Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Identifying and avoiding hazards interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Identifying and avoiding hazards Interview

Q 1. Describe your experience conducting a Job Safety Analysis (JSA).

Conducting a Job Safety Analysis (JSA) involves systematically breaking down a job into its individual steps to identify potential hazards and control measures. It’s a proactive approach to safety, preventing accidents before they happen. My experience involves leading JSA workshops with teams, guiding them through a structured process.

Typically, we use a worksheet or software to document each step, identify potential hazards associated with each step (e.g., slips, trips, falls, cuts, electrical shock), assess the risk level (likelihood and severity), and then develop and implement control measures to mitigate those risks. For example, in a JSA for warehouse operations, we might identify the hazard of a forklift collision. The risk assessment would consider the likelihood of a collision and the severity of potential injuries. Control measures could include implementing traffic rules, using designated walkways, and providing forklift operator training. After the JSA, we’d review and update the document regularly to reflect changes in the work process or equipment.

I’ve successfully implemented JSAs across diverse settings, including manufacturing, construction, and healthcare, consistently resulting in fewer workplace incidents and a safer work environment.

Q 2. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls prioritizes control measures from the most effective to the least. The goal is to eliminate hazards whenever possible, and if elimination isn’t feasible, to use the next best control option. Think of it as a ladder, starting from the safest rung and moving down.

- Elimination: This is the best option. It involves removing the hazard completely. For example, replacing a hazardous chemical with a less harmful alternative.

- Substitution: Replacing a hazardous substance, process, or piece of equipment with a safer one. For example, using a robotic arm to handle heavy materials instead of manual labor.

- Engineering Controls: Implementing physical changes to the workplace to reduce or eliminate hazards. This could involve installing machine guards, improving ventilation, or implementing lockout/tagout procedures.

- Administrative Controls: These are changes to work procedures, schedules, or training to reduce exposure to hazards. Examples include job rotation, providing safety training, and establishing safety rules and procedures.

- Personal Protective Equipment (PPE): This is the last line of defense and should only be used when other controls are insufficient. Examples include safety glasses, hard hats, and respirators. It protects the worker, but it doesn’t eliminate the hazard itself.

Following this hierarchy ensures the most effective and sustainable safety measures are in place.

Q 3. What methods do you use to identify potential hazards in a workplace?

Identifying potential hazards requires a multi-faceted approach. I use a combination of methods to ensure a comprehensive assessment.

- Workplace Inspections: Regularly walking through the workplace, observing processes, and looking for potential hazards. This involves checking for trip hazards, damaged equipment, and unsafe practices.

- Job Hazard Analysis (JSA): As previously discussed, this method systematically examines each step of a task to identify potential hazards.

- Incident Investigations: Thoroughly investigating past incidents or near misses to understand their root causes and prevent recurrence. This often reveals hidden hazards not previously identified.

- Checklists and Surveys: Using pre-designed checklists or surveys to systematically identify common hazards within specific industries or work areas.

- Employee Input: Encouraging workers to report hazards they observe, as they often have the most direct experience and understanding of the workplace.

- Legislation and Standards Review: Staying up-to-date on relevant health and safety legislation and industry standards to ensure compliance and identify potential areas of risk.

A combination of these techniques, combined with regular communication and feedback, provides a strong foundation for hazard identification.

Q 4. How would you conduct a risk assessment using a qualitative method?

Qualitative risk assessment uses descriptive scales and judgments to assess risk. It’s a simpler method, often used when quantitative data is unavailable or impractical to obtain. A common approach involves using a risk matrix.

- Identify Hazards: List all potential hazards, as described in the previous question.

- Determine Likelihood: Assign a likelihood rating to each hazard (e.g., low, medium, high) based on how often the hazard is likely to occur. This could be based on historical data, expert opinion, or observation.

- Determine Severity: Assign a severity rating (e.g., negligible, minor, moderate, major, catastrophic) based on the potential consequences if an incident occurs.

- Combine Likelihood and Severity: Use a risk matrix to combine the likelihood and severity ratings to determine an overall risk level. The matrix typically has a color-coded system (e.g., green for low risk, yellow for moderate risk, red for high risk).

- Risk Control: Develop and implement control measures to reduce the risk to an acceptable level. Prioritize hazards based on their risk level (highest risk first).

For example, a risk matrix might show that a hazard with a high likelihood and high severity is a high-risk hazard requiring immediate attention.

Q 5. How would you conduct a risk assessment using a quantitative method?

Quantitative risk assessment uses numerical data to determine the level of risk. This requires more data and statistical analysis than qualitative assessment but provides a more precise risk estimation. It often involves calculating the frequency and severity of potential incidents, then combining these values to arrive at a risk score.

- Data Collection: Gather historical data on the frequency of similar incidents, injury rates, equipment failure rates, or other relevant data.

- Frequency Analysis: Determine the probability of the hazard occurring (frequency of occurrence).

- Severity Analysis: Determine the potential severity of an incident if the hazard occurs. This could involve considering the potential for injuries, property damage, environmental impact, or other consequences. Often involves assigning a cost to each severity level.

- Risk Calculation: Combine the frequency and severity data using a mathematical formula to calculate a quantitative risk score. A common formula is Risk = Frequency x Severity.

- Risk Reduction: Develop and implement control measures to reduce the risk score to an acceptable level. The effectiveness of control measures can be quantified by recalculating the risk score after implementation.

For example, if the frequency of a specific incident is 0.1 per year and the average cost of an incident is $10,000, the annualized risk is $1,000 (0.1 x $10,000).

Q 6. How do you prioritize hazards based on risk levels?

Prioritizing hazards based on risk levels is crucial for effective risk management. It ensures that resources are allocated to address the most critical risks first.

Both qualitative and quantitative risk assessments provide a basis for prioritization. In qualitative assessments, the risk matrix color-coding or ranking (high, medium, low) will naturally prioritize the highest-risk hazards. In quantitative assessments, the numerical risk scores directly indicate which hazards pose the greatest risk, prioritizing those with the highest risk scores. For example, a hazard with a risk score of 1000 would be prioritized over a hazard with a risk score of 10.

It is important to consider other factors beyond just risk level, including legal requirements, public perception, and business impact. However, risk level serves as the primary basis for prioritization. This ensures that the most dangerous hazards are addressed first, even if they involve larger resource commitments.

Q 7. Explain the difference between a hazard and a risk.

A hazard is something that has the potential to cause harm. It’s a source of danger. A risk, on the other hand, is the likelihood that harm will actually occur. It is the combination of the hazard and the exposure to that hazard.

Think of it like this: a loaded gun is a hazard; the risk is the likelihood that someone will be injured by that gun, depending on factors like whether it’s stored securely, whether it’s handled by trained individuals, and the environment in which it is kept. A hazard exists whether or not someone is exposed to it, but a risk only exists if there is both a hazard and exposure to that hazard. The severity of the risk is affected by how dangerous the hazard is and how likely that hazard is to cause harm.

Q 8. Describe your experience with incident investigation and root cause analysis.

Incident investigation and root cause analysis are critical for preventing future accidents. My approach involves a systematic process, starting with securing the scene and gathering evidence. This includes taking photographs, interviewing witnesses, and reviewing relevant documentation like maintenance logs or safety reports. I utilize various techniques like the ‘5 Whys’ to drill down to the root cause, moving beyond simply identifying what happened to understanding *why* it happened. For example, in an incident involving a forklift collision, simply stating ‘the forklift hit a rack’ isn’t sufficient. Applying the ‘5 Whys’ might reveal issues such as inadequate training for forklift operators, poor lighting in the warehouse leading to reduced visibility, or a lack of appropriate safety procedures around forklift operation.

Beyond the ‘5 Whys,’ I’m proficient in using fault tree analysis (FTA) and fishbone diagrams (Ishikawa diagrams) to visually map contributing factors and identify multiple root causes. The goal is to develop comprehensive corrective actions that address both the immediate problem and the underlying systemic issues. This often includes recommending improvements to training programs, safety protocols, equipment maintenance schedules, and even facility design. I then document the entire investigation process meticulously, creating a comprehensive report that serves as a valuable learning tool for the organization.

Q 9. What are some common hazards in a [specific industry] environment?

Let’s consider the construction industry. Common hazards are numerous and varied, depending on the specific task. Some of the most prevalent include:

- Falls from heights: Working at heights is inherently risky; falls are a leading cause of serious injury and death in construction.

- Struck-by hazards: Workers can be struck by falling objects (e.g., tools, materials), swinging loads (e.g., cranes), or vehicles.

- Caught-in/between hazards: Workers can be caught between equipment, objects, or collapsing structures.

- Electrocution: Contact with exposed electrical wires or equipment is a significant risk.

- Exposure to hazardous materials: Construction sites often involve materials like asbestos, lead paint, and silica dust, which pose serious health risks.

- Heat stress/cold stress: Extreme temperatures can lead to heatstroke or hypothermia.

Managing these hazards requires a layered approach, incorporating engineering controls (e.g., guardrails, fall protection systems), administrative controls (e.g., safety training, work permits), and personal protective equipment (PPE) such as hard hats, safety harnesses, and safety glasses.

Q 10. How do you develop and implement safety procedures?

Developing and implementing safety procedures is an iterative process. It begins with a thorough hazard identification and risk assessment, identifying potential hazards and evaluating their likelihood and severity. This informs the design of specific procedures tailored to each hazard. For example, a lockout/tagout procedure for machinery maintenance would be distinct from a confined space entry procedure. Procedures should be clear, concise, and easy to understand, using simple language and visual aids where necessary. They need to be readily accessible to all workers, perhaps through a centralized online system or physical binders at relevant work locations.

Crucially, the development process should involve workers. Their on-the-ground experience provides invaluable insights into practical challenges and potential improvements. After implementation, regular review and updates are essential, ensuring procedures remain relevant and effective in response to changing conditions or new technologies. This continuous improvement cycle is critical for maintaining a strong safety culture.

Q 11. How do you ensure compliance with safety regulations?

Ensuring compliance involves a multi-faceted approach. Firstly, a thorough understanding of all applicable safety regulations is paramount. This includes federal, state, and local laws, as well as industry-specific standards. I regularly consult relevant codes and standards and keep abreast of any changes or updates. Secondly, I implement robust monitoring systems to track compliance. This includes regular inspections of work areas, equipment, and employee practices. Documentation is key; meticulous record-keeping demonstrates due diligence and facilitates proactive identification of potential issues. Thirdly, training programs must effectively convey regulatory requirements to all personnel. Finally, proactive measures, such as regular audits and safety meetings, reinforce a culture of compliance and encourage employee engagement in safety.

I would also develop and implement corrective actions should any non-compliance be discovered, reporting and rectifying those issues promptly and documenting the entire process.

Q 12. How do you communicate safety information to workers?

Effective communication is crucial for safety. I utilize a multi-channel approach to reach workers effectively. This might include:

- Toolbox talks: Short, informal discussions at the start of shifts to address specific safety concerns.

- Formal safety training: Comprehensive training programs tailored to specific job roles and hazards.

- Safety posters and signage: Visual reminders of key safety messages and procedures.

- Email and intranet communications: For disseminating important information and updates.

- Safety committees and meetings: Providing a platform for workers to raise concerns and share ideas.

- Interactive safety training modules: Engaging methods which improve retention.

The key is to use a variety of methods to cater to different learning styles and ensure everyone understands the safety information. Moreover, feedback mechanisms should be in place to gauge understanding and address any questions or concerns.

Q 13. Describe your experience using safety management systems (SMS).

Safety Management Systems (SMS) provide a structured framework for managing safety risks. My experience encompasses implementing and maintaining SMS across various organizations. I’m familiar with the key elements of a robust SMS, including hazard identification, risk assessment, risk mitigation, and monitoring. I’ve used SMS to develop and implement safety policies, procedures, and training programs, as well as to conduct regular audits and safety inspections. Data analysis, a core component of my work with SMS, provides valuable insights into accident trends and areas for improvement. This data-driven approach allows for targeted interventions and continuous enhancement of safety performance. For example, analyzing incident reports might reveal patterns in specific types of injuries or accidents, highlighting the need for targeted training or revised safety protocols.

Q 14. What is your experience with personal protective equipment (PPE)?

My experience with Personal Protective Equipment (PPE) extends beyond simply knowing what it is; it includes understanding its proper selection, use, maintenance, and limitations. I’m adept at conducting PPE assessments, determining the appropriate PPE for specific hazards. This involves considering factors like the type of hazard, the severity of the risk, and the comfort and practicality of the equipment. Beyond selection, I emphasize proper training in the correct use and care of PPE, ensuring workers understand how to use it correctly and when it’s necessary. Regular inspection and maintenance are also vital, ensuring PPE remains effective and doesn’t contribute to accidents. For instance, damaged hard hats or worn-out gloves can significantly reduce protection. Finally, I understand the limitations of PPE—it is a last line of defense, not a replacement for engineering controls or administrative controls.

Q 15. How do you train employees on safety procedures?

Employee safety training isn’t a one-size-fits-all approach; it needs to be tailored to the specific hazards present in the workplace and the roles of the employees. My approach involves a multi-faceted strategy encompassing various methods:

- Initial Training: This covers fundamental safety principles, emergency procedures, specific equipment operation, and relevant regulations. I use a combination of classroom lectures, interactive presentations, and videos to keep it engaging. For example, when training on forklift operation, we use simulations alongside hands-on practice to reinforce safe handling techniques.

- On-the-Job Training: Experienced workers mentor new hires, providing practical guidance and real-time feedback on safety practices. This ensures the theory translates into actual workplace behavior.

- Refresher Training: Regular refresher courses are crucial to reinforce learning and address new regulations or identified shortcomings. I incorporate scenario-based training, quizzes, and practical assessments to assess retention and comprehension. For instance, we might conduct mock emergency drills to refresh emergency response procedures.

- Specialized Training: Depending on the job, employees may need specialized training like working at heights, confined spaces, or handling hazardous materials. These trainings often involve certification programs and are meticulously documented.

- Documentation and Assessment: Each training module is documented, and employees are assessed to ensure understanding and competency. This ensures accountability and allows for continuous improvement of the training program.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle a workplace emergency?

Handling a workplace emergency requires a calm, decisive, and well-coordinated response. My approach follows these steps:

- Activate the Emergency Response Plan: This involves immediately notifying emergency services (911 or equivalent) and initiating our internal emergency response protocol. This could include activating alarms, evacuating the affected area, and implementing the appropriate procedures for the specific emergency.

- Account for Personnel: Ensure all employees are accounted for and evacuated safely. Designated personnel are responsible for conducting headcounts and assisting anyone needing help.

- Provide First Aid: If necessary, provide first aid to injured individuals until paramedics arrive, following established safety protocols.

- Secure the Area: Secure the affected area to prevent further incidents or injuries. This might involve shutting down equipment or isolating hazardous materials.

- Cooperate with Authorities: Cooperate fully with emergency responders and law enforcement, providing them with all necessary information and access.

- Post-Incident Investigation: A thorough investigation is conducted to determine the root cause of the emergency, identify any areas for improvement in safety procedures, and prevent future occurrences. This typically involves interviews with witnesses, reviewing safety logs, and analyzing the incident scene.

For example, during a chemical spill incident, we activated our emergency plan, which includes establishing a safe perimeter, contacting emergency services, and initiating decontamination procedures. Following the incident, a root cause analysis revealed a lapse in proper handling procedures, leading to changes in our training and chemical storage practices.

Q 17. What are your experience with safety audits and inspections?

I have extensive experience conducting and participating in safety audits and inspections. My approach is proactive and thorough, aiming to identify hazards and ensure compliance with all regulations.

- Planning: Before the audit or inspection, I develop a detailed checklist based on relevant regulations and industry best practices. This checklist considers all areas of the workplace, equipment, and processes.

- Conducting the Audit/Inspection: I systematically review each area, conducting visual inspections, reviewing documentation (safety logs, training records), and interviewing employees to gain diverse perspectives. I am attentive to detail and always look for potential hazards, even minor ones that could escalate.

- Documentation: I meticulously document all findings, including photographs and descriptions of hazards, along with recommendations for corrective actions. These findings are communicated in a clear and concise report.

- Follow-up: Following the audit or inspection, I ensure the identified corrective actions are implemented promptly and effectively. I conduct follow-up inspections to verify that these actions have been taken and to check their effectiveness.

For example, during a recent audit, I identified a potential tripping hazard caused by poorly maintained cabling. This resulted in the implementation of a cable management system, improving the workplace safety.

Q 18. Describe a time you identified a safety hazard that wasn’t immediately obvious.

In a previous role, we had a seemingly innocuous issue: employees frequently used their personal cell phones while operating machinery. While seemingly minor, this posed a significant safety risk by distracting operators and potentially causing accidents. It wasn’t immediately obvious as it wasn’t a blatant hazard like exposed wires or malfunctioning equipment.

I identified this hazard through observation, noticing a pattern of phone usage during critical machine operations. To address this, I implemented a policy prohibiting phone use during machine operation, coupled with awareness campaigns and regular reminders. We also provided designated break areas where employees could safely use their phones, reducing the temptation to use them while working.

Q 19. How do you stay up-to-date on safety regulations and best practices?

Staying current on safety regulations and best practices is paramount. I utilize several methods:

- Professional Organizations: I am an active member of relevant professional organizations like [mention relevant organizations, e.g., OSHA, relevant industry bodies], which provide access to up-to-date information, publications, and networking opportunities.

- Industry Publications and Journals: I regularly read industry publications and journals focusing on safety trends and new regulations.

- Government Websites: I frequently check government websites (OSHA, etc.) for updates on regulations and guidance.

- Training Courses and Webinars: I actively participate in continuing education courses and webinars focused on safety best practices and emerging hazards.

- Networking: I actively network with other safety professionals to share insights and knowledge.

Q 20. How do you involve workers in safety programs?

Worker involvement is crucial for a successful safety program. I use these strategies:

- Safety Committees: Establishing safety committees with worker representatives ensures their voices are heard and their concerns are addressed. This fosters a sense of ownership and responsibility.

- Safety Suggestions Programs: Implementing a formal system for workers to submit safety suggestions encourages proactive hazard identification and problem-solving. Recognition and rewards for valuable suggestions encourage participation.

- Regular Safety Meetings: Conducting regular meetings allows for open communication, updates on safety initiatives, and discussions of safety concerns. This keeps safety at the forefront and fosters a culture of open communication.

- Near Miss Reporting: Encouraging the reporting of near misses allows us to identify potential hazards before they result in accidents, emphasizing a proactive safety culture.

- Training and Education: Involving workers in the development and delivery of safety training programs helps to ensure that the training is relevant and effective.

For example, our safety committee recently suggested an improvement to our hand protection protocols which was implemented leading to a reduction in minor hand injuries.

Q 21. Describe your experience with lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization of equipment during maintenance or repair, safeguarding workers from serious injury or death. My experience includes developing, implementing, and enforcing LOTO programs that meet regulatory requirements.

- Training: I provide comprehensive LOTO training to all relevant personnel, covering the procedures, the importance of proper lockout/tagout, and the potential consequences of failure. Training includes both theoretical knowledge and hands-on practice.

- Procedure Development: I develop clear, concise, and easy-to-follow LOTO procedures tailored to the specific equipment in our workplace. These procedures are documented and readily accessible to all authorized personnel.

- Compliance Monitoring: I regularly monitor compliance with LOTO procedures through inspections, audits, and observations. Any deviations from procedures are immediately addressed.

- Equipment and Supplies: I ensure adequate provision and maintenance of lockout/tagout devices, including locks, tags, and other necessary equipment.

- Regular Audits: I conduct regular audits of the LOTO program to identify areas for improvement and ensure that it remains effective and compliant with all regulations.

Example of a LOTO procedure step: 1. Turn off the power source. 2. Lock out the power source using a designated lockout device. 3. Verify the power is off using a test instrument.

Q 22. How do you assess the effectiveness of safety programs?

Assessing the effectiveness of a safety program is crucial for ensuring a safe work environment. It involves a multi-faceted approach, going beyond simply looking at accident statistics. I typically employ a combination of leading and lagging indicators.

Lagging Indicators: These are reactive measures, looking at what has already happened. Examples include the number of accidents, injuries, illnesses, and lost-time incidents. Analyzing trends in these metrics over time provides insights into the program’s effectiveness in preventing incidents. A decreasing trend is positive, while an increase warrants immediate attention and investigation.

Leading Indicators: These are proactive measures that predict future performance. They focus on identifying potential hazards before incidents occur. Examples include the number of safety observations, near misses reported, safety training hours completed, and the implementation of corrective actions from audits. Regular monitoring of leading indicators helps us identify areas needing improvement before accidents occur.

Beyond Metrics: I also consider qualitative aspects, such as employee satisfaction with safety procedures, participation in safety initiatives, and the overall safety culture within the organization. Regular safety audits, employee feedback mechanisms (surveys, focus groups), and management commitment are all vital in evaluating program efficacy.

Example: In a previous role, we implemented a new safety training program focused on ergonomic practices. We tracked both the number of musculoskeletal injuries (lagging indicator) and the completion rate of the training (leading indicator). The reduction in injuries alongside a high training completion rate demonstrated the program’s success.

Q 23. What is your experience with near miss reporting and investigation?

Near miss reporting and investigation are fundamental to proactive safety management. A near miss is an incident that could have resulted in injury or damage but didn’t, often due to chance or luck. These events are invaluable learning opportunities, allowing us to identify and address latent hazards before they cause accidents.

My experience involves establishing a robust near miss reporting system, encouraging open communication and eliminating fear of retribution for reporting. I typically use a simple, user-friendly form accessible to all employees, both online and offline. Once reported, a thorough investigation follows. This isn’t simply about assigning blame; it’s about understanding the underlying causes and implementing corrective actions to prevent recurrence.

The investigation process generally involves:

- Fact-finding: Gathering information from witnesses, reviewing documentation, and examining the site of the near miss.

- Root cause analysis: Identifying the underlying factors that contributed to the near miss, using tools like the ‘5 Whys’ technique.

- Corrective action planning: Developing and implementing actions to eliminate or mitigate the identified hazards. This may include engineering controls, administrative controls, or training modifications.

- Follow-up: Verifying the effectiveness of the corrective actions and monitoring for recurrence.

Example: In a previous role, a near miss involved a forklift almost colliding with a pedestrian. The investigation revealed poor visibility at a blind corner. The solution was to install mirrors to improve visibility, coupled with enhanced training on pedestrian safety and forklift operation in confined spaces.

Q 24. What are your experience using safety data sheets (SDS)?

Safety Data Sheets (SDS), formerly known as Material Safety Data Sheets (MSDS), are crucial documents that provide comprehensive information on the hazards associated with a particular chemical or substance. My experience includes using SDSs to understand the risks associated with various chemicals in different workplaces, ensuring safe handling, storage, and disposal.

I’m proficient in interpreting SDS information, specifically identifying:

- Hazardous ingredients: Knowing the specific chemicals and their potential health effects.

- Physical and health hazards: Understanding the risks of fire, explosion, toxicity, carcinogenicity, etc.

- First aid measures: Knowing the appropriate responses in case of exposure.

- Protective measures: Determining the necessary personal protective equipment (PPE) and engineering controls.

- Disposal procedures: Understanding the safe methods for disposing of the substance.

I ensure SDSs are readily available and accessible to all employees who handle the relevant chemicals. I also conduct regular training on how to interpret and use SDS information. This ensures that employees understand the hazards they are working with and take the necessary precautions to minimize risks.

Example: When working with a particular solvent, I would consult its SDS to determine the appropriate respirator type needed, the correct ventilation requirements, and the designated storage area to ensure the safe handling of the solvent. This was crucial to protect the employees’ health and prevent potential incidents.

Q 25. How do you manage safety risks in a remote or geographically dispersed workforce?

Managing safety risks in a geographically dispersed workforce presents unique challenges, but with a strategic approach, it’s very manageable. It relies heavily on technology and effective communication.

My strategy involves:

- Robust communication systems: Using digital platforms like instant messaging apps, video conferencing, and online training portals to maintain consistent communication about safety procedures, updates, and emergency protocols.

- Remote training and monitoring: Implementing online safety training modules, and using virtual tools for remote safety audits and inspections. I also leverage digital technologies to track employee training completions and monitor the effectiveness of safety interventions.

- Standardized safety procedures: Establishing clear and consistent safety procedures that are applied consistently across all locations, irrespective of geographic distance. This ensures a uniform level of safety across the entire workforce.

- Effective incident reporting system: Implementing a system where employees can easily report incidents, near misses, and hazards from anywhere, using online platforms or mobile apps. Timely investigation and appropriate responses are critical, no matter the location.

- Local safety representatives: Engaging local personnel as safety representatives in each location to assist with implementing safety protocols and addressing location-specific hazards. This provides a more localized and responsive safety framework.

Example: In a previous role with a global workforce, we used a cloud-based system to deliver consistent safety training, track incident reporting, and conduct virtual safety audits. This ensured that all remote employees received the same level of safety training and support, regardless of their location.

Q 26. How do you deal with employees who refuse to follow safety procedures?

Dealing with employees who refuse to follow safety procedures requires a multi-pronged approach focusing on understanding the root cause of the non-compliance, and not simply punishment.

My approach starts with:

- Open Communication and Understanding: I start by engaging the employee in a private conversation to understand the reasons behind their refusal. Are they unclear about the procedures? Do they feel the procedures are cumbersome or impractical? Do they have safety concerns that haven’t been addressed? Addressing these underlying issues is key.

- Retraining and Clarification: If the refusal stems from a lack of understanding, I provide additional training and clarification. I ensure that the employee understands the rationale behind each procedure and the potential consequences of non-compliance.

- Addressing Underlying Concerns: If the refusal is due to genuine safety concerns, I work to address those concerns through collaborative problem-solving. This may involve making changes to the procedures or providing additional PPE.

- Disciplinary Actions (as a last resort): If the refusal continues despite reasonable efforts to address the underlying issues, progressive disciplinary actions may be necessary, adhering strictly to company policy and labor laws. Documentation of all interactions is crucial.

Example: I once encountered an employee who consistently bypassed a safety guard on a machine, claiming it slowed down their work. Instead of immediate punishment, I discussed their concerns, demonstrated the critical safety function of the guard, and collaboratively explored ways to improve their workflow without compromising safety.

Q 27. Explain your understanding of emergency preparedness planning and response.

Emergency preparedness planning and response are crucial aspects of any robust safety program. It involves anticipating potential emergencies, developing plans to mitigate their impact, and ensuring effective response procedures. My understanding encompasses a comprehensive approach.

Planning: This involves identifying potential hazards (fires, floods, earthquakes, chemical spills, etc.), assessing their likelihood and potential impact, and developing specific emergency response plans tailored to each hazard. These plans should outline:

- Emergency response teams: Defining roles and responsibilities of individuals within the response team.

- Evacuation procedures: Establishing clear and well-rehearsed evacuation routes and assembly points.

- Communication systems: Designating methods for communicating alerts and instructions during emergencies.

- Emergency supplies and equipment: Ensuring adequate supplies of first aid, fire extinguishers, and other necessary equipment.

Response: This involves executing the plans during an actual emergency, following established protocols, and coordinating the efforts of the emergency response teams. Post-emergency procedures are also crucial, including damage assessment, rescue and recovery efforts, and post-incident investigations to learn from the experience and improve future preparedness.

Drills and Exercises: Regularly conducting drills and exercises help ensure that emergency plans are effective and that employees are adequately trained to respond. These should be realistic and test the effectiveness of the entire system.

Example: In a previous role, I developed and implemented comprehensive emergency plans for various scenarios, including fire emergencies, chemical spills, and severe weather events. We conducted regular drills and simulations, which identified weaknesses in our plan and led to improvements in communication and evacuation procedures.

Q 28. Describe your experience working with regulatory bodies on safety-related matters.

Working with regulatory bodies on safety-related matters is crucial for compliance and maintaining a safe workplace. My experience includes interacting with various agencies, understanding their regulations, and ensuring complete compliance. This involves:

- Staying informed about regulations: Keeping abreast of changes and updates to relevant safety legislation, standards, and guidelines.

- Conducting regular safety inspections: Ensuring the workplace meets the required safety standards and conducting self-audits to identify potential non-compliances before inspections.

- Maintaining accurate records: Keeping meticulous records of safety training, inspections, incident reports, and corrective actions.

- Communicating with regulatory agencies: Responding promptly and professionally to requests for information, cooperating with inspections, and addressing any identified non-compliances.

- Implementing corrective actions: Taking prompt action to address any violations or deficiencies identified by regulatory bodies, and providing evidence to demonstrate compliance.

Example: In a past role, we worked closely with OSHA (Occupational Safety and Health Administration) during an inspection. Our meticulous record-keeping and proactive approach to safety management resulted in a successful inspection with no citations. This demonstrated our commitment to safety and compliance.

Key Topics to Learn for Identifying and Avoiding Hazards Interview

- Hazard Recognition: Understanding the different types of hazards (physical, chemical, biological, ergonomic, psychosocial) and their potential consequences. Learn to differentiate between inherent and created hazards.

- Risk Assessment Techniques: Mastering methods for evaluating the likelihood and severity of hazards, including qualitative and quantitative risk assessment approaches. Practice applying these methods to real-world scenarios.

- Control Measures: Familiarize yourself with the hierarchy of hazard controls (elimination, substitution, engineering controls, administrative controls, PPE). Be prepared to discuss the effectiveness and limitations of each.

- Incident Investigation and Reporting: Understand the process of investigating incidents, identifying root causes, and implementing corrective actions to prevent recurrence. Know the importance of accurate and timely reporting.

- Legislation and Compliance: Demonstrate awareness of relevant health and safety legislation and regulations applicable to your industry. Be prepared to discuss your understanding of compliance requirements.

- Communication and Teamwork: Highlight your ability to effectively communicate hazards and risks to others, and to work collaboratively to implement safety measures.

- Emergency Response Procedures: Understand emergency procedures, including evacuation plans, first aid, and reporting mechanisms. Be prepared to discuss your experience and training in emergency response.

- Personal Protective Equipment (PPE): Demonstrate knowledge of various types of PPE and their appropriate selection and use. Be able to discuss the limitations of PPE and the importance of other control measures.

Next Steps

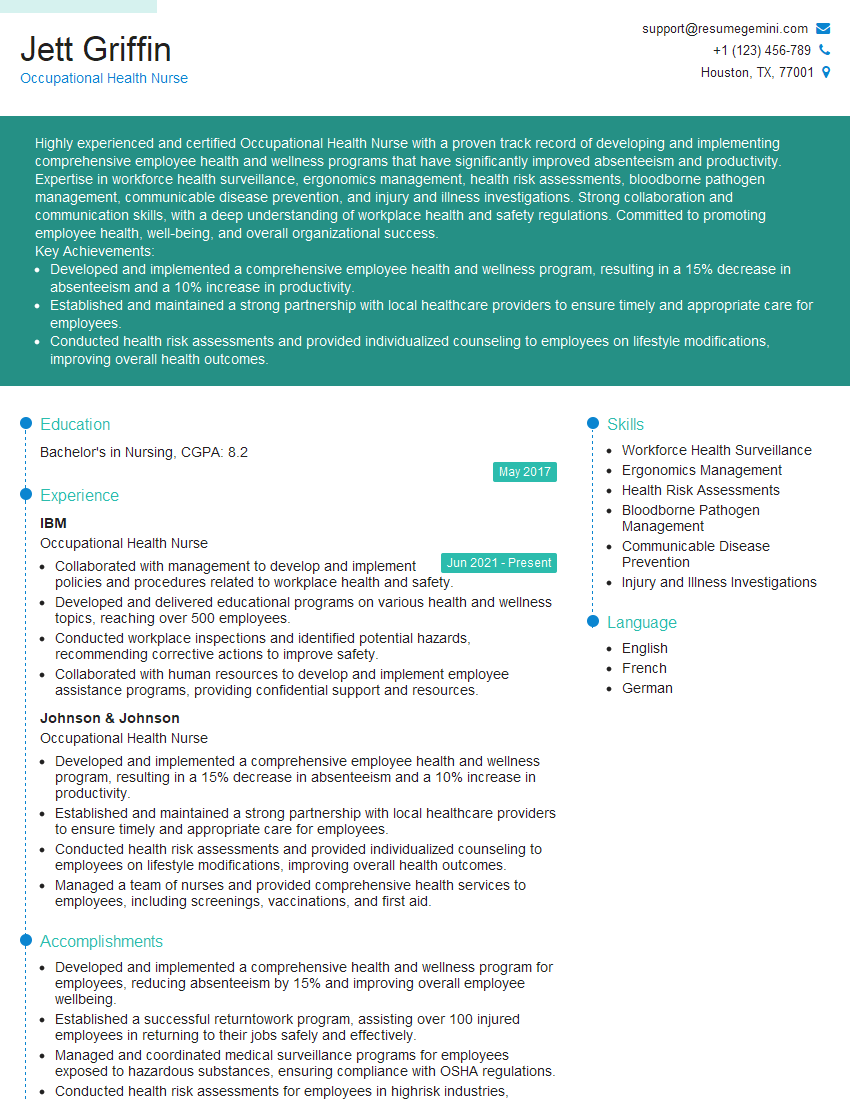

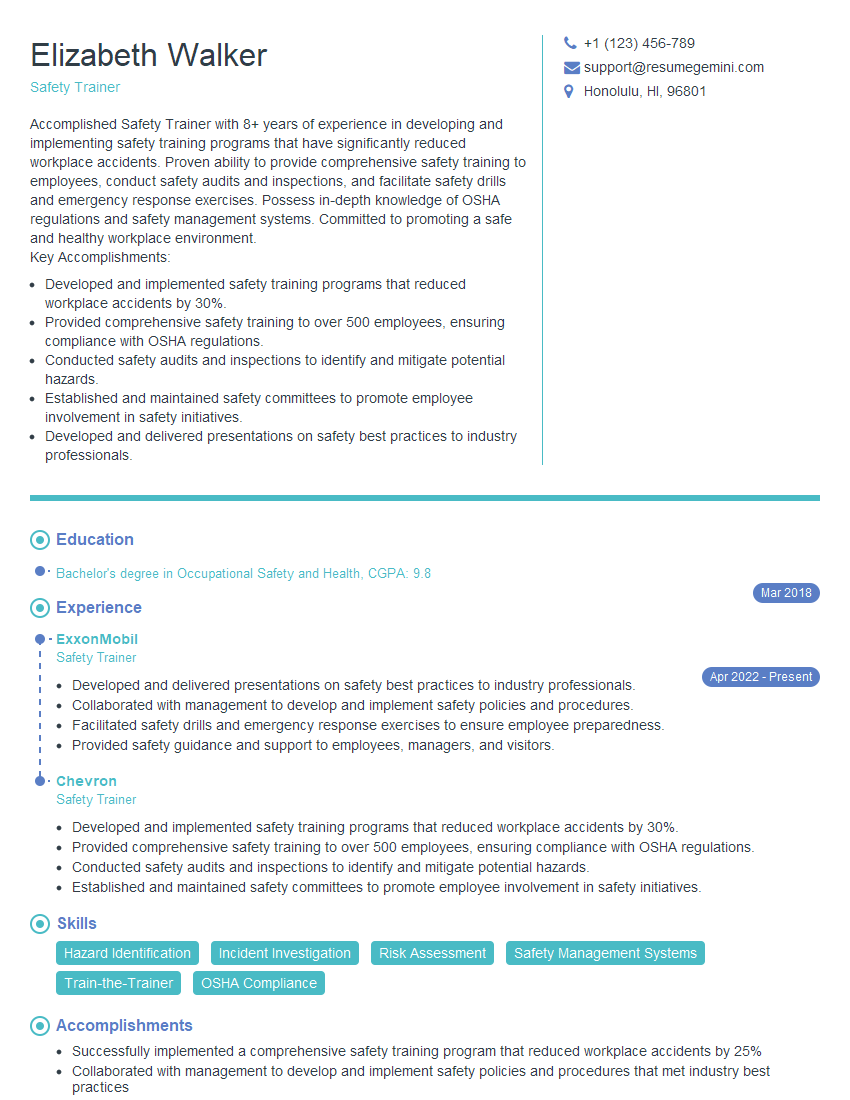

Mastering the art of identifying and avoiding hazards is crucial for career advancement in almost any field. It demonstrates your commitment to safety, a highly valued attribute by employers. To maximize your job prospects, focus on crafting an ATS-friendly resume that clearly highlights your skills and experience in this area. ResumeGemini can be a trusted resource to help you build a professional and impactful resume that showcases your expertise. Examples of resumes tailored to “Identifying and Avoiding Hazards” roles are provided to help guide your creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good