Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Maintenance and Rehabilitation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Maintenance and Rehabilitation Interview

Q 1. Describe your experience with preventative maintenance programs.

Preventative maintenance (PM) is the proactive approach to keeping equipment running smoothly by scheduling regular inspections and servicing before failures occur. Think of it like getting your car serviced regularly – you change the oil, check the tires, etc., to avoid a major breakdown down the road. In my experience, effective PM programs rely on a structured approach.

- Developing a PM Schedule: This involves analyzing equipment criticality, failure rates, and manufacturer recommendations to create a tailored schedule. For example, a critical piece of production equipment might require weekly inspections, while less critical equipment might only need monthly checks.

- Implementing a CMMS (Computerized Maintenance Management System): A CMMS is crucial for scheduling, tracking, and managing PM tasks. It allows for automated reminders, generates reports on PM completion rates, and helps ensure nothing falls through the cracks. I’ve used several CMMS systems including SAP PM and Fiix, and found them indispensable for efficient PM management.

- Training Technicians: Thorough training ensures technicians understand the PM procedures and can identify potential problems early. Regular refresher training is important, especially as equipment changes or technology advances.

- Documentation and Reporting: Meticulous record-keeping is essential. This includes documenting PM activities, noting any observed issues, and generating reports to track performance and identify trends. These reports are vital for continuous improvement of the PM program.

In a previous role, I implemented a new PM program for a food processing plant. By meticulously tracking PM completion rates and analyzing failure data, we reduced equipment downtime by 25% within the first year. This led to significant cost savings and increased production efficiency.

Q 2. Explain your process for troubleshooting malfunctioning equipment.

Troubleshooting malfunctioning equipment involves a systematic approach that combines technical knowledge, problem-solving skills, and diagnostic tools. My process typically follows these steps:

- Safety First: Ensure the area is safe before attempting any troubleshooting. This may involve lockout/tagout procedures to prevent accidental energization.

- Gather Information: Start by collecting as much information as possible about the malfunction. This includes when the problem started, what symptoms are present, any error messages displayed, and recent maintenance activities. Talking to the operators who noticed the problem first is often crucial.

- Visual Inspection: Carefully examine the equipment for obvious problems like loose connections, leaks, or physical damage.

- Diagnostic Testing: Use appropriate diagnostic tools, such as multimeters, pressure gauges, or specialized equipment, to identify the root cause. This might involve checking voltage, current, pressure, temperature, or other relevant parameters.

- Component Testing: If the problem isn’t immediately obvious, you may need to systematically test individual components to isolate the faulty part. This can be time-consuming but necessary to pinpoint the issue accurately.

- Repair or Replacement: Once the faulty component is identified, repair or replace it according to the manufacturer’s instructions. Proper documentation of the repair is important.

- Testing and Verification: After the repair, thoroughly test the equipment to verify that it’s functioning correctly and that the problem is resolved.

For example, if a conveyor belt stops working, I might first check the power supply, then examine the motor, belts, and sensors. If the problem persists, I might need to utilize a multimeter to check the motor’s windings or consult schematics to trace the wiring.

Q 3. How do you prioritize maintenance tasks in a high-pressure environment?

Prioritizing maintenance tasks in a high-pressure environment requires a structured approach that balances urgency and importance. I use a combination of methods:

- Criticality Assessment: Assign a priority level to each task based on its impact on production, safety, or regulatory compliance. A critical failure could shut down an entire production line, while a minor issue might only cause minor inconvenience. This often involves a risk assessment.

- Urgency Assessment: Consider the time sensitivity of the task. An immediate safety hazard needs to be addressed immediately, while a preventative maintenance task can often be scheduled.

- Impact Analysis: Evaluate the potential impact of delaying or not performing the task. This helps in ranking tasks based on their overall consequences.

- Maintenance Backlog Management: Use a CMMS to manage a backlog of tasks. The system can be configured to automatically prioritize tasks based on predefined rules and criteria.

- Collaboration and Communication: Regular communication with operations and production teams is crucial to understand their priorities and ensure alignment on maintenance tasks.

Think of it like a hospital emergency room. Life-threatening cases are prioritized over less urgent ones. Similarly, in maintenance, safety concerns and critical production issues always take precedence.

Q 4. What experience do you have with CMMS (Computerized Maintenance Management Systems)?

Computerized Maintenance Management Systems (CMMS) are essential tools for managing maintenance operations efficiently. My experience spans several CMMS platforms, including SAP PM and Fiix. I’m proficient in using these systems to:

- Schedule and Track Maintenance Tasks: Create and manage preventative maintenance schedules, track work orders, and monitor task completion.

- Manage Inventory: Track spare parts inventory levels, generate automated purchase requisitions, and optimize inventory control to minimize downtime.

- Generate Reports: Create various reports on maintenance costs, downtime, equipment performance, and PM compliance. These reports are essential for identifying trends, optimizing maintenance strategies, and demonstrating the effectiveness of maintenance programs.

- Manage Work Orders: Assign and track work orders, monitor progress, and capture labor and materials costs associated with each task.

- Data Analysis: Utilize the data within the CMMS to identify patterns, predict potential failures, and improve maintenance strategies through data-driven decision making.

In a previous role, I implemented a CMMS which resulted in a 15% reduction in maintenance costs and a 10% improvement in equipment uptime. The ability to generate comprehensive reports and track key metrics allowed me to justify maintenance investments and demonstrate the value of the maintenance department to the organization.

Q 5. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems to prevent recurrence. It goes beyond simply fixing a symptom to address the root issue. I commonly use the ‘5 Whys’ technique and the ‘Fishbone’ (Ishikawa) diagram.

- 5 Whys: This involves repeatedly asking ‘Why?’ to drill down to the root cause. For example, if a pump fails, we might ask: Why did the pump fail? (Overheating). Why did it overheat? (Insufficient lubrication). Why was there insufficient lubrication? (Faulty lubrication system). Why was the lubrication system faulty? (Lack of preventative maintenance). Why was there a lack of preventative maintenance? (Inadequate scheduling).

- Fishbone Diagram: This visual tool helps to brainstorm and categorize potential causes of a problem. The main problem is written at the head of the ‘fish’, and potential causes are categorized into branches (e.g., equipment, personnel, materials, environment).

- Fault Tree Analysis (FTA): This is a more complex technique used for analyzing complex systems and identifying multiple contributing factors that can lead to a single failure.

By performing a thorough RCA, we can avoid simply treating the symptoms and instead address the underlying problems, preventing future occurrences of the same issue. For instance, in one case, repeated failures of a specific piece of equipment were traced back to inadequate training for operators. Implementing new training programs prevented further failures and saved significant costs.

Q 6. How do you manage a team of maintenance technicians?

Managing a team of maintenance technicians involves effective leadership, communication, and training. My approach focuses on:

- Clear Communication: Establish clear expectations, provide regular feedback, and encourage open communication among team members. Daily briefings, weekly meetings, and regular one-on-one check-ins are important.

- Delegation and Empowerment: Delegate tasks appropriately based on skill levels and experience. Empower technicians to make decisions within their areas of expertise.

- Training and Development: Provide opportunities for professional development, including specialized training, certifications, and mentorship programs. This ensures the team’s skills stay up-to-date and allows them to advance in their careers.

- Performance Management: Implement a fair and transparent performance management system that includes regular performance reviews, goal setting, and feedback mechanisms.

- Safety Emphasis: Maintain a strong focus on safety, ensuring technicians follow safety protocols, and providing training on hazard identification and risk mitigation.

- Team Building: Foster a positive and collaborative team environment that promotes mutual respect and cooperation.

Building a strong team requires trust and mutual respect. By creating a culture of collaboration and continuous improvement, I empower my team to achieve high performance and maintain a safe and efficient work environment.

Q 7. What is your experience with budgeting and cost control in maintenance?

Budgeting and cost control in maintenance are critical for efficient operations. My experience includes:

- Budget Preparation: Developing detailed maintenance budgets that align with organizational goals. This involves forecasting maintenance costs based on historical data, equipment condition assessments, and planned maintenance activities.

- Cost Tracking and Monitoring: Regularly track maintenance expenses against the budget, identifying variances and investigating the causes of overspending or underspending.

- Cost Optimization: Continuously seek opportunities to optimize maintenance costs without compromising equipment reliability. This includes exploring alternative repair strategies, negotiating better prices with suppliers, and improving maintenance efficiency.

- Performance Measurement: Track key performance indicators (KPIs) such as maintenance costs per unit produced, equipment downtime, and PM completion rates. This allows for data-driven decision-making and helps in justifying maintenance investments.

- Inventory Management: Optimize inventory levels to minimize storage costs and reduce the risk of stockouts. This involves using inventory management techniques like ABC analysis and just-in-time (JIT) inventory management.

In one instance, I implemented a new inventory management system that reduced spare parts inventory by 20% while maintaining the same level of equipment uptime. This resulted in significant cost savings and freed up valuable storage space.

Q 8. Explain your knowledge of different maintenance strategies (e.g., predictive, preventive, reactive).

Maintenance strategies are crucial for ensuring the longevity and efficiency of assets. They can be broadly categorized into reactive, preventive, and predictive maintenance.

- Reactive Maintenance: This is a ‘fix-it-when-it-breaks’ approach. It’s the least efficient, often resulting in costly downtime and emergency repairs. Think of a car breaking down on the highway – you only fix it after it’s already failed. While sometimes unavoidable for unforeseen events, relying heavily on reactive maintenance is usually a sign of poor overall maintenance planning.

- Preventive Maintenance: This involves scheduled inspections and maintenance tasks performed at predetermined intervals, regardless of the asset’s condition. Think of regular oil changes for a car or scheduled HVAC filter replacements. This significantly reduces the likelihood of unexpected failures and extends the asset’s lifespan. However, it can lead to over-maintenance if not tailored to specific needs.

- Predictive Maintenance: This sophisticated approach uses data analysis and monitoring techniques (e.g., vibration analysis, thermal imaging) to predict potential equipment failures *before* they occur. This allows for timely interventions, optimizing maintenance schedules and minimizing downtime. Imagine using sensors on a machine to detect subtle changes indicating impending failure, allowing for proactive repair before a major breakdown occurs. This is often the most cost-effective approach in the long run.

The best strategy often involves a combination of these approaches, tailored to the specific asset and its criticality. For instance, a critical piece of equipment might benefit from a predictive maintenance strategy alongside a robust preventive program, while less critical equipment might only require preventive maintenance.

Q 9. Describe a time you had to deal with a critical equipment failure. How did you resolve it?

During my time at a large manufacturing plant, a critical compressor failed unexpectedly, halting production and costing thousands of dollars per hour in lost output. The initial diagnosis pointed to a potential motor winding failure. My immediate response was to activate our emergency response protocol:

- Safety First: Secured the area, ensuring no one could approach the malfunctioning equipment.

- Diagnostics: I leveraged our plant’s computerized maintenance management system (CMMS) to review the compressor’s historical data, including maintenance records and sensor readings. This helped pinpoint potential contributing factors.

- Troubleshooting: Along with the electrical team, we performed thorough tests, including resistance measurements and insulation tests on the motor windings. We discovered a short circuit in one of the windings.

- Repair/Replacement: Given the urgency and the extensive damage to the motor, we opted for a complete motor replacement rather than attempting repair. We worked with our suppliers to expedite delivery of a replacement motor.

- Root Cause Analysis: Once the replacement was installed and production resumed, we conducted a thorough root cause analysis to identify what led to the motor failure. It turned out that inadequate lubrication was a contributing factor, which we addressed by improving our lubrication schedule and training personnel.

This incident highlighted the importance of a robust maintenance strategy that combines preventive measures with prompt, effective troubleshooting and a detailed root cause analysis to prevent future occurrences.

Q 10. What safety protocols do you adhere to during maintenance tasks?

Safety is paramount in maintenance. My adherence to safety protocols is unwavering and encompasses several key elements:

- Lockout/Tagout (LOTO): Before undertaking any maintenance on equipment, I always follow strict LOTO procedures to prevent accidental energization or startup. This ensures the safety of myself and my colleagues.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, such as safety glasses, gloves, hearing protection, and steel-toe boots, depending on the specific task. This protects me from potential hazards such as electrical shocks, chemical spills, or falling objects.

- Risk Assessment: Before starting any job, I perform a thorough risk assessment to identify potential hazards and develop mitigation strategies. This includes considering factors like confined space entry, working at heights, and exposure to hazardous materials.

- Safe Work Practices: I strictly adhere to all company and industry-specific safe work practices and procedures. This includes proper lifting techniques, use of hand tools, and awareness of potential hazards in the work environment.

- Communication: Clear and effective communication with my team and supervisors is crucial, especially during complex or high-risk tasks. Keeping everyone informed ensures safety for the entire team.

Regular safety training and refresher courses are essential to maintaining a high standard of safety.

Q 11. How familiar are you with OSHA regulations related to maintenance?

I am very familiar with OSHA regulations related to maintenance, particularly those concerning:

- Lockout/Tagout (29 CFR 1910.147): Understanding and applying LOTO procedures is fundamental to my work.

- Hazard Communication (29 CFR 1910.1200): Proper handling and labeling of hazardous materials is critical.

- Personal Protective Equipment (29 CFR 1910.132): Selecting and using appropriate PPE is non-negotiable.

- Machine Guarding (29 CFR 1910.212): Ensuring machines are properly guarded to prevent injuries.

- Electrical Safety (29 CFR 1910.300-339): Safe practices for working with electrical equipment.

Staying updated with OSHA’s latest guidelines and changes is an ongoing process. I regularly attend training sessions and consult OSHA resources to maintain compliance. Understanding these regulations not only protects workers but also prevents legal and financial liabilities for the company.

Q 12. Explain your experience with different types of building systems (e.g., HVAC, plumbing, electrical).

My experience encompasses a wide range of building systems, including:

- HVAC (Heating, Ventilation, and Air Conditioning): I’m proficient in troubleshooting and maintaining various HVAC equipment, including chillers, boilers, air handling units, and ventilation systems. I understand the principles of refrigeration cycles, airflow dynamics, and energy efficiency in HVAC systems.

- Plumbing: My skills include working with water distribution systems, drainage systems, fixtures, and pumps. I can diagnose and repair leaks, clogs, and other plumbing issues.

- Electrical: I am familiar with electrical distribution systems, lighting systems, power distribution panels, and motor control centers. I possess a good understanding of electrical safety regulations and practices.

- Fire Protection Systems: I have experience working with fire sprinkler systems, fire alarms, and fire suppression systems. This includes routine inspections, testing, and maintenance to ensure system functionality.

I have successfully managed projects involving repairs, upgrades, and replacements for these systems, demonstrating my ability to integrate technical knowledge with practical problem-solving.

Q 13. How do you manage inventory for maintenance supplies and parts?

Effective inventory management is vital for efficient maintenance operations. My approach involves:

- CMMS Integration: Utilizing a CMMS (Computerized Maintenance Management System) to track inventory levels, order new parts, and manage stock rotation. This allows for real-time visibility into inventory status.

- ABC Analysis: Categorizing parts into A, B, and C categories based on their criticality and usage frequency. This prioritizes inventory control for high-value, critical parts (A-items).

- Just-in-Time (JIT) Inventory: For less critical items, adopting a JIT approach minimizes storage costs and reduces the risk of obsolescence.

- Regular Stock Audits: Conducting periodic physical audits to reconcile inventory records with actual stock. This helps identify discrepancies and adjust ordering strategies.

- Vendor Relationships: Building strong relationships with reliable vendors ensures timely delivery of parts and minimizes disruptions to maintenance schedules.

This multi-faceted approach ensures that necessary parts are readily available while avoiding unnecessary storage costs and minimizing waste.

Q 14. What software or tools are you proficient in for maintenance management?

My proficiency in maintenance management software and tools includes:

- CMMS (Computerized Maintenance Management System): I have extensive experience with several CMMS platforms, including

MP2, Fiix, and UpKeep.I’m adept at using these systems for work order management, scheduling, inventory control, and reporting. - Spreadsheet Software (Excel, Google Sheets): I use spreadsheets for data analysis, creating reports, tracking key performance indicators (KPIs), and managing maintenance budgets.

- Data Analytics Tools (e.g., Tableau, Power BI): I utilize these tools for visualizing maintenance data and identifying trends to improve maintenance strategies.

- Diagnostic Tools: I am skilled in using various diagnostic tools, including multimeters, thermal imagers, and vibration analyzers, to troubleshoot equipment problems.

My ability to effectively leverage these tools contributes significantly to my efficiency and effectiveness as a maintenance professional.

Q 15. How do you ensure compliance with building codes and regulations?

Ensuring compliance with building codes and regulations is paramount in maintenance and rehabilitation. It’s not just about avoiding penalties; it’s about ensuring the safety and well-being of building occupants and the public. My approach involves a multi-step process starting before the project even begins.

Proactive Code Review: I initiate a thorough review of all applicable local, state, and national building codes relevant to the project. This includes fire codes, accessibility requirements (ADA compliance), structural standards, and energy efficiency regulations. I often use online resources and consult with code officials early in the planning phase to address any potential ambiguities.

Permitting and Inspections: Obtaining the necessary permits is crucial. This involves submitting detailed plans and specifications that demonstrate compliance. I maintain open communication with building inspectors throughout the project, scheduling inspections at key milestones to ensure adherence to the approved plans. Addressing any discrepancies promptly is key to avoiding delays.

Documentation and Record Keeping: Meticulous documentation is vital. I ensure that all inspections, approvals, and any necessary modifications are meticulously recorded. This documentation serves as proof of compliance and is essential for future maintenance and potential legal issues.

Material Selection and Verification: I specify materials that meet or exceed the required code standards. We verify the compliance of all materials received using certificates of compliance and other documentation provided by suppliers.

For instance, in a recent school renovation, we meticulously checked all materials against fire codes and ensured all accessibility requirements were met according to ADA guidelines, resulting in a successful inspection and project completion.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with rehabilitation projects, including planning and execution.

My experience in rehabilitation projects spans over a decade, encompassing diverse building types from historical landmarks to modern structures. The process always begins with a comprehensive assessment of the existing building.

Planning Phase: This involves detailed site surveys, structural analysis, and assessment of existing systems (HVAC, electrical, plumbing). We then develop a thorough scope of work, detailing all necessary repairs, renovations, and upgrades. We engage specialists such as structural engineers, architects, and MEP engineers where needed.

Design Development: This phase refines the scope of work, producing detailed drawings and specifications. Here, cost estimates are developed and reviewed against available budget.

Execution Phase: This stage entails project management, coordinating contractors, and overseeing the work on-site. Regular quality control checks and inspections are crucial, ensuring that work adheres to specifications and building codes. This often requires conflict resolution and schedule adjustments.

Completion and Closeout: Final inspections are conducted, and documentation is completed. As-built drawings are prepared to accurately reflect the completed work.

For example, I recently led a rehabilitation project for a historic building. The planning phase included extensive historical research to ensure that renovations respected the building’s original character while bringing it up to current code. Careful coordination was needed to manage the work of different contractors, specialized in historical preservation, structural work, and modern systems installation.

Q 17. How do you assess the structural integrity of a building during rehabilitation?

Assessing structural integrity during rehabilitation is critical to preventing future problems. It’s a multifaceted process involving both visual inspection and non-destructive testing (NDT).

Visual Inspection: This involves a thorough examination of the building’s structure, including foundations, walls, roofs, and other structural elements. We look for cracks, settlement, deterioration, and signs of previous damage. Photography and detailed documentation are crucial.

Non-Destructive Testing (NDT): This includes methods like ultrasonic testing, ground penetrating radar (GPR), and core sampling. These techniques help to assess the internal condition of structural elements without causing damage. For example, ultrasonic testing can detect internal cracks in concrete or masonry.

Load Testing: In some cases, load testing might be necessary to verify the structural capacity of elements. This typically involves applying controlled loads to structural members to measure their response.

Review of Existing Documentation: Examining any existing structural drawings, reports, and maintenance records can provide valuable insights into the building’s history and potential weaknesses.

In one project, a visual inspection revealed significant cracking in a masonry wall. Further investigation using ultrasonic testing confirmed the presence of internal voids and required extensive repairs. This avoided a potential catastrophic failure.

Q 18. Explain your understanding of different construction methods used in rehabilitation.

Rehabilitation projects often utilize a variety of construction methods, depending on the specific needs of the building and the nature of the repairs or renovations.

Traditional Methods: These may include masonry repair using traditional lime mortars, timber framing repair, and the restoration of historical features using period-appropriate materials and techniques.

Modern Methods: Incorporating modern materials and techniques can improve energy efficiency and structural performance. This may include the use of high-performance insulation, structural strengthening techniques with steel or fiber-reinforced polymers (FRP), and the installation of modern building systems.

Repair vs. Replacement: Decisions about repairing existing elements versus replacing them are based on cost-effectiveness, the extent of damage, and the historical significance of the structure. For example, a severely damaged structural beam might be replaced, while minor cracks in a masonry wall could be repaired.

Sustainability Considerations: Many rehabilitation projects incorporate sustainable construction practices, including the reuse of existing materials, energy-efficient upgrades, and the use of environmentally friendly materials.

For example, in a recent project, we combined traditional methods of masonry repair with modern techniques to strengthen the building’s foundation. The approach balanced historical preservation with the need for improved structural performance and energy efficiency.

Q 19. What are some common challenges in rehabilitation projects, and how do you address them?

Rehabilitation projects often present unique challenges. Addressing them proactively is key to successful project completion.

Unforeseen Conditions: Discovering hidden damage or unexpected complexities during demolition or renovation is common. Contingency planning and a flexible approach are essential to mitigate these risks. This often includes setting aside a budget for unforeseen work.

Coordination of Trades: Managing multiple contractors with overlapping work is a constant juggling act. Detailed scheduling and communication are crucial to avoid conflicts and delays.

Material Availability: Sourcing specialized materials, particularly for historical restoration projects, can be challenging. Early procurement planning and the identification of alternative materials are important.

Balancing Preservation with Modernization: Preserving historical features while upgrading building systems to meet modern standards often requires creative solutions and compromise. This frequently requires collaboration with preservation specialists and regulatory bodies.

Budget and Timeline Constraints: Keeping projects on time and within budget requires careful planning, monitoring of progress, and effective change management.

One example: In a historic building renovation, we uncovered unexpected asbestos during demolition. We promptly halted work, followed proper abatement procedures, revised the schedule, and adjusted the budget to accommodate the extra cost. This transparent communication with the client ensured the project’s successful completion.

Q 20. Describe your experience with managing budgets and timelines in rehabilitation projects.

Budget and timeline management are critical to the success of any rehabilitation project. My approach involves a combination of careful planning and proactive monitoring.

Detailed Cost Estimating: Accurate cost estimation is crucial. This requires careful review of the scope of work, material costs, labor rates, and contingency allowances. I utilize various cost estimating software and techniques to create comprehensive budgets.

Value Engineering: Finding cost-effective alternatives without sacrificing quality is essential. Value engineering involves exploring different construction methods, materials, and designs to optimize the budget.

Project Scheduling: Creating a realistic project schedule is crucial, taking into account the dependencies between different tasks and potential delays. Critical path analysis is often used to identify the most time-sensitive activities.

Progress Monitoring: Regular monitoring of progress against the schedule and budget is essential. This involves reviewing invoices, tracking material deliveries, and conducting site visits to identify and address any potential problems early on.

Change Management: Changes to the scope of work are inevitable. A formal change order process is implemented to document, evaluate, and approve any changes, ensuring they are reflected in the budget and schedule.

In a recent project, we successfully managed a tight budget by using value engineering techniques to find cost-effective alternatives for certain materials without compromising the quality of the finished product. This involved close collaboration with the client and contractors throughout the project.

Q 21. How do you communicate effectively with contractors and stakeholders during rehabilitation?

Effective communication is the cornerstone of successful rehabilitation projects. It involves building strong relationships with contractors, stakeholders, and the client.

Regular Meetings: Conducting regular meetings with the project team ensures everyone is on the same page and allows for prompt identification and resolution of any issues. Minutes from these meetings are carefully documented and distributed.

Clear Communication Channels: Establishing clear communication channels is crucial. This may involve using project management software, email, or a combination of methods. All correspondence is documented and easily accessible to all parties.

Conflict Resolution: Disagreements are inevitable. I use a collaborative approach to conflict resolution, focusing on finding mutually acceptable solutions that benefit the project as a whole.

Transparent Reporting: Regular progress reports, including updates on budget and schedule, are provided to the client and stakeholders. This ensures transparency and fosters trust.

Active Listening: I actively listen to concerns and suggestions from all parties involved. This collaborative approach fosters a positive working environment and encourages problem-solving.

For example, during a complex renovation, a conflict arose between two contractors regarding their work schedules. Through facilitated discussions and a revised schedule, we successfully resolved the conflict without impacting the overall project timeline.

Q 22. How do you ensure quality control during rehabilitation work?

Quality control in rehabilitation is paramount to ensuring the project’s longevity and success. It’s not just about meeting specifications; it’s about exceeding expectations and building something that will stand the test of time. My approach is multi-faceted, starting even before the first hammer swings.

- Pre-Construction Quality Control: This involves meticulously reviewing blueprints, material specifications, and contractor proposals. We conduct thorough site assessments to identify potential challenges proactively. For example, during a recent school renovation, we discovered hidden asbestos, which, if undetected, could have caused significant delays and health risks. Early detection allowed us to implement a safe removal plan without disrupting the project schedule.

- In-Process Quality Control: Daily inspections and progress meetings are crucial. We utilize checklists and photographic documentation to track progress and identify any deviations from the plan. This includes verifying the quality of materials used and ensuring proper installation techniques are followed. For instance, during a bridge rehabilitation, we implemented a rigorous inspection protocol for each weld to guarantee structural integrity, using both visual inspections and non-destructive testing.

- Post-Construction Quality Control: This involves thorough final inspections to ensure all work meets or exceeds standards. We conduct functional testing and gather feedback from stakeholders. A follow-up inspection after a few months helps identify any unforeseen issues. For example, we implemented a post-construction inspection of a historical building’s roof after the first rainfall to ensure the waterproofing was effective.

Ultimately, effective quality control is a continuous process, not a single event. It requires a proactive and vigilant approach, coupled with clear communication and meticulous documentation.

Q 23. Describe your experience with different types of building materials and their properties.

My experience spans a wide range of building materials, and understanding their properties is fundamental to successful rehabilitation. Each material has its own strengths, weaknesses, and appropriate applications.

- Concrete: I’m very familiar with different concrete mixes, their compressive strengths, and how to repair or reinforce existing structures. I’ve worked on projects involving everything from minor crack repairs to major structural overhauls using techniques like carbon fiber reinforcement.

- Steel: Understanding steel’s behavior under stress, its susceptibility to corrosion, and various protection methods (like galvanization or painting) is crucial. In one project, we successfully rehabilitated a corroded steel bridge structure using specialized coatings and structural strengthening techniques.

- Masonry (Brick, Stone): I understand the nuances of different masonry types, their vulnerabilities to moisture damage and freeze-thaw cycles, and appropriate repair techniques. For example, we recently restored a historic brick building using traditional lime mortar to preserve its historical integrity.

- Wood: I’m experienced in assessing wood degradation from rot, insect infestation, and weathering. I know how to select appropriate treatments and repair methods. A project involving a wooden beam replacement taught me the importance of selecting the right type of wood, accounting for moisture content and structural load.

- Modern Composites: My experience extends to modern materials like fiber-reinforced polymers (FRP) and their applications in strengthening and repairing existing structures. These materials offer significant advantages in terms of strength-to-weight ratio and corrosion resistance.

This deep understanding of material properties allows me to make informed decisions about material selection, repair methods, and project cost-effectiveness.

Q 24. What safety measures do you take during rehabilitation work?

Safety is an absolute non-negotiable aspect of any rehabilitation project. My commitment starts with establishing a robust safety plan at the outset, involving all stakeholders.

- Risk Assessments: We conduct comprehensive risk assessments, identifying potential hazards like working at heights, exposure to hazardous materials (asbestos, lead paint), and the risk of machinery accidents. These assessments inform the development of detailed safety plans.

- Personal Protective Equipment (PPE): Ensuring workers have and properly use appropriate PPE, such as hard hats, safety glasses, respirators, and fall protection equipment, is essential. Regular checks are conducted to ensure proper usage.

- Site Safety Training: All workers receive thorough site-specific safety training before commencing work. This includes training on the safe handling of equipment, hazardous materials, and emergency procedures.

- Emergency Response Plan: A detailed emergency response plan, including communication protocols and evacuation procedures, is in place and regularly reviewed. Regular safety meetings and toolbox talks are also conducted to address specific safety concerns.

- Compliance with Regulations: We strictly adhere to all relevant health and safety regulations and actively monitor compliance throughout the project. This includes regular site inspections by qualified safety personnel.

My safety-first approach ensures a healthy and productive work environment, minimizing risks and protecting the well-being of everyone involved. It’s not just a matter of compliance; it’s a moral imperative.

Q 25. How do you handle unexpected issues or changes during a rehabilitation project?

Unexpected issues are inevitable in rehabilitation projects. My approach emphasizes proactive planning, but also embraces adaptability and problem-solving. The key is a structured process:

- Immediate Assessment: When an unexpected issue arises (e.g., discovering deteriorated structural elements not identified in the initial assessment), the first step is a thorough assessment to understand the nature and extent of the problem.

- Documentation: Thorough documentation is crucial, including photographic evidence, detailed descriptions, and input from relevant experts. This documentation informs decision-making and aids in potential future claims.

- Option Evaluation: We explore various solutions, considering their cost-effectiveness, feasibility, and impact on the project schedule. This often involves consultations with engineers, architects, and other specialists.

- Revised Plan: Based on the assessment and option evaluation, we develop a revised project plan, incorporating the necessary changes. This often involves amending budgets and timelines.

- Communication: Open communication with clients, stakeholders, and the project team is crucial. Transparency and timely updates are key to maintaining trust and managing expectations.

For example, during a recent historic building renovation, we discovered unexpected water damage. We swiftly assessed the extent of the damage, consulted with preservation experts, and developed a revised plan that preserved the historical elements while addressing the water damage, resulting in a successful project completion.

Q 26. What is your experience with sustainable building practices in maintenance and rehabilitation?

Sustainable building practices are no longer optional; they’re essential for responsible construction and rehabilitation. My experience includes implementing a range of sustainable strategies:

- Energy Efficiency: We incorporate energy-efficient materials and systems, such as high-performance insulation, energy-efficient windows, and LED lighting. In a recent school renovation, this resulted in a significant reduction in energy consumption.

- Water Conservation: We prioritize water-efficient fixtures and appliances, reducing water usage. Implementing rainwater harvesting systems is also considered.

- Waste Reduction: We minimize waste generation through careful planning, material selection, and recycling programs. Using reclaimed materials whenever possible is also a key consideration.

- Material Selection: Prioritizing locally sourced, recycled, or sustainably harvested materials reduces the environmental impact of the project. Choosing materials with low embodied carbon is also crucial.

- Lifecycle Analysis: Understanding the full lifecycle environmental impact of materials and systems is important. We assess the environmental cost from extraction and manufacturing to disposal and strive to minimize it.

By incorporating these sustainable practices, we deliver projects that are environmentally responsible, cost-effective in the long run, and contribute to a more sustainable built environment. It’s not just about greenwashing; it’s about genuine commitment.

Q 27. How do you stay up-to-date on the latest maintenance and rehabilitation technologies and techniques?

The field of maintenance and rehabilitation is constantly evolving, so continuous learning is crucial. I utilize several methods to stay up-to-date:

- Professional Organizations: Active membership in professional organizations like the American Society of Civil Engineers (ASCE) provides access to publications, conferences, and networking opportunities. This exposes me to the latest research, innovations, and best practices.

- Industry Publications and Journals: I regularly read industry publications and journals that cover the latest advancements in materials, techniques, and technologies. This allows me to keep abreast of new developments and emerging trends.

- Conferences and Workshops: Attending conferences and workshops provides opportunities for hands-on learning, networking with industry experts, and hearing about real-world applications of new technologies.

- Online Courses and Webinars: Online courses and webinars provide convenient and flexible learning opportunities. Many reputable organizations offer specialized training in areas like sustainable building practices, structural assessment, and new material technologies.

- Networking: Networking with colleagues and peers through professional organizations and industry events provides valuable insights and helps in sharing knowledge and best practices.

This multifaceted approach ensures I’m always equipped with the latest knowledge and skills to deliver high-quality, sustainable, and innovative solutions for my clients.

Key Topics to Learn for Maintenance and Rehabilitation Interview

- Preventive Maintenance Strategies: Understanding and implementing proactive maintenance schedules to minimize downtime and extend asset lifespan. Consider discussing specific methodologies like TPM (Total Productive Maintenance).

- Corrective Maintenance Procedures: Diagnosing, troubleshooting, and repairing equipment malfunctions efficiently and safely. Be prepared to discuss examples of problem-solving techniques you’ve used.

- Rehabilitation Techniques: Exploring methods for restoring damaged or deteriorated assets to their original condition or even improving their performance. This could include material selection, repair methodologies, and cost-benefit analysis.

- Safety Regulations and Compliance: Demonstrate your understanding of relevant safety standards and procedures within the Maintenance and Rehabilitation field. Be ready to discuss examples of how you ensure a safe work environment.

- Inventory Management and Procurement: Discuss your experience in managing spare parts, ordering supplies, and optimizing inventory control for cost-effectiveness.

- Budgeting and Cost Control: Explain how you contribute to efficient budget management within a maintenance and rehabilitation program. Highlight your experience in cost estimation and tracking.

- Teamwork and Communication: Maintenance and Rehabilitation often involve collaboration. Highlight your ability to work effectively in a team, communicate clearly with colleagues and supervisors, and contribute to a positive work environment.

- Data Analysis and Reporting: Showcase your skills in collecting, analyzing, and presenting maintenance data to track performance, identify trends, and support decision-making.

- Technological Proficiency: Discuss your familiarity with relevant software, tools, and technologies used in modern Maintenance and Rehabilitation practices (e.g., CMMS software).

Next Steps

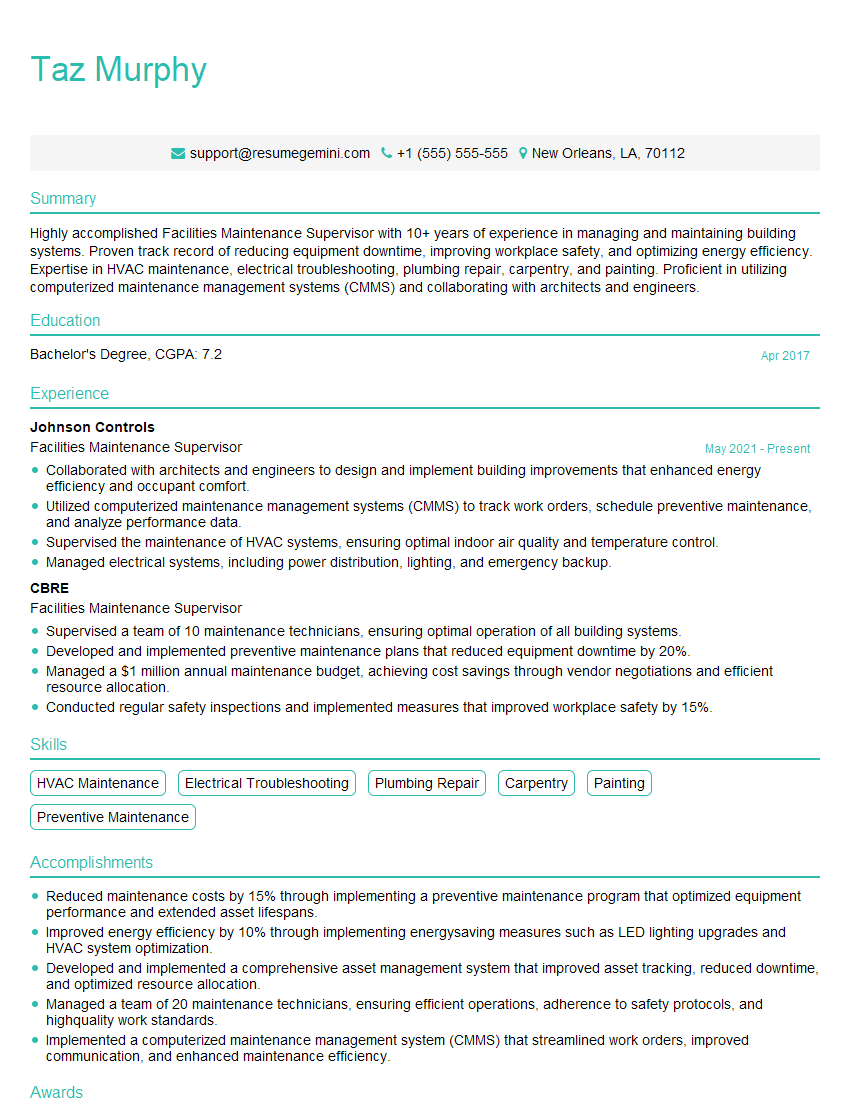

Mastering Maintenance and Rehabilitation principles is crucial for career advancement in this vital field. Strong problem-solving skills, a commitment to safety, and the ability to work efficiently within budget constraints are highly valued. To significantly boost your job prospects, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Maintenance and Rehabilitation to guide you through the process. Invest the time to create a standout resume – it’s your key to unlocking exciting opportunities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good