Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Demolition Planning and Execution interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Demolition Planning and Execution Interview

Q 1. Describe your experience in developing demolition plans.

Developing a demolition plan is like creating a detailed blueprint for a controlled dismantling process. It’s not just about knocking things down; it’s about ensuring safety, efficiency, and minimizing environmental impact. My approach involves several key steps:

- Site Survey and Assessment: This includes a thorough inspection of the structure, noting its material composition, structural integrity, potential hazards (asbestos, lead paint), and proximity to adjacent buildings and utilities.

- Demolition Methodology Selection: This depends on factors like the building’s size, materials, location, and environmental considerations. Options range from selective demolition (removing parts of a building) to complete demolition using various techniques (implosion, high-reach excavators, mechanical demolition).

- Sequence of Operations: We carefully plan the order of demolition, starting with less critical areas and progressing to the main structural elements. This minimizes risks and ensures controlled dismantling.

- Safety Plan Development: A critical component, this includes emergency procedures, worker training, personal protective equipment (PPE) requirements, and traffic control measures.

- Waste Management Plan: We detail how demolition waste will be sorted, transported, and disposed of according to environmental regulations.

- Permitting and Approvals: Obtaining the necessary permits from local authorities is crucial. The demolition plan is a key document in this process.

For example, in a recent project involving a multi-story office building, we opted for a phased demolition approach using high-reach excavators, starting with the upper floors to avoid impacting adjacent structures and utilities.

Q 2. Explain your process for assessing demolition site risks.

Assessing demolition site risks is paramount. It’s a systematic process that requires a keen eye for detail and experience. My process involves:

- Site Reconnaissance: A thorough visual inspection of the structure and its surroundings, identifying potential hazards such as unstable structures, hazardous materials (asbestos, lead, etc.), underground utilities, and nearby structures.

- Structural Analysis: Evaluating the building’s structural integrity to identify potential collapse risks during demolition. This often involves engineering assessments.

- Environmental Assessment: Identifying potential environmental hazards, including soil contamination, groundwater contamination, and the presence of hazardous materials.

- Risk Matrix Development: Creating a matrix that ranks identified risks based on their likelihood and potential severity. This helps prioritize mitigation strategies.

- Mitigation Planning: Developing detailed plans to mitigate identified risks. This might involve specialized equipment, worker training, and specific demolition techniques.

For instance, if asbestos is detected, we’d engage certified asbestos abatement contractors before starting any demolition work, following strict safety protocols.

Q 3. How do you ensure compliance with demolition safety regulations?

Ensuring compliance with demolition safety regulations is non-negotiable. It’s a core principle that guides every aspect of our operations. We achieve this through:

- Thorough Knowledge of Regulations: Staying updated on all relevant local, state, and federal regulations pertaining to demolition, including OSHA standards.

- Permitting and Approvals: Obtaining all necessary permits and approvals before commencing work, ensuring the plan adheres to regulatory requirements.

- Site Safety Officer: Employing a dedicated safety officer to monitor work practices and ensure adherence to safety procedures.

- Regular Safety Inspections: Conducting regular safety inspections to identify and rectify potential hazards.

- Worker Training: Providing comprehensive safety training to all personnel involved in the demolition process.

- Documentation: Meticulously documenting all safety procedures, inspections, and any incidents or near misses.

We maintain comprehensive records to demonstrate full compliance during audits or inspections. This proactive approach prevents accidents and protects workers and the public.

Q 4. What methods do you use to control demolition dust and debris?

Controlling demolition dust and debris is crucial for protecting both worker health and the environment. We employ a multi-pronged approach:

- Water Suppression Systems: Using water sprays to suppress dust generation during demolition activities.

- Dust Enclosures: Constructing temporary enclosures around demolition areas to contain dust.

- High-Efficiency Particulate Air (HEPA) Filters: Utilizing HEPA filters in vacuum systems and other equipment to capture fine dust particles.

- Debris Management Plan: Implementing a well-defined plan for collecting, sorting, and disposing of debris to minimize its spread.

- Regular Cleaning: Frequent cleaning of the site to prevent dust accumulation.

For example, during a recent high-rise demolition, we employed a combination of water sprays and dust enclosures to significantly reduce airborne dust levels, exceeding environmental protection agency standards.

Q 5. How do you manage demolition waste disposal?

Demolition waste management is a critical aspect, involving responsible disposal and minimizing environmental impact. Our process involves:

- Waste Segregation: Sorting demolition waste into different categories (e.g., concrete, wood, metal, hazardous materials) to facilitate recycling and proper disposal.

- Recycling and Reuse: Prioritizing the recycling and reuse of materials whenever possible to reduce landfill waste.

- Hazardous Waste Handling: Following strict procedures for handling and disposal of hazardous materials, in compliance with all relevant regulations.

- Transportation and Disposal: Using licensed haulers to transport demolition waste to approved disposal sites.

- Documentation: Maintaining detailed records of waste generation, transportation, and disposal to demonstrate compliance.

We often work with waste management specialists to ensure optimal recycling rates and environmentally responsible disposal of all materials.

Q 6. Explain your experience with different demolition techniques (e.g., implosion, high-reach excavators).

I have extensive experience with various demolition techniques, each suited to different scenarios. My expertise includes:

- Implosion: This method uses carefully placed explosives to bring down structures quickly and efficiently. It’s suitable for large, complex structures, but requires meticulous planning and safety protocols.

- High-Reach Excavators: These are versatile machines ideal for selective demolition or dismantling buildings piece by piece. They offer greater control and precision compared to implosion.

- Mechanical Demolition: This involves using various machinery such as excavators, crushers, and shears to dismantle structures. It’s cost-effective for smaller buildings or selective demolition.

- Hydraulic Breakers: These powerful attachments are used on excavators to break down concrete and other materials.

The choice of technique depends heavily on the structure’s characteristics, its location, and environmental considerations. For instance, implosion might be appropriate for a large, isolated building, while high-reach excavators would be preferred for a structure near other buildings.

Q 7. Describe your experience in managing demolition budgets and timelines.

Managing demolition budgets and timelines effectively requires careful planning and proactive monitoring. My approach involves:

- Detailed Cost Estimation: Developing a comprehensive budget that accounts for all aspects of the project, including labor, materials, equipment rental, permits, waste disposal, and potential unforeseen costs.

- Realistic Scheduling: Creating a realistic project schedule that considers all phases of the demolition process, including site preparation, demolition, waste removal, and site restoration.

- Regular Monitoring: Tracking progress against the budget and schedule, identifying potential deviations early on and implementing corrective actions.

- Risk Management: Identifying potential cost overruns and delays, developing mitigation strategies to prevent them, and having contingency plans in place.

- Communication: Maintaining clear and open communication with the client, subcontractors, and stakeholders to keep everyone informed of the project’s progress.

For example, in one project, we utilized advanced scheduling software to track progress and identify potential delays in real-time. This allowed us to proactively adjust our approach and complete the project on time and within budget.

Q 8. How do you coordinate demolition activities with other construction projects on-site?

Coordinating demolition with other on-site projects requires meticulous planning and proactive communication. Think of it like a well-orchestrated symphony – each instrument (project) needs to play its part at the right time without disrupting the others.

- Pre-planning is key: Before demolition begins, I meticulously review all project schedules, identifying potential overlaps and conflicts. This includes reviewing access points, material storage areas, and potential noise and dust impacts on adjacent construction activities.

- Dedicated communication channels: I establish clear communication lines with all project managers involved. Regular meetings and progress reports ensure everyone stays informed about the demolition timeline and any potential adjustments. For instance, if a delay occurs in demolition, I’ll immediately notify the team working on the next phase to adjust their schedule accordingly.

- Phased approach: We often break down demolition into phases to minimize disruption. This allows other construction activities to continue in unaffected areas while demolition progresses in a designated section. For example, we might demolish one building wing at a time, ensuring continuous access for other teams.

- Safety protocols: Comprehensive safety protocols are essential, considering the potential hazards of both demolition and ongoing construction activities. This includes establishing clear boundaries, designating safe zones, and implementing strict safety measures to prevent accidents.

Q 9. What software or tools do you use for demolition planning and modeling?

Effective demolition planning relies heavily on advanced software and tools. I utilize a combination of these to ensure accuracy and efficiency.

- 3D Modeling Software (e.g., Autodesk Revit, SketchUp): These programs allow me to create detailed 3D models of the structure, helping to visualize the demolition process, identify potential challenges, and optimize the sequence of operations. It’s like having a digital blueprint that we can manipulate and test different approaches on.

- Demolition Simulation Software (e.g., various specialized plugins for Revit): These tools simulate demolition sequences, including the impact of different demolition methods (e.g., explosives, mechanical demolition) on the structure and surrounding areas. This predictive capability helps prevent unexpected collapses or damage.

- Project Management Software (e.g., Microsoft Project, Primavera P6): These are crucial for scheduling, resource allocation, and tracking progress. They help us manage the complex timeline of the demolition project and integrate it seamlessly with other on-site projects.

- GIS Mapping and Surveying Tools: These tools help us in understanding the site’s geographical context, identifying underground utilities, and planning access routes, ensuring a thorough understanding of the site’s layout.

Q 10. How do you handle unexpected challenges or delays during demolition?

Unexpected challenges are inevitable in demolition. My approach focuses on proactive risk management and efficient problem-solving.

- Contingency Planning: Before demolition starts, we develop detailed contingency plans addressing potential issues like encountering unforeseen structural elements, unexpected hazardous materials, or equipment malfunctions. This ‘what-if’ analysis allows us to react quickly and decisively when problems arise.

- On-site problem-solving team: I assemble a team of experienced professionals with diverse expertise to address challenges collaboratively. This includes structural engineers, safety officers, and demolition specialists who can quickly analyze the situation and provide solutions.

- Regular inspections and monitoring: Constant monitoring of the demolition process, using both visual inspection and non-destructive testing methods where applicable, allows us to detect problems early. This proactive approach helps us prevent small problems from escalating into major delays.

- Adaptive approach: Instead of rigidly sticking to the initial plan, we adapt to unforeseen circumstances. This might involve modifying the demolition sequence, adjusting the use of equipment, or seeking expert advice to overcome specific challenges.

- Documentation and reporting: Detailed documentation of all changes, solutions, and delays ensures transparency and accountability. It also provides valuable lessons learned for future projects.

Q 11. Explain your experience in obtaining necessary permits for demolition projects.

Obtaining demolition permits is a critical and complex process that requires careful attention to detail and adherence to local regulations. It’s like navigating a legal maze, and getting lost can lead to significant delays.

- Thorough site investigation and assessment: Before applying for permits, we conduct a thorough investigation, including site surveys, structural assessments, and environmental analysis to identify any potential issues.

- Detailed permit application: We prepare comprehensive permit applications including detailed demolition plans, safety plans, waste management plans, and environmental impact assessments, tailored to the specific requirements of the local authorities.

- Communication and collaboration with authorities: We proactively communicate with the permitting authorities, addressing their queries promptly and providing any additional information required to expedite the process.

- Compliance with all regulations: We ensure full compliance with all applicable local, state, and federal regulations, including building codes, environmental protection laws, and worker safety regulations.

- Handling objections and appeals: We are prepared to address any objections or appeals filed against the permit application, working diligently to resolve any concerns raised.

Q 12. Describe your experience with asbestos abatement and other hazardous material removal.

Safe handling of asbestos and other hazardous materials is paramount in demolition. It’s not just a safety issue; it’s a legal requirement.

- Pre-demolition surveys: We conduct thorough pre-demolition surveys to identify and assess the presence of asbestos, lead paint, PCBs, and other hazardous materials. These surveys are often conducted by specialized environmental consultants.

- Abatement plans: We develop detailed abatement plans, which are critical for compliance, outlining procedures for safe removal and disposal of hazardous materials in accordance with all relevant regulations.

- Certified contractors: We engage licensed and certified contractors specializing in asbestos and hazardous materials abatement. Their expertise ensures compliance and minimizes risks.

- Air monitoring and quality control: During abatement, we implement rigorous air monitoring to ensure worker and public safety, confirming the effectiveness of our containment measures.

- Proper disposal: Hazardous materials are disposed of in accordance with local, state, and federal regulations, through licensed disposal facilities.

- Documentation and reporting: All abatement activities are meticulously documented and reported, including air monitoring results and waste disposal manifests. This documentation is essential for compliance and potential future audits.

Q 13. How do you ensure the safety of workers and the public during demolition?

Worker and public safety is our top priority. We employ a multi-layered approach to ensure a safe demolition process.

- Comprehensive safety plan: We develop a detailed safety plan that addresses all potential hazards, including fall protection, equipment safety, and emergency procedures. This plan is reviewed and approved by our safety officer and relevant authorities.

- Site security and access control: We implement strict access controls to limit access to the demolition site only to authorized personnel. This includes erecting barriers, posting warning signs, and employing security personnel.

- Worker training and competency: All demolition workers undergo comprehensive safety training and are required to demonstrate competency before participating in any demolition activities.

- PPE (Personal Protective Equipment): Workers are provided with appropriate PPE including hard hats, safety glasses, high-visibility clothing, and other necessary protective gear.

- Regular safety inspections and audits: We conduct regular safety inspections and audits to ensure compliance with safety protocols and identify any potential hazards.

- Emergency response plan: We have a detailed emergency response plan in place to handle any accidents or emergencies that might occur during demolition.

Q 14. How do you communicate effectively with stakeholders during a demolition project?

Effective communication is vital for a successful demolition project. It’s about keeping everyone informed and involved.

- Pre-construction meetings: We hold pre-construction meetings with all stakeholders, including property owners, residents, contractors, and local authorities. This is an opportunity to introduce the project, discuss expectations, and address any concerns.

- Regular updates and progress reports: We provide regular updates and progress reports to stakeholders through various channels such as email, phone calls, and on-site meetings. This keeps them informed about the project’s progress and any potential changes to the schedule.

- Addressing concerns promptly: We promptly address any concerns or questions raised by stakeholders. This might involve scheduling site visits, providing additional information, or modifying plans as needed.

- Open communication channels: We maintain open communication channels, making ourselves readily available to answer questions and provide updates. This could include establishing a dedicated contact person or utilizing a centralized communication platform.

- Post-demolition communication: After the demolition is complete, we provide a final report to stakeholders, summarizing the project’s outcomes, addressing any issues that arose, and highlighting any lessons learned.

Q 15. What is your experience with structural analysis in demolition planning?

Structural analysis is paramount in demolition planning. It’s like examining the skeleton of a building before dismantling it. We need to understand the building’s structural integrity – how its components (beams, columns, walls) interact and support each other. This involves reviewing architectural and engineering drawings, possibly conducting site surveys, and sometimes employing non-destructive testing methods like ground-penetrating radar or ultrasonic testing. The goal is to identify potential hazards like weak points, hidden utilities, or unexpected structural elements that could affect the demolition process and safety. For instance, a seemingly insignificant crack could indicate a much larger underlying problem that needs attention before demolition begins. We use this analysis to determine the safest and most efficient demolition sequence.

For example, in a recent project involving a multi-story office building, our structural analysis revealed that a central load-bearing column was significantly weakened by rust. This information influenced our demolition plan, requiring us to support this column before proceeding with the demolition of adjacent sections to prevent a catastrophic collapse.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you select appropriate demolition equipment for a specific project?

Selecting the right demolition equipment is crucial for safety, efficiency, and cost-effectiveness. It’s like choosing the right tools for a complex surgery. The choice depends on various factors, including the building’s size, materials (concrete, steel, wood), its structural integrity as revealed by our analysis, the site conditions (access, proximity to other structures), environmental regulations, and the desired demolition method (controlled demolition, selective demolition, etc.).

- Size and Type of Structure: A small residential building might only need a hydraulic excavator, whereas a large skyscraper would necessitate the use of explosives, heavy-duty cranes, and specialized equipment for cutting and dismantling steel structures.

- Material Composition: Concrete structures often require breakers and crushers, while steel structures might need specialized cutting torches or shears.

- Environmental Concerns: Noise and dust mitigation equipment might be necessary depending on the location and regulations.

For instance, in a recent project involving a high-rise building close to a busy highway, we opted for a top-down demolition approach using a high-reach excavator with a specialized demolition grapple to minimize disruption to traffic and surrounding areas.

Q 17. Describe your experience with demolition sequencing and phasing.

Demolition sequencing and phasing are akin to a well-orchestrated symphony. It’s a meticulously planned step-by-step process that ensures safety and efficiency. We analyze the structure’s components and their interconnectedness, identifying the optimal order to dismantle them. This often involves a phased approach, starting with less critical elements and gradually progressing towards the main structural components. Safety is paramount here – we’ll prioritize removing unstable sections first to avoid unexpected collapses. The plan also considers the best approach for debris management to minimize disruption and environmental impact.

For a large industrial facility, for example, we might first remove non-structural elements such as cladding, then proceed to demolish less critical areas before taking down main structural elements like columns and walls. Each phase is carefully monitored, and adjustments might be made based on real-time observations during the demolition process.

Q 18. How do you mitigate the impact of demolition on adjacent structures?

Protecting adjacent structures during demolition is crucial. It’s like performing a delicate surgery near vital organs. We employ various mitigation strategies, including:

- Structural Monitoring: We use instruments to continuously monitor the stability of neighboring buildings throughout the demolition process, looking for any signs of stress or movement. This data helps us make real-time adjustments if needed.

- Protective Barriers: These might include temporary shoring, bracing, or protective barriers to prevent debris from impacting adjacent structures.

- Vibration Monitoring and Control: We use vibration monitoring equipment to measure ground vibrations caused by demolition activities. If vibrations exceed pre-determined limits, we modify the demolition methods or reduce the impact force. This is particularly important for structures with older foundations.

- Controlled Demolition Techniques: Methods like implosion or controlled dismantling are used to minimize vibrations and debris.

In a recent project near a historic building, we used specialized vibration dampeners during the demolition of an adjacent structure to prevent damage to the historic building’s delicate façade.

Q 19. Explain your understanding of demolition engineering principles.

Demolition engineering principles encompass a holistic approach, merging structural analysis, material science, construction methods, safety procedures, and environmental considerations. It’s about understanding how structures behave under demolition loads and ensuring a safe and controlled demolition process. Key principles include:

- Understanding Structural Behavior: This involves understanding how loads are transferred within a structure and how the removal of elements affects the remaining structure.

- Material Properties: We need to know the strength and failure characteristics of the materials used in the structure (concrete, steel, masonry) to predict how they will react during demolition.

- Safe Demolition Methods: Selecting appropriate demolition methods (e.g., implosion, hydraulic demolition, selective dismantling) based on structural analysis and site conditions.

- Debris Management: Developing a safe and efficient plan for debris removal and disposal.

- Risk Assessment and Mitigation: Identifying potential hazards (e.g., collapse, fire, dust) and implementing safety measures to minimize risks.

Q 20. What are your strategies for minimizing environmental impact during demolition?

Minimizing environmental impact is a top priority. We strive for sustainable demolition, aiming to reduce waste, conserve resources, and protect the environment. This includes:

- Waste Management: We prioritize recycling and reuse of demolition materials, reducing the amount of waste sent to landfills. For example, we can separate concrete, metal, and wood for recycling.

- Dust and Noise Control: We implement measures to minimize dust and noise pollution through techniques such as water spraying during demolition, noise barriers, and the use of quieter equipment.

- Hazardous Material Management: We carefully handle and dispose of hazardous materials such as asbestos, lead paint, and PCB-containing materials according to environmental regulations.

- Soil and Groundwater Protection: We take measures to prevent soil and groundwater contamination during the demolition process.

For instance, in a recent project, we salvaged reusable materials like bricks and lumber from an old school building, donating them to a local community center for use in other projects. This significantly reduced the project’s environmental footprint.

Q 21. How do you ensure the accuracy of demolition cost estimations?

Accurate cost estimations are essential for successful project management. We achieve this through a detailed breakdown of all aspects of the project:

- Comprehensive Site Assessment: A thorough assessment of the structure, site conditions, and environmental considerations forms the basis for accurate estimations.

- Detailed Demolition Plan: The level of detail in the demolition plan directly affects the accuracy of cost estimations. A well-defined plan helps to identify all necessary tasks, equipment, and labor.

- Material Quantification: Precise quantities of materials to be demolished and disposed of are needed to calculate disposal and transportation costs.

- Labor Cost Estimation: Accurate assessment of the required labor hours based on the complexity of the project and the chosen demolition techniques.

- Equipment Rental or Purchase Costs: Accurate costs associated with the equipment needed for the demolition.

- Contingency Planning: Including a contingency budget to account for unforeseen circumstances.

We use specialized software and our experience to refine our estimations, constantly comparing them with historical data and actual project costs. This iterative approach helps us improve our accuracy over time.

Q 22. Describe your experience with emergency response procedures during demolition.

Emergency response during demolition is paramount. My experience involves establishing robust procedures, including pre-demolition risk assessments identifying potential hazards like unexpected structural weaknesses or utility line breaches. We develop detailed emergency plans, specifying communication protocols, evacuation routes, and the roles of each team member. These plans are regularly reviewed and updated. For instance, during the demolition of a large industrial complex, we anticipated the possibility of asbestos release. Our plan included immediate site isolation, specialized cleanup crews on standby, and notification of relevant authorities. Regular safety briefings and training drills keep the team prepared to handle unexpected events efficiently and safely. We also maintain close communication with emergency services to ensure a swift response if needed.

Q 23. How do you monitor and control demolition noise levels?

Controlling demolition noise is crucial for minimizing community disruption. My approach involves a multi-pronged strategy. First, we select quieter demolition techniques whenever possible, such as low-vibration hydraulic breakers instead of explosive methods. Second, we employ noise barriers, such as sound blankets or temporary walls, to contain noise at its source. Third, we strategically schedule noisy operations during less sensitive times of the day. We also use noise monitoring equipment to measure sound levels throughout the project, ensuring compliance with local regulations. For instance, on a recent high-rise demolition, the use of quieter equipment and strategically placed sound barriers reduced ambient noise levels by over 15dB within the nearby residential area. Documentation of noise levels ensures transparent compliance and helps address potential community concerns.

Q 24. What is your experience with post-demolition site cleanup and restoration?

Post-demolition site cleanup and restoration is critical for safety and environmental responsibility. My experience covers a wide range of activities, from debris removal and sorting to soil remediation and site landscaping. We follow stringent protocols for hazardous waste disposal, including asbestos, lead paint, and other potentially harmful materials. The process begins with a detailed waste management plan that identifies and segregates various waste streams. Then, we utilize specialized equipment and techniques to safely remove and dispose of hazardous materials in compliance with all relevant environmental regulations. For example, during the demolition of a hospital, we had a meticulous process for handling medical waste and contaminated materials, ensuring the protection of both workers and the environment. The final stage involves site restoration, which can include grading, landscaping, and the installation of erosion control measures, leaving the site prepared for future development.

Q 25. How do you manage conflicts between project stakeholders?

Managing stakeholder conflicts requires proactive communication and collaboration. I begin by clearly defining roles and responsibilities for all stakeholders, including the client, contractors, neighbors, and regulatory agencies. Regular meetings and open communication channels are essential to keep everyone informed and address potential issues early on. We use a collaborative approach, seeking consensus and finding mutually acceptable solutions. When disagreements arise, mediation techniques are employed to find common ground. For instance, during a demolition project near a historical landmark, we actively engaged with local heritage groups to address their concerns and incorporate their suggestions into the demolition plan. This proactive approach ensured the project proceeded smoothly and maintained positive relationships with all stakeholders.

Q 26. Describe your experience with demolition quality control measures.

Demolition quality control involves a series of checks and balances throughout the entire process. It starts with pre-demolition surveys and assessments to identify potential hazards and structural weaknesses. During demolition, regular inspections ensure compliance with safety protocols and the demolition plan. We use checklists and documented procedures to ensure consistency and accuracy. Progress reports and photographs are maintained throughout to document the process. The use of drone technology for progress monitoring and safety oversight is becoming increasingly common. Post-demolition, final inspections verify complete debris removal and site restoration according to specifications. For example, during the dismantling of a bridge, regular inspections ensured the safe removal of each structural element without compromising the stability of the remaining structure. This rigorous quality control minimizes risks and ensures a safe and efficient demolition project.

Q 27. How do you evaluate the success of a completed demolition project?

Evaluating the success of a demolition project goes beyond simply completing the task. It involves assessing whether the project was completed on time, within budget, and without any safety incidents. We review the project against the initial objectives, including the efficiency of the demolition process, adherence to environmental regulations, and the level of stakeholder satisfaction. Post-demolition surveys and feedback from stakeholders are used to gauge their overall experience. Key performance indicators (KPIs) like the number of safety incidents, waste diversion rates, and project completion time are analyzed. A successful project is characterized by a safe working environment, minimal environmental impact, and the fulfillment of all contractual obligations and stakeholder expectations.

Q 28. What are your strategies for improving demolition efficiency and productivity?

Improving demolition efficiency and productivity involves optimizing processes and adopting new technologies. This includes using advanced demolition equipment like high-reach excavators and robotic demolition systems to increase speed and precision. Pre-planning is crucial; detailed 3D modeling and simulation can help identify potential challenges and optimize the demolition sequence. Efficient waste management strategies, including on-site sorting and recycling, reduce disposal costs and environmental impact. Investing in employee training and safety programs minimizes downtime due to accidents. For instance, implementing a just-in-time material delivery system can minimize storage space and improve workflow. Continuous improvement through data analysis and feedback helps identify areas for optimization in future projects.

Key Topics to Learn for Demolition Planning and Execution Interview

- Site Assessment and Surveying: Understanding site conditions, identifying potential hazards (utilities, structural weaknesses), and utilizing surveying techniques for accurate measurements and modeling.

- Demolition Methodologies: Selecting appropriate demolition methods (e.g., implosion, high-reach demolition, selective demolition) based on site constraints, building materials, and environmental regulations. Practical application involves justifying method choices in a cost-effective and safe manner.

- Safety Planning and Risk Assessment: Developing comprehensive safety plans that comply with relevant regulations (OSHA, etc.). This includes hazard identification, risk mitigation strategies, emergency response planning, and worker training protocols.

- Sequencing and Methodology: Creating detailed demolition sequences, considering structural integrity, and minimizing environmental impact. This involves practical application of engineering principles and understanding the order of operations for efficient and safe demolition.

- Environmental Considerations: Understanding and complying with environmental regulations concerning dust control, noise pollution, waste management, and asbestos abatement. This includes practical application of best practices and knowledge of relevant permits and regulations.

- Cost Estimation and Budgeting: Accurately estimating demolition costs, including labor, materials, equipment, and disposal. Practical application involves detailed cost breakdown and understanding factors affecting project profitability.

- Permitting and Regulatory Compliance: Navigating the permitting process, ensuring compliance with local, state, and federal regulations throughout the project lifecycle. This includes understanding the intricacies of various permits and documentation requirements.

- Project Management and Communication: Effective project management skills, including scheduling, resource allocation, and communication with stakeholders (clients, contractors, authorities). This involves practical application of project management methodologies and excellent communication strategies.

- Technology in Demolition Planning: Familiarity with software and technologies used in demolition planning, such as 3D modeling, BIM, and simulation tools. Understanding how these tools enhance efficiency and safety.

- Problem-Solving and Contingency Planning: Developing proactive solutions to potential challenges during demolition projects and creating robust contingency plans for unforeseen circumstances.

Next Steps

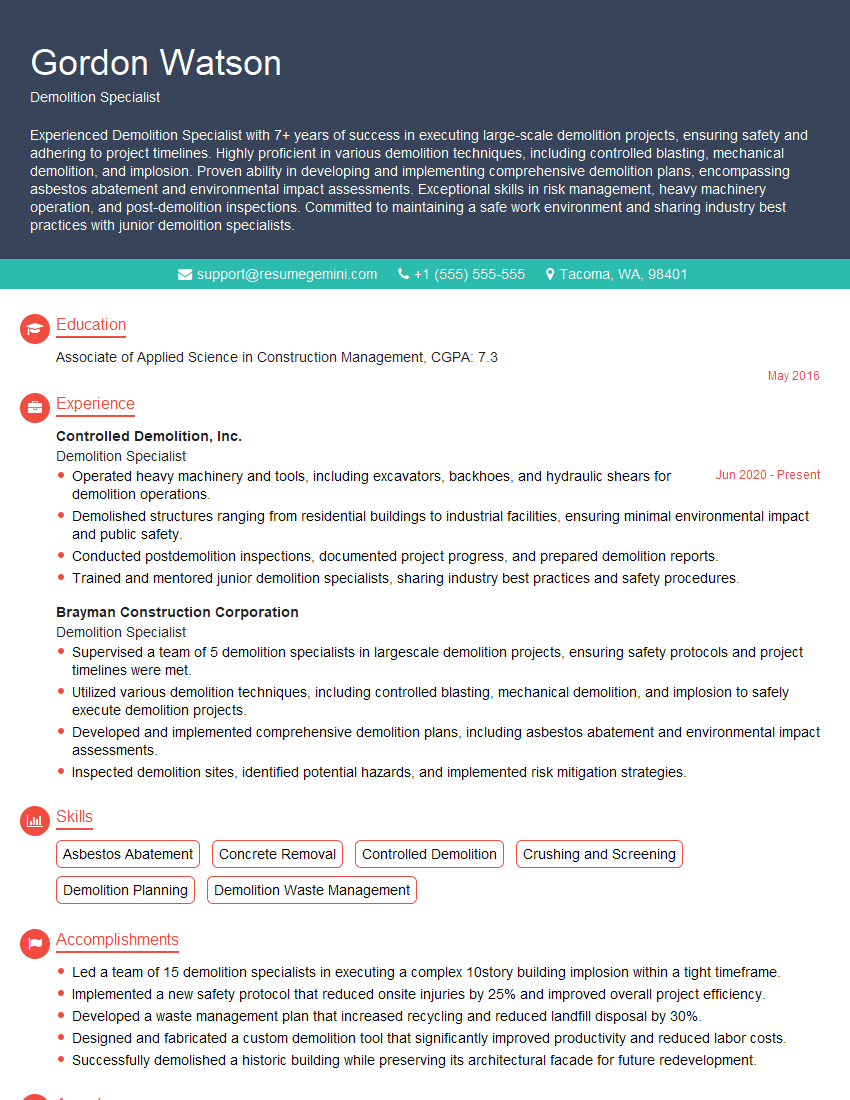

Mastering Demolition Planning and Execution opens doors to exciting career advancements, offering opportunities for specialization and leadership roles within the construction industry. Building an ATS-friendly resume is crucial for maximizing your job prospects. ResumeGemini is a trusted resource that can help you create a compelling and effective resume tailored to the specific requirements of Demolition Planning and Execution roles. Examples of resumes tailored to this field are available to help you build your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good