The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Folding and Packing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Folding and Packing Interview

Q 1. Describe your experience with different folding techniques.

My experience encompasses a wide range of folding techniques, tailored to the specific item and its destination. For example, I’m proficient in simple folds like the ‘envelope fold’ ideal for letters and small, flat items. For more complex items like clothing, I utilize techniques such as ‘roll folding’, minimizing wrinkles and maximizing space efficiency. With larger, irregular items, I often employ ‘accordion folds’ or customized folding based on the item’s shape and material. In industrial settings, I’ve worked with automated folding machines which implement more complex algorithms to optimize folding for automated packing lines. I also possess a good understanding of origami principles, which can be applied creatively to solve unique folding challenges.

- Envelope Fold: Simple, effective for flat items.

- Roll Fold: Great for minimizing wrinkles in clothing and fabrics.

- Accordion Fold: Useful for maps, brochures, and items needing multiple folds.

- Automated Folding: Industrial application involving specialized algorithms.

Q 2. How do you ensure efficient packing procedures?

Efficient packing procedures hinge on careful planning and execution. It begins with a thorough assessment of the items to be packed – their size, shape, fragility, and quantity. I then select appropriate packaging materials and optimize the packing order. For example, heavier items go at the bottom, fragile items are cushioned, and items are arranged to minimize empty space. Using standardized procedures and checklists ensures consistency and reduces errors. Regularly reviewing and refining our processes – based on feedback and data analysis – further enhance efficiency. This includes tracking packing times, material usage, and damage rates to identify bottlenecks and areas for improvement.

Consider this scenario: packing a moving truck. A haphazard approach could lead to damage, wasted space, and inefficient loading. A well-planned approach, prioritizing the placement of heavier items and strategic grouping, maximizes space and minimizes the risk of damage.

Q 3. What are your strategies for optimizing packing space?

Optimizing packing space requires a combination of techniques. This starts with utilizing different packing configurations, such as nesting smaller items inside larger ones or using void-fill materials. Understanding the geometry of the container is also crucial – filling awkward corners effectively can significantly increase space utilization. Software tools can aid in optimizing packing layouts, especially for irregularly shaped items or high-volume packing scenarios. For example, some software uses algorithms to determine the most efficient arrangement of boxes within a shipping container.

Imagine packing a suitcase for a trip. Rolling clothes instead of folding them saves a surprising amount of space. Strategic placement of shoes and toiletries in the corners and using compression sacks further optimizes the available space.

Q 4. Explain your experience with various packaging materials.

My experience extends to a variety of packaging materials, each with its strengths and limitations. I’m familiar with corrugated cardboard boxes (various strengths and sizes), bubble wrap, foam peanuts, air pillows, tissue paper, and various types of tapes (e.g., packing tape, reinforced tape). The selection of the right material depends on the item’s fragility, size, and shipping requirements. I also understand the environmental impact of packaging materials and strive to use sustainable options whenever feasible, such as recycled cardboard or biodegradable fillers. Knowing the specific properties of each material—its strength, cushioning ability, and environmental impact—is crucial for making informed decisions.

Q 5. How do you handle fragile items during packing?

Handling fragile items requires extra care and attention. I use ample cushioning materials, such as bubble wrap, foam peanuts, or air pillows, to surround fragile items. I often wrap them individually in tissue paper before adding further protection. The items are then carefully placed within the box, avoiding any potential movement or impact. Fragile labels are clearly affixed to the outside of the box to alert handlers to exercise caution. For extremely fragile items, custom-fit inserts or specialized crates might be necessary to ensure their safe arrival. Using appropriate sized boxes to minimize movement within the container is also a key factor in preventing breakage. For instance, when shipping a piece of art, I would create a custom fitted crate to ensure no movement occurs during transport.

Q 6. What safety measures do you follow while packing?

Safety during packing is paramount. This starts with maintaining a clean and organized workspace to prevent accidents. I always use appropriate personal protective equipment (PPE), such as gloves, to avoid cuts or abrasions. When lifting heavy boxes, I use proper lifting techniques to avoid injury. All sharp objects are carefully packaged to prevent cuts and punctures. Hazardous materials are handled according to regulations and labeled appropriately. Furthermore, I’m trained in the proper use and disposal of packing materials to minimize environmental impact and ensure workplace safety.

Q 7. How do you maintain quality control during the packing process?

Quality control is an ongoing process throughout the packing procedure. This involves regularly inspecting materials for defects and ensuring the proper use of packing techniques. Random audits of packed items are conducted to identify potential issues. We maintain detailed records to track damage rates and identify areas for process improvement. Employee training is crucial to ensure everyone understands and follows established procedures. Regularly reviewing and updating our packing standards, based on feedback and industry best practices, is essential to maintaining high-quality packing and shipping operations. Feedback from customers, such as damage claims or positive comments, is also invaluable in our continuous improvement efforts.

Q 8. Describe your experience with automated packing equipment.

My experience with automated packing equipment spans over eight years, encompassing various technologies from simple conveyor belt systems to highly sophisticated robotic palletizers. I’ve worked extensively with automated case erectors, taping machines, and labeling systems. For example, in my previous role at Acme Corp, I managed the implementation of a new robotic arm system for filling and sealing boxes, resulting in a 25% increase in packing efficiency and a significant reduction in manual labor.

I’m familiar with programming and troubleshooting these machines, understanding their limitations and maximizing their potential through efficient workflow design. I’ve also led training programs for operators, ensuring smooth and safe operation of the equipment. My expertise includes preventative maintenance scheduling and managing repairs to minimize downtime. I understand the importance of selecting the right equipment based on product type, volume, and budget constraints.

Q 9. How do you prioritize speed and accuracy while packing?

Balancing speed and accuracy in packing is crucial. It’s not about rushing; it’s about optimizing the process. My approach involves a multi-pronged strategy:

- Process Optimization: I analyze the workflow to identify bottlenecks and streamline operations. This might involve rearranging workspaces, improving material flow, or implementing lean manufacturing principles.

- Technology Integration: Leveraging automated systems reduces manual errors and increases throughput. Scanners and weight checkers help verify items and quantities against orders in real-time.

- Quality Control Checks: I incorporate regular quality checks throughout the packing process, including visual inspections and random audits. This ensures accuracy and catches potential errors before they leave the facility.

- Training and Empowerment: Properly training staff in efficient techniques and providing clear instructions is paramount. Empowering employees to flag issues and correct mistakes proactively improves quality control.

Think of it like a well-oiled machine – each component works smoothly and efficiently together. When this happens, you achieve both high speed and accuracy.

Q 10. How do you handle discrepancies between order and packed items?

Discrepancies between orders and packed items are addressed immediately and systematically. My approach includes:

- Immediate Investigation: The first step is to identify the exact nature of the discrepancy – are items missing, incorrect, or extra? The order details and packing slip are thoroughly compared.

- Root Cause Analysis: We investigate the cause of the error. Was it a picking error, a packing error, a system malfunction, or a labeling issue? Addressing the root cause prevents future occurrences.

- Corrective Action: Depending on the severity and nature of the discrepancy, we take corrective action, which may include repacking the order, issuing a replacement, or contacting the customer to inform them of the issue.

- Documentation: All discrepancies, their causes, and corrective actions are documented to track trends and improve processes. This data is crucial for continuous improvement.

For example, if a customer receives the wrong item, we immediately launch an investigation, trace the problem back to its source, send a replacement item, and learn from the mistake to enhance our order fulfillment procedures.

Q 11. Explain your understanding of different shipping methods and their impact on packing.

Understanding shipping methods is critical for effective packing. Different methods require different packing strategies to ensure the goods arrive safely and on time. For example:

- Ground Shipping: Typically less expensive but allows for larger and heavier packages with less stringent protection requirements. We might use standard cardboard boxes and adequate cushioning.

- Air Freight: More expensive, demanding lighter and smaller packages for efficient transport. We utilize lighter-weight packaging materials, prioritize compact packing techniques, and consider stricter labeling guidelines.

- Express Delivery: Requires quick turnaround time, and packaging needs to be durable and well-labeled for easy handling. We might use reinforced boxes and protective layers.

The choice of shipping method directly influences the type of packaging material, the packing technique, and the level of protection required. Consider fragile items sent via air freight—the cost-effective nature of packaging needs to be balanced with the risks involved in transit.

Q 12. How do you manage a high-volume packing workload?

Managing high-volume packing workloads requires a structured and efficient approach. My strategy includes:

- Workforce Planning: Accurately forecasting demand and ensuring sufficient staffing to meet peak periods. This might involve temporary staffing or overtime arrangements.

- Process Optimization: Implementing lean methodologies to eliminate waste and improve efficiency. This includes optimizing picking routes, reducing unnecessary movements, and improving workflow design.

- Automation: Utilizing automated packing equipment where possible to handle large volumes and minimize manual labor. This can also reduce errors.

- Technology Integration: Employing warehouse management systems (WMS) and order management systems (OMS) to optimize inventory and order fulfillment. This provides real-time visibility into stock levels and order status.

- Teamwork and Communication: Clear communication and efficient teamwork amongst the packing team are crucial for smooth operations during high-volume periods.

Visualizing the process as an assembly line, with each member executing their tasks efficiently and effectively, helps achieve the highest throughput.

Q 13. Describe your experience with inventory management related to packing.

Inventory management is intrinsically linked to efficient packing. Accurate inventory data is essential to ensure the correct items are available for packing. My experience includes:

- Cycle Counting: Regularly auditing inventory levels to ensure accuracy and identify discrepancies. This minimizes stockouts and prevents delays in order fulfillment.

- WMS Integration: Using warehouse management systems to track inventory in real-time, providing visibility into stock levels, location, and order status.

- Demand Forecasting: Analyzing historical data and market trends to predict future demand, enabling proactive inventory management and preventing stockouts.

- Inventory Optimization: Employing techniques like FIFO (first-in, first-out) to manage perishable goods and prevent spoilage. This also prevents older inventory from becoming obsolete.

Imagine inventory management as the foundation of the packing process; without accurate and up-to-date information, the entire operation would crumble.

Q 14. What is your experience with different types of packaging machinery?

My experience with various types of packaging machinery is extensive. I’m proficient in operating and maintaining a wide range of equipment, including:

- Case Erectors: Automated machines that form and assemble cardboard boxes from flat blanks.

- Taping Machines: Seal boxes with adhesive tape, improving speed and security.

- Labeling Machines: Apply shipping labels to packages accurately and quickly.

- Palletizers: Automatically stack boxes onto pallets, increasing efficiency and reducing manual effort.

- Shrink Wrappers: Securely wrap pallets with plastic film to protect the contents.

Beyond operating these machines, I understand the principles of their mechanics and troubleshooting procedures. My experience also extends to selecting appropriate machinery based on specific needs and budget constraints. Understanding the capabilities and limitations of each machine is crucial for optimizing the packing process.

Q 15. How do you adapt your folding and packing techniques to different product types?

Adapting folding and packing techniques to different product types is crucial for efficient and safe handling. It involves understanding the unique characteristics of each product and selecting the appropriate techniques to ensure its protection during transit.

- Fragile Items: These require extra cushioning and careful folding to prevent breakage. Think of packing a vase – you’d use plenty of bubble wrap, crumpled paper, or packing peanuts, and potentially a custom-fit insert. The folding might involve carefully wrapping the item in protective material before placing it in the box.

- Electronics: These need anti-static packaging to protect them from electrostatic discharge (ESD). Folding techniques might involve using specialized anti-static bags and ensuring proper alignment within the box to avoid pressure points.

- Clothing: Folding techniques for clothing often prioritize space efficiency and wrinkle prevention. Techniques like the KonMari method or roll-folding can be employed, depending on the type of garment and the desired outcome.

- Liquids: These require leak-proof containers and absorbent materials to contain spills. Packaging will involve secure sealing, potentially using secondary containment, and labeling clearly.

Essentially, the approach is always about risk assessment and mitigation. The more fragile or valuable the item, the more attention to detail the packaging requires.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay organized while packing multiple orders?

Staying organized while packing multiple orders is paramount for accuracy and efficiency. My approach uses a combination of tools and techniques.

- Order Sorting: I always start by sorting orders according to some consistent criteria, such as order number, shipping zone, or product type. This allows for a streamlined workflow.

- Designated Workspaces: Having dedicated zones for packing materials, order forms, and completed packages prevents chaos and confusion. Each area is kept tidy throughout the process.

- Pick Lists/Order Picking Sheets: Using pre-printed pick lists that match the order numbers, makes the process very efficient. I check items off as I pack them to minimize mistakes. This eliminates the risk of mis-picking orders or items.

- Visual Organization: Using clear labeling on boxes and bins for packing materials keeps things easy to find. Visual cues also help in quickly identifying different order types.

- Regular Breaks: To avoid errors, short breaks are crucial to maintain concentration.

Implementing these measures ensures a smooth packing process, reducing errors and improving speed.

Q 17. What are your problem-solving skills when encountering packing issues?

Problem-solving is a key skill in packing. When issues arise, my approach is systematic:

- Identify the Problem: Pinpoint the exact issue. Is it damaged packaging? Missing items? Incorrect labeling? An incompatible item and box size?

- Gather Information: Check order details, packaging specifications, and inventory to understand the root cause.

- Develop Solutions: Brainstorm potential solutions, considering available resources and time constraints. This might involve finding alternative packaging, substituting missing items, or adjusting packing methods.

- Implement and Test: Choose the most suitable solution and test it on a small scale before implementing it fully. This helps to avoid making the problem worse.

- Document and Learn: Record the issue and the solution implemented to prevent recurrence. Learn from the experience to improve future packing processes.

For example, if a box is too small for an item, I might opt for a larger box, or if there’s a damage to the packaging, I’ll look for an undamaged replacement. I prioritize solutions that ensure the item’s safe delivery.

Q 18. How do you ensure that all packed items are appropriately labeled and identified?

Accurate labeling and identification of packed items are critical to ensure timely and error-free delivery. I follow these steps:

- Clear and Concise Labels: Labels clearly indicate the order number, customer name and address, contents, handling instructions (fragile, etc.), and any other relevant information.

- Durable Labels: I use labels resistant to moisture, tearing, and smudging to withstand handling and transit.

- Multiple Labels: In some cases, multiple labels (one on the box, and one inside) are used for redundancy in case one label gets lost or damaged.

- Barcode/QR Code Integration: Using barcodes or QR codes helps automate the sorting and tracking of packages.

- Label Placement: Labels are placed prominently and securely on the box to be easily visible during handling.

By using a consistent labeling system, it’s easy to avoid confusion and track items efficiently throughout the shipping process.

Q 19. How familiar are you with relevant health and safety regulations regarding packing?

I am familiar with relevant health and safety regulations regarding packing, including those related to:

- Manual Handling: Proper lifting techniques, use of lifting aids to prevent back injuries.

- Hazardous Materials: Safe handling and labeling of hazardous materials, adhering to regulations like proper documentation and containment.

- Workplace Safety: Maintaining a clean and organized workspace to minimize trip hazards and injuries. Using appropriate personal protective equipment (PPE) like gloves, where necessary.

- Ergonomics: Using ergonomically designed tools and equipment to reduce strain on the body. Taking regular breaks to prevent fatigue.

Adhering to these regulations is crucial to maintain a safe and healthy work environment and to ensure that packed goods reach their destination without incident.

Q 20. Describe a time you had to troubleshoot a packing problem. What was your solution?

I once encountered a situation where a crucial component of an order was significantly larger than anticipated. The original packaging was insufficient. My solution involved:

- Assessment: I carefully measured the oversized component and the available packaging.

- Resource Check: I checked for available alternative boxes or packaging materials.

- Solution Implementation: I chose a larger, more appropriately sized box and used extra padding to protect the item during transit, ensuring it wouldn’t shift around within the box.

- Verification: Before sealing, I double-checked the package to ensure its security and protection.

- Documentation: I noted the issue and its resolution in the order details for future reference, and communicated the change to the shipping department.

This incident highlighted the importance of flexibility and adaptability in problem-solving when dealing with unexpected variations in product dimensions.

Q 21. What metrics do you use to measure your efficiency in packing?

I use several metrics to measure my packing efficiency:

- Units Packed per Hour (UPH): This indicates the number of units packed per hour, providing a measure of overall speed and output.

- Order Completion Rate: The percentage of orders packed and shipped accurately and on time, highlighting the accuracy and completeness of the process.

- Error Rate: Tracking the number of packing errors (incorrect items, damaged goods, mislabeling), helps identify areas for improvement and training.

- Waste Reduction: Monitoring the amount of packaging material used per unit, allowing for identification of areas where waste can be minimized.

- Customer Feedback: Customer reviews and satisfaction scores can reflect the quality and efficiency of the packing process. Feedback about damage or missing items will help to improve.

By tracking these metrics, I can continuously identify areas for improvement, optimize my workflow, and maintain a high standard of packing efficiency.

Q 22. How do you handle damaged or defective products during the packing process?

Handling damaged or defective products during packing is crucial for maintaining quality control and customer satisfaction. My process involves a few key steps. First, I visually inspect each product. If damage is detected, I carefully document the type and extent of the damage, often using photos or a detailed written description. This documentation is vital for later claims with suppliers or for informing the customer about the condition of their product. Second, depending on the severity and company policy, I may set aside the damaged item for return to the supplier or for internal disposition such as repair or disposal. For minor defects that don’t affect functionality, I might note them on the packing slip to inform the customer, giving them the opportunity to contact customer service if they have concerns. Finally, I always ensure that damaged products are packaged separately and appropriately labeled to avoid further damage during shipping.

For instance, if I find a cracked ceramic mug, I’ll take a picture of the crack, document it in our system, and repackage it with extra cushioning material to prevent further breakage during transit. If it’s a significant defect, rendering the mug unusable, it would be set aside for the return process.

Q 23. Explain your understanding of the importance of proper packing for product protection.

Proper packing is paramount for protecting products during transit and storage. It prevents damage, reduces losses, and ultimately safeguards the company’s reputation and profitability. Think of it like this: the packaging is the product’s shield against the hazards of shipping – bumps, drops, temperature fluctuations, and even theft. Inadequate packaging can lead to costly returns, customer dissatisfaction, and potential legal issues. A well-packed product arrives in perfect condition, enhancing the customer experience and fostering brand loyalty. This is especially crucial for fragile items, electronics, or temperature-sensitive goods. Different products require different packing strategies, ranging from simple bubble wrap for a small item to custom-made crates for large, heavy machinery.

For example, a delicate glass vase needs to be surrounded by ample cushioning material, possibly inside a rigid box, and then the outer box needs to be adequately reinforced with tape. For a heavier item like a piece of furniture, proper bracing and support within the package prevents shifting and damage during transport.

Q 24. How do you maintain a clean and organized work area during packing operations?

Maintaining a clean and organized packing area is essential for efficiency and safety. A cluttered workspace increases the risk of accidents, slows down the packing process, and can lead to damage or misplacement of products. My approach involves several strategies. First, I follow a ‘5S’ methodology (Sort, Set in Order, Shine, Standardize, Sustain). I regularly sort through materials, discarding unnecessary items and keeping everything in designated places. This involves organizing packing materials, such as boxes, tape, and filler, into easily accessible locations. Next, I thoroughly clean the area at the end of each shift, removing dust, debris, and any leftover packaging waste. Furthermore, I utilize visual cues like labels and signs to ensure everything remains neatly organized. We also have regular inventory checks to prevent stock pile ups and ensure materials are replenished as needed.

For example, I might label bins for different types of packing materials – ‘small boxes,’ ‘bubble wrap,’ ‘packing peanuts,’ etc., making it easy to locate the necessary materials quickly and efficiently.

Q 25. Describe your experience with using packing lists and order processing systems.

I’m proficient in using packing lists and order processing systems. Packing lists are essential for ensuring that the correct items are included in each order. I meticulously verify that the contents of each package match the packing list, minimizing errors and avoiding costly returns or customer complaints. I am also experienced with various order processing systems, from simple spreadsheets to sophisticated Warehouse Management Systems (WMS). These systems streamline the packing process, track orders efficiently, and provide real-time updates on inventory levels and order status. My experience includes utilizing barcode scanners to quickly identify products and update shipment information within the system.

For example, if a WMS indicates that an order requires three blue shirts, one pair of pants, and a belt, I use the packing list to confirm the correct items are included before sealing the package. The barcode scanner then registers the items, linking them to the order in the system.

Q 26. How do you handle customer returns and related repackaging procedures?

Handling customer returns and repackaging involves carefully inspecting the returned item for damage and ensuring it’s prepared for resale or disposal according to company policy. First, I assess the condition of the returned product, documenting any damage or defects. Then, I repackage the product using the same packaging standards as for new items, ensuring it’s protected from damage during transit. If the return is due to a fault with the product itself, I follow a specific procedure for handling it, often involving notifying the appropriate department. If it’s a customer change of mind, the process is different, and I may need to check for any return authorization documentation.

For example, a customer returns a dress, slightly wrinkled from trying it on. I would carefully fold the dress, place it in a garment bag, and then put the garment bag inside a protective box, ensuring a shipping label is clearly affixed.

Q 27. What are your strengths and weaknesses related to folding and packing?

My strengths in folding and packing lie in my speed, accuracy, and attention to detail. I’m efficient at organizing my workspace and completing tasks quickly without sacrificing quality. My strong organizational skills enable me to handle large volumes of orders without errors. I am also adaptable and comfortable learning new packing techniques or using different packing materials. My weakness, however, is sometimes getting bogged down in repetitive tasks. To overcome this, I proactively look for ways to improve efficiency, such as suggesting process improvements or streamlining workflows. I am always eager to learn new, faster packing methods to keep things moving effectively.

Q 28. How do you contribute to a team environment within a packing operation?

In a team environment, I actively contribute through collaboration and communication. I readily assist colleagues when needed, share best practices, and maintain a positive and supportive attitude. I’m a firm believer in teamwork; a well-coordinated packing team is far more efficient than a group of individuals working in isolation. I proactively communicate with my team regarding any potential issues or bottlenecks in the packing process. I’m always willing to help train new team members, passing on my knowledge and skills. In essence, I see myself as a valuable contributor to the team’s overall success.

Key Topics to Learn for Your Folding and Packing Interview

- Understanding Packaging Materials: Learn about different types of materials used in folding and packing (e.g., cardboard, plastic, paper), their properties, and suitability for various products.

- Folding Techniques & Efficiency: Master various folding techniques to minimize waste and maximize speed and efficiency. Practice with different product sizes and shapes.

- Packaging Design & Optimization: Understand the principles of effective packaging design, including considerations for product protection, ease of handling, and cost-effectiveness.

- Safety Procedures and Regulations: Familiarize yourself with workplace safety procedures related to handling packaging materials and equipment, as well as relevant industry regulations.

- Quality Control and Inspection: Learn how to identify and address defects in folded and packed items to maintain high quality standards. This includes understanding quality metrics and inspection techniques.

- Machine Operation (if applicable): If the role involves operating machinery, understand the specifics of the machines used, including safety protocols and maintenance procedures.

- Teamwork and Communication: Prepare to discuss your teamwork skills and ability to communicate effectively within a team environment, especially in fast-paced settings.

- Problem-Solving and Adaptability: Be ready to discuss examples of how you’ve solved problems on the job or adapted to changing circumstances in previous roles. Think about situations involving unexpected issues with materials or equipment.

Next Steps

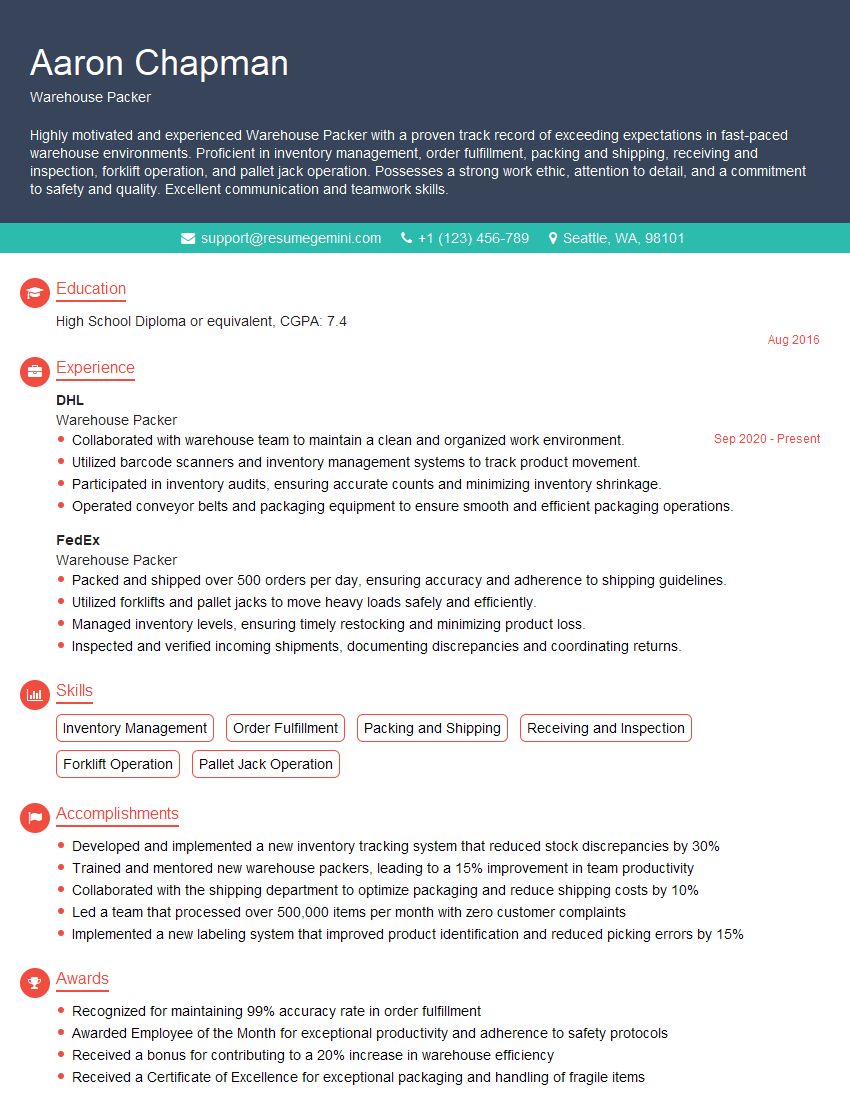

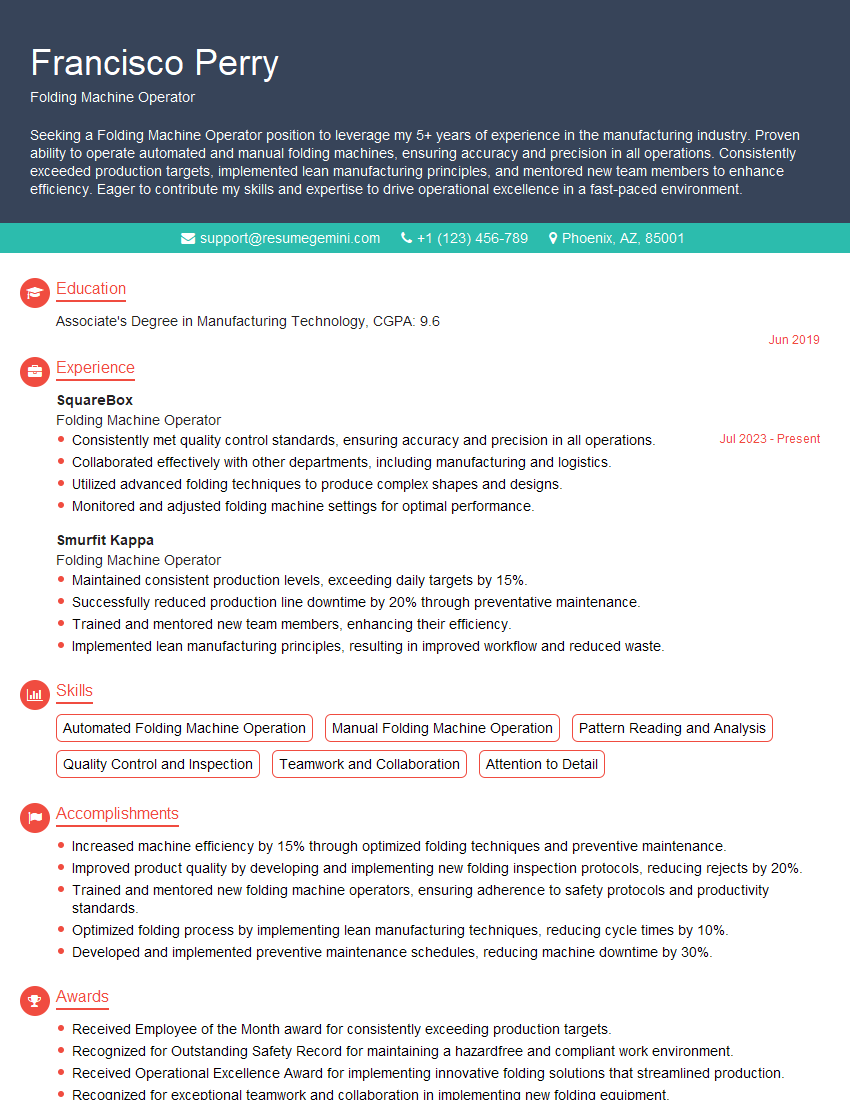

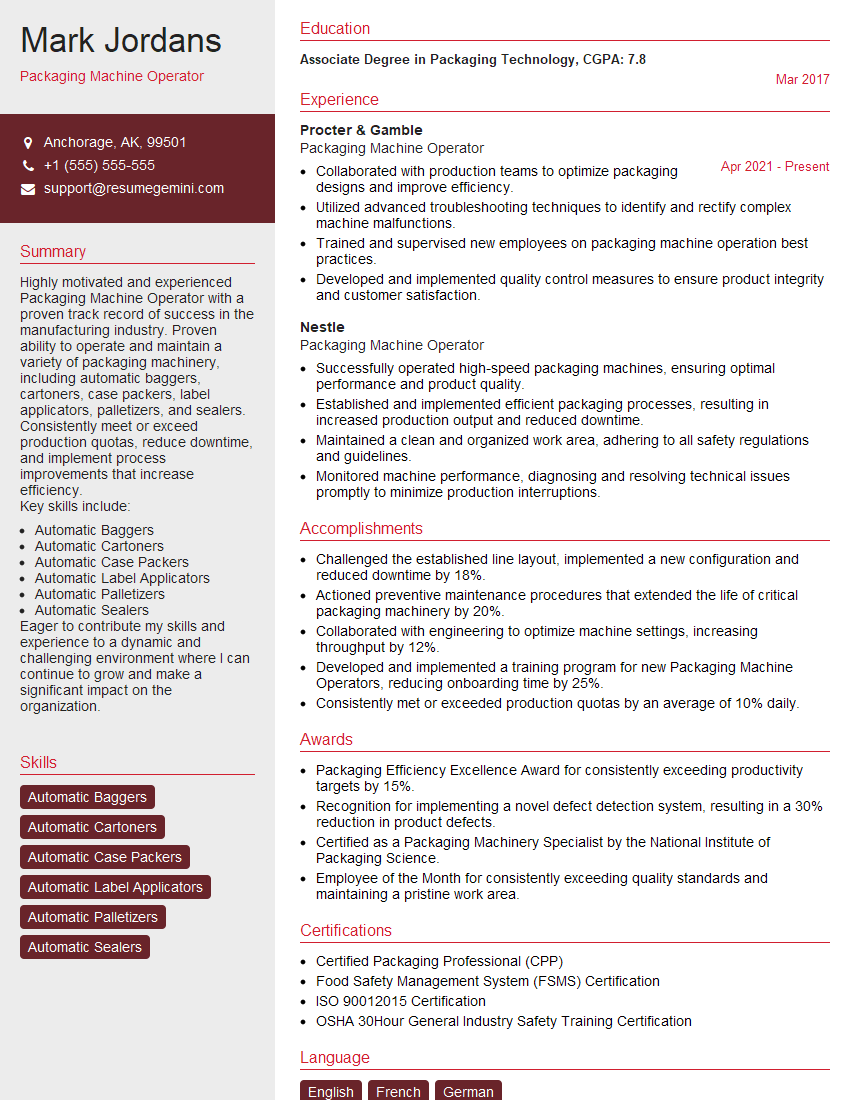

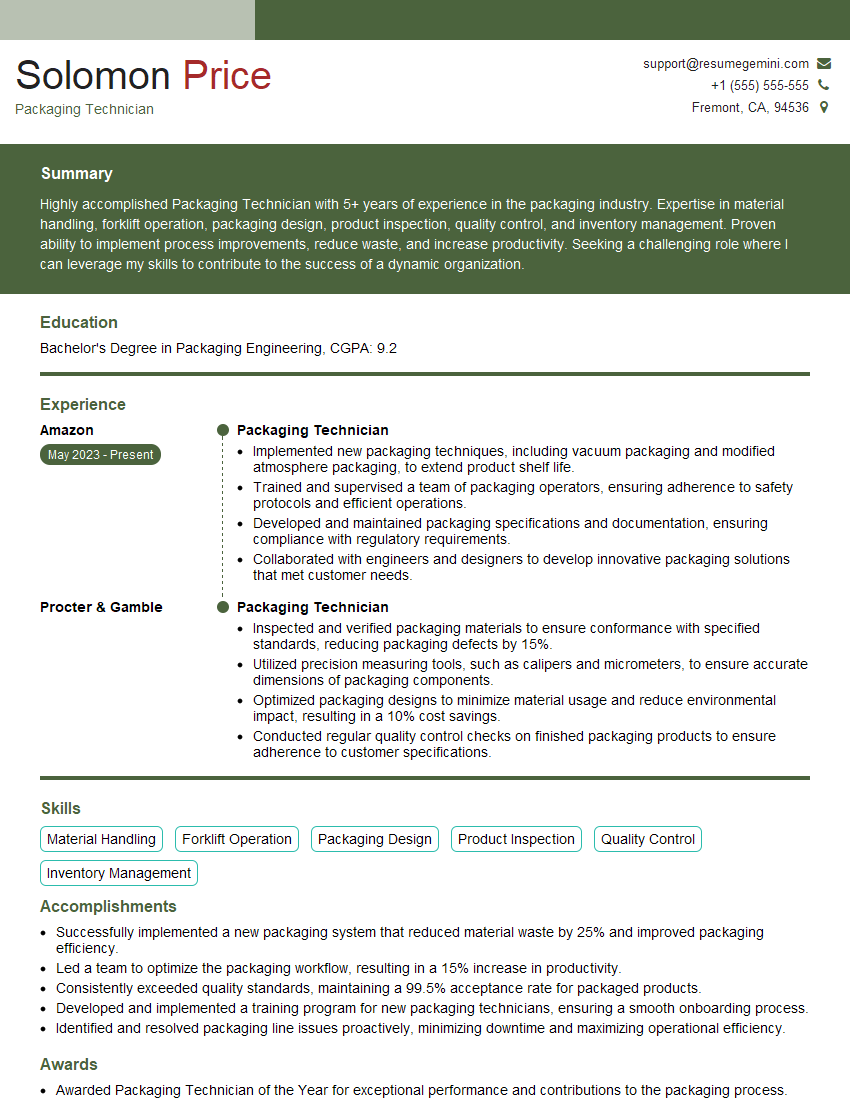

Mastering folding and packing skills opens doors to a variety of roles within logistics, manufacturing, and distribution, offering opportunities for career advancement and increased earning potential. To significantly improve your job prospects, crafting an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We strongly recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Folding and Packing roles to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good