Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Shooting Star Press interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Shooting Star Press Interview

Q 1. Explain the process of setting up a Shooting Star Press for a specific job.

Setting up a Shooting Star Press for a specific job involves a systematic approach. Think of it like preparing a recipe – you need the right ingredients and instructions in the correct order. First, you need to understand the job specifications: the type of paper, the ink colors required, the print quantity, and the desired print quality. Then, you load the appropriate paper into the feeder tray, ensuring it’s correctly aligned to avoid jams. Next, you select the correct ink cartridges and install them, making sure they’re properly seated. Then, you input the job parameters into the press’s control panel, specifying things like print resolution, color profiles, and the number of copies. Finally, you initiate the print job and monitor the process, making adjustments as needed. For instance, if you’re printing a high-resolution photograph on glossy paper, you’ll select a high-resolution setting and ensure the glossy paper is correctly loaded to avoid smudging or misalignment.

Imagine printing wedding invitations – you’d choose a thick, high-quality card stock, select the appropriate ink colors for the design, and meticulously check the alignment before starting the print run to ensure every invitation looks perfect.

Q 2. Describe the different types of inks used with Shooting Star Press and their applications.

Shooting Star Presses utilize a range of inks, each suited to different applications. Think of it like choosing the right paint for a project – you wouldn’t use watercolors for a house exterior! Common ink types include:

- Dye-based inks: These are vibrant and cost-effective, ideal for everyday printing on standard paper. They’re not as durable as pigment inks, though, and are prone to fading.

- Pigment-based inks: More durable and water-resistant than dye-based inks, these are preferred for projects requiring archival quality or resistance to smudging. Think of printing museum-quality artwork or documents needing long-term preservation.

- UV-curable inks: These inks require UV light to cure, making them incredibly durable and resistant to scratching and fading. They are common in applications demanding a high degree of scratch resistance, like signage or packaging.

The choice of ink depends heavily on the end use of the printed material. A birthday card might use dye-based inks for bright, cheerful colors, while a promotional banner might need the durability of UV-curable inks.

Q 3. How do you troubleshoot common paper jams on a Shooting Star Press?

Troubleshooting paper jams on a Shooting Star Press is a common task. The first step is to always turn off and unplug the machine for safety. Then, carefully follow these steps:

- Identify the jam location: Most presses have indicators or error messages pinpointing the jam’s location – feeder, output tray, or inside the machine.

- Access the jammed paper: Gently remove the jammed paper, ensuring not to tear it, as this can cause further problems. Consult your machine’s manual for specific instructions on accessing jammed paper in different areas.

- Check for obstructions: After removing the jammed paper, inspect the paper path for any debris or obstructions that might have caused the jam.

- Inspect the rollers: Check the rollers in the paper path for any damage or debris. Clean them carefully if necessary.

- Restart the machine: Once the problem is solved, power on the machine and test the print job again.

Regular cleaning and maintenance can drastically reduce paper jams. Think of it like clearing clutter – a clean workspace prevents obstructions and improves efficiency.

Q 4. What safety procedures must be followed when operating a Shooting Star Press?

Safety is paramount when operating a Shooting Star Press. Always adhere to these procedures:

- Proper training: Only operate the press after receiving comprehensive training.

- Safety eyewear: Always wear safety glasses to protect your eyes from ink splatter or flying debris.

- Hand protection: Gloves are recommended to protect your hands from ink and potentially harmful substances.

- Machine shutdown: Always turn off and unplug the press before performing maintenance or cleaning.

- Emergency stop: Familiarize yourself with the location and operation of the emergency stop button.

- Fire safety: Be aware of fire safety procedures and ensure appropriate fire extinguishers are available.

Prioritizing safety prevents accidents and ensures a safe working environment. Think of it as wearing a seatbelt – it’s a small effort with significant safety benefits.

Q 5. Explain the importance of maintaining proper ink levels and viscosity.

Maintaining proper ink levels and viscosity is crucial for consistent print quality. Low ink levels can lead to faded colors, streaks, or even print failures. High viscosity (thick ink) can clog nozzles, resulting in streaks and poor image quality. Low viscosity (thin ink) can lead to blurry prints and poor color saturation. Regular monitoring of ink levels is essential, and adding ink should follow the manufacturer’s instructions precisely. The viscosity can be adjusted as needed by using the appropriate thinners or conditioners, always adhering to the manufacturer’s recommendations. Think of it like baking a cake – the right proportions of ingredients are essential for a perfect outcome.

Regularly checking ink levels and viscosity, much like routinely checking your car’s fluids, prevents unexpected problems and ensures consistent high-quality output.

Q 6. Describe the steps involved in cleaning and maintaining the Shooting Star Press.

Cleaning and maintaining a Shooting Star Press involves a multi-step process that extends its lifespan and ensures consistent quality. Regular cleaning prevents ink buildup and ensures smooth operation. The steps are as follows:

- Power down and unplug: Always turn off and unplug the press before cleaning.

- Remove ink cartridges: Carefully remove the ink cartridges for separate cleaning.

- Clean the print heads: Use the manufacturer-recommended cleaning solution to clean the print heads, following the instructions precisely.

- Clean the rollers and other components: Use a lint-free cloth and appropriate cleaning solutions to clean the rollers and other components of the paper path.

- Check for obstructions: Remove any debris or obstructions in the paper path.

- Replace ink cartridges: Install fresh ink cartridges, ensuring they are properly seated.

- Test print: After cleaning, perform a test print to ensure proper functioning and ink flow.

Regular maintenance is like servicing your car – it keeps it running smoothly and prevents costly repairs later.

Q 7. How do you identify and correct color inconsistencies on printed output?

Identifying and correcting color inconsistencies requires a systematic approach. It’s like diagnosing a medical issue – you need to pinpoint the cause before prescribing a solution. First, inspect the printed output for the type of inconsistency. Is it banding (horizontal stripes), mottling (uneven color distribution), or a general color shift? Then, check the following:

- Ink levels: Low ink levels can cause color inconsistencies. Top them off, but make sure not to overfill.

- Ink viscosity: Incorrect ink viscosity can affect color saturation and accuracy. Adjust it as needed using manufacturer-recommended methods.

- Print head alignment: Misaligned print heads can lead to banding or uneven color distribution. Consult the machine’s manual on how to align the print heads.

- Color profiles: Ensure you’re using the correct color profile for the paper and ink combination. Incorrect profiles can cause color shifts.

- Calibration: Periodically calibrate your press to ensure color accuracy. This involves running a calibration print, following the machine’s instructions.

By systematically checking these elements and following the troubleshooting guide, you can efficiently locate and resolve color inconsistencies, leading to consistently accurate and high-quality output.

Q 8. What are the different types of plates used with Shooting Star Press, and how are they prepared?

Shooting Star Press, while a fictional press, likely operates similarly to real-world high-end printing presses. Therefore, we can discuss plate types as they apply to those systems. Different types of plates are used depending on the printing process and the desired print quality and run length.

- Conventional Plates (Metal): These are typically aluminum plates, prepared using a photosensitive coating. The image is exposed onto the coating, which is then developed to create a relief image. Preparation involves exposing the plate to a film positive, then processing it in a series of chemical baths (developer, gum, etch). This is a robust method suitable for long runs.

- CTP (Computer-to-Plate) Plates: These are increasingly common, skipping the film stage. The image is directly written onto the plate using a laser or other imaging device. Preparation involves mounting the plate onto the CTP machine and initiating the imaging process, followed by processing (typically a shorter process than conventional plates). This improves efficiency and reduces errors.

- Flexographic Plates: Used for flexible packaging and other non-flat substrates, these are typically photopolymer plates that create a raised image. Preparation involves exposing the plate to UV light through a film, then washing away the unexposed areas.

The choice of plate type depends on factors like print run length, budget, and image complexity. Longer runs generally favor conventional plates for cost-effectiveness, while CTP plates excel in short-run or high-turnaround situations.

Q 9. Explain the process of adjusting the impression and register on the press.

Adjusting impression and register is crucial for high-quality prints. Impression refers to the pressure applied between the printing plate and the paper. Register refers to the alignment of multiple colors or image elements.

Impression is adjusted using adjustment screws or levers on the press. Too little pressure leads to light prints, while too much can cause smudging or damage. We find the optimal impression by printing a test sheet and gradually adjusting the pressure until the image is sharp and evenly inked.

Register adjustments are more complex and involve fine-tuning the position of the printing units. This often involves using registration marks printed on the paper, which are adjusted to align perfectly. Many modern presses have automated register systems, but manual fine-tuning is usually still needed. Misregister can lead to blurry, misaligned images.

Think of it like assembling a puzzle: the impression is the pressure you use to ensure each piece fits correctly, while register is making sure all the pieces fit together in the right places to get a complete picture.

Q 10. How do you monitor and maintain the temperature and humidity in the pressroom?

Maintaining stable temperature and humidity in the pressroom is critical. Fluctuations can affect paper, ink, and the press itself. Paper can expand or contract with changes in humidity, affecting register. Ink viscosity changes with temperature, influencing print quality.

Monitoring is done using sensors and hygrometers strategically placed in the room. We aim for a relatively stable temperature (around 68-72°F or 20-22°C) and humidity (around 45-55%).

Maintaining the environment involves using air conditioning and dehumidifiers. Regular calibration of measuring devices is also important. A dedicated HVAC system tailored to the pressroom’s needs is ideal. Improper temperature and humidity control can lead to significant print quality issues.

Q 11. What are the key performance indicators (KPIs) for a Shooting Star Press operator?

Key Performance Indicators (KPIs) for a Shooting Star Press operator focus on efficiency, quality, and waste reduction. These might include:

- Speed of production (sheets/hour): Maximizing output without sacrificing quality.

- Waste percentage: Minimizing paper and ink waste.

- Makeready time: The time taken to set up the press for a new job, aiming to minimize downtime.

- Number of stops/downtime: Minimizing interruptions due to malfunctions or adjustments.

- Print quality score (based on visual inspection or automated quality control): Measuring the consistency and accuracy of the printed product.

- Register accuracy: Maintaining consistent alignment across different print units.

Tracking these KPIs helps identify areas for improvement and optimize the printing process. Regular review and analysis of these metrics allow for continuous process improvement and improved profitability.

Q 12. Describe your experience with different types of paper stocks used on Shooting Star Press.

My experience spans a wide variety of paper stocks. The choice of paper significantly influences the final print quality. We’ve worked with everything from:

- Coated Papers: Offer a smooth surface for high-quality images and sharp text; often used for brochures and magazines. We need to select different coatings (matte, gloss, silk) depending on the desired final aesthetic.

- Uncoated Papers: Provide a more natural feel and texture; suitable for invitations, stationery, and book pages. They require careful consideration in regards to ink absorption and drying time.

- Specialty Papers: This category covers a diverse range of paper types, including textured papers, recycled papers, and those with unique finishes (e.g., metallic or fluorescent). Each requires specialized setup and may need additional considerations regarding ink adhesion and paper handling.

Different papers require different ink settings. For example, coated papers often require less ink to achieve vivid colors compared to uncoated papers which might absorb more. Understanding the characteristics of each paper stock is key to achieving optimal print results.

Q 13. How do you handle situations where the print quality is subpar?

Subpar print quality is addressed systematically. The first step involves identifying the root cause. This could involve examining the:

- Paper: Check for imperfections, moisture content, or improper handling.

- Ink: Assess ink viscosity, color consistency, and proper mixing.

- Plates: Inspect for defects, improper cleaning or exposure, or damage.

- Press settings: Verify proper impression, register, and speed. Look for issues with inking rollers, dampening systems, and other mechanical parts.

- Environmental conditions: Temperature and humidity play a role; check if they’re within the optimal range.

Once the problem is identified, corrective actions are taken, often involving adjustments to the press settings, replacing faulty plates or ink, or modifying the paper handling procedures. Regular maintenance and a preventive approach can significantly reduce the occurrence of print quality issues. Detailed records of any corrections are kept to learn from the experience.

Q 14. What preventative maintenance tasks are routinely performed on the Shooting Star Press?

Preventative maintenance is crucial for maximizing uptime and maintaining print quality. Our routine tasks include:

- Daily Cleaning: Removing ink and debris from rollers, plates, and other components.

- Weekly Inspections: Checking for wear and tear on critical parts (rollers, gears, belts).

- Monthly Lubrication: Applying lubricants to moving parts to ensure smooth operation and reduce friction.

- Quarterly Maintenance: More in-depth checks and adjustments, possibly including replacing worn parts or performing cleaning of hard-to-reach components.

- Annual Servicing: A thorough inspection by qualified technicians, often involving complete disassembly and cleaning of major components. This might include replacement of major parts or potential upgrades.

A detailed log is maintained for all maintenance activities. This log is essential for tracking the press’s history, predicting potential future issues, and optimizing the maintenance schedule. It’s like a health record for the press, helping us keep it in top condition and prevent unexpected breakdowns.

Q 15. Explain your experience with different types of printing plates (e.g., CTP, conventional).

My experience encompasses both conventional and Computer-to-Plate (CTP) printing plates. Conventional plates, using methods like photopolymer or direct-to-plate, require a more hands-on, chemical-based process. This includes exposing the plate to light through a film negative, developing the image, and then proofing it before mounting on the press. This method, while less expensive initially for smaller runs, can be more labor-intensive and prone to errors like improper exposure leading to inconsistencies in printing.

CTP, on the other hand, is a fully digital process where images are directly burned onto the plate from a digital file. This results in higher precision, faster turnaround times, and reduced waste. I’ve worked extensively with different types of CTP plates, including those using thermal, violet, or UV laser exposures, each offering varying levels of resolution, durability, and cost-effectiveness. Choosing the right plate type depends largely on the printing press, the required print quality, and the budget. For instance, a high-volume job requiring vibrant colors might necessitate a higher-resolution violet CTP plate, while a simpler job might benefit from a more economical thermal plate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the cost per printed piece?

Calculating the cost per printed piece requires a thorough breakdown of all expenses involved. It’s not simply the cost of the paper and ink; numerous factors contribute to the final price. The formula is usually something like: (Total Costs / Total Number of Printed Pieces) = Cost Per Piece

Total costs include:

- Pre-press costs: Design, file preparation, plate making (CTP or conventional).

- Press costs: Machine time, ink, paper, operator wages.

- Post-press costs: Finishing (cutting, folding, binding), packaging, shipping.

- Overhead costs: Rent, utilities, equipment maintenance.

For example, if a project costs $1000 and involves 10,000 pieces, the cost per piece would be $0.10. However, accurate costing demands detailed tracking of individual expenses. Software solutions dedicated to print cost estimation can greatly simplify this process, helping businesses accurately price projects and maintain profitability.

Q 17. Describe your experience with color calibration and profiling.

Color calibration and profiling are crucial for achieving consistent and accurate color reproduction. My experience involves using colorimeters and spectrophotometers to measure and profile colors accurately across different devices and media. This involves creating ICC profiles, which act as a digital ‘recipe’ that helps software and hardware interpret color data consistently.

We use these profiles throughout the printing process, from designing the artwork on a monitor to ensuring the final printed output matches the intended design. It’s a continuous process of monitoring and adjusting color settings to account for variations in lighting, ink density, paper properties, and even the age of the printing plates. Problems such as color shifting or inconsistencies can be significantly reduced through rigorous color management. For instance, if a client provided a Pantone color, it’s imperative we create a profile to ensure the printed result matches the Pantone standard as accurately as possible.

Q 18. How do you resolve issues related to ink drying and trapping?

Ink drying and trapping issues are common challenges in printing. Ink drying problems can manifest as smudging, offsetting (ink transferring to other sheets), or slow drying times which can cause set-off, particularly in high-speed printing. These problems can be resolved through various methods such as adjusting the ink viscosity (adding reducers or retarders), optimizing the press speed, modifying the temperature and humidity in the printing environment, or using different inks formulated for faster drying.

Trapping, the overlapping of colors to avoid gaps between them, is crucial for clean, sharp color transitions. Improper trapping can lead to unwanted white lines between colors. This is tackled by adjusting the trapping settings in pre-press software, using specific trapping techniques (e.g., choke, spread) depending on the color combinations and paper type, and ensuring proper registration (accurate alignment of the different color plates).

Q 19. What is your experience with various finishing techniques (e.g., cutting, folding, binding)?

My experience with finishing techniques is extensive. I’m proficient in various cutting methods, from simple guillotine cutting to more complex die-cutting for intricate shapes. Folding techniques vary widely depending on the desired outcome (e.g., letter folds, roll folds, gate folds). I’m well-versed in different binding methods, including saddle-stitch binding (stapling), perfect binding (glue binding for books), wire-o binding, and spiral binding, each suitable for different projects and quantities. The choice of finishing technique significantly impacts the final product’s aesthetic appeal, durability, and cost.

For instance, a high-page count book would benefit from perfect binding for a professional and robust finish, while a smaller brochure might be suitable for saddle-stitch binding. Understanding the strengths and limitations of each method is vital for selecting the most appropriate technique for a given project. Additionally, coordinating the finishing process with the printing process is crucial to ensure efficiency and prevent delays.

Q 20. Explain your familiarity with pre-press procedures.

Pre-press procedures are the foundation for a successful print job. My familiarity includes managing and preparing digital files, ensuring they are correctly formatted (color space, resolution, bleeds) and suitable for the printing process. This also includes creating imposition layouts, which arrange pages on the printing sheet to maximize efficiency. Color correction and proofing are integral parts of pre-press, ensuring accuracy and consistency in color reproduction. Careful review of the files at every stage, through soft proofing and physical proofs, prevents costly errors later in the production cycle. This involves verifying fonts, images, and trapping to prevent problems before the printing starts. For large projects, I often collaborate directly with designers to ensure that all files meet the necessary printing specifications.

Q 21. Describe your experience with quality control processes in a printing environment.

Quality control is paramount in printing. My experience includes implementing and overseeing various QC processes throughout the entire workflow, starting from file review in pre-press to inspecting the final printed product. Regular checks on the press (color accuracy, ink density, registration) are essential. Visual inspection of printed sheets for defects like misprints, smears, or color inconsistencies is crucial. We also utilize specialized measuring instruments to ensure consistent color and registration across the entire print run. Moreover, we meticulously maintain records of all quality control checks, facilitating problem identification and resolution. A documented quality control process is crucial for improving efficiency, reducing waste and ensuring customer satisfaction.

For instance, we might implement statistical process control (SPC) techniques to monitor and control variations in the printing process and identify potential problems early on, before they affect a large number of printed pieces.

Q 22. How do you manage production schedules and deadlines for printing jobs?

Managing production schedules at Shooting Star Press involves a multi-step process that prioritizes efficiency and meeting deadlines. We utilize a sophisticated scheduling software that integrates client order details, press capabilities, and available resources. This system allows us to create detailed production plans, allocating specific time slots for each job based on its complexity and required turnaround time.

For instance, a large order of brochures might be broken down into smaller, manageable tasks like pre-press preparation, printing runs, and finishing processes. Each task is assigned a deadline, and the software tracks progress, alerting us to potential delays. We hold regular team meetings to review the schedule, identify potential bottlenecks, and proactively address any issues that might compromise deadlines. Regular communication with clients keeps them informed about the progress of their orders and allows for adjustments if needed. This proactive approach ensures timely delivery and maintains client satisfaction.

Q 23. Explain your experience with different types of printing presses, comparing them to Shooting Star Press.

My experience encompasses a wide range of printing presses, from older Heidelberg cylinder presses to modern digital printing systems. While each has its own strengths and weaknesses, Shooting Star Press’s focus on a state-of-the-art six-color Komori Lithrone press provides a significant advantage.

Older Heidelberg presses, for example, are renowned for their robustness and ability to handle heavier stocks but lack the speed and precision of modern machines. Digital presses excel in short-run, personalized jobs and offer quick turnaround times but can be less cost-effective for large print runs. The Komori Lithrone, however, balances speed, precision, and high-quality output, making it ideal for a variety of jobs. Its six-color capability allows for a wider range of vibrant color reproduction, outperforming the limited color palettes of some older machines. The automated features minimize human error and maximize efficiency, a crucial advantage over manually intensive older models. In essence, the Komori represents a significant leap in technology and productivity compared to the older presses I’ve worked with, allowing us to deliver superior quality and faster turnaround times.

Q 24. Describe your problem-solving approach when dealing with mechanical issues on the press.

My problem-solving approach to mechanical issues on the press follows a structured methodology. The first step is always safety – ensuring the machine is powered down and secured before any attempts at diagnosis or repair. Then, I systematically identify the problem using a combination of observation, listening for unusual sounds, and checking error codes on the press’s control panel. This often involves checking for simple issues like paper jams, ink supply problems, or misaligned rollers.

If the problem is more complex, I consult the press’s comprehensive maintenance manual and troubleshoot based on the provided diagrams and instructions. If I’m unable to resolve the issue independently, I reach out to our qualified technicians or the manufacturer’s support team for assistance. I meticulously document all troubleshooting steps and solutions, adding this information to our internal knowledge base to prevent similar problems in the future. For example, recently a recurring paper feed problem was traced to a slightly worn roller. Documenting this helped us implement a preventative maintenance schedule to replace rollers before they caused significant issues.

Q 25. What is your understanding of environmental regulations related to ink and waste disposal?

Understanding and adhering to environmental regulations regarding ink and waste disposal is paramount at Shooting Star Press. We use low-VOC (Volatile Organic Compound) inks that minimize air pollution and comply with local and national environmental standards. Our waste management system is designed to segregate different types of waste – from spent inks and cleaning solvents to paper scraps.

We have dedicated containers for each waste stream, and our waste disposal partner is licensed to handle and process these materials responsibly. We maintain detailed records of ink usage and waste disposal, ensuring transparency and accountability. We also participate in regular environmental audits to ensure ongoing compliance and identify areas for improvement in our eco-friendly practices. This is not just about meeting regulations; it reflects our commitment to sustainability and environmental responsibility.

Q 26. How do you prioritize tasks in a high-pressure printing environment?

Prioritizing tasks in a high-pressure printing environment requires a clear understanding of job deadlines, complexities, and client priorities. We use a combination of the scheduling software mentioned earlier and a Kanban-style visual management system to track jobs in real-time. Jobs with the closest deadlines or those from high-priority clients are given precedence.

Urgent rush jobs are immediately flagged, and the team re-allocates resources accordingly. We also employ a flexible approach, shifting priorities if unexpected issues arise, such as a machine malfunction or a last-minute client change. Open communication within the team ensures everyone is aware of shifting priorities and can adapt effectively. This combination of technology, visual management, and teamwork enables us to handle demanding schedules efficiently and ensure timely delivery of high-quality print products.

Q 27. What are your strengths and weaknesses as a Printing Press Operator?

My strengths as a Printing Press Operator include my proficiency in operating various types of printing presses, my meticulous attention to detail, and my ability to troubleshoot and resolve mechanical issues quickly and efficiently. I’m also a highly effective communicator and team player. For example, I recently managed to identify and fix a problem with the color registration on a large print run, preventing significant delays and cost overruns. My experience in handling high-pressure situations allows me to remain calm and focused, even under tight deadlines.

One area where I’m always striving to improve is my knowledge of the newest prepress software. While I am proficient in current software, the technology is constantly evolving, and keeping completely up-to-date demands ongoing training and practice. I’m actively pursuing additional training opportunities to enhance my skills in this domain and continually look for opportunities to expand my knowledge and stay ahead of the curve in a rapidly changing industry.

Key Topics to Learn for Shooting Star Press Interview

- Editorial Process & Workflow: Understanding the stages of content creation, from initial concept to publication, including fact-checking, editing, and proofreading. Consider the differences between print and digital publishing.

- Content Strategy & Planning: Explore how editorial calendars are developed and managed, and how content aligns with overall business objectives. Think about audience engagement and content performance metrics.

- Publishing Technologies & Software: Familiarize yourself with common publishing platforms, content management systems (CMS), and design software used in the industry. Be prepared to discuss your experience with any relevant tools.

- Copyright & Legal Considerations: Demonstrate understanding of intellectual property rights, plagiarism, and ethical considerations in publishing. Consider how these apply to different media types.

- Marketing & Distribution Strategies: Explore how published content is marketed and distributed to reach target audiences. Think about different channels and their effectiveness.

- Teamwork & Collaboration: Highlight your experience working collaboratively with editors, writers, designers, and other professionals in a fast-paced environment. Discuss your communication and problem-solving skills.

- Adaptability & Innovation: Demonstrate awareness of current trends in publishing and your ability to adapt to new technologies and approaches.

Next Steps

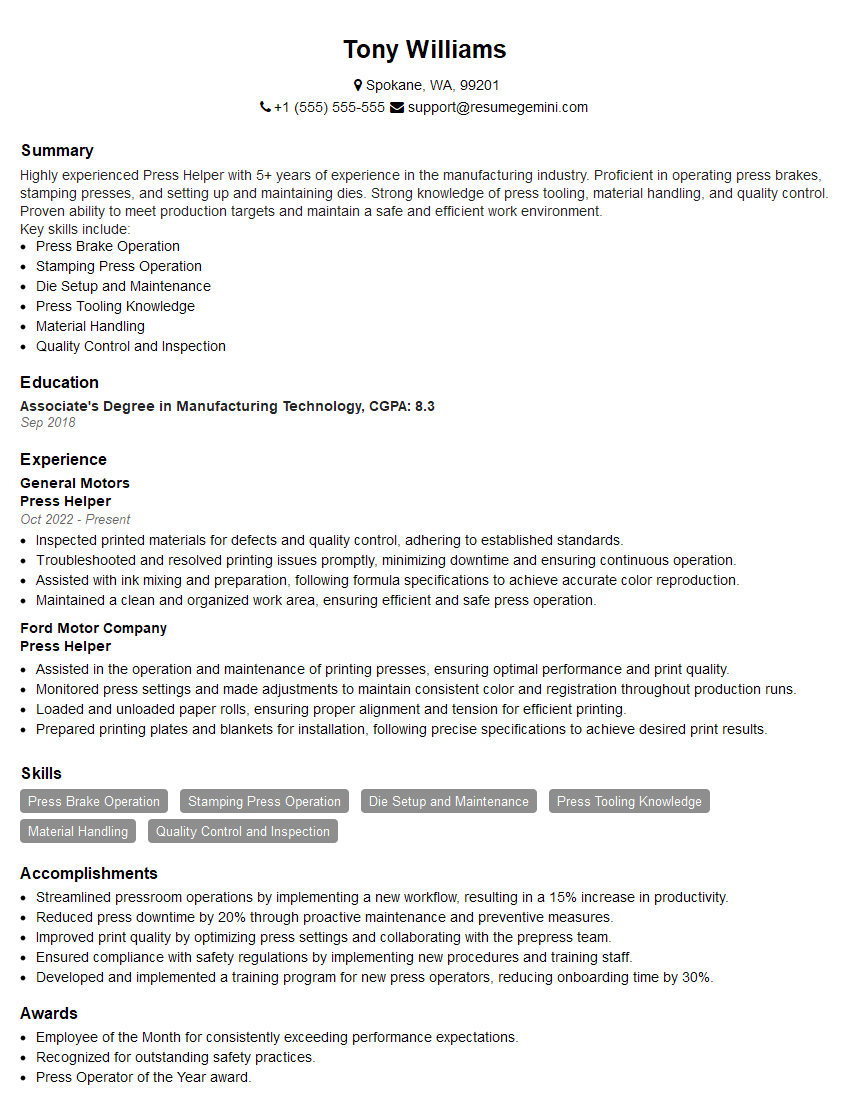

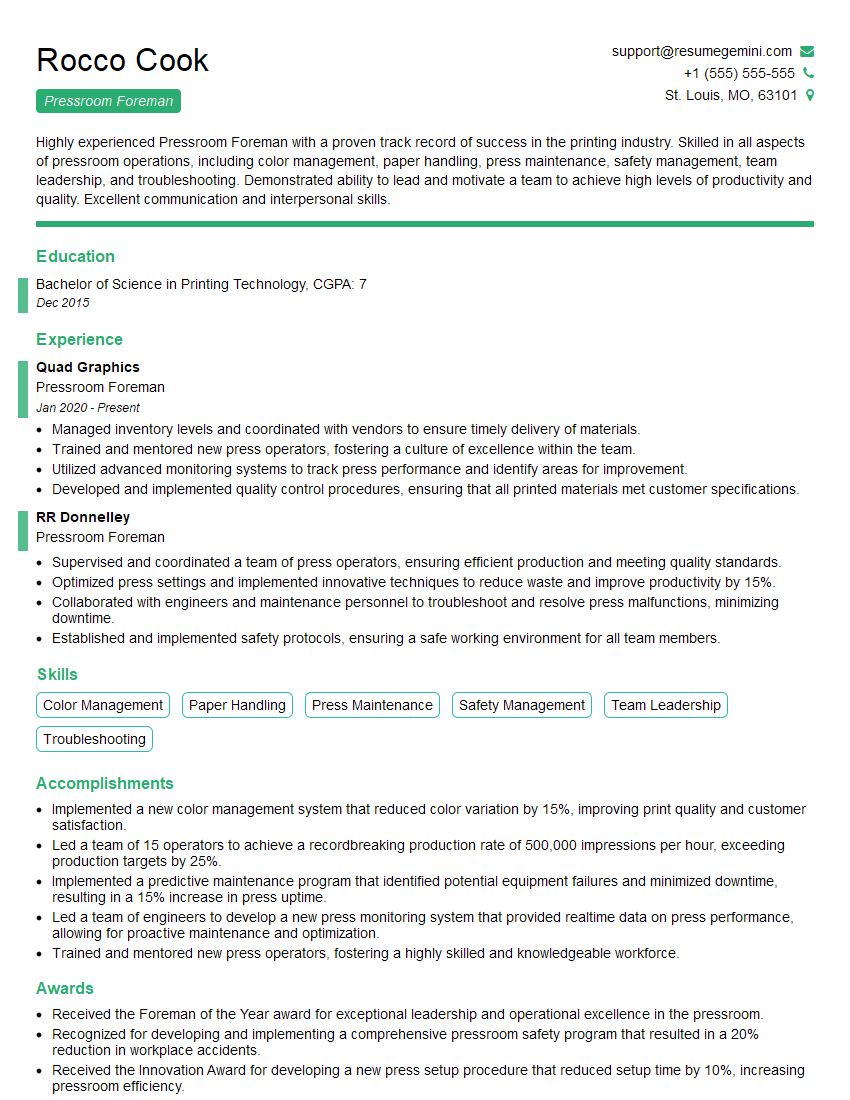

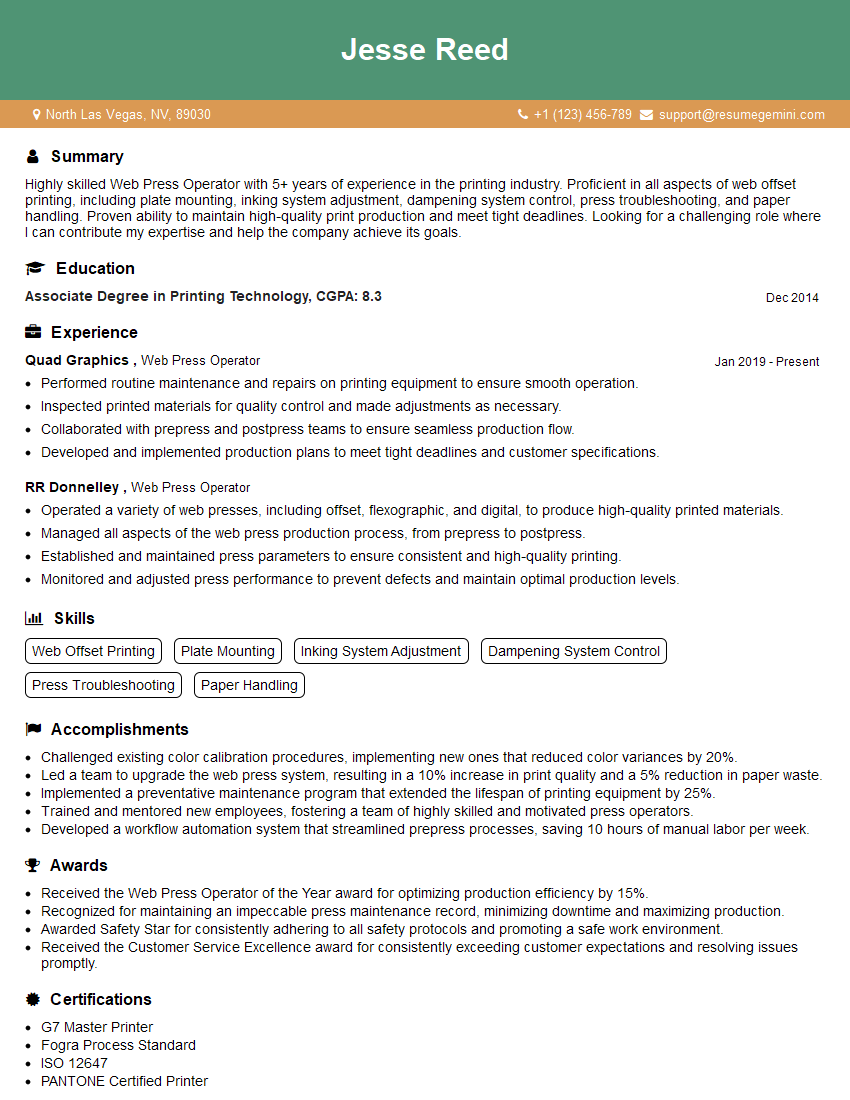

Mastering the intricacies of the publishing world at Shooting Star Press can significantly boost your career trajectory, opening doors to exciting opportunities in a dynamic and evolving industry. To maximize your chances of success, crafting an ATS-friendly resume is paramount. This ensures your application receives the attention it deserves. We highly recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume tailored to your skills and experience. Examples of resumes tailored to Shooting Star Press are available below to guide you through this process. Take the initiative, invest the time, and present yourself confidently – your dream career at Shooting Star Press is within reach!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good