Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Fabric Screen Printing interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Fabric Screen Printing Interview

Q 1. Explain the screen printing process step-by-step.

Screen printing, also known as silkscreen printing, is a versatile method for transferring images onto various substrates. It involves pushing ink through a mesh stencil onto the material. Let’s break down the process step-by-step:

- Design Preparation: Your artwork is prepared digitally, ensuring it’s optimized for screen printing. This might involve separating colors for multi-color prints.

- Film Output: The design is output onto a transparent film (usually a positive), using a high-resolution film output device. This film acts as a blueprint.

- Screen Preparation: A screen, which is a frame holding a fine mesh fabric, is coated with a photosensitive emulsion. The emulsion makes the mesh sensitive to light.

- Exposure: The film positive is placed on the coated screen and exposed to UV light. The light hardens the emulsion where it isn’t blocked by the film, creating the stencil. This leaves the areas that will receive ink open, while the other areas remain blocked.

- Washing Out: The unexposed emulsion is washed away, leaving behind a stencil representing the design.

- Screen Setup: The prepared screen is mounted on a screen printing press. The substrate (T-shirt, bag, poster etc.) is then placed on the press.

- Ink Application: Ink is applied to the screen’s top, and a squeegee is used to push the ink across the mesh. The ink passes through the open areas of the stencil and onto the substrate, forming your design.

- Drying and Curing: Depending on the type of ink used, the printed garment may need to be flash-cured (using a heat gun) or cured in a conveyor dryer to set the ink permanently.

- Post-Printing: The printed pieces are inspected and cleaned. In multi-color prints, this process is repeated for each color, aligning the screens precisely.

Imagine it like using a stencil with spray paint, but on a much larger scale and with more control.

Q 2. What are the different types of screen printing inks?

The world of screen printing inks is vast, offering various properties tailored to different substrates and desired effects. Here are some key types:

- Plastisol Inks: These are the most common, known for their vibrant colors, excellent opacity, and durability. They’re widely used for apparel and promotional items.

- Water-Based Inks: Environmentally friendly, these inks are softer to the touch and have a more natural feel. However, they may require special curing methods.

- Discharge Inks: These are used to remove color from already dyed fabrics, revealing a different color beneath or creating a bleached effect.

- UV-Curable Inks: These inks cure quickly upon exposure to ultraviolet light, making them suitable for high-speed production.

- High-Build Inks: These provide a raised, textured effect on the print. They are popular for adding dimension to a design.

- Specialty Inks: This category includes inks with glitter, metallic effects, glow-in-the-dark properties, and more.

Q 3. Describe the difference between plastisol and water-based inks.

Plastisol and water-based inks differ significantly in their composition, feel, and curing process.

- Plastisol: Oil-based and thicker, plastisol inks offer vibrant, opaque colors and exceptional durability. They are less likely to crack or fade when washed, making them ideal for t-shirts and items that will undergo frequent wear and tear. They require a heat cure to fully bond to the fabric.

- Water-Based: These are thinner and more environmentally friendly. They create a softer, more breathable feel on the fabric. Water-based inks cure faster than plastisols and require careful curing to avoid cracking, especially on stretchy fabrics. Water-based inks often have a slightly less vibrant color intensity than plastisols.

Think of it like this: plastisol is like a durable, glossy paint, whereas water-based ink is more like a softer, breathable fabric dye.

Q 4. How do you choose the correct mesh count for a specific design?

Mesh count refers to the number of threads per inch (TPI) in the screen’s mesh fabric. Choosing the right mesh count is crucial for achieving the desired print quality.

- Fine Mesh (high TPI, e.g., 156-230): Used for fine details and intricate designs, requiring more precise ink deposit. Ideal for delicate artwork and small text.

- Medium Mesh (medium TPI, e.g., 110-156): A versatile option suitable for a wide range of designs, balancing detail with ink flow. Works well for most applications.

- Coarse Mesh (low TPI, e.g., 43-86): Used for large areas of solid color and bold graphics where detailed reproduction isn’t critical. Allows for faster printing and higher ink deposit.

For example, a design with fine lines and small text would require a higher mesh count (e.g., 190 TPI), while a design with large, bold blocks of color could use a lower mesh count (e.g., 86 TPI). Always consider the design’s complexity and the ink viscosity when choosing a mesh count.

Q 5. Explain the importance of emulsion in screen printing.

Emulsion is a photosensitive coating applied to the screen fabric. It’s the crucial ingredient that creates the stencil. Without emulsion, there would be nothing to block the ink and create the design.

The emulsion’s light sensitivity allows it to harden when exposed to UV light. Areas exposed to light become insoluble, forming the stencil; areas shielded remain soluble and wash away, leaving open areas of the mesh for ink to pass through. There are diazo and photopolymer emulsions, each with their own properties.

Imagine emulsion as the invisible barrier that separates the areas where ink should print and where it shouldn’t.

Q 6. What are some common screen printing defects and how do you correct them?

Several defects can occur during screen printing. Identifying and addressing them is critical for quality control.

- Pinholes: Tiny holes in the stencil allow ink to seep through unwanted areas. This can be caused by improper emulsion coating or exposure. Solution: Re-coat the screen or use a finer mesh.

- Halftone Dots: The halftone dots of the image appear blurred or unclear. This is usually caused by an incorrect mesh count or poor image resolution. Solution: Increase mesh count for better detail; use higher-resolution artwork.

- Missing Areas: Portions of the design are missing. Possible causes include incomplete emulsion exposure, clogged stencil areas, or improper squeegee technique. Solution: Check for and remove any clogs. Ensure proper exposure of the emulsion and proper squeegee technique. Re-expose the screen, if necessary.

- Smearing: Ink bleeds into adjacent areas. Causes include using too much ink, improper squeegee pressure, or non-compatible inks. Solution: Reduce ink amount, adjust squeegee angle and pressure, and check ink compatibility.

Experienced screen printers carefully analyze print defects to determine root causes and adjust techniques accordingly.

Q 7. How do you register multiple colors in a multi-color print?

Registering multiple colors accurately is essential for multi-color prints. This involves aligning each color precisely to create a sharp, well-defined final image.

Several techniques are used:

- Using Registration Marks: Registration marks (small, precise marks) are included in the artwork and printed first. These marks serve as guides for aligning subsequent color screens.

- Precise Screen Placement: The screens are carefully positioned on the press using the registration marks as reference points. This requires precision and patience.

- Micro-Registration: Advanced presses employ micro-registration systems to ensure pinpoint accuracy, improving color alignment.

- Pallet System: Some printers use a pallet system where the screens are mounted on accurate plates, making sure that the print on the previous screen is not moved.

Imagine building with Lego; each color is a different brick that must be precisely placed to create the final image. Proper registration ensures that all the ‘bricks’ fit together perfectly.

Q 8. Describe your experience with different types of printing presses (e.g., manual, automatic).

My experience spans both manual and automatic screen printing presses. Manual presses, like the trusty Vastex V-1000, offer incredible control and are perfect for smaller runs or intricate designs. They require more physical effort but allow for precise adjustments on the fly, ideal for perfecting registration and ink deposition. Think of it like hand-painting – you have complete command over every detail. Automatic presses, such as those from M&R, significantly increase production speed and efficiency, making them essential for high-volume orders. These are like assembly lines for shirts, consistently producing prints with minimal variation. I’m proficient in setting up, operating, and troubleshooting both types, understanding their strengths and limitations depending on the job requirements.

For example, I’ve used a manual press to create unique, hand-numbered art prints on high-end fabrics, where the slight variations added character. Conversely, I’ve relied on an automatic press to fulfill a large order of t-shirts for a music festival, prioritizing speed and consistency.

Q 9. How do you maintain and clean your screen printing equipment?

Maintaining and cleaning screen printing equipment is crucial for consistent print quality and longevity. After each print run, I meticulously clean the screens using a degreaser and a pressure washer, ensuring no ink residue remains. This prevents clogging and ensures vibrant color in subsequent prints. The squeegee and flood bar are cleaned with appropriate solvents to remove ink build-up, maintaining their efficiency and reducing wear. The press itself is regularly inspected for any mechanical issues, and lubrication is applied as needed. I also routinely check the alignment and tension of the screens to maintain accurate registration.

Think of it like maintaining a finely-tuned engine; regular maintenance prevents costly breakdowns and ensures optimal performance. Neglecting this can result in poor print quality, screen damage, and costly downtime.

Q 10. What safety precautions do you take while screen printing?

Safety is paramount in screen printing. I always wear appropriate personal protective equipment (PPE), including safety glasses to protect my eyes from ink splashes and solvents, gloves to protect my hands from chemicals, and a respirator to prevent inhalation of potentially harmful fumes. The workspace is kept clean and organized to prevent accidents. I properly handle and store chemicals according to manufacturer instructions, ensuring adequate ventilation. Furthermore, I understand and adhere to all relevant OSHA regulations and company safety protocols.

For example, I never mix different chemicals without understanding the potential reactions, and I always ensure the area is well-ventilated when using harsh solvents.

Q 11. What is your experience with different types of fabrics?

My experience encompasses a wide variety of fabrics, including cotton, polyester, blends, and even more delicate materials like silk and linen. Each fabric has unique properties that influence the printing process. Cotton, for instance, is absorbent and generally easy to print on, while polyester requires different inks and curing techniques due to its synthetic nature. Delicate fabrics necessitate gentler handling and specialized low-temperature curing methods to prevent damage. I understand the different pretreatment needs based on the fabric composition, ensuring optimal ink adhesion and preventing bleeding.

Working with silk, for example, requires a much more delicate approach than printing on heavy cotton canvas. The choice of ink, pressure, and curing method is crucial for a successful print without damaging the fabric.

Q 12. How do you handle fabric pre-treatment?

Fabric pretreatment is crucial for achieving vibrant, long-lasting prints. It prepares the fabric to properly accept the ink, enhancing adhesion and preventing bleeding. The method depends on the fabric type. For cotton, a pre-wash might be sufficient to remove sizing, while other materials may require a chemical pretreatment to improve ink absorption. This might involve applying a bonding agent to enhance the ink’s grip on synthetic fabrics. The chosen pretreatment method will ensure that the ink adheres effectively and the print lasts for a longer time.

Imagine trying to paint on a greasy surface – the paint would bead up and wouldn’t adhere properly. Pretreatment is essentially preparing the fabric surface to be a perfect canvas for the ink.

Q 13. How do you troubleshoot a clogged screen?

A clogged screen is a common issue in screen printing. Troubleshooting begins with identifying the cause – is it dried ink, emulsion build-up, or a combination? I start by flushing the screen with a suitable solvent, using a pressure washer if necessary. If that doesn’t work, I might use a screen cleaning solution to dissolve stubborn ink clogs. For particularly stubborn clogs, I’ll use a specialized screen mesh cleaning tool. If the clog is within the emulsion itself, the screen may need to be reclaimed and re-coated with fresh emulsion.

Identifying the root cause – whether it’s old ink, improper cleaning, or emulsion breakdown – is key to effectively resolving the clog and preventing future occurrences. It’s like unclogging a drain; you need to identify what’s causing the blockage before you can effectively clear it.

Q 14. What is your experience with flash curing?

Flash curing is a crucial step in the screen printing process, partially curing the ink before the final cure. It sets the ink enough to prevent smudging during the printing process, especially when multiple colors are used. I use a flash dryer, adjusting the temperature and conveyor speed depending on the ink type and fabric. Flash curing ensures that the subsequent layers of ink don’t bleed into previously printed colors, maintaining sharp lines and accurate color registration. It also helps increase production speed by allowing faster layering of colors.

Think of it as a quick setting agent – it allows you to build upon your previous work without disturbing the layers underneath.

Q 15. Describe your experience with different drying methods.

Drying methods in fabric screen printing are crucial for ensuring the ink adheres properly and the final product is durable. I’ve extensive experience with several techniques, each with its own pros and cons.

- Flash curing: This uses a low-temperature dryer to partially cure the ink immediately after printing. It’s essential for multi-layered designs, preventing the next layer from smudging the previous one. For instance, when printing a complex design with fine details requiring several colors, flash curing is a must. It’s like setting a glue – you want it tacky enough to hold the next layer, but not fully set yet.

- Convection drying: This involves using a forced-air dryer, often a large oven-like unit, which circulates hot air around the garments. It’s efficient for larger batches and provides even drying. We use this method extensively for bulk orders of t-shirts or tote bags. Think of it like baking a batch of cookies – you want consistent heat distribution for even results.

- Conduction drying: Less common in our process, this method uses direct heat transfer, often through a heated platen. While fast, it requires careful control to prevent scorching. It might be preferable for certain heat-sensitive materials or specific inks. It’s a bit like grilling – you need close attention to avoid burning.

- Infrared drying: Infrared lamps emit heat that penetrates the ink, leading to quick drying. It’s particularly useful for water-based inks where faster drying is beneficial. Think of it like using a hairdryer – a focused and quick approach to drying.

The choice of drying method depends heavily on factors such as the type of ink used (plastisol, water-based, discharge), the fabric material, the design complexity, and the production volume. My experience allows me to select the optimal method for each project, ensuring quality and efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate ink costs for a project?

Calculating ink costs accurately is vital for profitability. I follow a structured approach:

- Determine ink usage per design: This involves testing the ink consumption for each color and design element. I maintain detailed records of ink usage per square inch or per garment. For example, a complex design with many fine details will naturally use more ink than a simple, solid-color print.

- Calculate the total ink needed: Once the per-unit ink usage is known, I multiply it by the total number of garments to be printed. I also factor in potential waste, typically around 5-10%, to account for screen cleaning, misprints, and other unforeseen circumstances. We might add a buffer for potential cleanup or minor errors; a 10% waste margin is common.

- Factor in ink cost per unit: The cost per unit volume (e.g., liter, gallon) of each ink is crucial. I keep a running spreadsheet of current ink prices from my suppliers, ensuring prices are up-to-date.

- Calculate total ink cost: Finally, I multiply the total volume of ink needed by the cost per unit volume to obtain the total ink cost for the project. This cost is then incorporated into the overall project pricing.

This approach ensures transparency and accuracy in project costing, which is critical for providing fair pricing to clients and maintaining a healthy profit margin.

Q 17. How do you manage inventory of inks and supplies?

Efficient inventory management is key to smooth production. My strategy involves a multi-pronged approach:

- Regular stock checks: Weekly physical checks of ink and supply levels ensure we don’t run out of crucial materials mid-project. I meticulously record the quantity of each item.

- First-In, First-Out (FIFO): To prevent ink from expiring, I use a FIFO system, ensuring older inks are used first. This minimizes waste and maintains ink quality.

- Digital inventory management system: I leverage a spreadsheet or dedicated inventory software to track stock levels, purchase dates, and expiration dates. This provides a real-time overview of our inventory.

- Minimum stock levels: We maintain minimum stock levels for commonly used inks and supplies, ensuring uninterrupted production. This is calculated based on average usage and lead times from our suppliers.

- Supplier relationships: Strong relationships with our suppliers allow for reliable, timely replenishment of materials.

This integrated system minimizes storage costs, prevents stockouts, and ensures we always have the materials needed for our projects.

Q 18. Explain your experience with color separation.

Color separation is the process of breaking down a complex design into individual color components, each destined for its own screen. My experience includes both manual and digital methods.

- Manual color separation: While less common now, I’ve experience in manually separating colors using techniques like tracing and overlaying. This requires a keen eye for detail and an understanding of color mixing. It’s like creating a layered painting, where each color layer is represented by its own screen.

- Digital color separation using software: Today, we primarily use software like Adobe Photoshop and Illustrator for digital color separation. This allows for precise control and efficient separation of even complex designs. The software automatically creates separate color channels, minimizing errors and maximizing accuracy. It is more efficient and accurate than manual processes.

My expertise lies in selecting the appropriate method based on design complexity and project requirements. I understand the importance of accurate color separation for achieving the desired result. An inaccurate separation can result in a mismatched or faded final product.

Q 19. How do you create a screen from a design?

Creating a screen from a design involves several key steps:

- Film positive creation: A high-resolution film positive, a reverse image of the design, is created using software such as Adobe Illustrator or Photoshop. This is the blueprint for the screen. Think of it as a photographic negative that dictates what will be printed.

- Coating the screen: A photosensitive emulsion is carefully coated onto the screen mesh, ensuring even coverage. This emulsion is light-sensitive, like photo paper, but used on fabric.

- Exposure: The coated screen is then exposed to a strong light source (usually UV light) through the film positive. The exposed areas harden, while the unexposed areas remain soft. This is the crucial step that creates the stencil.

- Washing out: The unexposed emulsion is washed away, leaving behind a hardened stencil on the mesh. This stencil defines the areas where the ink will pass through. Think of washing out unwanted parts of a stencil.

- Screen drying: The screen is thoroughly dried before use to ensure the stencil is stable and durable. This is similar to drying the photo paper after printing.

This process requires precision and attention to detail. Any inconsistencies can lead to blurred prints or ink bleeding. My years of experience ensure I consistently create high-quality screens that result in crisp, clean prints.

Q 20. What software are you proficient in for screen printing design?

I am proficient in several software applications crucial for screen printing design:

- Adobe Photoshop: Used for image editing, color correction, and raster-based design work. I use it to refine artwork, adjust colors, and prepare images for screen separation. For example, I’ll use Photoshop to fix image imperfections or adjust colors before separating layers for printing.

- Adobe Illustrator: Used for vector-based design, creating scalable artwork, and preparing files for screen separation. I use this to create sharp lines and design complex, repeatable elements. For logos or designs that need to be scaled, Illustrator is the go-to software.

- CorelDRAW: An alternative to Illustrator, used for vector design and file preparation for screen printing. I’ve used this extensively in the past and find it a robust option.

My skills extend to manipulating files in various formats (.ai, .eps, .psd, .pdf) and preparing them for optimal screen printing. This includes ensuring appropriate resolution and color modes for high-quality output.

Q 21. Describe your experience with film positives.

Film positives are crucial for screen printing; they act as the blueprint for creating the screen stencil. My experience encompasses various aspects of film positive creation and management.

- Film positive creation: I’m skilled in creating film positives using both traditional film output devices and digital methods using software. Digital methods offer greater control and precision.

- Film positive handling: I understand the importance of careful handling to prevent damage or scratching, which could impact print quality. The handling is very important; even a small scratch on the film can result in an imperfect print.

- Film positive storage: Proper storage is essential to maintain the quality and longevity of film positives. We store them in protective sleeves and in a cool, dark place to prevent deterioration.

- Troubleshooting film positive issues: I can diagnose and troubleshoot issues such as incorrect exposure, film defects, or alignment problems that can arise during the film positive creation and screen printing process.

My proficiency in this area ensures that each screen is created accurately, leading to consistent and high-quality prints. A good film positive directly translates to a quality screen, and therefore, a quality final product.

Q 22. How do you determine the appropriate amount of pressure for a print?

Determining the correct printing pressure is crucial for achieving high-quality prints in fabric screen printing. Too little pressure results in weak, faint prints, while too much pressure can cause the ink to seep under the screen, resulting in blurry or smeared images. The ideal pressure ensures a clean, crisp transfer of ink to the fabric.

We determine the appropriate pressure through a combination of experience and testing. Factors to consider include the mesh count of the screen (higher count means finer detail, requiring less pressure), the ink viscosity (thicker inks need more pressure), and the fabric type (thicker fabrics may need more pressure). We typically start with a lower pressure and gradually increase it, testing on a scrap piece of fabric until we achieve the desired result. This involves carefully observing the print’s sharpness, ink saturation, and absence of bleeding. Think of it like baking a cake; you need the right amount of heat and time for optimal results. Too little or too much pressure in screen printing is comparable to under or over-baking.

Q 23. How do you ensure consistent print quality?

Consistent print quality is paramount in screen printing. Maintaining consistency involves a multi-faceted approach, encompassing meticulous attention to detail throughout the entire process.

- Screen Preparation: Ensuring the screen is properly stretched, degreased, and emulsion is evenly applied is critical for consistent ink flow and print quality.

- Ink Consistency: Maintaining a uniform ink viscosity is essential. We regularly stir the inks and use color consistency charts. Adding a retarder to slow the drying process helps to minimize the variations that may occur with large printing runs

- Pressure and Speed: As mentioned earlier, maintaining consistent pressure is vital. A regulated squeegee stroke speed ensures even ink distribution across the print.

- Flash Curing: Flash curing between color layers (for multi-color prints) helps to prevent color smearing and ensures proper adhesion.

- Careful Handling: Avoid damaging prints during the drying and handling process. This includes using appropriate storage and transportation methods.

Regular quality checks are essential; we inspect prints at various stages of the process to immediately catch and correct any inconsistencies. This is a proactive method to ensure that a high standard is achieved before moving on.

Q 24. What are your strategies for improving efficiency in screen printing?

Improving efficiency in screen printing requires a streamlined workflow and the adoption of time-saving techniques. This involves optimizing each stage of the process.

- Automation: Where feasible, automated systems can significantly improve efficiency. Automated screen printing machines can handle large volumes of prints faster and with greater consistency.

- Optimized Workflow: Careful planning is vital to ensure that the process flows seamlessly, and we minimize downtime. This involves organizing the work area and pre-planning print layouts and designs.

- Pre-press Preparation: Creating efficient film positives, reducing the time needed for screen exposure and preparation.

- Proper Maintenance: Keeping equipment in peak condition minimizes downtime due to repairs.

- Teamwork and Training: A well-trained team is essential for efficient operations. Regular training on proper techniques and safety procedures ensures that the process remains fluent and that errors are minimized.

For example, we implemented a new workflow management system that reduced our turnaround time for large orders by 15%.

Q 25. How do you handle large-scale printing projects?

Handling large-scale printing projects requires careful planning and execution. We utilize a project management approach to ensure that everything runs smoothly.

- Detailed Planning: This involves breaking down the project into smaller, manageable tasks. Creating a detailed schedule allows us to accurately track progress and identify potential bottlenecks.

- Resource Allocation: Securing sufficient resources, such as screens, inks, and personnel is crucial. We always factor in contingency plans for unexpected delays or shortages.

- Quality Control: Rigorous quality control measures are implemented throughout the project. Regular checks help to identify and address any issues early on.

- Teamwork and Communication: Clear communication among the team is essential. Regular team meetings, progress updates, and clear task assignments help to ensure that everyone is on the same page.

- Automation and Technology: Employing automated equipment and technology whenever possible, streamlines production and reduces human error.

For instance, for a recent large-scale order of 5,000 t-shirts, we divided the project into smaller batches, using multiple printing stations, and implementing a quality check at each stage.

Q 26. Describe a time you had to solve a problem during a printing job.

During a large university apparel order, we encountered a significant problem with screen registration – the images on subsequent colors weren’t aligning properly, resulting in misaligned prints. This was devastating, as the university logo was multi-color, and the misalignment made the shirts unsellable.

First, we analyzed the root cause. We discovered that the problem wasn’t with the screen itself but with the alignment pins on the printing press, they were slightly loose and causing a minute shift between prints. Our problem-solving strategy involved: 1) immediately halting production; 2) carefully adjusting the alignment pins; 3) establishing a more rigid system for checking alignment before starting each batch; and finally 4) conducting test prints to ensure the corrected alignment before resuming the job.

This experience taught us the critical importance of meticulous preventative maintenance and thorough quality checks throughout the printing process. The lesson was learned at a cost, but it strengthened our preventative maintenance schedule.

Q 27. What are some industry best practices for sustainable screen printing?

Sustainable screen printing practices are crucial for minimizing environmental impact. It’s a growing concern among clients and is very important to us.

- Eco-Friendly Inks: Using water-based or solvent-free inks reduces the environmental impact significantly. These inks are less harmful and easier to clean up.

- Waste Reduction: Careful planning minimizes ink wastage and reduces the volume of waste generated. This includes accurately calculating ink requirements and reusing or recycling materials where possible.

- Energy Efficiency: Using energy-efficient equipment and minimizing energy consumption is important. This involves employing LED lighting and optimized equipment.

- Water Conservation: Implementing water-saving cleaning techniques and using water-efficient equipment significantly reduces water usage.

- Responsible Disposal: Proper disposal of waste materials, such as used screens and inks, is crucial. We adhere to all relevant environmental regulations and look for eco-friendly disposal solutions.

We’ve seen a growing demand for sustainable practices, and clients are increasingly willing to pay a premium for environmentally responsible products. We are proud to meet this demand.

Q 28. How do you stay updated on new trends and technologies in screen printing?

Staying updated on the latest trends and technologies in screen printing is essential for remaining competitive and providing cutting-edge services.

- Industry Publications and Trade Shows: Following industry publications, attending trade shows (like SGIA), and networking with other professionals help to stay informed about new technologies and techniques.

- Online Resources and Communities: Engaging with online communities, forums, and groups dedicated to screen printing provides access to valuable information and insights.

- Continuing Education: Attending workshops, seminars, and training courses helps to enhance skills and stay current on the latest industry developments.

- Supplier Relationships: Maintaining strong relationships with suppliers provides access to the latest products and materials.

- Experimentation and Innovation: Trying out new techniques and technologies allows for experimentation and the discovery of new methods that can enhance efficiency and quality.

For example, I recently attended a seminar on digital screen printing, learning new techniques that are improving our efficiency and print quality.

Key Topics to Learn for Fabric Screen Printing Interview

- Screen Preparation: Understanding emulsion types, coating techniques, and exposure methods for creating high-quality screens.

- Image Preparation & Film Positives: Preparing artwork for screen printing, including color separation, halftones, and creating accurate film positives.

- Ink Selection & Mixing: Knowledge of different ink types (plastisol, water-based, discharge), their properties, and techniques for mixing colors accurately.

- Printing Techniques: Mastering various printing methods (flood, flash, off-contact), understanding pressure, and achieving consistent print quality.

- Troubleshooting & Problem Solving: Identifying and resolving common issues like pinholes, screen clogging, and registration problems.

- Press Operation & Maintenance: Familiarity with different types of screen printing presses, their operation, and routine maintenance procedures.

- Safety Procedures & Regulations: Understanding and adhering to safety protocols related to ink handling, equipment use, and waste disposal.

- Fabric Types & Pre-Treatment: Knowledge of different fabrics and their suitability for screen printing, including pre-treatment processes for optimal results.

- Curing & Drying Techniques: Understanding the importance of proper curing and drying methods for different ink types to ensure durability and colorfastness.

- Quality Control & Inspection: Developing a keen eye for detail and implementing quality control measures to maintain consistent print quality throughout the production process.

Next Steps

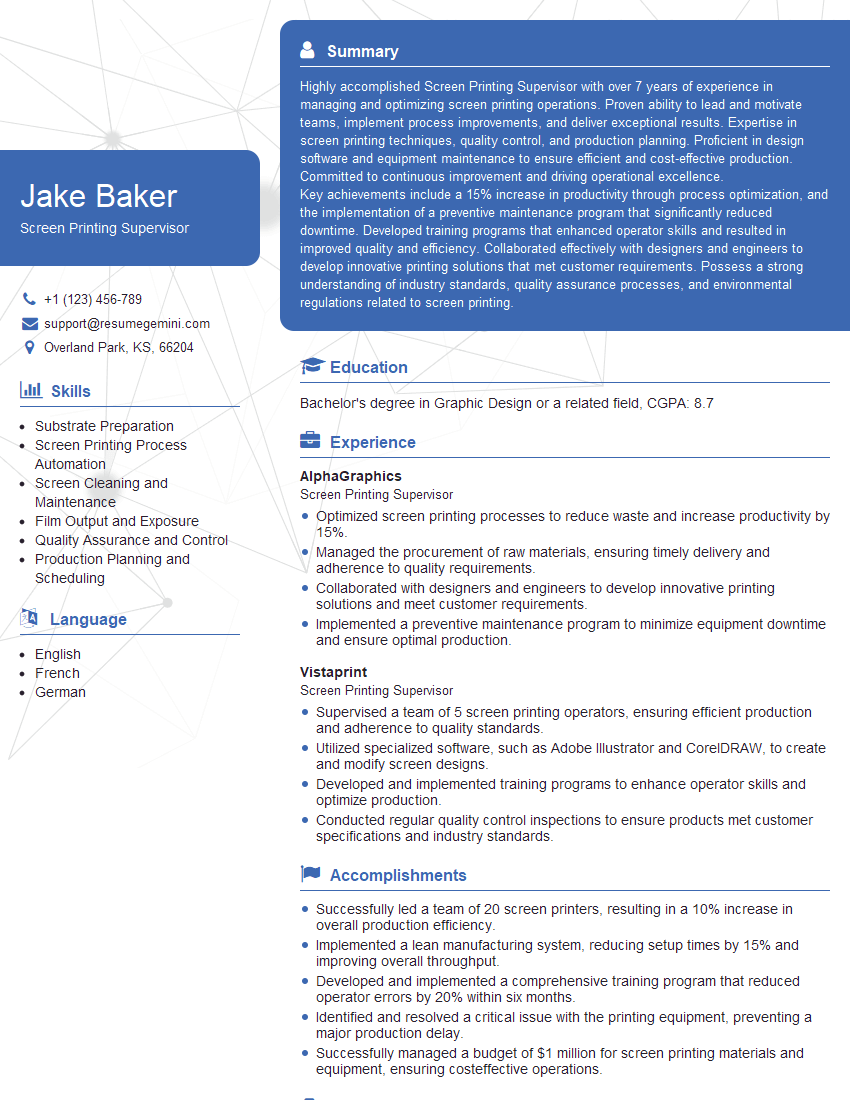

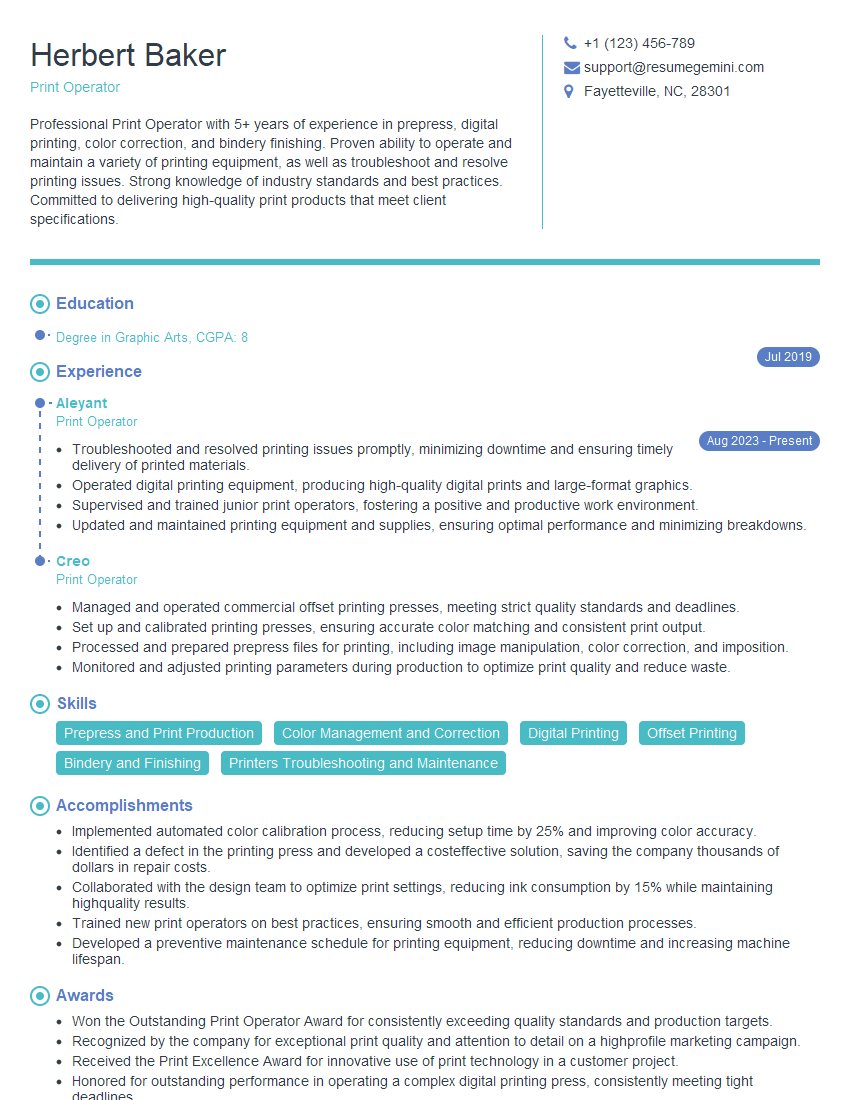

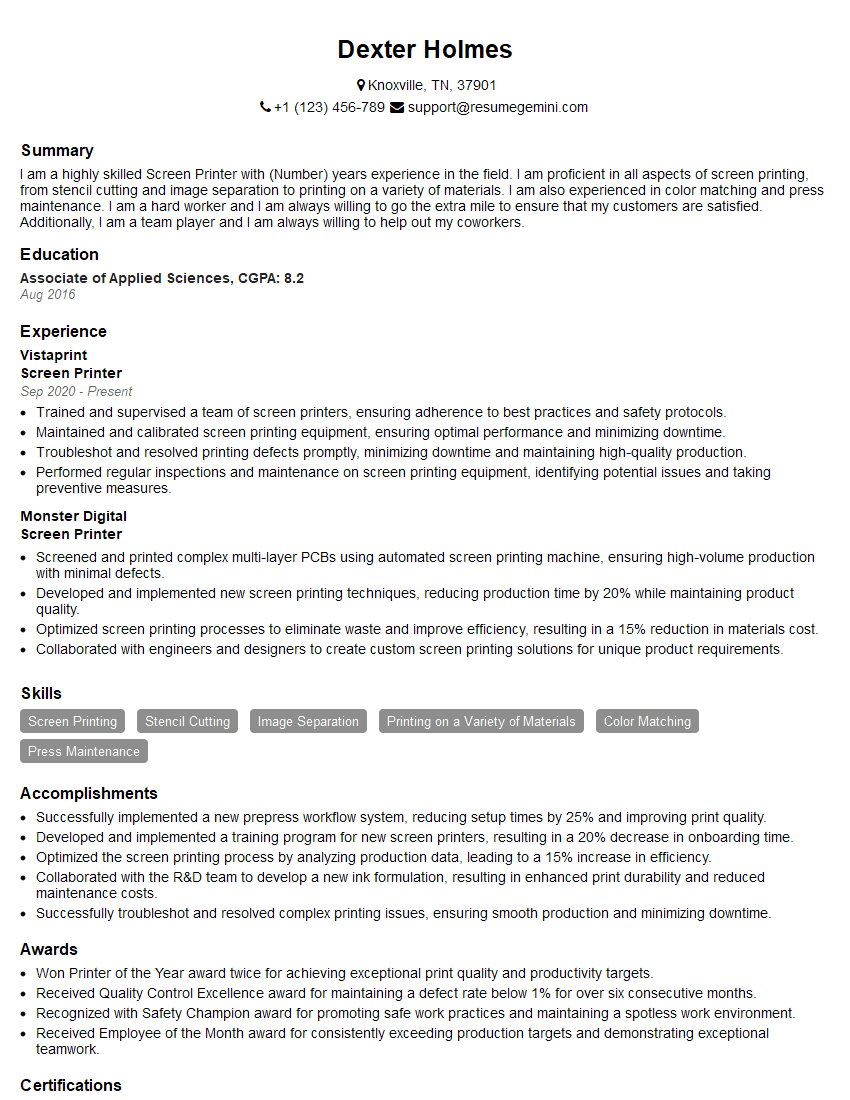

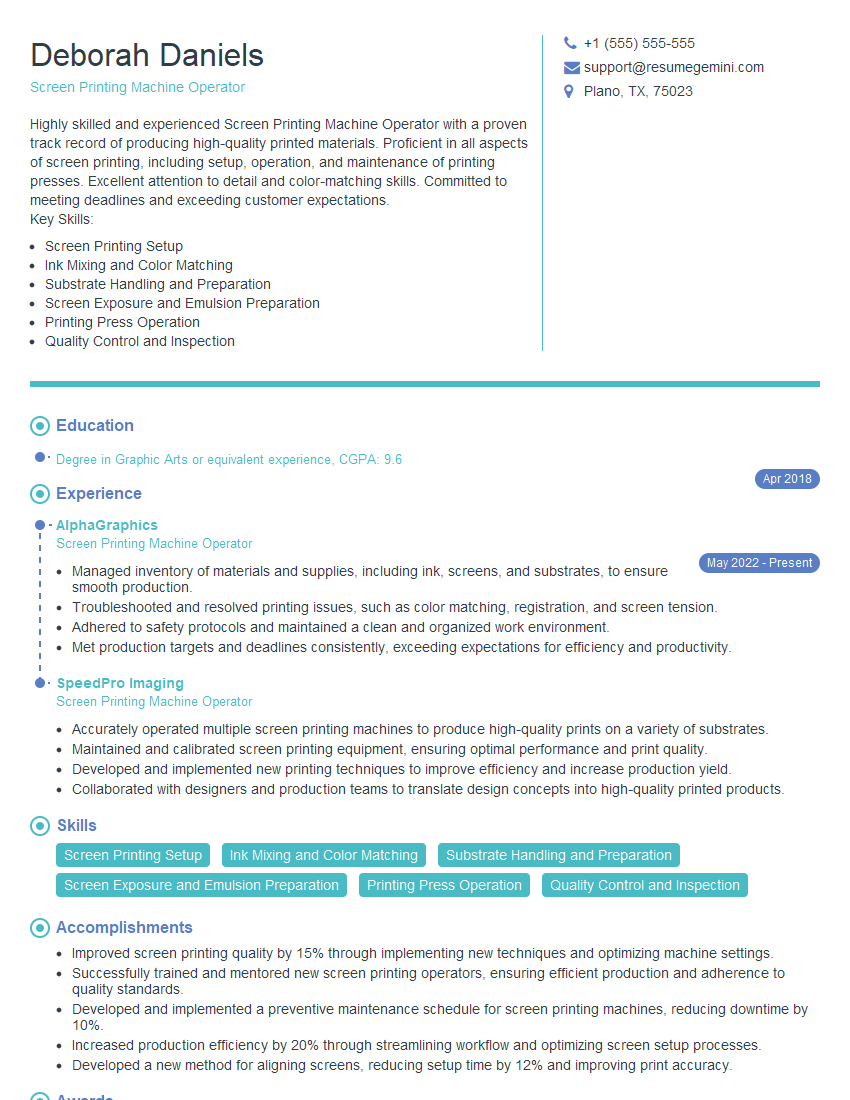

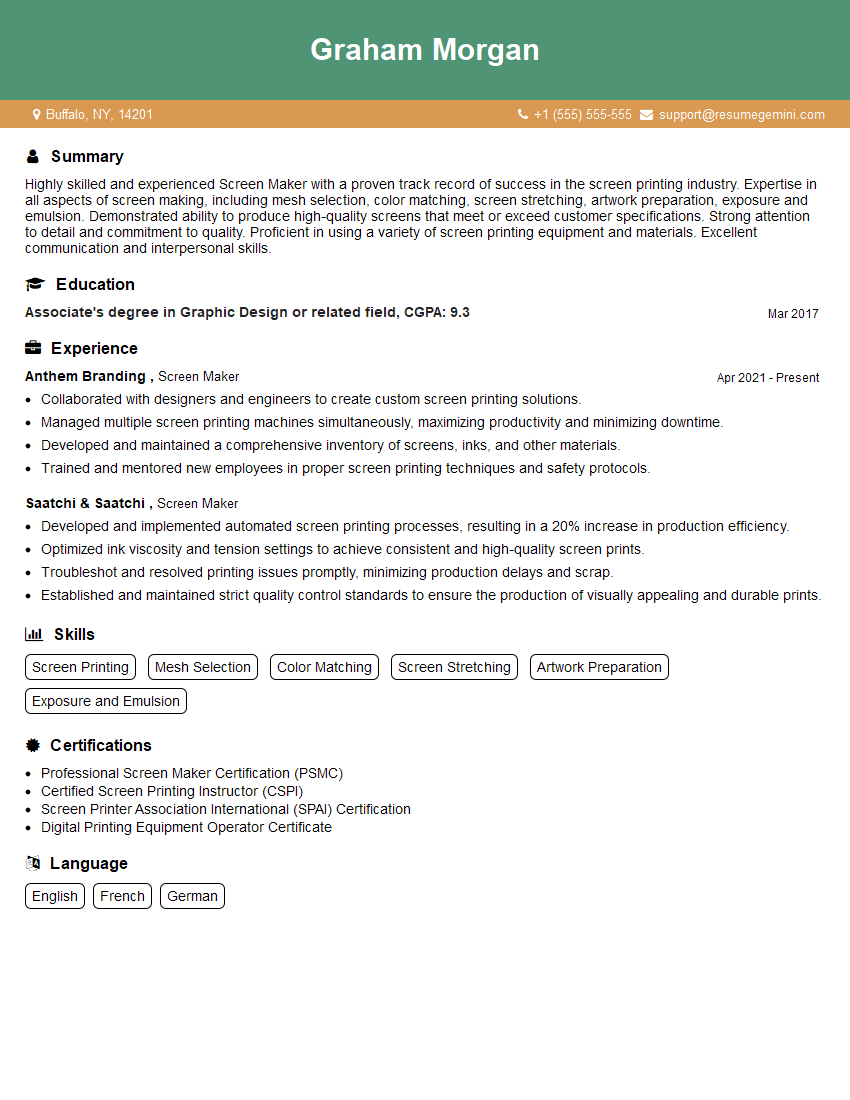

Mastering fabric screen printing opens doors to exciting career opportunities in the apparel, textile, and promotional products industries. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of fabric screen printing jobs. Examples of resumes tailored to this field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good