Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Carpet Padding Installation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Carpet Padding Installation Interview

Q 1. What types of carpet padding are you familiar with?

Carpet padding comes in various types, each offering different levels of comfort, resilience, and insulation. I’m familiar with several common types:

- Rebond Padding: This is a popular choice due to its affordability. It’s made from recycled fibers and offers decent cushioning but may compress over time.

- Foam Padding: Made from polyurethane foam, this padding offers excellent cushioning and is relatively lightweight. Different densities are available, influencing its comfort and durability.

- Fiber-Based Padding: These pads are made from natural or synthetic fibers, often offering superior resilience and longevity compared to rebond. They can be more expensive but often provide better long-term value.

- High-Density Padding: As the name suggests, these pads are very dense, providing exceptional support and cushioning. They are ideal for high-traffic areas and thicker carpets.

- Memory Foam Padding: This relatively new type conforms to the shape of your foot, providing superior comfort and pressure relief. It tends to be more expensive.

The choice of padding depends on factors like budget, carpet type, and the level of comfort and durability desired.

Q 2. Explain the process of measuring for carpet padding.

Accurate measuring is crucial for efficient padding installation. I always start by thoroughly inspecting the room for any irregularities like unusual shapes or obstructions. Then:

- Measure the length and width of the room: I use a measuring tape, ensuring accuracy to the nearest inch. For complex rooms, I break down the area into smaller, easily measurable sections.

- Account for doorways and other obstacles: I carefully measure around any fixed objects, ensuring I accurately calculate the amount of padding needed. This often involves creating a scaled diagram to visualize the room’s layout and potential waste.

- Add extra padding: I always add about 5-10% extra to account for any potential waste during cutting and installation. This prevents unexpected shortages during the project.

- Record measurements: All measurements are meticulously recorded, along with any relevant notes such as irregular shapes or obstacles. This prevents mistakes and ensures the right amount of padding is ordered.

A precise measurement process minimizes waste and ensures a smooth installation, leaving the customer satisfied with a perfectly fitted carpet.

Q 3. How do you determine the appropriate padding thickness for different carpet types?

Padding thickness is directly related to the carpet’s fiber type and thickness, as well as the intended level of comfort and insulation. Generally:

- Thin carpets (low pile): These benefit from thinner padding (6-8mm) to prevent an excessively plush feel, which could lead to bunching.

- Medium carpets (medium pile): A medium thickness of padding (8-10mm) provides a good balance of comfort and support.

- Thick carpets (high pile): Thicker padding (10-12mm or even more) is often appropriate for luxurious, plush carpets, enhancing comfort and sound insulation. However, excessively thick padding under very thick carpet can cause problems.

I always consider the customer’s preferences and the overall room aesthetics when choosing the appropriate thickness. A thicker carpet with thin padding would feel less luxurious than a thinner carpet with thicker padding.

Q 4. Describe your experience with different padding installation methods.

I’m experienced with various padding installation methods, including:

- Full-Spread Method: This is the most common method, where the padding is rolled out across the entire floor area before the carpet is laid. It’s great for even subfloors.

- Seamed Padding: For larger areas, padding rolls are seamed together using carpet tape. Careful seam alignment is essential to prevent unevenness or bunching.

- Cut-and-Fit Method: This method involves cutting the padding to fit around irregularities in the subfloor or obstacles like pipes. It requires more precision but is necessary for non-uniform spaces.

My experience allows me to select the most suitable method based on the specific project requirements, ensuring an efficient and high-quality installation, no matter the situation.

Q 5. What are the common challenges encountered during carpet padding installation?

Several challenges can arise during carpet padding installation:

- Uneven subfloors: Unevenness leads to bumps and dips in the finished carpet.

- Moisture problems: Excessive moisture can cause mold and mildew growth under the carpet.

- Poorly seamed padding: Improper seaming leads to unevenness and potential bunching.

- Improper padding selection: Using inappropriate padding thickness for the carpet can result in discomfort and premature wear.

- Difficult room shapes or obstacles: These require careful planning and precise cutting of the padding.

Addressing these challenges requires thorough preparation, proper tools, and experience in problem-solving, ensuring a successful installation despite unexpected hurdles.

Q 6. How do you handle uneven subfloors before padding installation?

Uneven subfloors are a significant challenge. Before padding installation, I address them through these steps:

- Assess the unevenness: I use a straight edge and level to identify the extent of the problem.

- Self-Leveling Compound: For minor unevenness, a self-leveling compound can create a smooth surface over the subfloor. I let it dry completely before proceeding.

- Underlayment: For more significant unevenness, a suitable underlayment (like plywood) can be used to level the surface. This requires more extensive preparation and may involve removing existing flooring.

Thoroughly leveling the subfloor is critical; otherwise, the finished carpet will reflect the imperfections, ultimately impacting the customer’s satisfaction and potentially leading to premature wear.

Q 7. Explain your experience with moisture barriers and their importance.

Moisture barriers are crucial in preventing moisture damage to the carpet and subfloor. My experience includes using polyethylene sheeting as a moisture barrier. It’s laid directly on the subfloor before the padding is installed. This helps protect against moisture from the ground or from spills.

I always emphasize the importance of moisture barriers, particularly in basements or areas prone to moisture. Ignoring moisture issues can lead to costly repairs down the line, including mold growth, carpet damage, and even structural damage. A small investment in a moisture barrier pays for itself in the long run by protecting the entire flooring system.

Q 8. What safety precautions do you take during padding installation?

Safety is paramount in carpet padding installation. Before I even begin, I always inspect the work area for potential hazards like loose nails, uneven surfaces, or electrical wires. I wear appropriate safety gear, including sturdy work boots with good traction to prevent slips and falls, safety glasses to protect my eyes from debris, and knee pads for comfort and protection during extended periods of kneeling. When using any cutting tools, such as a utility knife, I ensure I have a firm grip and make slow, controlled cuts away from my body. Proper ventilation is also crucial, especially when working with adhesives, to avoid inhaling harmful fumes. Finally, I always maintain a clean and organized workspace to minimize tripping hazards.

For example, on a recent job in an older home, I discovered some loose floorboards. Before proceeding, I secured those boards to prevent any accidents. This proactive approach ensures both my safety and the safety of others on the job site.

Q 9. How do you ensure proper seam alignment and secure transitions?

Achieving seamless transitions and proper seam alignment is key to a professional-looking and durable carpet installation. I start by carefully measuring and cutting the padding to the exact dimensions of each room or area. For seams, I ensure they are butted tightly together, creating a smooth, uninterrupted surface. Overlapping seams are a definite no-no as they can create unevenness and bunching under the carpet. To secure the seams, I use a strong carpet tape designed specifically for padding, applying it evenly along the entire length of the joint. This prevents shifting or separation over time. I always check for alignment from multiple angles, ensuring the seams are perfectly straight and not noticeably offset.

Imagine installing padding in a large living room. Careful seam alignment ensures the finished carpet lies flat and looks flawless. Any misalignment would be immediately noticeable and detract from the overall quality of the installation.

Q 10. Describe your experience with using various tools for padding installation.

My tool kit for padding installation is fairly comprehensive, reflecting years of experience. Essential tools include a sharp utility knife for precise cutting, a measuring tape for accurate measurements, a knee kicker for efficient and even padding placement, and a seam roller to firmly bond seams and eliminate air pockets. I also use a power stretcher in larger areas to ensure the padding is taut and wrinkle-free, and different types of adhesive applicators depending on the type of adhesive being used. For more intricate cuts, I use a carpet square to measure and mark the padding before cutting, ensuring neat and accurate results. I’m proficient in using both manual and power tools, selecting the most appropriate one for the specific task and job conditions.

For instance, in a tight corner, I’d rely on a sharp utility knife for precision cutting. But in a spacious room, a power stretcher is indispensable for ensuring the padding’s smooth and even placement.

Q 11. How do you calculate the amount of padding needed for a given project?

Accurately calculating the amount of padding needed is critical to avoid waste and ensure enough material. I begin by carefully measuring the length and width of each area to be padded, and use the calculation: Length x Width = Square Footage. It’s crucial to account for any irregular shapes or obstacles by breaking down the space into smaller, manageable sections and measuring each section separately. For example, if there are closets or built-in features, I will measure around them to avoid overestimation. I always add an extra 5-10% to the total square footage to account for waste during cutting and any unforeseen circumstances. This ensures I have enough padding to complete the job without having to make additional runs to the supply store.

For example, for a 12ft x 15ft room, the calculation would be 12ft x 15ft = 180 square feet. Adding 10% for waste brings the total to approximately 198 square feet.

Q 12. What are the signs of inadequate subfloor preparation?

Inadequate subfloor preparation is a significant problem that can lead to future issues with the carpet and padding. Common signs include uneven surfaces with dips, bumps or significant variations in height. These can be easily detected by running a straight edge across the floor. Loose floorboards or squeaky floorboards are another major warning sign, indicating a lack of proper support. Other signs include moisture or signs of previous water damage, which can cause mold and mildew growth, and ultimately damage the padding and carpet. Cracks or gaps in the subfloor also compromise stability and can lead to future problems. Before installing padding, I always thoroughly inspect the subfloor for all of these issues, ensuring it’s properly addressed by the appropriate professionals before proceeding.

For example, on a project where water damage had been previously repaired, I detected some subtle unevenness along one wall that would have eventually created problems for the new carpet and padding. Fortunately I caught it, and we were able to address this before the new carpet was installed.

Q 13. How do you address wrinkles or ripples in the installed padding?

Wrinkles and ripples in installed padding are usually caused by improper installation or inadequate subfloor preparation. My first step to address this is to identify the cause. If the subfloor is uneven, it needs to be addressed before any further padding is installed. If the cause is improper installation, then carefully lifting and smoothing out the affected areas often helps. For larger wrinkles I may use a knee kicker to gently stretch the padding in the affected areas. Using a seam roller can compress any ripples and ensure a tighter fit, providing a smooth, level base for the carpet. If the wrinkles persist, it might be necessary to remove the affected section of padding and reinstall it correctly. In some cases, the use of a tack strip might be necessary.

Think of it like smoothing out wrinkles in a sheet on a bed. Small wrinkles are easily addressed, but large ones may require removing and redoing the process.

Q 14. What is your experience with different types of adhesives for padding?

My experience encompasses working with a variety of adhesives for padding, each with its own advantages and disadvantages. Water-based adhesives are environmentally friendly and offer good adhesion, but they require longer drying times. Pressure-sensitive adhesives (PSA) offer quicker installation, ideal for fast-paced projects, however they can be less forgiving if the padding isn’t properly aligned. Solvent-based adhesives provide a strong bond and are resistant to moisture, but they release strong fumes and require more careful handling. The choice of adhesive depends on factors such as the type of padding, the subfloor material, and project deadlines. I always follow manufacturer’s instructions carefully, ensuring proper ventilation and safety precautions are taken when applying any adhesive.

For example, in a humid basement, I’d opt for a moisture-resistant adhesive to ensure long-lasting performance and prevent damage to the padding and the underlying floor.

Q 15. Explain the process of removing and disposing of old padding.

Removing old carpet padding is the crucial first step in any carpet installation. It’s not just about clearing the space; it’s about ensuring a smooth, level base for the new padding and carpet. We begin by carefully removing the existing padding, section by section. For tackless strips, we use a specialized tool to gently pry them up from the floor, avoiding damage to the subfloor. If the padding is glued down, we may need to use a scraper, being extra cautious not to gouge the floor. Once removed, the old padding is rolled up and disposed of responsibly, usually through a local recycling facility or landfill that accepts construction debris. In some cases, especially with older homes, we might find asbestos or other hazardous materials. In such situations, we immediately halt the work, contact the relevant authorities for safe removal, and prioritize the health and safety of everyone involved.

For example, I once encountered a house with padding containing asbestos. Proper protocol was followed, and we ensured the removal was handled safely and legally, avoiding a potentially dangerous health hazard. The extra time and cost involved were justified by the importance of safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure a smooth transition between different flooring types?

Ensuring a smooth transition between different flooring types, like carpet and hardwood, requires meticulous attention to detail. The goal is to create a seamless and aesthetically pleasing change that’s also functional and durable. We typically use transition strips, carefully selecting the right type to match the materials and height differences. For example, a reducer strip works well to transition from a thicker carpet to a thinner hardwood floor, creating a gradual slope to prevent tripping hazards. Before installing the transition strips, we make sure the subfloor is properly prepared to ensure a stable and level foundation for both the flooring types and the transition strip. We use specialized tools and precise measurements to ensure the strips are straight, flush, and securely fastened, blending perfectly between the two flooring surfaces. In some cases, we might employ other techniques like using a carpet ramp for steeper transitions or even employing custom-made transitions for unique architectural elements.

Q 17. What are the common causes of carpet buckling or wrinkling?

Carpet buckling or wrinkling is a common issue, often caused by a few key factors. Improper installation is a major culprit, including incorrect stretching, inadequate padding, or insufficient tacking. Uneven subfloors are another significant contributor; even minor variations in level can cause the carpet to ripple. Moisture beneath the carpet can also lead to buckling and stretching. This moisture could come from leaks, spills, or even high humidity. Finally, temperature fluctuations and changes in the room’s humidity can influence the carpet’s dimensions and contribute to buckling. In some cases, the incorrect type of padding can also contribute to this issue.

For instance, I once had a job where buckling was caused by inadequate stretching during installation. Careful re-stretching, using proper techniques and tools, solved the problem. It’s always important to identify the root cause before attempting a fix.

Q 18. How do you handle difficult areas, such as stairs or curved walls?

Stairs and curved walls present unique challenges in padding installation, requiring more precise cutting and fitting. For stairs, we measure carefully and cut the padding to fit snugly around the stair treads and risers, making sure to accommodate the rise and run of each step. Seams are precisely aligned to prevent bunching and unevenness. We use specialized tools and techniques to ensure a secure and comfortable fit. Curved walls require pattern cutting, where we cut the padding to match the curve, carefully accounting for any potential gaps or overlaps. This is a technique that requires experience and precision to get right. Think of it like creating a tailor-made suit for the floor; every curve and edge has to be measured and considered. The precision and attention to detail are critical in these situations, with frequent checking to make sure there are no inconsistencies or gaps.

Q 19. What is your experience with moisture testing before installation?

Moisture testing before carpet padding installation is essential to prevent future problems. Excessive moisture can lead to mold, mildew growth, and premature carpet degradation. I always use a moisture meter to check the subfloor’s moisture content. The meter gives a precise reading, which is compared against acceptable levels. The results will determine the next steps; if moisture is too high, addressing the source of the moisture before proceeding is crucial. This might involve addressing plumbing leaks, improving ventilation, or allowing the floor to dry completely before installation. Delaying installation until adequate moisture levels are achieved prevents expensive future repairs and avoids jeopardizing the quality of the work.

For example, I once discovered a significant moisture problem during a pre-installation inspection. The issue was traced to a leaky pipe, fixed by a plumber, and the floor was allowed to dry before installation, ensuring the longevity of the carpet installation.

Q 20. How do you maintain the quality of your work throughout the installation process?

Maintaining quality throughout the carpet padding installation process relies on several key practices. First, I always begin with meticulous preparation. This includes thorough subfloor inspection, proper moisture testing, and ensuring the workspace is clean and clear. Secondly, using the correct tools and materials is paramount. This prevents cutting corners and ensures a high-quality finish. Thirdly, precise measurements and careful cutting and fitting are non-negotiable. This prevents issues like unevenness and buckling down the line. Finally, a systematic approach, focusing on one section at a time and thoroughly inspecting each step, ensures no detail is missed. Quality control is a continuous process, not a one-time effort.

Q 21. Describe your troubleshooting skills regarding padding installation issues.

Troubleshooting padding installation issues requires a systematic approach. I start by carefully inspecting the problem area, identifying the cause of the issue. Is it improper stretching? Uneven subfloor? Moisture issues? My experience allows me to rapidly pinpoint the root cause in most situations. For example, if the carpet is bunching, I may need to re-stretch the carpet using a power stretcher to alleviate tension. If the cause is an uneven subfloor, leveling solutions may be necessary before further installation proceeds. If the issue is a moisture problem, this needs to be addressed and rectified before continuing. Documenting each step and any changes helps maintain quality control and facilitates troubleshooting during later stages.

I approach every issue with a combination of knowledge, experience, and a problem-solving mindset. My goal is to deliver a high-quality installation that meets client expectations.

Q 22. What are your preferred methods for cutting and trimming carpet padding?

Cutting and trimming carpet padding accurately is crucial for a professional finish. My preferred method involves a combination of tools depending on the situation. For straight cuts, a sharp utility knife with a new blade is essential for clean, precise lines. I always score the padding first, then apply even pressure to cut through cleanly, avoiding ragged edges that could later compress unevenly. For curved cuts, I use heavy-duty shears, ensuring a smooth, controlled cut. This prevents tearing or fraying, which would negatively impact the final installation and the longevity of the carpet.

For example, around pipes or irregular shapes, I’ll use a combination of the utility knife and shears, making small, precise cuts to get the perfect fit. Think of it like tailoring – you need the right tool for the right job. Always measure twice, cut once to minimize waste and ensure precision. A measuring tape and a pencil are my best friends in this process. Pre-measuring and marking help me avoid costly mistakes, especially in rooms with complex layouts.

Q 23. How do you work efficiently and effectively as part of a team?

Teamwork is fundamental in carpet padding installation. Efficient teamwork involves clear communication, defined roles, and mutual respect. On a team, I prioritize open communication to ensure everyone understands the project scope, individual responsibilities, and the overall workflow. I’m comfortable taking the lead when necessary, assigning tasks based on individual strengths, and offering support where needed. Conversely, I also readily accept direction and contribute my expertise to the collaborative effort. For instance, in a large installation, one person might focus on cutting padding while another stretches and secures it. This division of labor maximizes efficiency.

I believe in a collaborative problem-solving approach. If a challenge arises, I’ll actively participate in finding solutions, offering my suggestions, and actively listening to the ideas of my colleagues. My goal isn’t simply to complete the job, but to do it well, together.

Q 24. How do you adhere to safety regulations and company policies?

Adherence to safety regulations and company policies is paramount. I always prioritize safety by using appropriate personal protective equipment (PPE), including safety glasses, gloves, and work boots. I’m meticulous about proper tool handling, ensuring knives are sharp and stored safely, and that power tools are used according to manufacturer instructions. I follow all company-specific safety protocols, regularly attending safety briefings and trainings to stay updated on best practices. Furthermore, I make sure the work area is kept clean and free of obstacles to prevent accidents. For example, I am trained in proper lifting techniques to prevent back injuries and know how to handle sharp objects safely.

Similarly, I fully comply with company policies regarding attendance, reporting, and conduct. Integrity and professionalism are always at the forefront of my actions. I believe safety isn’t just a set of rules, it’s a mindset, and a shared responsibility.

Q 25. What are your experience with different types of tack strips?

My experience encompasses various tack strip types, each with its own advantages and applications. I’m familiar with standard galvanized tack strips, which are cost-effective and suitable for most residential installations. I also have experience with heavy-duty tack strips, designed for high-traffic areas or commercial settings. These strips provide superior strength and durability. Furthermore, I understand the use of resilient channel tack strips, which improve underlayment stability and minimize sound transmission, beneficial for installations in apartments or noise-sensitive environments.

The choice of tack strip depends on the project requirements. For example, in a high-traffic office, I would always recommend heavy-duty tack strips to ensure long-lasting performance. The selection process is a crucial aspect of planning and preparing the job.

Q 26. How do you deal with customer concerns or complaints?

Customer satisfaction is a top priority. When addressing customer concerns or complaints, I approach the situation with empathy and professionalism. I listen carefully to their concerns, asking clarifying questions to understand their perspective fully. Then, I present solutions clearly and concisely, offering options tailored to their needs and budget. It’s important to acknowledge their feelings, even if I don’t agree with their assessment. I focus on finding a resolution that satisfies everyone involved.

For example, if a customer isn’t happy with the appearance of the padding along a seam, I would carefully inspect the work, and if necessary, adjust or correct it. Clear, direct communication is key, as is a sincere desire to resolve the issue efficiently and amicably. A positive outcome leaves a good impression and builds trust.

Q 27. Explain your understanding of relevant building codes and regulations.

Understanding relevant building codes and regulations is crucial for ensuring safe and compliant installations. I’m familiar with local and national codes relating to fire safety, moisture barriers, and proper installation techniques. This knowledge extends to understanding requirements for specific materials and their applications. For example, I’m aware of requirements related to the proper installation of moisture barriers under carpet padding in areas prone to humidity or moisture buildup. This prevents mold and mildew formation, protecting both the carpet and the homeowner’s health.

Staying updated on changes in building codes and regulations is an ongoing process. I regularly consult industry publications and attend relevant workshops to maintain my knowledge and ensure that I’m following current best practices.

Q 28. Describe your experience with estimating materials and labor costs.

Accurately estimating materials and labor costs is essential for successful project management. My estimating process involves a detailed assessment of the project scope, including the area to be covered, the type of padding, the complexity of the installation, and the number of installers required. I carefully review blueprints or floor plans, taking accurate measurements to determine the amount of padding needed. I consider potential waste and always add a small contingency for unforeseen circumstances.

Labor costs are estimated based on the project’s complexity and the number of hours required. I factor in transportation costs and any other potential expenses. Experience helps in developing a strong intuition for estimating materials and labor accurately, leading to realistic bids and avoiding potential financial pitfalls for the client and the company. Regularly reviewing past projects, noting actual versus estimated costs, allows for constant refinement of my estimation skills.

Key Topics to Learn for Carpet Padding Installation Interview

- Understanding Padding Types: Learn the differences between various padding materials (foam, rebond, felt, etc.), their properties (density, thickness, cushioning), and suitability for different carpet types and applications.

- Measurement and Calculation: Master accurate room measurement techniques to determine the precise amount of padding needed, minimizing waste and ensuring a professional finish. Practice calculating square footage and understanding industry-standard waste factors.

- Installation Techniques: Familiarize yourself with different installation methods, including proper seaming, tacking, and stretching techniques to create a smooth, wrinkle-free surface. Understand the importance of proper moisture barrier application where necessary.

- Tools and Equipment: Demonstrate knowledge of essential tools and equipment used in carpet padding installation, including their proper use and maintenance (e.g., knee kicker, power stretcher, measuring tools).

- Problem-Solving and Troubleshooting: Be prepared to discuss common installation challenges (e.g., uneven subfloors, difficult transitions, moisture issues) and how to effectively troubleshoot and resolve them.

- Safety Procedures: Highlight your understanding of and commitment to safety protocols, including proper handling of tools, materials, and personal protective equipment (PPE).

- Industry Best Practices: Research and understand current industry standards and best practices for carpet padding installation to showcase your professionalism and commitment to quality workmanship.

Next Steps

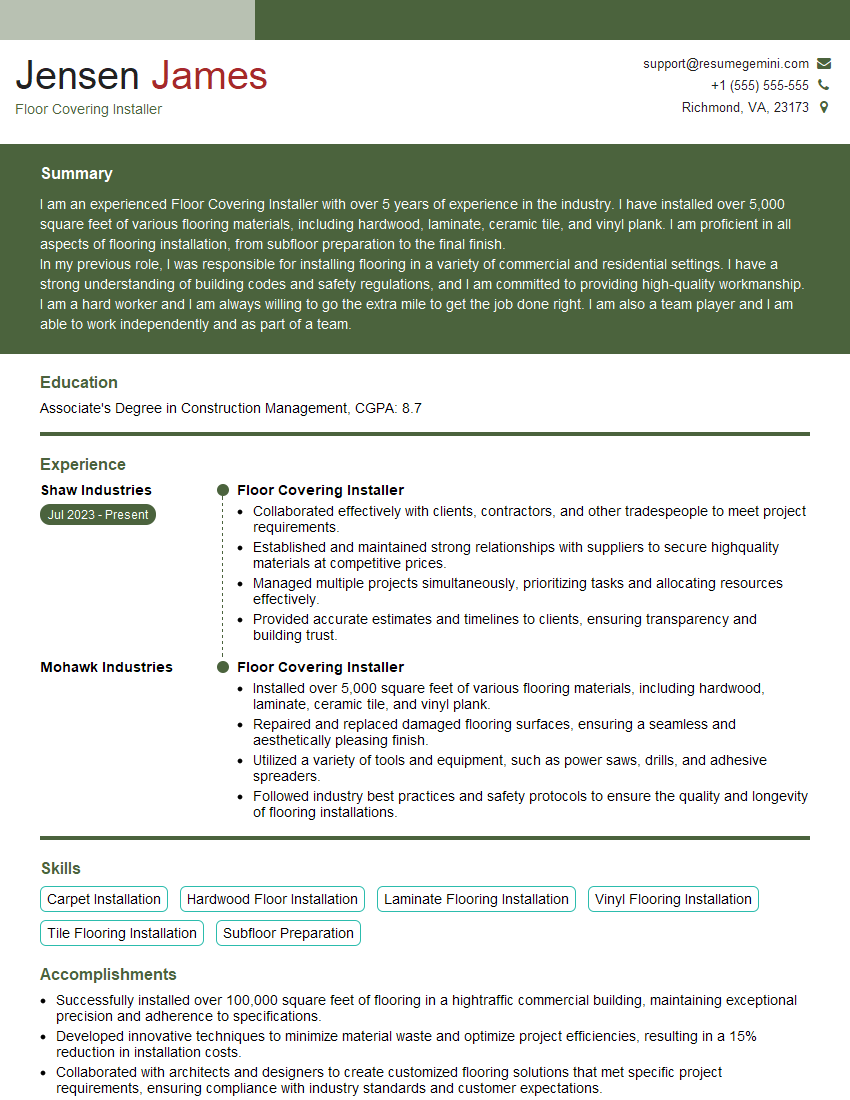

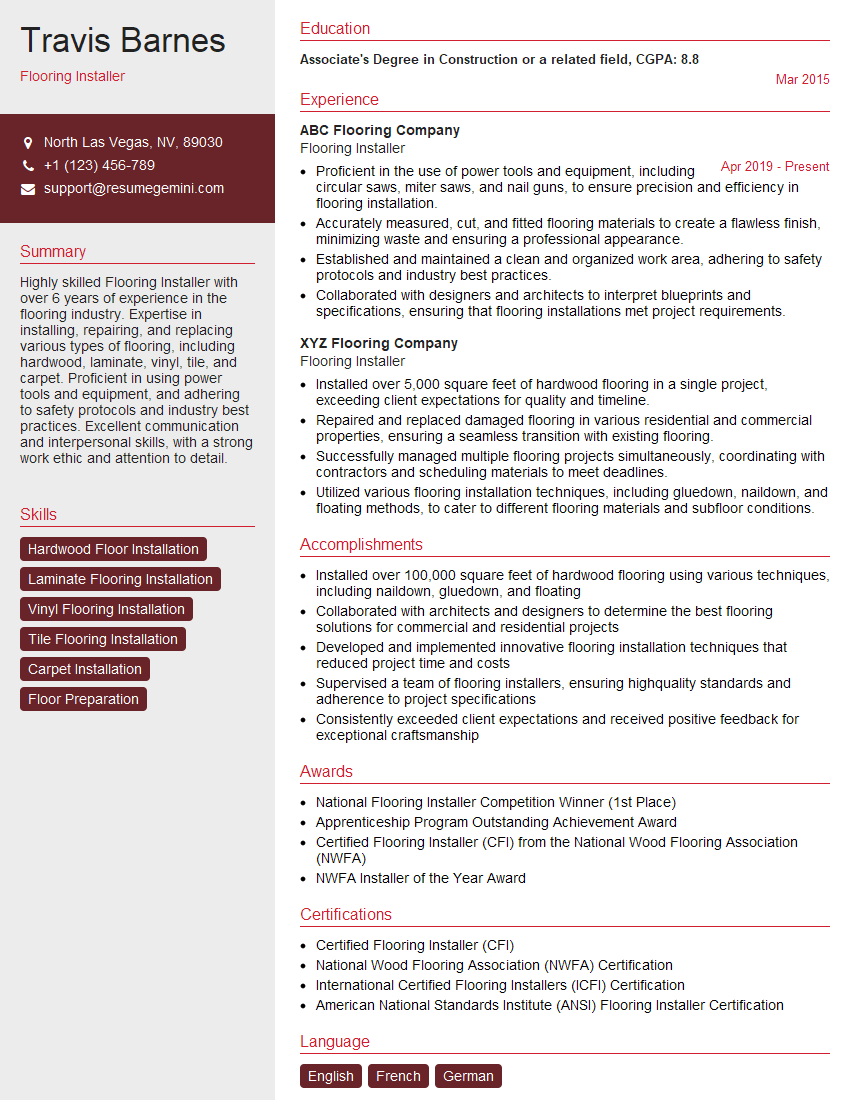

Mastering carpet padding installation opens doors to a rewarding career with opportunities for advancement and specialization. A strong understanding of these techniques is highly valued by employers and will significantly boost your job prospects. Creating an ATS-friendly resume is crucial for getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Carpet Padding Installation are available through ResumeGemini to guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good