Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Electrical Safety and Testing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Electrical Safety and Testing Interview

Q 1. Explain the difference between a ground fault and a short circuit.

Both ground faults and short circuits involve unwanted electrical flow, but they differ significantly in their paths and consequences. A short circuit is an unintended low-resistance path between two points of differing electrical potential, typically within the same circuit. This often involves a direct connection between a hot wire and a neutral or ground wire, resulting in a surge of current that can cause overheating, fire, and equipment damage. Think of it like creating a shortcut on a highway – all the traffic rushes through the shortcut, overwhelming the system.

A ground fault, on the other hand, occurs when an unintended path to ground exists. This could be due to faulty insulation, a damaged wire contacting a grounded metal surface, or someone accidentally touching a live wire. The current flows from the hot wire to the ground, bypassing the intended circuit. While a short circuit is entirely contained within the electrical system, a ground fault involves current escaping into the earth. This poses a significant shock hazard to humans and animals. Imagine it as a leak in a water pipe – the water (current) escapes, potentially causing damage and posing a danger.

In essence, a short circuit is an internal fault within the electrical system, while a ground fault involves current leaving the system and potentially interacting with the environment.

Q 2. Describe the process of performing a lockout/tagout procedure.

Lockout/Tagout (LOTO) is a crucial safety procedure designed to prevent accidental energization of equipment during maintenance or repair. It involves a series of steps to isolate energy sources and ensure no one can accidentally restart the equipment. The process is critical to prevent injuries and fatalities.

- Preparation: Identify all energy sources (electrical, hydraulic, pneumatic, etc.) connected to the equipment. Gather the necessary lockout/tagout devices (locks, tags, etc.).

- Lockout: Shut down the equipment following the manufacturer’s instructions. Once the equipment is off, apply physical locks to the energy isolating devices (e.g., circuit breakers, valves). Each authorized worker should apply their own lock.

- Tagout: Attach tags clearly stating ‘Do Not Operate’ and identifying the worker who has the equipment locked out. These tags act as visual warnings.

- Verification: After the lockout/tagout procedure, verify that the energy source is indeed isolated. Use appropriate testing equipment to confirm that the equipment is de-energized.

- Release: Only the person who applied the lockout/tagout device can remove it. They should ensure the equipment is safe to re-energize and that all personnel are clear before releasing the locks and tags.

Example: Before working on a panel, you would shut off the breaker supplying power, lock it out with your padlock, and then tag it with your name. After completing the work, only you can remove your lock and tag after ensuring it’s safe.

Q 3. What are the key safety regulations you need to be familiar with (e.g., NEC, OSHA)?

As an electrical safety professional, familiarity with several key regulations is paramount. These include:

- National Electrical Code (NEC): This is the most widely adopted standard for safe electrical installations in the United States. It covers everything from wiring methods and equipment installation to grounding and bonding.

- Occupational Safety and Health Administration (OSHA): OSHA sets safety standards in the workplace, including those related to electrical safety. Their regulations cover aspects such as lockout/tagout, personal protective equipment (PPE), and hazard communication.

- NFPA 70E: This standard focuses specifically on electrical safety in the workplace. It provides detailed guidance on arc flash hazard analysis, PPE selection, and safe work practices.

- Other relevant standards: Depending on the industry and specific tasks, other relevant standards might apply, such as those from ANSI, IEEE, and IEC.

Understanding these regulations is crucial for ensuring compliance, preventing accidents, and protecting workers.

Q 4. How do you interpret electrical schematics and drawings?

Interpreting electrical schematics and drawings is a fundamental skill. These documents provide a visual representation of the electrical system, showing components, their connections, and how current flows. It requires understanding electrical symbols, which are standardized representations of components (e.g., resistors, capacitors, switches, motors).

Interpretation involves:

- Identifying components: Recognize symbols for each component and understand their function within the circuit.

- Tracing current paths: Follow the lines and connections to understand how current flows through the circuit.

- Analyzing circuit behavior: Understand how different components interact and how the circuit functions as a whole.

- Understanding circuit logic: For control circuits, understand the logic and how the system responds to various inputs.

Practice and experience are key. Starting with simpler circuits and gradually working towards more complex ones is a good approach.

Q 5. What are the different types of electrical testing equipment and their applications?

Numerous testing equipment are used to ensure electrical safety and proper functioning of systems. These include:

- Multimeters: These versatile instruments measure voltage, current, and resistance, allowing for basic circuit testing and troubleshooting.

- Clamp meters: These measure current without breaking the circuit, useful for measuring high currents without interrupting the system.

- Meggers (Insulation Resistance Testers): These measure the insulation resistance of cables and equipment, identifying potential ground faults or insulation degradation.

- Ground testers: These assess the grounding system’s effectiveness, ensuring proper earthing to protect against electrical shock.

- Arc flash testers: These are used to perform arc flash hazard analysis by measuring short circuit current and other parameters.

- Loop testers: Used to measure the impedance of protective devices like circuit breakers and fuses, ensuring they operate correctly within expected parameters.

The selection of equipment depends on the specific task, but all measurements should be conducted safely, adhering to relevant safety standards.

Q 6. Explain the principles of arc flash hazard analysis.

Arc flash hazard analysis is crucial for preventing severe burns and other injuries from electrical arcs. An arc flash occurs when a high-current arc suddenly jumps across an air gap in a circuit, releasing a tremendous amount of energy in the form of heat, light, and pressure. The analysis determines the potential arc flash energy and the appropriate personal protective equipment (PPE).

The process typically involves:

- System modeling: Creating a model of the electrical system to understand fault currents and other parameters.

- Fault current calculations: Calculating the available short circuit current at different points in the system.

- Incident energy calculations: Determining the incident energy (energy reaching a person during an arc flash) using software or formulas.

- Arc flash boundary determination: Identifying the distance from the equipment where the incident energy exceeds safe levels.

The results of the analysis guide the selection of appropriate PPE and establish safe work practices to minimize the risk.

Q 7. How do you calculate the required personal protective equipment (PPE) for a specific electrical task?

Calculating the required PPE for a specific electrical task depends heavily on the results of the arc flash hazard analysis. The analysis provides the incident energy level (in calories per square centimeter) at various distances from the equipment. This value determines the necessary arc flash rating of the PPE.

Steps involved:

- Perform Arc Flash Hazard Analysis: This is the foundational step to determine the incident energy.

- Consult NFPA 70E: This standard provides tables correlating incident energy levels to required arc flash PPE categories.

- Select PPE: Based on the incident energy level, select clothing with an arc flash rating (ARC rating) equal to or greater than the calculated incident energy. This typically includes arc-rated jackets, pants, gloves, face shields, and arc-rated footwear.

- Consider other hazards: Account for other potential hazards, such as shock and impact, and select appropriate PPE to address those as well.

Remember, PPE is the last line of defense. Prioritizing proper lockout/tagout procedures and safe work practices is crucial for preventing arc flash incidents in the first place.

Q 8. What are the common causes of electrical accidents?

Electrical accidents stem from a variety of causes, often involving a combination of factors. Think of it like a chain reaction – one weak link can trigger a catastrophic event.

- Faulty Wiring and Equipment: Damaged insulation, loose connections, and overloaded circuits are primary culprits. Imagine frayed wires acting like a broken dam, allowing current to escape where it shouldn’t. This can lead to shocks, fires, and equipment malfunctions.

- Improper Grounding: A lack of proper grounding creates a pathway for fault currents to flow through people instead of safely to the earth. It’s like leaving a faulty appliance un-earthed – a dangerous electrical path is created.

- Human Error: This is a significant contributor. Ignoring safety procedures, working on energized equipment without proper lockout/tagout, or improper use of tools can lead to serious consequences. It’s like driving a car without wearing a seatbelt – reckless behavior increases risk significantly.

- Environmental Factors: Moisture, extreme temperatures, and corrosive environments can degrade insulation and increase the risk of electrical faults. Think of it as rust weakening a metal component, making it prone to failure under stress.

- Lack of Maintenance: Regular inspections and maintenance can prevent many accidents. Ignoring regular checks is like neglecting a car’s engine – eventually, it’ll break down.

Understanding these causes is crucial for effective safety measures and preventative maintenance programs.

Q 9. Describe your experience with different types of electrical testing, such as insulation resistance testing, continuity testing, and ground resistance testing.

My experience encompasses a wide range of electrical testing methods. I’m proficient in using various instruments to assess the safety and integrity of electrical systems.

- Insulation Resistance Testing: This measures the resistance of insulation to prevent current leakage. We use a megohmmeter (or insulation resistance tester) to apply a high voltage to the insulation and measure the leakage current. A low resistance indicates insulation breakdown, posing a shock hazard. I’ve used this extensively on motors, cables, and transformers to ensure their insulation is sound.

- Continuity Testing: This verifies the integrity of electrical circuits. A multimeter with a continuity test setting checks for closed circuits. I’ve used this to test wiring for breaks or shorts before energizing a circuit. A break in continuity could mean a potential fire hazard due to overheating or arcing.

- Ground Resistance Testing: This measures the effectiveness of the grounding system. A clamp-on earth resistance tester measures the resistance between a grounding electrode and the earth. Low resistance is essential for protecting against electric shock by providing a low impedance path to the ground during a fault. I’ve performed this testing on numerous grounding systems, ensuring they meet safety standards.

The results from these tests are crucial for determining the safety of electrical equipment and installations. A comprehensive testing regime is essential for preventing accidents and ensuring compliance with relevant safety codes.

Q 10. How do you ensure the safety of yourself and others when working with high-voltage equipment?

Safety is paramount when working with high-voltage equipment. It’s not just about following procedures; it’s about a mindset of caution and respect for the potential dangers.

- Lockout/Tagout Procedures: This is crucial before working on any energized equipment. I meticulously de-energize the equipment, lock it out, and tag it to prevent accidental energization. It’s a non-negotiable, life-saving step.

- Personal Protective Equipment (PPE): Appropriate PPE, including insulated gloves, safety glasses, and arc flash protective clothing, is always worn. I regularly inspect my PPE before every task to ensure it’s in perfect working order.

- Proper Training and Certification: I hold the necessary certifications and undergo regular training to stay up-to-date on the latest safety practices and technologies.

- Working with a qualified team: High voltage work is never a solo job. Having a team with complementary skillsets and expertise improves safety and efficiency.

- Regular Safety briefings and risk assessments: Thorough risk assessments are carried out before every job to identify and mitigate potential hazards. Regular safety meetings also ensure ongoing compliance with safety regulations.

Treating high-voltage work with the utmost respect and adhering strictly to safety protocols are essential to prevent accidents and ensure the well-being of myself and my colleagues.

Q 11. Explain the concept of fault current and its importance in safety.

Fault current is the excessive current that flows during a short circuit or ground fault. Think of it as an electrical flood – a surge of electricity where it shouldn’t be.

Its importance in safety is paramount because it can cause:

- Equipment damage: The high current can overheat and destroy equipment, leading to fires.

- Electric shock: Fault currents can travel through humans, causing severe burns or even death.

- Fires: The heat generated by fault currents can ignite flammable materials.

Protective devices like circuit breakers and fuses are designed to interrupt fault currents quickly, minimizing the risk of damage and injury. Proper grounding is also critical in diverting fault currents safely to the earth.

Understanding fault currents is crucial for designing safe electrical systems and ensuring the effectiveness of protective devices. It’s a fundamental concept in electrical safety engineering.

Q 12. What are the different types of grounding systems and their advantages and disadvantages?

Grounding systems are designed to provide a low-resistance path for fault currents to flow to the earth, protecting people and equipment.

- Grounding Electrode System (GES): This involves driving a grounding rod into the earth and connecting it to the electrical system. It’s simple but its effectiveness depends on soil conductivity.

- Plate Grounding: A large metal plate is buried in the ground, offering a larger surface area for better conductivity. It is more effective than a rod in areas with high resistivity.

- Multiple Grounding Electrodes: Combining several grounding electrodes (rods or plates) to create a more robust system that offers redundancy and improved conductivity.

- Counterpoise Grounding: A system where a conductor is buried parallel to the underground cable. This acts as an additional ground path along the cable’s length, helping to reduce voltage gradients.

Advantages: Protection against electric shock, improved equipment reliability, reduced risk of fires, and improved safety during lightning strikes.

Disadvantages: GES effectiveness varies depending on soil conditions, can be costly to install especially multiple electrode systems, and requires regular maintenance to ensure conductivity.

Choosing the right grounding system depends on the specific application, considering factors like soil resistivity and the sensitivity of the electrical equipment.

Q 13. How do you troubleshoot electrical faults?

Troubleshooting electrical faults requires a systematic and methodical approach. It’s like detective work, using observation, testing, and analysis to pinpoint the problem.

- Safety First: Always de-energize the circuit before starting any troubleshooting. Never assume a circuit is dead.

- Visual Inspection: Carefully inspect wiring, connections, and equipment for any visible damage, such as frayed wires, loose connections, or burn marks.

- Testing: Use appropriate testing equipment, such as multimeters, to check voltage, current, resistance, and continuity.

- Isolate the Fault: Systematically check sections of the circuit to narrow down the location of the fault.

- Repair or Replacement: Once the fault is identified, repair or replace the faulty component.

- Verification: After making repairs, retest the circuit to ensure the fault is resolved and the system is safe.

Effective troubleshooting depends on a strong understanding of electrical theory and practical experience in using testing equipment. Documenting the troubleshooting process is essential for tracking progress and maintaining a record of repairs.

Q 14. Describe your experience with electrical safety audits and inspections.

I have extensive experience conducting electrical safety audits and inspections, ensuring compliance with relevant safety standards and regulations. My approach is thorough and methodical, covering all aspects of electrical systems.

A typical audit/inspection includes:

- Review of electrical drawings and documentation: Checking for compliance with design standards and regulations.

- Visual inspection of electrical equipment and installations: Looking for signs of wear, damage, or improper installation.

- Testing of electrical systems: Conducting various tests like insulation resistance, continuity, and ground resistance tests to verify system integrity.

- Evaluation of safety procedures and practices: Assessing the effectiveness of lockout/tagout procedures, personal protective equipment usage, and employee training.

- Identification of hazards and recommendations for corrective actions: Documenting all findings and providing detailed reports with recommendations for improvements and necessary repairs.

I provide detailed reports highlighting any non-compliances or potential hazards, offering tailored recommendations to improve safety and prevent future accidents. My goal is to provide a safe and compliant electrical environment for all.

Q 15. What are the common safety hazards associated with working on electrical panels?

Working on electrical panels presents numerous hazards, the most significant being electric shock. This can range from a minor jolt to a fatal electrocution, depending on the voltage and current involved. Another major risk is arc flash, a sudden, powerful explosion of electrical energy that can cause severe burns, blindness, and even death. The intense heat generated during an arc flash can instantly ignite flammable materials nearby. Beyond these immediate dangers, there’s the risk of falling from ladders or elevated platforms while accessing the panel, and potential injuries from tools or equipment.

- Electric Shock: Contact with energized conductors can lead to severe burns and cardiac arrest.

- Arc Flash: A high-temperature plasma that can cause devastating injuries.

- Falls: Working at heights increases the risk of falls, especially on uneven surfaces or ladders.

- Burns: Contact with hot components or arc flash can cause severe burns.

Consider a scenario where a technician is working on a live panel without proper lockout/tagout procedures. A simple mistake, like accidentally contacting a live wire, could result in a fatal electric shock. Safety is paramount, and thorough training and adherence to safety protocols are crucial to mitigating these risks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret and apply electrical safety standards and codes?

Interpreting and applying electrical safety standards and codes is fundamental to my work. I meticulously review relevant codes like the National Electrical Code (NEC) in the US (or equivalent international standards), focusing on the specific requirements for the task at hand. This includes understanding voltage limits, grounding requirements, appropriate PPE (Personal Protective Equipment), and safe work practices. I don’t just read the codes; I understand the rationale behind them and how they apply to various scenarios. For example, the NEC dictates specific requirements for working clearances around energized equipment, and I ensure all work is conducted within those parameters. I regularly update my knowledge on code changes and amendments through professional development programs and industry publications.

Consider a project involving the installation of a new electrical panel in a commercial building. I would consult the NEC to determine the appropriate size of the panel, the type of wiring, the grounding requirements, and the necessary safety devices. I’d then translate these code requirements into a detailed installation plan that adheres to all relevant safety regulations.

Q 17. What is your experience with different types of safety devices, such as circuit breakers, fuses, and ground fault circuit interrupters (GFCIs)?

I have extensive experience with various safety devices. Circuit breakers are essential for overcurrent protection, instantly interrupting the circuit if the current exceeds a safe level. Fuses act similarly but are one-time use devices, requiring replacement after they blow. Ground Fault Circuit Interrupters (GFCIs) offer protection from ground faults, which can be lethal. They monitor the current balance between the hot and neutral wires, tripping if an imbalance occurs, typically indicating a current path to ground. I am proficient in identifying the appropriate type and rating of these devices for specific applications and regularly test their functionality during inspections. Knowing the differences between various types of breakers (e.g., thermal-magnetic, electronic) is critical for choosing the right one for specific applications.

For instance, in a kitchen, GFCIs are mandated to protect against electrocution from appliances near water. I’d verify their proper operation during inspections using a GFCI tester and replace any malfunctioning units immediately. In industrial settings, I’d select higher capacity breakers suited to handle heavier loads, again ensuring they meet the necessary safety and code requirements.

Q 18. Describe your experience with thermal imaging and its application in electrical safety inspections.

Thermal imaging is an invaluable tool in electrical safety inspections. It allows me to non-destructively detect excessive heat in electrical components and systems, which can indicate impending failures or existing problems. Overheated connections, loose terminations, and failing components all exhibit elevated temperatures that show up clearly on a thermal image. This early detection can prevent fires, equipment failures, and potentially hazardous situations. My experience involves using thermal cameras to scan electrical panels, switchgear, and wiring, analyzing the resulting images to pinpoint potential hazards. I understand how to interpret the temperature readings in relation to the components’ normal operating temperatures.

Imagine a situation where a thermal scan reveals an unusually hot connection in a motor controller. While the motor might still be functioning, the elevated temperature suggests a loose connection or a failing component. This early warning enables proactive repairs, preventing a potentially catastrophic failure that could cause a fire or equipment damage.

Q 19. How do you ensure the accuracy and reliability of electrical test results?

Ensuring accurate and reliable test results is achieved through a rigorous process. First, I use calibrated test equipment, meticulously checked and documented for accuracy before each use. Second, I adhere to established testing procedures and standards, performing tests multiple times to verify results and noting any inconsistencies. Third, I carefully document all test procedures, readings, and observations, including any environmental factors that could affect the readings. I know the limitations of each piece of testing equipment and I select the appropriate tools for specific measurements. I also maintain detailed records of the calibration and maintenance of the equipment.

For instance, when testing insulation resistance, I carefully clean the test leads to ensure accurate readings. I’ll also note the ambient temperature and humidity, factors that can influence the test results. By following these steps, I ensure the reliability and accuracy of my findings and provide a trustworthy assessment of the electrical system’s safety.

Q 20. How do you document and report the findings of electrical safety inspections?

I document my findings using comprehensive reports, including detailed descriptions of the inspection process, photographic evidence (including thermal images where applicable), schematics, and tables summarizing test results. These reports are organized logically and clearly presented to facilitate understanding. Any identified hazards are clearly highlighted, along with recommended corrective actions and their prioritization. The reports include the date and time of the inspection, the equipment used, and the names of individuals involved. The level of detail in the report is tailored to the audience and the specific requirements of the inspection.

A typical report might include sections on general observations, specific test results (e.g., insulation resistance, ground continuity), identified hazards, recommendations, and a conclusion summarizing the overall safety status of the electrical system. This detailed documentation provides a clear record of the inspection and is essential for future reference and liability purposes.

Q 21. What is your understanding of NFPA 70E?

NFPA 70E, Standard for Electrical Safety in the Workplace, is a crucial document that outlines safety requirements for electrical work. My understanding of NFPA 70E encompasses its key aspects, including arc flash hazard analysis, personal protective equipment (PPE) selection, safe work practices, and emergency response procedures. I understand the importance of performing arc flash risk assessments to determine the appropriate PPE required for specific tasks, and I ensure that all work is conducted in accordance with the identified risk levels. I’m familiar with the various categories and classes of PPE and their application in different scenarios. Furthermore, I understand the importance of lockout/tagout procedures to ensure that equipment is de-energized before any work is performed, as mandated by NFPA 70E.

For example, before working on a high-voltage switchgear, I would first conduct an arc flash risk assessment to determine the appropriate PPE, which could include arc-rated clothing, face shields, and insulated gloves. Then, I would follow strict lockout/tagout procedures to ensure the equipment is safely de-energized before commencing work. Adherence to NFPA 70E guidelines is essential in minimizing the risks associated with electrical work and ensuring the safety of all personnel involved.

Q 22. What are the different classes of electrical equipment?

Electrical equipment is classified into various classes based on their level of protection against electric shock and other hazards. The classification systems vary slightly depending on the region and standard (e.g., IEC, UL), but common classes focus on insulation, grounding, and ingress protection.

- Class I: These appliances rely on basic insulation and a protective earth ground connection for safety. If a fault occurs, the earth ground provides a low-impedance path for fault current to flow, tripping the circuit breaker or fuse and protecting the user. Think of most household appliances with a three-prong plug.

- Class II: These appliances have double or reinforced insulation, eliminating the need for an earth ground connection. They provide double the insulation protection, making them safer even in the absence of a ground. Examples include many hand-held power tools and appliances with two-prong plugs.

- Class III: These are safety extra-low voltage (SELV) appliances, operating at voltages too low to pose a direct shock hazard, usually 50V AC or 120V DC or less. Think of battery-operated devices or low-voltage landscape lighting.

- Ingress Protection (IP) ratings: These ratings indicate the level of protection against the ingress of solid objects (first digit) and water (second digit). For example, an IP65 rating means the equipment is fully protected against dust ingress and protected against low-pressure water jets. This is crucial in determining suitability for various environments.

Understanding these classes is vital for selecting and using equipment appropriately in different environments, ensuring safety and preventing accidents.

Q 23. Explain the importance of proper documentation in electrical safety.

Proper documentation in electrical safety is paramount for several reasons. It serves as a record of compliance, facilitates effective maintenance, and ensures safety for everyone involved.

- Proof of Compliance: Documentation provides evidence that electrical installations, testing, and inspections meet relevant safety standards and regulations. This is crucial for legal and insurance purposes.

- Maintenance and Troubleshooting: Detailed records of inspections, repairs, and modifications are essential for tracing problems and performing effective maintenance. Knowing the history of an electrical system greatly aids in troubleshooting.

- Safety and Risk Reduction: Clear documentation helps identify potential hazards, preventing accidents. It also facilitates communication among personnel involved in the work.

- Continuity and Accountability: When personnel change, documentation ensures a smooth transition and avoids potential gaps in knowledge. It promotes accountability by documenting who performed the work and when.

Examples of crucial documents include test certificates, inspection reports, schematics, maintenance logs, and safety procedures. Without thorough documentation, the system’s safety and reliability are significantly compromised.

Q 24. How do you handle emergency situations involving electrical hazards?

Handling electrical emergencies requires a calm, methodical approach prioritizing safety. The first and most important step is always to ensure your own safety.

- Isolate the Power Source: Immediately disconnect the power supply to the affected area if possible. This might involve switching off circuit breakers, unplugging equipment, or using appropriate lockout/tagout procedures.

- Assess the Situation: Once the power is isolated, assess the situation to determine the extent of the hazard and the injuries, if any. Do not approach the situation until the power is verified as off.

- Administer First Aid (if qualified): If anyone is injured, provide appropriate first aid. Know your limitations; if needed, call emergency medical services immediately.

- Call Emergency Services: Call emergency services (fire department, paramedics) as needed. Describe the situation clearly and concisely.

- Secure the Area: Prevent further access to the hazardous area until it is deemed safe by a qualified electrician or safety personnel.

- Investigate and Report: After the immediate emergency is over, conduct a thorough investigation to determine the root cause of the incident. Document the findings and implement corrective actions to prevent future occurrences. This typically includes filing incident reports.

Remember, in an electrical emergency, your safety is the top priority. Never attempt to handle a live electrical hazard without the proper training and equipment.

Q 25. What is your experience with using personal protective equipment (PPE) for electrical safety?

My experience with PPE for electrical safety is extensive. I understand that PPE is a crucial part of a layered safety approach and is not a substitute for proper engineering controls or safe work practices. The type of PPE used depends on the specific task and potential hazards.

- Insulated Tools: I’m proficient in using insulated tools rated for the appropriate voltage, checking their condition regularly for any damage to the insulation.

- Arc Flash Suits: I have experience using arc flash suits and other protective clothing designed to protect against the thermal hazards of an arc flash incident. These suits have specific ratings that are critical to select for the task and risk level.

- Rubber Insulated Gloves: I’m experienced in inspecting and using rubber insulated gloves according to manufacturer’s instructions, and using appropriate voltage testers to ensure their integrity before each use.

- Safety Glasses and Face Shields: Eye protection is critical, and I always wear safety glasses or a face shield when working with electricity, protecting against flying debris or arc flash.

- Safety Footwear: Insulated footwear is crucial to prevent ground faults. I consistently use appropriate footwear when working in environments with potential electrical hazards.

I always adhere to the manufacturer’s instructions for using, inspecting, and storing all PPE to ensure its effectiveness and prolong its lifespan. Regular inspections and maintenance are non-negotiable for personal safety.

Q 26. Describe your knowledge of relevant safety standards and regulations.

My knowledge of safety standards and regulations is comprehensive, encompassing national and international standards. I’m familiar with standards such as:

- NFPA 70E (National Fire Protection Association 70E): This standard provides guidance on electrical safety in the workplace and is crucial in North America.

- IEC 60068: This is a set of international standards for environmental testing of electrical equipment, crucial for ensuring that equipment can withstand various environmental conditions.

- OSHA Regulations (Occupational Safety and Health Administration): I am well-versed in relevant OSHA regulations that mandate safe electrical practices in the workplace.

- Local Electrical Codes: I understand the nuances of local electrical codes and regulations that may vary depending on the region.

My knowledge extends beyond simply knowing the standards; I understand the underlying principles behind these regulations, allowing me to apply them effectively in real-world scenarios and adapt to evolving safety guidelines.

Q 27. How would you train others on electrical safety procedures?

Training others on electrical safety procedures requires a multi-faceted approach, combining theoretical knowledge with practical hands-on experience. My training approach would be structured as follows:

- Needs Assessment: Begin by assessing the trainees’ existing knowledge and experience to tailor the training to their specific needs.

- Interactive Lectures: Employ interactive lectures, visual aids, and real-life case studies to enhance understanding and engagement.

- Hands-on Demonstrations and Practical Exercises: Provide ample opportunities for hands-on practice using simulated scenarios and appropriate tools.

- Role-playing and Simulations: Simulate emergency situations to allow trainees to practice response techniques in a safe environment.

- Regular Assessments and Feedback: Provide regular assessments and feedback to evaluate learning and address knowledge gaps. This could include written tests, practical examinations, or observation during exercises.

- Ongoing Reinforcement: Reinforce training through regular reminders, updates on new regulations, and opportunities for further learning.

My teaching style emphasizes clear communication, active learning, and a strong emphasis on safety. I believe a comprehensive training program that balances theory and practice is essential for creating a safety-conscious workforce.

Q 28. Explain your approach to risk assessment in electrical work.

My approach to risk assessment in electrical work follows a systematic process, ensuring a thorough evaluation of potential hazards and mitigation strategies.

- Identify Hazards: Begin by identifying all potential electrical hazards associated with the work, including shock, arc flash, fire, and falls from heights.

- Assess the Risks: Evaluate the likelihood and severity of each identified hazard. This involves considering factors such as voltage levels, working conditions, and the experience level of personnel.

- Evaluate Existing Controls: Assess the effectiveness of existing control measures, such as lockout/tagout procedures, safety equipment, and training programs.

- Develop Control Measures: If risks remain unacceptable, develop and implement additional control measures to mitigate the identified hazards. This might involve adding personal protective equipment (PPE), modifying work procedures, or using specialized equipment.

- Document and Communicate: Thoroughly document the risk assessment process, including identified hazards, risk levels, control measures, and responsibilities. Communicate the assessment findings to all involved personnel.

- Monitor and Review: Regularly monitor the effectiveness of control measures and review the risk assessment periodically, especially after incidents or changes in work procedures.

This process ensures that risks are minimized, providing a safer work environment for everyone involved. Regular review and updates to risk assessments are critical for adapting to changing conditions and maintaining a high level of electrical safety.

Key Topics to Learn for Electrical Safety and Testing Interview

- Electrical Codes and Standards: Understanding and applying relevant codes (e.g., NEC, IEC) to ensure compliance and safety in electrical installations.

- Test Equipment and Instrumentation: Familiarization with various testing instruments (multimeters, meggers, clamp meters, etc.) and their proper usage for accurate measurements.

- Electrical Safety Procedures and Practices: Mastering lockout/tagout procedures, arc flash hazard analysis, and safe work practices to prevent accidents and injuries.

- Fault Finding and Troubleshooting: Developing strong analytical skills to diagnose electrical faults, using systematic approaches and interpreting test results effectively.

- Grounding and Bonding: Understanding the principles of grounding and bonding, their importance in electrical safety, and methods for verifying effective grounding.

- Protective Devices: Knowledge of circuit breakers, fuses, GFCIs, and other protective devices, their operation, and selection criteria.

- Risk Assessment and Mitigation: Ability to conduct thorough risk assessments for electrical work, identify potential hazards, and implement appropriate mitigation strategies.

- Documentation and Reporting: Proficiency in generating accurate and detailed test reports, documenting findings, and communicating effectively with clients or supervisors.

- High Voltage Testing Techniques: Understanding specialized techniques for testing high-voltage equipment and systems, adhering to safety protocols.

- Regulations and Compliance: Staying updated on current regulations and industry best practices related to electrical safety and testing.

Next Steps

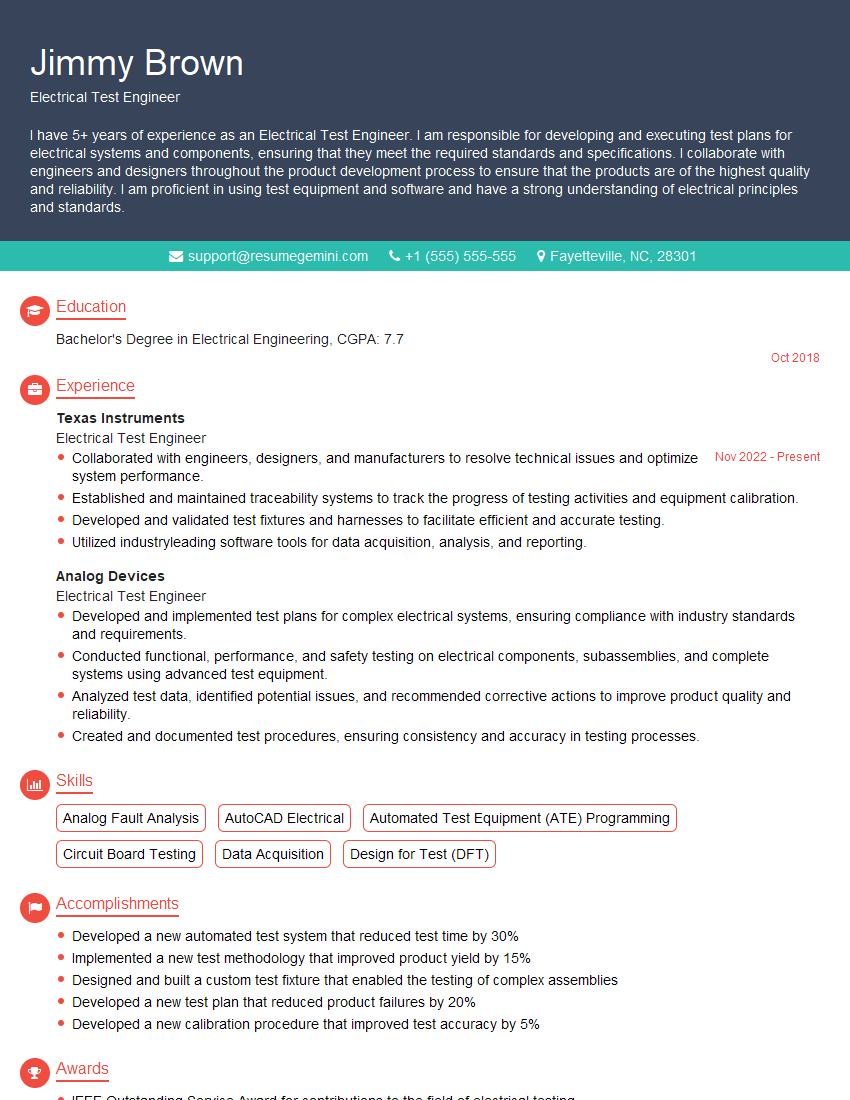

Mastering Electrical Safety and Testing is crucial for a successful and rewarding career, opening doors to exciting opportunities in diverse industries. A strong foundation in these areas demonstrates your commitment to safety and technical proficiency, highly valued by employers. To maximize your job prospects, it’s vital to create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to Electrical Safety and Testing are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good