Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Tie Saw Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Tie Saw Operation Interview

Q 1. Describe your experience operating a tie saw.

I have over eight years of experience operating tie saws in various construction projects, ranging from demolition work on large-scale infrastructure projects to precise cutting tasks in smaller renovation jobs. My expertise encompasses a wide range of saw types and applications, including both electric and petrol-powered models. I’m proficient in handling different materials, and I always prioritize safe and efficient operation. For instance, on a recent highway expansion project, I was responsible for cutting through reinforced concrete beams with a high-powered tie saw to facilitate the demolition of a structurally unsound bridge section. The project required precise cuts to minimize damage to surrounding areas. I successfully completed the task without incident, meeting all deadlines and safety standards.

Q 2. What safety precautions do you take when operating a tie saw?

Safety is paramount when operating a tie saw. My safety precautions always include:

- Personal Protective Equipment (PPE): This is non-negotiable and includes safety glasses with side shields, hearing protection, a dust mask (especially when cutting concrete), heavy-duty gloves, and sturdy work boots with steel toes.

- Proper Machine Setup: Before starting, I inspect the saw for any damage or loose parts. I ensure the blade is correctly mounted and tightened, and the machine is properly grounded (if electric).

- Work Area Safety: I clear the work area of obstructions and ensure adequate ventilation. I warn others in the vicinity and establish a safe perimeter to prevent accidents.

- Controlled Cuts: I always make slow, deliberate cuts, avoiding sudden movements or applying excessive force. I maintain a firm grip on the saw and control its movement throughout the operation.

- Regular Maintenance: I perform regular maintenance checks on the saw, including blade inspections and lubrication, to prevent malfunctions.

Think of it like this: treating the tie saw with respect and caution isn’t just about following rules; it’s about respecting your own safety and the safety of your coworkers. A moment’s lapse in attention can have serious consequences.

Q 3. Explain the different types of tie saw blades and their applications.

Tie saw blades vary significantly based on the material being cut and the desired cutting speed and precision. Common types include:

- Diamond Blades: These are the most common type for cutting concrete and masonry. They come in various segment designs (e.g., turbo, continuous rim) influencing cutting speed and smoothness. Turbo blades are known for aggressive cutting and are ideal for quick demolition; continuous rim blades offer smoother cuts, perfect for intricate work.

- Abrasive Blades: These blades are used for cutting softer materials like brick or softer stones and are generally less durable than diamond blades.

- Dry-Cut vs. Wet-Cut Blades: Wet-cut blades are designed to be used with water to minimize dust and heat buildup, prolonging blade life and improving cutting quality. Dry-cut blades are for situations where water isn’t practical or desirable. However, dry cutting generates significantly more dust, necessitating robust dust extraction.

Choosing the right blade is crucial for both efficiency and safety. A mismatched blade can quickly dull, damage the saw, or result in inaccurate cuts.

Q 4. How do you select the appropriate blade for a specific cutting task?

Selecting the right blade depends entirely on the material and the desired outcome. I consider several factors:

- Material Type: Reinforced concrete requires a diamond blade designed for reinforced material; softer brick might use an abrasive blade. The material’s hardness and density determine the blade’s aggressiveness and segment design.

- Cutting Depth: The blade’s diameter should be appropriate for the depth of cut required, ensuring the blade doesn’t bind or create unsafe conditions.

- Cut Quality: Do I need a rough, quick cut, or a precise, smooth finish? This will dictate the blade’s type (turbo for aggressive, continuous rim for smooth) and wet or dry-cutting preference.

- Blade Condition: I always inspect the blade for wear and tear; a worn blade will not only be less effective but could also cause safety hazards.

For example, when cutting through thick, heavily reinforced concrete, I would choose a large-diameter diamond blade with aggressive turbo segments designed for wet cutting. For delicate work on thinner sections of brick, I’d opt for a smaller, less aggressive blade designed for dry or wet cutting depending on the circumstances.

Q 5. What are the common causes of tie saw malfunctions and how do you troubleshoot them?

Common tie saw malfunctions often stem from improper maintenance or overuse. Some common issues and their troubleshooting steps include:

- Blade Binding: This often occurs due to a dull blade, improper blade alignment, or attempting to cut too quickly. Solution: Replace the blade, ensure proper alignment, and slow down cutting speed.

- Motor Overheating: This can result from prolonged use or insufficient cooling. Solution: Allow the saw to cool down, and avoid prolonged continuous operation.

- Power Issues (for electric saws): Check the power supply, cord for damage, and ensure proper grounding. Solution: Repair or replace the cord if damaged, check power supply, and ensure correct grounding.

- Vibrations and Noise: Excessive vibrations and noise can indicate a loose component or blade imbalance. Solution: Tighten loose bolts and parts, or replace an unbalanced blade.

Preventative maintenance is key; regular lubrication, blade inspections, and adherence to manufacturer’s recommendations greatly minimize the risk of malfunctions.

Q 6. How do you ensure the accuracy and precision of cuts using a tie saw?

Accurate and precise cuts require careful planning and technique. I use several methods:

- Marking and Measuring: Accurate pre-cutting measurements and clearly marked cutting lines are essential. I double-check all measurements to ensure precision.

- Stable Platform: The saw should be operated on a stable and level surface to prevent vibrations and inaccurate cuts.

- Steady Hand and Controlled Speed: Slow, deliberate movements are crucial for maintaining accuracy. Applying even pressure and avoiding jerky movements ensures clean cuts.

- Guide Rails (when applicable): Using guide rails or straight edges can provide superior accuracy, especially for long cuts.

- Regular Blade Inspections: Using a dull blade will impact the precision of the cut, so consistent inspections are necessary.

Accuracy isn’t just about the final cut; it’s about the entire process—from planning and preparation to execution. Thinking ahead and employing consistent techniques makes all the difference.

Q 7. Describe your experience working with various types of concrete.

My experience encompasses working with diverse concrete types, each requiring a slightly different approach. I’ve worked with:

- Standard Concrete: This is the most common type, and its cutting is relatively straightforward using standard diamond blades.

- Reinforced Concrete: This requires diamond blades specifically designed for reinforced materials to prevent blade damage and ensure clean cuts through rebar.

- High-Strength Concrete: This denser concrete demands more powerful saws and blades with higher segment density for efficient cutting.

- Pre-stressed Concrete: Cutting pre-stressed concrete is more challenging and often requires specialized techniques and blades due to internal tension. Safety is paramount here due to the high stress within the material.

Understanding the specific properties of each concrete type is critical to selecting the right equipment and techniques. It’s not just about brute force; it’s about adapting your approach to the specific challenge posed by each material.

Q 8. How do you manage the dust and debris generated during tie saw operation?

Dust and debris control is paramount in tie saw operation, not only for worker safety but also for environmental considerations. Think of it like this: a tie saw is essentially a miniature demolition machine, creating a significant amount of fine particulate matter. We manage this through a multi-pronged approach.

- Local Exhaust Ventilation (LEV): This is our primary method. We utilize powerful vacuums with specialized attachments designed to capture dust at the source – right where the blade meets the material. Think of it as a giant vacuum cleaner specifically engineered for this task.

- Water Suppression: In many cases, we use water to dampen the dust. A steady stream of water directed at the cutting area significantly reduces the amount of airborne dust. This is like using a hose to control dust during demolition, but on a smaller, more precise scale.

- Personal Protective Equipment (PPE): Beyond the LEV and water suppression, every operator wears a respirator rated for the specific type of dust generated (e.g., silica, concrete). We also use safety glasses, hearing protection, and appropriate work clothing. This is our final safety net, protecting the individual directly.

- Containment: Where possible, we create barriers or enclosures around the work area to further contain dust and debris. This limits the spread and keeps the surrounding environment cleaner.

Regular inspection and maintenance of all dust control equipment is crucial. A malfunctioning vacuum or insufficient water flow can severely compromise safety and lead to significant dust generation.

Q 9. What are the limitations of a tie saw, and when would you use alternative cutting methods?

Tie saws are powerful but have limitations. Their primary strength lies in cutting reinforced concrete and other dense materials with precision. However, they aren’t ideal for every cutting task.

- Material Limitations: Tie saws struggle with materials that are too brittle (risk of shattering) or too ductile (risk of blade binding). For example, cutting through some types of brick or extremely soft concrete might be better suited to other tools.

- Access Limitations: Their size and power requirements mean they are not always suitable for confined spaces or areas with limited access.

- Control and Precision: While generally precise, achieving extremely fine cuts or intricate shapes may require other cutting methods.

We’d consider alternative methods such as:

- Diamond Blades (with handheld or wall-mounted saws): For finer cuts or work in tight spaces.

- Hydraulic Shears: For cutting rebar or other metallic reinforcements separately.

- Demolition Hammers/Jackhammers: For larger demolition projects where precise cuts aren’t critical.

The choice depends on the material, required precision, access, and overall project goals. It’s about choosing the right tool for the job; using a tie saw for everything isn’t efficient or safe.

Q 10. Explain your understanding of the relevant safety regulations for tie saw operation.

Safety is paramount. Tie saw operation necessitates strict adherence to regulations, which vary by location but generally cover:

- Training and Certification: Operators must receive comprehensive training on safe operation, maintenance, and emergency procedures. Certification demonstrates competency.

- Personal Protective Equipment (PPE): As mentioned before, this includes respirators, safety glasses, hearing protection, gloves, and high-visibility clothing. Regular inspection and replacement of worn-out PPE is critical.

- Safe Work Procedures: Detailed plans must be in place, including risk assessments, emergency procedures, and communication protocols. This includes pre-job briefings and clear communication between team members.

- Machine Inspection: Before each use, a thorough inspection is mandatory to ensure the saw is in safe working condition. This includes checking blades, guards, and all safety mechanisms.

- Environmental Considerations: Controlling dust and debris as discussed previously, along with managing waste disposal appropriately is a vital part of safe operation.

- Permit-to-Work Systems: In many high-risk environments, a permit-to-work system ensures that all necessary safety precautions are in place before commencing work.

Ignoring these regulations is not only reckless but also illegal and can lead to serious injury or fatality. Compliance is not optional – it’s essential.

Q 11. How do you maintain and clean a tie saw after each use?

Maintaining a tie saw properly extends its lifespan and enhances safety. After each use, the process involves several steps.

- Cleaning: Remove all debris from the saw, paying close attention to the blade, guard, and motor housing. Compressed air is helpful for removing stubborn dust and debris.

- Blade Inspection: Carefully examine the blade for damage, cracks, or excessive wear. Replace the blade if necessary. This is essential for safety and optimal cutting performance.

- Lubrication: Lubricate moving parts according to the manufacturer’s instructions. This is often required on certain bearings and joints to prevent seizing and ensure smooth operation.

- Storage: Store the tie saw in a clean, dry location, protecting it from moisture and damage. Proper storage prevents corrosion and extends the lifespan.

- Documentation: Maintain a logbook detailing maintenance activities, blade changes, and any observed issues. This facilitates proactive maintenance and aids in troubleshooting any future problems.

Regular maintenance, going beyond post-use cleaning, should be performed according to the manufacturer’s recommendations. This usually includes more in-depth checks and potential repairs or adjustments, potentially requiring specialized tools and expertise.

Q 12. Describe your experience working at heights using a tie saw.

Working at heights with a tie saw presents significant additional challenges. It demands heightened awareness of safety protocols and a meticulous approach.

- Fall Protection: This is the most critical aspect. A robust fall arrest system, including harnesses, lanyards, and anchor points, is absolutely mandatory. Regular checks of this equipment are essential.

- Scaffolding/Access: Stable, properly constructed scaffolding or other access equipment is crucial. This must be inspected for stability and capacity before use. Unsafe access leads to many accidents.

- Additional PPE: Beyond the standard PPE, additional fall protection, such as helmets with chin straps, may be necessary.

- Communication: Clear communication with ground crew is vital, especially during maneuvers or in the event of an emergency.

- Weather Conditions: Adverse weather (wind, rain) can severely impact stability and visibility, demanding extra precautions or suspension of work.

I have extensive experience in high-rise construction using tie saws, and I always prioritize a thorough risk assessment before commencing work at height. Every step must be considered carefully, ensuring that the safety of myself and my fellow workers is never compromised. Safety isn’t just a checklist – it’s a mindset.

Q 13. How do you handle unexpected situations or emergencies during tie saw operation?

Unexpected situations can occur. Preparation is key. My approach involves:

- Immediate Response: If the saw malfunctions or an emergency arises (e.g., blade breakage, electrical fault, injury), the first step is to immediately shut down the saw, clear the area, and assess the situation.

- Emergency Procedures: Having a well-defined emergency procedure in place is critical. This includes knowing how to safely shut down the equipment, contacting emergency services, and administering first aid if necessary.

- Communication: Communicating clearly with team members and supervisors is crucial. Providing accurate information is vital to get the appropriate help and minimize any further hazards.

- Problem Solving: Once the immediate danger has passed, a thorough investigation should take place to determine the root cause of the incident to prevent recurrence. This involves documenting all aspects of the incident and implementing any necessary corrective actions.

- Reporting: All incidents must be meticulously documented and reported to the appropriate authorities (safety officers, management) according to company procedures.

Regular practice of emergency procedures builds confidence and preparedness. It is not just about reacting to problems, but preventing them in the first place through proactive risk assessments and regular maintenance.

Q 14. What is your experience with different tie saw models and brands?

My experience spans several tie saw models and brands. I’ve worked with:

- Husqvarna K760: A robust and reliable model, known for its power and durability. I’ve used this extensively in large-scale demolition projects.

- Makita SS1100: A lighter and more compact option, excellent for work in confined spaces or smaller projects. Its portability is a major advantage.

- Hilti DD 130: This model is known for its precision and low vibration, ideal for situations where accuracy is paramount.

Each model has its own strengths and weaknesses. The choice of model depends greatly on the nature of the project and the specific requirements. I have become comfortable and proficient with the maintenance and operation of these diverse models, adapting my technique to the specifics of each.

Beyond the specific models, I’m familiar with various blade types and their applications, understanding how to select the optimal blade for each material and cutting condition. This knowledge is crucial for efficient and safe operation.

Q 15. Describe your knowledge of various cutting techniques used with tie saws.

Tie saw cutting techniques vary depending on the material’s properties and the desired cut. The most common techniques include:

- Straight Cutting: This is the most basic technique, used for creating straight lines. It requires precise setup and steady operation to avoid deviations.

- Curved Cutting: Achieving smooth curves demands skill and careful control of the saw’s movement. The operator needs to gradually adjust the saw’s angle to follow the desired curve.

- Control Cutting: Involves meticulously managing the cut depth and speed to minimize damage to surrounding structures. This is particularly important when cutting close to reinforcement bars or other critical elements.

- Slotting: Creates narrow grooves or slots. This is used for creating expansion joints or removing sections of concrete.

- Undercutting: Used to create recesses or undercut sections within a concrete structure. This requires precision to ensure the desired depth and shape are achieved.

For example, creating expansion joints in a large concrete slab might require straight cutting, while cutting around a complex shape would require curved cutting. The choice of technique directly impacts the quality and precision of the cut.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess the structural integrity of a concrete surface before cutting?

Assessing the structural integrity of concrete before cutting is crucial for safety. My assessment typically involves:

- Visual Inspection: Checking for cracks, spalling, or other signs of damage or weakness. I look for inconsistencies in the concrete’s surface and color.

- Sound Testing: Tapping the concrete surface with a hammer to listen for hollow sounds, which can indicate voids or weaknesses within the concrete.

- Rebar Location: Identifying the location of reinforcing bars is critical. Hitting rebar with a diamond blade can damage the blade and cause dangerous sparks. I’d use a metal detector or rely on construction drawings.

- Checking Existing Documentation: Reviewing blueprints or previous inspection reports can reveal information about the concrete’s composition and any known weaknesses.

For instance, if I find significant cracks or hollow sounds, I’d adjust the cutting plan or consult with a structural engineer to determine the safest approach. A thorough inspection minimizes risks and ensures a successful cutting operation.

Q 17. What are the environmental considerations related to tie saw operation?

Environmental considerations during tie saw operation are important due to potential dust and water usage. Key aspects include:

- Dust Control: Tie saw operations generate significant concrete dust, which is harmful to both operators and the environment. I always use appropriate dust suppression methods like water misting systems or vacuum collection systems to minimize dust generation and maintain air quality.

- Water Management: Efficient water management is critical. Excessive water can lead to runoff and potential contamination of soil or waterways. I use the minimum water necessary for effective dust control and dispose of wastewater responsibly.

- Noise Pollution: Tie saws are noisy. Using appropriate hearing protection and scheduling work during permissible hours helps minimize noise pollution.

- Waste Disposal: Proper disposal of concrete dust and debris is essential to avoid environmental contamination. I adhere to all relevant local regulations for waste disposal.

In a project, proper dust and water management might involve setting up containment barriers and using a slurry recycling system, ensuring all waste is collected and disposed of correctly.

Q 18. How do you calculate the required cutting depth and blade size?

Calculating cutting depth and blade size requires understanding the project requirements.

- Cutting Depth: This is determined by the depth of the cut needed. For example, if you need to cut through a 12-inch concrete slab, the cutting depth must be at least 12 inches. Adding a small safety margin is recommended.

- Blade Size: The blade diameter should be sufficient to accommodate the cutting depth. A simple formula isn’t always sufficient; manufacturers provide charts correlating blade diameter to maximum cutting depth for different materials. For instance, a 14-inch diameter blade might offer a maximum cutting depth of 6 inches.

For a specific project, you’d start with the required cut depth, then select a blade with a diameter that exceeds this depth by the manufacturer’s recommended margin.

Q 19. Explain your understanding of water management during tie saw operation.

Water management during tie saw operation is crucial for dust control and blade life. My approach involves:

- Water Supply: Ensuring an adequate and consistent water supply to the saw. This often involves using a dedicated water pump and a large water tank to prevent interruptions.

- Water Flow Control: Regulating the water flow to optimize dust suppression while minimizing water waste. Too little water results in excessive dust; too much leads to unnecessary water usage and potential damage to the concrete.

- Water Collection: Collecting and disposing of wastewater responsibly. This often involves setting up containment systems or using a slurry recycling system to minimize environmental impact.

- Water Quality: Using clean water to avoid clogging the blade or damaging the saw. In some situations, adding a filtration system may be required.

In one instance, I had to modify a water management system on-site to handle a particularly dusty concrete mix, implementing a high-pressure misting system to improve dust suppression.

Q 20. How do you ensure the stability of the tie saw during operation?

Ensuring tie saw stability is paramount for safety and cut quality. I achieve this through:

- Secure Mounting: Using appropriate mounting systems to securely attach the saw to a stable base or platform. This prevents the saw from moving during operation.

- Proper Weight Distribution: Ensuring the weight of the saw and the operator is evenly distributed. This prevents vibrations and improves control.

- Level Surface: Working on a level surface to prevent the saw from tilting or vibrating excessively. This ensures a precise and controlled cut.

- Regular Maintenance: Keeping the saw in good working order, including regular lubrication and inspection. This prevents unexpected failures or vibrations that could affect stability.

For instance, when working on uneven surfaces, I’ve used adjustable supports to create a stable base for the saw, ensuring a smooth and controlled cut even on challenging terrain.

Q 21. Describe your experience with using different types of cutting fluids.

My experience includes using various cutting fluids, each with its own advantages and disadvantages. These include:

- Water: The most common cutting fluid, effective for dust suppression and cooling the blade. However, it can lead to excessive slurry and requires careful management.

- Water-Based Additives: These additives improve the performance of water by enhancing its lubricating and cooling properties. They often reduce slurry volume and improve dust suppression.

- Oil-Based Cutting Fluids: These are used in specialized situations where higher lubrication or cooling is needed. However, they are more environmentally concerning and require careful handling and disposal.

The choice of cutting fluid depends on the specific application and environmental concerns. For example, in a sensitive environmental area, I would opt for water-based additives to minimize environmental impact, while in situations requiring extended cuts or harder concrete, I might consider a water-based additive with enhanced lubrication properties.

Q 22. How do you handle different types of reinforcement within concrete during cutting?

Handling reinforcement during tie saw cutting requires a methodical approach. Different types of reinforcement – rebar, wire mesh, and fiber reinforcement – present unique challenges. The key is to identify the reinforcement before cutting and adjust the cutting technique accordingly.

Rebar: For rebar, I assess its diameter and location. Thick rebar might require pre-drilling to prevent blade damage or stalling. I always use a blade designed for cutting reinforced concrete, ensuring it’s sharp and properly tensioned. Slow and steady cutting is crucial to avoid kickback.

Wire Mesh: Wire mesh generally poses less of a problem, but I still proceed cautiously. A high-quality blade is important to cleanly cut through the mesh without significant deflection. If the mesh is particularly dense or heavy-gauge, a slower cutting speed is recommended.

Fiber Reinforcement: Fiber reinforcement, like fiber-reinforced polymers (FRP), often requires specialized blades designed to cut composite materials. These blades often have a different tooth configuration than those used for concrete alone. This material may also require different cutting speeds and techniques depending on the specific fiber type and resin used.

In all cases, safety is paramount. Proper personal protective equipment (PPE), including eye protection, hearing protection, and gloves, is essential. I also make sure the area is clear of obstacles and personnel before beginning the cut.

Q 23. What is your experience with different power sources for tie saws?

My experience encompasses various power sources for tie saws, each with its own advantages and disadvantages.

Hydraulic Power: Hydraulic power provides consistent cutting power, even under heavy load. This is particularly useful for cutting dense concrete or heavily reinforced sections. However, hydraulic tie saws require a separate hydraulic power unit, which adds to the overall setup complexity and requires regular maintenance of hydraulic lines and fluid.

Electric Power: Electric tie saws are generally more portable and convenient, offering a cleaner operation without oil spills or fumes associated with hydraulic systems. They are best suited for lighter-duty applications or where access to hydraulic power is limited. However, power availability and cable management become considerations.

Pneumatic Power: Pneumatic tie saws, powered by compressed air, are also used, although less common. They are lightweight and relatively portable. The power is usually less consistent than hydraulic systems and may require a substantial air compressor.

The choice of power source depends heavily on the job requirements, site conditions, and the available resources. For example, in confined spaces, an electric saw might be preferred for its portability. For large-scale demolition projects with heavy reinforcement, a hydraulic saw offers superior cutting power.

Q 24. Explain the process of setting up a tie saw for a specific cutting task.

Setting up a tie saw is a crucial step ensuring accuracy and safety. The steps I follow are:

Assess the cut: Carefully determine the precise location, depth, and angle of the cut. Mark the cut line clearly.

Secure the saw: Firmly mount the tie saw to a stable base or using the appropriate clamps and supports to prevent movement during the cut. This includes ensuring the blade is properly aligned with the cut line.

Blade selection: Choose a blade appropriate for the material and reinforcement type. A dull or damaged blade can lead to inefficient cutting and potential accidents.

Adjust the depth: Set the cutting depth according to the requirements of the cut. Adjust this carefully and precisely.

Test cut (if necessary): Perform a test cut in a less conspicuous area to verify the saw’s settings and cutting efficiency.

Safety precautions: Ensure the area is clear of personnel and obstructions. PPE is mandatory and checked before commencing. Appropriate warning signals, if needed, are put in place.

A proper setup prevents accidents and ensures a clean and efficient cut. Failing to properly set up the saw can lead to inaccurate cuts, blade damage, or even injury.

Q 25. How do you perform regular maintenance checks on a tie saw?

Regular maintenance is critical for the longevity and safe operation of a tie saw. My routine includes:

Blade inspection: Check for damage, wear, and proper tensioning. Replace worn or damaged blades immediately.

Lubrication: Lubricate moving parts according to the manufacturer’s recommendations, usually using the correct specified grease or oil.

Hydraulic system check (if applicable): Inspect hydraulic lines for leaks and ensure proper fluid levels. Regularly check the hydraulic oil for contamination.

Electrical system check (if applicable): Inspect electrical cords and connections for any damage or wear.Ensure all electrical components are correctly grounded.

Overall inspection: Check for loose bolts, cracks, or any other signs of damage.

Detailed records of maintenance activities are kept, including dates and observations, helping to track potential issues and plan for future maintenance.

Q 26. Describe your experience working as part of a team during tie saw operations.

Teamwork is fundamental in tie saw operations, especially on large-scale projects. Effective teamwork involves clear communication, coordinated efforts, and a shared commitment to safety.

On one particular project, our team was tasked with cutting through a heavily reinforced concrete wall. I coordinated with a colleague who was responsible for supporting and stabilizing the concrete section during the cutting operation. His precise positioning helped to prevent vibration and ensure a clean, accurate cut. Our constant communication, including verbal cues and hand signals, ensured the safety of both of us throughout the process. We also had a designated spotter to ensure nobody approached the area during the work.

This collaborative approach ensured not only efficiency but also significantly reduced the risk of accidents.

Q 27. How do you ensure the safety of yourself and others during the operation?

Safety is always my top priority. My safety procedures include:

Risk assessment: Before starting any cut, I perform a thorough risk assessment identifying potential hazards and implementing appropriate control measures.

PPE: I always wear appropriate PPE, including safety glasses, hearing protection, gloves, and steel-toed boots. Depending on the conditions I will also add a dust mask or respirator.

Clear area: I ensure the cutting area is clear of obstructions and personnel. I use barriers or warning signs to prevent unauthorized access.

Emergency plan: I’m familiar with emergency procedures and have access to first aid equipment.

Safe practices: I follow all safe operating procedures outlined by the manufacturer and company policies. This includes checking the equipment before commencing any work.

I treat safety as a non-negotiable element; it’s not merely a checklist but an ingrained part of my approach. I believe safety is a collective responsibility. I proactively monitor my team members to ensure that they are following safety procedures.

Q 28. Describe a time you had to solve a challenging problem related to tie saw operation.

On one occasion, we encountered a particularly challenging situation involving a heavily reinforced concrete beam that needed to be cut precisely to accommodate new plumbing installations. The limited access and the risk of damaging nearby utilities made this a complex task.

My solution involved a phased approach. We first used a smaller, more maneuverable saw to create a pilot cut, carefully marking the cut line. This allowed us to better visualize the location of the reinforcement bars and to adjust the larger tie saw’s path to avoid damaging the utilities. We used a combination of smaller cuts and larger cuts to get the right size without making one large, potentially hazardous cut. The pilot cut method was safer and minimized the risk of unforeseen problems during the actual cut. After completing this precise cut, we were able to install the new plumbing without issues.

This incident highlighted the importance of careful planning, adaptability, and a willingness to adopt alternative strategies when facing unforeseen challenges.

Key Topics to Learn for Tie Saw Operation Interview

- Safety Procedures and Regulations: Understanding and adhering to all safety protocols, including proper PPE usage, lockout/tagout procedures, and emergency response plans. Practical application includes demonstrating knowledge of specific safety regulations relevant to your work environment.

- Tie Saw Mechanics and Operation: Thorough understanding of the tie saw’s mechanical components, functionality, and operational procedures. This includes knowing how to troubleshoot common malfunctions and perform routine maintenance.

- Material Handling and Selection: Knowing how to safely handle and select the appropriate materials for different cutting applications. Practical experience demonstrates proficiency in judging material quality and adapting techniques based on material properties.

- Cutting Techniques and Precision: Mastering various cutting techniques to achieve precise cuts with minimal waste. This includes understanding the impact of blade speed, angle, and pressure on the final cut.

- Quality Control and Inspection: Understanding quality control measures and performing thorough inspections to ensure the accuracy and quality of cuts. This involves identifying and rectifying defects and understanding tolerance levels.

- Maintenance and Troubleshooting: Proficiency in performing routine maintenance tasks and troubleshooting common problems. This includes understanding the causes of malfunctions and performing preventative maintenance to extend the lifespan of the equipment.

- Working with Different Materials: Experience with various materials commonly cut with a tie saw, understanding their unique properties and the necessary adjustments in technique.

Next Steps

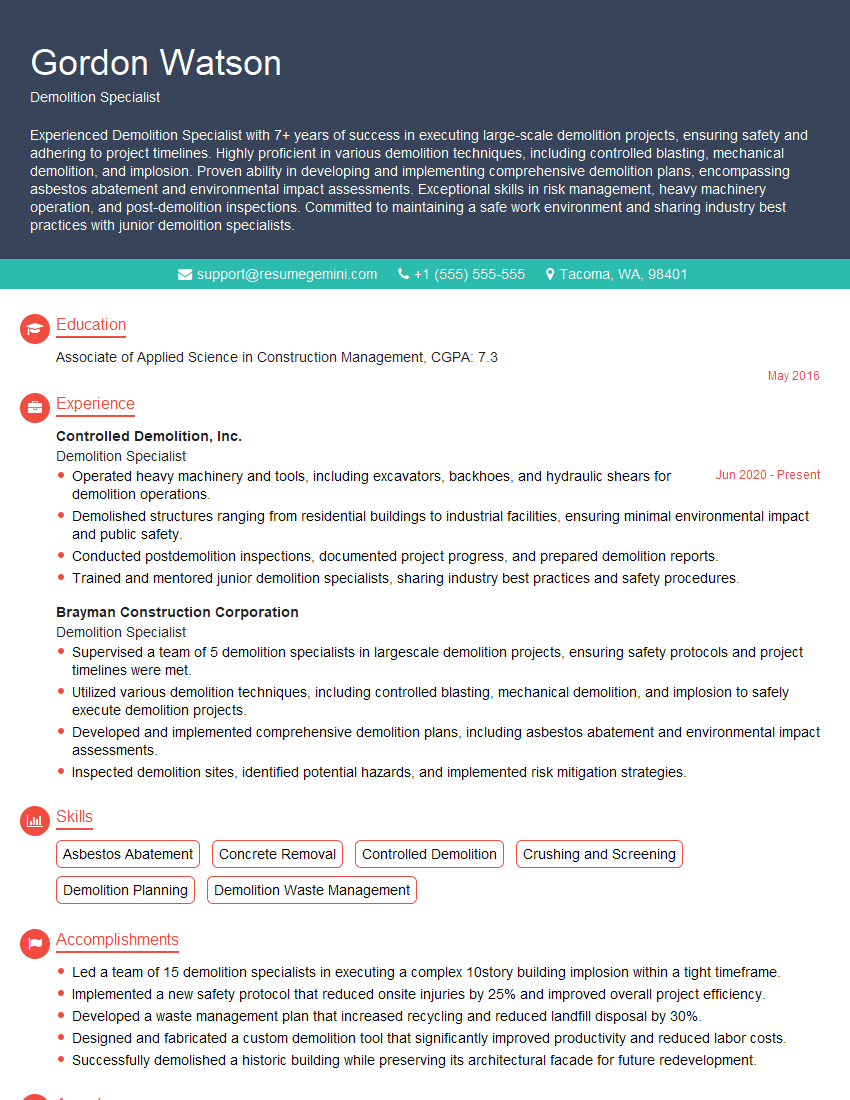

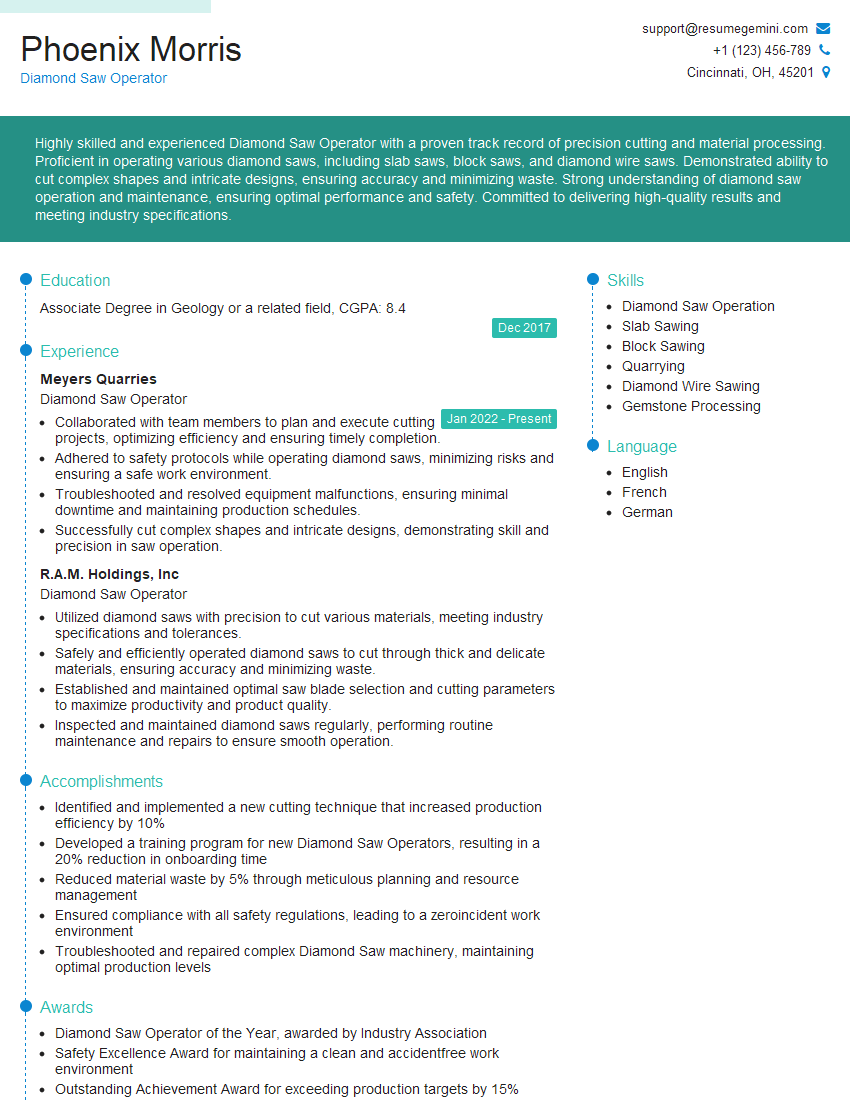

Mastering Tie Saw Operation opens doors to exciting career opportunities within the manufacturing, construction, and forestry industries, offering competitive salaries and growth potential. To maximize your chances of securing your ideal role, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out. They offer examples of resumes tailored to Tie Saw Operation to guide you through the process, ensuring your qualifications are presented in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good