Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Reactor Core Physics and Design interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Reactor Core Physics and Design Interview

Q 1. Explain the six-factor formula and its significance in reactor criticality.

The six-factor formula is a fundamental equation in reactor physics that quantifies the multiplication factor (k), which determines whether a nuclear reactor is critical, subcritical, or supercritical. A reactor is critical when k=1, meaning one neutron from a fission event leads to another fission event, sustaining the chain reaction. The formula breaks down the multiplication factor into six key components, each representing a stage in the neutron lifecycle:

- η (Eta): The number of neutrons produced per thermal neutron absorbed in the fuel. This depends on the fuel’s isotopic composition and the energy spectrum of neutrons.

- ε (Epsilon): The fast fission factor, representing the increase in neutron production due to fast fission in fertile isotopes (like U-238) before thermalization.

- p (p): The resonance escape probability, the fraction of neutrons that avoid resonance absorption in the fuel before thermalization. This is crucial for achieving efficient fuel utilization.

- f (f): The thermal utilization factor, the fraction of thermal neutrons absorbed in the fuel. A higher value indicates better fuel utilization.

- PNL (PNL): The non-leakage probability during fast neutron slowing down. It signifies the fraction of fast neutrons that don’t escape the core during moderation.

- PTL (PTL): The non-leakage probability for thermal neutrons. This reflects the fraction of thermal neutrons that remain within the core for absorption.

The formula is: k = ηεpfPNLPTL. Understanding each factor is vital for reactor design because adjusting parameters like fuel enrichment, moderator density, and core geometry directly influences these factors, ultimately impacting reactor criticality and efficiency.

For example, increasing the fuel enrichment (higher U-235 concentration) increases η, potentially leading to a higher k. Similarly, using a better moderator (like heavy water) can increase both p and PTL. Careful consideration of these factors ensures safe and efficient reactor operation.

Q 2. Describe the different types of nuclear reactor cores and their advantages/disadvantages.

Nuclear reactor cores are categorized based on several factors including the type of fuel, moderator, coolant, and neutron energy spectrum. Here are some examples:

- Pressurized Water Reactor (PWR): Uses enriched uranium fuel, water as both moderator and coolant. Advantages include well-established technology and relatively high power density. Disadvantages include lower thermal efficiency and potential for steam explosions under accident conditions.

- Boiling Water Reactor (BWR): Similar to PWRs but allows water to boil within the core, producing steam directly. Advantages include simplified design and potential for higher thermal efficiency. Disadvantages include potential for void reactivity effects, making control more challenging.

- CANDU (CANada Deuterium Uranium): Uses natural uranium fuel and heavy water as both moderator and coolant. Advantages include utilizing natural uranium, minimizing enrichment needs and proliferation concerns. Disadvantages include larger core size and slower response to control adjustments.

- Fast Breeder Reactor (FBR): Uses enriched fuel and a liquid metal coolant (sodium or lead) without a moderator. Advantages include high breeding ratio, effectively utilizing fertile isotopes like U-238 and Th-232. Disadvantages include challenging material compatibility and safety concerns related to sodium fires.

- Gas-Cooled Reactor (GCR): Uses graphite as a moderator and a gas (CO2 or helium) as a coolant. Advantages include high operating temperatures, potential for high thermal efficiency, and inherent safety features. Disadvantages include large core size and potential for graphite degradation.

The choice of reactor core type depends on various factors, including power output requirements, fuel availability, safety considerations, and economic factors.

Q 3. What are the key considerations in designing a reactor core for optimal fuel utilization?

Optimal fuel utilization in reactor core design centers on maximizing the energy extracted from each fuel assembly before it needs replacement. Key considerations include:

- Fuel Enrichment: Higher enrichment increases initial reactivity but might lead to higher fuel costs and less efficient long-term burnup. A careful balance is required.

- Fuel Management Strategies: Strategies like shuffling fuel assemblies between core locations during refueling to equalize burnup and optimize neutron flux distribution are crucial for efficient fuel use.

- Moderator Design: The moderator’s properties influence neutron moderation and absorption, thus impacting the resonance escape probability and thermal utilization factor, significantly influencing fuel burnup.

- Core Geometry and Design: Optimizing the core geometry can enhance neutron economy and improve fuel utilization. The optimal core design depends on the specific reactor type and fuel cycle.

- Burnable Poisons: Incorporating burnable poisons, which absorb neutrons during operation and gradually disappear, helps to flatten the power distribution and improve fuel utilization.

For instance, a PWR might employ a radial fuel shuffling strategy where fuel assemblies from the periphery are moved towards the center during refueling. This equalizes burnup across different fuel assemblies and enhances fuel utilization, potentially extending the time between refueling outages.

Q 4. How do you account for neutron leakage in reactor core calculations?

Neutron leakage is a crucial aspect of reactor core calculations because neutrons escaping the core contribute neither to fission nor power generation. We account for neutron leakage through:

- Diffusion Theory: This method utilizes the diffusion equation to model neutron transport, considering the leakage term to estimate the neutron flux distribution and its reduction due to leakage.

- Transport Theory: A more accurate but computationally intensive method than diffusion theory, directly solving the Boltzmann transport equation to model neutron behavior, including leakage.

- Monte Carlo Methods: These statistical methods simulate individual neutron interactions within the core, providing a detailed picture of neutron transport and leakage. They are computationally expensive but offer higher accuracy.

The non-leakage probability (PNL and PTL in the six-factor formula) explicitly accounts for the fraction of neutrons that do not leak from the core. These probabilities are calculated based on the core geometry, material properties, and the neutron energy spectrum. The goal is to design a core with low neutron leakage to enhance criticality and improve fuel utilization. This might involve selecting an optimal core size and shape, using reflectors surrounding the core to reduce leakage, and other design considerations.

Q 5. Explain the concept of burnup and its impact on reactor performance.

Burnup refers to the fraction of heavy metal atoms (primarily uranium and plutonium) that undergo fission in a nuclear fuel assembly during its operational lifetime. It’s usually measured in megawatt-days per metric ton of heavy metal (MWd/MTU). Higher burnup means a greater amount of energy has been extracted from the fuel before disposal or reprocessing.

Burnup significantly impacts reactor performance because it alters the isotopic composition of the fuel. As fission proceeds, the concentration of fissile isotopes (like U-235 and Pu-239) decreases, while the concentration of fission products and actinides (like plutonium isotopes and minor actinides) increases. This change impacts:

- Reactivity: As burnup increases, reactivity generally decreases due to the depletion of fissile isotopes. This necessitates control adjustments to maintain criticality.

- Power Distribution: The change in isotopic composition can lead to changes in power distribution across the core, potentially requiring adjustments to fuel management strategies.

- Fuel Cycle Costs: Higher burnup reduces the amount of spent fuel generated per unit of energy, leading to lower costs associated with fuel disposal and/or reprocessing.

High burnup designs are favored for their economic and environmental benefits, but they demand careful design considerations to ensure safe and efficient reactor operation over the entire fuel cycle. Advanced reactor designs frequently strive for increased burnup to maximize fuel utilization.

Q 6. Describe different methods for controlling reactor power and reactivity.

Reactor power and reactivity are controlled through various methods:

- Control Rods: These rods, typically made of neutron-absorbing materials (like boron or cadmium), are inserted into or withdrawn from the core to adjust neutron absorption, thereby controlling reactivity and power level. This is the primary method of power control.

- Chemical Shim Control: This involves adding or removing soluble neutron poisons (like boric acid) in the coolant to fine-tune reactivity. It’s often used for long-term reactivity control.

- Moderator Control: In reactors using water or heavy water as moderators, adjusting the moderator density or temperature can influence the moderation process, affecting reactivity. This method is employed in some reactor types.

- Burnable Poisons: As mentioned earlier, these materials absorb neutrons during operation, gradually reducing their concentration, thus providing a controlled reactivity decrease over time.

Reactor power is typically controlled through a combination of these methods. For example, control rods provide fast-acting reactivity adjustments for immediate power changes, whereas chemical shim control helps manage longer-term reactivity changes associated with fuel burnup. Sophisticated control systems continuously monitor reactor parameters and automatically adjust control mechanisms to maintain safe and stable operation.

Q 7. What are the safety features incorporated in modern reactor core designs?

Modern reactor core designs incorporate several safety features to mitigate potential accidents and prevent releases of radioactive materials:

- Passive Safety Systems: These systems rely on natural physical processes (like gravity or convection) to enhance safety, requiring minimal operator intervention during accidents. Examples include passive residual heat removal systems and gravity-driven core flooding systems.

- Redundant Safety Systems: Multiple independent safety systems are implemented to ensure that even if one system fails, others can still function to prevent accidents. This includes redundant shutdown systems, emergency core cooling systems, and containment systems.

- Inherent Safety Features: These features, often related to the reactor’s design, minimize the likelihood or consequences of accidents. Examples include negative void coefficient (where increased void fraction reduces reactivity) and inherent shutdown mechanisms.

- Containment Structures: Robust containment structures designed to withstand pressure and temperature changes prevent the release of radioactive materials to the environment in case of accidents.

- Advanced Instrumentation and Control Systems: Sophisticated instrumentation and control systems continuously monitor reactor parameters, provide early warning of anomalies, and automatically initiate safety actions if needed.

The selection and design of safety features depend on many factors, including the reactor type, its power level, and site-specific considerations. However, the primary goal is to design a system that can withstand a range of anticipated and beyond-design-basis accidents with minimal environmental impact and human harm.

Q 8. Explain the role of moderator and coolant in a reactor core.

In a nuclear reactor, the moderator and coolant play crucial, yet distinct, roles in controlling the fission chain reaction and managing the heat generated.

The moderator‘s primary function is to slow down fast neutrons produced during fission. These fast neutrons are less likely to cause further fission compared to thermal neutrons (slow neutrons). Common moderators include water (light water reactors – LWRs), heavy water (heavy water reactors – HWRs), and graphite. Think of the moderator as a billiard ball slowing down others—the fast neutrons lose energy upon collision with moderator atoms, allowing them to more effectively interact with the fuel and sustain a chain reaction.

The coolant, on the other hand, is responsible for removing the substantial heat generated by fission. This heat, if not removed, can cause core damage and potential meltdowns. Coolants, such as water, heavy water, helium, or liquid sodium, circulate through the reactor core, absorbing the heat and transporting it to a heat exchanger where it’s used to generate electricity.

Sometimes, a single substance serves as both moderator and coolant, as in pressurized water reactors (PWRs), where water performs both functions. Other designs, like gas-cooled reactors, use separate moderator and coolant materials for enhanced performance and safety.

Q 9. Discuss different types of nuclear fuel and their properties.

Nuclear fuel is the heart of a reactor, containing fissile isotopes capable of sustaining a chain reaction. Several types are used, each with unique characteristics:

- Uranium Dioxide (UO2): This is the most common fuel, typically enriched to increase the proportion of the fissile isotope 235U. Enrichment increases the probability of fission and improves reactor efficiency. UO2 is chosen because of its high melting point, chemical stability, and relatively easy fabrication.

- Plutonium Dioxide (PuO2): Plutonium-239, a fissile isotope, is produced as a byproduct in uranium-fueled reactors. PuO2 can be used as a fuel in various reactor types, including fast breeder reactors (FBRs), where it can even be bred from 238U, resulting in a significant increase in fuel efficiency.

- Mixed Oxide Fuel (MOX): MOX fuel is a mixture of UO2 and PuO2, allowing for the effective use of plutonium stockpiles and reducing long-term waste management challenges. It’s used in several commercial reactors.

- Thorium Dioxide (ThO2): Thorium-232 is fertile material that can be converted to fissile 233U through neutron capture. Thorium reactors offer potential advantages in terms of proliferation resistance and waste management, though their widespread adoption remains a work in progress.

The choice of fuel depends on various factors including reactor type, performance requirements, economic considerations, and safety aspects. For instance, the high neutron flux in fast reactors necessitates fuels with superior radiation resistance compared to those used in thermal reactors.

Q 10. How do you model the spatial distribution of neutrons in a reactor core?

Modeling the spatial distribution of neutrons in a reactor core is crucial for predicting reactor behavior, power distribution, and safety. This is typically achieved using numerical methods to solve the neutron transport equation, a complex equation governing the movement and interaction of neutrons within the core.

Several approaches exist:

- Diffusion Theory: A simplified approach useful for large, homogeneous cores. It approximates the neutron transport equation, making calculations less computationally intensive but less accurate than other methods.

- Transport Theory: A more accurate approach providing a detailed description of neutron behavior but is computationally expensive, requiring significant resources for complex geometries. Methods like discrete ordinates (SN) or Monte Carlo are commonly employed.

- Monte Carlo Methods: Stochastic methods that simulate neutron behavior statistically. This is highly accurate but computationally intensive, often used for detailed core simulations and specialized analyses like shielding calculations.

The chosen method depends on the desired accuracy and computational resources available. Most advanced reactor designs utilize sophisticated software packages employing combinations of these techniques to precisely model neutron behavior across diverse geometries and compositions. For example, MCNP or Serpent are commonly used codes for detailed neutron transport calculations, while simpler diffusion codes are useful for initial estimations.

Q 11. What are the challenges associated with designing a high-burnup reactor core?

Designing a high-burnup reactor core, where fuel remains in the reactor for an extended period before replacement, presents several challenges:

- Fuel Swelling and Fission Gas Release: As fuel undergoes fission, it swells due to the formation of fission products, causing potential mechanical stresses and the release of gaseous fission products that can pressurize the fuel cladding and impact reactor safety.

- Increased Radiation Damage: Prolonged irradiation leads to significant damage to the fuel and cladding materials, affecting their mechanical properties and integrity. The degradation of the cladding can lead to the release of fission products into the coolant.

- Complex Depletion Behavior: Accurate prediction of isotopic changes and burnup profiles over extended periods becomes crucial, requiring complex depletion calculations and sophisticated modeling techniques.

- Increased Plutonium Isotope Production: High burnup leads to the accumulation of minor actinides and other long-lived fission products, posing waste management challenges.

- Material Compatibility: Ensuring the compatibility of fuel, cladding, and structural materials under extreme conditions of temperature, pressure, and radiation becomes exceedingly important.

Addressing these challenges requires advanced fuel designs, robust cladding materials, detailed modeling, and stringent quality control throughout the fuel cycle. For instance, using advanced fuel designs with optimized compositions and microstructures or incorporating ceramic matrix composites as cladding can mitigate some of these issues.

Q 12. Explain the concept of void coefficient and its implications for reactor safety.

The void coefficient describes the change in reactor reactivity (the ability to sustain a chain reaction) as a function of changes in coolant density. A positive void coefficient implies that an increase in voids (bubbles of steam in the coolant, for example) increases reactor reactivity, potentially leading to a dangerous power surge. Conversely, a negative void coefficient indicates that increasing voids decreases reactivity, providing an inherent safety mechanism.

Implications for Reactor Safety: A positive void coefficient can be extremely dangerous. If a coolant channel experiences a partial blockage or begins to boil, the formation of voids can lead to a rapid increase in power, potentially leading to a runaway chain reaction. This was a significant factor in the Chernobyl accident. Therefore, reactor designs strive for a strongly negative void coefficient, ensuring that any coolant loss or void formation results in reduced reactivity, promoting inherent reactor stability and safety.

For example, in pressurized water reactors, the large negative void coefficient in the thermal range acts as a safety feature limiting the consequences of potential accidents.

Q 13. How do you perform a depletion calculation for a reactor core?

A depletion calculation simulates the change in isotopic composition and power distribution within a reactor core over time. This is essential for predicting fuel burnup, isotopic inventory, and reactor performance. The process involves solving a system of coupled differential equations that describe the changes in the concentration of various isotopes due to fission, decay, and neutron absorption.

The steps typically involve:

- Defining Initial Conditions: Specifying the initial isotopic composition of the fuel, the reactor geometry, and operating parameters.

- Neutronics Calculation: Determining the neutron flux distribution throughout the reactor core, using methods such as diffusion theory or Monte Carlo methods.

- Solving the Bateman Equations: Employing numerical methods to solve a set of coupled differential equations (Bateman equations) that govern the evolution of different nuclides’ concentrations as a function of time and neutron flux.

- Iteration and Feedback: Repeating the neutronics and depletion calculations iteratively since the changes in isotopic composition affect the neutron flux distribution and vice versa. This process continues until convergence is achieved.

- Post-Processing: Analyzing the results to obtain key parameters such as burnup, isotopic composition, power distribution, and fuel depletion profiles.

Sophisticated depletion codes, such as ORIGEN or CASMO, are used to perform these calculations, employing advanced numerical techniques to ensure accuracy and efficiency. The output of these calculations is crucial for fuel management, reactor operation planning, and waste management assessments.

Q 14. Describe the different types of reactor kinetics models.

Reactor kinetics models describe the time-dependent behavior of a nuclear reactor, particularly its response to perturbations (like reactivity changes). Several models exist with varying degrees of complexity:

- Point Kinetics Model: The simplest model, assuming uniform neutron flux throughout the core. This is computationally efficient but lacks spatial detail. It is useful for understanding overall reactor dynamics but is insufficient for analyzing spatial power oscillations.

- Space-Time Kinetics Models: These models account for the spatial variation of neutron flux, providing a more accurate description of reactor dynamics, especially in larger, heterogeneous cores. Numerical methods, such as finite differences or finite elements, are often employed to solve these equations. These are crucial for understanding localized power oscillations, xenon oscillations and the overall core behavior following transients or accidents.

- Multi-group Kinetics Models: These consider the energy dependence of neutrons, improving accuracy in regions with significant energy spectrum variations. This provides a more detailed picture of neutron behavior.

The choice of model depends on the specific application. Point kinetics are suitable for quick estimations and preliminary analyses, while space-time kinetics are necessary for detailed simulations and safety analyses, especially under transient conditions. Sophisticated codes, incorporating advanced numerical methods, are commonly used for performing reactor kinetics simulations and analyzing reactor safety features.

Q 15. Explain the importance of feedback mechanisms in reactor operation.

Feedback mechanisms in reactor operation are crucial for maintaining stable and safe power levels. They represent the intricate interplay between various reactor parameters and how changes in one affect others, creating a self-regulating system (or, if not properly managed, a runaway reaction). Imagine a thermostat controlling room temperature: If the room gets too hot, the thermostat reduces the heating; if it gets too cold, it increases the heating. Similarly, a nuclear reactor uses feedback mechanisms to control its power output.

These mechanisms can be positive or negative. Negative feedback, the most desirable type, works to dampen changes, returning the reactor to its operating point. For example, as reactor power increases, the fuel temperature rises, causing a decrease in reactivity (the ability to sustain a chain reaction), thus reducing power. This is a crucial safety feature. Positive feedback, on the other hand, amplifies changes, potentially leading to instability or even a reactor excursion (a rapid increase in power). It’s essential to design and operate reactors to minimize positive feedback effects.

- Temperature Feedback: Changes in fuel and coolant temperature affect reactivity.

- Xenon Poisoning: Xenon-135, a fission product, absorbs neutrons and reduces reactivity (discussed in more detail later).

- Control Rods: These neutron absorbers are manually or automatically adjusted to regulate power levels.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common methods used for measuring reactor parameters?

Measuring reactor parameters accurately and reliably is paramount for safe and efficient operation. A multitude of instruments are used, often operating redundantly for safety reasons. Think of it as having multiple independent witnesses verifying a critical process.

- Neutron Flux Measurement: This is fundamental. Instruments like fission chambers and ion chambers detect neutron flux, directly related to reactor power. These often employ a variety of neutron-sensitive materials to ensure a wide range of flux detection.

- Temperature Sensors: Thermocouples and resistance temperature detectors (RTDs) monitor temperatures of the fuel, coolant, and other reactor components. This is essential for preventing overheating and ensuring coolant remains in its appropriate phase (liquid).

- Pressure Sensors: These gauge coolant pressure within the reactor vessel and the primary coolant loops. Pressure monitoring is critical for ensuring the integrity of the system and detecting potential leaks.

- Radiation Detectors: Geiger-Müller counters, scintillation detectors, and others monitor radiation levels at various points, providing a comprehensive view of radiation emitted by the reactor.

- Chemical Analysis: Samples of coolant are periodically taken and analyzed to monitor the concentration of dissolved fission products and other chemical species. This is important in determining the reactor’s operational health and anticipating potential problems.

Data from these instruments is continuously monitored and analyzed to ensure the reactor operates within its safety limits and performance targets.

Q 17. Discuss the principles of radiation shielding in reactor design.

Radiation shielding in reactor design is critical for protecting personnel, the environment, and the reactor itself from harmful radiation. The goal is to reduce radiation levels to safe, manageable levels. Imagine building a fortress around a powerful energy source. We use multiple layers of defense.

- Biological Shield: This is the primary shield, usually made of high-density concrete or steel, which surrounds the reactor core. It significantly attenuates (reduces) the intensity of the radiation.

- Thermal Shield: Located between the core and the biological shield, this shield protects the biological shield from excessive heat generated by the reactor.

- Neutron Shielding: Certain materials are particularly effective at absorbing neutrons. Common examples include boron-containing materials and water, due to boron’s high neutron absorption cross-section, and water’s ability to moderate neutrons which then makes them easier to absorb.

- Gamma Shielding: Lead and high-density concrete are used extensively to attenuate gamma radiation, a type of high energy electromagnetic radiation that is very penetrating.

The design of the shielding is carefully optimized using sophisticated calculations and simulations to ensure sufficient protection while minimizing weight and cost. The thickness and composition of each shielding layer are determined based on the type and energy of the radiation being shielded, and the desired level of radiation reduction.

Q 18. How do you ensure the integrity of the reactor core during operation?

Ensuring the integrity of the reactor core during operation is paramount. It involves multiple layers of safety and monitoring systems, continuously assessing and mitigating risks.

- Material Selection: Fuel elements (typically uranium dioxide pellets) and cladding materials (e.g., zirconium alloys) are meticulously chosen for their high-temperature resistance, radiation resistance, and ability to withstand high pressures.

- Non-Destructive Testing (NDT): Before use, fuel assemblies undergo rigorous NDT to detect any flaws or defects. Techniques like ultrasonic testing and radiography help ensure that the fuel is sound.

- Online Monitoring: During operation, various sensors monitor fuel temperature, cladding integrity, and other critical parameters. This allows for early detection of anomalies.

- Coolant System Integrity: A robust coolant system is vital. Leaks or failures in the coolant system can lead to core damage. Redundancy and safety systems are built in to mitigate risks.

- Safety Systems: Multiple independent safety systems are designed to shut down the reactor in case of an emergency, preventing core damage or a meltdown.

The design and operation of the reactor incorporate substantial safety margins to account for uncertainties and unexpected events. Regular inspections and maintenance are crucial in maintaining the core’s structural integrity over its operational lifetime.

Q 19. Describe the process of refueling a nuclear reactor.

Refueling a nuclear reactor is a complex and carefully planned procedure, typically involving shutting down the reactor, removing spent fuel assemblies, and inserting fresh ones. It’s like performing major surgery on a power plant, requiring precise coordination and specialized equipment.

- Reactor Shutdown: The reactor is carefully and safely shut down to allow for safe access to the core.

- Spent Fuel Removal: Spent fuel assemblies, which are highly radioactive, are removed from the core using specialized equipment. They are placed in storage pools within the reactor building for cooling and later transport.

- Core Inspection: The reactor core is inspected for damage or wear. Sophisticated cameras and other inspection tools are used to assess the condition of the fuel assemblies, control rods, and other core components.

- New Fuel Insertion: Fresh fuel assemblies are carefully inserted into the core, often in a precise arrangement designed to optimize power distribution and burnup.

- Startup and Testing: Once refueling is complete, the reactor undergoes a comprehensive testing program to ensure its safe and reliable operation before returning to full power.

The entire process is meticulously documented and adheres to stringent safety regulations to prevent accidents and radiation exposure. Highly trained personnel conduct this complex process.

Q 20. What are the effects of xenon poisoning on reactor operation?

Xenon poisoning is a phenomenon where Xenon-135, a fission product with a high neutron absorption cross-section, builds up in the reactor core, reducing its reactivity and thus power output. Imagine a sponge absorbing the neutrons necessary to sustain the chain reaction. This is particularly important during reactor startups and power maneuvering.

After a reactor shutdown, the concentration of Xenon-135 increases because its precursor, Iodine-135 (which decays into Xenon-135), continues to be produced through fission. This leads to a period of time when the reactor cannot easily be restarted, known as the ‘xenon override’ period. To overcome this, the reactor may need to wait until the Xenon-135 decays sufficiently or use extra reactivity (e.g., by withdrawing more control rods than normal).

During power changes, especially reductions, Xenon poisoning can cause temporary reactivity dips that need to be managed carefully to maintain stable operation. Reactor operators need to carefully model and compensate for xenon effects to prevent unexpected power oscillations or shutdowns.

Q 21. Explain the concept of Doppler broadening and its impact on reactor stability.

Doppler broadening is a phenomenon where the absorption of neutrons by fuel atoms (primarily Uranium-238) changes with temperature. It’s a critical negative feedback mechanism crucial for reactor stability. Think of it as a temperature-dependent safety valve.

As the fuel temperature increases, the resonant absorption of neutrons by Uranium-238 broadens and thus increases. This means more neutrons are absorbed, reducing the number of neutrons available for fission and thereby reducing the reactor’s power. This negative feedback effect is incredibly important for stabilizing reactor power and preventing runaway reactions.

Without Doppler broadening, changes in reactor power would be less controlled, leading to potentially dangerous power oscillations or excursions. It provides inherent safety in many reactor designs by acting as a self-regulating mechanism against power surges.

Q 22. How do you analyze the thermal-hydraulics of a reactor core?

Analyzing a reactor core’s thermal-hydraulics involves understanding the interplay between heat generation, fluid flow, and heat transfer within the core. It’s crucial for ensuring safe and efficient reactor operation. We use a combination of experimental data and sophisticated computational models to achieve this.

The process typically involves:

- Heat Source Modeling: Accurately determining the power distribution within the core using neutronics codes (like those mentioned in the next question). This provides the heat generation profile as the input for thermal-hydraulic analysis.

- Fluid Flow Modeling: Simulating the coolant flow through the fuel assemblies, considering factors like pressure drop, flow distribution, and coolant properties (density, viscosity, etc.). This often involves solving the Navier-Stokes equations, possibly with turbulence models.

- Heat Transfer Modeling: Calculating the heat transfer from the fuel rods to the coolant, considering conduction within the fuel and cladding, convection from the cladding to the coolant, and boiling (if applicable). This requires understanding heat transfer coefficients and correlations.

- Subchannel Analysis: Detailed analysis of the coolant flow and temperature in individual subchannels within a fuel assembly to identify potential hot spots.

- System-Level Modeling: Coupling the core thermal-hydraulics model with the rest of the reactor system (primary loop, steam generators, etc.) to assess overall system performance and safety.

Example: Imagine analyzing the thermal performance of a Pressurized Water Reactor (PWR). We would model the heat generation from nuclear fission, simulate the flow of pressurized water through the fuel assemblies, and calculate the temperature rise of the coolant. We’d then verify that the cladding temperature remains below the safety limits, avoiding fuel damage or departure from nucleate boiling (DNB).

Q 23. Discuss the use of computational tools (e.g., MCNP, Serpent) in reactor physics.

Computational tools like MCNP (Monte Carlo N-Particle Transport Code) and Serpent are indispensable in reactor physics. They allow us to simulate neutron transport and predict various core parameters with high accuracy. These tools are essential for core design, safety analysis, and operational optimization.

- MCNP: A widely used general-purpose Monte Carlo code. It’s excellent for complex geometries and detailed modeling of neutron interactions. Its strength lies in its ability to handle sophisticated material compositions and detailed descriptions of reactor components. It’s often used for shielding calculations and criticality safety analyses.

- Serpent: A continuous-energy Monte Carlo reactor physics burnup code. It’s particularly efficient for performing burnup calculations, predicting isotopic changes over the reactor’s lifetime, and accurately modeling the depletion of fissile materials. It’s often preferred for its speed and efficiency in large-scale simulations.

Practical Application: Imagine designing a new reactor core. We’d use Serpent to simulate the fuel depletion over several cycles, predicting isotopic changes and the resulting reactivity variations. Then, we’d use MCNP to verify the shielding design and ensure radiation levels remain within acceptable limits. Both codes allow us to perform sensitivity studies to assess the impact of design changes on core performance and safety.

Example Serpent input snippet: # Material definition mat fuel 1.0 0.0 U235 0.05 U238 0.95 Q 24. Explain the concept of criticality safety.

Criticality safety is paramount in nuclear reactor design and operation. It focuses on preventing accidental criticality—a self-sustaining nuclear chain reaction—which could lead to a power excursion and potentially severe consequences. The goal is to ensure that the number of neutrons produced in fission does not exceed the number of neutrons absorbed or lost, maintaining a subcritical state when the reactor is shut down or during fuel handling.

Key aspects include:

- Subcriticality Limits: Establishing and maintaining a sufficient margin of subcriticality during all phases of operation, such as refueling, maintenance, and shutdown.

- Administrative Controls: Implementing strict procedures and protocols for fuel handling, storage, and transportation, to prevent accidental configurations that could lead to criticality.

- Geometric Considerations: Designing fuel storage and processing facilities with specific shapes and arrangements to ensure subcriticality, even with maximum fuel density.

- Neutron Absorbers: Incorporating neutron-absorbing materials (like boron or cadmium) to reduce neutron multiplication and enhance safety.

- Criticality Calculations: Using computational tools (like MCNP) to perform criticality safety analyses and predict the behavior of different fuel configurations under various conditions.

Example: During fuel handling, we must ensure that the arrangement of fuel assemblies in the storage pool maintains a significant margin of subcriticality, preventing even an accidental criticality. This involves careful design of the pool geometry and rigorous calculations using MCNP to confirm its safety.

Q 25. What are the regulations and standards governing reactor core design?

Reactor core design is heavily regulated to ensure public safety and environmental protection. Specific regulations vary by country but generally encompass several key areas:

- Licensing: Reactor designs and operating procedures require rigorous licensing procedures from relevant regulatory bodies (e.g., the Nuclear Regulatory Commission (NRC) in the US, the Office for Nuclear Regulation (ONR) in the UK).

- Safety Standards: Design must adhere to international and national safety standards, like those from the International Atomic Energy Agency (IAEA) or national standards organizations. These standards cover numerous aspects, including thermal-hydraulics, materials, instrumentation, and emergency systems.

- Quality Assurance (QA): Stringent QA programs must be implemented throughout the design, construction, and operation phases to ensure quality control and prevent defects.

- Accident Analysis: Comprehensive safety analyses must be performed to demonstrate that the reactor can withstand various accident scenarios, including loss-of-coolant accidents (LOCAs), and maintain the integrity of the containment.

- Environmental Protection: Environmental impact assessments must be conducted and environmental regulations adhered to to minimize the reactor’s environmental footprint.

Example: A new reactor design must demonstrate compliance with the NRC’s requirements for accident tolerance, including the ability to withstand a station blackout without fuel damage, fulfilling stringent requirements related to safety and environmental impact.

Q 26. Describe different methods for evaluating reactor safety.

Evaluating reactor safety involves a multi-faceted approach combining probabilistic and deterministic methods:

- Deterministic Safety Analysis: This involves analyzing the behavior of the reactor under specific accident scenarios using detailed computer models (e.g., thermal-hydraulic codes like RELAP5). These analyses aim to demonstrate that the reactor can withstand these events without exceeding safety limits.

- Probabilistic Safety Assessment (PSA): PSA utilizes probabilistic methods to assess the likelihood of accidents and their potential consequences. It involves identifying potential failure modes, estimating their probabilities, and calculating the risks associated with various accident scenarios. This provides a quantitative measure of reactor safety.

- Experimental Validation: Experimental data from research reactors and component testing are essential for validating the accuracy of computational models used in safety analyses. This is crucial for ensuring the reliability of the predicted reactor behavior.

- Human Factors Analysis: Assessing the role of human factors (operator actions, training, etc.) in contributing to or mitigating accidents is crucial. This involves analyzing human error probabilities and designing procedures to minimize their impact.

Example: A PSA might quantify the probability of a LOCA occurring and the potential consequences, such as core damage or radioactive release. This information helps inform design choices and emergency procedures to reduce the risk.

Q 27. How would you approach the problem of a positive void coefficient in a reactor design?

A positive void coefficient, where an increase in coolant void fraction (steam bubbles) leads to an increase in reactivity, poses a significant safety concern. This can lead to a dangerous positive feedback loop, potentially resulting in a rapid power increase and potential core damage. Addressing this requires a multi-pronged approach:

- Design Modifications: Altering the core design to mitigate the positive void coefficient is crucial. This might involve:

- Fuel enrichment optimization: Carefully selecting fuel enrichment levels to minimize reactivity changes with void fraction.

- Moderator choice and distribution: Utilizing moderators that exhibit a less pronounced positive void coefficient, or optimizing their distribution within the core.

- Poison management: Implementing effective poison management strategies to control reactivity and mitigate the impact of voiding.

- Operational Strategies: Developing operational strategies to prevent voiding and maintain reactor stability, including tighter control of operating parameters.

- Safety Systems: Implementing robust safety systems (like SCRAM systems) that can quickly shut down the reactor in case of abnormal voiding.

- Further Analysis: Performing detailed thermal-hydraulic and neutronic calculations to thoroughly understand and quantify the positive void coefficient.

Example: In Boiling Water Reactors (BWRs), the positive void coefficient is inherent to their design. Mitigation strategies include careful control of coolant flow and pressure, and the use of sophisticated control rod systems to quickly compensate for any reactivity increase due to void formation.

Q 28. Explain the significance of isotopic composition changes during reactor operation.

Isotopic composition changes during reactor operation significantly affect reactor behavior and performance. This is a consequence of nuclear reactions, including fission, radioactive decay, and neutron capture.

Key implications include:

- Fuel Depletion: Fissile isotopes (like U-235 and Pu-239) are consumed during fission, leading to a reduction in reactivity over time. This necessitates periodic refueling.

- Buildup of Fission Products: Fission products are created during fission, many of which are neutron absorbers. This buildup gradually reduces reactor reactivity, impacting the operational lifetime and requiring careful management.

- Production of Plutonium: Neutron capture by U-238 leads to the formation of plutonium isotopes (like Pu-239), which are also fissile. This can extend the fuel cycle and enhance fuel utilization.

- Reactivity Changes: Changes in isotopic composition directly influence the reactor’s reactivity, affecting its power level and operational characteristics. Accurate prediction of these changes is essential for safe and efficient reactor operation.

- Waste Management: The accumulation of fission products and other radioactive materials requires careful management and disposal. The isotopic composition of the waste determines its radioactivity and its handling requirements.

Example: In a PWR, the concentration of U-235 decreases throughout the fuel cycle, while fission products like Xenon-135 build up, affecting the reactor’s reactivity. Accurate prediction of these changes is crucial for planning refueling operations and maintaining core stability.

Key Topics to Learn for Reactor Core Physics and Design Interview

- Neutronics: Understanding neutron transport, cross-sections, and criticality calculations. Practical application: Analyzing the reactivity of a reactor core under different operating conditions.

- Thermal Hydraulics: Mastering the principles of heat transfer and fluid flow within the reactor core. Practical application: Designing efficient cooling systems to prevent overheating and fuel damage.

- Fuel Management: Learning about fuel cycle analysis, burnup calculations, and strategies for optimizing fuel utilization. Practical application: Developing refueling schedules to maximize reactor efficiency and minimize waste.

- Reactor Kinetics and Dynamics: Understanding reactor response to changes in operating parameters and potential transient events. Practical application: Designing control systems to maintain stable reactor operation.

- Reactor Safety Analysis: Familiarizing yourself with safety criteria, accident analysis methods, and safety system design. Practical application: Evaluating the safety performance of a reactor design under various accident scenarios.

- Core Design and Optimization: Exploring different core designs, fuel assemblies, and control rod arrangements. Practical application: Optimizing core design for improved performance, safety, and economics.

- Nuclear Data and Codes: Gaining familiarity with nuclear data libraries and computational tools used in reactor analysis. Practical application: Performing simulations and calculations to predict reactor behavior.

Next Steps

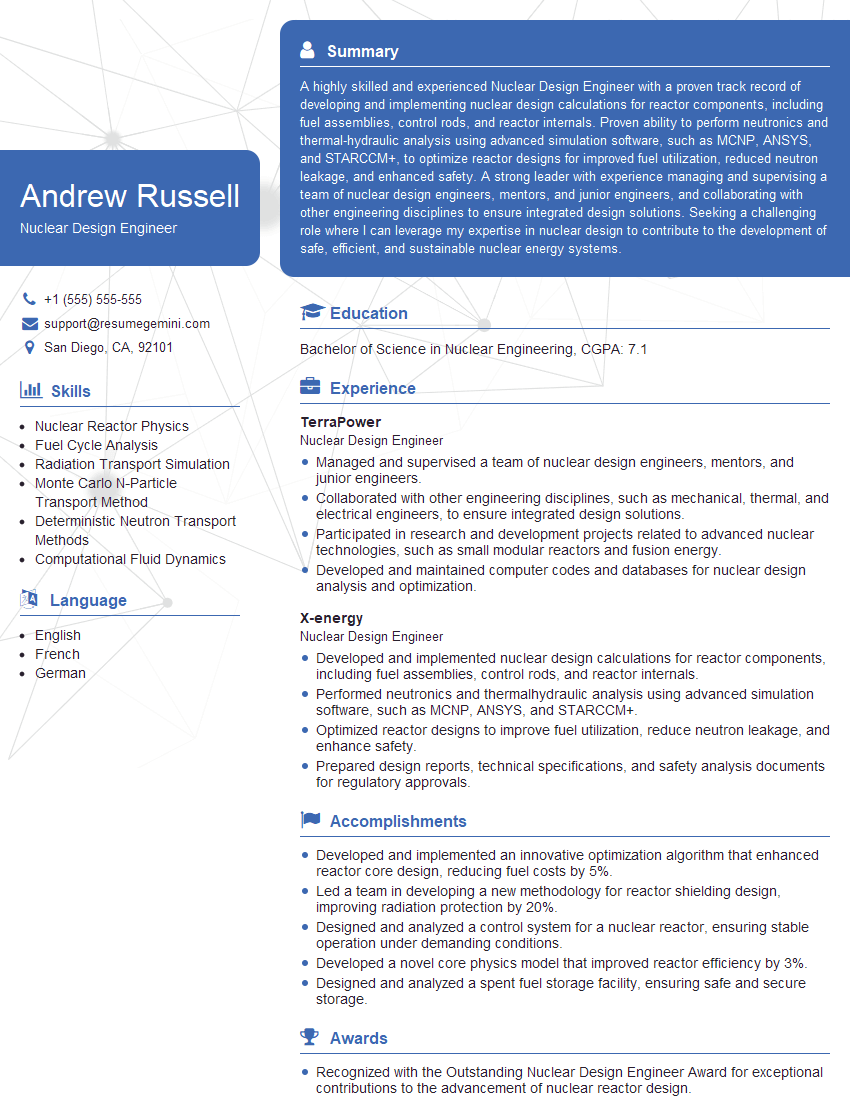

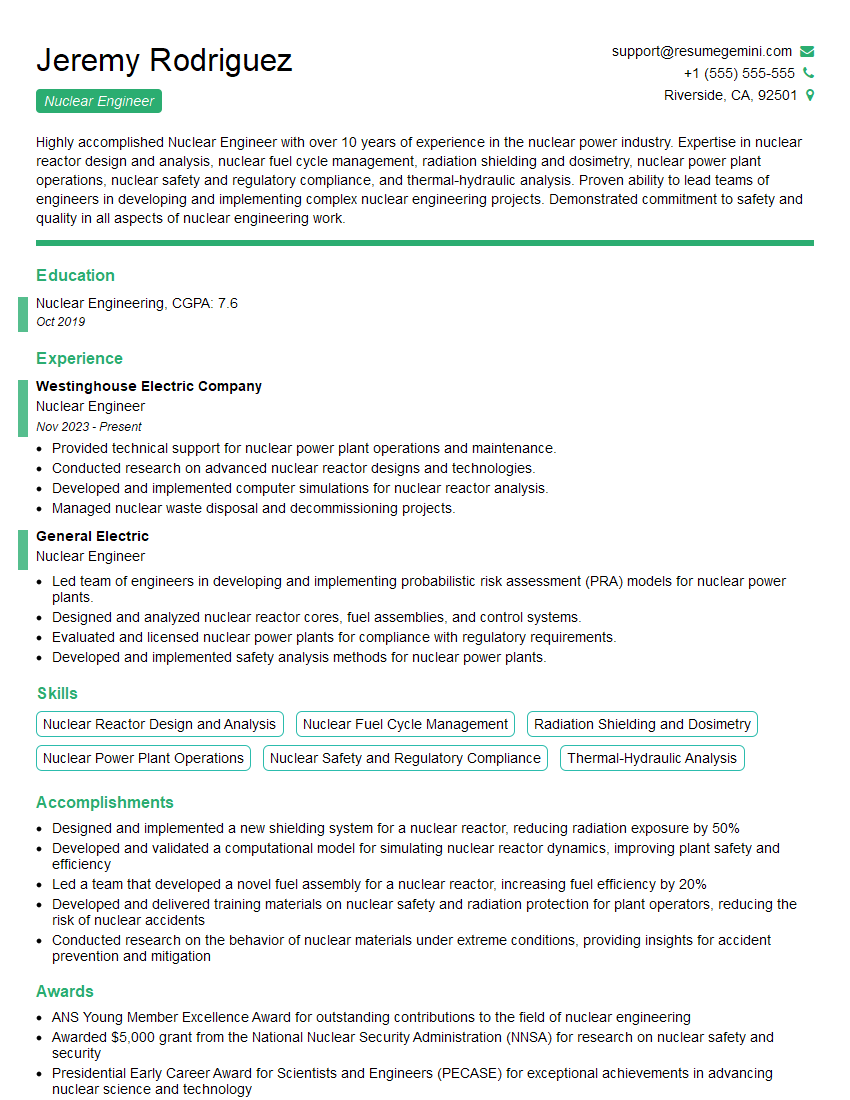

Mastering Reactor Core Physics and Design opens doors to exciting and impactful careers in the nuclear industry, offering opportunities for innovation and contributing to a sustainable energy future. To maximize your job prospects, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to Reactor Core Physics and Design positions to guide you through the process. Invest time in perfecting your resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good