Cracking a skill-specific interview, like one for Nuclear Criticality Safety Facility Design, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Nuclear Criticality Safety Facility Design Interview

Q 1. Explain the concept of criticality and its safety implications.

Criticality is the state where a nuclear chain reaction becomes self-sustaining. Imagine a campfire: you need enough kindling (fissile material) and a certain arrangement (geometry) to get it going and keep it burning. Similarly, in nuclear fission, if enough fissile material like Uranium-235 or Plutonium-239 is brought together in the right configuration, neutrons released from one fission event will trigger further fissions, leading to a rapidly escalating chain reaction. This release of energy can be immense, resulting in a criticality accident. The safety implications are severe, including potential for significant radiation release, causing immediate fatalities, long-term health problems, and environmental contamination, requiring extensive and costly remediation efforts.

For example, a criticality accident could occur during the processing of nuclear fuel if the concentration of fissile material unexpectedly increases, exceeding the criticality limit.

Q 2. Describe different methods used to prevent criticality accidents.

Preventing criticality accidents relies on a robust defense-in-depth strategy, combining multiple independent methods. These include:

- Geometric control: Carefully controlling the shape and size of fissile material containers ensures that the material cannot achieve a critical configuration. Think of it like arranging the campfire wood in a way that prevents a fast-burning blaze.

- Mass control: Limiting the amount of fissile material in a given area prevents reaching critical mass. This is like limiting the amount of wood in a campfire to control its size.

- Neutron absorption (poisoning): Introducing neutron-absorbing materials, such as boron or cadmium, reduces the number of neutrons available to sustain a chain reaction. These act like a fire extinguisher, slowing down or stopping the reaction.

- Moderation control: Controlling the presence of neutron moderators (materials that slow down neutrons) can impact the likelihood of criticality. Certain moderators can accelerate a chain reaction; controlling their presence or absence is crucial.

- Administrative controls: Establishing strict procedures, training, and work permits helps prevent accidental criticality events. This is analogous to having a strict set of rules and training for operating a campfire safely.

Q 3. What are the key design features of a nuclear criticality safety facility?

Nuclear criticality safety facilities are designed with numerous features to mitigate criticality risks. Key design aspects include:

- Subcritical geometry: Equipment and storage containers are specifically designed to ensure that even under abnormal conditions (e.g., accidental spillage or accumulation of material), the fissile material cannot reach a critical configuration.

- Remote handling equipment: Operations involving fissile materials are typically conducted remotely to minimize human exposure and the potential for accidental criticality.

- Shielding: Thick concrete, lead, or other shielding materials are used to absorb radiation generated during normal operations and in the event of a criticality excursion.

- Ventilation systems: Specialized ventilation systems ensure rapid dispersal of airborne radioactive materials in the event of an accident, reducing personnel exposure and environmental impact.

- Emergency systems: Facilities include emergency shut-down systems, alarms, and evacuation plans to respond effectively to potential accidents.

- Criticality alarm systems: These systems rapidly detect an increase in neutron radiation levels, providing an early warning of a potential criticality incident.

Q 4. How do you assess the risk associated with nuclear material handling processes?

Risk assessment for nuclear material handling processes involves a systematic approach, typically employing a combination of qualitative and quantitative methods. It identifies potential hazards, evaluates the likelihood of those hazards occurring, and estimates the potential consequences. This is often done using techniques like Fault Tree Analysis (FTA) and Event Tree Analysis (ETA). For example, FTA could be used to trace back a potential criticality event from its consequences to its root causes, revealing which factors contribute most to the overall risk.

A key aspect is identifying the possible scenarios that could lead to an accident, such as a spill, inadvertent mixing of materials, or equipment malfunction. Then, each scenario’s probability and the severity of its consequences are evaluated. This might involve using models to simulate the spread of radiation or the potential for human exposure. This assessment is then used to justify the safety features and procedures employed in the facility.

Q 5. Explain the role of administrative controls in criticality safety.

Administrative controls are crucial for nuclear criticality safety, acting as a critical layer of defense. They establish a framework of procedures, training, and oversight that ensures safe handling practices are consistently followed. These are the non-physical barriers that prevent accidents.

Examples include: detailed work instructions, strict material accountability procedures, comprehensive training programs for personnel, regular inspections and audits, and the implementation of a robust permit-to-work system for all operations involving fissile material. They also include the use of checklists to ensure that procedures are consistently followed and the implementation of safety reviews before any new procedures or equipment are introduced.

These administrative controls work in conjunction with engineered safety features to create a robust safety system. They often represent the first line of defense against criticality accidents.

Q 6. What are the regulatory requirements for nuclear criticality safety?

Regulatory requirements for nuclear criticality safety vary by country, but generally involve rigorous standards and oversight from regulatory bodies. These regulations cover all aspects of nuclear material handling, from design and construction of facilities to operational procedures and emergency response plans. They often mandate detailed safety analyses, regular inspections, and strict adherence to safety limits and standards. For example, in the US, the Nuclear Regulatory Commission (NRC) sets the standards and enforces them through licensing, inspections, and enforcement actions.

Compliance with these regulations is crucial for ensuring the safety of workers, the public, and the environment. Non-compliance can result in penalties and legal actions.

Q 7. Describe different types of criticality accident scenarios.

Criticality accident scenarios can vary widely, depending on the circumstances. Some examples include:

- Accidental accumulation: Fissile material unexpectedly accumulating in a particular area, exceeding the critical mass and initiating a chain reaction. This could occur due to a spill, equipment malfunction, or human error.

- Uncontrolled chemical reaction: During processing, a chemical reaction could inadvertently increase the concentration of fissile material or alter its geometry, leading to criticality.

- Equipment malfunction: A failure in process control systems or equipment could lead to an uncontrolled increase in the concentration or configuration of fissile material.

- Human error: Incorrect procedures or actions by personnel, such as the incorrect placement or handling of fissile materials, can trigger a criticality accident. This emphasizes the importance of comprehensive training and thorough procedures.

The severity of consequences varies greatly depending on factors such as the amount of fissile material involved, the geometry of the material at the time of the accident, and the effectiveness of the safety systems in place.

Q 8. Explain the importance of criticality safety analysis in facility design.

Criticality safety analysis is paramount in nuclear facility design because it ensures that the concentration and arrangement of fissile materials never reach a critical state, preventing a potential nuclear chain reaction. Imagine a campfire: a few twigs burn slowly, but too many, arranged just right, create a raging fire. Similarly, fissile material needs specific conditions to achieve criticality. The analysis meticulously assesses these conditions to prevent an uncontrolled chain reaction, which could lead to a radiation release, severe damage, and potential loss of life.

This analysis informs every aspect of the facility design, from the arrangement of storage tanks and process equipment to the geometry of the building itself. It guides the selection of materials, the implementation of safety systems, and the establishment of operational procedures. Without a thorough criticality safety analysis, a nuclear facility would be inherently unsafe and pose an unacceptable risk.

Q 9. How do you perform a criticality safety evaluation?

A criticality safety evaluation is a rigorous process involving several steps. Firstly, we identify all fissile materials present within the facility and their potential interactions. Secondly, we employ validated computational tools, such as Monte Carlo codes (like MCNP or SERPENT), to model various scenarios, including normal operation, process upsets, and accidents. These codes simulate neutron transport and interactions, predicting the likelihood of a criticality event under different conditions.

Thirdly, we employ administrative controls, such as limiting the amount of fissile material in a given area and implementing strict procedures for material handling and transfer. Subsequently, we verify the accuracy of our models through experimental validation or criticality benchmark experiments where feasible. Finally, a comprehensive safety report is prepared, documenting the analysis, the results, and any mitigating measures implemented. This iterative process ensures that the design is safe and robust, taking into account both uncertainties and worst-case scenarios.

Q 10. What are the different types of nuclear materials and their criticality characteristics?

Nuclear materials vary significantly in their criticality characteristics. Uranium, for example, exists in different isotopes, with Uranium-235 (235U) being the most fissile. Highly enriched uranium (HEU), with a high percentage of 235U, is far more likely to reach criticality than low-enriched uranium (LEU). Plutonium (Pu), particularly 239Pu, is also a highly fissile material and requires stringent safety measures.

- Uranium: The critical mass, the minimum amount of material needed to sustain a chain reaction, varies significantly with enrichment and geometry.

- Plutonium: Plutonium isotopes have even smaller critical masses than Uranium-235, making them especially hazardous.

- Thorium: While not fissile itself, 232Th can be converted into fissile isotopes, demanding careful consideration in its handling and processing.

The criticality characteristics are influenced by many factors, including the material’s isotopic composition, density, geometry (shape and size), the presence of moderators (materials slowing down neutrons), and reflectors (materials reflecting neutrons back into the fissile material).

Q 11. Discuss the role of shielding in nuclear criticality safety.

Shielding plays a vital role in nuclear criticality safety by reducing the radiation exposure to personnel and the environment. This is particularly crucial in case of an accidental criticality. Shielding materials are chosen based on their ability to absorb neutrons and gamma radiation. Common materials include concrete, water, lead, and borated polyethylene.

The design and thickness of shielding are determined by the source strength, the type of radiation emitted, and the required level of radiation protection. For example, a thick concrete wall might suffice for shielding low-level radiation sources, while a combination of materials and more substantial shielding might be needed for handling high-intensity radiation. Shielding is incorporated into the facility design strategically, minimizing radiation leakage and creating safe working environments.

Q 12. Explain the concept of subcriticality and its significance.

Subcriticality means that a system containing fissile material is in a state where a self-sustaining chain reaction cannot occur. The neutron multiplication factor (keff) is less than 1. Imagine a campfire again; if you continuously remove burning embers, the fire will eventually die out. Similarly, in a subcritical system, neutrons are lost more rapidly than they are produced, preventing a runaway reaction.

Ensuring subcriticality is fundamental to nuclear safety. Maintaining the system in a subcritical state effectively prevents any risk of criticality. All operational and storage procedures are designed and reviewed to keep the keff substantially below 1, usually with a significant safety margin to account for uncertainties in the calculations.

Q 13. How do you manage and control nuclear materials to prevent criticality?

Managing and controlling nuclear materials to prevent criticality involves a multi-layered approach. This includes:

- Geometric control: Limiting the amount of fissile material in a given geometry (shape and size) to ensure it remains subcritical.

- Administrative controls: Implementing strict procedures for material handling, storage, and transportation, including rigorous documentation and accountability.

- Criticality alarms: Installing neutron detectors that trigger alarms in case of an unexpected increase in neutron flux indicating a potential criticality.

- Safety limits and controls: Defining clear limits on the amount and arrangement of fissile material, with automatic safety systems to shut down processes if those limits are exceeded.

- Process safety: Designing processes to minimise the possibility of accidental accumulation of fissile materials.

This comprehensive approach ensures that the risk of criticality is minimized throughout the entire life cycle of the nuclear materials, from acquisition to disposal.

Q 14. What is the importance of process safety in criticality safety?

Process safety is intrinsically linked to criticality safety. Process upsets, such as leaks, spills, or equipment failures, can lead to unintended accumulations of fissile materials, potentially triggering a criticality accident. Therefore, robust process safety measures are essential in preventing criticality events.

This includes implementing proper process controls, regular equipment maintenance, and comprehensive emergency response plans. Moreover, robust safety analysis considers the potential for process deviations and includes safety margins that account for uncertainties. A well-designed process aims to keep the system in a safe subcritical state even under potentially adverse process conditions. For example, redundant safety systems or multiple layers of protection can ensure that if one system fails, other systems are in place to prevent criticality.

Q 15. Explain the use of computational tools in criticality safety analysis (e.g., MCNP, SERPENT).

Computational tools are indispensable in criticality safety analysis, allowing us to simulate complex nuclear systems and predict the likelihood of a criticality accident. Monte Carlo methods, in particular, are widely used. Tools like MCNP (Monte Carlo N-Particle Transport Code) and SERPENT (Stochastic European Research code for Neutron Transport) simulate the transport of neutrons within a system, providing detailed information about neutron flux, multiplication factor (keff), and power distribution. A keff value below 1 indicates a subcritical system, while a value above 1 indicates a supercritical system, posing a criticality risk.

For example, imagine designing a spent fuel storage pool. Using MCNP, we can model the geometry of the pool, the arrangement of spent fuel assemblies, and the surrounding materials. The simulation then tracks the movement of neutrons, estimating the probability of a chain reaction. This allows us to determine the safe limits for fuel loading density and ensure the system remains safely subcritical under various operational conditions, including potential accidents like water loss.

SERPENT offers similar capabilities but often with faster computational times for certain problem types. The choice between MCNP and SERPENT often depends on the specific application, computational resources, and the desired level of detail in the simulation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the role of quality assurance in nuclear criticality safety.

Quality assurance (QA) in nuclear criticality safety is paramount; it’s not just about following procedures, but about consistently demonstrating that our safety systems and analyses are reliable and robust. This includes rigorous documentation, regular audits, and independent verification and validation of our computational models and safety assessments. We use documented procedures for everything, from handling fissile materials to performing calculations and interpreting results. A comprehensive QA program ensures that the results we use to inform decisions are accurate, consistent, and defensible.

Imagine a mistake in a calculation leading to an incorrect assessment of keff. A robust QA program would have checks and balances, perhaps including peer reviews or independent verification, that would identify and correct this error before it could lead to a dangerous situation. QA is the backbone of a safe and reliable criticality safety program, preventing potentially catastrophic consequences.

Q 17. How do you address human factors in criticality safety?

Human factors are a critical consideration in criticality safety. Even the best design and safety procedures can be compromised by human error. We address this through a multi-faceted approach, focusing on training, procedures, and design considerations that minimize the likelihood of human error. This includes designing facilities and procedures to be intuitive and user-friendly. Error-preventing features like interlocks and safety systems are essential.

For instance, we might design a system with clear, unambiguous labeling and standardized procedures to reduce the potential for misidentification of materials. Implementing procedures that require multiple confirmations for critical operations (e.g., adding fissile material) reduces the risk of accidental criticality. Regular training and drills prepare personnel to respond to unexpected situations and handle emergencies effectively. Human Reliability Analysis (HRA) techniques can be used to systematically identify and mitigate the potential for human error in specific operations and tasks.

Q 18. What are the emergency procedures in case of a criticality accident?

Emergency procedures for a criticality accident are designed to minimize exposure to radiation and mitigate the consequences. The immediate actions involve evacuating personnel from the immediate area and implementing radiation monitoring to assess the extent of the event. Emergency response teams, specifically trained in handling criticality accidents, will then follow pre-established protocols. These procedures are thoroughly tested and practiced regularly to ensure effectiveness.

Depending on the severity, this may include deploying shielding materials, initiating emergency shutdown systems, and providing medical attention to those affected. Communication is critical; clear and timely communication between personnel, emergency services, and regulatory bodies is crucial for effective response and minimizing negative impacts. Post-accident investigations will focus on identifying the root cause to prevent future occurrences.

Q 19. Explain the importance of training and qualifications for personnel involved in criticality safety.

Thorough training and qualification are fundamental for personnel involved in criticality safety. This includes theoretical knowledge of nuclear physics, criticality safety principles, and practical skills in handling fissile materials and operating associated equipment. Training programs often incorporate hands-on exercises and simulations to prepare personnel for real-world scenarios. Regular refresher courses and competency assessments ensure that personnel maintain their skills and knowledge over time.

Imagine a situation where an untrained person misinterprets a safety procedure. Comprehensive training and qualification programs reduce this risk by ensuring that everyone involved understands their responsibilities and can perform their tasks safely and effectively. The consequences of inadequate training can be catastrophic, emphasizing the importance of this aspect of nuclear safety.

Q 20. How do you ensure the safety of workers during the decommissioning of a nuclear facility?

Decommissioning a nuclear facility requires meticulous planning and execution to ensure worker safety. The process involves several steps, including thorough characterization of the facility and its contents, development of a detailed decommissioning plan, and implementation of appropriate safety measures. Radiation levels must be carefully monitored and controlled, and personnel must utilize appropriate personal protective equipment (PPE), such as respirators, radiation suits, and dosimeters.

For example, before dismantling equipment, the facility may undergo extensive decontamination and shielding procedures to reduce radiation exposure. Waste management is also crucial; all radioactive materials must be properly packaged, transported, and disposed of in accordance with regulatory requirements. Regular safety audits and reviews are essential throughout the decommissioning process to ensure the safety of workers and compliance with regulatory standards. The ultimate goal is to return the site to a safe and environmentally acceptable condition.

Q 21. What are the key aspects of a criticality safety program?

A comprehensive criticality safety program is multifaceted, encompassing several key aspects. First, it requires a thorough understanding of the materials and processes involved. This involves meticulous inventory control of fissile materials, detailed process descriptions, and comprehensive safety analyses using computational tools like MCNP or SERPENT. Secondly, robust administrative controls are crucial. This includes strict procedures for material handling, storage, and processing, as well as clear lines of responsibility and authority.

Thirdly, engineering controls play a vital role. This may involve the use of geometrical limitations (e.g., limiting the mass or geometry of fissile materials), neutron absorbers (e.g., cadmium or boron), or other physical barriers to prevent accidental criticality. Finally, an effective emergency response plan is necessary, including well-defined procedures, trained personnel, and emergency equipment. A criticality safety program is a continuous process of improvement, involving regular reviews, audits, and updates to ensure ongoing effectiveness and the safety of all involved.

Q 22. Explain the role of the Nuclear Regulatory Commission (NRC) in criticality safety.

The Nuclear Regulatory Commission (NRC) plays a crucial role in ensuring the safety of nuclear facilities, including criticality safety. Their oversight primarily focuses on preventing accidental nuclear criticality – a chain reaction resulting in a sustained nuclear fission – through regulations, inspections, and licensing. The NRC establishes standards and regulations for the design, construction, operation, and decommissioning of nuclear facilities. These regulations encompass various aspects of criticality safety, including the limits on fissile material mass and enrichment, the geometry of storage and processing equipment, and the implementation of administrative controls and safety systems. They conduct regular inspections to verify compliance and impose penalties for violations. Essentially, the NRC acts as the primary safety watchdog, ensuring that nuclear facilities operate within safe parameters to prevent criticality accidents.

Q 23. Describe your experience with different types of nuclear reactors and their criticality concerns.

My experience encompasses a broad range of nuclear reactor types, each presenting unique criticality concerns. I’ve worked with Pressurized Water Reactors (PWRs), Boiling Water Reactors (BWRs), and research reactors. PWRs and BWRs, used for electricity generation, pose criticality challenges during refueling and maintenance, where the handling of spent fuel assemblies requires strict adherence to procedures and criticality safety limits. Research reactors, often operating at lower power levels, demand meticulous control over fuel enrichment and experimental configurations to prevent accidental criticality during experiments. A key difference lies in the inherent safety features incorporated into power reactors compared to research reactors. Power reactors usually have built-in safety mechanisms to prevent uncontrolled chain reactions, while research reactors rely more heavily on strict operational procedures and safety protocols. For example, in PWRs, the complex geometry of fuel assemblies and the presence of neutron-absorbing control rods are crucial design features for criticality control. In contrast, research reactor criticality control might involve manual adjustments of control rods and the precise arrangement of fuel elements. Each reactor type necessitates a tailored approach to criticality safety analysis and management.

Q 24. How do you handle and manage nuclear waste in relation to criticality safety?

Nuclear waste management is intrinsically linked to criticality safety. Spent nuclear fuel, containing significant quantities of fissile material, must be handled and stored in ways that prevent criticality. This involves careful attention to storage geometry, ensuring sufficient separation between fuel assemblies, and potentially utilizing neutron-absorbing materials to reduce the likelihood of a chain reaction. The design of storage facilities, such as spent fuel pools and dry storage casks, incorporates features designed to minimize the possibility of criticality, such as geometric control and the use of neutron poisons. Similarly, the processing and treatment of nuclear waste, particularly in reprocessing facilities, demand rigorous criticality safety controls throughout the entire process, from receiving and storage to handling and chemical separation. For instance, the concentration and geometry of fissile materials during reprocessing steps are carefully monitored and controlled to maintain subcriticality. Failure to properly manage these aspects could have catastrophic consequences.

Q 25. Explain your familiarity with different types of criticality alarms and detection systems.

My familiarity with criticality alarms and detection systems spans various technologies. These systems serve as essential safeguards against accidental criticality. Neutron detectors, such as fission chambers and proportional counters, are frequently employed to monitor neutron flux levels. Exceeding pre-set thresholds triggers alarms, alerting personnel to a potential criticality event. These detectors may be strategically located throughout a facility to provide comprehensive coverage. In addition to neutron detection, some systems incorporate gamma radiation detectors which can detect the prompt gamma radiation emitted during fission. The choice of detection system depends on the specific facility and the type of fissile material being handled. For example, a facility processing highly enriched uranium may require a more sensitive detection system than one handling low-enriched uranium. Furthermore, the alarm systems integrate with other safety systems, such as automatic shutdown mechanisms and emergency ventilation systems, ensuring a layered approach to safety.

Q 26. Describe your experience with performing criticality safety audits.

I have extensive experience conducting criticality safety audits. These audits encompass a comprehensive review of all aspects of a facility’s criticality safety program, from its administrative controls to its physical safeguards. The process involves reviewing operational procedures, inspecting equipment, verifying the accuracy of calculations, and assessing the effectiveness of safety systems. A typical audit includes examining documentation, observing personnel conducting tasks, and conducting interviews with staff members. I use established checklists and procedures to ensure thoroughness and consistency. My audits often result in recommendations for improvements to enhance criticality safety. This can include modifications to equipment, improvements to procedures, or additional training for personnel. The objective is to identify potential weaknesses in the safety program and to recommend corrective actions to mitigate risks. In one instance, an audit revealed an oversight in the handling of a particular type of fissile material. The resulting improvement recommendation was an enhanced safety procedure that has significantly reduced the risk of accidental criticality.

Q 27. How do you ensure the integrity of criticality safety documentation?

Maintaining the integrity of criticality safety documentation is paramount. This involves implementing a robust document control system, ensuring that all documents are accurate, up-to-date, and readily accessible. We use version control to track changes and revisions, ensuring only the latest approved versions are used. Access control measures restrict access to documentation to authorized personnel, maintaining confidentiality and preventing unauthorized modifications. Regular reviews and audits of documentation are conducted to ensure its completeness, accuracy, and relevance. Any discrepancies or inconsistencies are promptly addressed. In addition to formal document control procedures, we promote a culture of accountability and careful record-keeping within the organization. This culture includes regular training on document control procedures and clear responsibilities for maintaining the integrity of the documentation.

Q 28. What are some common challenges in nuclear criticality safety and how have you overcome them?

Some common challenges in nuclear criticality safety include managing the increasing complexity of nuclear facilities, ensuring effective communication and training of personnel, and staying abreast of evolving regulations and technologies. One challenge I’ve encountered involves incorporating new processes and materials into existing facilities without compromising criticality safety. To overcome this, we developed a systematic approach that involves detailed modeling and simulation, rigorous hazard analysis, and a multidisciplinary team effort. This process enables us to assess potential criticality risks, implement appropriate control measures, and ensure that the changes don’t jeopardize safety. Another challenge lies in communicating complex safety concepts to individuals with varying technical backgrounds. To address this, we utilize clear and concise training materials, interactive workshops, and regular refresher courses to ensure that everyone understands their role in maintaining criticality safety. Ongoing professional development for myself and the team ensures we remain updated on current best practices and regulations.

Key Topics to Learn for Nuclear Criticality Safety Facility Design Interview

- Nuclear Criticality Fundamentals: Understanding fission processes, criticality conditions, and the factors influencing reactivity (e.g., geometry, material composition, neutron moderation).

- Criticality Safety Analysis Methods: Familiarity with various analytical techniques, including hand calculations, computational methods (e.g., MCNP, SERPENT), and the application of safety limits and margins.

- Facility Design Principles: Knowledge of geometric considerations to minimize reactivity, material handling procedures, and the design of safety systems (e.g., neutron absorbers, shielding).

- Safety Regulations and Standards: Understanding relevant codes and standards (e.g., ANSI, IAEA) related to nuclear criticality safety and their application in facility design and operation.

- Process Safety Analysis: Experience with hazard identification, risk assessment methodologies (e.g., HAZOP, What-If analysis), and development of safety procedures.

- Emergency Response Planning: Understanding the importance of emergency preparedness and response procedures for criticality accidents, including alarm systems and mitigation strategies.

- Material Accountability and Control: Knowledge of methods for tracking nuclear materials and ensuring their safe handling and storage within the facility.

- Practical Application: Designing a specific facility component (e.g., storage vault, processing cell) considering criticality safety aspects and regulatory requirements. This includes selecting appropriate materials, geometries, and safety systems.

- Problem-Solving Approach: Demonstrating the ability to identify potential criticality hazards, evaluate risks, and propose effective solutions to mitigate those risks within a design context.

Next Steps

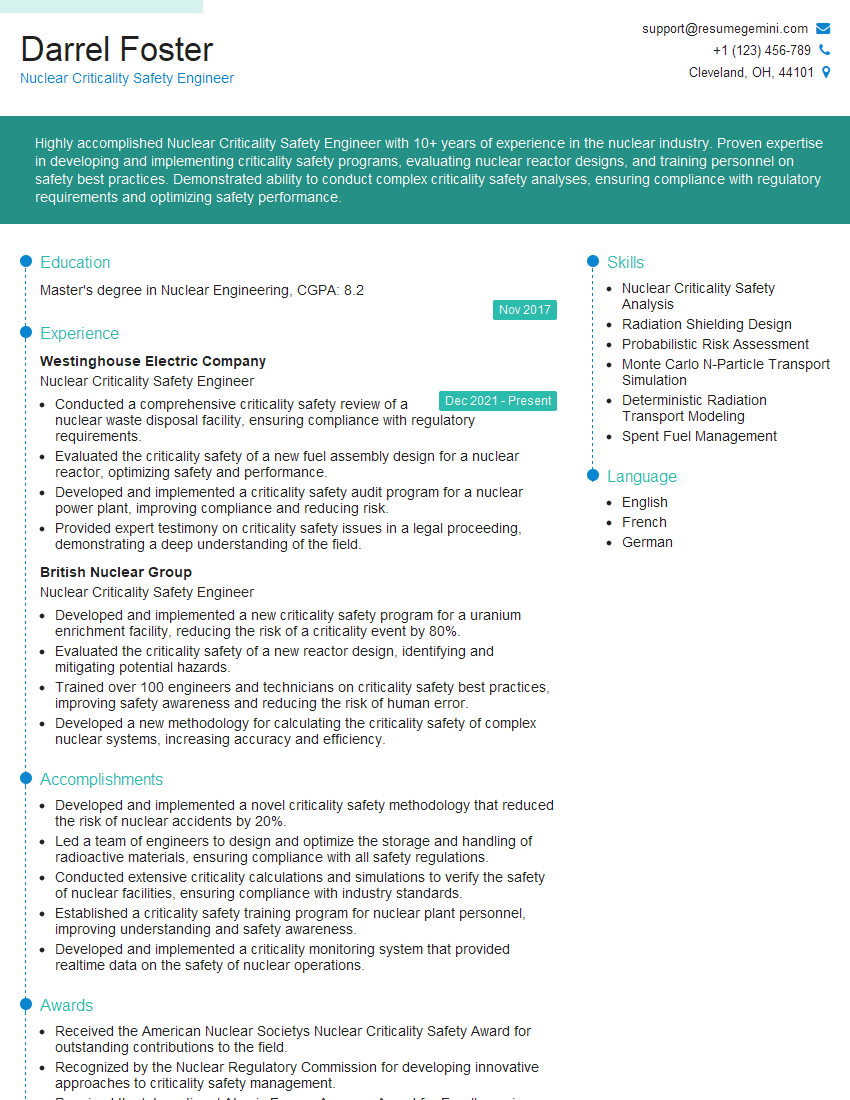

Mastering Nuclear Criticality Safety Facility Design is crucial for a successful and rewarding career in the nuclear industry. This specialized knowledge opens doors to challenging and impactful roles, offering significant opportunities for professional growth and advancement. To maximize your job prospects, it’s essential to present your skills and experience effectively. Creating an ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to build a compelling and effective resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored specifically to Nuclear Criticality Safety Facility Design, helping you showcase your expertise and stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good