The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Contaminant Control interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Contaminant Control Interview

Q 1. Explain the difference between contamination and contamination control.

Contamination refers to the unwanted presence of impurities or substances in a product, process, or environment. Think of it like a drop of ink in a glass of clear water – the ink is the contaminant. Contamination control, on the other hand, is the systematic process of preventing, minimizing, or eliminating contamination to maintain the desired level of cleanliness or purity. It’s like having a strategy to prevent the ink from getting into the water in the first place, or having a plan to remove it if it does.

For instance, in a pharmaceutical setting, contamination could involve microbial growth on a drug product, leading to spoilage or infection. Contamination control would encompass procedures such as sterilization, aseptic techniques, and environmental monitoring to prevent this.

Q 2. Describe various methods for controlling particulate contamination.

Controlling particulate contamination involves various strategies focusing on reducing the number and size of airborne particles. These methods can be broadly classified as:

- Source Control: This focuses on minimizing the generation of particles at the source. Examples include using good housekeeping practices (regular cleaning, minimizing traffic), using sealed equipment to prevent particle release, and utilizing low-shedding materials.

- Engineering Controls: These encompass the design features of the controlled environment. High-efficiency particulate air (HEPA) filters within air handling units remove particles from the air supply. Cleanroom design principles minimize particle generation and movement through features such as unidirectional airflow and specialized flooring.

- Administrative Controls: These involve work practices and procedures designed to minimize contamination. Examples include restricted access, gowning protocols, and regular cleaning and disinfection schedules.

- Personal Protective Equipment (PPE): This includes protective clothing (gowns, gloves, masks) to prevent the introduction and spread of particles from personnel.

Imagine a microelectronics fabrication facility. Source control involves using specialized equipment with minimal particle shedding; engineering controls rely on a highly filtered cleanroom environment with laminar flow; administrative controls include strict protocols for gowning and materials handling; and PPE ensures personnel don’t introduce contaminants.

Q 3. What are the key principles of cleanroom design and operation?

Cleanroom design and operation hinge on several key principles aimed at controlling contamination levels. These include:

- Air Filtration: Using HEPA filters to remove airborne particles. The air changes per hour (ACH) are crucial for effective particle removal.

- Airflow Control: Establishing unidirectional airflow (laminar flow) or carefully controlled air patterns to minimize particle circulation and deposition.

- Environmental Monitoring: Regularly monitoring parameters like particle counts, temperature, humidity, and pressure differentials to ensure compliance with standards.

- Construction Materials: Utilizing smooth, non-shedding materials for walls, floors, and ceilings to minimize particle generation and facilitate cleaning.

- Gowning Procedures: Implementing strict procedures for personnel to minimize the introduction of contaminants.

- Cleaning and Disinfection: Regular and thorough cleaning and disinfection of the cleanroom environment using validated procedures.

Think of a cleanroom as a meticulously designed and controlled ecosystem. Every aspect, from the air handling system to the cleaning protocols, works together to maintain a specific level of cleanliness.

Q 4. How do you monitor and control microbial contamination?

Monitoring and controlling microbial contamination involves a multifaceted approach:

- Environmental Monitoring: Regularly sampling surfaces, air, and equipment to identify and quantify microbial contamination. This involves using techniques like contact plates, air samplers, and swabs.

- Personnel Monitoring: Monitoring personnel for microbial contamination through hand and glove testing.

- Cleaning and Disinfection: Employing effective cleaning and disinfection agents and procedures to eliminate or reduce microbial populations.

- Sterilization: Utilizing methods like autoclaving, gamma irradiation, or ethylene oxide to eliminate microbial contamination on equipment and materials.

- Process Validation: Validating procedures that ensure effective microbial control throughout the manufacturing process.

For example, a pharmaceutical company would perform routine environmental monitoring in a cleanroom to ensure that microbial limits defined by GMP guidelines are maintained. Any deviation triggers an investigation and corrective actions.

Q 5. Explain the importance of gowning procedures in a controlled environment.

Gowning procedures are critical in controlled environments to prevent the introduction of contaminants from personnel to the product, process, or environment. A well-defined gowning procedure should minimize the shedding of particles and microorganisms from the person’s clothing, skin, and hair. This typically involves:

- Progressive Gowning: A stepwise approach to gowning, starting with the most basic garments (shoe covers, hair covers) and progressing to the most critical (gloves, gowns).

- Garment Selection: Using appropriate garments depending on the cleanroom classification and the process being performed. For example, a higher-grade cleanroom may require special, low-shedding garments.

- Gowning Technique: Following specific techniques to prevent contamination during the gowning process, such as avoiding touching the inside of garments.

- Gowning Verification: Often, a gowning verification process is performed to ensure the personnel’s attire meets the required cleanliness standards.

Imagine a medical device manufacturing facility; a poorly executed gowning procedure could lead to contamination of the product, jeopardizing patient safety.

Q 6. Describe different types of air filtration systems used in contaminant control.

Various air filtration systems are used in contaminant control, each designed to remove different types and sizes of contaminants. Key systems include:

- HEPA Filters (High-Efficiency Particulate Air): These filters remove at least 99.97% of particles 0.3 microns or larger. They are essential for cleanroom applications.

- ULPA Filters (Ultra-Low Penetration Air): These filters offer even higher efficiency than HEPA, removing at least 99.9995% of particles 0.12 microns or larger. Used in more stringent cleanrooms.

- Activated Carbon Filters: These filters remove gaseous contaminants and volatile organic compounds (VOCs). Often used in conjunction with HEPA/ULPA filters.

- Other Filters: Specialized filters might target specific contaminants, such as those removing biological contaminants or specific chemicals.

The choice of air filter depends on the required cleanliness level and the types of contaminants being controlled. A pharmaceutical cleanroom might use a combination of HEPA filters and activated carbon filters, while a semiconductor facility might employ ULPA filters for maximum particle removal.

Q 7. How do you validate a cleaning process for a controlled environment?

Validation of a cleaning process ensures its effectiveness in removing contaminants from surfaces within a controlled environment. This involves a systematic approach:

- Defining Cleaning Objectives: Clearly defining the desired level of cleanliness and the types of contaminants to be removed.

- Selecting Cleaning Agents and Methods: Choosing appropriate cleaning agents and methods based on the types of contaminants and the materials being cleaned. This includes selecting validated cleaning agents.

- Developing a Cleaning Procedure: Creating a detailed, documented cleaning procedure that outlines the steps involved.

- Sampling and Testing: Collecting samples before and after cleaning to assess the effectiveness of the cleaning process. This could involve using ATP bioluminescence, swabbing, or other appropriate tests.

- Data Analysis: Analyzing the collected data to determine if the cleaning process meets the defined objectives.

- Documentation: Thoroughly documenting the entire validation process, including procedures, results, and conclusions.

Imagine validating a cleaning process for a medical device assembly area. You would define acceptable limits for microbial contamination and particulate matter, then design a cleaning procedure, sample surfaces before and after cleaning, and analyze the data to confirm that the process consistently meets the defined cleanliness standards.

Q 8. What are the common sources of contamination in a manufacturing facility?

Contamination sources in a manufacturing facility are diverse and depend heavily on the specific industry and processes involved. Think of it like this: anything that can shed particles or introduce unwanted substances can be a source. Common culprits include:

- Personnel: Skin cells, hair, clothing fibers, and even cosmetics are major contributors. We shed microscopic particles constantly!

- Equipment: Wear and tear on machinery can release particles, and improperly maintained equipment can harbor contaminants. Think of a rusty machine shedding rust particles.

- Processes: Manufacturing processes themselves can generate particles or release volatile organic compounds (VOCs). For example, grinding generates dust, while certain chemical reactions release gaseous contaminants.

- Environment: External factors like airborne pollutants, insects, and even building materials can introduce contaminants into the cleanroom. This might include pollen from outside or fibers from the ceiling.

- Materials: Raw materials, packaging, and components can introduce contaminants if not properly handled. A poorly cleaned raw material could add bacteria or other impurities.

- Utilities: Compressed air, water, and other utility systems can introduce contaminants if they aren’t properly filtered. Consider the possibility of bacteria in unfiltered water.

Identifying and controlling these sources is critical for maintaining product quality and complying with regulatory requirements.

Q 9. Explain your understanding of ISO 14644 cleanroom standards.

ISO 14644 is the international standard defining the cleanliness classes for cleanrooms and associated controlled environments. It specifies the maximum allowable concentration of airborne particles of various sizes per cubic meter of air. The lower the number, the cleaner the room. For example, ISO Class 5 has far fewer particles than ISO Class 8.

Think of it as a grading system: ISO Class 1 is the cleanest, suitable for extremely sensitive applications like pharmaceutical drug manufacturing, while ISO Class 9 is less clean and suitable for less sensitive processes. The standard also covers environmental monitoring methods, which allows us to verify that the cleanroom is meeting its required cleanliness classification.

The standard is crucial for ensuring product quality and consistency. It provides a framework for designing, constructing, and operating cleanrooms, ensuring that they meet the specific requirements of their intended use.

Q 10. Describe your experience with contamination control in a specific industry (e.g., pharmaceutical, semiconductor).

My experience in contamination control primarily involves the pharmaceutical industry. I’ve worked extensively in facilities manufacturing sterile injectable drugs. In this context, contamination control is paramount because even a single contaminant can have severe consequences. My responsibilities included:

- Developing and implementing cleaning and disinfection protocols: This involved selecting appropriate cleaning agents, establishing cleaning frequencies, and documenting procedures. We used validated methods to ensure effectiveness.

- Environmental monitoring: Regularly monitoring air and surface samples for microbial and particulate contamination using techniques such as settle plates, contact plates, and air samplers. We used this data to identify trends and potential contamination sources.

- Investigating and resolving contamination events: When contamination was detected, I led investigations to identify the source, implement corrective actions, and prevent recurrence. This often involved meticulous record review, personnel interviews, and environmental assessments.

- Cleanroom qualification and validation: Participating in the qualification and validation of cleanrooms, including testing for particle counts, air pressure differentials, and air changes per hour. This ensured the cleanrooms met the stringent requirements of cGMP.

These experiences taught me the importance of meticulous attention to detail, rigorous documentation, and proactive risk management in maintaining a contamination-free environment.

Q 11. How do you investigate and resolve a contamination event?

Investigating and resolving a contamination event requires a systematic approach. It’s like solving a detective mystery!

- Identify and contain the contamination: The first step is to isolate the affected area to prevent further spread. This may involve temporarily shutting down production lines or restricting access to the affected zone.

- Gather information: Collect data regarding the nature, extent, and location of the contamination. This includes reviewing production records, environmental monitoring data, and interviewing personnel who may have been involved.

- Identify the source: This is often the most challenging step. Thorough investigation is needed, which could involve reviewing the source of materials, identifying equipment failures, examining personnel practices, and evaluating environmental factors. We use statistical methods and data analysis to link the contamination to its source.

- Implement corrective actions: Once the source is identified, corrective actions are implemented to eliminate the contamination and prevent recurrence. This may include replacing equipment, retraining personnel, modifying processes, or improving cleaning protocols.

- Validate the effectiveness of corrective actions: After corrective actions are implemented, monitoring is crucial to ensure effectiveness. This may involve repeat environmental monitoring and process checks.

- Document everything: Meticulous documentation of the entire investigation and resolution process is essential, allowing for continuous improvement and compliance with regulatory requirements.

Q 12. What are your experience with different cleaning agents and their applications?

My experience encompasses a wide range of cleaning agents, each with its own advantages and limitations. The selection depends heavily on the type of contamination, the material being cleaned, and the regulatory requirements.

- Isopropyl alcohol (IPA): Commonly used for disinfecting surfaces, especially in electronics and pharmaceutical settings. It’s effective against many microorganisms but can be damaging to certain materials.

- Hydrogen peroxide: A powerful disinfectant effective against a broad range of microorganisms, including spores. Various concentrations are used, from low concentrations for surface disinfection to high concentrations for sterilization.

- Sodium hypochlorite (bleach): A cost-effective disinfectant effective against bacteria and viruses but corrosive and potentially damaging to certain materials. Its use often requires careful dilution and rinsing.

- Detergents: Used for removing particulate matter and organic residues before disinfection. Different detergents are designed for various materials and cleaning tasks. This removes the bulk of the dirt before you disinfect.

I always ensure that cleaning agents are compatible with the materials being cleaned and are used according to the manufacturer’s instructions. Proper selection and use are key to effective cleaning and preventing damage to equipment or surfaces.

Q 13. Explain the principles of surface disinfection and sterilization.

Surface disinfection and sterilization are both crucial processes for controlling contamination, but they differ in their effectiveness and scope. Think of it this way: disinfection reduces the number of microorganisms, while sterilization eliminates all forms of microbial life.

Surface disinfection typically involves using chemical agents (disinfectants) to kill or inactivate microorganisms on surfaces. The effectiveness depends on the chosen disinfectant, concentration, contact time, and the type and level of contamination. Disinfection aims to reduce the microbial load to a safe level.

Sterilization involves using more aggressive methods to eliminate all forms of microbial life, including spores. Methods include autoclaving (steam sterilization), dry heat sterilization, ethylene oxide gas sterilization, and irradiation. Sterilization is necessary for applications where even a single microorganism is unacceptable, like in medical devices or pharmaceutical manufacturing.

The choice between disinfection and sterilization depends on the specific application and the required level of microbial control.

Q 14. How do you ensure the effectiveness of your cleaning and disinfection procedures?

Ensuring the effectiveness of cleaning and disinfection procedures is crucial for maintaining a contamination-free environment. It’s an ongoing process that involves several steps.

- Validation and Verification: We regularly validate our cleaning and disinfection procedures using standardized methods, to demonstrate that they consistently achieve the desired level of cleanliness. This might involve microbial testing to show log reduction of microorganisms.

- Monitoring: Continuous monitoring of environmental conditions and surface cleanliness is essential. This includes regular environmental monitoring to detect contamination events early and trending data to identify potential problems. We use data-driven decision making to adjust protocols as needed.

- Personnel Training: Thorough training and competency assessment of personnel are critical. They need to understand the importance of proper techniques, the use of personal protective equipment (PPE), and the significance of meticulous documentation. This is a crucial element that’s often overlooked.

- Procedure Review and Updates: Procedures should be regularly reviewed and updated based on new technologies, findings from monitoring, and emerging regulatory requirements. This adaptive approach is key to success.

- Documentation and Record Keeping: Comprehensive documentation of all aspects of cleaning and disinfection activities, including procedures, training records, and monitoring data, is critical. This information is valuable for auditing and regulatory compliance.

A robust quality control system, coupled with ongoing vigilance and improvement, ensures that cleaning and disinfection procedures remain effective and reliable.

Q 15. What is your experience with environmental monitoring techniques?

Environmental monitoring is crucial in contaminant control. It involves systematically collecting and analyzing samples from the environment to assess the presence and levels of contaminants. This helps to identify potential sources of contamination and track the effectiveness of control measures. My experience spans various techniques, including:

- Air sampling: Using particle counters, impaction samplers, and viable air samplers to quantify airborne particles and microorganisms.

- Surface sampling: Employing contact plates, swabs, and wipes to detect contaminants on surfaces. I’ve used ATP bioluminescence testing extensively for rapid surface cleanliness verification.

- Water sampling: Analyzing water quality for microbial and chemical contaminants using techniques like membrane filtration and spectrophotometry. I have a strong background in validating these methods and interpreting the results.

- Environmental monitoring of cleanrooms: I have extensive experience in designing and executing environmental monitoring programs for ISO Class 5-8 cleanrooms, including particulate matter, microbial, and non-viable surface contamination testing. This includes developing and implementing sampling plans and frequency based on risk assessments.

For example, in a pharmaceutical manufacturing setting, I implemented a real-time particle monitoring system that provided immediate alerts to any excursions in particle counts, allowing for rapid intervention and prevention of contamination events.

Career Expert Tips:

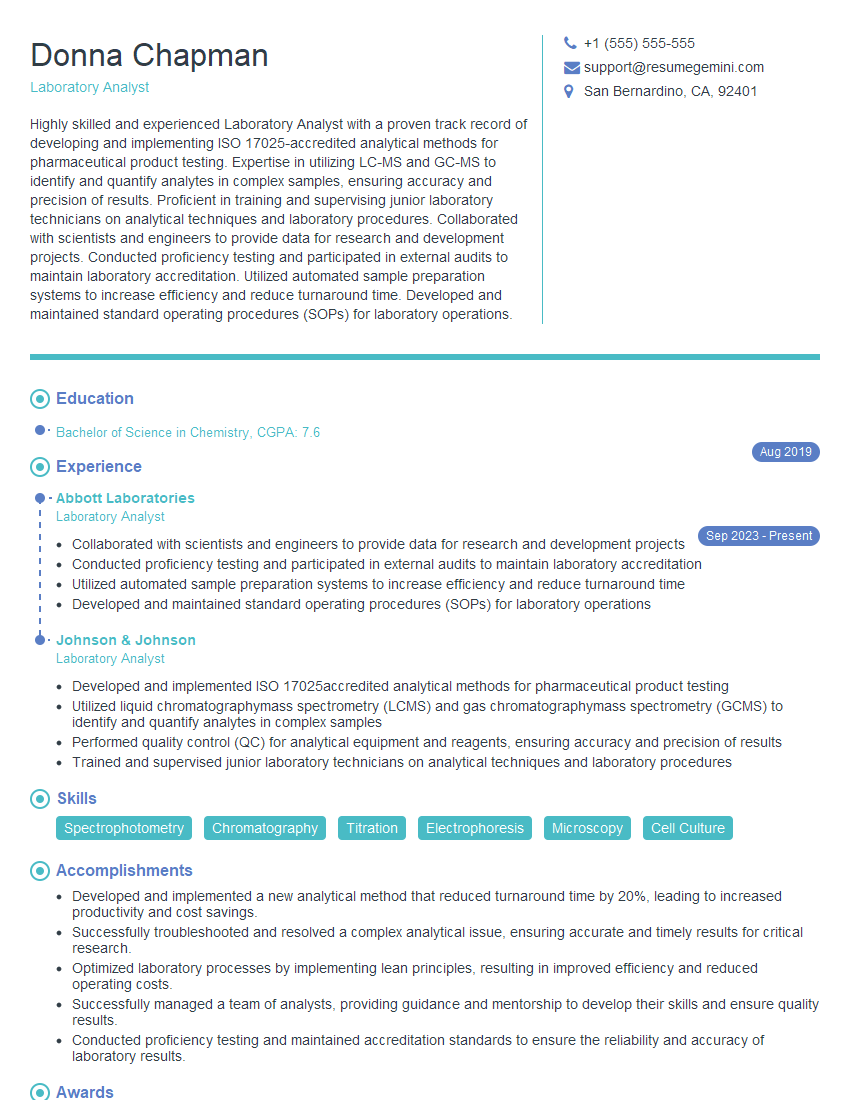

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with data analysis and reporting related to contamination control.

Data analysis and reporting are the cornerstones of effective contamination control. I use statistical software (like Minitab and JMP) to analyze environmental monitoring data, identifying trends, outliers, and potential sources of contamination. My reporting focuses on clear, concise communication of findings to stakeholders. This includes:

- Trend analysis: Identifying patterns in contamination levels over time to anticipate potential problems and optimize control strategies.

- Statistical process control (SPC): Using control charts to monitor processes and identify deviations from established limits.

- Root cause analysis: Employing tools like the 5 Whys and Fishbone diagrams to investigate the causes of contamination events.

- Data visualization: Using charts and graphs to present data in an easily understandable format. Clear, concise reports are paramount to influence decision-making.

For instance, during an investigation into increased particle counts in a cleanroom, my analysis revealed a correlation with a specific HVAC maintenance procedure. The report, complete with data visualization, led to changes in the procedure and a significant reduction in contamination levels.

Q 17. Explain your understanding of regulatory compliance concerning contamination control.

Regulatory compliance is paramount in contaminant control, especially in industries like pharmaceuticals, medical devices, and food processing. My understanding encompasses regulations such as:

- GMP (Good Manufacturing Practices): I am intimately familiar with the GMP guidelines, including their impact on environmental monitoring, cleaning validation, and personnel training.

- ISO standards (e.g., ISO 14644 for cleanrooms): I have direct experience in designing and implementing cleanroom environments that meet ISO standards.

- FDA regulations (e.g., 21 CFR Part 11 for electronic records): I understand the requirements for data integrity and electronic record-keeping in regulated industries.

- Specific industry-specific guidelines: My experience extends to various industries, and I adapt my understanding of regulatory compliance to specific industry guidelines.

For example, I’ve guided several companies through FDA inspections, ensuring their contamination control programs complied with all relevant regulations and resulted in successful audits. Proactive compliance reduces risks and minimizes costly setbacks.

Q 18. How do you manage risks associated with contamination?

Risk management in contamination control is a proactive process involving identification, assessment, and mitigation of potential risks. I utilize a structured approach involving:

- Risk assessment: Identifying potential sources of contamination and evaluating the likelihood and impact of contamination events. This frequently involves Failure Mode and Effects Analysis (FMEA).

- Mitigation strategies: Implementing control measures to reduce or eliminate identified risks, such as improved cleaning and disinfection procedures, enhanced personnel training, and improved environmental monitoring.

- Contingency planning: Developing plans to address contamination events should they occur, including investigation, corrective actions, and preventative measures.

- Regular review: Periodically reviewing and updating risk assessments and control measures to ensure continued effectiveness.

Imagine a scenario where a new piece of equipment is introduced into a cleanroom. A thorough risk assessment would identify potential sources of contamination from the equipment and lead to the implementation of specific controls like specialized cleaning protocols, or even an air filtration upgrade to minimize risks.

Q 19. What are the different types of personal protective equipment (PPE) used in contaminant control?

Personal Protective Equipment (PPE) is critical for protecting personnel from contamination. The choice of PPE depends on the specific contaminants and the level of risk. Common types include:

- Gloves: Nitrile, latex, or neoprene gloves, selected based on chemical compatibility and the level of protection needed.

- Gowns/Coveralls: Disposable or reusable garments, providing varying levels of protection from liquid splashes, particulates, or biological contaminants.

- Respirators: These protect against airborne contaminants, ranging from simple dust masks to more sophisticated respirators (e.g., PAPRs) for use with hazardous materials.

- Eye protection: Safety glasses, goggles, or face shields provide protection against splashes or airborne particles.

- Footwear: Cleanroom boots or overshoes prevent the introduction of contaminants from the outside environment.

- Hairnets/hoods: Minimize the shedding of hair and skin particles.

Selecting appropriate PPE is not just about choosing the right type, but also ensuring proper fit, training on correct use and disposal, and regular inspection for damage or wear. A poorly fitting respirator, for example, renders it useless and increases risk to the wearer.

Q 20. Describe the importance of training personnel in contamination control practices.

Training personnel is fundamental to a successful contamination control program. Effective training ensures that all personnel understand the risks of contamination, and know how to follow proper procedures. Training should cover:

- Good hygiene practices: Handwashing, gowning and gloving techniques.

- Cleanroom protocols: Proper entry and exit procedures, movement within the cleanroom, and equipment operation.

- Use of PPE: Selection, correct use, and disposal of PPE.

- Environmental monitoring procedures: Sampling techniques, data recording, and reporting.

- Contamination incident response: Procedures to follow if a contamination event occurs.

Regular refresher training and competency assessments are critical to ensure knowledge retention and consistency. Failing to train personnel adequately can lead to contamination events, product recalls, or regulatory non-compliance, potentially causing significant financial loss and reputational damage.

Q 21. How do you select appropriate cleaning validation methods?

Selecting appropriate cleaning validation methods involves considering the specific materials, equipment, and contaminants involved. The goal is to demonstrate that the cleaning process effectively removes residues to acceptable levels. Several factors influence the method selection:

- Type of residue: Chemical analysis is often used for drug product residues, while microbiological methods may be required for microorganisms.

- Surface material: The method must be suitable for the material being cleaned, avoiding damage or interference.

- Cleaning process: The validation method must reflect the actual cleaning process employed.

- Regulatory requirements: The method must comply with all relevant regulations and guidelines.

Common methods include:

- Visual inspection: A simple initial check for visible residues.

- Residue analysis: Techniques like HPLC, GC, or spectrophotometry are used to quantify residues.

- Microbiological testing: Methods like plate counting or ATP bioluminescence are used to detect microorganisms.

- Swab sampling and analysis: This is a common method for evaluating the effectiveness of cleaning on surfaces.

A risk-based approach is essential; highly sensitive analytical methods are not always necessary, and the chosen method must be appropriate for the level of risk associated with the specific cleaning process. Overly complex or expensive methods might not be justified.

Q 22. What is your understanding of aseptic techniques?

Aseptic techniques are a collection of methods designed to prevent contamination of sterile materials and environments. Think of it like preparing a surgical field – every step is taken to eliminate any unwanted microorganisms or particles. This is crucial in various industries, particularly pharmaceuticals, biotechnology, and food processing, where contamination can compromise product quality, safety, and efficacy.

These techniques include things like using sterile equipment, working in a laminar flow hood or cleanroom to minimize airborne contamination, employing proper hand hygiene, and utilizing sterile clothing and personal protective equipment (PPE). For example, in a pharmaceutical setting, aseptic filling of vials requires meticulous adherence to these protocols to guarantee the drug remains free from any bacterial or fungal contamination that could cause harm to the patient.

- Sterile equipment and supplies: Using only pre-sterilized materials and disposables.

- Environmental control: Maintaining a clean and disinfected workspace, often involving cleanrooms with HEPA filtration.

- Personal hygiene: Strict adherence to handwashing and gowning procedures to minimize the introduction of microorganisms.

- Proper techniques: Using specific methods for handling sterile equipment to avoid accidental contamination.

Q 23. What are some common challenges faced in contamination control, and how did you overcome them?

Common challenges in contamination control often revolve around human error, environmental factors, and equipment limitations. One frequent challenge is maintaining a consistent level of cleanliness across all personnel and processes. In one project involving sterile compounding, we noticed inconsistent gowning techniques leading to increased particle counts. To overcome this, we implemented a comprehensive training program with hands-on practice and standardized procedures, leading to a significant reduction in contamination events.

Another challenge involves controlling environmental factors. For instance, airflow patterns in a cleanroom can be affected by even minor changes, potentially creating dead zones where contaminants can accumulate. We addressed this by using computational fluid dynamics (CFD) modelling to optimize airflow and identify areas needing improvement, followed by adjustments to the HVAC system. We also faced challenges with equipment maintenance and calibration, which can directly impact contamination levels. Implementing a rigorous preventative maintenance schedule and establishing a thorough calibration program solved this issue.

Q 24. Explain your understanding of particle counting and sizing techniques.

Particle counting and sizing are critical for assessing the cleanliness of an environment or product. Particle counters use light scattering to detect and count particles in the air or liquids, providing information on the number and size of these particles. Different techniques exist depending on the application. For example, optical particle counters are widely used for cleanroom monitoring, while liquid particle counters are used for assessing the cleanliness of pharmaceutical products.

Sizing techniques use various methods to determine particle size, ranging from laser diffraction to microscopy. The size distribution is important, as smaller particles often pose greater risks than larger ones due to their ability to penetrate deeper into sensitive areas or systems. For instance, submicron particles are a greater concern in semiconductor manufacturing than larger particles.

Data from these techniques is essential for evaluating the effectiveness of contamination control measures. For example, by tracking particle counts over time, we can identify trends and potential contamination sources. We use this information to continuously improve our cleanroom protocols, maintenance schedules, and equipment effectiveness.

Q 25. How do you ensure the integrity of sampling and testing procedures?

Ensuring the integrity of sampling and testing procedures is paramount. This involves several key steps, starting with proper sample selection and preparation. For example, samples must be representative of the area or product being tested. We use statistically valid sampling plans to ensure this. We also utilize chain-of-custody documentation to track every step of the process, from sample collection to analysis and reporting. This ensures the samples remain untampered with and their integrity is maintained throughout the process.

The testing procedures themselves must be validated to ensure accuracy and reliability. We use reference standards and proficiency testing programs to verify the accuracy of our analytical methods. In addition, we implement rigorous quality control checks throughout the testing process to detect any potential errors. This includes using controls, blanks, and duplicates to identify potential biases and inconsistencies. Documenting everything, from equipment calibration to personnel qualifications, forms a critical part of our quality assurance system.

Q 26. Explain your experience in implementing and maintaining a contamination control program.

My experience with implementing and maintaining contamination control programs spans across various industries. It always begins with a thorough risk assessment to identify potential contamination sources and critical control points. This leads to the development of a comprehensive contamination control plan that details the specific procedures, equipment, and training required. This plan includes protocols for cleanroom maintenance, personnel training, material handling, and environmental monitoring.

A key element of successful program implementation is regular monitoring and auditing. This includes performing regular environmental monitoring, equipment calibration and maintenance, and reviewing personnel practices. We use Key Performance Indicators (KPIs), such as particle counts and contamination event rates, to monitor the effectiveness of the program. Regular internal audits ensure compliance with established protocols. In one project involving a pharmaceutical manufacturing facility, implementing a comprehensive contamination control program resulted in a 70% reduction in product rejects due to contamination.

Q 27. Describe your experience with different types of contamination (e.g., chemical, biological, particulate).

My experience encompasses various types of contamination. Particulate contamination, such as dust and fibers, is a common issue, often addressed through cleanroom design and HEPA filtration. We use particle counters to monitor particle levels and identify potential sources of contamination. Biological contamination, involving microorganisms such as bacteria and fungi, is controlled through sterilization and disinfection procedures. Methods such as autoclaving and gamma irradiation are used to ensure sterility.

Chemical contamination can stem from residual cleaning agents, process chemicals, or environmental pollutants. We address chemical contamination through meticulous cleaning validation, proper material selection, and the use of appropriate personal protective equipment. The approach varies depending on the specific contaminant: for example, handling volatile organic compounds (VOCs) necessitates specialized ventilation and control measures, whereas heavy metal contamination requires specialized decontamination procedures. Every case requires a tailored strategy, drawing on various techniques and technologies.

Q 28. How do you stay updated on the latest trends and technologies in contamination control?

Staying updated in contamination control requires a multi-pronged approach. I regularly attend industry conferences and workshops, such as those organized by professional bodies like the Institute of Environmental Sciences and Technology (IEST). This allows me to network with other professionals and learn about the latest advancements. I also actively read peer-reviewed scientific journals and trade publications specializing in contamination control and related fields. Furthermore, I actively participate in online forums and discussion groups related to contamination control, exchanging knowledge and insights with other experts.

Keeping abreast of regulatory updates and standards, such as those from the FDA or other relevant regulatory bodies, is also crucial. Manufacturers’ training and technical bulletins are also invaluable resources. Finally, participating in relevant training programs and workshops is an integral part of maintaining my expertise and ensuring I’m at the cutting edge of this field.

Key Topics to Learn for Contaminant Control Interview

- Contamination Sources & Types: Understanding the origins (airborne, waterborne, etc.) and characteristics of various contaminants (microbial, chemical, particulate).

- Contamination Control Strategies: Explore practical applications of different control methods such as HEPA filtration, cleanroom design, sterilization techniques, and personal protective equipment (PPE).

- Monitoring & Measurement Techniques: Learn about various methods for detecting and quantifying contaminants, including microbial assays, particle counters, and chemical analysis techniques.

- Regulatory Compliance & Standards: Familiarize yourself with relevant industry standards and regulations (e.g., ISO 14644, GMP) and their implications for contaminant control practices.

- Risk Assessment & Mitigation: Understand how to conduct risk assessments to identify potential contamination sources and develop effective mitigation strategies.

- Cleanroom Technology & Design: Explore the principles behind cleanroom design, including airflow management, material selection, and operational procedures.

- Validation & Qualification: Learn about the processes involved in validating cleaning and sterilization procedures and qualifying equipment for contamination control.

- Data Analysis & Interpretation: Develop your ability to analyze contamination data, identify trends, and draw meaningful conclusions to improve control strategies.

- Problem-Solving & Troubleshooting: Practice identifying and resolving issues related to contamination events, including root cause analysis and corrective actions.

Next Steps

Mastering contaminant control opens doors to exciting and impactful careers in various industries, offering excellent growth potential and high demand. To maximize your job prospects, it’s crucial to present your skills effectively. Crafting an ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your expertise. ResumeGemini provides tailored resume examples specifically for Contaminant Control professionals, allowing you to showcase your skills and experience effectively. Invest time in building a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good