Unlock your full potential by mastering the most common Garment Care interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Garment Care Interview

Q 1. Explain the differences between various fabric types (e.g., cotton, silk, wool) and their care requirements.

Different fabrics have unique compositions and structures, leading to varied care requirements. Understanding these differences is crucial for preserving garment quality.

- Cotton: A natural fiber known for its breathability and absorbency. Generally durable, it can withstand machine washing (though pre-shrinking is recommended for new items) and high heat drying. However, high heat can cause shrinkage and damage. Always check the care label for specific instructions.

- Silk: A delicate natural protein fiber, luxurious and smooth. Requires hand washing in cool water with a mild detergent; never machine wash or put it in a dryer. Gently squeeze out excess water and lay flat to dry away from direct sunlight.

- Wool: Another natural protein fiber, known for its warmth and insulation. Many wool garments can be machine washed on a delicate cycle with cold water and a wool detergent, but hand washing is often preferred to prevent felting (matting of the fibers). Always lay flat to dry; avoid direct heat or sunlight.

For example, a cotton t-shirt can handle a vigorous machine wash, while a silk scarf needs the gentle touch of hand washing. Ignoring these differences can lead to shrinkage, damage, and color fading.

Q 2. Describe the proper procedures for handling delicate fabrics.

Handling delicate fabrics requires a gentle approach to prevent damage. Think of these fabrics as precious treasures needing careful handling.

- Hand washing: Use cool or lukewarm water and a mild detergent specifically designed for delicates. Avoid harsh rubbing or twisting. Gently squeeze out excess water, never wring.

- Drying: Lay flat to dry on a clean, dry towel. Avoid direct sunlight or heat, which can cause discoloration and damage.

- Ironing: If ironing is necessary, use a low heat setting and a pressing cloth to protect the fabric. Always iron on the wrong side of the garment.

- Storage: Store delicate garments in breathable fabric bags or boxes to prevent mildew and wrinkles. Avoid using plastic bags, which can trap moisture.

Imagine washing a cashmere sweater like you would a pair of jeans – disaster! The gentle approach outlined above ensures that delicate garments maintain their shape, color, and luxurious feel.

Q 3. How would you remove common stains (e.g., grease, wine, blood) from different fabrics?

Stain removal depends on the type of stain, the fabric, and how quickly you address it. The key is to act fast!

- Grease: Blot (don’t rub!) with a clean cloth or paper towel to absorb excess grease. Pre-treat with a stain remover or dish soap, then launder as usual.

- Wine: Immediately blot up as much wine as possible. Rinse the area with cold water, and if needed, pre-treat with a stain remover before laundering. For stubborn stains, consider soaking in a solution of cold water and white vinegar.

- Blood: Rinse the area thoroughly with cold (not hot!) water. Avoid using hot water, as it sets the stain. Pre-treat with a stain remover or hydrogen peroxide (test in an inconspicuous area first), and launder as usual.

Remember, always test any cleaning solution in an inconspicuous area first to ensure it doesn’t damage the fabric. Treating a stain promptly increases your chances of successful removal.

Q 4. What are the different types of laundry detergents and when should each be used?

Laundry detergents are formulated for different needs and fabric types. Selecting the right one is essential for optimal cleaning and garment care.

- Powder Detergents: Generally less expensive and effective in hot water, but can leave residue on fabrics if not rinsed thoroughly. Suitable for heavily soiled items or for use in high-efficiency washing machines that require less detergent.

- Liquid Detergents: Dissolve easily in cold water, making them ideal for delicates and pre-treating stains. Often come in concentrated forms, reducing environmental impact.

- Pods/Pacs: Convenient and pre-measured, they can be effective but potentially more expensive per load. Follow instructions carefully to avoid damage to the washing machine.

- HE (High-Efficiency) Detergents: Specifically formulated for high-efficiency washing machines, which use less water and energy. Using a regular detergent in an HE machine can lead to excessive suds and poor rinsing.

Consider your washing machine type, the type of fabrics you’re washing, and the level of soil when selecting a detergent. A high-quality detergent, used appropriately, extends the life of your garments.

Q 5. Explain the process of using a dry cleaning machine.

Dry cleaning machines use solvents rather than water to clean garments. The process involves several key steps.

- Pre-spotting: Examining garments for stains and pre-treating them with appropriate solvents.

- Washing: Placing garments in the dry cleaning machine, which uses a specialized solvent to dissolve dirt and oil.

- Extraction: Removing the solvent from the garments.

- Drying: Using heat or air to dry the garments completely.

- Finishing: Pressing and steaming garments to restore their shape and appearance.

Operating a dry cleaning machine requires specialized training. Improper use can lead to damage to the machine, the garments, or even injury to the operator due to the use of flammable solvents. It is crucial to follow all safety protocols and manufacturer’s instructions.

Q 6. How do you identify and address damage to garments during cleaning?

Identifying and addressing damage during cleaning is critical for maintaining garment quality and customer satisfaction.

- Careful Inspection: Before and after cleaning, inspect garments thoroughly for rips, tears, loose buttons, or other damage. Note any pre-existing damage before cleaning.

- Damage Assessment: Determine the cause and extent of the damage. Some damage may be repairable, while others may require specialized repair or may be irreparable.

- Repair or Replacement: Repair minor damages like loose buttons or small tears. If the damage is extensive, offer repair services or inform the customer about the damage and any potential replacement options.

- Documentation: Maintain records of damage, repairs, and communication with customers. This helps to manage expectations and resolve any issues professionally.

For example, if a garment is damaged during cleaning, documenting the damage with photos and a detailed description is crucial for handling potential claims or refunds fairly and transparently.

Q 7. What safety precautions should be followed when handling industrial laundry equipment?

Industrial laundry equipment presents significant safety hazards. Adherence to strict safety protocols is paramount.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and closed-toe shoes, to protect against chemical exposure, burns, and other hazards.

- Machine Safety: Follow all manufacturer’s instructions for operating, maintaining, and cleaning the equipment. Never operate a machine with damaged parts or safety guards.

- Chemical Handling: Handle chemicals safely and according to their Safety Data Sheets (SDS). Ensure adequate ventilation and wear appropriate respiratory protection if needed. Store chemicals properly and keep them away from incompatible materials.

- Lockout/Tagout Procedures: Utilize lockout/tagout procedures when performing maintenance or repairs to prevent accidental start-up and injury.

- Emergency Procedures: Be familiar with emergency procedures, including how to respond to fires, chemical spills, or equipment malfunctions.

Ignoring safety precautions can result in serious injury or even death. Regular training and adherence to safety protocols are essential for working safely with industrial laundry equipment.

Q 8. What are the best practices for ironing different types of fabrics?

Ironing different fabrics requires understanding their unique properties. Think of it like cooking – you wouldn’t cook a delicate fish the same way you’d cook a tough steak! The key is to adjust temperature and pressure accordingly.

- Cotton: Cotton is a durable fiber that can withstand high heat. Use a hot iron and plenty of steam. For stubborn wrinkles, a damp pressing cloth can help prevent scorching.

- Linen: Similar to cotton, linen benefits from high heat and steam. However, be mindful of its tendency to wrinkle easily, so quick, decisive strokes are key. A slightly lower temperature might be preferable for delicate linen garments.

- Silk and Wool: These are delicate fabrics that require a low iron setting and a pressing cloth. Too much heat can damage the fibers and cause irreversible shine. Always iron these on the reverse side if possible.

- Synthetic Fabrics (Polyester, Nylon): These fabrics usually require low to medium heat. Excessive heat can melt or scorch them. Always check the garment label for specific instructions.

- Velvet: Velvet requires a very low heat and a gentle touch. Steam can flatten the pile, so use it sparingly, if at all. Iron on the reverse side if possible, using a pressing cloth.

Remember to always test the iron’s heat on a hidden seam before ironing the entire garment. Start with a lower setting and gradually increase the heat as needed.

Q 9. How do you handle customer complaints regarding damaged garments?

Handling customer complaints about damaged garments requires a calm, professional, and empathetic approach. My first step is to listen carefully to the customer’s concerns and acknowledge their frustration. I then visually inspect the garment to assess the damage and determine the likely cause. Transparency is vital.

- Gather Information: Ask detailed questions about how the damage occurred, when it was noticed, and any relevant information.

- Assess the Damage: Carefully examine the garment for the type, extent, and location of the damage. Take photos for documentation.

- Determine Responsibility: Based on my assessment and the information gathered, I determine if the damage is due to negligence on our part (e.g., incorrect ironing temperature) or due to inherent garment flaws or pre-existing damage.

- Offer a Solution: Depending on the cause, I offer a solution such as re-cleaning, repair, replacement, or refund. I always aim to exceed customer expectations.

- Document Everything: Maintain detailed records of the complaint, investigation, and the resolution. This helps prevent future occurrences and provides a reference point.

For instance, if a silk blouse was damaged due to incorrect ironing temperature on our part, we would offer a full refund or a replacement blouse. Effective communication and a willingness to resolve the issue are essential to maintaining customer loyalty.

Q 10. Describe your experience with different pressing techniques.

My experience encompasses a wide range of pressing techniques, each suited to different fabrics and garment types. Think of pressing as a form of sculpting with heat and pressure.

- Flat Pressing: This is the most common technique, ideal for large, flat surfaces like tablecloths, sheets, or shirt fronts. It involves placing the garment on a flat, padded surface and applying even pressure with the iron.

- Pleat Pressing: This technique is crucial for creating and maintaining sharp pleats in skirts, trousers, or other garments. It typically involves using a pressing cloth, careful placement of the pleats, and a press cloth to shape.

- Point Pressing: Often used for delicate fabrics like silk or lace, point pressing involves using the tip of the iron to press only small, specific areas, minimizing risk of damage.

- Seam Pressing: Essential for achieving a professional finish, seam pressing involves using a pressing cloth to open and flatten seams, avoiding excess bulk and creating a crisp appearance.

- Blocking: This is a technique commonly used for shaping delicate garments like sweaters or hats. It often involves using a blocking board and pins to mold the garment into the desired shape while damp.

I’m proficient in all these methods and adapt my approach based on the fabric, garment construction, and desired outcome. Proper pressing is critical to achieving a high-quality finish.

Q 11. What are the signs of fabric damage and how can it be prevented?

Fabric damage can manifest in various ways, and prevention is always better than cure. Recognizing the signs early is crucial.

- Burns and Scorch Marks: These are easily noticeable as discolored or damaged areas from excessive heat. Prevention involves using the appropriate iron temperature and pressing cloth.

- Color Fading: This can occur due to exposure to sunlight, improper washing, or the use of harsh chemicals. Prevention involves using color-safe detergents and avoiding direct sunlight.

- Stretching and Distortion: Pulling or stretching a garment while wet can cause irreversible damage. Prevention involves gentle handling and proper drying techniques.

- Weakening and Tears: Rough handling or improper storage can lead to weakened fibers and tears. Prevention involves careful handling and appropriate storage methods.

- Pilling: This involves the formation of small balls of fiber on the surface of the fabric, often seen on sweaters. Prevention involves regular cleaning and using a lint remover.

Regular inspection of garments, careful handling, and following proper care instructions are key to preventing fabric damage. It’s like caring for a valuable piece of art—gentle handling ensures longevity.

Q 12. Explain your knowledge of different garment finishing techniques.

Garment finishing techniques are the final steps in the garment production process, ensuring a professional and polished look. They significantly impact the garment’s quality and appeal.

- Hemming: Creating a neat and even hem is crucial for a professional finish. Different techniques exist, such as machine hemming, hand hemming, and blind hemming, each suited to different fabric types and garment styles.

- Seaming: Seams should be flat and even, avoiding bulkiness and ensuring durability. Proper seam finishing techniques, such as serging, overlocking, or zigzag stitching, prevent fraying and improve the garment’s overall quality.

- Button and Buttonhole Sewing: These seemingly simple details significantly influence the overall appearance and functionality of the garment. Proper techniques ensure buttons are securely attached and buttonholes are neatly finished.

- Zipper Insertion: A properly inserted zipper should be smooth, even, and functional. Different zipper types require specific techniques.

- Pressing and Shaping: As discussed earlier, pressing plays a crucial role in achieving a crisp, professional finish, eliminating wrinkles and ensuring the garment retains its intended shape.

My experience includes proficiency in all these techniques, enabling me to create high-quality, well-finished garments that meet industry standards.

Q 13. How do you maintain the cleanliness and hygiene of laundry equipment?

Maintaining the cleanliness and hygiene of laundry equipment is crucial for preventing cross-contamination and ensuring the longevity of the equipment. It’s all about preventing bacteria and mildew growth.

- Regular Cleaning: This includes regularly wiping down surfaces, emptying lint traps, and cleaning detergent dispensers. Frequency depends on usage; high-volume operations require more frequent cleaning.

- Periodic Deep Cleaning: This involves a more thorough cleaning, including descaling of irons and washing machines. This process typically involves using specialized cleaning solutions.

- Disinfection: Regular disinfection of equipment, especially washers and dryers, helps prevent the spread of bacteria and viruses. Using appropriate disinfectants is important and following label instructions is critical.

- Maintenance Schedule: Implementing a regular maintenance schedule, including checks for malfunctions or wear and tear, helps prolong the lifespan of the equipment and ensures smooth operation.

- Proper Ventilation: Ensuring good ventilation in the laundry area helps prevent the build-up of moisture, reducing the risk of mildew growth and creating a more pleasant working environment.

I’m meticulous about hygiene and preventative maintenance. I see it as an investment that protects both our equipment and our customers’ garments.

Q 14. Describe your experience with commercial laundry operations.

My experience in commercial laundry operations includes working in a high-volume facility, where efficiency and quality were paramount. My responsibilities ranged from sorting and washing to finishing and packaging.

- Process Optimization: I’ve been involved in optimizing the laundry process to improve efficiency and reduce turnaround time. This involved streamlining workflows, improving organization, and implementing better inventory management systems.

- Equipment Operation and Maintenance: I’m proficient in operating and maintaining a variety of commercial laundry equipment, including industrial washing machines, dryers, and finishing equipment. This includes routine maintenance and troubleshooting.

- Quality Control: I’ve played a critical role in ensuring the quality of the finished laundry, identifying and addressing any issues promptly. This involved implementing and adhering to strict quality control protocols.

- Teamwork and Collaboration: Working in a commercial laundry environment often involves teamwork and collaboration with other staff members. I’ve always prioritized a cooperative and supportive working atmosphere.

- Safety Procedures: Adherence to stringent safety protocols is vital in commercial laundry operations. I’m familiar with and strictly adhere to all safety regulations to protect both myself and my colleagues.

I thrive in fast-paced environments and am adept at managing multiple tasks simultaneously while maintaining high standards of quality and efficiency.

Q 15. How do you handle large volumes of laundry efficiently?

Handling large laundry volumes efficiently requires a systematic approach combining optimized processes and appropriate equipment. Think of it like an orchestra – each instrument (person or machine) plays its part for a harmonious outcome.

- Pre-sorting: This is crucial. We categorize laundry by fabric type (cotton, linen, silk, etc.), color (whites, lights, darks), and soil level (heavily soiled items are separated). This prevents color bleeding and ensures appropriate washing cycles are used.

- Batching: Once sorted, items are batched according to washing machine capacity. Overloading machines leads to poor cleaning and increased wear on fabrics. Imagine trying to fit too many ingredients into a cake mix – the result won’t be optimal.

- Equipment Utilization: High-capacity washers and dryers, industrial-sized folding tables, and possibly automated systems significantly speed up the process. Think conveyor belts in a factory, but for clothing.

- Workflow Optimization: A well-defined workflow minimizes movement and maximizes efficiency. This often involves using a dedicated space for each stage: sorting, washing, drying, folding, and ironing. It’s like an assembly line for clothing.

- Staff Training: Properly trained staff understands best practices, saving time and preventing errors. This includes knowledge of fabric care instructions and handling delicate items.

In my previous role, we implemented a color-coded sorting system that reduced processing time by 15%, minimizing errors and improving overall efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with stain removal products and techniques?

Stain removal is a science and an art. It involves understanding the stain’s composition and the fabric it’s on. I’ve extensive experience using a variety of commercial and homemade stain removers. The key is to act quickly – the longer a stain sits, the harder it is to remove.

- Identification: The first step is identifying the stain (e.g., grease, blood, wine). Different stains require different treatments.

- Pre-treatment: This involves applying a stain remover directly to the stain, gently working it in, and allowing it to sit for a specified time. I always test any new product on an inconspicuous area first to check for colorfastness.

- Washing: Appropriate washing techniques – temperature, cycle, and detergent – are chosen depending on the fabric type and the stain’s nature.

- Post-treatment: After washing, checking for remaining stains is crucial. Sometimes, a second pre-treatment or specialized cleaning might be needed.

For example, I once successfully removed a stubborn red wine stain from a white linen tablecloth using a combination of enzymatic cleaner and oxygen bleach. It was a challenging case, but the successful result was incredibly satisfying.

Q 17. Describe your experience with garment alterations and repairs.

Garment alterations and repairs demand precision and attention to detail. I’m proficient in various techniques, from basic hemming and patching to more complex alterations like taking in seams, replacing zippers, and repairing tears.

- Assessment: The first step is a careful assessment of the garment and the required alteration. This involves determining the feasibility of the repair and choosing the most appropriate techniques.

- Measurement and Marking: Precise measurements are vital. Using tailor’s chalk or marking pens, I carefully mark the areas for alteration or repair.

- Repair/Alteration Techniques: This involves utilizing various sewing skills and tools, such as hand-sewing, machine sewing, and pressing techniques. Specific techniques depend on the fabric type and the nature of the repair.

- Finishing: The final step involves pressing and finishing the altered or repaired garment to ensure a professional look.

I once successfully altered a wedding dress, taking in the seams and shortening the length while preserving the delicate lace detailing. The client was overjoyed with the result, which highlights the importance of careful work and precision.

Q 18. How do you manage inventory and supplies in a laundry or garment care setting?

Inventory management in a garment care setting is essential for smooth operations and cost control. This involves tracking supplies and ensuring sufficient stock without unnecessary overstocking.

- Inventory Tracking System: I use a system to track the quantity of detergents, bleach, stain removers, buttons, zippers, and other supplies. This could be a simple spreadsheet or dedicated inventory management software.

- Regular Stock Checks: Regular stock checks help identify low-stock items and prevent unexpected shortages. This ensures uninterrupted workflow and avoids delays in service.

- Ordering and Replenishment: A systematic approach to ordering ensures timely replenishment of supplies. This also involves negotiating with suppliers for favorable pricing and consistent quality.

- Storage: Proper storage is crucial to prevent damage and spoilage. Detergents and other chemicals should be stored safely, away from heat and moisture.

In a previous role, I implemented a just-in-time inventory system, reducing storage costs and minimizing waste by 10%.

Q 19. What is your experience with using specialized cleaning agents for specific materials?

Different fabrics require specialized cleaning agents to avoid damage. For instance, wool requires a gentle detergent designed for delicate fabrics, while silk may need a specialized dry-cleaning fluid. Understanding these nuances is key to preserving the integrity of garments.

- Fabric Knowledge: A thorough understanding of different fabric types and their properties is crucial. This includes knowing which fabrics are colorfast, which are prone to shrinking, and which require special handling.

- Agent Selection: Choosing the right cleaning agent involves considering the fabric type, the stain (if any), and the desired outcome. The label instructions on the garment should always be followed.

- Application Techniques: The correct application of the cleaning agent is as important as the agent itself. For example, some delicate fabrics require hand-washing and gentle agitation.

- Testing: Always test any new cleaning agent on an inconspicuous area of the garment first to ensure it doesn’t cause damage or discoloration.

For example, I once used a specialized enzyme-based cleaner to remove a stubborn grass stain from a cashmere sweater without damaging the delicate fibers. It required a gentle hand-washing approach and careful rinsing.

Q 20. Describe your experience with colorfastness testing.

Colorfastness testing determines a fabric’s resistance to color fading due to washing, light exposure, or rubbing. It’s crucial for preventing color bleeding and maintaining garment appearance. There are standardized tests, but visual assessment also plays a vital role.

- Standard Tests: These involve subjecting fabric swatches to controlled washing, light exposure, and rubbing. Color changes are then measured using a spectrophotometer to quantify the degree of fading.

- Visual Assessment: Even with standardized tests, visual assessment is important to detect subtle changes in color that might not be picked up by instruments.

- Fabric Type: Colorfastness varies greatly depending on the fabric type, dye used, and manufacturing process.

- Practical Application: The results of colorfastness testing guide the selection of washing techniques, drying methods, and even storage conditions to prevent premature fading.

In my experience, I’ve often used visual assessment in conjunction with basic wash tests to determine the appropriate washing instructions for new garments.

Q 21. Explain your understanding of different washing machine cycles and their applications.

Washing machine cycles are designed to cater to different fabrics and soil levels. Understanding these cycles is crucial for effective and safe cleaning.

- Delicates: This cycle uses a gentle agitation and low spin speed, ideal for delicate fabrics like silk, lace, and wool. Think of it as a gentle hand-wash simulation.

- Permanent Press: This cycle minimizes wrinkling, suitable for wrinkle-resistant fabrics. It typically involves a slower spin speed to reduce creasing.

- Normal/Regular: This is a standard cycle for everyday items, offering a balance between cleaning power and fabric care. It’s a versatile option for most fabrics, excluding delicates.

- Heavy Duty: This cycle uses more vigorous agitation and longer wash times, suitable for heavily soiled items or durable fabrics. Imagine this as a deep clean for tougher stains.

- Quick Wash: This cycle is designed for lightly soiled items and offers a shorter wash time. It’s perfect for quick turnaround and smaller loads.

Choosing the correct cycle not only ensures optimal cleaning but also protects the garments from damage. For instance, using a heavy-duty cycle on a delicate garment could lead to shrinkage or damage.

Q 22. How do you maintain quality control throughout the garment care process?

Maintaining quality control in garment care is paramount. It’s a multifaceted process encompassing every step, from receiving garments to their final delivery. We begin with a thorough inspection upon intake, noting any existing damage or special care requirements. This information is meticulously documented and attached to the garment. Throughout the cleaning process, we employ standardized procedures for sorting, washing (utilizing appropriate detergents and water temperatures based on fabric type), drying (avoiding excessive heat to prevent shrinkage), and pressing (using techniques that minimize creasing and damage). Regular equipment maintenance is crucial to prevent damage to the garments. Finally, a second inspection is performed before the garments are packaged and returned, ensuring that all quality standards have been met. Any discrepancies are immediately addressed and documented.

For example, if a silk blouse is received, it will be hand-washed and air-dried to avoid damage. The entire process is tracked digitally, so we can readily identify any issues and make improvements to our workflows. This system helps us maintain consistent quality and quickly address any problems that arise.

Q 23. What is your experience with garment storage and preservation techniques?

Proper garment storage and preservation are vital for extending the lifespan of clothing. I have extensive experience in this area, applying a range of techniques depending on the fabric and the garment’s value. For delicate items like silk or cashmere, acid-free tissue paper is used to prevent discoloration and protect against abrasion. These items are ideally stored in breathable garment bags, protecting them from dust and light. For everyday clothing, appropriate hangers are key – padded hangers prevent shoulder bumps and maintain shape. Items should be stored in a cool, dry environment, away from direct sunlight, which can cause fading. For long-term storage, adding cedar chips or sachets of lavender can repel insects and maintain a pleasant scent. Proper folding techniques are also important to prevent creases. In the case of archiving or preserving valuable garments, specialized climate-controlled storage is often necessary.

For instance, when storing a vintage wedding dress, I would use a museum-quality archival box lined with acid-free tissue paper, ensuring the dress is stored flat to avoid stressing the seams and fabric. This demonstrates my commitment to preserving historical or sentimental value.

Q 24. Describe your problem-solving skills in handling unexpected garment care challenges.

Unexpected challenges are inevitable in garment care. My approach involves a systematic problem-solving process: First, I identify the problem – is it a stain, a tear, a color run, or equipment malfunction? Then, I analyze the garment and the cause of the problem. What fabric is it made of? What cleaning method was used? Once the cause is understood, I can develop a solution. This might involve using specialized stain removers, employing different cleaning techniques, or even recommending minor repairs by a tailor. Throughout this process, clear communication with the customer is key. They need to understand the situation, the proposed solution, and any limitations.

For example, if a garment is severely damaged due to improper cleaning, I’ll explain the extent of the damage to the customer, and explore options for repair or compensation depending on the circumstances. Documentation of the entire process helps avoid future misunderstandings and improve our procedures for handling such situations.

Q 25. How would you handle a situation with a garment requiring special care instructions?

Handling garments with special care instructions requires meticulous attention to detail. I start by carefully reading and interpreting the care label. This involves understanding symbols and instructions, differentiating between hand wash, machine wash, dry clean, bleach safe, and tumble dry instructions. The fabric composition plays a crucial role in determining the appropriate cleaning method and temperature settings. Following the instructions precisely is paramount to prevent damage. If instructions are unclear or absent, I utilize my expertise and knowledge of different fabrics to select the most suitable cleaning method. For especially delicate or valuable items, I might consult additional resources or seek expert advice before proceeding.

For instance, if a garment label indicates ‘Dry Clean Only’, I would never attempt to machine wash or hand wash it, as this would likely damage the fabric. Instead, I would either send it to a specialized dry cleaner or use the appropriate dry cleaning solvents and procedures in-house, depending on our facility’s capabilities.

Q 26. What is your understanding of OSHA regulations related to garment care and laundry?

My understanding of OSHA (Occupational Safety and Health Administration) regulations regarding garment care and laundry is comprehensive. I’m familiar with regulations concerning hazardous chemicals (proper handling, storage, and disposal of detergents, bleaches, and solvents), machine safety (proper operation and maintenance of industrial washing machines, dryers, and pressing equipment), personal protective equipment (PPE) requirements (gloves, eye protection, and respirators for handling chemicals), and ergonomics (preventing work-related injuries through proper lifting techniques and workstation design). I also understand the importance of regular training for employees on safety protocols and the proper use of equipment. Compliance with OSHA standards is non-negotiable and a core element of our operational procedures. Regular safety audits are conducted to ensure ongoing compliance.

For example, we strictly adhere to guidelines for the proper ventilation of our laundry facilities to mitigate exposure to chemical fumes, and we maintain detailed records of all chemical usage and disposal.

Q 27. Describe your experience with operating different types of industrial laundry equipment.

I possess extensive experience operating various types of industrial laundry equipment, including high-capacity washing machines, industrial dryers, steam presses, and finishing equipment like folders and automated sorting systems. This encompasses both understanding the technical aspects of the machines and the ability to troubleshoot and maintain them. I am proficient in adjusting settings based on fabric type and desired outcome. My expertise includes understanding the various cycles, water temperature control, and the appropriate use of detergents and other chemicals for optimal cleaning and preservation. Regular maintenance and preventative care are key to preventing breakdowns and ensuring the longevity of the equipment, which translates directly to maintaining garment quality.

For example, I know how to adjust the water temperature and spin cycle of a commercial washer to avoid shrinkage when cleaning delicate garments, and I am skilled at identifying and addressing minor mechanical issues before they escalate into significant problems.

Q 28. What are your strategies for optimizing efficiency and productivity in a garment care setting?

Optimizing efficiency and productivity in a garment care setting involves a combination of strategies. First, we employ efficient sorting techniques to streamline the cleaning process. This minimizes handling time and reduces the risk of mismatched fabrics being processed together. We also leverage automation wherever possible. Automated sorting systems, conveyor belts, and folding machines significantly reduce labor costs and increase throughput. Work-flow analysis is critical; it helps us identify bottlenecks and optimize processes. Regular maintenance of equipment reduces downtime. Finally, effective staff training and empowerment contribute to improved productivity and quality of service. We continuously monitor key performance indicators (KPIs) such as garment turnaround time, efficiency rates, and customer satisfaction to measure our progress and identify areas for improvement.

For instance, implementing a new automated sorting system reduced our processing time by 20% and significantly improved the accuracy of garment sorting.

Key Topics to Learn for Garment Care Interview

- Fabric Identification and Properties: Understanding different fiber types (natural and synthetic), their characteristics (e.g., absorbency, durability, wrinkle resistance), and appropriate care methods.

- Stain Removal Techniques: Mastering various stain removal methods based on stain type (e.g., oil-based, water-based), fabric type, and available cleaning agents. Practical application includes knowing the limitations of different techniques and avoiding fabric damage.

- Laundry Processes and Equipment: Familiarity with different washing machines (e.g., front-load, top-load), dryers, and their settings. Understanding the impact of water temperature, detergent type, and drying cycles on garment quality.

- Dry Cleaning Procedures: Knowledge of dry cleaning solvents, the dry cleaning process, and the care of delicate garments. This includes understanding the limitations of dry cleaning and potential risks.

- Garment Finishing and Pressing Techniques: Proficiency in ironing, steaming, and pressing techniques for various fabrics. Understanding how to avoid scorching or damaging fabrics during finishing.

- Understanding Garment Labels and Care Symbols: Ability to correctly interpret garment care symbols and apply appropriate cleaning and finishing methods based on manufacturer recommendations.

- Troubleshooting Common Garment Care Issues: Problem-solving skills to address issues like shrinkage, color fading, and fabric damage. Knowing how to identify the cause of the problem and propose effective solutions.

- Health and Safety in Garment Care: Awareness of safety precautions related to handling cleaning agents, using laundry equipment, and maintaining a safe work environment.

- Sustainable Garment Care Practices: Knowledge of eco-friendly cleaning methods and the importance of reducing water and energy consumption in garment care.

Next Steps

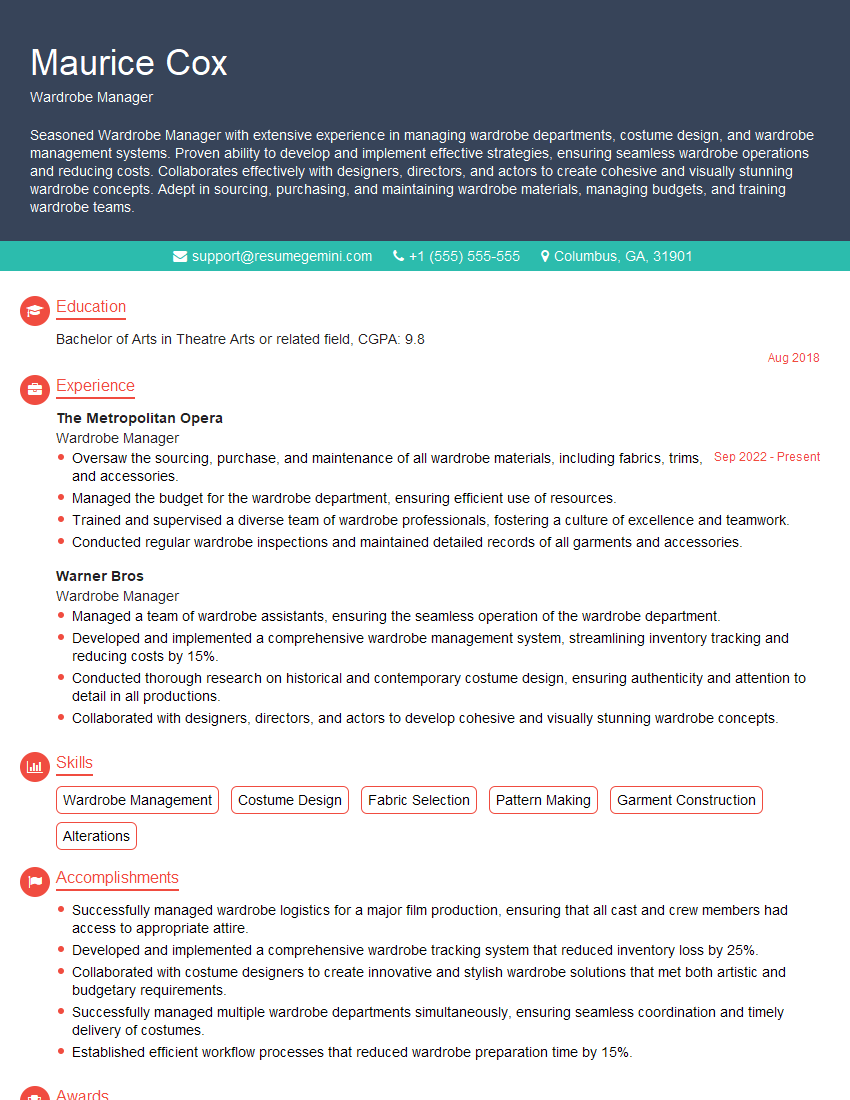

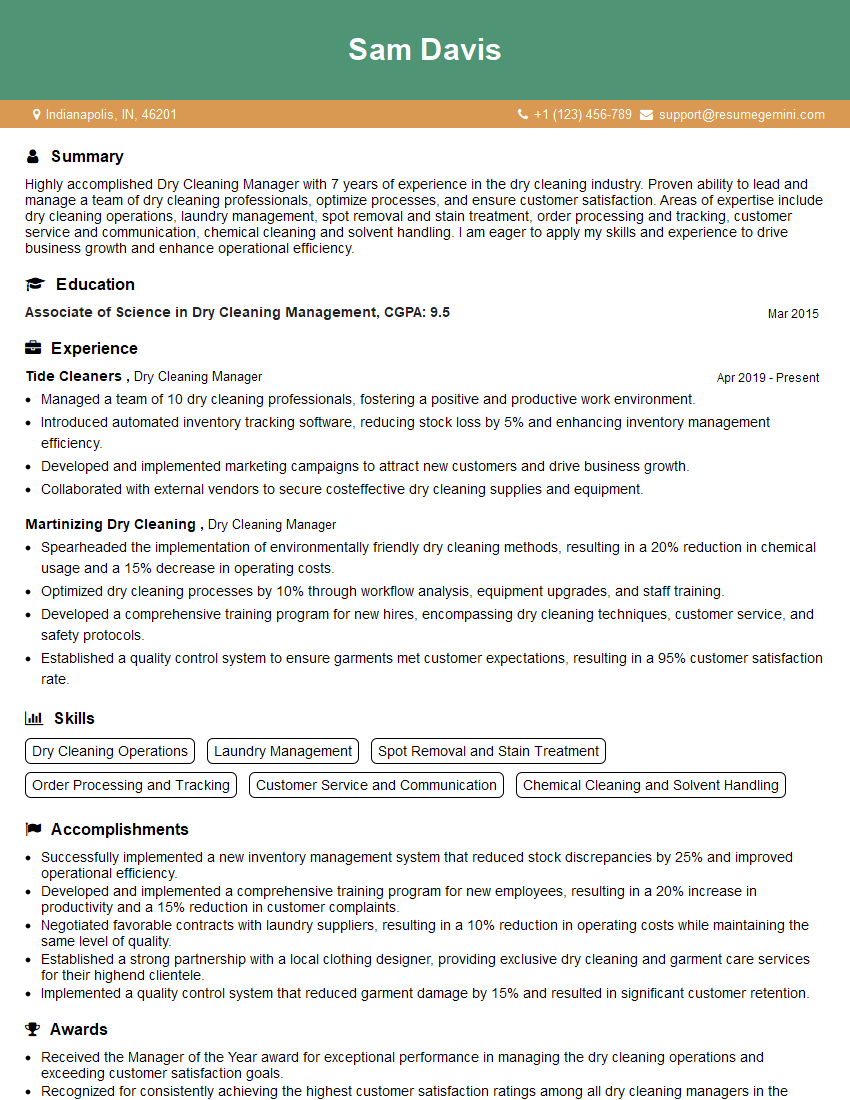

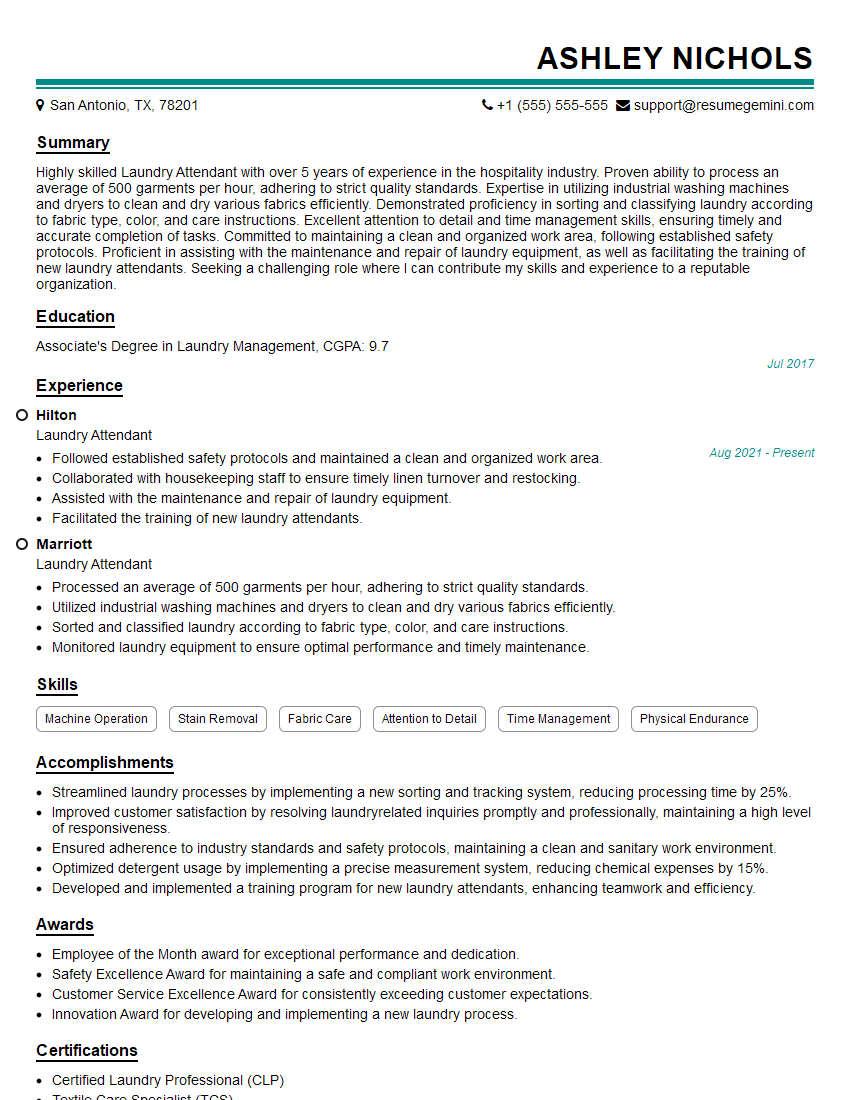

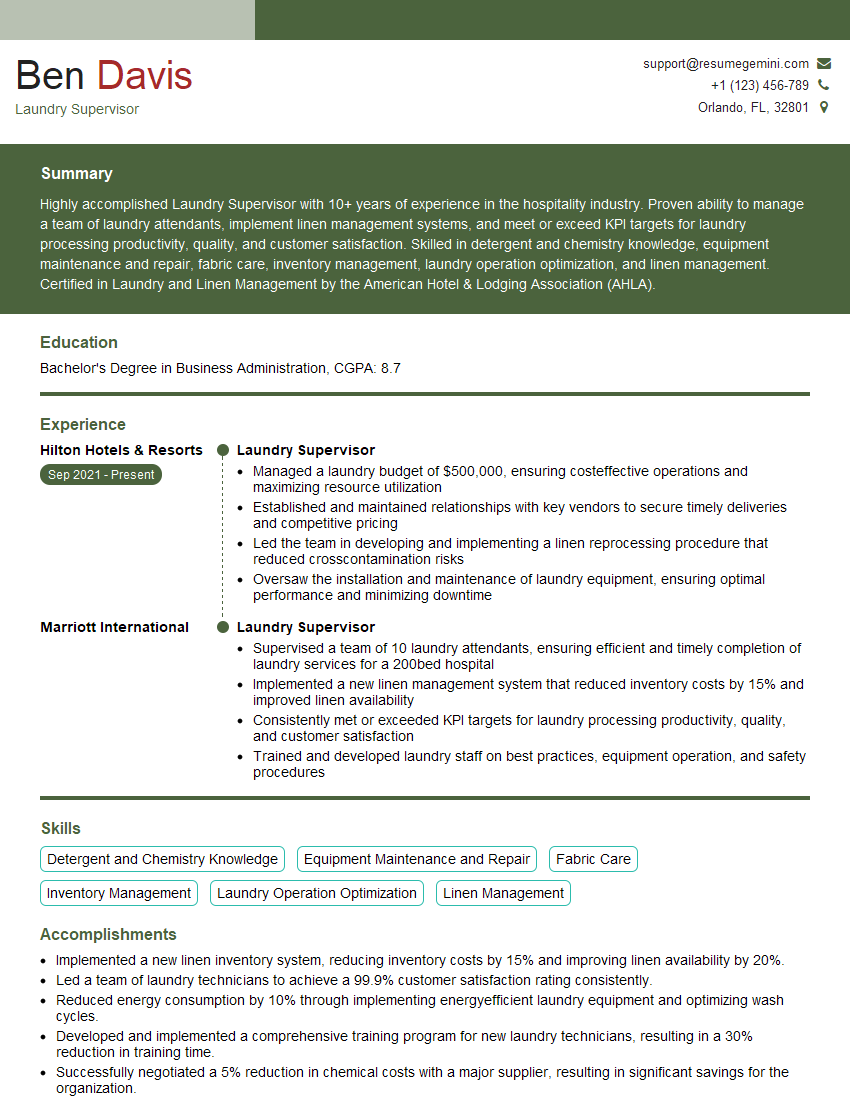

Mastering garment care opens doors to exciting opportunities in various industries, from high-end boutiques to large-scale laundry facilities. To stand out, creating an ATS-friendly resume is crucial. This ensures your application reaches the hiring manager. ResumeGemini can help you build a professional, impactful resume that showcases your skills and experience effectively. We provide examples of resumes tailored specifically to the Garment Care industry to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good