topics to Learn for Screen Printing on Paper Interview

- Screen Preparation: Understanding emulsion types, coating techniques, exposure methods (UV and contact), and proper screen cleaning and maintenance. Consider the impact of different mesh counts on print quality.

- Ink Selection and Application: Knowing the properties of various inks (plastisol, water-based, discharge), their application techniques (flood strokes, squeegee pressure), and troubleshooting issues like clogging or uneven ink deposition. Practical experience with different ink types is invaluable.

- Image Creation and Transfer: Familiarize yourself with film positives, creating accurate separations, and the process of burning images onto the screen. Discuss techniques for achieving sharp, detailed prints and managing registration issues.

- Paper Selection and Preparation: Understanding the properties of different paper types (weight, texture, absorbency) and how these influence print quality and ink adhesion. Discuss pre-treatment methods to optimize results.

- Printing Techniques and Troubleshooting: Mastering consistent printing techniques, including proper squeegee angle and pressure. Be prepared to discuss common problems like pinholes, halftones, and misregistration, and your approach to solving them.

- Health and Safety: Demonstrate knowledge of safe handling procedures for inks, chemicals, and equipment, including proper ventilation and waste disposal.

- Print Finishing and Quality Control: Understanding post-printing processes like drying and curing, and methods for ensuring consistent print quality and color accuracy. Discuss quality control checks and how you would identify and rectify defects.

Next Steps

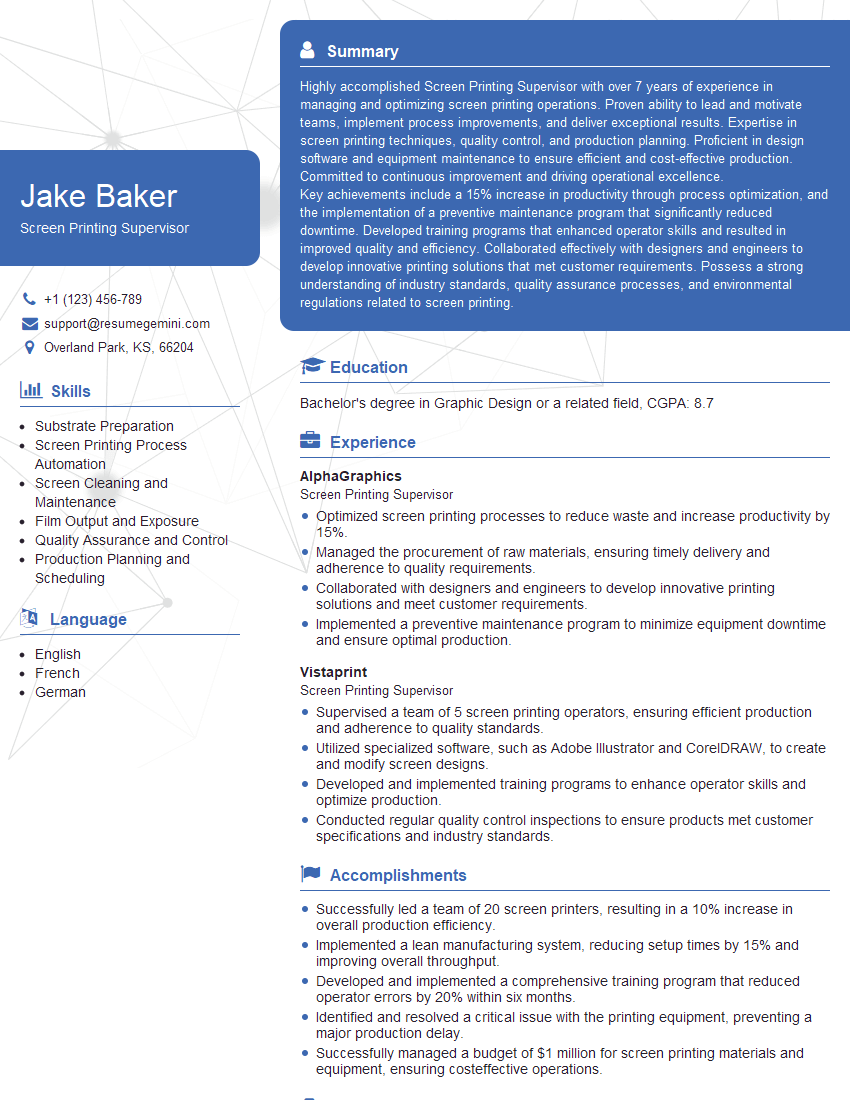

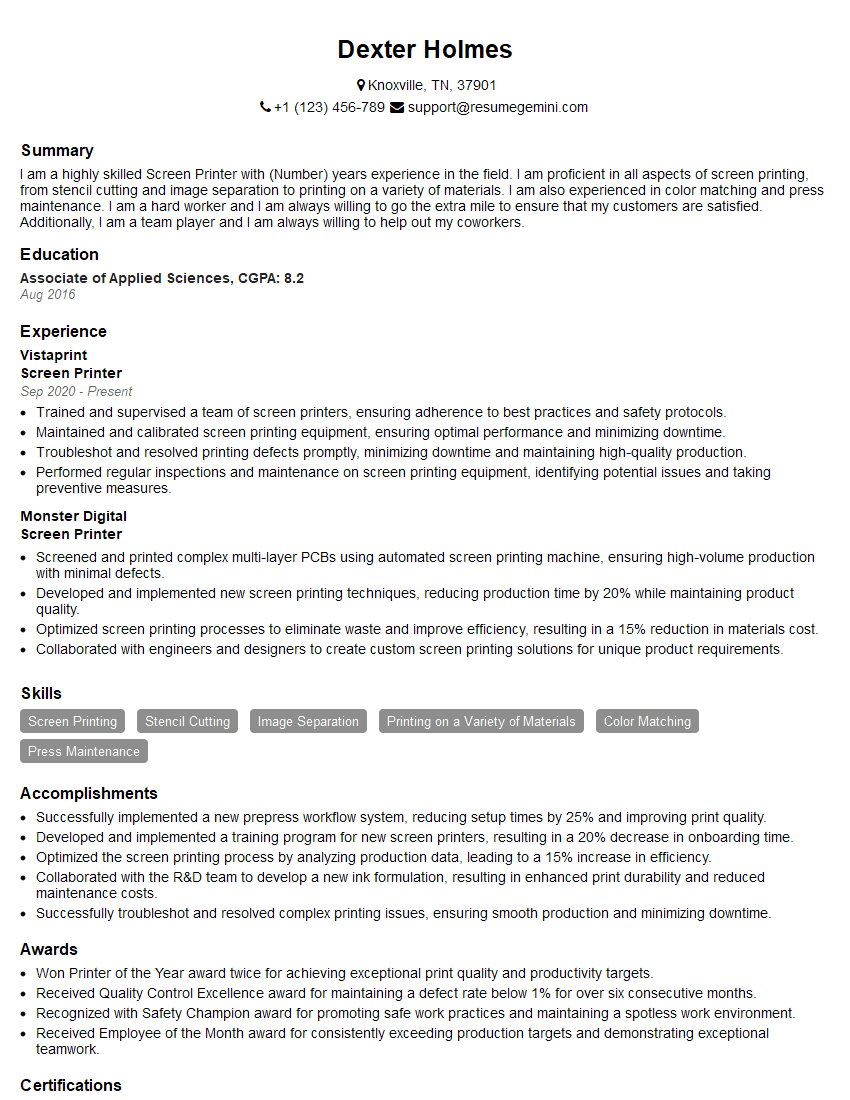

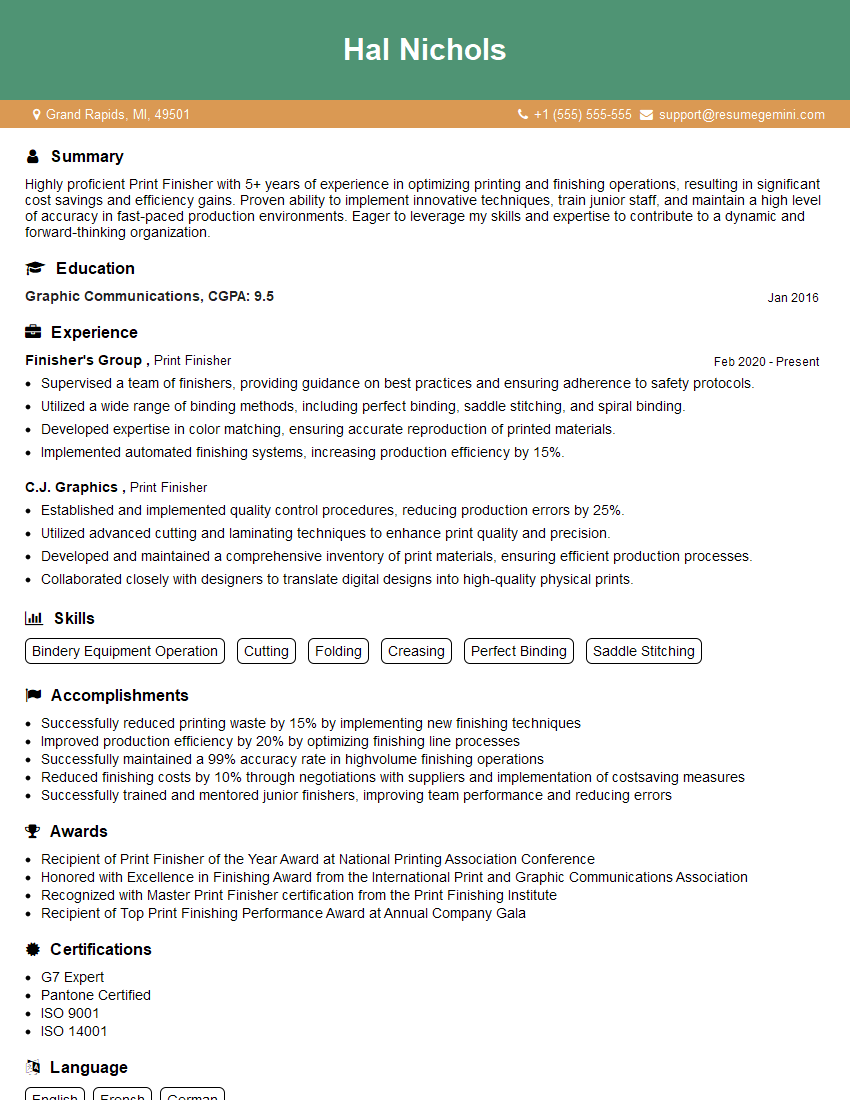

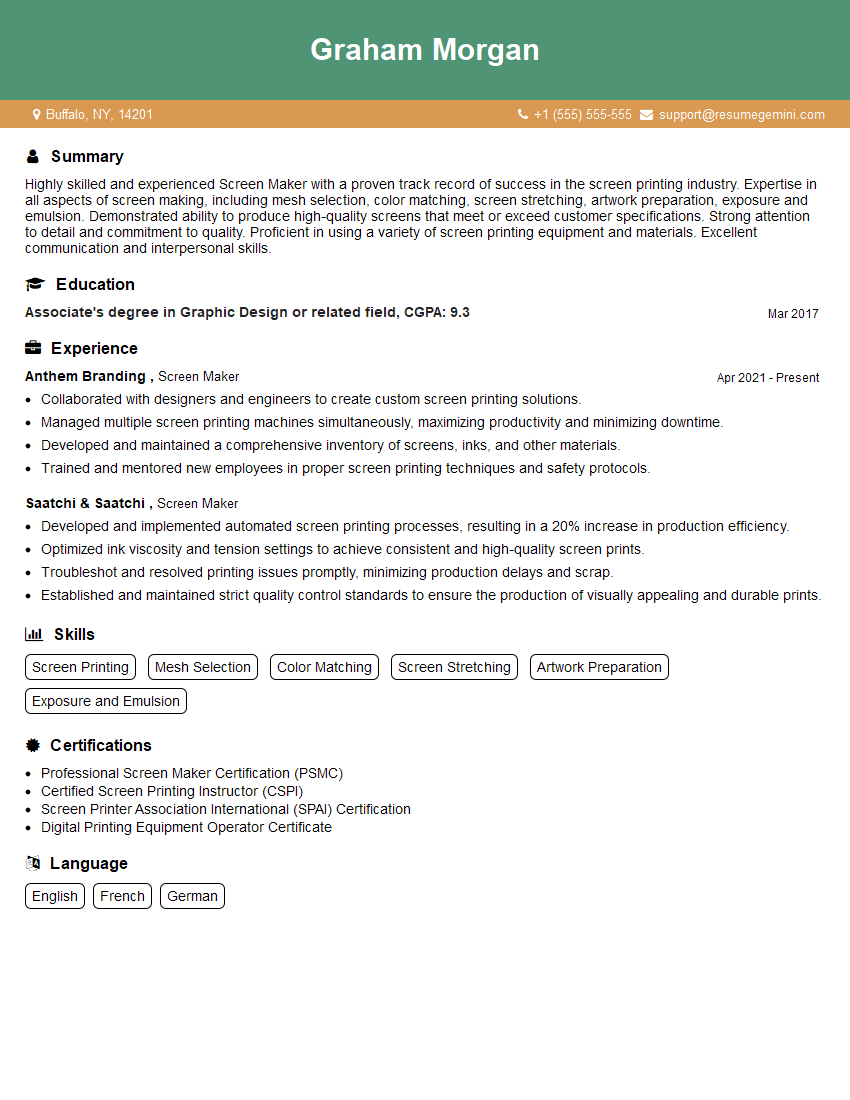

Mastering screen printing on paper opens doors to diverse roles in the graphic arts, packaging, and publishing industries. A strong understanding of the technical aspects, combined with practical experience, significantly enhances your job prospects. To maximize your chances, create a compelling, ATS-friendly resume that highlights your skills and accomplishments. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your experience. Examples of resumes tailored to Screen Printing on Paper are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good