Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Safety and Health Management Systems (SHMS) interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Safety and Health Management Systems (SHMS) Interview

Q 1. Describe your experience implementing a Safety and Health Management System (SHMS).

Implementing a Safety and Health Management System (SHMS) is a multifaceted process that requires a systematic approach. My experience involves leading the design, implementation, and ongoing improvement of SHMSs across various industries. This includes conducting gap analyses against relevant standards like ISO 45001, developing policies and procedures, establishing risk assessment processes, delivering training programs, and managing incident investigations. For instance, in my previous role at a construction company, I spearheaded the implementation of a new SHMS, starting with a comprehensive risk assessment of all job sites, followed by the development of site-specific safety plans and the rollout of a new safety training program. The result was a significant reduction in recordable incidents and a noticeable improvement in employee safety culture.

Another example was working with a manufacturing plant where we integrated the SHMS into their existing quality management system to create synergies and efficiencies. This approach proved highly successful in streamlining processes and promoting a holistic approach to safety and quality.

Q 2. Explain the key elements of a successful SHMS.

A successful SHMS hinges on several key elements. Think of it as a sturdy house – each element is a critical supporting beam.

- Leadership Commitment: Top-down support is paramount. Leaders must actively champion safety, allocate resources, and demonstrate a visible commitment to the SHMS.

- Risk Assessment and Control: Regular and thorough risk assessments are crucial to identify and mitigate hazards proactively. This isn’t a one-time event but an ongoing cycle of identification, evaluation, control, and monitoring.

- Emergency Preparedness and Response: Having well-defined emergency procedures, practiced regularly, is vital. Employees should know what to do in case of an accident or emergency.

- Training and Competency: Employees must be adequately trained on safe work practices and procedures relevant to their roles. Regular refresher training keeps skills sharp and addresses emerging hazards.

- Communication and Consultation: Open communication channels are essential. Workers need a safe space to voice concerns and participate in the SHMS’s development and improvement. Regular safety meetings and feedback mechanisms are critical.

- Monitoring and Review: The SHMS needs regular auditing and review to ensure its effectiveness. Key performance indicators (KPIs) should be tracked, and the system should be adapted to evolving needs.

- Continuous Improvement: Safety should be a continuous journey, not a destination. Regularly review performance, investigate incidents, and implement improvements based on lessons learned.

Q 3. How do you conduct a risk assessment?

Conducting a risk assessment involves a systematic process to identify hazards, analyze their risks, and determine appropriate control measures. I typically follow a structured approach:

- Hazard Identification: This involves brainstorming potential hazards using various methods like checklists, site inspections, hazard and operability studies (HAZOP), and job safety analyses (JSA).

- Risk Analysis: This step involves evaluating the likelihood and severity of each identified hazard. I often use a risk matrix, assigning probability and consequence scores to each hazard, leading to a risk rating (e.g., low, medium, high).

- Risk Evaluation: This involves comparing the identified risks against acceptable risk criteria to determine if the risks are tolerable or require further control measures.

- Risk Control: This is where we determine and implement appropriate control measures to mitigate risks. These controls can be hierarchical, following the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE).

- Risk Monitoring and Review: This is an ongoing process of monitoring the effectiveness of the implemented controls and reviewing the risk assessment periodically to ensure it remains relevant and accurate.

For example, in assessing a construction site, we would identify hazards like falls from heights, struck-by hazards, and electrocution. We would then analyze the likelihood and severity of each, prioritize them according to their risk rating, and implement controls such as scaffolding, safety harnesses, lockout/tagout procedures, and appropriate PPE.

Q 4. What are the common hazards in a [Specific Industry] setting, and how would you mitigate them?

Let’s assume the specific industry is construction. Common hazards include falls from heights, struck-by objects, caught-between hazards, electrocution, and exposure to hazardous materials. Mitigation strategies would be tailored to each hazard:

- Falls from Heights: Implement fall protection systems (e.g., guardrails, safety nets, harnesses), provide thorough training on fall protection equipment, and enforce strict adherence to fall protection protocols.

- Struck-by Objects: Establish designated material handling areas, utilize appropriate lifting equipment, implement traffic management plans, and ensure proper use of PPE such as hard hats and safety glasses.

- Caught-Between Hazards: Use proper lockout/tagout procedures on machinery, provide training on machine operation and safety, and implement machine guarding.

- Electrocution: Use Ground Fault Circuit Interrupters (GFCIs), implement lockout/tagout procedures, and ensure proper insulation and grounding of electrical equipment.

- Hazardous Materials: Provide proper training on handling and storage of hazardous materials, establish Material Safety Data Sheets (MSDS) access, and ensure proper ventilation and PPE usage.

A proactive approach, including regular inspections, toolbox talks, and consistent enforcement of safety rules, is crucial to minimizing these risks.

Q 5. What methods do you use to ensure compliance with safety regulations?

Ensuring compliance with safety regulations involves a multi-pronged strategy. It begins with a thorough understanding of all applicable regulations and standards, which can vary by jurisdiction and industry. I then establish a system for monitoring compliance, which might include:

- Regular Audits and Inspections: Conducting routine safety inspections, both planned and unplanned, to identify non-compliances.

- Documentation and Record Keeping: Meticulous record-keeping is essential, documenting safety training, inspections, incident investigations, and corrective actions. This ensures traceability and accountability.

- Training and Communication: Regular training and clear communication ensure employees understand the regulations and their roles in compliance.

- Corrective Actions: Develop and implement corrective actions to address any identified non-compliances promptly and effectively.

- Utilizing Technology: Implementing software solutions for safety management can automate tasks, improve data collection and analysis, and facilitate compliance tracking.

- Staying Updated: Regulatory landscape constantly evolves, so staying abreast of changes through professional development and industry updates is critical.

For example, a regular audit of our safety management system might reveal a lapse in the use of specific PPE. This would trigger corrective action, potentially including retraining, improved communication, and stricter enforcement.

Q 6. How do you develop and deliver safety training programs?

Developing and delivering effective safety training programs requires a needs assessment to determine employee skill gaps. The training should be tailored to the specific hazards and tasks within the workplace. I use a blended learning approach:

- Needs Assessment: This involves identifying the specific safety knowledge and skills required by each job role.

- Curriculum Development: Create a training program that addresses the identified needs, using engaging and varied methods.

- Delivery Methods: I incorporate various training methods, including classroom instruction, online modules, on-the-job training, and simulations to cater to different learning styles. For example, a hands-on workshop for operating machinery, complemented by online modules for regulatory updates.

- Assessment and Evaluation: Use quizzes, practical demonstrations, and observations to assess learning and program effectiveness. Feedback should be incorporated into future iterations of the training program.

- Documentation: Maintain thorough records of training attendance, assessments, and certifications.

For instance, I once developed a comprehensive safety training program for a manufacturing facility that incorporated virtual reality simulations for hazardous material handling, reducing the risk of real-world accidents during training. The program’s effectiveness was measured through pre- and post-training assessments, which demonstrated a significant improvement in employee knowledge and skills.

Q 7. Describe your experience with incident investigation and reporting.

Incident investigation and reporting are crucial for identifying root causes and preventing future occurrences. My approach follows a systematic process:

- Immediate Response: Secure the scene, provide first aid if necessary, and notify relevant personnel.

- Incident Investigation: Gather information from witnesses, review documents (e.g., permits, training records), and examine the physical evidence.

- Root Cause Analysis: Use techniques like the “5 Whys” or fault tree analysis to identify the root cause(s) of the incident, going beyond the immediate symptoms to uncover underlying systemic issues.

- Corrective Actions: Develop and implement effective corrective actions to prevent similar incidents from happening again. This might involve changes to procedures, equipment upgrades, or additional training.

- Reporting: Document the investigation thoroughly, including findings, root causes, and corrective actions. Report the incident to relevant authorities as required.

- Follow-up: Monitor the effectiveness of the corrective actions to ensure they have resolved the underlying issues.

For example, investigating a near-miss incident involving a forklift could reveal inadequate training on safe operating procedures. The corrective action would include updated training, a review of existing procedures, and additional supervision.

Q 8. How do you measure the effectiveness of your SHMS?

Measuring the effectiveness of a Safety and Health Management System (SHMS) isn’t a one-size-fits-all approach. It requires a multi-faceted strategy using both lagging and leading indicators. Lagging indicators reflect past performance, while leading indicators predict future performance.

Lagging Indicators: These are retrospective measures. Examples include:

- Accident frequency rate (AFR): Number of accidents per 100 employees per year. A lower AFR indicates better safety performance.

- Lost Time Injury Frequency Rate (LTIFR): Number of lost-time injuries per 100 employees per year. A reduction signifies improvement.

- Days lost due to injury: Total number of days employees are absent due to work-related injuries. Lower numbers are better.

- Number of near misses reported: While not accidents, near misses highlight potential hazards that need attention. A higher number, initially, may reflect improved reporting rather than worsening safety.

Leading Indicators: These are proactive measures that anticipate future performance. Examples include:

- Safety training participation rates: Higher rates suggest a commitment to safety improvement.

- Number of safety inspections conducted: Regular inspections identify potential hazards early.

- Employee safety observation scores: Assessing compliance with safety procedures.

- Number of safety suggestions made by employees: Active employee participation is crucial for a strong safety culture.

By analyzing both lagging and leading indicators, we build a comprehensive picture of SHMS effectiveness. Trends in these metrics help identify areas needing improvement and measure the success of implemented changes. For example, if we see a decrease in AFR alongside an increase in safety training participation, it suggests the training is positively impacting safety performance.

Q 9. What are your strategies for improving safety performance?

Improving safety performance relies on a proactive, multi-pronged approach. It’s not just about fixing problems after they occur; it’s about preventing them in the first place.

Proactive Hazard Identification and Risk Assessment: Regularly conduct thorough hazard identification and risk assessments using methods like Job Safety Analyses (JSAs), HAZOP (Hazard and Operability studies), or bow-tie analysis. This helps to identify potential hazards and implement control measures before incidents occur.

Invest in Safety Training: Regular, relevant, and engaging safety training is crucial. Training should go beyond simple compliance; it needs to empower employees to identify and mitigate hazards independently. We use interactive training, case studies, and simulations to keep it engaging.

Implement and Enforce Safety Procedures: Clearly defined and consistently enforced safety procedures are vital. This includes regular audits and inspections to ensure compliance. We use checklists and observation programs to monitor procedure adherence.

Encourage Employee Participation: Employees are often the first to identify hazards. Establishing a system for reporting near misses and hazards, and actively involving employees in safety committees or suggestion programs, promotes a culture of ownership.

Use Technology: Implementing technology such as wearable safety devices or safety management software can provide real-time data and improve efficiency of safety management.

Regular Review and Improvement: The SHMS should be regularly reviewed and updated to ensure it remains relevant and effective. Data analysis from lagging and leading indicators is vital for identifying areas for improvement.

For instance, after identifying a high number of near misses related to a specific machine, we implemented additional safety guards and revised the operating procedure, accompanied by retraining. This resulted in a significant drop in near misses related to that machine.

Q 10. How do you manage safety during project planning and execution?

Safety is integrated into every stage of project planning and execution. It’s not an afterthought, but a core principle.

Planning Phase: Safety is considered from the outset. This includes a thorough hazard identification and risk assessment for all project activities. The risk assessment informs the development of a comprehensive safety plan, detailing the control measures, responsibilities, and emergency procedures. We involve key stakeholders in this process to gain diverse perspectives.

Execution Phase: The safety plan is implemented, monitored, and revised as needed. This includes regular safety inspections, toolbox talks, and safety training specific to the project. We establish clear communication channels to ensure immediate reporting of any incidents or near misses.

Post-Project Review: After project completion, a safety review is conducted to analyze the effectiveness of the safety plan, identify lessons learned, and inform future projects. This helps continuously improve our safety processes.

For example, during a recent construction project, we integrated safety considerations into the design phase by choosing safer materials and equipment. This proactive approach reduced the risk of accidents and ultimately led to a safer and more efficient project.

Q 11. Explain your understanding of hazard identification and control.

Hazard identification and control are the cornerstones of any effective SHMS. Hazard identification is the process of recognizing potential sources of harm, while hazard control involves implementing measures to eliminate or reduce the risk associated with those hazards.

Hazard Identification: This involves systematically identifying potential hazards through various methods, including:

- Walkthrough inspections: Physically inspecting the workplace to identify potential hazards.

- Job safety analyses (JSAs): Step-by-step analysis of tasks to identify potential hazards.

- Checklists: Using pre-defined lists of potential hazards for a specific task or area.

- Hazard and Operability studies (HAZOP): Systematic examination of a process to identify potential hazards.

Hazard Control: Once hazards are identified, appropriate control measures are implemented using the hierarchy of controls:

- Elimination: Removing the hazard altogether (e.g., replacing a hazardous chemical with a safer alternative).

- Substitution: Replacing the hazard with a less hazardous alternative (e.g., using a less powerful machine).

- Engineering controls: Implementing physical changes to the workplace to reduce the risk (e.g., installing safety guards on machinery).

- Administrative controls: Changing work practices or procedures to reduce risk (e.g., implementing a permit-to-work system).

- Personal protective equipment (PPE): Providing workers with equipment to protect them from hazards (e.g., safety glasses, hard hats). This is the last line of defense.

For example, if we identify a risk of slips and falls due to a wet floor, we could implement engineering controls like improved drainage, administrative controls like providing warning signs, and PPE like non-slip footwear. The goal is always to prioritize the higher levels of the hierarchy of controls before resorting to PPE.

Q 12. How do you communicate safety information effectively to workers?

Effective communication is paramount for a successful SHMS. Safety information needs to be clear, concise, and easily understood by all workers, regardless of their language or literacy level.

Multi-Modal Communication: We use a variety of communication methods to ensure information reaches everyone. This includes toolbox talks, safety posters, training materials, email updates, and intranet postings. We also use visual aids, such as diagrams and videos, to make complex information easier to understand.

Tailored Communication: Information should be tailored to the specific audience and their needs. For example, instructions for operating heavy machinery will differ from general safety reminders.

Feedback Mechanisms: We provide opportunities for workers to provide feedback on safety information and suggest improvements. This demonstrates that their opinions are valued and fosters a culture of open communication.

Regular Communication: Safety shouldn’t be discussed only during incidents. Regular communication reinforces safety awareness and keeps it top-of-mind.

Language Accessibility: We ensure that safety information is available in all relevant languages spoken by the workforce.

For example, we recently implemented a system where workers can easily report hazards using a mobile app. This has increased the number of hazards reported, allowing for quicker intervention and preventive action. We also translate all key safety documents into the multiple languages spoken by our employees.

Q 13. What are your strategies for promoting a safety culture?

Promoting a strong safety culture is crucial for long-term safety success. It’s not just about rules and regulations; it’s about a shared belief that safety is everyone’s responsibility.

Leadership Commitment: Visible commitment from senior management is essential. Leaders must champion safety, actively participate in safety initiatives, and hold themselves and others accountable.

Employee Empowerment: Empowering employees to identify and report hazards is crucial. This involves creating a blame-free culture where reporting near misses is encouraged, not penalized. We use regular safety meetings and feedback sessions to encourage open dialogue.

Recognition and Rewards: Recognizing and rewarding safe behaviors reinforces positive actions. We use various incentives to acknowledge individuals and teams who consistently demonstrate commitment to safety.

Open Communication: Open communication and feedback channels are vital for a strong safety culture. This includes regular safety meetings, surveys, and suggestion boxes.

Continuous Improvement: Regularly reviewing and improving safety procedures and practices demonstrates a commitment to continuous improvement and learning from past experiences.

One successful strategy we’ve implemented is a peer-to-peer safety observation program. Employees are trained to observe and coach each other on safe work practices. This not only promotes safety but also fosters teamwork and a shared sense of responsibility.

Q 14. How do you handle conflicts or disagreements regarding safety procedures?

Conflicts or disagreements regarding safety procedures need to be addressed promptly and fairly. Ignoring them can undermine safety and damage morale.

Open Dialogue: The first step is to encourage open communication and dialogue between all parties involved. Create a safe space where everyone feels comfortable expressing their concerns without fear of retribution.

Collaborative Problem-Solving: Facilitate a collaborative problem-solving session, bringing together all stakeholders to discuss the issue and find a mutually agreeable solution. Focus on finding a solution that addresses the safety concerns while respecting everyone’s perspectives.

Objective Assessment: Where necessary, involve an objective third party to assess the situation and provide an unbiased opinion. This could be a safety professional, a manager from a different department, or an external consultant.

Documentation: Document all discussions, decisions, and agreed-upon actions. This ensures accountability and transparency.

Clear Communication: Communicate the final decision and the rationale behind it to all parties involved. Ensure that everyone understands the agreed-upon procedures and their responsibilities.

For example, if there was a disagreement about the use of a particular piece of equipment, we would gather everyone involved – the workers, supervisors, and safety officers – to discuss the concerns, review the relevant safety data, and collaboratively decide on the safest course of action. The decision would be documented and communicated to the entire team.

Q 15. Describe your experience with emergency response planning and execution.

Emergency response planning is the cornerstone of any robust SHMS. It involves anticipating potential hazards, developing procedures to mitigate them, and ensuring everyone is trained to respond effectively. My experience encompasses developing comprehensive emergency response plans, including evacuation procedures, incident command systems, and post-incident investigations.

For example, at my previous role in a manufacturing plant, I led the development of a plan for chemical spills. This included identifying potential spill locations, designating response teams, outlining procedures for containment and cleanup, and establishing communication protocols. We conducted regular drills to ensure team readiness and identify areas for improvement. During one particular drill, we discovered a communication bottleneck, which we immediately addressed by implementing a dedicated emergency radio system. This iterative process of planning, training, and continuous improvement is crucial for effective emergency response.

Execution involves activating the plan during an actual emergency, coordinating personnel, and ensuring compliance with all relevant regulations. This includes communicating with emergency services, managing the scene, and conducting post-incident reviews to identify lessons learned and refine the plan for future events. Effective execution requires clear communication, decisive leadership, and a commitment to safety above all else.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure that safety equipment is properly maintained and used?

Proper maintenance and use of safety equipment are paramount to a safe workplace. My approach involves a multi-faceted strategy that starts with a comprehensive inventory of all equipment, including regular inspections and scheduled maintenance. This includes visual inspections for damage, functional testing to ensure equipment operates as intended, and adherence to manufacturer’s recommendations for maintenance intervals.

For instance, we maintain a detailed log for each piece of equipment, documenting inspections, maintenance activities, and any repairs carried out. This enables us to track equipment lifespan and anticipate potential issues before they become major problems. We also provide regular training for employees on the proper use and care of equipment, reinforcing the importance of reporting any defects immediately. Think of it like regularly servicing your car – neglecting maintenance increases the risk of failure and potential accidents.

This proactive approach significantly reduces the likelihood of equipment malfunction or failure during critical situations, protecting workers and ensuring operational efficiency. Further, we utilize a system of color-coded tags to indicate the status of equipment (e.g., green for operational, yellow for needing inspection, red for out of service). This simple visual cue ensures quick identification of any equipment requiring attention.

Q 17. Explain your understanding of legislation relevant to workplace safety.

A strong understanding of relevant workplace safety legislation is fundamental to my role. This includes federal, state, and local regulations, as well as industry-specific standards. I stay abreast of changes in legislation through continuous professional development, subscriptions to relevant publications, and participation in industry events.

For example, I’m familiar with the Occupational Safety and Health Act (OSHA) in the US, and equivalent legislation in other jurisdictions. This knowledge informs the development and implementation of safety policies and procedures within the workplace. I ensure that our practices comply with all relevant legal requirements, safeguarding our workers and the company from potential liabilities. Specific regulations concerning hazardous materials handling, machine guarding, personal protective equipment (PPE), and emergency response are particularly important, and I ensure that our policies reflect these requirements. I regularly review and update our safety documentation to ensure compliance with any changes in legislation or industry best practices.

Q 18. How do you conduct safety inspections and audits?

Safety inspections and audits are proactive measures to identify hazards and ensure compliance with safety standards. My approach uses a combination of planned inspections and random spot checks, focusing on high-risk areas and equipment. Inspections involve a systematic review of the workplace, checking for potential hazards, such as damaged equipment, unsafe working conditions, and non-compliance with safety procedures. I typically utilize checklists to ensure consistency and thoroughness.

Audits are more comprehensive reviews of the overall SHMS. They assess the effectiveness of the system, the training provided, and the enforcement of safety rules. Audits may involve interviews with employees, review of safety documentation, and observation of work practices. A key part of my approach is to involve employees in the process – their firsthand observations often reveal hidden hazards or areas needing improvement. The findings from both inspections and audits are documented and used to develop corrective actions, preventing future incidents. For instance, a recent audit revealed a lack of awareness regarding lockout/tagout procedures. We responded by providing refresher training and updating our communication materials.

Q 19. What are your experience with personal protective equipment (PPE)?

My experience with personal protective equipment (PPE) involves ensuring its proper selection, use, maintenance, and disposal. This starts with a thorough hazard assessment to determine the appropriate PPE for each job. Selection considers factors such as the type of hazard (e.g., chemical, electrical, physical), the level of risk, and worker comfort.

For instance, in a construction environment, this might include hard hats, safety glasses, high-visibility clothing, and steel-toed boots. Beyond selection, I emphasize proper training on the correct usage and limitations of PPE. Regular inspections ensure PPE is in good condition and replaced as necessary. We also adhere to strict disposal procedures for contaminated or damaged PPE, minimizing environmental impact and protecting worker health. Providing employees with the right PPE and training them on its use is not just a legal requirement, it’s a critical step in ensuring their wellbeing and preventing injuries.

Q 20. How do you manage contractor safety on a worksite?

Managing contractor safety on a worksite requires proactive collaboration and clear communication. Before any contractor commences work, I ensure they provide their own safety plan, demonstrating their commitment to compliance with our site-specific safety rules and relevant legislation. This plan is reviewed and approved before work begins.

Regular safety meetings with contractors are essential to identify and address any potential hazards or concerns. We conduct joint site inspections to ensure their work practices align with our safety standards. Pre-task planning meetings are crucial to discuss the specifics of the job, including potential risks and the necessary precautions. I also monitor contractors’ adherence to safety rules throughout the project, addressing any issues promptly. This collaborative approach ensures a safe working environment for both our employees and contractors, fostering a culture of shared responsibility for safety.

Q 21. What are some common workplace safety violations, and how do you address them?

Common workplace safety violations often stem from a lack of awareness, training, or enforcement of safety rules. Some examples include inadequate machine guarding, improper use of PPE, failure to follow lockout/tagout procedures, and unsafe handling of hazardous materials. Addressing these violations requires a multi-pronged approach.

First, we conduct thorough investigations to understand the root cause of the violation. This often involves interviews with involved personnel, review of documentation, and site observations. Once the root cause is identified, we develop and implement corrective actions, which might include additional training, improved safety procedures, or equipment modifications. Furthermore, we emphasize the importance of reporting near misses and incidents, fostering a culture where safety concerns are raised without fear of reprisal. Regular reinforcement of safety rules through training, communication, and visible reminders, creates a safety-conscious environment. For example, if we discover workers are not using hearing protection in a noisy environment, we immediately provide training on the importance of hearing protection, and enforce its use, perhaps incorporating regular spot checks.

Q 22. Explain your understanding of ergonomics and its importance in workplace safety.

Ergonomics is the science of designing the workplace, equipment, and tasks to fit the capabilities and limitations of the human body. It focuses on creating a work environment that minimizes the risk of musculoskeletal disorders (MSDs) and other injuries by reducing physical strain, fatigue, and discomfort. Its importance in workplace safety is paramount because MSDs are a leading cause of workplace injuries and lost productivity.

- Reduced Injuries: By designing workstations and tools to match the worker’s physical dimensions and capabilities, we minimize awkward postures, repetitive movements, and excessive force, all major contributors to MSDs.

- Increased Productivity: When workers are comfortable and not experiencing pain, their productivity increases. They’re more focused and less likely to take time off due to injury.

- Improved Morale: A safe and ergonomically designed workplace shows employees that their well-being is valued, boosting morale and fostering a positive work environment.

For example, consider a warehouse setting. Implementing ergonomic principles might involve using adjustable height workstations for order pickers, providing ergonomic chairs with proper lumbar support, and using equipment that minimizes repetitive lifting and twisting. Another example would be adjusting the computer monitor height and keyboard placement for office workers to maintain a neutral posture.

Q 23. How do you utilize data to improve safety performance?

Data is the cornerstone of effective safety management. I utilize data in several ways to continuously improve safety performance:

- Incident Tracking and Analysis: I meticulously track all safety incidents, recording details such as the date, time, location, nature of the incident, contributing factors, and any resulting injuries. Analyzing this data helps identify trends, pinpoint high-risk areas, and proactively implement corrective actions. For example, a spike in slips and falls in a specific area might lead to improved floor maintenance or additional safety signage.

- Near Miss Reporting: Near misses, events that could have resulted in an accident but didn’t, are invaluable. Analyzing near misses helps identify potential hazards before they cause injury. I encourage open reporting and provide a safe space for employees to report near misses without fear of reprisal.

- Safety Observation Data: Regular safety observations, conducted by both safety professionals and employees, generate data on compliance with safety procedures and the presence of potential hazards. This data guides improvements in training, enforcement, and hazard control.

- Leading Indicators: I monitor leading indicators, such as the number of safety training sessions conducted, the completion rate of safety checklists, and the usage of personal protective equipment (PPE). These indicators offer insights into the effectiveness of safety programs before incidents occur.

I use data visualization techniques, such as charts and graphs, to present findings clearly and concisely. This ensures data-driven decision-making to improve safety performance.

Q 24. Describe your experience with safety program development and implementation.

I have extensive experience in developing and implementing safety programs tailored to various industries and operational contexts. My approach is typically iterative, involving the following steps:

- Hazard Identification and Risk Assessment: I use various methods, including job hazard analyses (JHAs), walkthroughs, and employee input, to identify potential hazards and assess their risks.

- Development of Control Measures: Once hazards are identified, I develop and implement appropriate control measures, prioritizing elimination, substitution, engineering controls, administrative controls, and lastly, personal protective equipment (PPE).

- Training and Communication: Comprehensive training programs are crucial. I develop and deliver training materials tailored to different roles and responsibilities, ensuring employees understand safety procedures and are competent in using safety equipment.

- Program Implementation and Monitoring: I work closely with management and employees to ensure the program is implemented effectively. Regular monitoring and auditing are vital to track performance, identify any gaps, and make necessary adjustments.

- Continuous Improvement: Safety is an ongoing process. I regularly review and update safety programs based on performance data, incident reports, and changes in regulations or best practices.

For instance, in a previous role, I developed a comprehensive safety program for a construction site, which included detailed risk assessments, specific procedures for operating heavy machinery, regular tool box talks, and a robust incident reporting system. This resulted in a significant reduction in workplace injuries.

Q 25. Explain your experience using safety management software or tools.

I have extensive experience utilizing several safety management software and tools. These tools significantly improve efficiency and data management. Some examples include:

- Incident Reporting Software: Software that allows employees to easily report incidents, track investigations, and generate reports. This streamlines the process and ensures consistent data collection.

- Permit-to-Work Systems: Software that manages and controls access to hazardous work areas. This ensures that appropriate safety measures are in place before work commences.

- Risk Assessment Software: Software that helps in conducting, documenting, and managing risk assessments. This facilitates consistent and comprehensive hazard identification and risk control.

- Training Management Systems: Software that tracks employee training records, ensures compliance with training requirements, and facilitates scheduling and record-keeping.

I am proficient in using these tools to analyze data, generate reports, and improve the overall effectiveness of safety management systems. My familiarity with these tools enables efficient documentation, streamlined processes, and improved decision-making. For example, using a specific incident reporting software in a past role allowed us to quickly identify a pattern of near misses related to a particular machine, enabling prompt preventative maintenance and retraining on safe operating procedures.

Q 26. How do you stay updated on changes in safety regulations and best practices?

Staying current on safety regulations and best practices is crucial. I employ several methods to maintain my expertise:

- Professional Organizations: I am an active member of relevant professional organizations like the American Society of Safety Professionals (ASSP) or the British Safety Council (BSC). These organizations provide access to resources, training, and networking opportunities.

- Industry Publications and Journals: I regularly read industry publications, journals, and newsletters to stay informed on the latest research, regulations, and best practices.

- Conferences and Workshops: Attending conferences and workshops allows for direct interaction with leading experts and learning about emerging trends and new technologies.

- Online Resources and Webinars: I leverage online resources, webinars, and training courses to supplement my knowledge and stay up-to-date with current regulations.

- Regulatory Agencies: I regularly consult the websites of relevant regulatory agencies (e.g., OSHA in the US) to ensure compliance with all applicable regulations.

Continuous learning is essential in the field of safety, and these various channels guarantee that I remain proficient and adept at handling evolving workplace safety challenges.

Q 27. Describe a time when you had to address a serious safety incident. What was your approach?

In a previous role, we experienced a serious incident involving a worker’s hand getting caught in a conveyor belt. My immediate approach followed a structured process:

- Emergency Response: The first priority was to ensure the injured worker received immediate medical attention. I coordinated with emergency services and followed established emergency response protocols.

- Secure the Scene: The conveyor belt was immediately shut down to prevent further injuries. The area was secured to preserve the scene for investigation.

- Incident Investigation: A thorough investigation was conducted to determine the root causes of the incident. This included interviewing witnesses, reviewing safety procedures, and examining the equipment. We used a root cause analysis technique to identify the underlying systemic issues.

- Corrective Actions: Based on the findings of the investigation, corrective actions were implemented. This included installing additional safety guards on the conveyor belt, reinforcing training on lockout/tagout procedures, and revising the safety procedures to prevent similar incidents.

- Reporting and Documentation: A comprehensive report was filed detailing the incident, the investigation findings, and the corrective actions taken. This ensured proper documentation for regulatory compliance and future reference.

This incident highlighted the importance of rigorous safety procedures, thorough training, and proactive hazard identification. The experience underscored the need for a robust system to promptly address serious safety incidents and learn from them to prevent future occurrences.

Q 28. How would you handle a situation where employees are resistant to following safety procedures?

Employee resistance to safety procedures is a common challenge. My approach focuses on understanding the root cause of the resistance and addressing it effectively:

- Communication and Engagement: I start by understanding why employees are resisting. Open communication is crucial. I facilitate discussions to address their concerns, listen to their feedback, and foster a collaborative environment where they feel heard and valued.

- Education and Training: I ensure employees thoroughly understand the reasons behind the safety procedures and their importance in preventing injuries. Effective training programs that engage employees and tailor to their individual needs are key.

- Demonstrate Value: I highlight the direct benefits of following safety procedures. This might involve showcasing real-world examples of how safety procedures prevented injuries or demonstrating how the procedures make the work easier and safer.

- Enforce Consistently and Fairly: While fostering a collaborative environment is important, consistent and fair enforcement of safety rules is also necessary. Disciplinary action should be a last resort, used only when other approaches have failed.

- Lead by Example: Safety professionals must set a positive example by consistently following safety procedures themselves. This demonstrates the importance of the rules and builds trust.

Ultimately, a successful approach involves building a safety culture where employees feel empowered to contribute to a safe working environment, understand the value of procedures, and actively participate in their implementation. It’s a long-term commitment requiring ongoing dialogue, education, and leadership. It’s important to remember that sometimes resistance is a sign that the procedures themselves may need revision or that the communication around them has been lacking.

Key Topics to Learn for Safety and Health Management Systems (SHMS) Interview

- Hazard Identification and Risk Assessment: Understand various methods for identifying hazards (e.g., checklists, inspections, job safety analysis) and conducting thorough risk assessments using techniques like HAZOP or FMEA. Consider how to prioritize risks based on likelihood and severity.

- Legal and Regulatory Compliance: Demonstrate familiarity with relevant legislation, standards (e.g., OSHA, ISO 45001), and regulations pertaining to occupational safety and health. Be prepared to discuss practical application of these regulations within a workplace setting.

- Control Measures and Hierarchy of Controls: Discuss the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE) and how to select and implement appropriate control measures to mitigate identified risks. Be ready to explain your decision-making process.

- Emergency Preparedness and Response: Outline the key components of a comprehensive emergency preparedness plan, including emergency response procedures, evacuation plans, and training programs. Discuss your experience in developing or implementing such plans.

- Incident Investigation and Reporting: Explain the process of investigating incidents, identifying root causes, and implementing corrective actions to prevent recurrence. Understand the importance of accurate record-keeping and reporting.

- Safety Training and Communication: Discuss the importance of effective safety training programs, methods for communicating safety information to workers, and strategies for promoting a strong safety culture within an organization.

- Performance Monitoring and Auditing: Explain how to monitor the effectiveness of SHMS, conduct internal audits, and identify areas for improvement. Discuss key performance indicators (KPIs) used to track safety performance.

- Continuous Improvement: Demonstrate an understanding of continuous improvement methodologies (e.g., Plan-Do-Check-Act) and how they can be applied to enhance SHMS effectiveness.

Next Steps

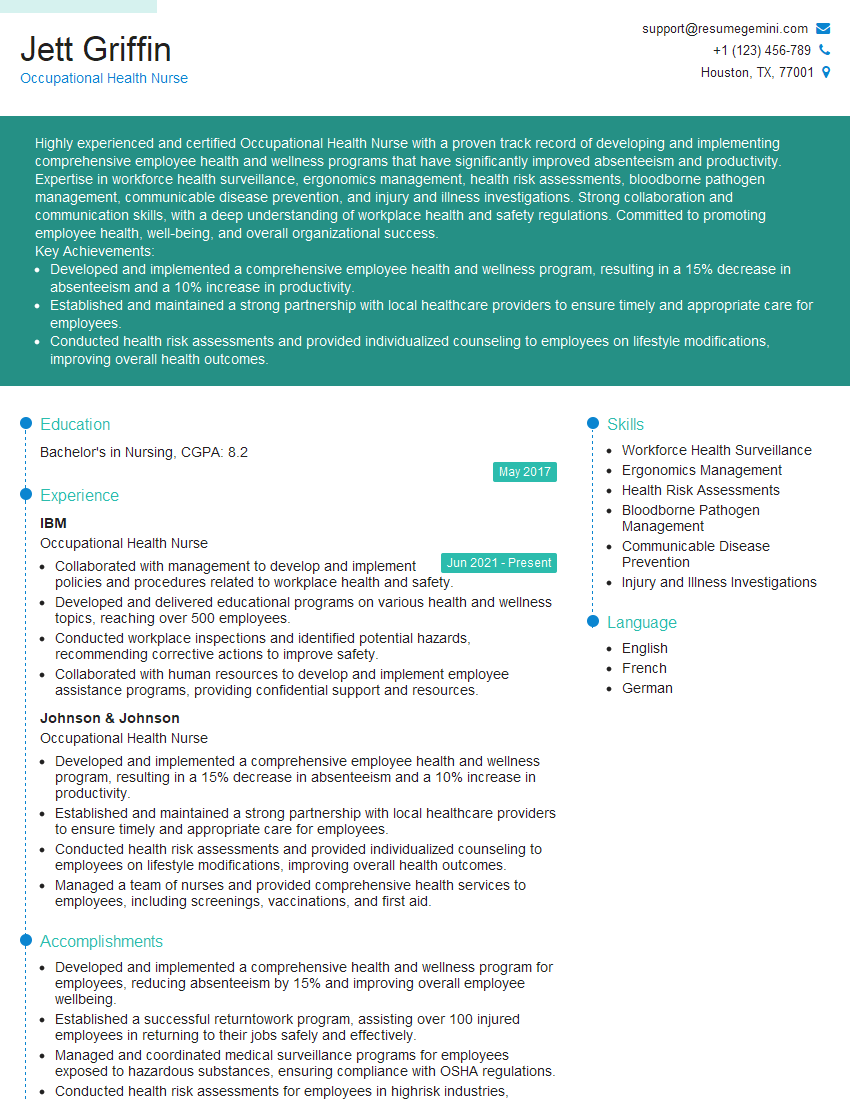

Mastering Safety and Health Management Systems is crucial for career advancement in this vital field. A strong understanding of SHMS principles and practical application demonstrates your commitment to workplace safety and opens doors to leadership roles and higher earning potential. To significantly increase your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to Safety and Health Management Systems (SHMS) are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good