Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Embroidery Pressing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Embroidery Pressing Interview

Q 1. What types of embroidery machines are you familiar with?

My experience encompasses a wide range of embroidery machines, from single-needle domestic machines like those from Brother and Singer, to multi-needle industrial machines such as Tajima and Barudan. I’m also familiar with computerized machines that allow for intricate designs and various stitch types, and even some older mechanical models. Each type presents unique challenges and opportunities, requiring a tailored approach to operation and maintenance.

- Domestic Machines: These are excellent for smaller projects and hobbyists, offering user-friendly interfaces and relatively simple maintenance.

- Industrial Machines: These are high-speed, heavy-duty machines used for large-scale production, often featuring multiple heads and advanced automation. They demand specialized knowledge for operation and repair.

- Computerized Machines: These bridge the gap, providing the precision of industrial machines with the accessibility of domestic models. They rely heavily on digital design software and require proficiency in operating the software and the machine.

Q 2. Explain the process of setting up an embroidery machine for a specific design.

Setting up an embroidery machine for a specific design is a multi-step process that requires precision. Think of it like preparing a canvas before painting a masterpiece. First, you import the design into the machine’s software, ensuring the size and placement are correct for the fabric. You then select the appropriate needle, thread, and stabilizer based on the fabric type and design complexity. For example, a delicate design on a lightweight fabric would require a fine needle and a lightweight stabilizer to avoid puckering. After that, you hoop the fabric securely, ensuring it’s taut but not stretched to the point of damage. Finally, you thread the machine, ensuring correct tension and alignment before starting the embroidery process.

For example, if I’m embroidering a logo on a denim jacket, I’d use a heavier-weight needle, tear-away stabilizer, and stronger threads. Conversely, for a floral design on a silk scarf, I’d choose a fine needle, cut-away stabilizer, and fine-quality embroidery threads.

Q 3. How do you ensure the proper tension of the embroidery thread?

Proper thread tension is crucial for beautiful embroidery, preventing issues like broken threads, skipped stitches, or puckering. Think of it as finding the ‘sweet spot’ between the top and bottom threads. Most machines have tension dials for adjusting the upper thread, while the bobbin tension is often pre-set. I usually start with the manufacturer’s recommended settings and then fine-tune them based on the fabric, thread, and design. Observing the stitching—looking for consistency and the formation of a neat ‘stitch ladder’ where the top and bottom threads interlock correctly—is key. If the top thread is showing too much on the underside or vice-versa, adjustments to the tension are needed. This often involves a process of trial and error, adjusting the tension dial slightly and testing until you achieve optimal results.

Q 4. Describe your experience with different embroidery stitch types.

My experience with embroidery stitch types is extensive. I’m proficient in a wide range, from basic stitches like satin stitch and running stitch, to more complex ones like fill stitches (e.g., dense satin, feather stitch), and decorative stitches (e.g., chain stitch, cross stitch). Different stitches are suited to different designs and fabric types. For instance, satin stitch is ideal for solid blocks of color, but requires careful attention to tension to avoid puckering. Fill stitches offer more texture and depth. Understanding the nuances of each stitch allows for creativity and control over the final embroidered product. I’ve worked with many different stitch types in my experience, from simple running stitches to intricate patterns using complex algorithms and machine functions to generate varied stitch patterns.

Q 5. How do you identify and correct common embroidery machine errors?

Identifying and correcting embroidery machine errors requires systematic troubleshooting. Common errors include broken needles, thread jams, skipped stitches, and inconsistent tension. I approach these issues by first inspecting the machine and the stitching carefully. For example, broken needles are often caused by hitting a pin or a hard object on the fabric. A systematic approach is critical. Start with the most probable causes and work your way through more complex issues. Always consult the machine’s manual for specific troubleshooting guides. A systematic approach, experience and knowledge of common problems are essential for efficient error correction. I often start by checking the obvious, like the needle, thread, bobbin, and tension settings. Then, I’ll delve into more complex issues like the timing belt or sensor if needed.

Q 6. What are your troubleshooting skills when dealing with bobbin issues?

Bobbin issues are a frequent source of problems. I address them systematically: First, I check if the bobbin is correctly wound and seated in the bobbin case. A poorly wound bobbin, or one improperly placed, will cause inconsistent stitching or thread breakage. Second, I verify the bobbin case is correctly installed and that there’s no lint or debris obstructing it. If the problem persists, I check the bobbin tension—too loose and the thread will be loose, too tight and it could break. Sometimes, simply cleaning the bobbin case and re-threading solves the issue. In more complex situations, it could indicate a problem with the bobbin mechanism itself requiring more extensive troubleshooting or professional maintenance.

Q 7. How do you maintain the cleanliness and optimal functioning of an embroidery machine?

Maintaining an embroidery machine’s cleanliness and optimal functioning is crucial for its longevity and performance. I regularly clean the machine, removing lint and dust from all accessible areas, including the bobbin area, feed dogs, and needle plate. Using compressed air or a small brush is effective. I also lubricate moving parts as recommended by the manufacturer to prevent friction and wear. Regularly changing needles, especially when working with different fabrics or threads, is also important. A well-maintained machine will stitch consistently, creating clean, accurate designs. Neglecting regular maintenance can lead to unnecessary wear, costly repairs, and compromised stitch quality. Think of it like servicing your car; regular attention keeps it running smoothly.

Q 8. Explain your experience with different types of embroidery fabrics.

My experience encompasses a wide range of embroidery fabrics, from delicate silks and linens to durable cottons and heavy-weight canvas. Understanding the properties of each fabric is crucial for achieving optimal results. For instance, delicate fabrics like silk require careful hooping and stabilization to prevent puckering or damage during the embroidery process. Conversely, heavier fabrics like canvas might need less stabilization but require a more robust needle and thread to prevent breakage. I adapt my techniques, including needle selection, thread tension, and stitch density, based on the specific fabric’s weight, weave, and drape.

- Silk: Requires careful handling, minimal tension, and often needs a water-soluble stabilizer to prevent distortion.

- Linen: Can be slightly more challenging due to its uneven texture, requiring careful hooping and potentially tear-away stabilizer.

- Cotton: A versatile fabric, readily accepting various embroidery techniques and requiring moderate stabilization depending on the weight.

- Canvas: A robust fabric, ideal for dense embroidery patterns, and can handle heavier threads; typically requires minimal stabilization.

I’ve worked with various blends as well, each presenting a unique set of challenges and requiring a nuanced approach to achieve the desired outcome. Experience has taught me to always test a small sample before beginning a large project to determine the optimal settings.

Q 9. Describe your process for inspecting finished embroidery work for quality control.

My quality control process is meticulous and involves several steps. First, I visually inspect the finished embroidery for any inconsistencies in stitching, such as skipped stitches, broken threads, or uneven tension. Then, I carefully examine the design placement, ensuring it’s accurately centered and aligned. Next, I check for any fabric puckering or distortion, which often indicates improper hooping or stabilization. Finally, I assess the overall color accuracy and clarity of the design, paying attention to any bleeding or color inconsistencies.

I use a combination of magnifying glasses and bright, even lighting to thoroughly examine the finer details. Any imperfections are documented, and I analyze the cause to prevent similar issues in future projects. This process isn’t just about identifying flaws but also understanding why they occurred – whether it’s a machine malfunction, a problem with the design digitization, or an issue with fabric or thread selection.

Q 10. How do you handle inconsistencies in embroidery stitching?

Inconsistencies in embroidery stitching can stem from various factors including thread tension, needle type, fabric type, and machine settings. Addressing these inconsistencies requires a systematic approach. I first identify the cause of the problem through careful observation. For example, loose stitches may indicate low thread tension, while broken threads may point to a dull needle or incorrect thread type.

Once the cause is identified, I adjust the settings accordingly. This might involve: adjusting the thread tension dial on the machine, changing to a sharper needle appropriate for the fabric, switching to a higher-quality thread, or even re-hooping the fabric for better stability. In some cases, slight inconsistencies might be corrected by hand using a needle and thread to neatly repair the affected areas. If the inconsistency is widespread and affects a significant portion of the embroidery, I may need to re-embroidery the piece.

Prevention is key. This includes regularly cleaning and maintaining the embroidery machine, ensuring proper hooping techniques, and selecting the right needles and threads for the fabric. Using good quality, consistent threads and proper tension are also crucial.

Q 11. What are the safety precautions you take when operating embroidery machinery?

Safety is paramount when operating embroidery machinery. My routine includes several key precautions:

- Proper Machine Maintenance: Regularly cleaning and lubricating the machine prevents malfunctions and potential injuries.

- Needle Handling: Always using appropriate needles for the fabric and avoiding touching the needle while the machine is running. Broken needles should be immediately discarded in a designated container.

- Finger Protection: Keeping fingers away from moving parts and using appropriate tools to adjust materials.

- Eye Protection: Wearing safety glasses to prevent potential eye injuries from flying threads or debris.

- Proper Ventilation: Ensuring adequate ventilation to reduce exposure to any dust or fumes created during the process.

- Emergency Shut-off Procedure: Being familiar with the location and operation of the emergency stop button.

Following these protocols not only minimizes the risk of accidents but also ensures the longevity and efficiency of the equipment. Regular safety checks and training are part of my standard operating procedure.

Q 12. Describe your experience with hooping and stabilizing different fabrics.

Hooping and stabilizing fabrics are crucial for achieving high-quality embroidery. My experience covers a variety of techniques adapted to different fabrics. For delicate fabrics like silk or chiffon, I use water-soluble stabilizers, applying them carefully to avoid wrinkles. Tear-away stabilizers are a good choice for many fabrics, offering support during stitching and easily removed afterward. Cut-away stabilizers provide even more support, ideal for dense embroidery or intricate designs on stretchy fabrics. The type of hoop used also matters; I use different hoop sizes depending on the project, ensuring a secure and even tension across the fabric to minimize puckering. For very large projects or those with unusual shapes, I may need to use multiple hoops or alternative methods like magnetic hooping systems.

Proper hooping involves ensuring the fabric is smooth and taut within the hoop, without stretching or pulling it. Too much tension can distort the fabric, and too little tension can lead to puckering or inconsistent stitching. I carefully check the tension across the fabric before starting each project. The process often needs adjustments based on the fabric and design.

Q 13. How do you manage large-scale embroidery projects?

Managing large-scale embroidery projects requires meticulous planning and organization. My approach involves several key steps:

- Project Breakdown: Dividing the project into smaller, manageable sections, often using a template or markings on the fabric.

- Sequential Embroidery: Embroidering one section at a time to maintain accuracy and consistency.

- Careful Fabric Handling: Maintaining the fabric’s integrity throughout the process, minimizing handling to prevent damage or wrinkling.

- Efficient Time Management: Setting realistic timelines and prioritizing tasks, often employing a Gantt chart or similar project management tool.

- Teamwork (when applicable): If the project is too large for a single operator, I’d coordinate efficiently with a team, ensuring clear communication and consistent quality across all parts of the project.

- Quality Checks at Each Stage: Performing regular quality checks at various stages of production to identify and rectify any issues early on.

Efficient workflow and preventative measures are key to completing large-scale projects successfully and on time, maintaining the high standards of quality I maintain in smaller projects.

Q 14. What is your understanding of color separation in embroidery?

Color separation in embroidery is the process of separating a design into individual color layers, each to be embroidered with a different thread color. This is crucial for creating complex designs with multiple colors. My understanding includes both the manual and digital aspects of this process.

Manually, it involves careful analysis of the design and selecting the appropriate thread colors for each section. This is a skill developed over years of experience in matching colors and understanding how different thread colors interact. Digitally, this is often handled using embroidery design software. This software automatically separates the design into different color layers based on the color palette defined by the designer. This allows for precise control over color placement and ensures efficient embroidery. Understanding the limitations of both manual and digital methods is important for achieving optimal results, especially for intricate designs or those with many color changes.

Proper color separation impacts the overall quality and aesthetic appeal of the final embroidered piece significantly. An accurate color separation leads to a clean, professional finish, whereas a poorly executed separation can result in color bleeding, overlapping, or undesirable color combinations.

Q 15. Explain your experience with different embroidery design software.

My experience with embroidery design software spans several leading programs. I’m proficient in industry-standard software like Wilcom EmbroideryStudio, which is known for its advanced features and precision. I also have extensive experience with simpler software like Embird, suitable for smaller projects and quick designs. My proficiency extends to utilizing the design features of each software, including digitizing, editing, and color separation. For example, in Wilcom, I frequently utilize its advanced features for creating complex designs with multiple layers and intricate details, while Embird helps me quickly create smaller designs for personalized items or simple projects. This varied experience allows me to choose the optimal software for any given project, based on its complexity and deadline.

- Wilcom EmbroideryStudio: Expert level, used for complex designs requiring high precision.

- Embird: Proficient level, used for quick designs and smaller projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle urgent or time-sensitive embroidery orders?

Handling urgent orders requires a structured approach. Firstly, I assess the complexity of the design and the required turnaround time. I immediately communicate with the client to confirm all details and expectations. This includes verifying the design files, confirming the fabric type and quantity, and discussing any potential challenges. Next, I prioritize this order by adjusting my schedule, possibly working overtime or delegating non-critical tasks. In some cases, I might suggest alternative solutions like simplifying the design or using faster production methods. For instance, a recent request for 100 embroidered logos needed within 48 hours required me to optimize the design for faster stitching and to work extended hours to complete the project. Clear and consistent communication with the client throughout the process is crucial to ensure a successful outcome.

Q 17. How do you prioritize tasks in a busy embroidery production environment?

In a busy environment, task prioritization is essential. I use a combination of techniques, including a first-in, first-out (FIFO) approach for simpler tasks and a prioritization matrix for more complex projects based on factors such as urgency, complexity, and client importance. For example, orders with tight deadlines are always prioritized over those with longer lead times. Orders from high-value clients are given similar consideration. I use a digital task management system to track all projects, their progress, and their deadlines, allowing for proactive management and efficient resource allocation. This ensures that I’m not only meeting deadlines but also managing my workload effectively to avoid burnout and maintain a high level of quality.

Q 18. Describe your experience working with various embroidery threads and their properties.

My experience with various embroidery threads is extensive. I’m familiar with the properties of different thread types, including rayon, polyester, metallic, and cotton threads. Rayon offers a beautiful sheen and is suitable for delicate designs, while polyester is durable and cost-effective for bulk orders. Metallic threads add a touch of glamour but require careful handling due to their sensitivity. Cotton thread, while more traditional, can be less vibrant than other options. Understanding these properties is crucial for choosing the right thread for the project and ensuring the final product meets both aesthetic and durability requirements. For instance, I would choose a durable polyester thread for a corporate logo on workwear, but I might select rayon for a delicate wedding invitation design.

Q 19. How familiar are you with different types of embroidery backing and stabilizers?

I’m well-versed in various embroidery backings and stabilizers, understanding their importance in achieving high-quality results. The choice of backing or stabilizer depends heavily on the fabric type and the embroidery design. For instance, tear-away stabilizer is ideal for delicate fabrics where the backing needs to be removed easily, while wash-away stabilizer is perfect for situations where the backing dissolves after washing. Cut-away stabilizer provides additional support for heavy embroidery and dense designs. Choosing the correct stabilizer prevents puckering, distortion, and ensures the stitches remain crisp and defined. Using the wrong stabilizer could ruin an otherwise perfect design. For example, not using enough stabilizer for a heavy design will result in a puckered finished piece.

Q 20. Explain your knowledge of digital embroidery designs and their transfer to the machine.

My knowledge of digital embroidery designs and their transfer to the machine is paramount to my work. I typically receive designs in formats such as .DST, .PES, or .EXP. I carefully inspect the design file for any potential errors before transferring it to the embroidery machine. This involves checking stitch density, color changes, and overall design integrity. The transfer process itself is straightforward; I typically use a USB drive or direct connection to upload the file. However, proper file preparation and machine setup are critical for a smooth process. I pay close attention to the machine’s settings, such as needle type, thread tension, and stitch speed, adjusting them as needed based on the design and fabric. A simple error in file preparation or machine settings can have catastrophic results. Therefore, careful attention to detail is very important.

Q 21. How do you deal with a broken needle during embroidery?

A broken needle during embroidery is a common occurrence, and handling it efficiently is vital. My first step is to always prioritize safety. I immediately switch off the embroidery machine and unplug it to prevent further damage. Next, I carefully remove the broken needle, ensuring I don’t injure myself. Then, I visually inspect the surrounding area for any thread or fabric damage. Finally, I insert a new needle of the correct type and size before resuming the embroidery process. I always keep a supply of needles on hand, categorized by type and size for quick replacement. It’s also important to regularly inspect needles for wear and tear to prevent unexpected breakages and ensure high quality in the work.

Q 22. What are the common causes of thread breakage and how do you prevent them?

Thread breakage in embroidery is a common frustration, but often preventable. It’s usually caused by a combination of factors, not just one single issue. Think of it like a chain – if one link is weak, the whole chain breaks.

Low-quality thread: Using cheap or damaged thread is the most frequent culprit. The thread might be too thin, too easily frayed, or simply not strong enough for the machine’s tension.

Incorrect tension: Improperly adjusted machine tension can put excessive strain on the thread, causing it to snap. Imagine trying to pull a rope too tightly – it’ll eventually break! This requires careful calibration based on thread type and fabric.

Needle issues: A bent, dull, or incorrect needle size for the thread type can also lead to breakage. A dull needle creates friction and weakens the thread, while an incorrect size can cause the thread to rub against the needle incorrectly.

Fabric type: Working with heavy fabrics or stiff materials that resist the needle movement can place extra stress on the thread. It’s like trying to sew through leather with a normal needle; you need a stronger thread.

Machine maintenance: A poorly maintained machine, such as a machine with lint build-up that increases friction, will also contribute to thread breakage. Regular cleaning and lubrication are crucial.

Prevention: Using high-quality thread, correctly setting the machine tension, regularly checking and replacing needles, choosing appropriate needles for the thread and fabric, and maintaining the embroidery machine are key to preventing thread breakage. Regular cleaning and preventative maintenance will minimize problems and save time and materials.

Q 23. How do you accurately read and follow embroidery design specifications?

Accurately reading and following embroidery design specifications is fundamental for producing high-quality work. It’s like following a recipe – if you miss a step or ingredient, the outcome will be affected.

I start by carefully examining the design file for all specifications: stitch count, thread colors, fabric type, hoop size, and any special instructions. I then check the color chart for accurate thread selection, ensuring I have the right shades. Software often helps to visualize the design and identify potential problems before the embroidery begins.

I pay close attention to details such as stitch density and underlay instructions to ensure appropriate fabric stabilization and prevent puckering or distortion. If any ambiguities are present, I always clarify them with the designer before proceeding to ensure a flawless result. The design’s file format is also important; checking for compatibility with my machine is essential.

Q 24. Describe your experience with different types of embroidery trims and embellishments.

My experience encompasses a wide range of embroidery trims and embellishments. I’m proficient in working with various materials, each possessing unique properties requiring specialized techniques.

Sequins and beads: These add sparkle and texture, but careful placement and secure stitching are needed to prevent them from falling off.

Ribbons and cords: These can create interesting three-dimensional effects, but require specific needle types and stitching techniques to avoid damage or uneven application.

Appliqués: These involve applying fabric shapes onto the base garment, demanding precise placement and secure stitching to prevent fraying or lifting.

3D elements: These add volume and depth and require specialized techniques and supporting materials to maintain their shape during and after the embroidery process.

I understand the importance of selecting appropriate embellishments based on the design, fabric, and desired outcome. This involves not just choosing the right material but also ensuring the embellishment’s longevity and durability within the finished product.

Q 25. How do you maintain accurate records and tracking of embroidery production?

Maintaining accurate records and tracking of embroidery production is crucial for efficiency and quality control. I use a combination of digital and physical methods.

I utilize a digital database to track orders – recording client details, design specifications, materials used, production start and end times, and any relevant notes. This allows me to easily search for previous orders, analyze production times, and identify trends. I also maintain physical logs, recording daily output and materials inventory. This ensures a clear audit trail and facilitates accurate invoicing. A barcoding system could further streamline the tracking of materials and finished products.

Regular inventory checks and updating the database are part of my daily routine. This ensures accuracy and prevents discrepancies, ensuring that every project is accounted for and managed with precision.

Q 26. How do you handle customer complaints related to embroidery quality?

Handling customer complaints regarding embroidery quality requires a professional and empathetic approach. I listen attentively to the customer’s concerns, taking detailed notes to understand the nature of the issue. I then carefully examine the finished product, comparing it to the original design specifications.

If the problem is due to a production error, I apologize for the inconvenience and discuss possible solutions, such as redoing the embroidery or offering a partial or full refund. If the issue is due to unrealistic customer expectations or incorrect design specifications, I calmly explain the situation, providing solutions or offering alternatives. I strive for a win-win outcome, aiming for customer satisfaction and retaining their trust. Transparency and professional communication are key in resolving any dissatisfaction.

Q 27. What are your techniques for problem-solving in embroidery production?

Problem-solving in embroidery production involves a systematic approach. I start by identifying the problem precisely – is it a thread breakage issue, a design flaw, or a machine malfunction?

Then I gather relevant information – examining the fabric, the design file, and the machine settings. I might consult reference materials or seek advice from experienced colleagues if needed. Testing different solutions, one by one, to pinpoint the root cause is crucial. I document each step, recording the issue, the solutions tried, and the results achieved. This helps in future troubleshooting and enhances my learning process. It’s like detective work, systematically eliminating possibilities until the root cause is found.

Q 28. What are your career goals related to embroidery pressing?

My career goals center around enhancing my expertise in embroidery pressing and expanding my contributions to the industry. I aim to master advanced techniques in 3D embroidery and embellishment, and to continuously improve my efficiency and precision in production. I also aspire to mentor and train others, sharing my knowledge and passion for this craft. In the long term, I’d like to contribute to the innovation of embroidery techniques and tools, potentially leading a team or starting my own specialized embroidery business.

Key Topics to Learn for Embroidery Pressing Interview

- Understanding Fabric Types and Their Pressing Needs: Knowing how different fabrics (cotton, linen, silk, synthetics) react to heat and pressure is crucial for achieving professional results. This includes understanding potential shrinkage and damage risks.

- Pressing Techniques for Various Embroidery Styles: Mastering techniques for different embroidery types (e.g., appliqué, free-motion, cross-stitch) ensures you can handle a wide range of projects and client requests. This includes using appropriate tools and pressure levels.

- Identifying and Correcting Pressing Issues: Troubleshooting is key! Learn to identify common problems like puckering, uneven pressing, or scorching, and implement effective solutions to maintain high-quality results.

- Maintaining and Caring for Pressing Equipment: Understanding the proper maintenance of irons, pressing cloths, and other tools is essential for prolonging their lifespan and ensuring consistent performance. This also demonstrates responsibility and attention to detail.

- Safety Procedures and Ergonomics: Knowing and adhering to safety protocols around high-temperature equipment and practicing good ergonomics to prevent injuries is vital for a successful and sustainable career. This demonstrates professionalism and a proactive approach to workplace safety.

- Quality Control and Inspection: Developing a keen eye for detail is crucial in ensuring each piece meets the highest standards of quality before leaving your care. This showcases your commitment to excellence.

Next Steps

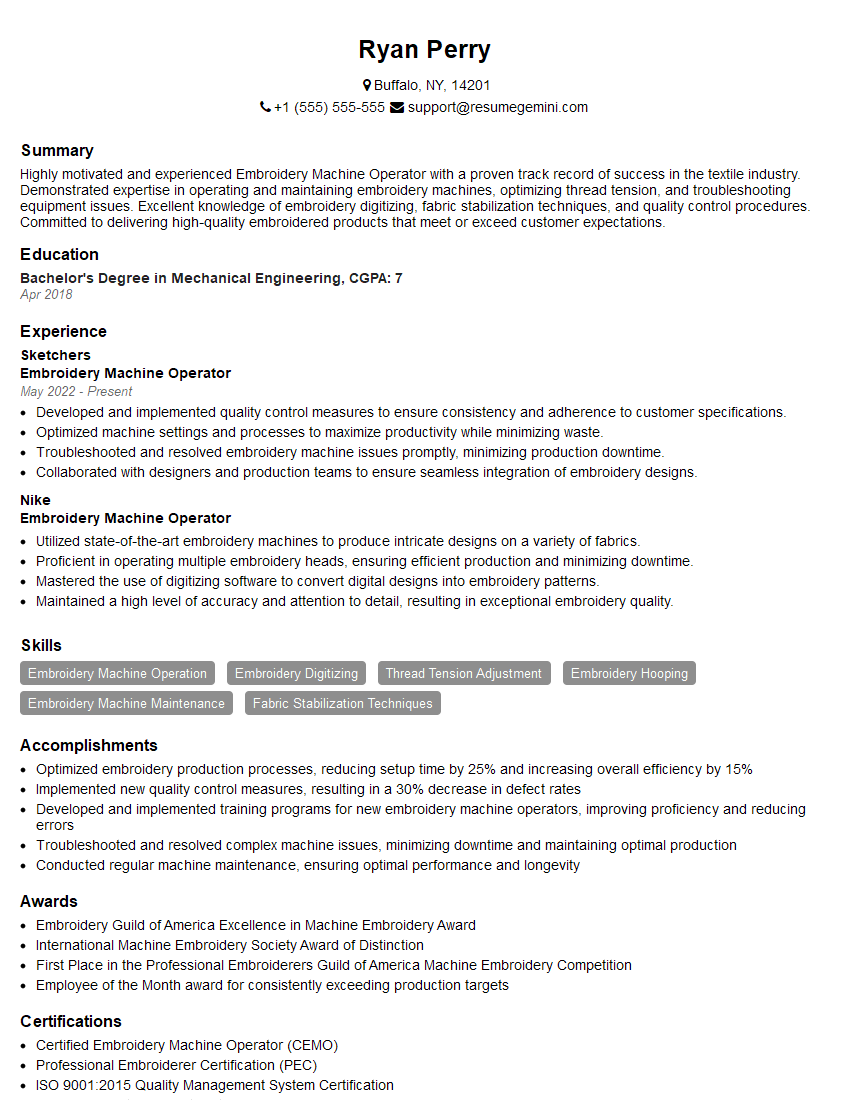

Mastering embroidery pressing opens doors to diverse and rewarding career opportunities, from working in high-end fashion houses to running your own successful business. To maximize your job prospects, creating a strong, ATS-friendly resume is critical. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience in embroidery pressing. Examples of resumes tailored to this field are available to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good