Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Garment Care and Handling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Garment Care and Handling Interview

Q 1. Explain the difference between dry cleaning and wet cleaning.

Dry cleaning and wet cleaning are two distinct garment cleaning methods. Dry cleaning uses a solvent, typically perchloroethylene (perc) or a safer alternative like hydrocarbon, to clean garments without water. Wet cleaning, on the other hand, uses water and detergents, similar to how you’d wash clothes at home, but often with specialized detergents and techniques optimized for delicate fabrics.

Think of it like this: dry cleaning is like gently dusting a delicate sculpture, removing surface dirt without immersing it in water; wet cleaning is like carefully washing a fine china plate by hand.

The choice between the two depends on the fabric’s composition and the care instructions. Delicate fabrics like silk or wool are often best dry cleaned to avoid shrinkage or damage, while more durable fabrics like cotton or linen can usually be wet cleaned.

Q 2. What are the common types of fabric stains and how would you treat them?

Common fabric stains fall into several categories, each requiring a slightly different approach. Here are a few examples and treatment strategies:

- Oil-based stains (grease, oil, makeup): These are best tackled with a dry-cleaning solvent or a pre-treatment stain remover specifically designed for oils. Blot (don’t rub!), and then launder as usual or dry clean.

- Water-based stains (juice, coffee, wine): Flush these stains with cold water immediately. Then, blot and pre-treat with a stain remover before washing or dry cleaning. For stubborn stains, consider soaking the garment in cold water with a gentle detergent.

- Protein-based stains (blood, milk, egg): Cold water is key here too! Avoid hot water, as it sets the stain. Rinse with cold water, then pre-treat and launder or dry clean.

- Dye stains: These can be tricky. Test a small, inconspicuous area with a stain remover or bleach alternative designed for colorfast fabrics. Always test first, as harsh chemicals can damage the fabric.

Remember to always test any cleaning solution on an inconspicuous area first to ensure it doesn’t damage the fabric.

Q 3. Describe the proper handling procedures for delicate fabrics like silk and lace.

Handling delicate fabrics like silk and lace requires extra care and attention to detail. Here’s a step-by-step guide:

- Pre-treatment: Gently brush away any loose dirt or debris before cleaning.

- Washing (if applicable): Use a gentle detergent designed for delicates, and hand-wash in cool water. Avoid harsh scrubbing or twisting. Support the fabric’s weight while washing to prevent stretching or damage.

- Rinsing: Rinse thoroughly in cool water until all detergent is removed. Avoid harsh water pressure.

- Drying: Never wring or twist delicate fabrics. Gently roll them in a clean towel to absorb excess water. Then, lay them flat on a clean, dry towel to air dry. Avoid direct sunlight or heat, which can cause discoloration or damage.

- Ironing (if necessary): Iron on a low setting with a pressing cloth to protect the fabric. Always test the heat on an inconspicuous area first.

For items heavily embellished with lace, consider professional dry cleaning to avoid potential damage.

Q 4. How do you identify different fabric types?

Identifying fabric types involves a combination of visual inspection, touch, and sometimes even a burn test (always test on a hidden area!).

- Visual Inspection: Look at the weave – is it tight or loose? Are the fibers smooth or textured? What is the overall sheen or luster?

- Touch Test: How does the fabric feel? Is it rough, smooth, soft, stiff, etc.? Does it drape well or hold its shape?

- Burn Test (Use with caution!): A small, hidden thread can be carefully burned to determine fiber type. Wool smells like burning hair, cotton burns quickly and smells like paper, silk smells slightly sweet, and synthetics melt or fuse instead of burning.

There are also more advanced techniques like microscopic analysis used in textile laboratories for precise identification, but the methods described above work well in most garment care settings.

Q 5. What are the safety precautions to observe when handling industrial laundry equipment?

Safety is paramount when handling industrial laundry equipment. Here are some key precautions:

- Proper Training: Never operate any equipment without adequate training. Understand the controls, safety features, and potential hazards.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and hearing protection, especially when handling hot surfaces or chemicals.

- Machine Safety: Ensure all guards and safety interlocks are in place and functioning correctly before starting any equipment. Never reach into a running machine.

- Chemical Handling: Follow all safety data sheets (SDS) for any cleaning agents or chemicals used. Proper ventilation is crucial when working with solvents or other potentially hazardous materials.

- Emergency Procedures: Be familiar with emergency shut-off procedures and emergency contacts in case of an accident or malfunction.

- Maintenance: Regularly inspect and maintain equipment to prevent malfunctions and ensure safe operation.

Q 6. Explain the process of ironing different types of fabrics.

Ironing different fabrics requires adjusting the temperature and technique to avoid damage. Here’s a general guideline:

- Cotton and Linen: High heat is usually fine, but always check the care label. Iron when slightly damp for best results.

- Silk and Wool: Low heat and a pressing cloth are essential to protect these delicate fabrics. Steam can also damage some silks, so use caution.

- Synthetics (Polyester, Nylon): Use a low to medium heat setting. High heat can melt or damage these fabrics.

- Delicates (Lace, Embroidered fabrics): Iron on the reverse side with a pressing cloth on a low setting. Steam can be harmful.

Always test the heat on an inconspicuous area before ironing the whole garment.

Q 7. How do you handle garment repairs and alterations?

Garment repair and alteration require precision and attention to detail. The process usually involves:

- Assessment: Carefully examine the garment to identify the damage or area needing alteration.

- Planning: Decide on the repair or alteration method. This might involve mending tears, replacing buttons, adjusting seams, or altering the length or fit.

- Repair/Alteration: Use appropriate tools and techniques for the specific repair. This can range from hand-sewing to using a sewing machine. Precise stitching is key to a professional finish.

- Quality Control: Carefully inspect the finished work for any imperfections or areas that need further attention. A well-executed repair or alteration should blend seamlessly with the garment.

For complex repairs or alterations, especially those requiring specialized skills, consider consulting a professional tailor or seamstress.

Q 8. What are the common issues encountered in a laundry facility and how would you resolve them?

Common laundry facility issues often revolve around equipment malfunctions, inefficient processes, and stain removal challenges. For instance, a malfunctioning washing machine might lead to uneven cleaning or damage to garments. Improper sorting can result in color bleeding or damage to delicate fabrics. Persistent stains, especially those from grease or blood, require specialized techniques.

- Equipment Malfunctions: Regular preventative maintenance, including cleaning and lubrication, is crucial. A proactive approach, such as scheduling routine inspections and prompt repairs, minimizes downtime and ensures consistent performance. Keeping detailed maintenance logs is essential for tracking issues and identifying recurring problems.

- Inefficient Processes: Implementing a standardized workflow, including clear garment sorting protocols and efficient machine loading, enhances productivity and reduces errors. Training staff on best practices and using productivity tracking tools helps monitor efficiency and identify areas for improvement. For example, color-coded bins for different garment types can significantly streamline sorting.

- Stain Removal Challenges: A well-stocked supply of stain removers tailored to various stain types is essential. Staff training on proper stain treatment techniques, including pre-treatment methods and appropriate cleaning agents, is crucial. This might include using enzyme detergents for protein-based stains or oxygen bleach for organic stains. Maintaining a stain chart as a quick reference guide for staff is highly beneficial.

Q 9. How do you maintain quality control in a garment care setting?

Maintaining quality control in garment care involves a multi-faceted approach focusing on staff training, process standardization, and regular quality checks. Think of it like baking a cake – you need the right ingredients (supplies), the right method (processes), and the right checks (quality control) to ensure a consistently delicious result.

- Staff Training: Thorough training on fabric identification, appropriate cleaning methods, stain removal techniques, and machine operation is paramount. Regular refresher courses ensure consistent application of best practices. Role-playing scenarios involving difficult stains or delicate fabrics enhance practical skills.

- Process Standardization: Establishing clear, documented procedures for each stage of the garment care process, from receiving to delivery, ensures consistency. This includes standardized sorting methods, washing parameters (temperature, cycle), and drying techniques. Visual aids like flowcharts or checklists help maintain consistency across shifts.

- Regular Quality Checks: Implementing a system of regular inspections at various stages of the process, including pre-washing, post-washing, and final inspection before delivery, is critical. This includes checking for stains, damage, and adherence to client specifications. A feedback mechanism allows for continuous improvement by identifying and addressing recurring issues.

Q 10. Describe your experience with various stain removal techniques.

My experience with stain removal techniques spans a wide range of methods, from simple pre-treatment to specialized chemical applications. Understanding the nature of the stain is crucial; different stains respond to different treatments. Think of it like fighting different enemies with different weapons.

- Water-Based Stains: Often easily removed with cold water and a mild detergent. For instance, juice or coffee stains usually respond well to this approach.

- Oil-Based Stains: Require pre-treatment with a solvent-based stain remover, followed by washing with a detergent. Grease stains, for example, often necessitate this two-step process.

- Protein-Based Stains: Enzyme-based detergents are most effective. Blood stains, for instance, should be treated with cold water and an enzyme detergent before washing.

- Ink Stains: Specialized ink removers may be necessary, and sometimes professional dry cleaning is the best option.

- Grass Stains: Oxygen bleach can be highly effective.

Each stain necessitates a customized approach; sometimes, a combination of techniques is required for complete removal.

Q 11. What are the different types of detergents and their appropriate uses?

Detergents vary widely in their formulation and intended use. Selecting the right detergent is essential for effective cleaning while protecting the garment’s fibers.

- Powder Detergents: Generally cost-effective and suitable for heavily soiled items. However, they can leave residue on fabrics.

- Liquid Detergents: Dissolve readily, are gentler on fabrics, and are ideal for pre-treating stains. They’re suitable for most laundry types.

- Enzyme Detergents: Contain enzymes that break down protein-based stains (blood, grass). Excellent for heavily soiled garments and those with stubborn protein stains.

- High-Efficiency (HE) Detergents: Formulated for use in high-efficiency washing machines. They produce less suds, preventing residue build-up.

- Specialty Detergents: Designed for specific fabric types (wool, silk) or colors (dark colors).

Choosing the wrong detergent can lead to ineffective cleaning, damage to fabrics, or residue build-up.

Q 12. How do you manage inventory of cleaning supplies and garments?

Effective inventory management involves a combination of meticulous tracking, regular stock checks, and strategic ordering. It’s like managing a restaurant’s inventory; you need to ensure you have enough supplies without overstocking.

- Software-Based Systems: Using inventory management software allows for real-time tracking of cleaning supplies and garments. This enables precise monitoring of stock levels, automates reordering processes, and generates reports on consumption trends.

- Regular Stock Checks: Conducting regular physical stock checks helps verify the accuracy of inventory records. This identifies discrepancies and prevents stock-outs.

- FIFO (First-In, First-Out) System: Implementing a FIFO system for cleaning supplies ensures that older items are used first, reducing the risk of expiry.

- Garment Tracking: A robust system for tracking garments, from receiving to delivery, is essential. Barcoding or RFID tagging can enhance efficiency and minimize the risk of loss or misplacement.

Q 13. What is the significance of water temperature in washing different fabrics?

Water temperature plays a crucial role in garment care, impacting both cleaning efficacy and fabric preservation. Using the wrong temperature can damage fabrics or leave stains behind.

- Cold Water (30°C or less): Ideal for delicate fabrics like silk, wool, and lace. It helps prevent shrinkage and color fading.

- Warm Water (30-40°C): Suitable for moderately soiled items and most synthetic fabrics. It provides a balance between effective cleaning and fabric protection.

- Hot Water (60°C or more): Effective for removing heavy soil and killing bacteria. However, it should only be used for durable fabrics like cotton and linen that can withstand high temperatures. Avoid using hot water on delicate fabrics or those with vibrant colors.

Always refer to the garment care label for specific temperature recommendations.

Q 14. How do you ensure the safety of garments during the washing and drying process?

Ensuring garment safety during washing and drying involves careful attention to detail at each step of the process. It’s about protecting the garments from damage – think of it like carefully handling precious artifacts.

- Proper Sorting: Separating garments by fabric type, color, and soil level is crucial. This prevents color bleeding and damage to delicate fabrics.

- Appropriate Detergent and Water Temperature: Using the correct detergent and water temperature protects fabrics from damage and ensures effective cleaning.

- Gentle Handling: Avoiding overloading washing machines and dryers prevents excessive wear and tear on garments. Properly loading and unloading machines minimizes the risk of damage.

- Monitoring Washing and Drying Cycles: Regular checks during washing and drying cycles help prevent over-washing or over-drying, which can damage or shrink garments. Using the appropriate drying settings is crucial for different fabric types.

- Protection from Damage: Using mesh laundry bags for delicate items prevents snagging or tearing. Avoid using harsh chemicals that could damage fabrics.

Q 15. Explain your experience with different types of pressing equipment.

My experience encompasses a wide range of pressing equipment, from basic steam irons to industrial-grade pressing machines. I’m proficient with both manual and automated systems. For example, I’ve extensively used industrial steam presses for high-volume production runs, ensuring consistent results across various fabrics. These machines offer adjustable temperature and pressure controls, crucial for delicate materials like silk or sturdy fabrics like denim. I’m also comfortable with smaller, tabletop presses ideal for specialized garments or intricate detailing. Furthermore, I’m familiar with vacuum pressing systems which remove wrinkles and restore the garment’s shape without leaving water marks. Understanding the nuances of each machine allows me to select the most appropriate tool for each garment and achieve optimal results.

For delicate items, I prefer using a smaller, more controllable steam iron. The precision allows me to target wrinkles and avoid causing damage. For larger items or items requiring a more even press, the industrial press is my go-to. I understand the importance of properly maintaining all equipment, including regular cleaning and timely servicing to ensure efficiency and longevity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you handle a customer complaint regarding damaged garments?

Handling customer complaints regarding damaged garments requires a calm, professional, and empathetic approach. My first step is to listen attentively to the customer’s concerns, validating their feelings and acknowledging the problem. I avoid becoming defensive and actively seek to understand their perspective. Then, I thoroughly inspect the garment to identify the nature and extent of the damage. This investigation helps determine the cause and identify the most appropriate solution.

Depending on the situation, I might offer solutions such as repairing the garment (if feasible), providing a discount or credit on future services, or replacing the garment completely. Documentation of the complaint, investigation, and resolution is crucial for future reference. Transparency is key – I explain my findings and the steps taken towards a resolution clearly and honestly. My goal is not just to resolve the immediate issue but to rebuild trust and ensure customer satisfaction. For instance, a minor stain might be easily removed with specialized cleaning agents, while a significant tear might require professional tailoring. Each situation requires a tailored response.

Q 17. Describe your experience with working with different types of industrial washing machines.

My experience with industrial washing machines includes working with various models from different manufacturers, each with unique features and capabilities. I’m familiar with both front-loading and top-loading machines, and understand the importance of selecting the appropriate machine based on the type of garment and the desired outcome. For example, front-loading machines are generally better for delicate fabrics and reduce wrinkling, while top-loading machines might be more suitable for heavier items. I understand the various wash cycles, water temperatures, and spin speeds, and adjust them according to the fabric type and care instructions.

I’m also experienced in managing and maintaining these machines, including regular cleaning to prevent buildup, checking for malfunctions, and performing routine maintenance tasks to ensure optimal performance and longevity. Proper water treatment is essential, to prevent mineral deposits and ensure fabric quality. I consider myself a skilled operator, capable of maximizing the lifespan of the washing machines and optimizing their efficiency and cleaning ability.

Q 18. How do you organize and maintain a clean and efficient workspace?

Maintaining a clean and efficient workspace is paramount in garment care. My organizational system is based on a combination of spatial organization and workflow optimization. I utilize designated areas for receiving, sorting, cleaning, pressing, and storing garments. Each area is clearly marked and has sufficient space for all necessary equipment. I employ color-coded bins or containers for sorting items based on fabric type, color, or cleaning requirements. This streamlined system minimizes handling time and reduces the risk of misplacing or damaging garments.

Regular cleaning is crucial. I clean all surfaces and equipment daily, ensuring the workspace is free of dust, lint, and debris. Proper hygiene practices, such as handwashing, are strictly followed to prevent contamination and maintain the highest standards of cleanliness. Furthermore, I regularly review and refine my system based on feedback and operational needs. A visually appealing and organized workspace creates a more productive and enjoyable environment.

Q 19. What are some common problems with garment storage and how do you prevent them?

Common problems with garment storage include wrinkling, mildew growth, discoloration from light exposure, and pest infestation. To prevent wrinkling, garments should be properly folded or hung using appropriate hangers. To prevent mildew, garments must be completely dry before storage. They should be stored in a cool, dry place with good air circulation. Acid-free tissue paper can help absorb moisture. For light-sensitive fabrics, storage in dark or dimly lit areas is recommended, possibly using UV-resistant garment bags. To prevent pest infestation, using airtight containers or cedar chests is beneficial. Regular inspection and timely cleaning prevent infestations from developing.

For example, storing wool sweaters folded in drawers with cedar blocks helps prevent moth damage, while silk scarves should be stored flat in acid-free tissue paper within a dark drawer or storage box. Understanding the fabric and its needs is crucial to prevent damage during storage. Regular checks of stored garments for signs of damage or pest infestation allow for early intervention and prevent further issues.

Q 20. What is your experience with specialized garment care such as leather or fur?

My experience with specialized garment care extends to leather and fur. I understand the unique properties and care requirements of these materials. Leather garments require specialized cleaning agents and conditioners to maintain their suppleness and prevent cracking. I use gentle cleaning methods, avoiding harsh chemicals that could damage the leather’s finish. I am familiar with various leather conditioning techniques to restore and maintain the leather’s natural oils. Fur, similarly, requires specific handling techniques. I understand the importance of proper brushing to remove dirt and maintain the fur’s natural luster. Storage of fur garments involves maintaining cool, dry conditions and using appropriate storage bags or containers to prevent damage or pest infestations. I’m also aware of the importance of avoiding direct heat or sunlight.

I have worked with various types of leather and fur, including suede, lambskin, mink, and fox, each with specific characteristics and care requirements. Experience has enabled me to identify the appropriate cleaning and conditioning methods for each unique situation.

Q 21. How do you ensure the longevity of garments through proper care?

Ensuring the longevity of garments hinges on proper care and maintenance, starting from the moment of purchase. Following the garment’s care label instructions is fundamental. This includes understanding the fabric composition and selecting the appropriate washing methods, drying techniques, and ironing temperatures. Gentle handling during washing and drying minimizes wear and tear. Proper storage, as discussed earlier, plays a vital role in preventing damage and maintaining the garment’s quality. Regular cleaning and maintenance, such as removing stains promptly and using appropriate cleaning agents, are crucial. For delicate fabrics, professional cleaning services might be necessary to avoid potential damage.

Beyond this, understanding the inherent properties of different fabrics and their susceptibility to damage helps in making informed decisions regarding care. For instance, knowing that excessive heat can damage delicate fabrics or that wool shrinks when exposed to hot water allows for more cautious and effective treatment. Avoiding over-washing also extends the life of the garments. Through a combination of careful handling and proper maintenance, one can ensure garments retain their quality and appeal for years to come.

Q 22. Explain the importance of pre-treatment before washing stained garments.

Pre-treating stained garments before washing is crucial for effective stain removal and preventing permanent damage. Think of it like this: pre-treatment is the first strike against a stain, weakening its hold on the fabric before the main washing process. Without it, the stain might set, becoming much harder, if not impossible, to remove.

The process involves applying a stain remover or detergent directly to the stain, gently working it into the fabric. This breaks down the stain molecules, making them easier to lift during the wash cycle. Different stains require different pre-treatment methods. For example, oily stains might benefit from a pre-wash with dish soap, while blood stains often require cold water rinsing before washing.

- Step 1: Identify the Stain: Knowing the stain type (e.g., oil, blood, wine) determines the best pre-treatment approach.

- Step 2: Choose the Right Product: Select a stain remover specific to the stain type, or use a gentle detergent for general stains.

- Step 3: Apply and Work In: Gently rub the stain remover into the stain, ensuring it penetrates the fabric. Avoid harsh scrubbing, which can damage delicate fabrics.

- Step 4: Allow to Dwell: Let the pre-treatment sit for the recommended time (usually 15-30 minutes) to allow it to work its magic.

- Step 5: Rinse: Rinse the treated area thoroughly with cold water before proceeding with the washing process.

Q 23. What are some environmentally friendly garment care practices?

Environmentally friendly garment care focuses on minimizing water and energy consumption, reducing chemical use, and promoting sustainable practices. It’s all about being kinder to the planet while still keeping your clothes clean and well-maintained.

- Washing Efficiently: Using cold water instead of hot significantly reduces energy consumption. Opt for full loads to maximize efficiency, and consider using eco-friendly detergents that are biodegradable and phosphate-free.

- Air Drying: Skip the dryer whenever possible and air dry your clothes. This saves a substantial amount of energy and extends the life of your garments. Think of it as a natural wrinkle-release technique!

- Choosing Sustainable Products: Opt for eco-friendly detergents, stain removers, and fabric softeners that are plant-based, biodegradable, and packaged responsibly.

- Repair and Repurpose: Before discarding damaged garments, consider repairing minor tears or rips. Alternatively, repurpose old clothes into rags or other useful items. Extending the life of your clothing reduces the need for new production, saving resources and minimizing waste.

- Proper Sorting and Washing: This prevents unnecessary wear and tear and reduces the need for rewashing.

Q 24. How would you handle a large volume of garments in a short timeframe?

Handling a large volume of garments in a short timeframe requires efficiency and a systematic approach. Think of it as an assembly line, with each step optimized for speed without compromising quality.

First, I would assess the type and condition of the garments, then divide the work into smaller tasks. A team approach, assigning specific roles to each person, would greatly enhance productivity. This might involve setting up multiple washing machines, organizing drying racks, and establishing a clear workflow for sorting, pre-treating, washing, drying, and finishing. Regular breaks and communication within the team are crucial to maintain consistency and prevent errors.

Furthermore, implementing technology, like a garment sorting system (for example, color and fabric type based automated sorting), would assist in efficient processing and reduce time significantly.

Q 25. What are your skills in garment sorting and classification?

My garment sorting and classification skills are highly developed. I can accurately sort garments based on various criteria, including fabric type (cotton, silk, wool, synthetics), color, and level of soiling. This helps to prevent color bleeding and ensures the appropriate washing and drying methods are used for each item. I have experience with a range of garment types, from delicate lingerie to heavy-duty workwear. My proficiency in sorting is crucial for maximizing efficiency and preventing damage to garments.

For example, I am adept at recognizing the subtle differences between various fabrics, which is essential for preventing shrinkage or damage. My ability to quickly and efficiently sort a large volume of garments into appropriate categories is a key strength.

Q 26. Describe your experience with using different finishing techniques like steaming or pressing.

I am proficient in various finishing techniques, including steaming and pressing. Steaming is a gentler method, ideal for delicate fabrics like silk and lace. It refreshes the garment, removes wrinkles, and reduces the risk of damage. Pressing, on the other hand, uses more direct heat and pressure, providing a crisp, professional finish for stiffer fabrics like cotton or linen. I am skilled in using both techniques appropriately and achieving the desired results.

My experience includes using industrial-grade steam presses and irons, ensuring I can handle large volumes of garments efficiently. I understand the importance of using the correct temperature and pressure settings to prevent scorching or damage to the fabric, maintaining its integrity and ensuring a high-quality finish.

Q 27. How do you identify and address fabric shrinkage issues?

Fabric shrinkage is often caused by washing in hot water or using improper drying methods. To address this, it’s crucial to understand the fabric composition. Natural fibers like wool and cotton are more prone to shrinkage than synthetic materials. I usually recommend checking the garment’s care label, following the washing instructions meticulously.

If shrinkage has already occurred, there are limited options. Sometimes, gentle stretching and reshaping while the garment is damp can help restore its original size, but success isn’t guaranteed. To prevent future shrinkage, always wash and dry garments according to the care label’s instructions and use cold water whenever possible. For delicate items, hand washing or a gentle machine cycle with a mesh laundry bag is recommended. Avoiding high heat during drying is also vital.

Q 28. What is your experience with using specialized cleaning solvents?

My experience with specialized cleaning solvents is extensive, but always prioritizing safety and environmental consciousness. I am familiar with a range of solvents, including those designed for specific stain types, such as oil-based solvents for grease stains or dry cleaning solvents for delicate fabrics.

The safe and effective use of these solvents necessitates proper training and adherence to strict safety procedures. I am fully aware of the hazards associated with certain solvents and take appropriate precautions, including wearing protective gear, working in a well-ventilated area, and following the manufacturer’s instructions meticulously. I am always mindful of environmentally friendly alternatives, preferring water-based solutions whenever possible.

Key Topics to Learn for Garment Care and Handling Interview

- Fabric Identification and Properties: Understanding different fiber types (natural vs. synthetic), their characteristics (e.g., absorbency, durability, wrinkle resistance), and appropriate care methods.

- Stain Removal Techniques: Mastering various stain removal methods for common stains (e.g., grease, wine, blood) using appropriate solvents and techniques while minimizing fabric damage.

- Laundry Processes and Equipment: Familiarity with different washing machines (commercial and residential), dryers, and pressing equipment; understanding wash cycles, water temperatures, and detergent selection for optimal cleaning and preservation.

- Garment Finishing and Pressing: Proper techniques for ironing, steaming, and pressing various garments to achieve a professional finish, considering fabric type and garment construction.

- Dry Cleaning Processes: Understanding the dry cleaning process, including the use of solvents, appropriate garment preparation, and post-cleaning handling.

- Storage and Preservation: Proper techniques for storing garments to prevent damage, including appropriate hangers, folding methods, and environmental considerations (e.g., temperature, humidity).

- Quality Control and Inspection: Identifying and addressing garment defects, ensuring high standards of quality in cleaning and finishing processes.

- Safety and Hygiene Protocols: Understanding and adhering to safety regulations concerning handling chemicals, equipment, and maintaining a hygienic work environment.

- Problem-Solving and Troubleshooting: Developing strategies for handling unexpected issues, such as identifying and resolving garment damage, dealing with difficult stains, and managing equipment malfunctions.

Next Steps

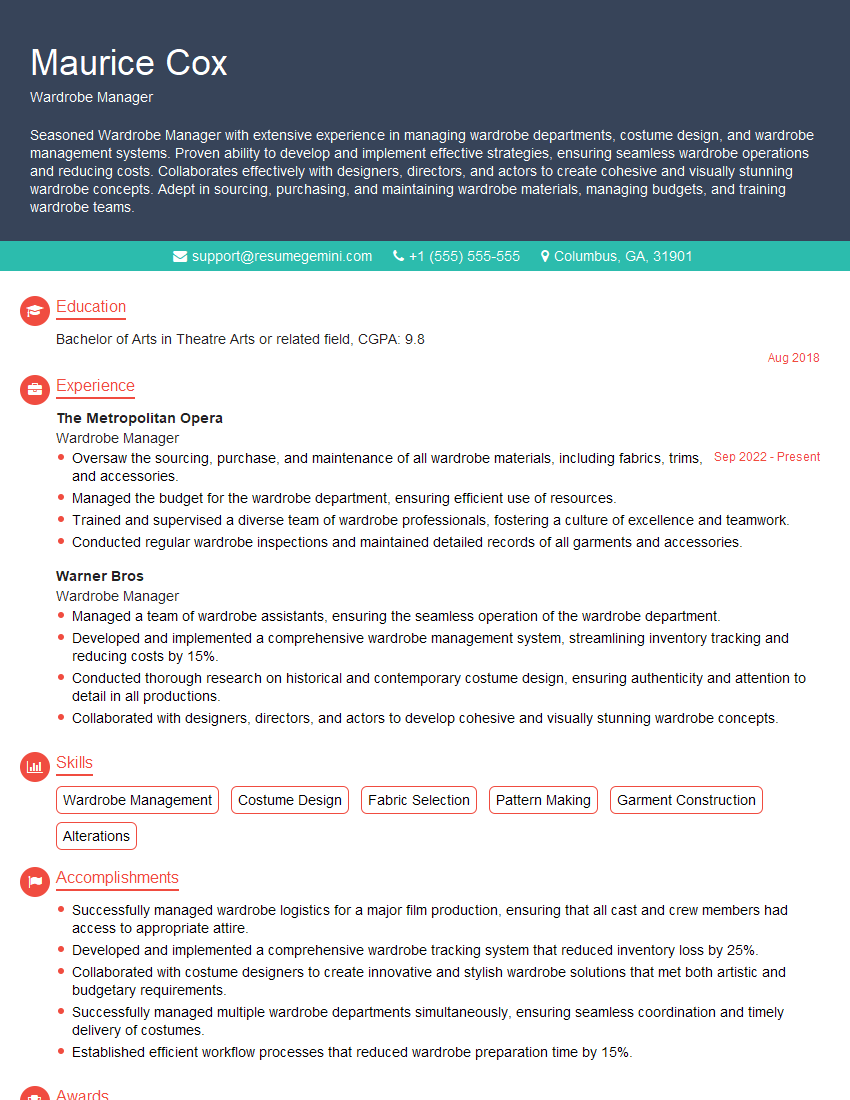

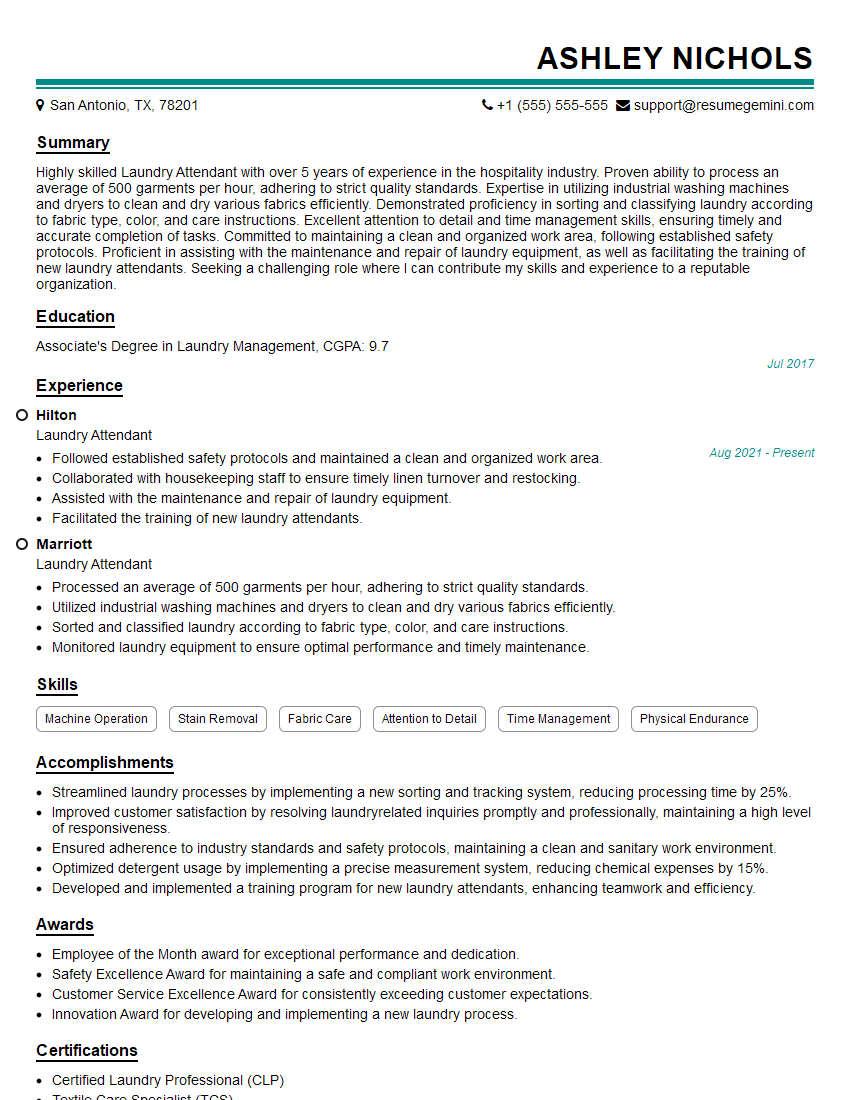

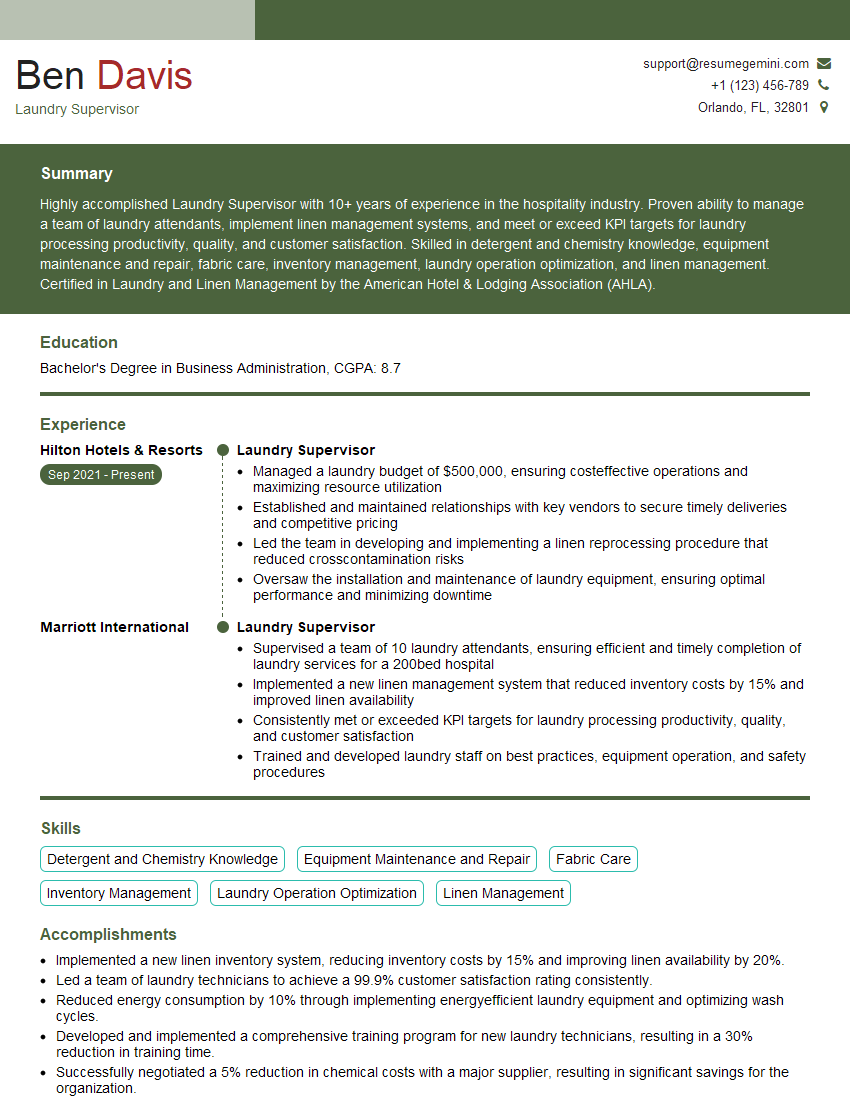

Mastering Garment Care and Handling is crucial for career advancement in this dynamic field. A strong understanding of these principles demonstrates professionalism, attention to detail, and a commitment to quality – highly valued attributes by employers. To significantly increase your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. We recommend using ResumeGemini, a trusted resource, to build a professional resume that stands out. Examples of resumes tailored specifically to Garment Care and Handling are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good