The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Derrick Operations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Derrick Operations Interview

Q 1. Describe the different types of derricks used in drilling operations.

Derricks are crucial for oil and gas drilling, providing the structure for hoisting and lowering the drilling string. Several types exist, each suited to different needs and well conditions.

- Mast Derrick: The most common type, characterized by a simple, triangular, or square wooden or steel structure. They’re relatively easy to assemble and disassemble, making them suitable for land-based operations with moderate drilling depths.

- Substructure Derrick: This design utilizes a steel substructure for added strength and stability, especially beneficial in challenging terrains or deeper drilling scenarios. They’re more robust and often used for offshore or demanding onshore operations.

- Guyed Mast: These derricks use guy wires to support the mast, making them lightweight and portable. Primarily used for smaller drilling rigs and shallow wells.

- Mobile Derrick: Mounted on a trailer or self-propelled unit, this design offers ease of transport and setup, ideal for moving between locations quickly.

The choice depends on factors like well depth, terrain, drilling budget, and accessibility.

Q 2. Explain the process of assembling and disassembling a derrick.

Assembling and disassembling a derrick is a complex, multi-step process requiring skilled personnel and adherence to strict safety protocols. The process is largely similar across derrick types, but specific details vary.

Assembly: This typically starts with the foundation, followed by the erection of the derrick legs, the main mast or structure, the crown block, traveling block, and finally, the hoisting system. Each component is meticulously inspected and secured to ensure structural integrity. Detailed engineering drawings and assembly manuals are strictly followed. Heavy lifting equipment like cranes is usually employed.

Disassembly: This is the reverse of assembly, starting with the removal of the hoisting system and other components, followed by the careful dismantling of the derrick structure, ensuring that each section is properly secured and lowered to the ground. Safety is paramount, with rigorous checks at each stage.

Think of it like building a giant, incredibly strong LEGO structure: each piece must be placed correctly, securely fastened, and then carefully removed in reverse order.

Q 3. What are the safety procedures for working on a derrick?

Safety on a derrick is paramount. A single mistake can lead to severe injury or fatality. Key safety procedures include:

- Rigorous Pre-use Inspections: Every component, from the derrick legs to the hoisting system, is meticulously inspected before each operation. This includes checking for any signs of wear, damage, or loose connections.

- Lockout/Tagout Procedures: Before any maintenance or repair work, the power to the hoisting system is completely isolated and locked out, preventing accidental activation.

- Personal Protective Equipment (PPE): All personnel must wear appropriate PPE, including hard hats, safety glasses, safety shoes, and fall protection harnesses.

- Trained Personnel: Only qualified and trained personnel are allowed to work on derricks. They must be familiar with all safety procedures and emergency response plans.

- Regular Maintenance: Scheduled maintenance is crucial to prevent failures and ensure the derrick is in good working order.

- Emergency Response Plan: A well-defined plan should be in place to address potential emergencies, including procedures for evacuations and rescue operations.

Safety briefings and regular training are crucial to instill a strong safety culture.

Q 4. How do you ensure the proper functioning of the crown block and traveling block?

The crown block and traveling block are critical components of the hoisting system. Their proper functioning is essential for safe and efficient drilling operations.

Crown Block: This is the stationary sheave assembly at the top of the derrick. Regular lubrication and inspection for wear and tear on the sheaves and pins are vital. Proper alignment is crucial to prevent uneven wear and rope damage. We check for any signs of cracking or deformation.

Traveling Block: This movable sheave assembly is suspended from the crown block and travels up and down the derrick. Its proper operation relies on smooth movement, which is checked through lubrication of sheaves and pins. We inspect the shackle pins and all connections for wear and damage.

Regular inspections and lubrication, along with prompt replacement of worn components, are essential to maintain the efficiency and safety of these crucial elements.

Q 5. What are the common causes of derrick failures, and how can they be prevented?

Derrick failures can have catastrophic consequences. Common causes include:

- Material Fatigue: Prolonged stress and cyclic loading can lead to metal fatigue, weakening the derrick structure and increasing the risk of failure. Regular inspections and appropriate maintenance schedules are key.

- Corrosion: Exposure to harsh environmental conditions (such as saltwater or acidic environments) can cause corrosion, compromising the structural integrity of the derrick. Protective coatings and regular inspections can mitigate this.

- Improper Assembly or Maintenance: Errors during assembly or inadequate maintenance can create weak points in the structure, leading to failure. Strict adherence to procedures and thorough inspections are crucial.

- Overloading: Exceeding the derrick’s weight capacity can cause structural failure. Always adhere to the derrick’s rated capacity.

- Environmental Factors: Severe weather events (such as high winds or earthquakes) can also damage the derrick.

Preventive measures involve regular inspections, adhering to maintenance schedules, using high-quality materials, and ensuring proper training for personnel.

Q 6. Explain the role of the derrick hand in a drilling operation.

The derrick hand is a key member of the drilling crew, responsible for the safe and efficient operation of the derrick. Their duties include:

- Operating the hoisting system: This involves raising and lowering the drilling string under the instructions of the driller.

- Managing the drilling line: Ensuring the proper handling and maintenance of the drilling line to prevent tangling or damage.

- Assisting with derrick maintenance: Performing routine inspections and maintenance tasks, such as lubrication of sheaves and pins.

- Maintaining a clean and organized workspace: A clean and organized workspace minimizes risks and improves efficiency.

- Adhering to all safety procedures: This is crucial for the safety of themselves and their co-workers.

The derrick hand plays a crucial role in ensuring smooth and safe drilling operations. Their expertise and vigilance are crucial for the success and safety of the entire operation.

Q 7. Describe your experience with different types of hoisting equipment used on a derrick.

My experience includes working with various hoisting equipment, each with its unique characteristics and applications:

- Top Drives: These provide precise control over the drilling string, enhancing efficiency and safety, especially in challenging drilling conditions. I’ve worked extensively with various top drive models, understanding their operational nuances and maintenance requirements.

- Drawworks: These are the heart of the hoisting system, responsible for controlling the speed and tension on the drilling line. My experience includes troubleshooting issues, performing routine maintenance, and ensuring optimal performance. I’m familiar with different drawwork configurations and their applications.

- Crown and Traveling Blocks: I’m proficient in selecting the right sheaves for specific applications, understanding load distribution principles, and ensuring proper lubrication and maintenance to avoid failures. I understand the critical safety considerations when working with these components.

- Hydraulic and Electric Hoisting Systems: I’ve worked with both hydraulic and electric hoisting systems, troubleshooting malfunctions and understanding the safety implications of both types. I am proficient in their operation and maintenance procedures.

I’m comfortable working with a range of hoisting systems, understanding their limitations and strengths, and ensuring they are used safely and efficiently.

Q 8. How do you maintain the derrick’s structural integrity during operations?

Maintaining a derrick’s structural integrity is paramount for safety and operational efficiency. It’s a multi-faceted process that begins long before the first operation. We start with rigorous pre-operational inspections (detailed in answer 3) to identify any potential weaknesses. During operation, we adhere strictly to the derrick’s weight and load limits (discussed in answer 2), avoiding overloading. Regular maintenance, including lubrication of moving parts and timely repairs of any identified damage, is crucial. Furthermore, we monitor environmental factors like wind speed and direction, adjusting operations as necessary to mitigate risks. Think of it like maintaining a bridge – regular inspections, load limits, and timely repairs are vital to prevent catastrophic failure.

Beyond routine maintenance, we employ advanced techniques like Finite Element Analysis (FEA) for complex situations. FEA helps predict stress points and structural behavior under various load conditions, allowing for proactive adjustments and reinforcement. This ensures the derrick remains structurally sound even under demanding drilling conditions.

Q 9. What are the weight limits and load capacity of the derrick you have experience with?

The derricks I’ve worked with typically have varying weight and load capacities depending on the specific model and configuration. For instance, I’ve worked extensively with a 2,000-ton capacity derrick, capable of handling loads up to that weight. However, the safe working load (SWL) is always less than the maximum capacity and is crucial to adhere to. This SWL is usually clearly marked on the derrick itself, along with other critical information. The weight limits are also dynamically affected by factors like the wind speed and the type of load being handled. We always factor in these variables, employing load charts and calculations to ensure the safety of personnel and equipment.

For example, lifting a heavy drill string requires careful calculation, accounting for the weight of the string, the weight of the hook, and any additional equipment. We might have to use a lighter-weight drilling mud if the overall weight is approaching the SWL of the derrick to avoid exceeding the maximum allowable load.

Q 10. How do you perform a pre-operational inspection of a derrick?

A pre-operational inspection of a derrick is a meticulous process that follows a standardized checklist. We begin with a visual inspection, checking for any visible damage like cracks, corrosion, or loose bolts on the derrick’s structure, including the mast, substructure, crown block, and all related components. We then verify the proper functioning of all mechanical components such as the hoisting system, brakes, and the safety mechanisms (e.g., emergency brakes, load indicators). We pay close attention to the condition of the wire ropes, checking for wear and tear and ensuring they meet the minimum diameter requirements for safe operations. The condition of sheaves and drums are also checked for wear or damage.

Following the visual inspection, we might employ non-destructive testing (NDT) methods, such as ultrasonic testing (UT), to detect subsurface flaws in critical structural elements if there’s any concern. All findings are meticulously documented and any defects are addressed before commencing operations. Think of it like a thorough pre-flight check for an airplane; it’s crucial for preventing accidents and ensuring smooth operations. Failing to carry out a proper inspection could lead to catastrophic failures.

Q 11. What are the emergency procedures for a derrick malfunction?

Emergency procedures for derrick malfunctions are strictly defined and practiced regularly. The initial response involves immediately stopping all hoisting and lowering operations. We then conduct a rapid assessment of the situation to identify the root cause of the malfunction. This is critical for determining the appropriate course of action. All personnel are evacuated from the danger zone as a top priority. Once the immediate danger has been mitigated, we proceed to a more thorough investigation, documenting all details of the incident.

Depending on the nature of the malfunction, we might initiate emergency repairs or contact specialized support teams. Emergency communication procedures, including alerting relevant personnel and regulatory authorities, are crucial in these scenarios. Regular drills and simulations are essential for ensuring all personnel are well-versed in the emergency procedures. Each member of the team plays a specific role, similar to a well-coordinated orchestra, to ensure a safe and efficient response. For instance, one person might be in charge of communication while others may focus on securing the equipment.

Q 12. Explain the process of managing the hoisting and lowering operations of the drilling string.

Managing hoisting and lowering operations of the drilling string is a delicate balancing act between speed and safety. It involves a coordinated effort between the driller, the derrick hand, and other crew members. The process typically begins with a careful planning phase, where the weight of the string, the type of drilling fluid, and anticipated speed are factored into the operation. The driller monitors the load indicators and makes adjustments to the hoisting speed as needed. The derrick hand monitors the movement of the drilling string, ensuring it runs smoothly and remains within the safe working limits.

During hoisting, we maintain a steady, controlled pace, ensuring that the load is evenly distributed on all components. Lowering operations require even more caution, as uncontrolled descent can lead to serious incidents. We use the derrick’s braking system to control the descent speed and prevent sudden drops. Communication throughout the process is critical, with continuous verbal confirmations between team members to ensure everyone is aware of the ongoing operation and any potential issues. Furthermore, we utilize various equipment like slip-jaw tongs and elevators to ensure a safe and secure connection between the derrick and the drill string, reducing the risk of slippage or detachment.

Q 13. How do you handle different types of drilling fluids during derrick operations?

Handling different types of drilling fluids during derrick operations requires careful consideration of their properties. Drilling muds vary significantly in density, viscosity, and chemical composition. These properties impact the overall weight and the pressure exerted on the derrick and drilling string. Heavier muds can increase the load on the derrick, necessitating careful attention to weight limits. The handling also involves making sure the equipment is compatible with the chemicals present in the fluid to prevent corrosion or other damage.

For example, water-based muds are common and relatively straightforward, but oil-based muds require specialized equipment to prevent contamination. We use different types of pumps and mud tanks optimized for the specific mud type. We also need to follow safety procedures for handling any hazardous components in the mud. Regular monitoring of the mud properties is crucial to ensure optimal drilling performance and to prevent any issues with the derrick or the entire drilling process.

Q 14. Describe your experience with various types of derrick components and their functions.

My experience encompasses a wide range of derrick components. I’m familiar with the structural components like the mast, substructure, and crown block, understanding their roles in supporting the load and providing stability. I’m also well-versed in the operating systems, including the hoisting system with its drums, sheaves, and wire ropes. I understand the importance of the braking systems, both main and emergency brakes, and their role in ensuring controlled movements of the drilling string. Safety devices like the safety hooks, load indicators, and weight indicators are critical elements I’m deeply familiar with.

Beyond the main components, I have experience with various ancillary equipment, such as mud pumps, drawworks, and top drives. Understanding the interplay between these components and the derrick is crucial for safe and efficient operations. For instance, the interaction between the top drive’s torque and the derrick’s load capacity necessitates careful consideration during high-torque operations such as tripping operations. This comprehensive understanding ensures I can effectively identify, troubleshoot, and resolve issues related to any component within the entire derrick system.

Q 15. How do you identify and report potential hazards related to derrick operations?

Identifying and reporting potential hazards in derrick operations is paramount to ensuring safety. My approach involves a multi-faceted strategy, beginning with a thorough pre-operation inspection. This includes visually checking all components for wear and tear, loose bolts, hydraulic leaks, and proper functioning of safety mechanisms like brakes and locking pins. I also assess the environmental conditions, looking for things like high winds, unstable ground, or proximity to power lines.

Beyond the visual inspection, I rely on established checklists and standardized procedures. These checklists cover every aspect of the derrick, from the crown block to the foundation. Any deviation from the norm or any observation that raises concern is immediately documented. For example, if I notice unusual wear on a wire rope, I’d immediately report it and recommend its replacement to prevent a potential catastrophic failure.

Reporting is done through established channels, usually starting with my immediate supervisor, followed by formal reporting systems, depending on the severity of the hazard. Minor issues might be resolved at the crew level with corrective actions logged, while more serious concerns necessitate immediate work stoppage and a detailed report to safety management, potentially triggering a formal investigation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of communication and teamwork during derrick operations.

Communication and teamwork are absolutely critical during derrick operations; they are the cornerstones of safety and efficiency. Imagine a symphony orchestra: each musician plays their part, but without precise coordination and communication, the performance is chaotic and ineffective. Derrick operations are similar; each crew member has a specific role – the derrick hand, the hooker, the signaler – and clear, concise communication is essential.

We use standardized hand signals, two-way radios, and pre-job briefings to ensure everyone is on the same page. Pre-job briefings allow us to identify potential hazards, discuss specific tasks, and assign roles and responsibilities. During the operation, clear communication prevents accidents. For instance, a simple miscommunication about the weight of the load can lead to overloading and catastrophic failure. Hand signals are crucial for confirming that everyone understands the instructions before starting a lift. I always emphasize open communication; any doubt or concern voiced by a crew member is taken seriously and addressed immediately. A strong team relies on mutual trust and respect, fostered by clear communication.

Q 17. Describe your experience with troubleshooting derrick problems.

My experience with troubleshooting derrick problems is extensive. I’ve encountered various issues, ranging from hydraulic leaks and malfunctioning brakes to problems with the hoisting mechanism. My approach is methodical and systematic. I begin with a thorough inspection of the system, visually checking for obvious problems. Then, I consult the derrick’s operating manual, using the troubleshooting sections to diagnose the issue.

For example, if the hoisting mechanism is malfunctioning, I would first check the power supply, then the hydraulic system for leaks or pressure issues. I might utilize diagnostic tools, like pressure gauges or electrical meters, to pinpoint the problem. It’s important to identify the root cause, not just the symptom. Simply patching a hydraulic leak without addressing the underlying cause could lead to a recurrence. Once the problem is identified, I coordinate with the maintenance crew for repairs, ensuring the repairs are carried out according to the manufacturer’s guidelines and all safety precautions are taken. Throughout this process, thorough documentation is crucial for future reference and record-keeping.

Q 18. How do you ensure the safe handling of heavy equipment and materials on the derrick?

Safe handling of heavy equipment and materials is paramount. We employ several safety measures, including using appropriate rigging techniques and equipment, ensuring proper load calculations, and adhering to weight limits. Before any lift, the weight of the load is accurately determined and compared against the derrick’s capacity. We use load charts and certified scales to avoid overloading.

Rigging is crucial; we meticulously inspect all slings, shackles, and hooks before use, ensuring they are free from damage and properly rated for the load. We follow strict procedures for attaching the load, using multiple points of contact when necessary to ensure stability. The derrick crew operates under a strict system of hand signals and verbal communication to coordinate each movement during lifting, lowering, and placement of materials. Furthermore, the area around the derrick is kept clear of personnel and obstacles to prevent accidents. Finally, the use of personal protective equipment (PPE) is mandatory, and this includes safety helmets, safety shoes, and high-visibility clothing.

Q 19. What are the regulatory compliance requirements for derrick operations in your region?

Regulatory compliance for derrick operations varies by region, but generally involves adherence to national and local safety standards. In my region, we must comply with [Insert relevant regional/national safety regulations, e.g., OSHA, API, etc.]. These regulations cover aspects such as derrick inspection and maintenance schedules, operator qualifications, load capacity limitations, and emergency response procedures.

We maintain detailed records of all inspections, maintenance activities, and operational logs. These records are subject to regular audits by regulatory bodies. Compliance is not just a matter of following rules; it’s a commitment to safety. We conduct regular training sessions to ensure our crew is up-to-date on all regulations and best practices. Non-compliance can lead to hefty fines, operational shutdowns, and, most importantly, potential injury or loss of life. Therefore, a proactive approach to compliance is crucial.

Q 20. How do you maintain accurate records of derrick operations and maintenance?

Maintaining accurate records is crucial for safety, maintenance, and regulatory compliance. We use a combination of digital and physical records. All inspections, maintenance, and operational data are meticulously documented using standardized forms and software designed specifically for derrick operations.

These records include pre-operation checklists, operational logs detailing the date, time, load weight, crew members involved, and any incidents or near misses. Maintenance records detail all repairs, inspections, and component replacements, including dates, parts used, and the technician’s signature. Digital records allow for easier retrieval and analysis of data, contributing to better maintenance scheduling and safety analysis. Physical records are archived for long-term storage. This comprehensive record-keeping allows us to track equipment performance, identify potential problems early on, and demonstrate compliance to regulatory authorities.

Q 21. Explain the process of securing the derrick during inclement weather.

Securing the derrick during inclement weather is vital to prevent damage and accidents. Our procedure begins with assessing the weather forecast and identifying potential risks. High winds are the major concern; strong winds can cause the derrick to sway excessively, resulting in damage or even collapse.

Our response depends on the severity of the weather. For mild conditions like light rain, we might simply cover exposed components to protect them from the elements. For more severe conditions, including high winds or heavy rain, we lower the derrick to its lowest position, secure all moving parts using locking mechanisms, and firmly anchor the base to prevent movement. In extreme cases, we might need to completely dismantle the derrick and store it in a protected location until the weather improves. The decision to secure or dismantle the derrick is always made based on a careful risk assessment considering weather conditions and structural integrity. Safety is always our top priority.

Q 22. What are the procedures for handling a stuck pipe situation involving the derrick?

A stuck pipe situation is a serious incident in drilling operations, potentially leading to significant delays and financial losses. The initial response requires a calm and methodical approach. We first attempt to free the pipe using various techniques, starting with the least invasive. This might involve applying weight, rotating the pipe slowly, or circulating drilling fluid to lubricate and clear the obstruction. If these methods fail, we’ll carefully analyze the situation using downhole tools like a wireline logging tool to assess the problem’s nature and location.

The derrick plays a crucial role here. Its stability and load-bearing capacity are vital for applying the necessary force during freeing operations. We’ll use the derrick’s crown block and traveling block systems to carefully apply weight and rotation. Safety is paramount. Throughout the process, we’ll continuously monitor the derrick’s structure, ensuring it can handle the load. If the situation deteriorates or we’re unsure of the best approach, we’ll immediately consult with senior drilling engineers and potentially specialized well intervention companies. We might need to use specialized equipment like a jar or fishing tools deployed from the derrick to retrieve the stuck pipe or cut and remove it. Documentation is crucial for investigating why the pipe became stuck and implementing preventative measures in the future.

- Initial Attempts: Weight application, rotation, fluid circulation

- Diagnostic Tools: Wireline logging

- Heavy Lifting: Derrick’s crown block and traveling block system

- Specialized Tools: Jars, fishing tools

- Safety Procedures: Continuous monitoring, expert consultation

Q 23. How do you contribute to a safe working environment on the derrick?

Contributing to a safe working environment on the derrick involves a multi-faceted approach, emphasizing both proactive measures and reactive responses to potential hazards. It starts with meticulous adherence to safety procedures and regulations. This includes regular inspections of equipment, including the derrick itself, the crown block, the hoisting system, and all associated components. We look for any signs of wear and tear, damage, or potential malfunction. Before any operation, we conduct thorough pre-job risk assessments, identifying potential hazards and implementing mitigation strategies. This is where teamwork is crucial. We communicate openly and effectively with colleagues, addressing concerns and clarifying instructions. We utilize proper Personal Protective Equipment (PPE), and ensure everyone understands and follows the established safety protocols.

Further, we promote a culture of safety where reporting near misses and incidents is actively encouraged, fostering a safe and collaborative work environment. I believe in leading by example; I always ensure my own actions adhere to the highest safety standards. My commitment extends beyond personal safety to actively identifying and reporting any unsafe conditions or practices, contributing to a consistently safe work environment for everyone on the rig.

Q 24. Describe your experience with different types of drilling rigs and their associated derricks.

My experience encompasses a variety of drilling rigs, from land-based jack-up rigs to offshore platform rigs. Each rig type presents unique challenges and operational considerations which necessitate adapting derrick operations. For example, on land-based rigs, the derrick’s setup and dismantling processes are simpler compared to the intricate procedures involved in an offshore platform or jack-up rig, where sea conditions significantly impact operations. I’ve worked with various derrick designs, including the standard mast derrick prevalent in onshore drilling and the more advanced derrick systems often found on high-capacity offshore rigs.

Specific examples of rigs include experience with conventional land-based rigs using a standard A-frame or mast derrick, as well as experience with jack-up rigs employing stronger, more robust derricks designed to withstand higher loads and more dynamic conditions at sea. I am familiar with the different hoisting systems, such as drawworks and top drives, and understand the nuances of coordinating their functions with the derrick’s mechanics. My experience also covers working with different derrick sizes, each tailored to accommodate varied drilling depths and wellbore sizes. Understanding the limitations and capacities of each derrick type is critical for safe and efficient drilling operations.

Q 25. Explain your knowledge of the different types of drilling methods and how they relate to derrick operations.

Drilling methods significantly influence derrick operations. For instance, rotary drilling, the most common method, requires the derrick to handle the weight of the drill string, which can reach thousands of tons. The derrick’s hoisting system plays a central role in rotating and raising/lowering the drill string during drilling and tripping operations. In directional drilling, used to reach targets offset from the rig location, the derrick must handle the additional weight and torque imposed by the downhole tools employed for directional control. The derrick is critical for precisely managing the direction and depth of the wellbore, requiring specialized equipment and intricate coordination.

Other methods, such as air drilling or mud drilling, present different demands. Air drilling, for instance, may need modifications to the derrick’s air handling systems, while mud drilling requires careful management of mud pressure to avoid derrick-related issues. The type of drilling fluid used will also affect maintenance needs on the derrick. My experience encompasses these variations, allowing me to adapt derrick operations effectively according to the chosen drilling method, always prioritizing safety and efficiency.

Q 26. How do you adapt to changing operational conditions during a drilling operation?

Adaptability is crucial in drilling operations, which are frequently impacted by unexpected events like weather changes, equipment malfunctions, or geological surprises. My approach is to remain flexible and proactive. When conditions change, we initiate a thorough reassessment of the situation. This involves collaborating with the drilling team and other relevant personnel to determine the best course of action. For example, if bad weather threatens to halt operations, we will prioritize securing the derrick and all equipment to prevent damage.

My experience in handling unexpected scenarios equips me with the ability to make quick and informed decisions. I prioritize safety and make sure that every change in the plan is communicated clearly to the team. I also keep a close eye on the overall efficiency of the operations, balancing the need to adapt with the need to avoid unnecessary delays. For instance, if a component malfunctions, we will use the downtime for planned maintenance, reducing future downtime. We document all changes and lessons learned for future reference and improvement.

Q 27. Describe your experience in planning and scheduling derrick-related tasks.

Derrick-related tasks require careful planning and scheduling to ensure smooth and efficient operations. My approach involves meticulous pre-planning, creating detailed schedules that account for various factors like rig move times, derrick erection and dismantling timelines, equipment availability, and personnel scheduling. This often includes creating Gantt charts or similar visual schedules that allow for easy tracking of progress and resource allocation. We use specialized software to optimize scheduling, minimizing downtime and maximizing the use of available resources.

I consider potential risks and develop contingency plans to address potential delays or unforeseen circumstances. My experience helps anticipate potential problems, integrating buffer times to handle unexpected events, thus minimizing operational disruptions. For example, we might schedule extra time for equipment maintenance or inspection to reduce the chances of delays caused by equipment failures. Post-operation analysis and feedback are key; I review completed schedules, comparing actual timelines with planned ones to identify areas for optimization in future projects.

Q 28. How do you ensure the efficiency and productivity of derrick operations?

Ensuring efficiency and productivity in derrick operations requires a combination of proactive planning, effective teamwork, and continuous improvement. First, we optimize the derrick’s utilization, minimizing non-productive time. This includes optimizing hoisting speeds, minimizing time spent on rigging and unrigging operations, and coordinating effectively with other rig functions to minimize wait times. We regularly review and update our operating procedures, identifying inefficiencies and areas for improvement through data analysis and feedback sessions. This may include streamlining workflows, improving equipment maintenance protocols, or implementing new technologies that enhance speed and reliability.

A critical element is the training and development of the team. A well-trained team understands the intricacies of derrick operations and works seamlessly together. Clear communication channels and a collaborative work environment are essential for maximizing productivity. We employ techniques like preventative maintenance, ensuring that regular inspection and maintenance activities prevent costly breakdowns and associated delays. Regular training and drills help ensure that the team is proficient in handling any emergency or unexpected situation. By constantly monitoring and analyzing key performance indicators (KPIs), such as rig-up/rig-down times and operational efficiency, we identify areas requiring improvement, continually enhancing efficiency and productivity.

Key Topics to Learn for Derrick Operations Interview

- Derrick Assembly and Disassembly: Understanding the procedures, safety protocols, and potential challenges involved in setting up and dismantling derricks.

- Rigging and Hoisting Techniques: Mastering safe and efficient load handling, including weight calculations, slinging methods, and communication protocols during lifting operations.

- Derrick Maintenance and Inspection: Familiarize yourself with routine maintenance tasks, recognizing potential wear and tear, and performing safety checks to ensure operational efficiency and prevent accidents.

- Hydraulic Systems and Components: Gain a strong understanding of the hydraulic systems powering derricks, including troubleshooting common issues and performing preventative maintenance.

- Safety Regulations and Procedures: Thorough knowledge of relevant safety standards, emergency protocols, and best practices to ensure a safe working environment.

- Troubleshooting and Problem-Solving: Develop the ability to identify and resolve mechanical and operational issues efficiently and safely, minimizing downtime.

- Communication and Teamwork: Understanding the importance of clear communication and effective teamwork within a derrick crew.

- Load Capacity and Stability Calculations: Ability to perform calculations to determine safe working loads and ensure derrick stability in various conditions.

- Environmental Considerations: Understanding the environmental impact of derrick operations and adhering to relevant regulations.

Next Steps

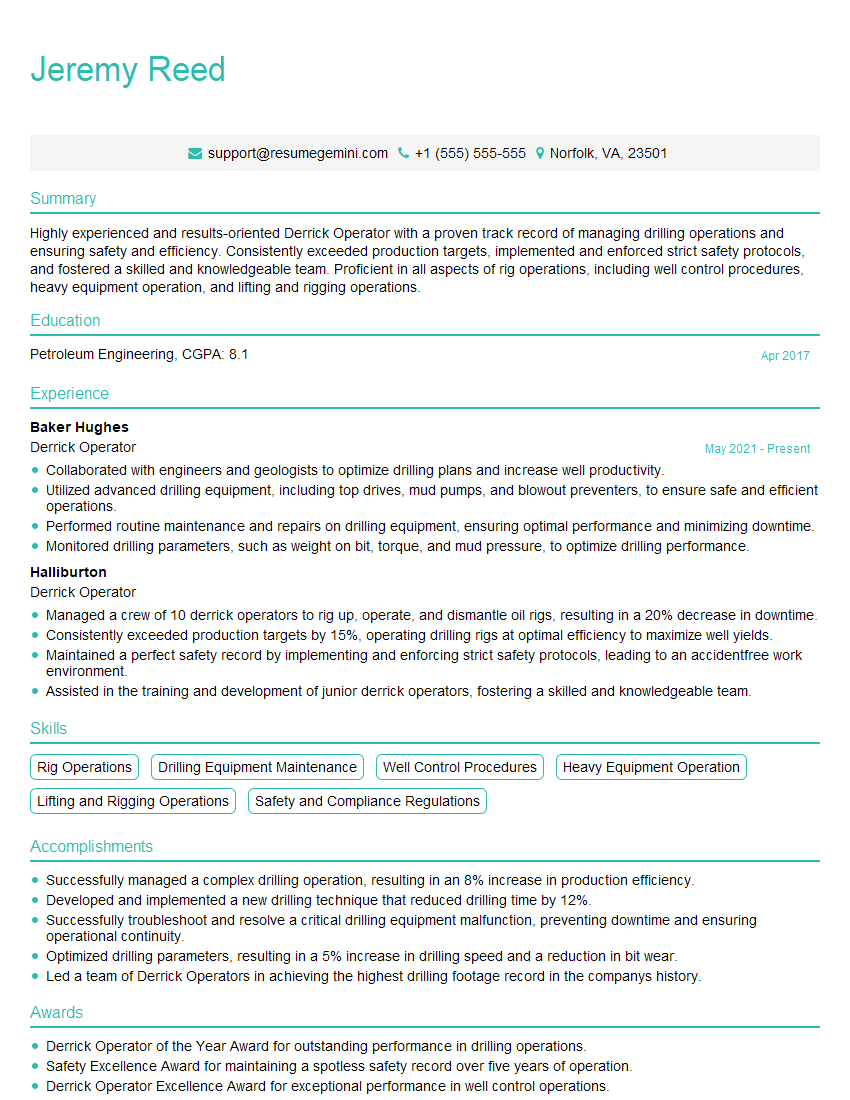

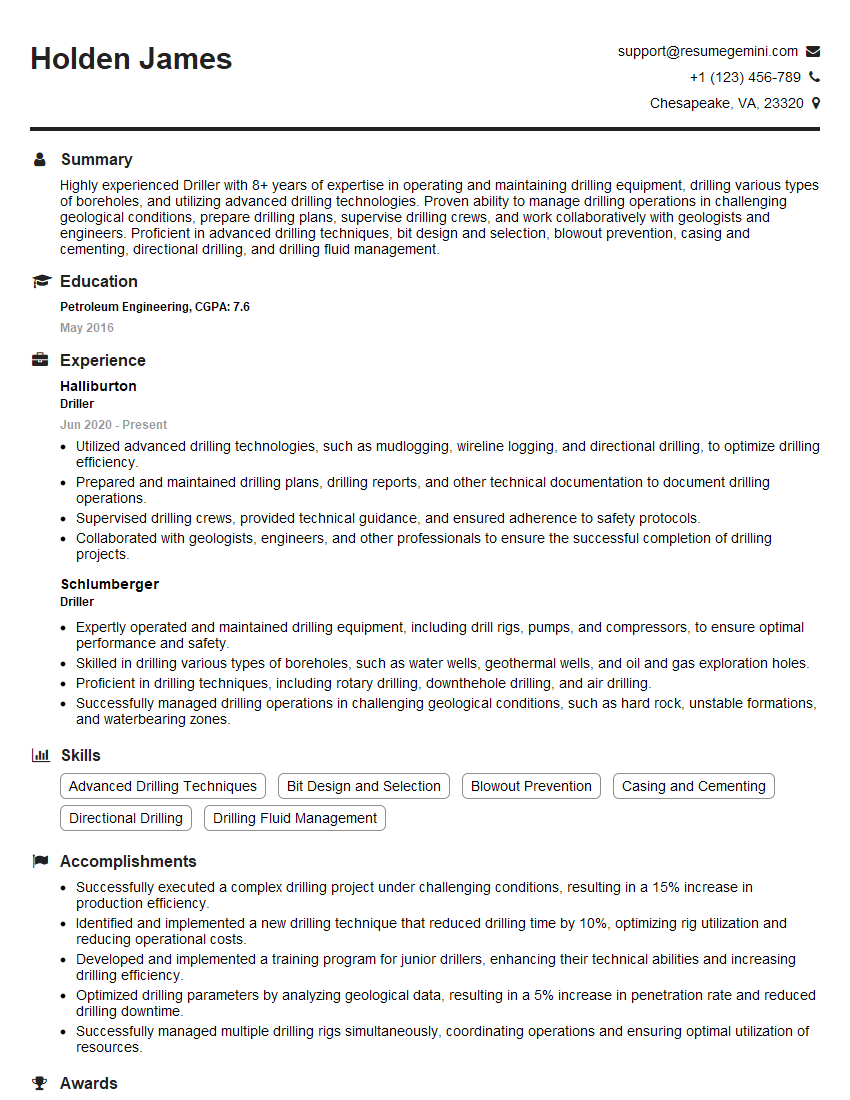

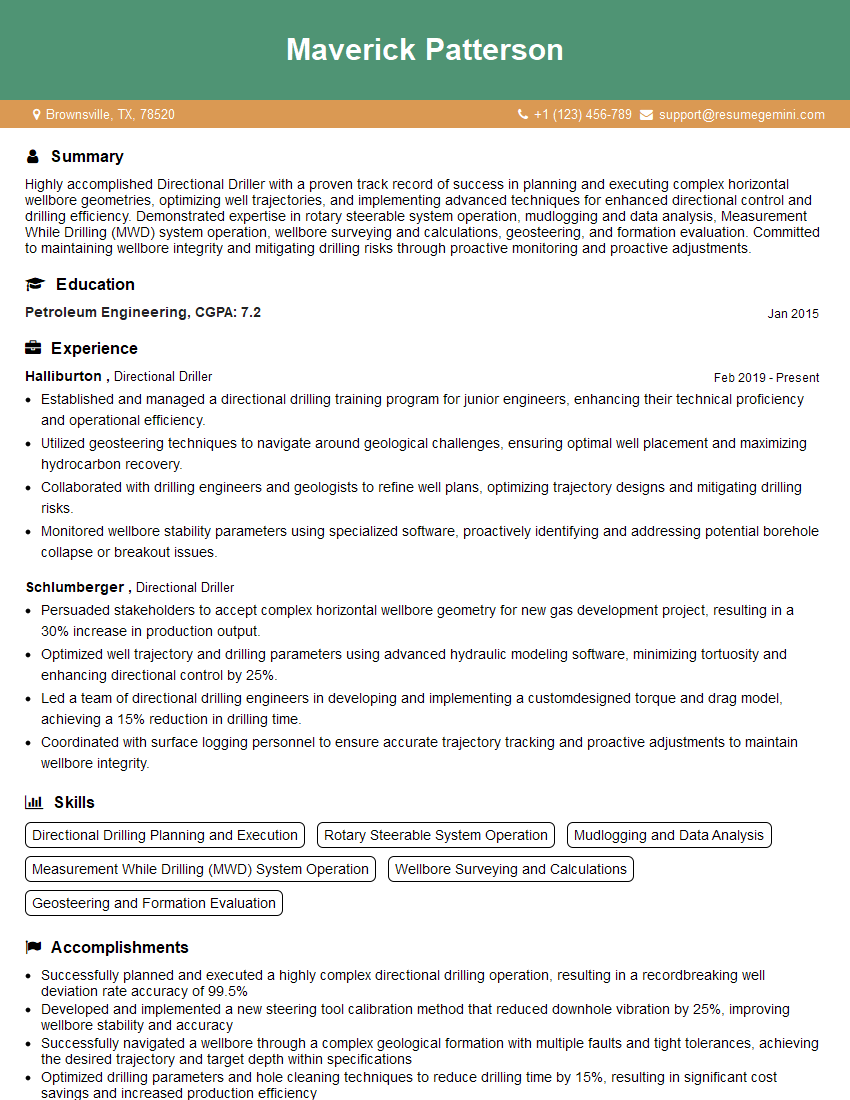

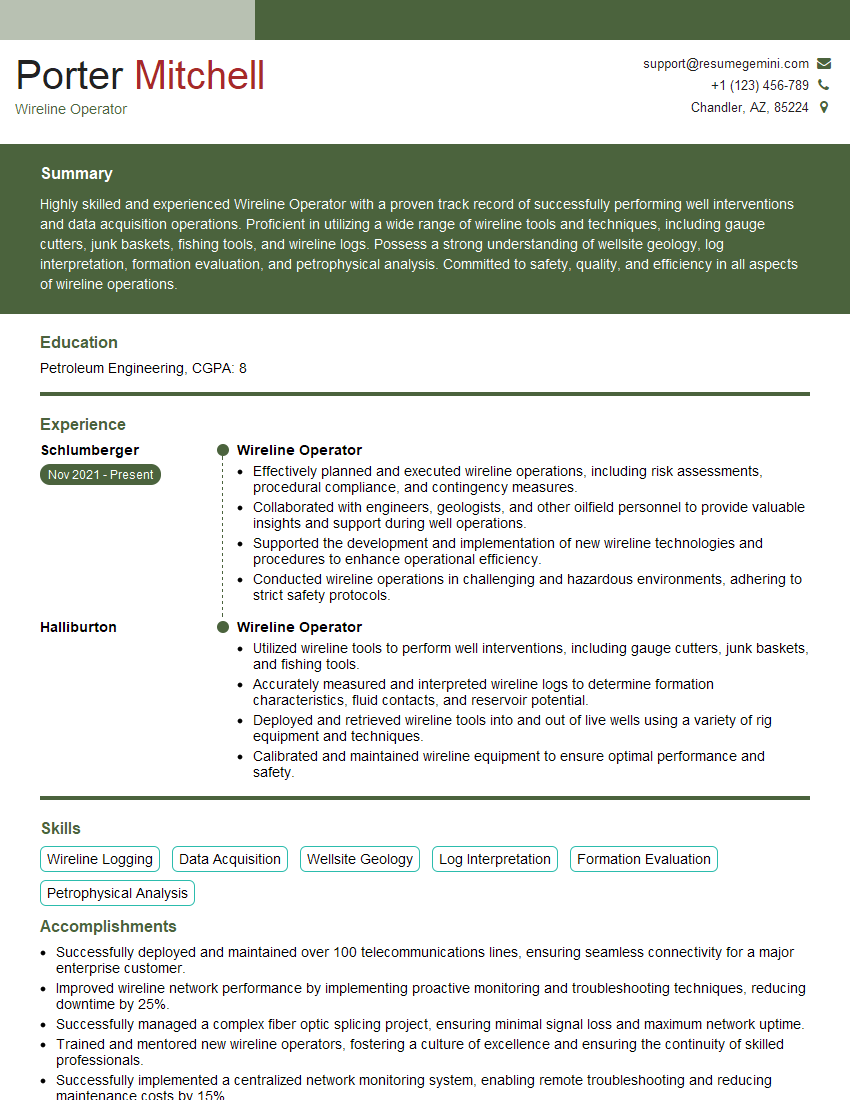

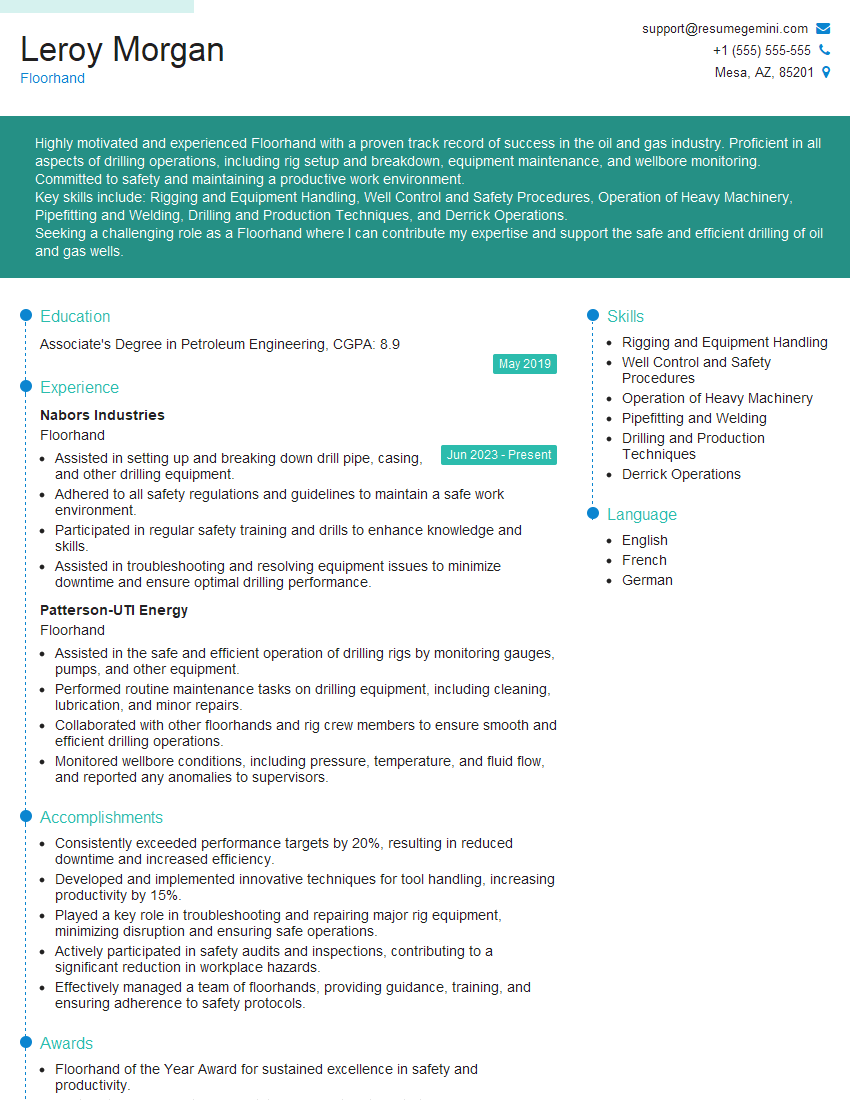

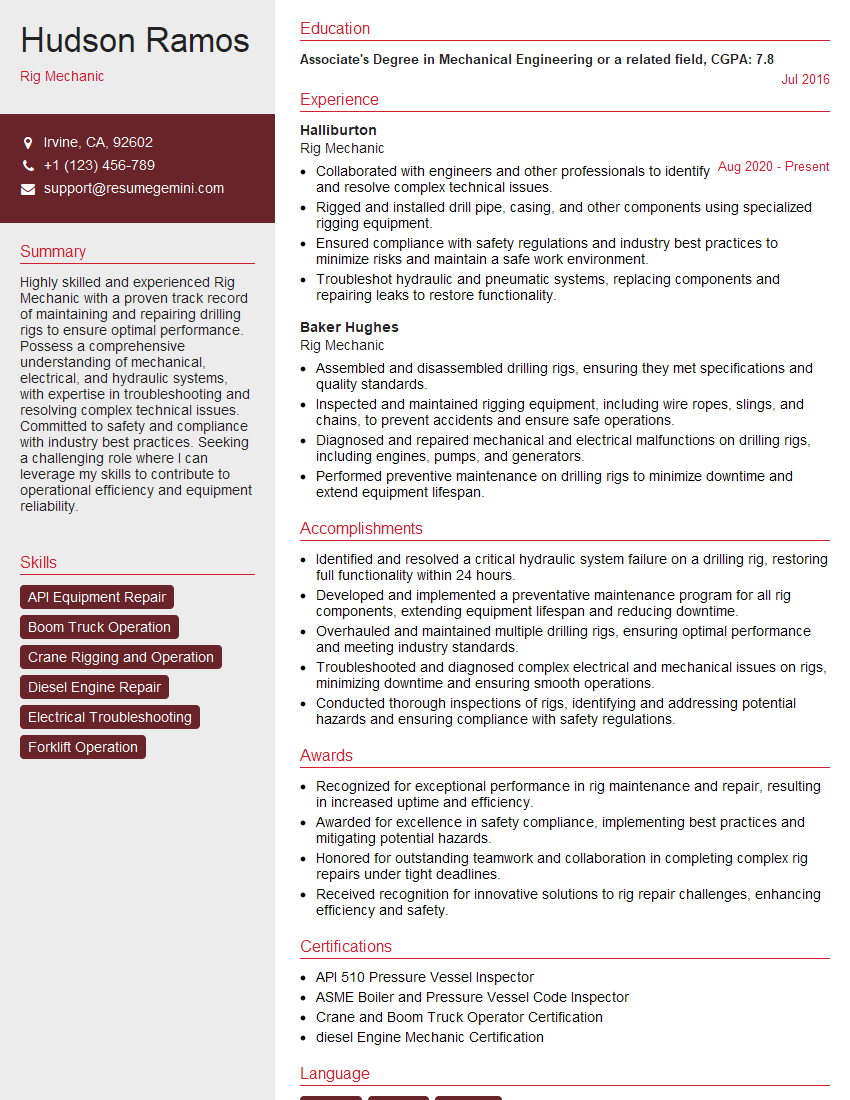

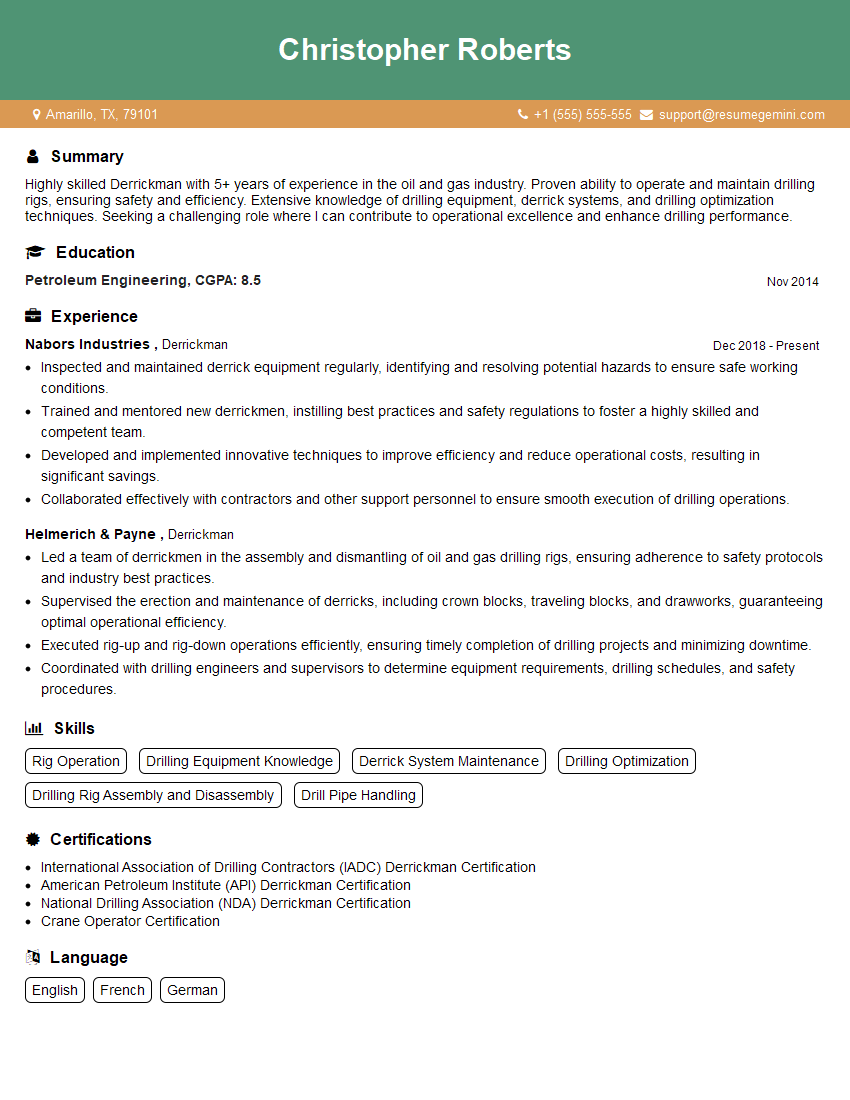

Mastering Derrick Operations opens doors to rewarding and challenging careers in the energy sector, offering opportunities for growth and specialization. A strong resume is crucial to showcasing your skills and experience to potential employers. To increase your chances of getting noticed by Applicant Tracking Systems (ATS), consider building an ATS-friendly resume. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume tailored to the demands of the Derrick Operations industry. Examples of resumes tailored specifically to Derrick Operations are available to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good