Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Cathode and Anode Analysis interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Cathode and Anode Analysis Interview

Q 1. Explain the difference between a cathode and an anode in an electrochemical cell.

In an electrochemical cell, the cathode and anode are electrodes where oxidation and reduction reactions occur. Think of it like a seesaw: one side goes up (reduction at the cathode), the other goes down (oxidation at the anode). The cathode is the electrode where reduction takes place – it gains electrons. Electrons flow towards the cathode. The anode is the electrode where oxidation takes place – it loses electrons. Electrons flow away from the anode. This electron flow creates an electric current, which is the basis of the cell’s functionality. For example, in a simple zinc-copper cell, the zinc electrode (anode) is oxidized (Zn → Zn2+ + 2e–), while the copper electrode (cathode) is reduced (Cu2+ + 2e– → Cu).

Q 2. Describe the function of a cathode in a lithium-ion battery.

In a lithium-ion battery, the cathode’s function is to accept lithium ions (Li+) and electrons during the discharge process. Imagine it as a storage facility for lithium. During discharge, lithium ions move from the anode through the electrolyte to the cathode, where they combine with electrons that have flowed through the external circuit, completing the reduction reaction. This process generates the electrical energy that powers our devices. The specific cathode material dictates the battery’s voltage, energy density, and lifespan. For instance, layered transition metal oxides like LiCoO2 are commonly used cathodes, but their lithium-ion storage capacity has limitations compared to newer materials.

Q 3. What are the key characteristics of a good cathode material?

A good cathode material needs a unique combination of properties to ensure high-performance batteries. Key characteristics include:

- High specific capacity: The ability to store a large amount of lithium ions per unit mass or volume. This translates to a longer battery life for the same size.

- High operating voltage: A higher voltage leads to greater energy density (energy stored per unit volume or weight). This means more power for the same battery size.

- Good rate capability: The ability to deliver high currents efficiently. This is crucial for applications needing quick bursts of power, like electric vehicles.

- Excellent cycling stability: The ability to withstand numerous charge-discharge cycles without significant degradation in capacity or performance. This ensures long-term battery life.

- Thermal stability: Resistance to thermal runaway, which is a dangerous process where internal heat build-up can lead to fire or explosion.

- Cost-effectiveness and environmental friendliness: The material should be relatively inexpensive and its production should have minimal environmental impact.

Finding a material that balances all these characteristics is a significant challenge in battery research.

Q 4. What are the common anode materials used in lithium-ion batteries, and what are their advantages and disadvantages?

Common anode materials in lithium-ion batteries include:

- Graphite: Widely used due to its low cost, good safety, and relatively high capacity. However, its capacity is limited compared to other materials.

- Silicon: Offers significantly higher theoretical capacity than graphite, leading to greater energy density. However, it suffers from significant volume expansion during cycling, causing structural damage and capacity fade.

- Lithium titanate (Li4Ti5O12): A safe and fast-charging anode material with excellent cycle life, but with lower energy density compared to graphite and silicon.

The choice of anode material depends on the desired battery characteristics. For example, electric vehicles may prioritize high energy density, favoring silicon-based anodes despite their drawbacks, while consumer electronics may prioritize safety and cost, making graphite a suitable choice.

Q 5. Explain the concept of electrochemical potential and its relevance to cathode and anode reactions.

Electrochemical potential, often measured in volts (V), describes the tendency of a material to gain or lose electrons. It’s a crucial concept for understanding cathode and anode reactions. Each material has a standard reduction potential, indicating its relative ease of reduction (gaining electrons). In an electrochemical cell, the difference in electrochemical potential between the cathode and anode drives the electron flow. A larger potential difference results in a higher cell voltage and greater energy output. For instance, the reduction potential of a cathode material should be higher than that of the anode to facilitate electron flow from the anode to the cathode during discharge. The difference between the reduction potentials of the cathode and anode gives the cell voltage. This concept is fundamental in designing high-voltage, high-energy batteries.

Q 6. Describe different types of electrochemical techniques used to characterize cathode and anode materials.

Several electrochemical techniques characterize cathode and anode materials. These include:

- Cyclic voltammetry (CV): Studies redox reactions by cycling the potential and measuring the current. It provides information about electrochemical reversibility, redox potentials, and reaction kinetics.

- Galvanostatic charge-discharge cycling: Measures the capacity and cycle life by charging and discharging the cell at a constant current. This provides critical data on battery performance.

- Electrochemical impedance spectroscopy (EIS): Investigates the internal resistance of the cell using small AC signals. It helps understand factors like ion transport, interfacial resistance, and electrode kinetics, which affects battery performance.

- X-ray diffraction (XRD): A non-electrochemical technique used to determine the crystal structure and phase composition of materials. It helps understand structural changes during cycling.

These techniques provide a comprehensive understanding of the material’s electrochemical behavior and help optimize battery design and performance. A combination of techniques is often necessary for a thorough characterization.

Q 7. How do you analyze the performance of a cathode material?

Analyzing the performance of a cathode material involves a multi-faceted approach using the techniques described above. Key performance indicators include:

- Specific capacity: Measured through galvanostatic charge-discharge cycling. A higher capacity indicates better energy storage capability.

- Rate capability: Determined by performing charge-discharge cycles at varying current rates. Good rate capability means the battery can deliver high power when needed.

- Cycling stability: Assessed by monitoring capacity retention over many cycles. High cycling stability implies longer battery life.

- Coulombic efficiency: The ratio of charge capacity to discharge capacity. High coulombic efficiency indicates minimal energy loss during charging and discharging.

- Voltage profile: Obtained during charge-discharge cycling, it provides insights into the reaction mechanism and potential phase transitions.

- Structural analysis: Techniques like XRD are used to analyze changes in crystal structure during cycling. This helps identify degradation mechanisms.

By carefully analyzing these parameters, researchers can understand the strengths and weaknesses of a cathode material and improve its design for optimal battery performance. The analysis allows for a comprehensive evaluation and drives innovation in the field of energy storage.

Q 8. How do you analyze the performance of an anode material?

Analyzing anode performance involves a multifaceted approach focusing on its ability to facilitate electrochemical reactions efficiently and reliably over numerous charge-discharge cycles. We assess several key parameters:

Specific Capacity: This measures the amount of charge the anode can store per unit mass (mAh/g). A higher specific capacity is desirable for energy-dense batteries. We typically determine this through electrochemical testing, specifically galvanostatic charge-discharge cycling.

Rate Capability: This assesses the anode’s ability to deliver charge rapidly. We measure the capacity at different charge/discharge rates (C-rates). A good anode maintains high capacity even at high C-rates.

Cycle Life: This determines the anode’s longevity. We perform extended cycling tests to observe capacity fading and changes in impedance over time. A long cycle life is crucial for practical applications.

Coulombic Efficiency: This indicates the percentage of charge that can be effectively stored and retrieved. A high coulombic efficiency is important for minimizing energy losses. We calculate this from the charge and discharge capacities.

Electrochemical Impedance Spectroscopy (EIS): EIS is a powerful technique to understand the kinetics of electrochemical processes at the anode-electrolyte interface. It can identify factors such as resistance and capacitance that influence performance.

For example, analyzing a graphite anode in a lithium-ion battery involves measuring its capacity at various C-rates to determine its suitability for applications requiring high power delivery, such as electric vehicles. Extended cycling tests will reveal its capacity retention over time and any degradation mechanisms that might affect battery lifespan.

Q 9. What are the common failure mechanisms of cathodes and anodes in batteries?

Cathode and anode failure mechanisms are complex and often intertwined. Common issues include:

Cathode:

Structural Degradation: Repeated expansion and contraction during cycling can lead to cracking and pulverization of the cathode material, reducing its surface area and contact with the electrolyte.

Loss of Active Material: Dissolution or loss of active material into the electrolyte can decrease the cathode’s capacity.

Phase Transitions: Some cathode materials undergo phase transitions during cycling, which can lead to changes in their crystal structure and reduced performance.

Electrolyte Decomposition: Reactions between the cathode and the electrolyte can cause electrolyte decomposition and the formation of passivation layers that hinder ion transport.

Anode:

Solid Electrolyte Interphase (SEI) Layer Growth: The formation of a SEI layer on the anode surface is a common phenomenon in lithium-ion batteries. While initially protecting the anode, excessive SEI growth consumes lithium ions and increases impedance, reducing capacity.

Lithium Plating: At high charge rates or low temperatures, lithium ions can deposit as metallic lithium on the anode surface, forming dendrites that can pierce the separator and cause short circuits.

Mechanical Degradation: Similar to cathodes, volume changes during cycling can lead to cracking and pulverization of the anode material.

Understanding these failure mechanisms is crucial for developing improved battery materials and designs to enhance battery lifespan and safety.

Q 10. How does temperature affect the performance of cathode and anode materials?

Temperature significantly impacts cathode and anode performance. Generally, higher temperatures accelerate both positive and negative reactions, increasing the rate of capacity fade and degradation mechanisms.

Cathodes: Elevated temperatures can accelerate the rate of structural degradation, increase the risk of thermal runaway (excessive heat generation leading to potential fire or explosion), and promote electrolyte decomposition. Low temperatures can slow down ionic conductivity and reduce capacity.

Anodes: High temperatures can increase the rate of SEI layer growth and promote lithium plating, while low temperatures reduce lithium-ion diffusivity and increase the cell’s resistance.

For example, a lithium-ion battery operating at high temperatures might show a rapid decrease in capacity due to increased side reactions and structural degradation in both the cathode and anode. Conversely, operation at low temperatures might result in a reduction in available capacity due to the slowed ion transport kinetics.

Battery thermal management systems are essential to maintaining optimal operating temperatures and prolonging battery life.

Q 11. Explain the concept of overpotential and its impact on cell efficiency.

Overpotential represents the extra voltage required beyond the thermodynamic potential to drive an electrochemical reaction at a desired rate. It is a measure of the energy losses within a cell and has a direct impact on efficiency.

Imagine pushing a heavy box across a floor. The thermodynamic potential is the theoretical minimum force required to move the box. Overpotential is the extra force you need to apply to move the box at a certain speed. A higher overpotential means more energy is wasted in the process.

Overpotential arises from several sources:

Activation Overpotential: This is the energy barrier needed to initiate the electrochemical reaction at the electrode surface.

Ohmic Overpotential: This arises from the resistance to electron flow within the cell components, including the electrodes, electrolyte, and current collectors.

Concentration Overpotential: This results from concentration gradients within the electrolyte near the electrode surfaces, due to differences in reactant concentration.

High overpotential reduces cell efficiency as a significant portion of the applied voltage is lost, preventing it from contributing to usable energy storage. Minimizing overpotential is vital for improving battery performance and energy density.

Q 12. What is impedance spectroscopy, and how is it used to characterize electrochemical cells?

Electrochemical Impedance Spectroscopy (EIS) is a powerful non-destructive technique used to characterize electrochemical cells by applying a small sinusoidal voltage and measuring the resulting current response over a range of frequencies.

Think of it as a ‘listening test’ for the cell. The response across frequencies reveals information about the various resistive and capacitive elements within the cell.

The data obtained is represented by a Nyquist plot (complex impedance plane plot) which is analyzed to extract parameters such as:

Solution Resistance (Rs): Resistance of the electrolyte.

Charge Transfer Resistance (Rct): Resistance associated with electron transfer at the electrode/electrolyte interface.

Double Layer Capacitance (Cdl): Capacitance at the electrode/electrolyte interface.

Warburg Impedance (Zw): Represents the diffusion of ions in the electrolyte.

By analyzing the impedance spectrum, researchers can gain insights into the various processes occurring within the cell and identify potential issues, such as poor electrode conductivity or slow ion diffusion.

EIS is widely used to evaluate cell components and the effects of aging, temperature, and state of charge on battery performance.

Q 13. Explain the concept of charge-discharge cycling and its significance in battery testing.

Charge-discharge cycling involves repeatedly charging and discharging a battery cell under controlled conditions to evaluate its performance and longevity. It’s the primary method for assessing critical battery parameters.

This process involves applying a constant current (galvanostatic cycling) or a constant voltage (potentiostatic cycling) to charge the battery to a specific state of charge and then discharging it until a certain cut-off voltage is reached. This cycle is repeated numerous times.

The significance of charge-discharge cycling in battery testing lies in its ability to provide valuable information such as:

Capacity Fade: Determines how much the battery’s capacity decreases over many cycles.

Cycle Life: Evaluates the number of cycles a battery can endure before its capacity drops below a certain threshold.

Coulombic Efficiency: Measures the efficiency of charge and discharge processes.

Voltage Profile: Analyzes the voltage changes during charging and discharging, which can reveal information about the battery’s internal processes and potential problems.

The data obtained from charge-discharge cycling is used to understand battery degradation mechanisms, optimize cell design and predict its lifespan under various operating conditions.

Q 14. Describe different types of batteries and their corresponding cathode and anode materials.

Various battery types utilize different cathode and anode materials, each tailored to their specific applications and performance requirements.

Lithium-ion Batteries (LIBs): These are the most prevalent rechargeable batteries. Common cathode materials include lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), and lithium nickel manganese cobalt oxide (NMC). Common anode materials are graphite and silicon.

Lead-Acid Batteries: These are relatively inexpensive and robust, but have lower energy density. The cathode is lead dioxide (PbO2) and the anode is lead (Pb), both immersed in sulfuric acid.

Nickel-Metal Hydride (NiMH) Batteries: These offer higher energy density than lead-acid batteries. The cathode is typically nickel hydroxide (Ni(OH)2), and the anode is a hydrogen-absorbing alloy (e.g., LaNi5).

Nickel-Cadmium (NiCd) Batteries: These are older technology, less prevalent now due to toxicity concerns. The cathode is nickel hydroxide (Ni(OH)2) and the anode is cadmium (Cd).

Solid-State Batteries: Emerging technology using solid electrolytes, promising higher energy density and safety. Cathode and anode materials vary widely depending on the specific design.

The choice of cathode and anode materials significantly impacts a battery’s performance characteristics, such as energy density, power density, cycle life, cost, and safety.

Q 15. How do you determine the capacity and rate capability of a battery?

Determining the capacity and rate capability of a battery involves rigorously testing its performance under various conditions. Capacity, measured in mAh (milliampere-hours) or Ah (ampere-hours), represents the total amount of charge the battery can store. Rate capability refers to how quickly that charge can be delivered or accepted.

To measure capacity, we perform a constant current discharge test. The battery is fully charged and then discharged at a constant current (e.g., C/10 rate, where C represents the nominal capacity) until a predetermined cut-off voltage is reached. The total charge delivered during this discharge is the battery’s capacity.

Rate capability is evaluated by performing discharge tests at different C-rates. For instance, a 1C rate means the battery is discharged in one hour, a 2C rate in 30 minutes, and so on. By comparing the capacity obtained at different C-rates, we determine how well the battery performs under various demands. A higher capacity at higher C-rates indicates better rate capability. Imagine a sprinter (high rate capability) versus a marathon runner (high capacity). Both are valuable but serve different purposes.

Further analysis may include electrochemical impedance spectroscopy (EIS) which provides insights into the internal resistance of the battery, a key factor influencing rate capability. Higher internal resistance limits the rate at which charge can flow.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret cyclic voltammetry data for cathode and anode materials?

Cyclic voltammetry (CV) is a powerful electrochemical technique used to study the redox reactions occurring at the electrode-electrolyte interface. In the context of battery materials, CV reveals valuable information about the electrochemical properties of both cathodes and anodes.

A typical CV curve plots current (i) against potential (V). For a cathode material, we look for characteristic redox peaks corresponding to the insertion/extraction of lithium ions (or other ions). The peak separation provides information about the reversibility of the redox reaction, with smaller separations indicating better reversibility. The peak area is proportional to the amount of charge transferred, which is related to the capacity of the material.

Similarly, for an anode material, the CV curve reveals redox peaks related to the lithiation/delithiation processes. We assess peak positions, shapes, and areas to characterize the electrochemical performance. For example, broad peaks might suggest poor crystallinity, while sharp peaks often indicate good crystallinity and reversibility.

Analyzing the changes in CV curves over multiple cycles provides insights into the long-term stability and cycling performance of the material. Any significant changes in peak intensity or potential could indicate degradation or side reactions occurring during cycling.

Q 17. What are the common methods for synthesizing cathode and anode materials?

The synthesis of cathode and anode materials is a crucial step in battery development, and various methods are employed depending on the desired material and properties. These methods can be broadly classified into solid-state and solution-based approaches.

- Solid-state methods: These include solid-state reactions, often involving high-temperature calcination of precursor materials. For example, LiFePO4 (a common cathode material) can be synthesized by heating a mixture of Li2CO3, Fe2O3, and H3PO4 at elevated temperatures. This method is often cost-effective but can result in larger particle sizes.

- Solution-based methods: These methods include sol-gel, co-precipitation, hydrothermal, and solvothermal techniques. These methods offer better control over particle size, morphology, and composition. For instance, hydrothermal synthesis allows the growth of nanostructures under controlled temperature and pressure in an aqueous solution. Solution-based methods are particularly useful for creating materials with tailored properties, such as high surface area or specific morphologies.

The choice of synthesis method is crucial, influencing the final material properties and subsequently the battery performance. Factors to consider include cost, scalability, control over particle size and morphology, and purity of the final product.

Q 18. What are the challenges in developing high-energy-density cathodes?

Developing high-energy-density cathodes presents significant challenges. The energy density of a cathode is directly related to its capacity and operating voltage. Achieving higher energy density requires addressing several key issues:

- Voltage limitations: Higher voltage cathodes are desirable, but they often suffer from increased instability and degradation during cycling. This can lead to capacity fading and safety concerns.

- Structural stability: Repeated lithium ion insertion and extraction can cause structural changes within the cathode material, leading to capacity fade and poor cycle life. Finding materials with robust crystal structures is critical.

- Oxygen evolution: At high voltages, some cathode materials can undergo oxygen evolution, leading to irreversible capacity loss and safety hazards. Stabilizing the oxygen lattice is important.

- Electrolyte compatibility: The cathode material must be compatible with the electrolyte to prevent side reactions and degradation. Finding electrolytes that are stable at high voltages and exhibit high ionic conductivity is a major challenge.

Research focuses on innovative material design, including exploring new compositions and structures, surface modifications, and the use of protective coatings to address these challenges.

Q 19. What are the challenges in developing high-power-density anodes?

Developing high-power-density anodes presents its own set of challenges. Power density is related to the rate at which the anode can deliver or accept charge.

- Low Li+ ion conductivity: Some anode materials, especially those with high theoretical capacities, can exhibit low lithium-ion conductivity, hindering fast charge/discharge rates. Strategies to improve ionic conductivity, such as nanostructuring, are employed.

- Large volume changes: During lithiation/delithiation, many anode materials undergo significant volume changes, leading to pulverization and loss of electrical contact. This reduces cycle life and rate capability. Strategies include designing nano-architectures, composites, or using buffer layers to mitigate volume changes.

- Safety concerns: Some high-capacity anodes, such as lithium metal, pose safety risks due to the formation of dendrites during cycling. Dendrites can cause short circuits and thermal runaway. Controlling dendrite formation is paramount for safe and high-power batteries.

- Electrolyte compatibility: Anode materials need to be compatible with the electrolyte to avoid unwanted side reactions that can degrade performance. Finding suitable electrolytes that are stable and provide high ionic conductivity at the anode potential is crucial.

Research focuses on optimizing material structure, morphology, and electrolyte selection to tackle these challenges and enhance the power density of anodes.

Q 20. How does the surface area of cathode and anode materials affect battery performance?

The surface area of cathode and anode materials significantly impacts battery performance. A higher surface area generally leads to improved electrochemical performance, particularly rate capability.

Increased surface area provides more active sites for electrochemical reactions, allowing for faster ion transport and electron transfer. This results in faster charging and discharging rates, as well as increased power density. Think of it like a sponge – a sponge with a larger surface area absorbs water (ions) much faster.

However, an excessively large surface area can also lead to increased side reactions with the electrolyte, resulting in capacity fading and poor cycle life. Therefore, an optimal surface area is needed to balance improved kinetics with minimized side reactions.

Techniques such as nanostructuring or creating porous structures are often employed to increase the surface area of electrode materials without sacrificing structural integrity or significantly increasing side reactions.

Q 21. Discuss the importance of particle size and morphology in cathode and anode materials.

Particle size and morphology are critical factors influencing the performance of cathode and anode materials. These factors affect several key aspects of battery behavior:

- Lithium-ion diffusion: Smaller particles provide shorter diffusion paths for lithium ions, leading to faster charging and discharging rates. A well-defined morphology can also facilitate ion diffusion.

- Electron transport: The connectivity between particles impacts electron transport within the electrode. Proper particle size and morphology ensure good electrical contact among particles, facilitating efficient electron transfer.

- Volume change accommodation: During cycling, many electrode materials experience volume changes. Optimizing particle size and morphology can better accommodate these volume changes, mitigating pulverization and capacity fading. For example, nanostructured materials offer more flexibility to accommodate volume changes.

- Electrolyte accessibility: The morphology of the particles influences the accessibility of the electrolyte to the active material. A porous structure with a large surface area maximizes electrolyte contact, improving reaction kinetics.

Careful control over particle size and morphology during the synthesis process is crucial for achieving optimal battery performance. Techniques like controlled precipitation, hydrothermal synthesis, and surface coatings are used to achieve the desired particle characteristics.

Q 22. Explain the role of electrolytes in electrochemical cells.

Electrolytes are the lifeblood of any electrochemical cell, acting as the crucial pathway for ion transport between the cathode and anode. Think of them as the highway system for charged particles. Without a functioning electrolyte, the electrons generated at the anode cannot complete their circuit to the cathode, rendering the battery useless. They facilitate the flow of ions (like lithium ions in lithium-ion batteries) to balance the charge transfer that occurs during electrochemical reactions. This ion movement is what generates the electric current we use to power our devices.

Specifically, the electrolyte must be a good ionic conductor but a poor electronic conductor. This ensures that ions can move freely to maintain electroneutrality, while preventing direct electron flow, which would short-circuit the battery. The electrolyte’s properties, such as its ionic conductivity, viscosity, and electrochemical stability window, greatly influence the battery’s performance and lifespan.

Q 23. What are the different types of electrolytes used in batteries?

The choice of electrolyte significantly impacts battery characteristics. Different battery chemistries utilize different electrolytes, tailored to their specific needs. Here are some common types:

- Liquid electrolytes: These are the most common, typically consisting of a lithium salt (like LiPF6) dissolved in an organic solvent (like ethylene carbonate or propylene carbonate). They offer high ionic conductivity, but suffer from leakage and flammability concerns.

- Solid-state electrolytes: These are gaining traction due to their enhanced safety profile. They can be ceramic oxides, sulfide-based glasses, or polymer-based materials. However, their ionic conductivity is often lower than liquid electrolytes, limiting their power density.

- Gel polymer electrolytes: These are a hybrid approach, combining the flexibility of polymers with the high ionic conductivity of liquid electrolytes. They offer a good balance between safety and performance, but their long-term stability can be a challenge.

The selection process considers factors such as ionic conductivity, electrochemical window (the voltage range where the electrolyte remains stable), thermal stability, safety, and cost. For instance, high-temperature applications might necessitate electrolytes with higher thermal stability, while those for electric vehicles need to balance high energy density with safety.

Q 24. How do you analyze the degradation mechanisms of cathode and anode materials?

Analyzing cathode and anode degradation is crucial for improving battery lifespan and performance. We employ a multi-pronged approach involving various characterization techniques.

- Electrochemical techniques: Cycling tests (repeated charge-discharge cycles) assess capacity fade and impedance growth. Techniques like cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) probe the electrochemical kinetics and reveal degradation mechanisms.

- Material characterization techniques: X-ray diffraction (XRD) monitors structural changes (like phase transitions or particle growth). Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) visualize morphological changes (like crack formation or surface film formation). X-ray photoelectron spectroscopy (XPS) analyzes the chemical states of surface species and helps understand the formation of solid-electrolyte interphase (SEI) layers.

- Gas chromatography-mass spectrometry (GC-MS): This technique identifies gaseous byproducts released during battery operation, revealing potential decomposition pathways.

By combining these methods, we can build a comprehensive picture of degradation mechanisms, pinpoint the root causes of capacity fade and power loss, and guide the design of more durable materials. For example, observing SEI growth on the anode through SEM and XPS helps us understand how to design electrolytes that minimize this phenomenon.

Q 25. How can you improve the cycle life of a battery?

Extending a battery’s cycle life requires a holistic approach focusing on both materials and cell design. Here are key strategies:

- Optimize electrode materials: Using materials with inherent structural stability, such as those with robust crystal structures, and reducing particle size to minimize strain during cycling. This lessens mechanical stress and improves cycling stability.

- Improve electrolyte formulation: Developing electrolytes with wider electrochemical windows, higher ionic conductivity, and better compatibility with electrode materials minimizes parasitic reactions and SEI growth.

- Enhance cell design: Optimizing the cell architecture (e.g., using 3D structures to enhance electrode utilization) and employing effective thermal management strategies to reduce temperature-induced degradation.

- Surface modifications: Coating electrode materials with protective layers to prevent direct contact with the electrolyte and inhibit side reactions.

- Pre-lithiation strategies: Ensuring sufficient lithium ions are present in the anode initially, avoiding initial capacity loss and enhancing cycle life.

For instance, using silicon as an anode material can drastically improve energy density but at the cost of rapid capacity fading. Research focuses on strategies like nano-structuring and surface coating to enhance silicon’s cycle life and make it commercially viable.

Q 26. Describe the process of designing a new cathode or anode material.

Designing new cathode or anode materials is a complex process involving iterative cycles of material synthesis, characterization, and electrochemical testing. It often involves a deep understanding of materials science, electrochemistry, and computational modeling.

- Identify target properties: Define desired performance metrics such as energy density, power density, cycle life, safety, and cost.

- Material selection: Choose candidate materials based on theoretical predictions, literature reviews, and existing knowledge of relevant material properties. This stage might involve using computational tools to predict material properties and screen potential candidates.

- Synthesis and characterization: Synthesize the chosen materials using various techniques like sol-gel, solid-state reactions, or co-precipitation. Characterize the synthesized materials using various methods mentioned previously (XRD, SEM, TEM, etc.) to ensure they have the desired properties and crystal structures.

- Electrochemical testing: Evaluate the electrochemical performance of the new material in a battery cell using techniques such as cycling tests, rate capability tests, and electrochemical impedance spectroscopy.

- Iterative optimization: Analyze the electrochemical data and material characterization results to identify areas for improvement and modify the material synthesis process or explore alternative materials. This involves multiple rounds of synthesis, characterization, and testing until the desired performance is achieved.

For example, the design of high-nickel layered oxide cathodes involves manipulating the composition and morphology to balance energy density and cycle life. This is an iterative process, where each iteration refines the material properties and improves the overall performance.

Q 27. What are some current research trends in cathode and anode materials?

Current research trends in cathode and anode materials are driven by the need for higher energy density, improved safety, faster charging rates, and lower cost. Key areas include:

- High-energy-density cathodes: Development of high-nickel layered oxides, lithium-rich layered oxides, and other advanced cathode materials to increase energy density. These materials face challenges related to structural stability and cycle life.

- Silicon-based anodes: Overcoming the limitations of silicon anodes (huge volume change during cycling) through nano-structuring, alloying, or coating strategies.

- Lithium-sulfur batteries: Exploring high-energy-density lithium-sulfur batteries, despite challenges related to the dissolution of polysulfides and shuttle effect.

- Solid-state batteries: Researching novel solid-state electrolytes with high ionic conductivity and wide electrochemical windows, aiming to enhance safety and energy density.

- Sustainable and cost-effective materials: Investigating earth-abundant and low-cost materials for cathodes and anodes to reduce the reliance on critical raw materials.

These advancements are often intertwined, with improvements in one area necessitating progress in others. For example, high-energy-density cathodes often require improved electrolytes and anodes to fully realize their potential.

Q 28. How can you ensure the safety of lithium-ion batteries?

Ensuring the safety of lithium-ion batteries is paramount, particularly given their widespread use in portable electronics, electric vehicles, and energy storage systems. Safety measures encompass various aspects:

- Material selection: Choosing inherently safe materials with high thermal stability and low flammability. This includes using safer electrolytes, separator materials, and cathode/anode materials with improved thermal stability.

- Cell design: Incorporating safety features like internal pressure relief valves and current interrupt devices to prevent thermal runaway. This might also involve using specific cell designs that inherently reduce the likelihood of thermal events.

- Battery management systems (BMS): Implementing sophisticated BMS to monitor critical parameters such as temperature, voltage, and current. The BMS can take actions like limiting charging/discharging rates or shutting down the battery if unsafe conditions are detected.

- Thermal management: Designing effective thermal management strategies, such as using cooling systems or thermally conductive materials, to regulate battery temperature and prevent overheating.

- Testing and certification: Rigorous testing procedures are vital to evaluate battery safety under various conditions (overcharge, short circuit, mechanical abuse, etc.). Independent certifications ensure that batteries meet safety standards.

For instance, the use of solid-state electrolytes is a significant step toward enhancing battery safety by eliminating the flammable liquid electrolytes. However, these new materials need further development to address their limitations in ionic conductivity and cost.

Key Topics to Learn for Cathode and Anode Analysis Interview

- Electrode Potentials and Standard Reduction Potentials: Understanding the principles governing electrode potential and its significance in predicting redox reactions at the cathode and anode.

- Electrolytic and Galvanic Cells: Differentiating between these cell types, analyzing their operation, and predicting the reactions occurring at each electrode.

- Faraday’s Laws of Electrolysis: Applying Faraday’s laws to quantitatively determine the amount of substance deposited or liberated during electrolysis.

- Nernst Equation: Calculating electrode potentials under non-standard conditions and understanding its implications for electrochemical analysis.

- Overpotential and Polarization: Analyzing the factors influencing overpotential and its impact on the efficiency of electrochemical processes.

- Corrosion and its Prevention: Applying principles of cathode and anode analysis to understand corrosion mechanisms and develop effective prevention strategies.

- Practical Applications: Exploring real-world applications of cathode and anode analysis in various industries, such as electroplating, battery technology, and corrosion engineering.

- Troubleshooting Electrochemical Experiments: Identifying and resolving common issues encountered during experiments involving cathode and anode analysis.

- Advanced Techniques: Familiarizing yourself with advanced techniques like voltammetry, amperometry, and chronopotentiometry if relevant to the specific role.

Next Steps

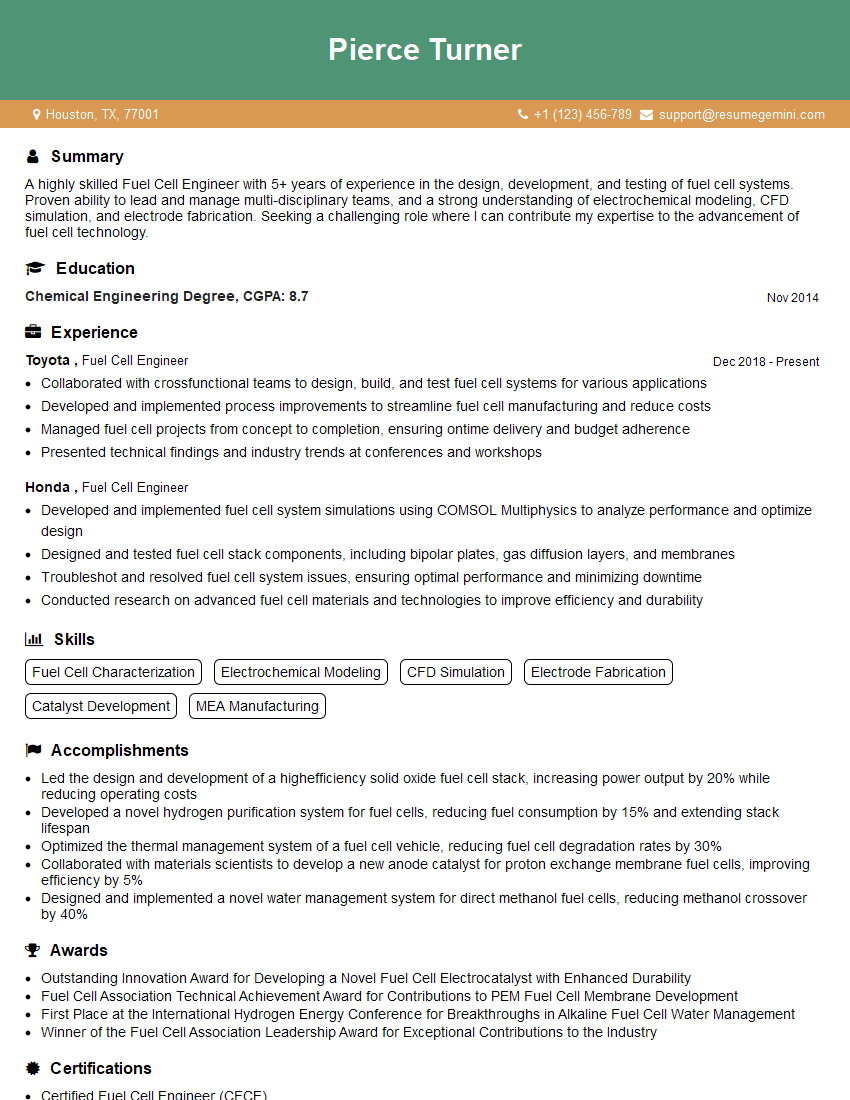

Mastering Cathode and Anode Analysis is crucial for career advancement in many scientific and engineering fields. A strong understanding of these principles opens doors to exciting opportunities in research, development, and manufacturing. To maximize your job prospects, it’s essential to present your skills effectively. Building an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that highlights your expertise in Cathode and Anode Analysis. We provide examples of resumes tailored to this specific field to guide you in creating a standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good