Are you ready to stand out in your next interview? Understanding and preparing for ERP or Production Management Software Experience interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in ERP or Production Management Software Experience Interview

Q 1. Explain the core functionalities of an ERP system.

At its core, an Enterprise Resource Planning (ERP) system is an integrated software solution designed to manage and automate business processes across various departments within an organization. Think of it as a central nervous system for your business, connecting all the vital organs (departments) and allowing them to communicate and work together seamlessly.

- Financials: Handles accounting, financial reporting, budgeting, and forecasting. Imagine effortlessly tracking revenue, expenses, and profits across all projects.

- Human Resources (HR): Manages employee information, payroll, benefits, and recruitment. This streamlines HR processes and provides valuable workforce analytics.

- Supply Chain Management (SCM): Oversees procurement, inventory management, warehousing, and logistics. This allows for efficient tracking and management of goods from supplier to customer.

- Production Planning and Manufacturing: Schedules production, manages materials, and tracks output. This is crucial for optimizing manufacturing processes and meeting deadlines.

- Customer Relationship Management (CRM): Manages customer interactions, sales, and marketing. This enables personalized customer service and improved sales.

A key benefit is the centralization of data, providing a single source of truth for all business information, improving decision-making and reducing errors.

Q 2. Describe your experience with MRP (Material Requirements Planning).

My experience with Material Requirements Planning (MRP) spans several years, working with both legacy and cloud-based ERP systems. MRP is a production planning and inventory control system used to determine the materials and components needed to meet a production schedule. I’ve used it to effectively manage bill of materials (BOMs), forecast demand, and optimize inventory levels.

For example, in a previous role at a manufacturing company, we used MRP to manage the production of custom-designed furniture. By inputting the sales orders and the BOM for each piece, the system automatically calculated the required raw materials (wood, fabrics, hardware), their quantities, and the optimal purchasing and delivery schedule, preventing shortages and minimizing storage costs. We also leveraged the system’s capacity planning features to identify potential bottlenecks in production and adjust schedules accordingly.

My expertise extends to using MRP II (Manufacturing Resource Planning), which expands upon basic MRP to include capacity planning, shop floor control, and financial planning, providing a more holistic view of the production process.

Q 3. How do you handle inventory discrepancies in an ERP system?

Inventory discrepancies are a common challenge in any business. In an ERP system, we address these using a systematic approach.

- Identify the Discrepancy: The first step is to pinpoint the difference between the physical inventory count and the system’s recorded inventory. This often involves cycle counting or a full physical inventory.

- Investigate the Cause: Once identified, we investigate potential root causes. This might include data entry errors, stock losses due to damage or theft, inaccurate scanning, or issues with the receiving process.

- Implement Corrective Actions: Based on the identified cause, we implement corrective actions. This could involve retraining staff on data entry procedures, improving security measures, upgrading scanning equipment, or refining the receiving and putaway procedures.

- Adjust Inventory Records: Once the cause is understood and resolved, the ERP system’s inventory records are adjusted to reflect the actual physical count.

- Implement Preventative Measures: To prevent future discrepancies, we often implement preventative measures such as regular cycle counting, improved inventory management procedures, and better integration between the ERP system and warehouse management system (WMS).

Utilizing ERP’s reporting capabilities, we can track the frequency and types of discrepancies over time to identify recurring problems and refine our processes further.

Q 4. What are the key performance indicators (KPIs) you monitor in production management?

In production management, I monitor several key performance indicators (KPIs) to gauge efficiency, quality, and overall performance. These KPIs can be categorized into several areas:

- Production Efficiency: This includes Overall Equipment Effectiveness (OEE), production lead time, production cycle time, and production yield. These metrics assess how effectively resources are utilized in the production process.

- Inventory Management: Key KPIs here are inventory turnover rate, inventory holding costs, and stockout rates. These help optimize inventory levels and minimize waste.

- Quality Management: Defect rate, rework rate, and customer returns are crucial KPIs to ensure product quality meets expectations.

- On-Time Delivery: On-time delivery rate is a vital metric reflecting the ability to meet customer deadlines.

- Cost Management: Production costs per unit, direct and indirect labor costs, and material costs are essential for cost control.

Regular monitoring of these KPIs, using the ERP system’s reporting features, allows for timely identification of areas for improvement and proactive management of production processes.

Q 5. Explain your experience with different ERP modules (e.g., Financials, Production Planning, Inventory Management).

My ERP experience encompasses a wide range of modules. I’ve worked extensively with Financials, Production Planning, and Inventory Management modules, but also have experience with other modules like CRM, HR, and Procurement.

- Financials: I’ve used financial modules to manage budgeting, forecasting, and financial reporting. I’m proficient in generating financial statements and analyzing key financial performance metrics.

- Production Planning: I have a strong understanding of production scheduling, capacity planning, and material requirements planning. I’ve used ERP systems to optimize production schedules, minimize waste, and improve on-time delivery.

- Inventory Management: I’ve worked extensively with inventory tracking, cycle counting, and warehouse management. I’m skilled in optimizing inventory levels, minimizing stockouts, and reducing carrying costs.

The interconnectivity between these modules is vital. For example, accurate inventory data from the Inventory Management module feeds directly into the Production Planning module, ensuring accurate production scheduling. Furthermore, actual production costs are captured and reflected in the Financial module, providing a clear picture of profitability.

Q 6. How do you optimize production schedules to minimize costs and maximize efficiency?

Optimizing production schedules requires a multi-faceted approach. It’s not just about meeting deadlines, but doing so cost-effectively and efficiently.

- Demand Forecasting: Accurate demand forecasting is crucial. Using historical data and market trends, we can anticipate future demand and adjust production accordingly.

- Capacity Planning: Understanding production capacity—the maximum output achievable—is critical. This involves considering machine availability, labor resources, and potential bottlenecks.

- Material Management: Efficient material management is vital. Minimizing lead times for procuring raw materials and optimizing inventory levels are crucial to avoid delays.

- Lean Manufacturing Principles: Incorporating lean principles, such as eliminating waste and improving workflow, is crucial. Techniques like Kanban or Six Sigma can drastically improve efficiency.

- Scheduling Techniques: Utilizing advanced scheduling algorithms within the ERP system, such as Finite Capacity Scheduling or Material Requirements Planning (MRP), helps optimize resource allocation and minimize production lead times.

- Real-time Monitoring: Continuous monitoring of production progress using the ERP system’s real-time dashboards enables quick identification and resolution of any issues, preventing costly delays.

By strategically implementing these steps, we can ensure a production schedule that is both efficient and cost-effective, leading to improved profitability and customer satisfaction.

Q 7. Describe your experience with implementing or upgrading an ERP system.

I have extensive experience in both implementing and upgrading ERP systems. This process is complex and requires careful planning and execution.

- Needs Assessment: The first step is to thoroughly understand the organization’s current and future needs. This includes identifying pain points, business goals, and required functionalities.

- Vendor Selection: Choosing the right ERP vendor is critical. Factors to consider include the vendor’s reputation, the software’s capabilities, and the level of support offered.

- Project Planning: A detailed project plan should outline all phases of implementation, including timelines, resources, and responsibilities. This plan should also include a risk mitigation strategy.

- Data Migration: Migrating data from legacy systems to the new ERP system requires meticulous planning and execution to ensure data integrity and accuracy.

- System Configuration and Customization: The ERP system needs to be configured to meet the organization’s specific requirements. This might involve customization of existing modules or development of new modules.

- Training and User Adoption: Thorough training for all users is vital for successful system adoption. User engagement and feedback throughout the process are key to ensuring smooth transition.

- Go-Live and Post-Implementation Support: The go-live phase requires careful coordination and monitoring. Post-implementation support is essential to address any issues and ensure ongoing system optimization.

In one particular project, we successfully migrated a mid-sized manufacturing company from a legacy system to a cloud-based ERP solution. This involved careful data cleansing, extensive user training, and close collaboration with the client throughout the process. The result was a significant improvement in efficiency and a reduction in operational costs.

Q 8. How do you handle production delays or unexpected issues?

Handling production delays requires a proactive and systematic approach. My strategy involves a three-pronged attack: identification, mitigation, and communication.

First, we pinpoint the root cause of the delay. This could involve anything from equipment malfunction to material shortages or unexpected quality issues. We use the ERP system’s reporting tools to track key performance indicators (KPIs) and identify bottlenecks. For instance, if a particular machine is consistently delaying production, we’d analyze its maintenance history and potentially schedule preventative maintenance to avoid future problems. If a material shortage is the culprit, we’ll immediately contact suppliers to expedite delivery.

Next, we implement mitigation strategies. This could include re-scheduling production, adjusting resource allocation, or exploring alternative suppliers. Let’s say we have a critical part shortage impacting a high-priority order. We might prioritize the production of that part by reassigning resources or even subcontracting the production of that specific component to an external vendor. The ERP system helps us track the progress of the mitigation plan, allowing for real-time adjustments.

Finally, transparent communication is key. We immediately inform relevant stakeholders – clients, internal teams, and management – about the delay and the mitigation plan. This prevents misunderstandings and maintains trust. Regular status updates, perhaps using automated reports generated by the ERP system, ensure everyone is kept abreast of the situation and aware of the revised timeline.

Q 9. What are the advantages and disadvantages of using cloud-based ERP systems?

Cloud-based ERP systems offer several advantages, but also present some challenges. The main benefits revolve around accessibility, scalability, and cost-effectiveness.

- Accessibility: Employees can access the system from anywhere with an internet connection, improving collaboration and efficiency. Imagine a situation where a sales team needs to quickly access inventory information while on the road – a cloud-based system makes this readily available.

- Scalability: Cloud systems easily adapt to changing business needs. If your company experiences rapid growth, scaling up resources is straightforward, unlike on-premise systems which require significant hardware investments.

- Cost-effectiveness: Cloud solutions often involve lower upfront costs, reducing the burden on IT infrastructure and maintenance.

However, there are drawbacks:

- Dependency on internet connectivity: System downtime occurs if internet access is interrupted, halting operations. A robust backup plan is essential.

- Security concerns: Data security is a primary concern. Choosing a reputable cloud provider with strong security measures is crucial. Regular security audits are also vital.

- Vendor lock-in: Migrating to a different provider can be complex and costly. Careful consideration should be given to the provider’s reputation and long-term viability.

Q 10. How do you ensure data accuracy and integrity within an ERP system?

Data accuracy and integrity are paramount in any ERP system. My approach involves a multi-layered strategy focusing on data validation, access control, and regular audits.

Data validation involves implementing checks and balances at various stages of data entry. For example, we could use predefined data lists to prevent typos and inconsistencies in product codes or customer names. We can also use data validation rules to ensure that numerical fields are within a defined range, such as quantity ordered. The ERP system should be configured to flag potential errors or inconsistencies.

Access control is essential to prevent unauthorized modifications or deletions. Role-based access control (RBAC) limits access to sensitive data based on an individual’s job responsibilities. Only authorized personnel can modify critical production parameters, and all changes are logged for auditing purposes. The audit trail can be crucial in tracing errors or inconsistencies.

Finally, regular audits are vital for identifying and correcting errors. We would conduct periodic checks to verify data accuracy against physical inventory counts and other independent sources. This helps prevent undetected errors from propagating through the system. The findings of such audits are documented and utilized for continuous improvement and system refinement.

Q 11. Explain your experience with demand forecasting and planning.

Demand forecasting is crucial for efficient production planning. My experience involves leveraging a combination of qualitative and quantitative methods.

Quantitative methods rely on historical sales data, market trends, and statistical models. We utilize time series analysis, regression analysis, and exponential smoothing techniques to predict future demand. For instance, if we notice a seasonal increase in demand for a particular product during the holiday season, we can use historical data to forecast demand for the upcoming holiday season, and adjust production accordingly.

Qualitative methods incorporate expert opinions and market research. We conduct surveys, interviews, and focus groups to gather insights that might not be captured in historical data. This is particularly useful for new products or during periods of significant market disruption. For example, in anticipation of a new product launch, we may consult with marketing and sales teams to gauge their expectations about initial demand.

The ERP system plays a vital role by providing the data required for quantitative analysis and facilitating the collection and analysis of qualitative information. The system also allows for scenario planning, allowing us to compare forecasts under different assumptions and adapt our production plans to changing market conditions.

Q 12. Describe your experience with capacity planning and resource allocation.

Capacity planning and resource allocation are intrinsically linked and critical for optimizing production. My approach involves a multi-step process: demand forecasting, resource assessment, and allocation optimization.

We begin by forecasting the demand for each product, as discussed earlier. Next, we assess available resources, including machinery, labor, and raw materials. The ERP system helps us to track resource utilization, identifying potential bottlenecks and areas where capacity is constrained. We might analyze machine downtime, labor availability, and inventory levels to identify constraints.

Finally, we optimize resource allocation to meet forecasted demand while minimizing costs and maximizing efficiency. We use various techniques, such as linear programming or simulation modeling, to develop optimal production schedules and resource assignments. For example, we might shift production of certain items to less-constrained machines or adjust work schedules to better utilize labor resources. The ERP system then tracks actual resource utilization against planned utilization, enabling continuous improvement through identifying discrepancies and adjusting plans.

Q 13. How do you manage supplier relationships within a production environment?

Managing supplier relationships is crucial for a smooth production process. My approach emphasizes collaboration, communication, and performance monitoring.

Collaboration involves working closely with suppliers to understand their capabilities, capacity, and potential risks. We establish clear communication channels and use the ERP system to track orders, shipments, and delivery dates. We also use the system to share forecasts and production plans with suppliers to ensure they can meet our demands.

Communication is paramount. Regular meetings and updates, both formal and informal, keep communication flowing and allow for prompt resolution of any arising issues. This prevents minor issues from escalating into significant production delays. The ERP system facilitates this by providing a centralized platform for communication and information sharing.

Performance monitoring is crucial. We track supplier performance based on key metrics, such as on-time delivery, quality of materials, and responsiveness. The ERP system allows us to collect and analyze data on supplier performance, enabling us to identify top performers and address issues with underperforming suppliers. This can lead to continuous improvement in supply chain efficiency and quality.

Q 14. What are your preferred methods for data analysis in production management?

My preferred methods for data analysis in production management involve a blend of descriptive, diagnostic, predictive, and prescriptive analytics.

Descriptive analytics involves summarizing historical data to understand past performance. We utilize the ERP system’s reporting tools to generate dashboards and reports on KPIs such as production output, efficiency rates, and defect rates. This provides valuable insights into overall performance trends.

Diagnostic analytics focuses on identifying the root causes of problems. We use data mining techniques and statistical methods to analyze data and pinpoint the source of production inefficiencies or quality issues. For instance, identifying bottlenecks through analyzing machine downtime, identifying areas needing improvement.

Predictive analytics leverages historical data and statistical models to forecast future trends. This is crucial for demand forecasting, as discussed previously, as well as predicting equipment failures or potential supply chain disruptions.

Prescriptive analytics uses data and algorithms to recommend actions to improve future performance. We can use simulation models and optimization techniques to determine the best course of action in various scenarios, such as determining optimal production schedules or resource allocations. This allows us to proactively address issues and improve overall efficiency.

Q 15. How do you use ERP data to identify areas for improvement in production processes?

ERP systems are treasure troves of data that, when analyzed correctly, reveal bottlenecks and inefficiencies in production. I typically start by focusing on key performance indicators (KPIs) directly related to production. This includes metrics like cycle time, production lead time, machine utilization, and defect rates.

For example, let’s say an analysis reveals consistently high cycle times on a specific assembly line. I would then drill down into the ERP data to investigate the root cause. This might involve examining individual work order completion times, identifying machine downtime events, or analyzing material availability issues. The ERP system allows me to trace the flow of materials and track the progress of each order, isolating the problem areas.

Once identified, I use this data to propose solutions, such as optimizing the line layout, implementing preventative maintenance, or improving the material handling process. The impact of these improvements can then be tracked using the ERP system, allowing for continuous monitoring and fine-tuning.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with Lean Manufacturing principles.

Lean manufacturing is all about eliminating waste and maximizing value. In my experience, implementing Lean principles starts with mapping the value stream. This involves visually charting every step in the production process from raw materials to finished goods, identifying steps that don’t add value (waste). This could be excess inventory, unnecessary movement of materials, or waiting time.

I’ve used techniques like 5S (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace organization, Kaizen (continuous improvement) events to identify and eliminate small inefficiencies, and Kanban systems to manage inventory and workflow. For instance, in one project, we implemented a Kanban system to control the flow of parts between assembly stations, reducing lead times by 20% and significantly decreasing work-in-progress inventory.

Lean isn’t just about tools; it’s a culture of continuous improvement and employee empowerment. I actively involve teams in identifying waste and implementing solutions, fostering a sense of ownership and driving sustainable change.

Q 17. What are your experiences with Six Sigma methodologies in production?

Six Sigma methodologies focus on reducing variation and defects in production processes. My experience with Six Sigma involves applying DMAIC (Define, Measure, Analyze, Improve, Control) to address quality issues.

For example, I once led a Six Sigma project focused on reducing the defect rate in a specific component. We started by defining the problem (high defect rate) and measuring the current defect rate and its sources using ERP data and quality control reports. Then, we analyzed the root causes of defects using tools like Pareto charts and fishbone diagrams. This analysis often involved data from ERP systems related to material specifications, machine performance, and operator training.

Based on this analysis, we implemented improvements, such as refining the manufacturing process, enhancing operator training, and improving quality control procedures. Finally, we established controls to ensure the improvements are sustained. Post-implementation monitoring using ERP data demonstrated a significant reduction in the defect rate, exceeding our project goals.

Q 18. How do you ensure compliance with industry regulations and standards?

Ensuring compliance is crucial. My approach involves understanding the relevant industry regulations and standards—such as ISO 9001, FDA regulations (if applicable), and environmental regulations—and embedding compliance into every aspect of the production process. This starts with clearly documented procedures and training programs for all personnel.

The ERP system plays a vital role here. We use it to track materials, maintain calibration records for equipment, manage documentation related to audits and certifications, and ensure traceability throughout the production process. We also leverage the ERP system’s reporting capabilities to generate reports that demonstrate compliance and facilitate internal and external audits. Regularly scheduled reviews of compliance measures are conducted, and any deviations are immediately addressed.

Q 19. Explain your experience with different types of production planning (e.g., push vs. pull).

Production planning can be broadly categorized as push and pull systems. In a push system, production is based on forecasts and planned schedules. Materials are pushed through the production process based on anticipated demand, regardless of actual customer orders. This often leads to higher inventory levels and potentially obsolete stock.

In a pull system, such as Kanban, production is triggered by actual customer demand. Only the required materials are pulled through the process as needed. This minimizes inventory and reduces waste.

I’ve worked with both systems. The choice depends on various factors including demand variability, product complexity, and inventory holding costs. In some cases, a hybrid approach is optimal, combining elements of both push and pull systems to leverage their respective strengths. For example, we might use a push system for standardized products with stable demand and a pull system for customized products with fluctuating orders.

Q 20. How do you utilize reporting and analytics to track production performance?

ERP systems provide robust reporting and analytics tools for tracking production performance. I regularly utilize these tools to monitor KPIs, such as on-time delivery, production efficiency, and overall equipment effectiveness (OEE). Custom reports are often created to specifically address areas of concern or to monitor the impact of implemented changes.

For example, I might create a report that shows the daily production output of each assembly line, highlighting any significant deviations from the planned schedule. This data is crucial for identifying bottlenecks and addressing potential problems before they significantly impact production. Data visualization tools within the ERP system help present this information clearly and concisely, making it easy to identify trends and patterns.

Beyond standard reports, I also use the ERP data to perform more in-depth analyses, leveraging the system’s query capabilities to identify correlations between different variables and understand the root causes of performance issues. This data-driven approach helps inform decision-making and drives continuous improvements in production processes.

Q 21. Describe your experience with different inventory management techniques (e.g., FIFO, LIFO).

Inventory management techniques like FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) significantly impact production efficiency and profitability. FIFO ensures that older inventory is used first, minimizing the risk of spoilage or obsolescence. This is particularly important for perishable goods or items with limited shelf life.

LIFO, on the other hand, assumes the most recently received inventory is used first. This can be advantageous for tax purposes in some situations but may lead to higher costs if prices are volatile and the value of inventory declines.

In my experience, the choice of inventory management technique depends on the nature of the inventory. For products with short shelf lives or potential for spoilage, FIFO is almost always preferred. Other techniques such as FEFO (First-Expired, First-Out) might also be used. ERP systems are essential for managing inventory using any of these methods, providing real-time visibility into stock levels, facilitating automated ordering, and enabling accurate cost accounting.

Q 22. How do you handle production bottlenecks?

Identifying and resolving production bottlenecks requires a systematic approach. Think of a production line as a chain; the weakest link determines the overall strength. The first step is to pinpoint the bottleneck – this often involves analyzing production data, identifying areas with high work-in-progress (WIP) inventory, long lead times, or frequent machine downtime. Tools like ERP systems are invaluable here, providing real-time visibility into production processes.

Once the bottleneck is identified, we need to analyze the root cause. Is it due to machine malfunction, insufficient skilled labor, material shortages, inefficient processes, or poor planning? A structured problem-solving approach like the 5 Whys can be very effective. For example, if the bottleneck is a slow machine, asking ‘Why is the machine slow?’ repeatedly might reveal a lack of preventative maintenance, inadequate training for operators, or even a design flaw in the machine itself.

Solutions vary depending on the root cause. It might involve scheduling overtime, investing in new equipment, improving operator training, optimizing the production process through lean manufacturing techniques, or improving supply chain management to ensure timely material delivery. Regular monitoring and performance analysis are crucial to ensure that the implemented solution is effective and that new bottlenecks don’t emerge.

For instance, in a previous role, we identified a bottleneck in the packaging department of a food manufacturing plant. Analysis showed the bottleneck stemmed from a poorly designed packaging machine that frequently malfunctioned. By replacing the machine with a more efficient model and providing additional operator training, we improved packaging speed by 25%, significantly boosting overall production output.

Q 23. What is your experience with different types of ERP software (e.g., SAP, Oracle, Microsoft Dynamics)?

I have extensive experience with several leading ERP systems, including SAP, Oracle NetSuite, and Microsoft Dynamics 365. Each system offers unique strengths and weaknesses depending on the specific needs of the organization. SAP, for instance, is a robust solution well-suited for large enterprises with complex operations. Its strength lies in its comprehensive functionalities, deep industry expertise, and highly customizable modules.

Oracle NetSuite, on the other hand, is a cloud-based solution particularly well-suited for mid-sized companies needing a more readily deployable, integrated solution. It’s known for its ease of use and scalability. Microsoft Dynamics 365 offers a range of solutions tailored for different business sizes and industries, often integrating well with other Microsoft products. My experience involves implementing, customizing, and supporting these systems, covering everything from financial management to supply chain optimization.

In a past project, we migrated a client from a legacy system to SAP S/4HANA. This involved a comprehensive analysis of their current processes, data migration, system configuration, and extensive user training. The project delivered significant improvements in efficiency, data accuracy, and reporting capabilities.

Q 24. How do you ensure data security and compliance within an ERP system?

Data security and compliance are paramount in any ERP system. We must adopt a multi-layered approach to protect sensitive business data. This includes implementing robust access controls, encryption at rest and in transit, regular security audits, and adhering to relevant regulations like GDPR, CCPA, and SOX.

Access controls should be granular, ensuring that each user only has access to the data and functionalities necessary for their role. Regular security audits help identify vulnerabilities and ensure compliance with security policies. Encryption safeguards data from unauthorized access, even if a breach occurs. Finally, continuous monitoring and logging of system activities provide a trail for auditing and incident response.

For example, in a previous role, we implemented multi-factor authentication (MFA) for all ERP users, significantly reducing the risk of unauthorized access. We also conducted regular penetration testing to identify and address vulnerabilities before they could be exploited. This proactive approach was crucial in maintaining data security and compliance.

Q 25. Explain your experience with integrating different software systems with an ERP system.

Integrating different software systems with an ERP system is crucial for achieving end-to-end business process automation. This often involves using APIs (Application Programming Interfaces) or middleware solutions to establish seamless communication between the systems. The challenge lies in ensuring data consistency and accuracy across all integrated systems.

For instance, integrating a CRM (Customer Relationship Management) system with an ERP system allows for real-time updates of customer data, order tracking, and sales forecasting. Integrating a warehouse management system (WMS) provides real-time inventory visibility and streamlines warehouse operations. Successful integration requires careful planning, understanding the capabilities of each system, and addressing potential data mapping and transformation issues.

In a previous project, we integrated a client’s ERP system with their e-commerce platform using APIs. This enabled real-time order processing, inventory updates, and automated shipping notifications, resulting in a significant improvement in customer service and operational efficiency.

Q 26. Describe a time you had to troubleshoot a significant issue within an ERP system.

One time, we experienced a critical issue where a critical ERP database update caused the entire system to crash during peak business hours. The immediate impact was a complete halt to all business processes, resulting in significant financial losses and impacting customer orders. Our initial response involved engaging our emergency response team and activating our disaster recovery plan.

We quickly diagnosed the issue as a faulty database script that had corrupted the production database. Our step-by-step approach involved restoring the database from a recent backup, verifying data integrity, and implementing a more robust testing procedure for future database updates. After the system was restored, we conducted a thorough post-mortem analysis to identify the root cause and implement preventative measures to avoid similar incidents in the future. This included improving the database update process, enhancing monitoring capabilities, and strengthening our change management protocols. We also provided extensive communication updates to the stakeholders to keep them informed of the progress.

Q 27. How do you prioritize tasks and manage multiple projects simultaneously?

Prioritizing tasks and managing multiple projects simultaneously requires a structured approach. I typically use a combination of techniques like project prioritization matrices, Agile methodologies, and time management tools. A prioritization matrix, such as a MoSCoW method (Must have, Should have, Could have, Won’t have), helps to clearly define the importance and urgency of different tasks.

Agile methodologies, such as Scrum or Kanban, provide frameworks for managing complex projects iteratively, allowing for flexibility and adaptation to changing priorities. Time management tools like task management software (e.g., Jira, Asana) help to track progress, manage deadlines, and allocate resources effectively. Communication is key—regular updates with team members and stakeholders are essential to ensure everyone is aligned and informed.

For example, in managing multiple ERP implementation projects concurrently, I utilized a Kanban board to visualize the progress of each project. This allowed me to easily identify and re-allocate resources based on priorities and project roadblocks.

Q 28. What are your long-term career goals in production management or ERP?

My long-term career goals involve leveraging my expertise in ERP and production management to lead and mentor teams in the implementation and optimization of advanced manufacturing technologies. I am particularly interested in exploring the potential of AI and machine learning in optimizing production processes, improving predictive maintenance, and enhancing overall operational efficiency. This includes staying abreast of emerging technologies and industry best practices.

I also aspire to take on leadership roles where I can contribute to the strategic direction of organizations and drive innovation within the manufacturing sector. Continuously improving my knowledge and skills, staying current on industry trends, and actively seeking opportunities for professional development are key to achieving these long-term objectives.

Key Topics to Learn for ERP or Production Management Software Experience Interview

- Master Data Management: Understand the crucial role of accurate and consistent data within ERP systems. Explore how data errors impact production planning and decision-making.

- Production Planning & Scheduling: Learn about different scheduling methodologies (MRP, Kanban, etc.) and how to optimize production schedules to meet demand while minimizing costs and inventory.

- Inventory Management: Discuss strategies for effective inventory control, including forecasting, stock level management, and the impact of inventory on production efficiency.

- Quality Control & Management: Explore how ERP systems are used to track quality metrics, identify defects, and implement corrective actions to ensure product quality.

- Reporting & Analytics: Understand how to extract meaningful insights from ERP data to monitor key performance indicators (KPIs), identify trends, and support data-driven decision-making in production.

- Module Integration & Workflow: Discuss the interconnectedness of different ERP modules (e.g., production, finance, sales) and how efficient workflow processes enhance overall operational efficiency.

- Problem-Solving & Troubleshooting: Practice identifying and resolving common issues within ERP systems, including data inconsistencies, system errors, and production bottlenecks. Develop your approach to debugging and solution implementation.

- Specific Software Knowledge: Depending on the job description, familiarize yourself with the specific ERP software mentioned (e.g., SAP, Oracle, Microsoft Dynamics 365). Focus on relevant modules and functionalities.

Next Steps

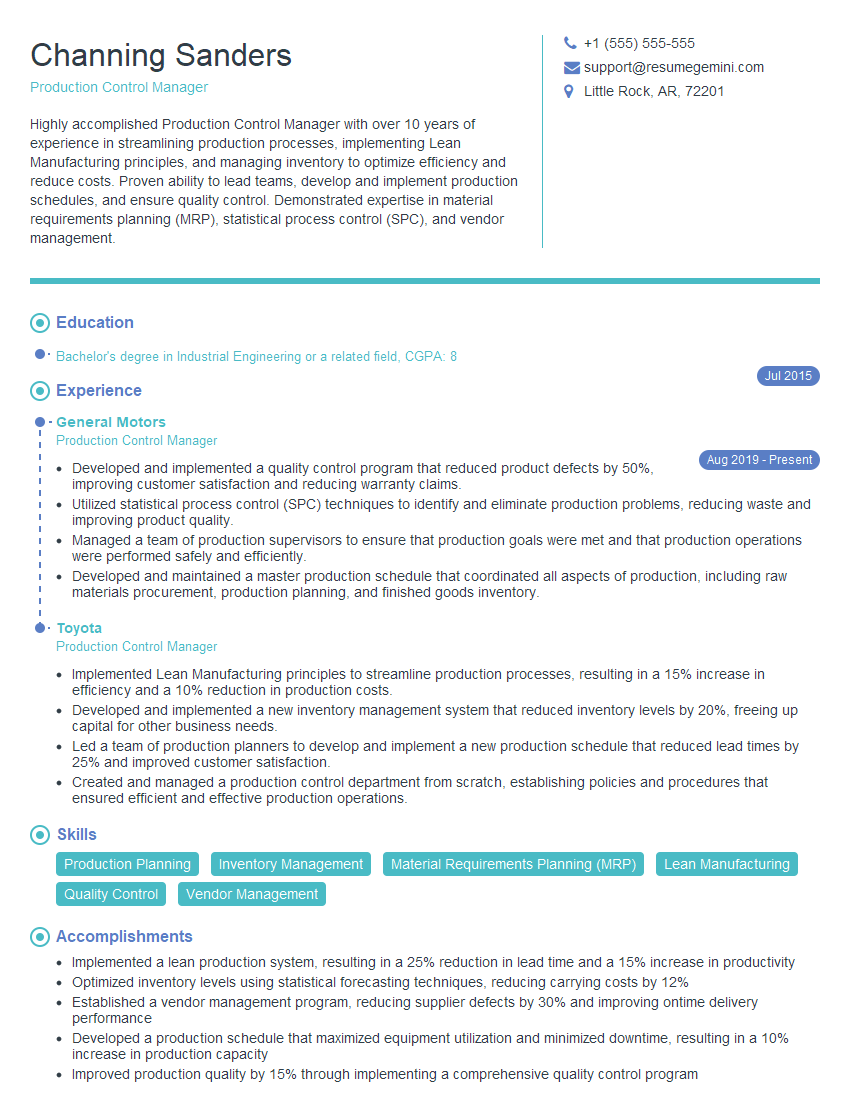

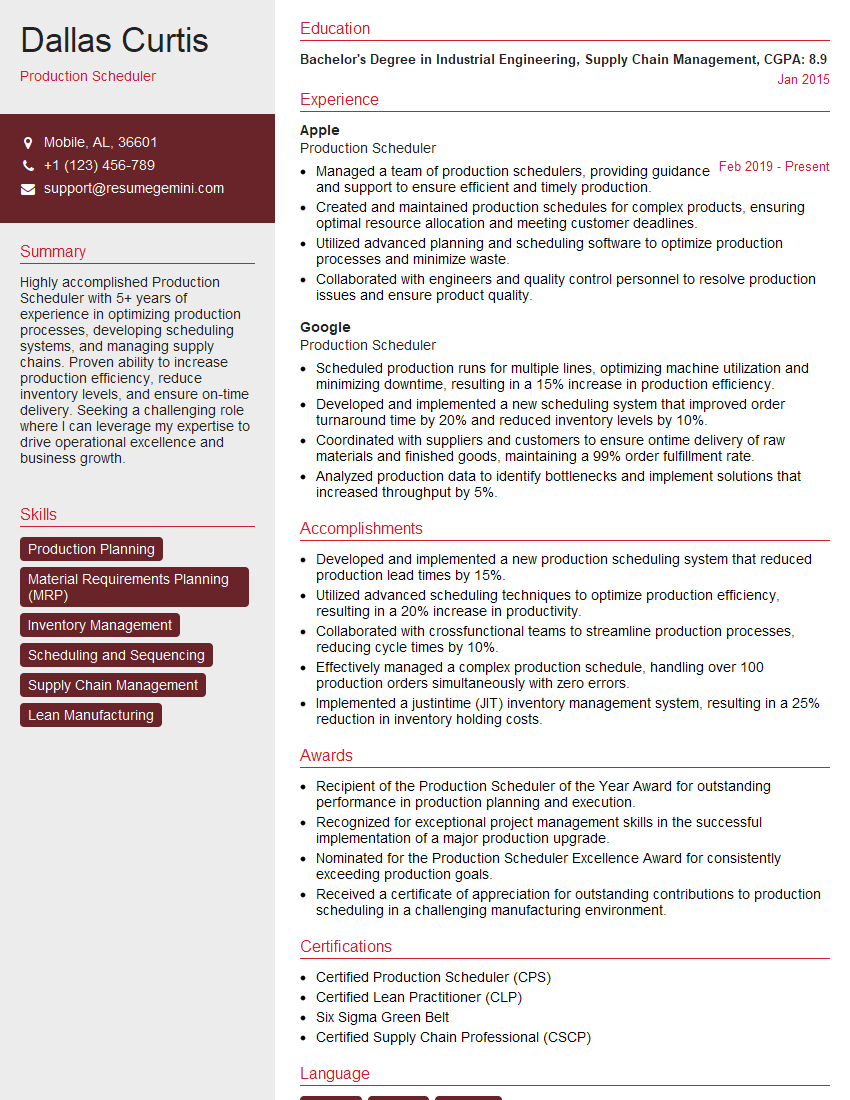

Mastering ERP or Production Management Software experience is crucial for accelerating your career growth in today’s competitive market. Companies highly value professionals who can efficiently utilize these systems to optimize production processes and improve overall business performance. To significantly enhance your job prospects, creating an ATS-friendly resume is essential. This ensures your qualifications are easily identified by applicant tracking systems. We highly recommend leveraging ResumeGemini, a trusted resource, to build a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to ERP or Production Management Software experience are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good