Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Farm Vehicle Driving interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Farm Vehicle Driving Interview

Q 1. Describe your experience operating various farm vehicles.

My experience encompasses a wide range of farm vehicles, from tractors of varying horsepower and configurations (including articulated and crawler tractors), to harvesters (combines, forage harvesters), planters, sprayers, and various smaller support vehicles like ATVs and utility vehicles. I’m proficient in operating both older, mechanically simpler machines and modern, technologically advanced equipment with GPS guidance and automated features. For example, I’ve spent considerable time operating a John Deere 8400 series tractor for tillage and planting, and a Claas Lexion combine for harvesting wheat and corn. I am comfortable working with both manual and hydraulic controls, adapting my approach based on the specific vehicle and task at hand. This adaptability extends to mastering different implements attached to the tractors, ensuring efficient and productive operation.

Q 2. What safety procedures do you follow when operating farm machinery?

Safety is paramount in farm vehicle operation. My procedures always begin with pre-operational checks: inspecting tires, fluid levels (oil, coolant, fuel), brakes, lights, and the overall condition of the machine. I ensure all safety devices, like seatbelts, PTO shields, and ROPS (Roll-Over Protective Structures), are functioning correctly. Before starting any work, I thoroughly survey the field for obstacles – including buried objects, power lines, and uneven terrain. I maintain awareness of my surroundings, especially when operating near roads or other personnel. During operation, I maintain a safe speed appropriate for conditions and carefully observe blind spots. I always follow manufacturer’s guidelines and any relevant regulations. Furthermore, I utilize appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and sturdy work boots. Communicating clearly with others on the farm is vital; I use hand signals or radio communication to ensure everyone’s safety. For example, if I’m operating near a road, I’ll employ additional caution and signage to alert drivers.

Q 3. Explain your knowledge of preventative maintenance for farm vehicles.

Preventative maintenance is crucial for ensuring both safety and operational efficiency. My approach is systematic and follows a regular schedule. This involves daily checks of fluid levels, tire pressure, and overall machine condition. Regular lubrication of moving parts is essential. I adhere to the manufacturer’s recommended maintenance schedule for tasks like oil and filter changes, belt inspections, and component adjustments. I perform tasks like greasing moving parts, and cleaning filters regularly. I also meticulously inspect the machine after each use, noting any potential problems. I’m proficient in basic repairs, but for more complex issues, I work with qualified mechanics to ensure proper repairs and maintenance. This preventative approach not only extends the lifespan of the equipment but also minimizes downtime and operational disruptions, ultimately improving efficiency and saving money in the long run.

Q 4. How do you handle challenging weather conditions while driving farm equipment?

Operating farm equipment in challenging weather conditions requires careful planning and adaptation. In rain, reduced speeds are essential to prevent skidding and ensure visibility. I also use appropriate lighting and adjust operations to manage visibility challenges. In snowy or icy conditions, I use chains on tires or even postpone work altogether if conditions are too hazardous. Extreme heat necessitates regular breaks and hydration. Strong winds can affect machinery stability; therefore, I take precautions to ensure stability and reduce speed. I am always mindful of the potential impact of weather on soil conditions, adjusting my technique and speed accordingly. My judgment is key; safety always takes precedence over deadlines, and I prioritize postponing work if conditions are unsafe.

Q 5. Describe your experience with GPS-guided agricultural machinery.

I have extensive experience with GPS-guided agricultural machinery. This technology significantly improves efficiency and accuracy. I’m comfortable using various GPS systems for auto-steering, variable rate application, and yield mapping. For instance, I’ve used John Deere’s AutoTrac system and have experience creating and managing field boundaries. GPS guidance allows for precise overlap management during spraying and planting, reducing input costs and environmental impact. Yield mapping provides valuable data for improved field management decisions in subsequent seasons. I understand the principles of RTK (Real-Time Kinematic) and understand how to troubleshoot GPS-related issues; this ensures minimal downtime when precision farming techniques are employed.

Q 6. What is your understanding of different tractor attachments and their uses?

My understanding of tractor attachments is comprehensive. I’m familiar with a wide variety of implements used for various operations:

- Tillage: Plows, discs, harrows, subsoilers for soil preparation.

- Planting: Planters for seeds and various types of crops.

- Cultivation: Cultivators, row weeders to manage weeds.

- Harvesting: Headers and attachments specific to different crops (e.g., corn heads, grain platforms).

- Hay and Forage: Mowers, conditioners, rakes, balers.

- Other: Loaders, backhoes, spreaders, sprayers, post hole diggers.

Q 7. How do you ensure the safe transportation of livestock?

Safe livestock transportation involves adhering to strict guidelines for animal welfare and safety. Before loading, animals should be properly restrained and handled to avoid stress and injury. The trailer or vehicle must be appropriately sized and equipped for the number and type of animals being transported. Proper ventilation and space are essential to prevent overheating or suffocation. During transport, regular checks are vital to monitor animal health and well-being, providing necessary water and ensuring that they are not subjected to extreme conditions. Adherence to all relevant regulations and best practices is non-negotiable. For example, I ensure that all livestock trailers are properly maintained, with functioning ramps and gates. I also know the signs of animal stress and know when to contact a veterinarian if needed.

Q 8. Explain your experience with loading and unloading agricultural products.

Loading and unloading agricultural products efficiently and safely is crucial for minimizing losses and maximizing productivity. My experience spans various methods and products, from delicate fruits and vegetables to bulk grains and hay bales. I’m proficient in using various loading equipment, including front-end loaders, telescopic handlers, and conveyor belts, adapting my technique to the specific crop and its handling requirements.

For instance, when loading delicate tomatoes, I’d use a gentle approach with a conveyor belt system to avoid bruising. With bulk grains, I’d ensure the auger is properly set to avoid spills and clogging. For hay bales, I utilize the telehandler’s forks, carefully placing them to prevent damage and secure transport. I always prioritize safety, ensuring the area is clear, the equipment is in good working order, and that appropriate lifting and securing techniques are employed to prevent accidents and product damage.

I also meticulously monitor the weight and volume of each load to optimize transportation efficiency and prevent overloading. Proper documentation of the loads, including type, weight, and destination, is a standard practice for accurate inventory management and traceability.

Q 9. How do you troubleshoot common mechanical issues in farm vehicles?

Troubleshooting mechanical issues is a critical skill for a farm vehicle operator. My approach is systematic, combining preventative maintenance with quick diagnostic skills. It starts with identifying the problem; I listen carefully for unusual sounds, observe unusual behavior, and check for leaks or obvious damage.

For example, if a tractor engine is overheating, I’d first check the coolant level, then inspect the radiator for obstructions, check the fan belt for tension, and finally, assess the thermostat for proper function. If a hydraulic system fails, I might systematically check the fluid level, look for leaks in the lines, and investigate the pump or control valves. I have the experience to utilize diagnostic tools such as pressure gauges, multimeters, and specialized diagnostic software on more modern equipment.

Beyond simple fixes, I know when it’s necessary to call in a qualified mechanic for more complex repairs. I always prioritize safety; If a problem could lead to a dangerous situation, I would immediately stop operation and seek assistance. Knowing your limits and acting responsibly is as important as knowing how to fix things.

Q 10. What is your understanding of fuel efficiency and its importance in farm operations?

Fuel efficiency is paramount in farm operations, directly impacting profitability and environmental sustainability. Every gallon saved translates to reduced operating costs and a smaller carbon footprint. My understanding encompasses several key aspects:

- Proper vehicle maintenance: Regular servicing, including cleaning air filters, changing oil and lubricating moving parts, maintains optimal engine performance and fuel economy.

- Driving techniques: Smooth acceleration and deceleration, maintaining appropriate speeds, and avoiding unnecessary idling all contribute significantly to better fuel consumption.

- Appropriate equipment selection: Choosing the right machinery for the job minimizes fuel waste. A smaller tractor is often more fuel-efficient for lighter tasks than a larger one.

- Load management: Optimizing loads to avoid unnecessary trips and weight distribution also improves efficiency.

For example, I’ve seen a significant difference in fuel consumption by simply changing from aggressive acceleration to a smoother approach. I also keep an eye on the fuel consumption data provided by modern farm vehicles to identify areas for improvement. Tracking fuel usage allows me to assess the efficiency of different machines and driving practices, helping me continually improve fuel economy.

Q 11. Describe your experience with various types of agricultural spraying equipment.

My experience encompasses various types of agricultural spraying equipment, including boom sprayers, knapsack sprayers, and airblast sprayers. I’m familiar with the operation and maintenance of each, understanding their strengths and limitations for different applications.

Boom sprayers are ideal for large-scale field applications, providing even coverage. I understand the importance of calibrating boom sprayers correctly to ensure the accurate application of pesticides or fertilizers. Knapsack sprayers are more suitable for smaller areas or targeted applications, and their versatility allows me to handle varied tasks such as spot treating weeds or applying fungicides to individual plants. Airblast sprayers, with their high-volume airflow, are particularly effective for orchard and vineyard applications, ensuring thorough coverage of foliage.

Regardless of the type of sprayer, I always prioritize safe handling of chemicals, adhering to all safety guidelines and regulations. This includes wearing appropriate personal protective equipment (PPE) and properly disposing of any leftover chemicals. I am familiar with the different types of nozzles and their application ranges ensuring optimal spray pattern for different crops.

Q 12. How do you maintain accurate records of vehicle operation and maintenance?

Maintaining accurate records is essential for efficient farm management and compliance. My method involves a combination of digital and physical record-keeping.

For vehicle operation, I use electronic logbooks to record daily hours of operation, fuel consumption, tasks performed, and any maintenance issues encountered. Modern vehicles often have onboard computers which automatically record much of this data, which simplifies the process. For maintenance, I meticulously document all service intervals, parts replaced, and repairs conducted in a dedicated maintenance log. This information is crucial for tracking expenses, scheduling future maintenance, and ensuring the vehicles remain in optimal condition.

All this data is backed up electronically, and hard copies of key documents are stored for archival purposes. This system is simple, organized, and makes it easy to generate reports, track costs, and ensure everything is compliant with regulations.

Q 13. What are the legal requirements for operating farm vehicles in your area?

Legal requirements for operating farm vehicles vary by location, but generally include licensing, registration, safety inspections, and adherence to traffic laws. In my area, operators of larger farm vehicles often require a specific class of driver’s license, reflecting the size and complexity of the machine. Regular vehicle safety inspections are mandatory, ensuring that brakes, lights, and other critical components are functioning correctly.

Furthermore, we must comply with all relevant environmental regulations, particularly concerning the transportation and handling of agricultural chemicals and waste materials. It’s crucial to stay updated on all legal requirements and any changes in regulations, as non-compliance can result in penalties and safety hazards. I actively participate in relevant safety training programs to ensure ongoing compliance and best practices.

Q 14. How do you ensure the safe operation of farm machinery around other personnel?

Ensuring safe operation around personnel is paramount. My approach combines clear communication, established safety protocols, and the responsible use of machinery.

Before starting any operation, I visually inspect the area to identify potential hazards, ensuring the vicinity is clear of people and obstacles. I use audible warnings, such as horns or backup alarms, to alert others to the machine’s movement. Clear hand signals or designated communication procedures are employed for directing traffic or coordinating activities with other personnel. I always maintain a safe distance from others and observe speed limits.

In addition to these practices, I ensure that all safety devices on the machinery, such as guards, shields, and emergency stops, are functioning correctly and utilized as needed. Regular safety training and a cautious approach create a culture of safety that keeps everyone on the farm safe and productive.

Q 15. Describe your experience with harvesting equipment, specifically [mention specific equipment, e.g., combines].

My experience with combines spans over eight years, encompassing all aspects from pre-harvest preparation to post-harvest cleaning. I’m proficient in operating various models, including the John Deere S790 and Claas Lexion 770. My expertise extends beyond basic operation; I’m skilled in adjusting settings for optimal performance based on crop type and field conditions. For example, I’ve learned to fine-tune the concave and rotor speed on a combine to minimize grain loss in varying wheat densities, maximizing yield. I also possess a deep understanding of combine maintenance, troubleshooting minor mechanical issues, and performing preventative maintenance to ensure peak efficiency and uptime.

I’ve worked on large-scale operations harvesting hundreds of acres of wheat, corn, and soybeans, consistently meeting or exceeding production targets. I’m comfortable working both independently and as part of a larger harvesting team, coordinating efficiently with other machinery operators to ensure a smooth and productive operation. I understand the importance of safe harvesting practices, adhering to all relevant safety regulations and protocols. This includes regular inspection of machinery, proper use of personal protective equipment (PPE), and awareness of potential hazards within the working environment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your skills in using precision agriculture technology?

I’m highly proficient in using a range of precision agriculture technologies to optimize farm operations. My skills encompass GPS-guided systems for automated steering, variable rate technology (VRT) for fertilizer and seed application, and yield monitoring systems. I’m familiar with various software platforms used to manage and analyze data gathered from these technologies, such as AgLeader and John Deere Operations Center. I can utilize this data to create detailed field maps highlighting areas needing specific attention, like uneven fertilization or varying crop density. This information helps in making informed decisions regarding future planting and harvesting strategies. For instance, using yield maps from the previous season allowed us to identify and address soil nutrient deficiencies in specific zones, resulting in a 15% increase in yield the following year.

Furthermore, I’m comfortable using sensors and other data acquisition devices for real-time monitoring of soil conditions, weather patterns and crop health. The ability to integrate and interpret data from multiple sources is key to effective precision agriculture, and I’m adept at this process. It’s like having a digital assistant in the field, guiding my decisions and optimizing every aspect of the operation for maximum efficiency and sustainability.

Q 17. How do you adapt your driving techniques to different terrain types?

Adapting driving techniques to different terrains is crucial for safe and efficient farm vehicle operation. My experience covers a wide range of conditions, including flat fields, rolling hills, and uneven terrain. I adjust my speed according to the ground’s firmness and slope, prioritizing safety and preventing damage to the equipment and the soil. On uneven terrain, for instance, I use a lower gear and maintain a slower speed to avoid jarring the vehicle or causing tire slippage. I’m very mindful of the vehicle’s weight distribution and adjust my route to avoid areas that could lead to getting stuck.

In wet or muddy conditions, I might need to reduce tire pressure to increase surface area contact and improve traction. Conversely, in dry, compacted soil, I might increase tire pressure to reduce soil compaction. This careful management of pressure and speed prevents damage to crops and the soil structure while preserving machine integrity. Think of it like driving a car in the snow versus driving it on a smooth highway – you need to adjust your techniques for optimal performance and safety.

Q 18. Explain your experience with night-time farm vehicle operation.

Night-time farm vehicle operation requires heightened awareness and a different set of skills. I’ve extensive experience operating farm vehicles at night, mainly during harvest seasons when time is of the essence. This involves utilizing powerful and well-maintained lighting systems on the vehicles to ensure excellent visibility. I always ensure that all lights are functioning correctly and that I’m comfortable with their range and intensity. Furthermore, I utilize GPS guidance systems that accurately track the vehicle’s position even in low-light conditions. These systems also help prevent overlap and ensure complete coverage of the field.

Besides technology, I rely on situational awareness and careful driving practices. This includes maintaining a slower speed, being highly attentive to my surroundings, and being extremely careful while maneuvering near field edges or other obstacles. It’s about being extra cautious and adapting my driving style to compensate for the limitations of visibility at night. Safety is paramount and I always prioritize it over speed or expediency.

Q 19. How do you handle unexpected equipment malfunctions in the field?

Handling unexpected equipment malfunctions in the field requires a combination of problem-solving skills, technical knowledge, and resourcefulness. My first step is always to assess the situation, ensuring the safety of myself and those around me. Then, I systematically try to diagnose the problem based on my experience and the equipment’s error codes. I will attempt basic troubleshooting based on my understanding of the equipment’s mechanics. If the issue is minor, such as a belt slipping or a hydraulic leak, I have the knowledge and tools to often rectify it on the spot.

However, if the malfunction is more complex or beyond my ability to resolve it, I will immediately contact the farm manager or mechanic to assess the issue. If needed, I’ll also utilize the equipment’s integrated diagnostic systems or contact the manufacturer’s support line. I document the issue thoroughly, including details such as the time of failure, location in the field, and any error messages displayed. This methodical approach minimizes downtime and prevents further damage to the equipment.

Q 20. Describe your experience working with different types of soil conditions.

My experience working with different soil conditions is extensive, covering various types like sandy loam, clay loam, and silt loam. I understand how soil type affects vehicle traction, soil compaction, and crop yields. For example, sandy soils require different driving techniques than clay soils; I adjust my speed and tire pressure to minimize compaction and maximize traction. In clay soils, driving too fast can easily lead to compaction and rutting, damaging the soil structure. In sandy soils, the risk of getting stuck increases unless careful attention is paid to the amount of moisture.

I also understand the importance of soil conservation practices. I carefully manage my driving routes to avoid unnecessary soil disturbance. I know to plan my routes to minimize the impact on soil health and optimize yield. This includes understanding the soil’s water-holding capacity and ensuring adequate drainage to prevent waterlogging. It’s a fine balance between getting the work done efficiently and protecting the land for future productivity.

Q 21. How do you prioritize tasks and manage your time effectively during farm operations?

Prioritizing tasks and managing time effectively during farm operations is crucial for maximizing efficiency and meeting deadlines. I typically start by reviewing the day’s schedule and assessing the priorities. This might involve coordinating with other operators, checking weather forecasts, and reviewing field maps to identify areas requiring immediate attention. For instance, harvesting crops at the optimal ripeness is a key priority, so I prioritize fields nearing that stage first. I use GPS-based technology to monitor progress and identify areas where extra effort is needed. This system also facilitates precise tracking of machine-hours and overall productivity levels.

I also practice good time management techniques like breaking down large tasks into smaller, more manageable ones. Regular maintenance checks on equipment are integrated into the schedule to minimize downtime. I use technology to track progress, and regular communication with fellow operators keeps the operation running smoothly. This proactive approach ensures all tasks are completed efficiently within established timelines. It’s about strategic planning and staying adaptable so that you’re able to tackle whatever comes your way on a given day.

Q 22. How familiar are you with different types of farm trailers and their capacity?

Farm trailers come in a wide variety of types, each designed for specific tasks and capacities. Understanding their differences is crucial for safe and efficient operation.

- Grain trailers: These typically have large capacities, ranging from a few hundred bushels to over a thousand, and are used for transporting harvested grains like corn, wheat, and soybeans. Their capacity is often measured in bushels or tonnes.

- Hay trailers: These can be round bale trailers, capable of carrying numerous large round bales, or square bale trailers, designed for transporting smaller, square bales. Capacity varies greatly depending on bale size and trailer dimensions.

- Livestock trailers: These prioritize the safety and well-being of animals. Their capacity is usually expressed as the number of head of livestock they can hold, varying greatly depending on animal size and trailer design. Some even have specialized compartments for different types of animals.

- Utility trailers: These are versatile trailers used for transporting a variety of goods, from equipment to supplies. Their capacity is often measured in weight (pounds or kilograms) and volume (cubic feet or cubic meters).

Choosing the right trailer for the job is paramount. Overloading a trailer compromises safety and can lead to accidents. Always check the manufacturer’s stated weight and volume limits before loading.

Q 23. What is your experience with operating equipment with various power sources (diesel, gasoline, electric)?

My experience spans across various power sources commonly used in farm equipment. Understanding the nuances of each is vital for optimal performance and maintenance.

- Diesel: Diesel engines are prevalent in larger farm machinery due to their high torque and fuel efficiency, especially for demanding tasks like plowing or harvesting. I’m proficient in maintaining and operating diesel equipment, including routine checks and troubleshooting minor issues.

- Gasoline: Gasoline-powered equipment is commonly used for smaller tasks or where a lighter-weight machine is preferred. I’m familiar with the appropriate safety precautions and maintenance procedures specific to gasoline engines.

- Electric: The agricultural sector is increasingly adopting electric equipment, particularly for tasks like spraying and smaller tractors. I’m adept at understanding the charging requirements, battery management systems, and the unique operational characteristics of electric-powered farm vehicles.

The key is adaptability. I can easily transition between different power sources, adjusting my approach based on the specific machine and its requirements. I also prioritize safety procedures related to each type, such as proper fuel handling and electrical safety.

Q 24. Describe a time you had to make a quick decision to prevent an accident while operating farm equipment.

During harvest season, I was operating a combine harvester in a field with a significant slope. I noticed a sudden drop in the hydraulic pressure, indicating a potential malfunction. The combine was nearly full of grain, making it very heavy and difficult to maneuver safely.

My quick decision was to immediately stop the harvester, avoid any sudden movements, and assess the situation. I contacted my supervisor, who dispatched a mechanic. While waiting, I carefully secured the machine and ensured the area was safe. This prevented a potential rollover accident due to the unstable position on the slope and a possible spillage of the valuable harvest.

The incident highlighted the importance of proactive monitoring of equipment, recognizing subtle warning signs, and responding decisively to prevent accidents.

Q 25. How do you contribute to the overall efficiency of farm operations?

Contributing to overall farm efficiency involves a multi-faceted approach. It’s not just about speed, but optimizing processes and minimizing downtime.

- Proactive Maintenance: Regularly inspecting and maintaining my equipment prevents costly breakdowns and delays. This includes daily checks, preventative maintenance schedules, and promptly reporting any issues.

- Efficient Operation: I prioritize efficient operation by optimizing speed and techniques for specific tasks. For instance, adjusting the combine’s settings based on crop density maximizes yield and minimizes losses.

- Effective Communication: Open communication with other team members ensures smooth workflow. This includes coordinating tasks, sharing information about field conditions, and reporting any problems promptly.

- Safety-Focused Approach: A safe working environment is crucial for efficiency. By adhering to safety protocols, I minimize the risk of accidents that could disrupt operations.

Ultimately, my contribution isn’t just about operating the machinery but actively contributing to a well-oiled operation, where every aspect is optimized for maximum productivity and minimal downtime.

Q 26. What are the different types of hitches you’re familiar with and their uses?

Understanding different hitches is fundamental for connecting farm implements to tractors safely and effectively. Mismatched hitches can be dangerous.

- Category 1 and Category 2 Hitches: These are the most common three-point hitches used on tractors. Category 1 is used for smaller implements, while Category 2 is for larger, heavier equipment. The dimensions of the hitch pins and mounting points differ between categories.

- Drawbar Hitch: This is a simple hitch, usually a pin or ball, for attaching trailers or other implements. It’s commonly found on smaller tractors and is suitable for less demanding applications.

- Fifth Wheel Hitch: This hitch is used for connecting semi-trailers to tractors, typically for transporting large quantities of goods over long distances. It provides stability and allows for greater maneuverability.

- Quick Hitch Systems: These systems allow for rapid changing of implements without the need for manual pin adjustments, boosting efficiency.

Selecting the right hitch is critical for safety and performance. Using an incorrect hitch can damage the equipment or create unsafe operating conditions. I always ensure the right hitch is used for the specific implement and tractor combination.

Q 27. Explain your understanding of load balancing and its importance in safe operation.

Load balancing is crucial for safe and efficient operation of farm vehicles. An unbalanced load can compromise stability, leading to accidents.

It involves distributing the weight evenly across the vehicle’s axles and ensuring the center of gravity remains within the vehicle’s stability limits. This is especially crucial when transporting heavy loads in trailers or when using implements that have significant weight distribution on one side.

For example, when loading a grain trailer, I ensure the grain is evenly distributed to prevent the trailer from tilting. Similarly, when using a side-mounted implement like a mower, I operate the tractor carefully, ensuring it remains stable. An unbalanced load can lead to rollovers, especially on slopes or uneven terrain. Understanding the weight distribution of the equipment and load is fundamental to safe operation.

Q 28. How do you stay up-to-date with the latest advancements in farm vehicle technology?

Staying current with advancements in farm vehicle technology is essential for maintaining a competitive edge and improving efficiency. I utilize several methods to achieve this:

- Industry Publications and Journals: I regularly read agricultural publications and journals to learn about new technologies and innovations.

- Trade Shows and Conferences: Attending industry trade shows and conferences allows me to see new equipment firsthand and network with other professionals.

- Manufacturer Websites and Training: I access manufacturers’ websites and training materials to learn about the latest features and maintenance procedures of specific equipment.

- Online Forums and Communities: Online forums and communities provide opportunities to discuss best practices and challenges with other farmers and professionals.

Continuous learning ensures I’m proficient in operating and maintaining modern equipment. This improves my efficiency and contributes to the farm’s overall success.

Key Topics to Learn for Farm Vehicle Driving Interview

- Vehicle Operation & Maintenance: Understanding the mechanics of various farm vehicles (tractors, harvesters, sprayers etc.), including routine checks, preventative maintenance, and troubleshooting common issues.

- Safety Procedures & Regulations: Demonstrating knowledge of safe operating procedures, adhering to all relevant safety regulations, and understanding hazard identification and risk mitigation techniques on the farm.

- Navigation & Precision Farming: Familiarity with GPS systems, precision farming techniques, and efficient route planning for optimal field coverage and minimizing fuel consumption.

- Crop Handling & Transportation: Understanding best practices for loading, transporting, and unloading crops and other agricultural goods safely and efficiently, minimizing damage and spoilage.

- Environmental Awareness: Demonstrating an understanding of environmentally sound practices, including minimizing fuel consumption, responsible pesticide application, and soil conservation techniques.

- Legal Compliance & Documentation: Knowledge of relevant legislation, licensing requirements, and accurate record-keeping related to vehicle operation and maintenance.

- Problem-Solving & Decision-Making: Ability to analyze situations, identify problems, and make sound decisions in challenging conditions (e.g., equipment malfunction, adverse weather).

- Teamwork & Communication: Demonstrating the ability to work effectively as part of a team, communicate clearly with colleagues and supervisors, and follow instructions.

Next Steps

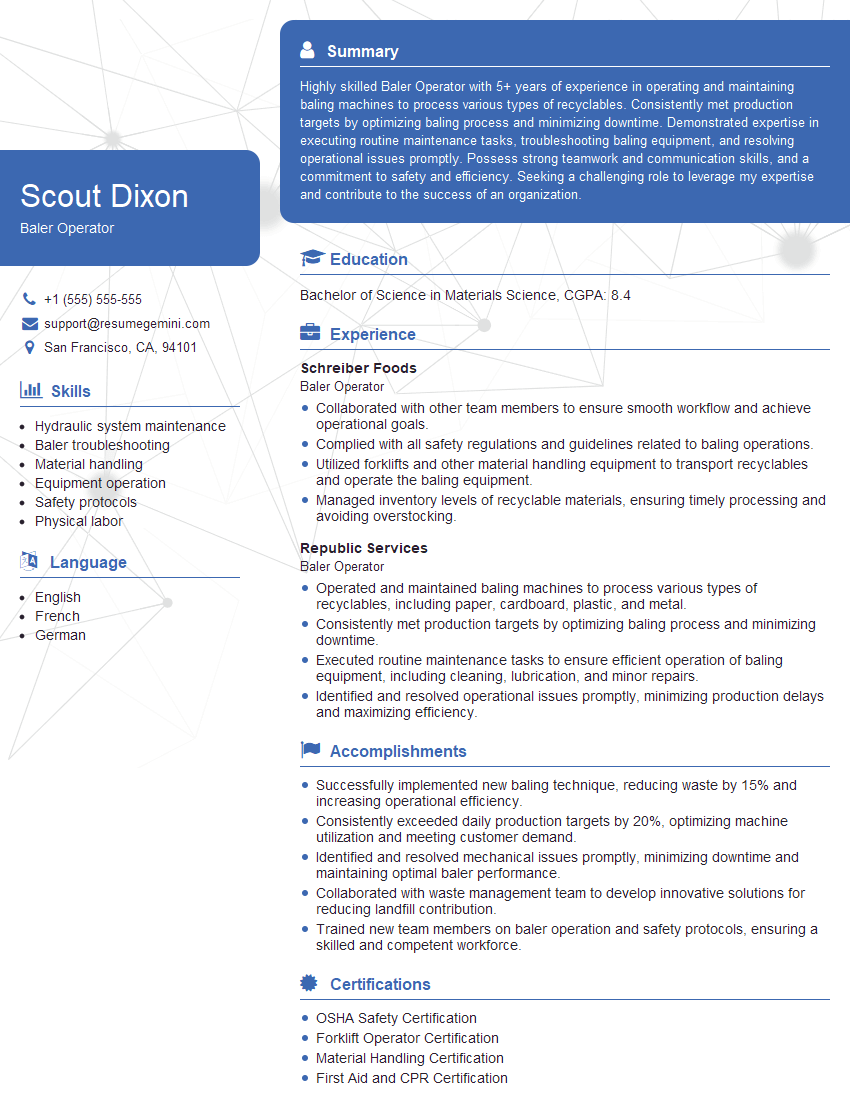

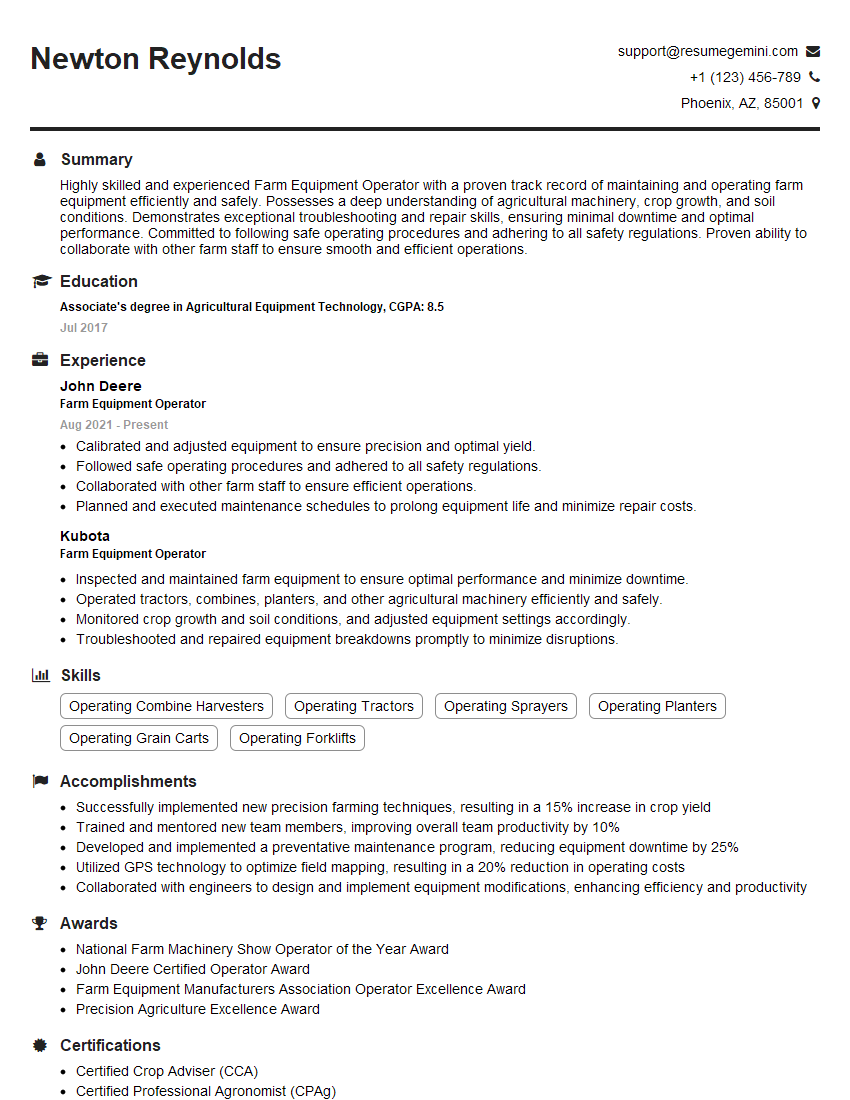

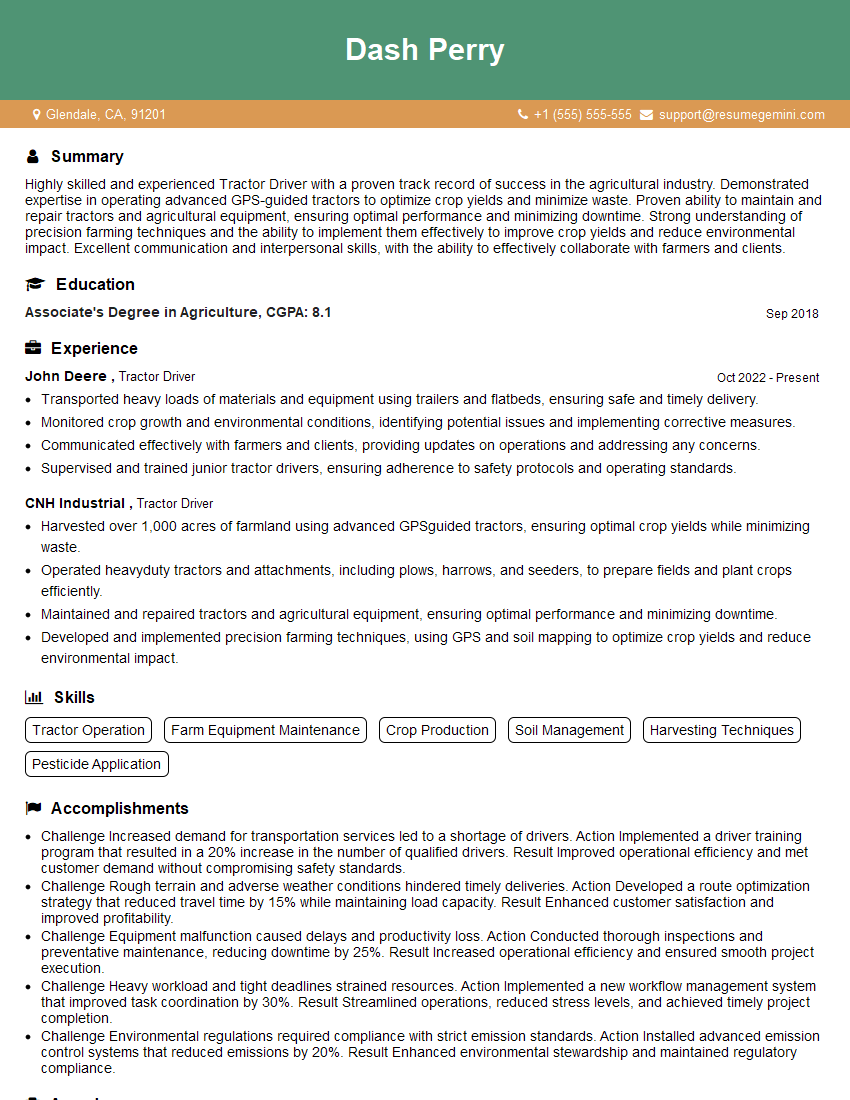

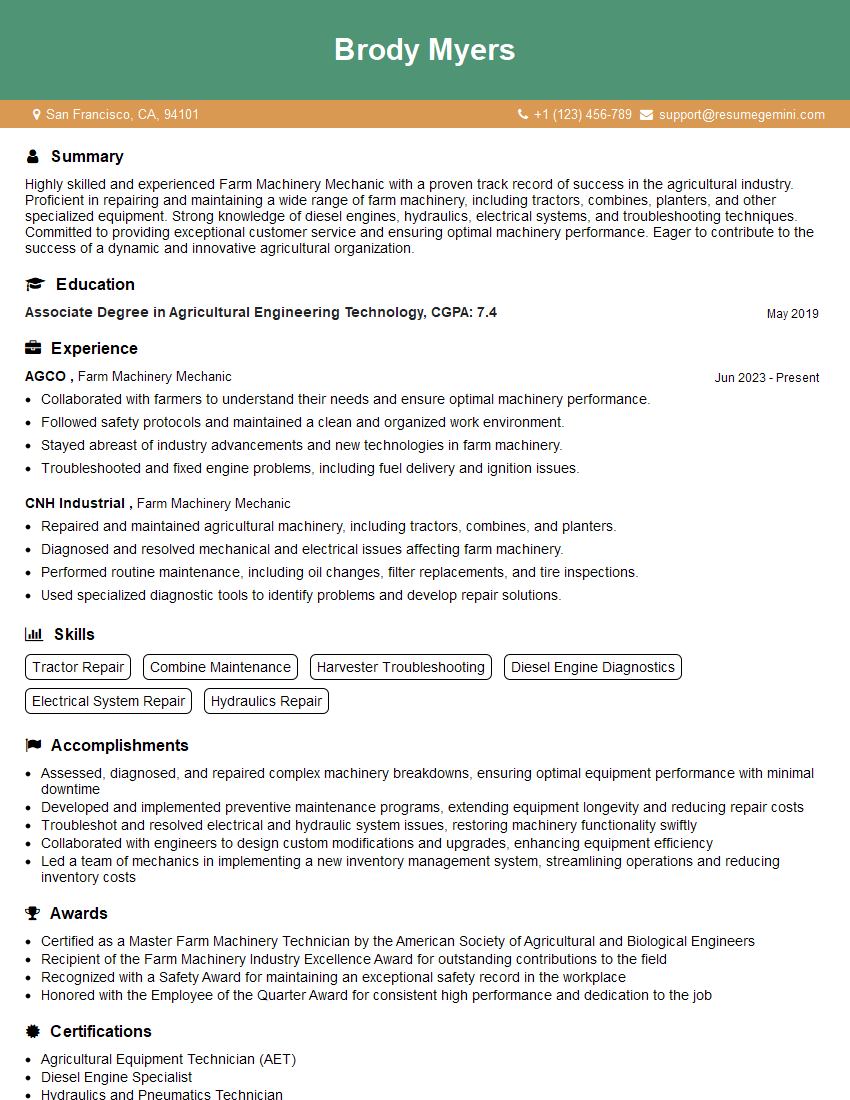

Mastering Farm Vehicle Driving opens doors to a rewarding career with excellent growth potential within the agricultural sector. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes specifically designed for Farm Vehicle Driving roles are available to help you get started. Invest time in crafting a compelling resume – it’s your first impression and a critical step towards landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good