Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Lockout/Tagout (LOTO) Procedures interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Lockout/Tagout (LOTO) Procedures Interview

Q 1. Describe the five steps of a typical LOTO procedure.

A typical LOTO procedure involves five crucial steps to ensure worker safety during maintenance or repair of equipment. Think of it like this: you’re carefully securing a powerful machine before working on it, preventing any unexpected energy release.

- Preparation: This involves identifying all hazardous energy sources (electrical, mechanical, hydraulic, pneumatic, etc.) associated with the equipment. You’ll need to consult relevant documentation like machine schematics or operation manuals. For example, a conveyor belt might require isolating its electrical power, its mechanical drive, and any hydraulic systems that control its movement.

- Energy Isolation: This is the critical step where you physically disconnect the energy sources identified in step one. This might include turning off breakers, closing valves, locking out hydraulic pumps, or physically blocking moving parts. Imagine turning off the main power switch to a machine—that’s energy isolation.

- Lockout/Tagout Device Application: Once the energy is isolated, you apply your personal lockout device (lock) and tag to the energy isolation point(s). This clearly indicates that the equipment is locked out and under maintenance. Your lock prevents unauthorized energization. The tag provides additional information, such as your name and the date. It’s like adding a ‘Do Not Disturb’ sign with your signature.

- Verification of Isolation: Before starting the work, you must verify that the energy source is indeed isolated. This often involves testing the equipment to confirm no energy is present (e.g., checking for voltage with a multimeter). Imagine double-checking that the lights are truly off before you begin replacing a bulb—that’s verification.

- Release: After completing the work, remove the lockout and tagout devices in the reverse order of their application. Only the person who applied the lock should remove it. Once again, everyone is notified that the equipment is no longer secured.

Q 2. What are the different types of lockout devices?

Lockout devices come in various forms, each designed for specific applications. They all serve the same fundamental purpose: preventing the accidental re-energization of equipment.

- Padlocks: The most common type, offering individual accountability through unique keys. Each worker involved has their own padlock.

- Lockout Hasps: These devices allow multiple padlocks to be attached to a single energy isolation point, allowing multiple workers to lockout equipment collectively.

- Valve Locks: Specifically designed for isolating valves, preventing unwanted opening or closing.

- Circuit Breakers with Lockout Mechanisms: Integrated lockout features within circuit breakers offer a convenient and safe method of lockout for electrical systems.

- Cable Locks: Used to secure moving parts or other mechanical components.

The choice of device depends on the specific energy source and the complexity of the equipment. For instance, a simple light switch might only need a padlock, while a complex industrial machine might require a combination of lockout hasps and valve locks.

Q 3. Explain the concept of ‘energy isolation’ in LOTO.

Energy isolation in LOTO is the process of completely disconnecting all energy sources from a piece of equipment. This is the heart of LOTO; preventing the unexpected release of stored or residual energy which could cause injury. It’s about removing the power completely, leaving the machine inert and safe to work on.

This involves identifying all potential energy sources – electrical, mechanical (kinetic, potential, gravitational), hydraulic, pneumatic, thermal, chemical, and more – and then using appropriate methods to isolate them. For instance, isolating a hydraulic press involves not just turning off the motor but also depressurizing the hydraulic system and blocking the ram.

Failing to properly isolate all energy sources before commencing work is a critical failure, rendering the entire LOTO procedure ineffective and putting workers at risk.

Q 4. What is the role of an authorized employee in LOTO?

An authorized employee is a trained individual specifically designated to perform LOTO procedures. They’re the ones who are responsible for the entire process, from identifying hazardous energy sources to releasing the equipment after maintenance. Think of them as the ‘master keyholders’ of this safety system.

Their responsibilities include:

- Identifying and isolating energy sources.

- Applying lockout/tagout devices.

- Verifying energy isolation.

- Authorizing others to work on the equipment.

- Removing lockout/tagout devices after work is complete.

Authorized employees must receive specific training on LOTO procedures and are held accountable for the safety of themselves and their co-workers during the procedure. It’s a job that demands precision and thoroughness.

Q 5. What is the role of an affected employee in LOTO?

Affected employees are those who work near or with the equipment being locked out. They aren’t directly performing the maintenance but could be impacted by the procedure. Think of them as nearby workers whose tasks might be disrupted.

Their role involves understanding the LOTO procedure and respecting the lockout. They must not attempt to bypass or remove the locks and tags. They also need to understand the risks associated with the work being done and may need to take alternative precautions.

Effective communication between authorized and affected employees is vital, ensuring everyone understands the procedure and their responsibilities. It’s a matter of teamwork towards a common goal of safety.

Q 6. Describe the proper procedure for tagging equipment.

Tagging equipment is a crucial part of LOTO. While a lock prevents unauthorized access, the tag provides important information. The tag should be attached securely to the energy isolation device alongside the lock, ideally in a manner that cannot be removed without removing the lock.

Proper tagging involves including the following:

- The name of the authorized employee.

- The date the lockout/tagout was applied.

- A description of the work being performed.

- A warning not to energize the equipment.

The tag should be durable, clearly visible, and unambiguous. Imagine a brightly colored tag with bold lettering; this kind of tag makes it easier for others to understand what is going on.

Q 7. What are the limitations of using only a tagout device?

Using only a tagout device—without a lockout device—presents significant limitations and poses considerable safety risks. A tag simply serves as a warning; it doesn’t physically prevent the equipment from being energized.

The limitations include:

- Lack of physical prevention: A tag can be easily ignored or removed, leaving the equipment vulnerable to accidental energization.

- No individual accountability: Unlike padlocks which provide a clear record of who has applied the lockout, tags can easily be misplaced or ignored, providing no clear responsibility.

- Greater risk of accidents: The absence of a physical barrier significantly increases the chance of accidental equipment activation, leading to potentially serious injuries or fatalities.

Therefore, reliance on tagout alone is generally discouraged except in specific, well-defined, and low-risk scenarios where a full lockout is not feasible. For most applications, a physical lockout device remains necessary.

Q 8. How often should LOTO procedures be reviewed and updated?

LOTO procedures should be reviewed and updated at least annually, or more frequently depending on several factors. Think of it like a car’s safety inspection – regular checks ensure everything is in optimal working condition. These factors include changes in equipment, processes, personnel, or any incident involving the LOTO system. For example, if a new machine is installed, its specific LOTO procedure needs to be incorporated into the overall system. Similarly, if an employee reports a near miss or hazard related to a LOTO procedure, the procedure must be reviewed and potentially revised to prevent future occurrences. Regular reviews also help to keep the procedures up-to-date with evolving industry best practices and regulatory changes.

Beyond annual reviews, any time there’s a significant change – a new machine, process modification, or regulatory update – requires an immediate review and potential update. Consider maintaining a version control system for your LOTO procedures to ensure everyone is using the latest, safest version.

Q 9. What are the potential consequences of failing to follow LOTO procedures?

Failure to follow LOTO procedures can have devastating consequences, ranging from minor injuries to fatalities. Imagine a scenario where a technician fails to properly lock out a power source before performing maintenance. The equipment could unexpectedly energize, leading to severe electric shock, burns, or even death. Beyond the human cost, there are significant legal and financial repercussions. Companies can face hefty fines, lawsuits, and damage to their reputation. A failure could also lead to significant downtime and repair costs if the equipment is damaged.

- Serious Injury or Death: The most severe consequence is the potential for workers to suffer fatal injuries due to unexpected energization.

- Equipment Damage: Incorrect LOTO can damage equipment due to improper handling or unexpected operation.

- Legal and Financial Penalties: Companies can face substantial fines and lawsuits from regulatory bodies and injured workers.

- Reputational Damage: Accidents related to LOTO failures can damage a company’s reputation and erode public trust.

Q 10. Explain the importance of proper training in LOTO procedures.

Proper training is absolutely crucial for effective LOTO. It’s not just about reading a manual; it’s about building a safety culture. Think of it like learning to drive – you need both theoretical knowledge and practical experience. Training must cover theoretical aspects of energy sources, lockout devices, and procedure steps. But it must also include hands-on practice, where employees actually perform LOTO on equipment under the supervision of a qualified trainer. This ensures they understand the practical application of the procedures and can identify potential hazards. This practical aspect is critical to ensuring that employees aren’t just following steps; they understand why those steps are essential for safety.

Effective training also emphasizes the importance of reporting near misses or any issues with the LOTO process. It should encourage a culture of safety where reporting is not only accepted but expected, contributing to continuous improvement of LOTO procedures and overall safety.

Q 11. How do you verify that energy has been isolated?

Verifying energy isolation is a critical step, and it should never be taken lightly. You must use multiple methods to ensure that the energy source is truly isolated and cannot be accidentally re-energized. First, you visually inspect the equipment, looking for indicators of energy, such as glowing lights, spinning components or humming sounds. Then, you use testing equipment like voltage testers or amp meters to confirm the absence of energy. Finally, if possible, attempt to operate the equipment to confirm it will not start, emphasizing that you are only attempting operation for verification purposes after following all lockout procedures. This multi-step verification process reduces the chance of human error.

Remember, relying on just one method is risky. A visual check alone isn’t sufficient. Always use appropriate testing equipment. Thorough verification ensures that no energy is present before starting any work.

Q 12. What are the common energy sources that need to be controlled in LOTO?

Many energy sources need control in LOTO. These aren’t limited to just electricity. Think beyond the obvious. Common energy sources include:

- Electrical Energy: This is the most common and perhaps most dangerous. It can come from various sources, including power lines, electrical panels, and machinery.

- Mechanical Energy: This includes stored energy in springs, rotating equipment (like flywheels), or pressurized systems. A sudden release can cause serious injuries.

- Hydraulic and Pneumatic Energy: Pressurized liquids or gases can cause powerful and dangerous releases if not properly isolated.

- Thermal Energy: Hot surfaces, steam, and other heat sources can cause burns if not handled carefully.

- Chemical Energy: Reactions involving hazardous chemicals require specific lockout procedures to prevent accidental exposure or release.

- Gravitational Energy: Think about heavy objects that could fall, causing injuries. Proper blocking or securing is a part of LOTO in these situations.

The LOTO procedure must address all potential energy sources associated with the equipment being serviced.

Q 13. How do you handle situations where equipment cannot be fully isolated?

When equipment cannot be fully isolated, you need a different strategy. This is a high-risk situation that requires careful planning and additional safety measures. One approach might be using alternative methods to control the energy source, such as reducing the equipment’s operating pressure or employing physical barriers. Another approach might be to use additional personnel to monitor the system during the maintenance work, acting as a secondary safeguard. You might also have to significantly alter or even cancel the planned work, re-evaluating the potential hazards and whether the job can be safely accomplished under those conditions. This situation necessitates thorough risk assessment and a detailed safety plan that ensures worker safety.

Remember, worker safety is paramount. If the risks cannot be adequately mitigated, the work should be postponed until a safer method can be implemented.

Q 14. What are the documentation requirements for LOTO procedures?

LOTO documentation is crucial for accountability and traceability. It proves that procedures were followed correctly and allows for incident investigation if necessary. Essential documentation typically includes:

- LOTO Program: A comprehensive document outlining the organization’s LOTO policies, procedures, and responsibilities.

- Procedure-Specific Documents: Detailed step-by-step instructions for isolating energy for each piece of equipment.

- Lockout/Tagout Log: This log should record the date, time, equipment, personnel involved, and any relevant details of the LOTO procedure.

- Training Records: Documentation proving that all personnel have received adequate LOTO training.

- Inspection and Testing Records: Records of routine inspections and testing of LOTO devices to ensure they’re in good working order.

- Incident Reports: Any incidents or near misses related to LOTO must be documented to identify areas for improvement.

Maintaining thorough and accurate documentation is essential for demonstrating compliance with safety regulations and preventing future incidents.

Q 15. How do you handle emergencies that occur during a LOTO procedure?

Emergencies during a LOTO procedure are serious and require immediate, controlled action. The priority is always the safety of personnel. Our established procedure dictates that the first step is to immediately de-energize the equipment if it’s safe to do so. This may involve using an emergency shut-off switch, if available, or following emergency shutdown procedures specific to the equipment.

Secondly, we need to assess the situation. Determine the nature of the emergency, the potential hazards involved, and the extent of injuries, if any. Thirdly, we need to secure the area, preventing further access and ensuring the safety of those nearby. This might entail additional LOTO procedures on other related equipment to prevent cascading failures or unintended energy release.

Fourth, we proceed with emergency response procedures, which might include medical aid, contacting emergency services, and informing relevant personnel. Finally, a thorough incident investigation is conducted to determine the root cause of the emergency, identify areas for improvement in the LOTO process, and implement any necessary corrective actions. Think of it like this: Stop, Assess, Secure, Respond, Investigate. This acronym – SASRI – helps us remember the key steps.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the types of hazards that LOTO procedures protect against.

LOTO procedures are crucial for protecting workers from a wide range of hazards associated with the unexpected release of stored energy. This includes:

- Electrical hazards: Electric shock, burns, and electrocution from energized equipment.

- Mechanical hazards: Crushing, shearing, cutting, or entanglement injuries from moving machinery parts.

- Hydraulic/Pneumatic hazards: Being struck by high-pressure fluids or equipment movement.

- Thermal hazards: Burns from hot surfaces or steam.

- Chemical hazards: Exposure to hazardous chemicals due to uncontrolled release or spills.

For instance, imagine working on a conveyor belt. Without LOTO, unexpected start-up could lead to severe injury. LOTO prevents this by ensuring the power source is completely isolated before maintenance begins.

Q 17. What are the OSHA regulations related to LOTO?

OSHA’s standard for control of hazardous energy (LOTO), 29 CFR 1910.147, outlines detailed requirements for developing, implementing, and maintaining a LOTO program. Key aspects include:

- Energy isolation procedures: Detailed steps for safely disconnecting all energy sources.

- LOTO device selection and application: Ensuring the use of appropriate devices for each energy source.

- Authorized employee training: All personnel involved must receive adequate training on LOTO procedures.

- Periodic inspections and audits: Regularly reviewing the LOTO program’s effectiveness and making updates.

- Employee participation: Actively involving employees in the development and improvement of LOTO procedures.

Non-compliance can result in significant fines and potential legal action. It’s not just about following the rules; it’s about preventing workplace tragedies.

Q 18. How do you ensure that only authorized personnel have access to the equipment during LOTO?

Controlling access during LOTO is paramount. We achieve this through several measures:

- Clear signage and barriers: Physically restricting access to the equipment being serviced, using warning signs and physical barriers.

- Authorized employee lists: Maintaining an up-to-date list of personnel authorized to perform LOTO on specific equipment.

- LOTO device identification: Unique identification numbers, names, or symbols on each device to verify only authorized personnel are working on the equipment.

- Lockbox systems: Utilizing lockboxes to store LOTO devices, providing controlled access for those authorized.

- Regular audits and checks: Periodically confirming that only authorized personnel have access to the equipment during LOTO procedures.

Imagine a scenario where unauthorized access could result in equipment re-energizing and causing injury. Robust access control prevents such incidents.

Q 19. What is the difference between a lockout and a tagout?

While both lockout and tagout aim to prevent accidental energy release, they differ in their methods:

- Lockout: Physically securing energy-isolating devices with a lock, preventing unauthorized operation. This is the most effective method, providing a physical barrier against re-energization.

- Tagout: Using a tag to warn against energizing equipment. This relies on human compliance and is typically used as a secondary measure or where lockout isn’t feasible.

Think of it this way: a lockout is like a strong lock on a door, while a tagout is like a warning sign – the lock provides much more robust protection. Often, both are used together for enhanced safety.

Q 20. Explain the concept of group lockout/tagout.

Group lockout/tagout is employed when multiple employees work on the same equipment simultaneously. A designated team leader coordinates the process, ensuring everyone is properly trained and that each worker utilizes their own LOTO device on the same energy-isolating device. This prevents one person from accidentally releasing the energy while others are still working.

Each team member is responsible for their own lock or tag and is only permitted to remove their device after verifying it is safe to do so and after all other team members have confirmed that it’s safe for them to remove their devices. A clear communication and coordination system is essential during group LOTO.

Q 21. How do you handle situations where multiple energy sources are involved?

When multiple energy sources are present, the LOTO procedure must address each source individually. This involves identifying all potential energy sources (electrical, hydraulic, pneumatic, thermal, etc.), isolating each source using appropriate LOTO devices, and verifying that each source is completely de-energized before commencing work. This may require multiple locks and tags, one for each energy source.

Imagine a machine powered by both electricity and compressed air. We must isolate both the electrical circuit and the air supply using separate lockout devices. Failure to properly address all energy sources significantly increases the risk of accidents.

Q 22. Describe the importance of using a consistent and standardized LOTO program.

A consistent and standardized LOTO program is crucial for preventing workplace accidents involving hazardous energy. Think of it like a well-rehearsed play – everyone knows their part, minimizing the risk of errors. Standardization ensures that every employee, regardless of their experience level or the specific equipment, understands and follows the same procedures. This reduces confusion, improves efficiency, and most importantly, significantly lowers the risk of injury or fatality.

- Consistency: The same steps, lockout devices, and documentation are used across the entire facility for similar tasks, preventing deviations that could compromise safety.

- Standardization: Formal procedures are documented, reviewed, and regularly updated, incorporating best practices and addressing specific equipment needs. This ensures that all employees are on the same page and reduces the potential for human error.

For example, a standardized procedure for a specific press would detail the exact steps, energy sources to isolate (hydraulic, pneumatic, electrical), types of lockout devices required, and verification checks. This same format would be applied across all presses in the facility, preventing confusion and ensuring consistency.

Q 23. How do you handle equipment with multiple energy sources or complex systems?

Handling equipment with multiple energy sources or complex systems requires a meticulous and layered approach to LOTO. It’s like securing a multi-faceted fortress – you need to address each gate (energy source) individually. A comprehensive energy isolation survey is paramount to identify all potential energy sources. We must then develop a detailed LOTO procedure addressing each individually.

- Energy Isolation Survey: This detailed survey identifies all energy sources, including electrical, hydraulic, pneumatic, mechanical, thermal, and chemical, then determines the proper isolation methods for each.

- Multiple Lockout Devices: Each energy source should be individually isolated and secured with the appropriate lockout device, and verified before proceeding to the next step.

- Sequence of Isolation: A strict sequence is established to ensure the energy is fully isolated and the risk of re-energization is minimized.

- Verification and Documentation: Every step of the procedure is documented and signed off by the authorized personnel. This includes the isolation method employed, the energy sources addressed, and individual tag numbers.

Imagine a large industrial oven: it may have electrical power, gas supply, and potentially steam heating. Each must be individually isolated and locked out according to its specific procedure before maintenance can begin.

Q 24. What are the key elements of a comprehensive LOTO program?

A comprehensive LOTO program is much more than just a set of procedures; it’s a safety culture. Key elements include:

- Energy Control Program: This is the overarching document outlining the policy, procedures, responsibilities, and training requirements for the entire LOTO system.

- Written Procedures: Detailed, step-by-step instructions for isolating energy for specific equipment or processes.

- Training and Competency: Employees must receive regular and documented training on recognizing hazards, selecting and using appropriate lockout devices, performing LOTO procedures correctly, and understanding relevant regulations.

- Periodic Inspections: Regular inspections of lockout devices, procedures, and equipment to ensure proper functionality and address any potential issues.

- Audits and Reviews: Regular audits are essential to assess the effectiveness of the program and identify areas for improvement. The program must be reviewed, and updated regularly to account for new equipment and changes in regulations.

- Hazard Identification and Risk Assessment: This critical step involves analyzing the equipment and processes to recognize and assess hazards that may be present.

- Emergency Procedures: Specific procedures to follow in case of unexpected equipment re-energization during a LOTO operation.

A robust program ensures that everyone involved understands the importance of LOTO and their role in maintaining a safe work environment.

Q 25. How do you conduct regular inspections of LOTO devices and procedures?

Regular inspections of LOTO devices and procedures are critical for preventing accidents. It’s like a car’s routine maintenance – it catches small problems before they become major issues. Inspections should be conducted on a scheduled basis, and after any incidents or equipment modifications. The frequency depends on the usage and risk level of the equipment.

- Visual Inspections: Check for physical damage, wear, corrosion, or missing parts on lockout devices.

- Functionality Tests: Ensure that the lockout devices are functioning correctly and are able to effectively isolate the energy sources.

- Procedure Review: Verify that the LOTO procedures are accurate, clear, and up-to-date, addressing any changes to equipment or processes.

- Documentation: Maintain thorough records of all inspections, including dates, findings, corrective actions, and employee signatures.

For example, monthly inspections might involve checking for damage to padlocks and verifying that the appropriate lockout devices are available for each piece of equipment. Annual inspections could involve more thorough testing of the equipment’s isolation mechanisms.

Q 26. Describe your experience with different types of energy sources and isolation methods.

My experience encompasses a wide range of energy sources and isolation methods. Each requires a specific approach to ensure safety:

- Electrical: Lockout/Tagout using circuit breakers, disconnecting switches, and properly rated lockout devices. Always verify isolation with a voltage tester.

- Hydraulic: Isolation involves closing block valves, ensuring the pressure is relieved, and using appropriate lockout devices to prevent unintentional opening.

- Pneumatic: Similar to hydraulic, this involves shutting off air compressors and air lines, relieving pressure, and securing valves with lockout devices.

- Mechanical: This often includes using mechanical locks, blocking devices, and other means to prevent movement or rotation of machinery.

- Thermal: This requires shutting off heating elements, allowing them to cool down, and potentially using insulation to prevent accidental burns.

In a recent project involving a high-pressure hydraulic press, we used a combination of blind flanges, lockout devices, and pressure gauges to ensure complete energy isolation. Each step was meticulously documented and verified before starting maintenance.

Q 27. How would you address an incident where a LOTO procedure was not properly followed?

An incident where LOTO wasn’t properly followed requires immediate attention. It’s critical to investigate promptly and thoroughly to prevent future incidents. Think of it like a medical emergency: swift action is vital.

- Incident Investigation: This must be conducted immediately involving personnel with experience in LOTO procedures. Witness interviews, equipment inspection, and documentation review are critical.

- Root Cause Analysis: Determine the underlying cause of the non-compliance: was there insufficient training, unclear procedures, or a breakdown in safety culture?

- Corrective Actions: Implement steps to rectify the issue, whether it’s retraining employees, clarifying procedures, or modifying equipment design.

- Reporting and Documentation: Thoroughly document the incident, root cause analysis, corrective actions, and measures taken to prevent recurrence.

For instance, if an incident happened because of improper training, a retraining program with hands-on practice would be implemented. If the procedure was unclear, the documentation would be reviewed and revised. All this is documented and reviewed by management.

Q 28. How do you stay up-to-date with changes in LOTO regulations and best practices?

Staying updated on LOTO regulations and best practices is ongoing professional development, not a one-time task. It’s like subscribing to a vital newsletter for your profession.

- OSHA Website: Regularly review the Occupational Safety and Health Administration (OSHA) website for updates on regulations and best practices related to LOTO.

- Industry Publications and Conferences: Stay informed through professional publications, journals, and attending conferences and workshops.

- Professional Organizations: Membership in professional organizations provides access to industry updates and networking opportunities.

- Training Courses: Periodic refresher courses enhance knowledge and skills.

By consistently updating my knowledge base, I can ensure the LOTO program I implement and maintain aligns with the most current standards and best practices, helping to maintain the highest safety standards for the workplace.

Key Topics to Learn for Lockout/Tagout (LOTO) Procedures Interview

- LOTO Fundamentals: Understanding the purpose, scope, and legal requirements of LOTO procedures. This includes OSHA regulations and industry best practices.

- Energy Isolation: Identifying and isolating all potential energy sources (electrical, mechanical, hydraulic, pneumatic, etc.) before commencing any work. Practical application: Describing the steps involved in safely isolating various types of energy sources in different work scenarios.

- Lockout/Tagout Devices: Understanding the different types of lockout/tagout devices, their proper application, and limitations. Practical application: Explaining the selection criteria for choosing the appropriate device for a specific task.

- Procedure Development & Implementation: Understanding the process of developing, implementing, and auditing LOTO procedures. Practical application: Describing how to create a site-specific LOTO procedure for a complex piece of equipment.

- Inspection & Testing: Regular inspection and testing of lockout/tagout devices and procedures to ensure effectiveness. Practical application: Describing the proper inspection techniques and identifying potential failure points.

- Hazard Recognition & Risk Assessment: Identifying potential hazards associated with energy sources and developing appropriate control measures before performing LOTO procedures. Practical application: Performing a risk assessment of a specific task and selecting appropriate control measures.

- Teamwork & Communication: The crucial role of communication and teamwork in ensuring the safe implementation of LOTO procedures. Practical application: Describing effective communication strategies within a team during a LOTO procedure.

- Emergency Procedures: Understanding emergency procedures in case of LOTO failures or unexpected events. Practical application: Describing the steps to take in an emergency scenario.

Next Steps

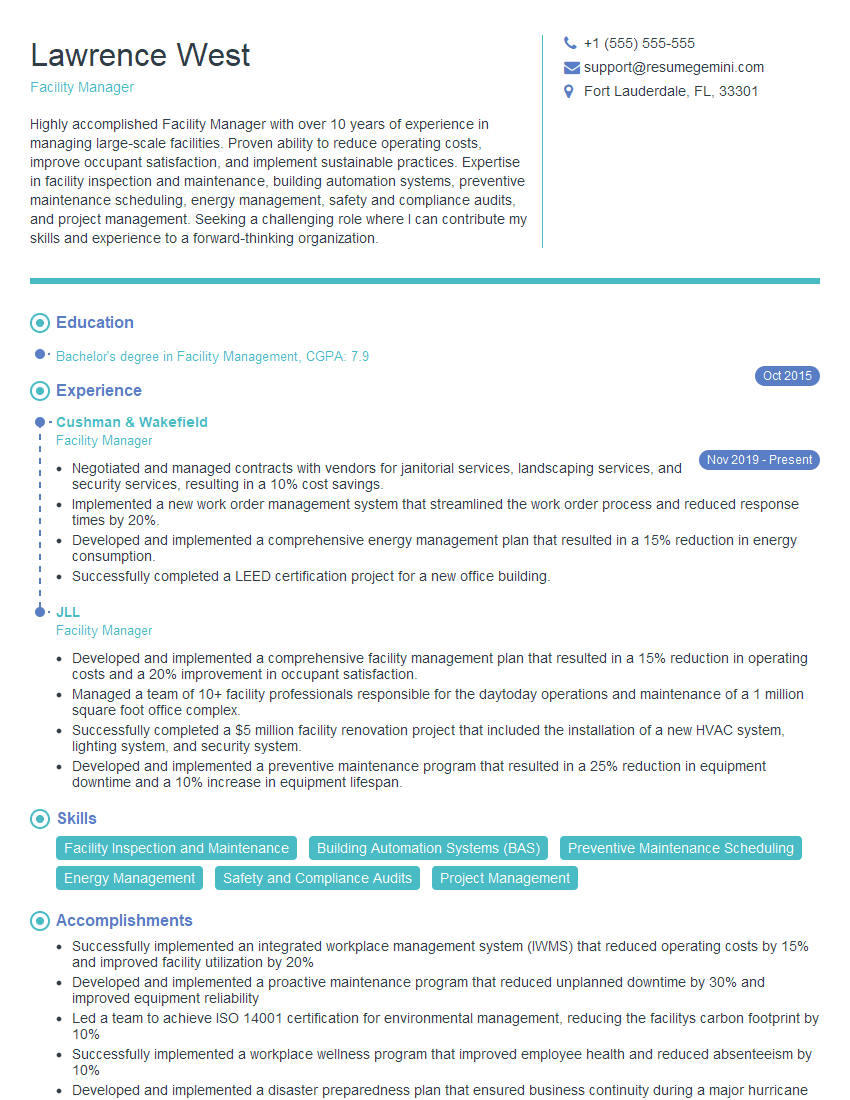

Mastering Lockout/Tagout (LOTO) procedures is essential for a successful and safe career in many industrial settings. Demonstrating a thorough understanding of these procedures will significantly boost your job prospects. To further enhance your chances, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume, highlighting your LOTO expertise. Examples of resumes tailored to Lockout/Tagout (LOTO) Procedures are available to help guide you. Invest the time to present yourself effectively – your safety and career success depend on it!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good