Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Grinding Technology interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Grinding Technology Interview

Q 1. Explain the different types of grinding processes.

Grinding is a material removal process that uses abrasive particles to shape and finish workpieces. Different grinding processes are categorized primarily by the type of abrasive used, the method of material removal, and the application.

- Cylindrical Grinding: This is used to grind cylindrical parts, achieving high precision and surface finish. Think of grinding engine crankshafts or roller bearings.

- Surface Grinding: This process grinds flat surfaces, commonly used in machining parts like engine blocks or large plates. It can be done with a rotating wheel moving across a stationary workpiece or vice-versa.

- Internal Grinding: This involves grinding the internal surfaces of holes or bores, useful for creating precise internal diameters in components like engine cylinders.

- Centerless Grinding: This method grinds cylindrical parts without the need for a center fixture, ideal for high-volume production of parts like pins or shafts.

- Creep Feed Grinding: This uses a very slow feed rate and deep depth of cut to remove large amounts of material quickly and efficiently, often used for roughing operations.

- Honing and Lapping: These are fine finishing processes used to achieve extremely smooth surfaces and tight tolerances. Honing uses abrasive stones, while lapping uses a flat abrasive plate.

The choice of grinding process depends heavily on the workpiece geometry, material, desired surface finish, and production volume.

Q 2. Describe the various types of grinding wheels and their applications.

Grinding wheels are made of abrasive grains bonded together. The type of abrasive, bond, and grain size significantly influence the wheel’s performance.

- Aluminum Oxide (Al2O3): A common abrasive, suitable for grinding steels, cast irons, and other ferrous materials. It offers good strength and sharpness.

- Silicon Carbide (SiC): Used for grinding non-ferrous materials like aluminum, brass, stone, and ceramics. It’s sharper than aluminum oxide but less durable.

- Vitrified Bond: The most common bond type; it’s durable, resistant to heat and water, and suitable for a wide range of applications.

- Resinoid Bond: Offers flexibility and is used for grinding softer materials or creating shaped grinding wheels. It’s also well-suited for high-speed applications.

- Metal Bond: Highly durable, used for applications demanding high stock removal rates, often in tough materials or situations with high temperatures.

Applications: A vitrified bond aluminum oxide wheel might be used for grinding steel, while a resinoid bond silicon carbide wheel could be used for grinding aluminum. The choice depends on the material being ground, the required surface finish, and the specific grinding process.

Q 3. What are the key factors affecting grinding wheel selection?

Selecting the right grinding wheel is crucial for efficient and effective grinding. Key factors include:

- Workpiece Material: Harder materials require harder wheels with stronger abrasives. For example, grinding hardened steel necessitates a different wheel than grinding aluminum.

- Desired Surface Finish: A finer grit size yields a smoother finish. A roughing operation might use a coarse grit, while finishing requires a fine grit.

- Stock Removal Rate: High stock removal rates are achievable with coarser grits and open structures, while finer finishing operations benefit from finer grits and denser structures.

- Machining Process: Different grinding processes (e.g., surface, cylindrical, internal) demand specific wheel shapes and sizes.

- Machine Capabilities: The grinding machine’s power, speed, and rigidity influence the wheel selection. A high-powered machine can handle a more aggressive wheel.

- Cost and Availability: Balancing performance with cost and accessibility is essential.

Imagine trying to grind hardened steel with a wheel designed for aluminum; it would likely be inefficient and lead to wheel wear or damage. Careful wheel selection is paramount.

Q 4. How do you determine the appropriate grinding parameters (speed, feed, depth of cut)?

Determining appropriate grinding parameters is a balance between material removal rate, surface finish, and wheel life. These parameters interact significantly:

- Wheel Speed: Too slow, and material removal is sluggish; too fast, and the wheel might glaze or overheat. The manufacturer’s recommendations provide a starting point, and adjustments are often needed based on the material and process.

- Feed Rate: The rate at which the workpiece is fed into the wheel. A slower feed produces a finer finish but slower stock removal. A faster feed achieves higher stock removal but might cause burnishing or poor surface quality.

- Depth of Cut: The amount of material removed in each pass. Small depths of cut produce finer finishes, but more passes are needed. Large depths of cut are faster but risk burning or damaging the workpiece or wheel.

Often, a trial-and-error approach, informed by experience and experimentation, is necessary to optimize these parameters. Monitoring factors like surface temperature and wheel wear is critical to preventing problems and maximizing efficiency.

Example: Starting with manufacturer’s recommendations as a baseline, one might systematically vary one parameter (e.g., depth of cut) while keeping others constant, observing the results (surface finish, wheel wear, and material removal rate) to find the optimal settings.

Q 5. Explain the concept of grinding fluid and its importance.

Grinding fluids, also known as coolants or lubricants, are essential in grinding for several reasons:

- Cooling: They dissipate the heat generated during the grinding process, preventing workpiece and wheel damage from overheating. This is especially important for high-speed grinding or hard materials.

- Lubrication: They reduce friction between the wheel and workpiece, preventing wear and improving surface finish. This extends the life of both the wheel and the workpiece.

- Chip Removal: They help flush away the metal chips and debris produced during grinding, preventing clogging of the wheel and ensuring consistent performance.

- Improved Surface Finish: By reducing friction and heat, the grinding fluid contributes to a superior surface finish.

The choice of grinding fluid depends on the material being ground and the specific application. Water-based coolants are common, but oil-based coolants offer better lubrication for some applications. Neglecting proper cooling and lubrication can lead to poor surface finish, wheel wear, and workpiece damage.

Q 6. Describe different methods for grinding wheel dressing and truing.

Grinding wheel dressing and truing are crucial maintenance steps that restore the wheel’s cutting ability and ensure dimensional accuracy.

- Dressing: This process sharpens the grinding wheel by removing dull or worn abrasive grains, usually using a diamond or silicon carbide dresser. It restores cutting efficiency and improves the surface finish.

- Truing: This process corrects the wheel’s shape and ensures dimensional accuracy, removing any irregularities or imbalances that may have developed during use. Truing is often done with a diamond or CBN (Cubic Boron Nitride) trueing tool, ensuring the wheel is precisely round and consistent.

Dressing is usually performed more frequently than truing. Both are critical to preventing defects in the workpiece and maintaining consistency throughout the grinding operation. Improperly dressed or trued wheels can lead to inaccurate dimensions and poor surface quality.

Q 7. How do you measure and control surface roughness after grinding?

Surface roughness after grinding is measured using profilometers or surface roughness testers. These instruments measure the height variations in the surface profile.

Measurement Methods:

- Profilometry: A stylus traces the surface, and its vertical movements are recorded to create a surface profile. Parameters like Ra (average roughness), Rz (maximum height of profile), and Rq (root mean square roughness) are calculated.

- Optical Methods: These use light interference or scattering to determine surface roughness. They are often non-contact methods suitable for delicate surfaces.

Control: Surface roughness is controlled through proper grinding parameters (speed, feed, depth of cut), wheel selection (grit size, bond type), and the use of appropriate grinding fluids. Regular dressing and truing of the wheel are also critical. Monitoring the surface roughness during the grinding process, using in-process metrology where possible, can provide real-time feedback, enabling adjustments to achieve the desired surface finish.

Q 8. Explain the importance of workholding and its effect on grinding accuracy.

Workholding in grinding is crucial; it’s the system that securely holds the workpiece during the grinding process. Think of it as the foundation of a skyscraper – if the foundation is shaky, the entire structure suffers. Improper workholding directly impacts grinding accuracy by causing workpiece deflection, vibration, and inconsistent contact with the grinding wheel. This leads to dimensional inaccuracies, poor surface finish, and even workpiece damage.

For example, if you’re grinding a slender shaft and the chuck isn’t properly tightened, the shaft might flex under the grinding force, resulting in a non-uniform diameter. Similarly, insufficient support can lead to vibration, creating chatter marks on the surface. Effective workholding solutions use fixtures specifically designed for the workpiece geometry, ensuring rigid support and minimizing deflection. This includes using chucks, collets, magnetic chucks, or specialized fixtures depending on the workpiece shape and material.

In precision grinding, choosing the right workholding method is paramount. For instance, using a three-jaw chuck with compensating jaws ensures concentricity for cylindrical parts, minimizing runout and enhancing accuracy. Conversely, using an inadequate workholding system on a delicate part can render the entire process inaccurate and potentially ruin the workpiece.

Q 9. What are the common causes of grinding defects and how are they addressed?

Grinding defects can be frustrating, but understanding their root causes is key to prevention. Common causes include:

- Wheel dressing issues: A poorly dressed wheel can lead to uneven material removal, resulting in surface imperfections like chatter marks or waviness.

- Workpiece clamping problems: As discussed earlier, improper clamping results in workpiece deflection, leading to inaccuracies.

- Incorrect grinding parameters: Using excessive downfeed, inappropriate wheel speed, or incorrect coolant flow can cause burns, cracks, or surface roughness.

- Wheel wear: A worn-out wheel will lose its sharpness and profile, leading to poor surface finish and inaccurate dimensions.

- Workpiece material defects: Internal flaws or inconsistencies within the workpiece can cause uneven grinding and unexpected breakage.

Addressing these issues involves a multifaceted approach. Regular wheel dressing is essential to maintain wheel sharpness. Careful workpiece clamping procedures and fixture design are critical. Optimizing grinding parameters through experimentation and process monitoring helps prevent issues like burning. Regular wheel inspection and replacement are essential for consistent performance. Finally, careful workpiece selection and pre-grinding inspection can minimize issues stemming from material defects.

Q 10. Describe different methods for grinding internal and external cylindrical surfaces.

Grinding internal and external cylindrical surfaces utilizes different techniques and machines. For external cylindrical grinding, common methods include:

- Through-feed grinding: The workpiece passes through the grinding wheel continuously.

- Infeed grinding: The workpiece is fed radially into the rotating grinding wheel.

- Centerless grinding: The workpiece is ground between a rotating grinding wheel and a regulating wheel.

Internal grinding, on the other hand, employs specialized machines and techniques. These include:

- Internal cylindrical grinding: A small diameter grinding wheel is used within the workpiece’s bore.

- Internal centerless grinding: A similar principle to external centerless grinding, but adapted for internal surfaces.

- Honing and superfinishing: Often used after grinding to achieve superior surface finishes on internal diameters.

The choice of method depends on factors like workpiece size, required accuracy, surface finish, and production volume. For instance, through-feed grinding is efficient for high-volume production of relatively simple parts, while infeed grinding offers higher precision for smaller batches of complex parts. Internal grinding is often a more specialized and challenging process, requiring skilled operators and precise machine setup.

Q 11. How do you troubleshoot common grinding machine malfunctions?

Troubleshooting grinding machine malfunctions requires a systematic approach. I typically follow these steps:

- Identify the symptom: Is there unusual noise, vibration, poor surface finish, dimensional inaccuracy, or machine stoppage?

- Check the obvious: Verify coolant flow, wheel condition, workpiece clamping, and power supply. Often, simple issues are overlooked.

- Consult machine manuals: Manufacturer’s manuals offer valuable insights into machine operation, troubleshooting, and error codes.

- Systematic elimination: If the problem persists, systematically check individual components, starting from simple to complex. For example, check wheel balance before investigating more intricate aspects of the machine’s hydraulic or control systems.

- Data analysis: If possible, review machine data logs to identify trends or anomalies that may point to the cause of the malfunction.

- Seek expert assistance: If the problem remains unsolved, contacting a qualified service technician is essential. A qualified technician can diagnose more complex problems and perform necessary repairs.

A recent example involved a grinding machine producing unusually rough surfaces. By systematically checking each parameter, I discovered the problem was due to coolant flow restriction, leading to increased wheel temperature and subsequent surface degradation. Addressing the coolant issue resolved the problem, highlighting the importance of a methodical approach.

Q 12. Explain the concept of grinding force and its measurement.

Grinding force is the force exerted by the grinding wheel on the workpiece during the material removal process. It’s a crucial parameter influencing grinding efficiency, surface quality, and wheel wear. This force is composed of several components: the tangential force (cutting force), the radial force (thrust force), and the axial force.

Measuring grinding force is essential for process optimization and control. Common methods include:

- Strain gauge dynamometers: These devices use strain gauges attached to the machine structure to measure the forces acting on the workpiece.

- Load cells: These sensors directly measure the force applied to the workpiece or the grinding wheel.

Accurate measurement of grinding force allows for real-time process monitoring and adjustments. This is especially useful in CNC grinding where the grinding parameters can be dynamically adjusted based on the measured force. For instance, if the grinding force exceeds a predefined threshold, the feed rate can be reduced to prevent wheel damage or workpiece burning. Understanding grinding forces allows for optimization of parameters, prolonging wheel life, improving surface quality, and enhancing overall productivity.

Q 13. How do you ensure dimensional accuracy and surface finish in precision grinding?

Achieving dimensional accuracy and superior surface finish in precision grinding is a meticulous process that demands attention to detail throughout the entire operation. Key factors include:

- Precise machine setup: This includes accurate alignment of the wheel and workpiece, ensuring minimal runout and vibration.

- Proper wheel selection: Choosing a wheel with the correct bond, grain size, and hardness is vital for achieving the desired surface finish and material removal rate. The selection should be optimized for the specific workpiece material and desired tolerances.

- Controlled grinding parameters: Optimizing wheel speed, feed rate, and depth of cut is crucial. Parameters should be carefully selected to balance material removal rate and surface finish.

- Consistent coolant supply: Coolant plays a vital role in preventing wheel and workpiece heating, ensuring consistent cutting conditions and preventing surface burning.

- Regular wheel dressing: Maintaining a sharp, clean grinding wheel is essential for consistent material removal and a precise surface finish.

- Workpiece preparation: Proper preparation of the workpiece, including appropriate cleaning and pre-grinding operations, prevents contamination and enhances the accuracy of the final grinding process.

- In-process measurement: Employing in-process measurement techniques, such as laser or air gauging, allows for real-time monitoring of dimensional accuracy and surface finish.

For instance, in grinding high-precision cylindrical parts, I often use a combination of through-feed grinding with in-process gauging to ensure the desired tolerances are consistently met. This level of control significantly reduces scrap and improves overall productivity.

Q 14. Describe your experience with CNC grinding machines and programming.

I have extensive experience with CNC grinding machines, covering both operation and programming. My experience ranges from simple profile grinding to complex 5-axis machining using advanced CAD/CAM software. I’m proficient in programming various CNC grinding machines, including those from leading manufacturers. This includes using both conversational programming and G-code. My proficiency includes generating efficient and optimized toolpaths, selecting appropriate cutting parameters, and performing simulations to predict machining results and prevent potential issues.

A recent project involved programming a CNC cylindrical grinder to produce a complex camshaft profile with tight tolerances. This involved extensive use of CAD/CAM software to design the toolpath, accounting for wheel wear compensation and ensuring the final geometry conforms to the design specifications. This required a thorough understanding of both the machine’s capabilities and the intricacies of the grinding process, ensuring both efficiency and accuracy in production.

I’m also experienced in utilizing machine sensors and feedback loops to optimize the grinding process. This includes integrating data from in-process measuring systems to dynamically adapt cutting parameters, ensuring high dimensional accuracy and surface finish even with complex geometries.

Q 15. Explain the principles of centerless grinding.

Centerless grinding is a fascinating process where a workpiece is ground without using a traditional chuck or fixture. Instead, it relies on two grinding wheels and a regulating wheel. Think of it like this: Imagine you’re smoothing a cylindrical piece of wood using sandpaper. In centerless grinding, one wheel (the grinding wheel) provides the abrading action, much like your sandpaper. The other wheel (the regulating wheel) controls the workpiece’s speed and feed rate, ensuring a consistent surface finish and size. This regulating wheel also helps to keep the workpiece stable and prevents it from spinning uncontrollably.

The principles are based on friction and controlled movement. The grinding wheel removes material, and the regulating wheel precisely controls the workpiece’s rotation and infeed. The workpiece is guided between the grinding wheel and regulating wheel, being progressively ground to the desired dimensions. The process allows for high production rates and excellent surface finishes, making it ideal for mass-producing parts like pins, shafts, and rollers. The absence of a chuck also eliminates the need for workpiece setup, speeding up the entire process.

There are two main configurations: through-feed and in-feed. In through-feed, workpieces are fed continuously through the grinding zone. In-feed, the workpieces are pushed against the grinding wheel for a short duration.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the safety precautions associated with operating grinding machines?

Safety is paramount in grinding operations. Grinding machines are powerful and can cause serious injuries if not handled correctly. The most critical safety precautions include:

- Eye Protection: Always wear safety glasses or a face shield. Grinding generates sparks and fragments of material that can cause eye damage.

- Hearing Protection: The noise level from grinding machines can be extremely high. Ear plugs or muffs are essential to prevent hearing loss.

- Proper Clothing: Wear close-fitting clothing, no loose sleeves or jewelry, to prevent entanglement. Safety shoes are also crucial.

- Machine Guards: Ensure all machine guards are in place and functioning correctly. These prevent accidental contact with the rotating parts.

- Workpiece Securement: Properly secure the workpiece to prevent it from flying off during operation. Use appropriate fixtures and clamps.

- Wheel Inspection: Always inspect grinding wheels for cracks or damage before use. A damaged wheel can shatter and cause serious injury.

- Emergency Stops: Know the location and operation of the emergency stop button and other safety mechanisms.

- Training: Always receive proper training and authorization before operating any grinding machine. Proper training significantly reduces the risk of accidents.

Remember, a moment of carelessness can lead to severe consequences. Maintaining a safe working environment is everyone’s responsibility.

Q 17. How do you maintain grinding equipment to ensure optimal performance?

Maintaining grinding equipment is vital for optimal performance, safety, and extending the machine’s lifespan. It involves a combination of preventative maintenance and regular inspections.

- Regular Cleaning: Regularly remove dust, metal chips, and debris from the machine. This prevents buildup that can affect performance and damage machine components.

- Wheel Dressing: Periodically dress the grinding wheel to maintain its sharpness and profile. This ensures consistent surface finish and dimensional accuracy. Improper dressing can lead to premature wheel wear and poor part quality.

- Lubrication: Regularly lubricate moving parts according to the manufacturer’s recommendations. This reduces friction and wear, preventing premature failure of components.

- Vibration Checks: Monitor the machine for excessive vibration. Vibration can be an indication of an imbalance, worn bearings, or other problems that could lead to major damage.

- Fluid Management (for coolant systems): Maintain the correct fluid levels and ensure the coolant is clean and free from contaminants. Dirty coolant can clog the system and negatively impact the grinding process.

- Bearing Inspection: Regularly inspect bearings for wear or damage. Worn bearings can lead to excessive vibration, noise, and potential failure.

- Preventative Maintenance Schedules: Develop and adhere to a regular preventative maintenance schedule that covers all aspects of the machine’s operation.

A well-maintained grinding machine not only operates more efficiently but also enhances operator safety and minimizes downtime caused by unexpected failures.

Q 18. Describe your experience with different types of grinding abrasives.

My experience spans a wide range of grinding abrasives, including aluminum oxide, silicon carbide, cubic boron nitride (CBN), and diamond. Each abrasive has unique properties that make it suitable for specific applications.

- Aluminum Oxide (Al2O3): A common and versatile abrasive, good for grinding steels and ferrous metals. It offers a good balance of cutting ability and durability. I’ve used it extensively in general-purpose grinding applications.

- Silicon Carbide (SiC): Ideal for grinding non-ferrous metals, ceramics, and stones. It’s harder than aluminum oxide but slightly less durable. I remember a project where its sharpness and precise finish were crucial for grinding brittle materials.

- Cubic Boron Nitride (CBN): A superabrasive known for its exceptional hardness and ability to grind hardened steels and superalloys. I used CBN in a demanding application involving the finishing of aerospace components, requiring superior hardness and wear resistance.

- Diamond: The hardest material known, used for grinding very hard materials like carbides and ceramics, and for precision grinding. Its extremely fine grit size allows for exceptionally smooth finishes. A recent project required the use of diamond abrasives for ultra-fine polishing of a specialized optical component.

The selection of the appropriate abrasive depends on factors like the workpiece material, desired finish, and removal rate. It’s a crucial decision affecting the overall efficiency and quality of the grinding process.

Q 19. Explain the concept of grinding wheel wear and its effect on the grinding process.

Grinding wheel wear is a natural consequence of the grinding process. It’s the gradual decrease in the wheel’s diameter and the change in its profile due to abrasive material removal. Think of it like the gradual wearing down of a pencil tip as you write – except the ‘writing’ is material removal.

The effect of wheel wear on the grinding process can be significant. Excessive wear can lead to:

- Dimensional Inaccuracy: A worn wheel may not maintain the desired dimensions of the workpiece, resulting in out-of-tolerance parts.

- Poor Surface Finish: A worn wheel can produce a rougher surface finish than intended.

- Reduced Material Removal Rate: A dull wheel requires more time and energy to remove the same amount of material, decreasing efficiency.

- Increased Grinding Forces: A worn wheel can lead to increased grinding forces, causing vibrations and potentially damaging the machine or the workpiece.

- Wheel Breakage: Extreme wear can lead to structural weaknesses in the grinding wheel, increasing the risk of breakage.

Monitoring wheel wear and implementing strategies like wheel dressing and timely replacement is critical for maintaining consistent quality and preventing issues related to excessive wear.

Q 20. How do you perform a grinding process capability study?

A grinding process capability study aims to determine whether the grinding process is capable of consistently producing parts within specified tolerance limits. It involves collecting data from the grinding process, analyzing the data statistically, and comparing the process variation to the allowable tolerance.

The steps typically involved are:

- Define the critical-to-quality (CTQ) characteristics: Identify the key dimensions and surface finish parameters that must be controlled.

- Establish the specifications: Define the upper and lower tolerance limits for each CTQ characteristic.

- Collect data: Gather a representative sample of parts produced by the grinding process and measure the CTQ characteristics.

- Analyze the data: Calculate descriptive statistics (mean, standard deviation, range) and construct control charts to assess the process stability and identify any special causes of variation.

- Calculate process capability indices: Use statistical methods (such as Cpk or Ppk) to compare the process variability to the tolerance limits. Cpk considers the process’s centering and spread relative to the specification limits. Ppk considers the overall performance of the process, accounting for both common and special causes of variation. A Cpk value greater than 1.33 generally indicates a capable process.

- Interpret the results: Based on the process capability indices and control chart analysis, determine whether the process is capable of meeting the specifications. If the process is not capable, identify potential improvement opportunities.

A process capability study is a valuable tool for understanding and improving grinding processes. The results provide quantitative evidence to support decisions regarding process improvements, process control strategies, and investment in new equipment.

Q 21. Describe your experience with statistical process control (SPC) in grinding operations.

Statistical Process Control (SPC) is indispensable in optimizing grinding operations. I have extensive experience applying SPC techniques like control charts (X-bar and R charts, individuals and moving range charts) to monitor key process parameters in real-time.

In grinding, SPC helps in:

- Monitoring key variables: Tracking parameters such as workpiece dimensions, surface roughness, grinding force, and wheel wear to detect deviations from the target values.

- Early detection of problems: Identifying potential issues early on, before they lead to significant quality problems or scrap. I recall an instance where a control chart indicated a gradual shift in the mean diameter. Investigating this led to the discovery of a loose component in the machine which was promptly fixed, preventing a large batch of defective parts.

- Process optimization: By analyzing the data collected through SPC, we can identify areas for improvement in the grinding process – such as adjustments to the grinding parameters or machine settings.

- Reducing variation: SPC helps reduce the variability in the grinding process, resulting in more consistent and higher-quality parts.

- Continuous improvement: SPC allows for continuous monitoring and improvement of the grinding process. It encourages data-driven decision-making to achieve a better process outcome.

SPC is not just a set of charts; it’s a mindset. It promotes a culture of data-driven decision-making, continuous improvement, and a proactive approach to managing process variation. It empowers operators and engineers to actively manage and enhance the grinding process continuously.

Q 22. What is your experience with automated grinding systems?

My experience with automated grinding systems spans over 15 years, encompassing various levels from basic CNC controlled grinders to fully automated, robotic cell configurations. I’ve worked extensively with systems integrating automated workpiece loading and unloading, in-process gauging and adaptive control systems. For example, I led a project implementing a robotic cell for cylindrical grinding of automotive crankshafts. This involved programming the robot for precise part handling, integrating the robot with the CNC grinder, and developing a system for automated quality control. The result was a 30% increase in throughput and a significant reduction in operator error.

I’m proficient in programming various CNC control systems (Fanuc, Siemens, Heidenhain) and experienced in troubleshooting and maintaining automated grinding systems, including understanding PLC programming and robotic integration. My expertise also extends to the selection and integration of automated gauging systems, essential for ensuring consistent part quality within automated workflows.

Q 23. How do you optimize grinding processes for improved productivity and reduced costs?

Optimizing grinding processes for improved productivity and reduced costs involves a multi-faceted approach. It begins with a thorough understanding of the grinding process itself – the material being ground, the desired surface finish, the tolerances required, and the available equipment. Key aspects include:

- Wheel Selection: Choosing the right grinding wheel (type, grain size, bond, etc.) is crucial. Incorrect wheel selection can lead to excessive wear, poor surface finish, or even wheel breakage.

- Grinding Parameters: Optimizing parameters like wheel speed, workpiece speed, depth of cut, and feed rate significantly impacts productivity and part quality. This often involves experimentation and data analysis to find the optimal settings.

- Coolant Selection and Application: Proper coolant selection and application is vital for removing heat and preventing wheel glazing and workpiece burn. This aspect is often overlooked but can drastically affect efficiency and surface finish.

- Fixture Design: Efficient fixturing ensures repeatable and accurate part location, minimizing setup time and improving process consistency. Poorly designed fixtures can lead to inaccurate grinding and part rejection.

- Process Monitoring and Control: Implementing in-process gauging and adaptive control systems allows for real-time adjustments to grinding parameters, ensuring consistent part quality and minimizing scrap.

For instance, in one project, we implemented a statistical process control (SPC) system for a surface grinding operation, leading to a 15% reduction in scrap and a 10% increase in output by identifying and correcting subtle variations in the process in real-time. The process optimization requires a systematic approach involving data analysis, experimentation, and continuous improvement.

Q 24. Describe your experience with different types of grinding fixtures.

My experience with grinding fixtures is extensive, encompassing various designs for different applications. I’ve worked with:

- Magnetic Chucks: Used extensively in surface grinding for holding ferrous workpieces. Expertise includes selecting the appropriate chuck size and strength, optimizing magnetization patterns, and understanding limitations for complex shapes.

- Hydraulic Chucks: Provide more holding force than magnetic chucks and are suitable for larger or more complex workpieces. Experience includes troubleshooting hydraulic systems and understanding the interplay between hydraulic pressure and holding force.

- Collets and Mandrels: Used for holding cylindrical workpieces in cylindrical grinding operations. Expertise includes selecting the right collet or mandrel based on workpiece size and material, ensuring accurate workpiece alignment, and preventing workpiece slippage.

For example, I designed a custom fixture for grinding a complex turbine blade profile, enabling consistent and accurate grinding of a challenging geometry that would have been impossible with standard fixtures. This involved close collaboration with the design engineers and machinists to create a fixture capable of holding the blade securely while allowing access to all grinding areas.

Q 25. How do you manage and resolve grinding process issues?

Managing and resolving grinding process issues requires a systematic approach, starting with identifying the root cause of the problem. This often involves:

- Data Analysis: Reviewing process data (part dimensions, surface finish, grinding wheel wear) to identify trends and patterns indicative of a problem.

- Visual Inspection: Examining the workpiece and grinding wheel for signs of damage, wear, or improper grinding.

- Process Parameter Review: Checking the accuracy and consistency of grinding parameters (speeds, feeds, depth of cut).

- Equipment Check: Verifying the proper functioning of the grinding machine and its components (spindles, coolant system, etc.).

- Material Analysis: Sometimes, issues stem from the material properties of the workpiece. Analyzing the workpiece material can identify potential causes.

For example, I once encountered a situation where parts were consistently out of tolerance. Through a thorough analysis of the process data, coupled with visual inspection, I identified a worn-out grinding wheel as the root cause. Replacing the wheel immediately solved the problem. In another instance, consistently poor surface finish was traced to a malfunctioning coolant system, which was promptly repaired.

Q 26. Explain your understanding of different grinding wheel bonding systems.

Grinding wheel bonding systems determine the wheel’s ability to hold its abrasive grains. The bond type influences wheel life, aggressiveness, and suitability for various applications. Common bonding systems include:

- Vitrified Bonds: Made from ceramic materials, vitrified bonds offer high strength, good wear resistance, and are suitable for a wide range of grinding applications. They are relatively rigid and less flexible.

- Resinoid Bonds: Composed of synthetic resins, resinoid bonds offer flexibility and are used for grinding softer materials or for creating wheels with a more aggressive cutting action. They tend to be less durable than vitrified bonds.

- Silicate Bonds: These bonds are less common but offer properties between vitrified and resinoid bonds. They are often used for special applications requiring specific performance characteristics.

- Metal Bonds: These are typically used for high-speed grinding and heavy-duty applications, providing superior strength and wear resistance.

Choosing the right bond is critical. A vitrified bond might be ideal for precision grinding of hardened steel, while a resinoid bond may be better suited for grinding softer materials like aluminum. The selection depends heavily on the material being ground, the required surface finish, and the desired grinding efficiency.

Q 27. Describe your experience with surface grinding, cylindrical grinding and creep feed grinding.

I have extensive experience in surface grinding, cylindrical grinding, and creep feed grinding. Let’s break down each:

- Surface Grinding: This involves removing material from the surface of a workpiece using a rotating wheel. My experience includes flat surface grinding, angular grinding, and various surface finishing techniques. I’m familiar with various surface grinding machines, including automated systems with in-process gauging.

- Cylindrical Grinding: This process is used to grind cylindrical workpieces, achieving precise diameters and surface finishes. My experience encompasses both internal and external cylindrical grinding, including centerless grinding. I’m proficient in selecting appropriate grinding wheels, optimizing parameters for various materials and tolerances, and troubleshooting common issues like chatter and burn.

- Creep Feed Grinding: This high-material removal process employs very slow feed rates and deep cuts, ideal for high-efficiency grinding of large workpieces or hard materials. I have experience implementing creep feed grinding for specific applications requiring high stock removal rates, while managing the increased heat generation and potential for wheel wear.

The choice between these methods depends on the workpiece geometry, material properties, desired accuracy, and the required surface finish. For instance, creep feed grinding excels in applications where high material removal rates are paramount, while surface grinding is ideal for precise surface finishing of flat workpieces.

Q 28. What is your experience with implementing lean manufacturing principles in grinding operations?

Implementing lean manufacturing principles in grinding operations involves eliminating waste and maximizing efficiency. This can be achieved through:

- 5S Methodology: Organizing the workspace to improve efficiency and reduce waste. This involves sorting, setting in order, shining, standardizing, and sustaining.

- Value Stream Mapping: Identifying and eliminating non-value-added steps in the grinding process. This helps to streamline the workflow and reduce lead times.

- Kaizen Events: Conducting focused improvement projects to address specific issues or inefficiencies in the grinding process. These events involve cross-functional teams working together to identify and implement solutions.

- Just-in-Time (JIT) Inventory: Minimizing inventory levels to reduce storage costs and improve workflow efficiency. This often requires close coordination with other departments.

- Total Productive Maintenance (TPM): Implementing preventative maintenance programs to reduce downtime and improve equipment reliability. This helps to minimize interruptions in the grinding process and maintain consistent output.

In a previous role, we implemented a Kaizen event focused on reducing setup time in a cylindrical grinding operation. Through collaboration between operators, engineers, and maintenance personnel, we identified and eliminated several bottlenecks, resulting in a 25% reduction in setup time.

Key Topics to Learn for Grinding Technology Interview

- Grinding Wheel Selection: Understanding wheel types (bonded, coated, etc.), abrasive materials, and their impact on surface finish, material removal rate, and workpiece quality. Consider factors influencing wheel selection such as workpiece material and desired tolerances.

- Grinding Processes: Become familiar with various grinding processes like cylindrical grinding, surface grinding, centerless grinding, and creep feed grinding. Understand their applications, advantages, and limitations.

- Grinding Machine Operation & Maintenance: Develop a solid understanding of the components of various grinding machines (e.g., CNC controlled grinders, manual machines). Know basic maintenance procedures, troubleshooting common issues, and safety protocols.

- Grinding Fluids & Coolants: Explore the role of coolants in grinding, their properties (e.g., viscosity, lubricity), and the impact of coolant selection on grinding performance and workpiece quality. Understand the environmental considerations related to coolant usage and disposal.

- Precision Measurement & Quality Control: Mastering techniques for precise measurement of ground surfaces (e.g., using CMMs, micrometers). Understanding statistical process control (SPC) and its application in maintaining consistent grinding quality.

- Material Science & Metallurgy: Develop a foundational understanding of the materials being ground and how their properties influence the grinding process. This includes knowledge of material hardness, microstructure, and machinability.

- Process Optimization & Troubleshooting: Learn to identify and solve common grinding problems such as surface defects, dimensional inaccuracies, and excessive wear. Understand techniques for optimizing grinding parameters to improve efficiency and quality.

Next Steps

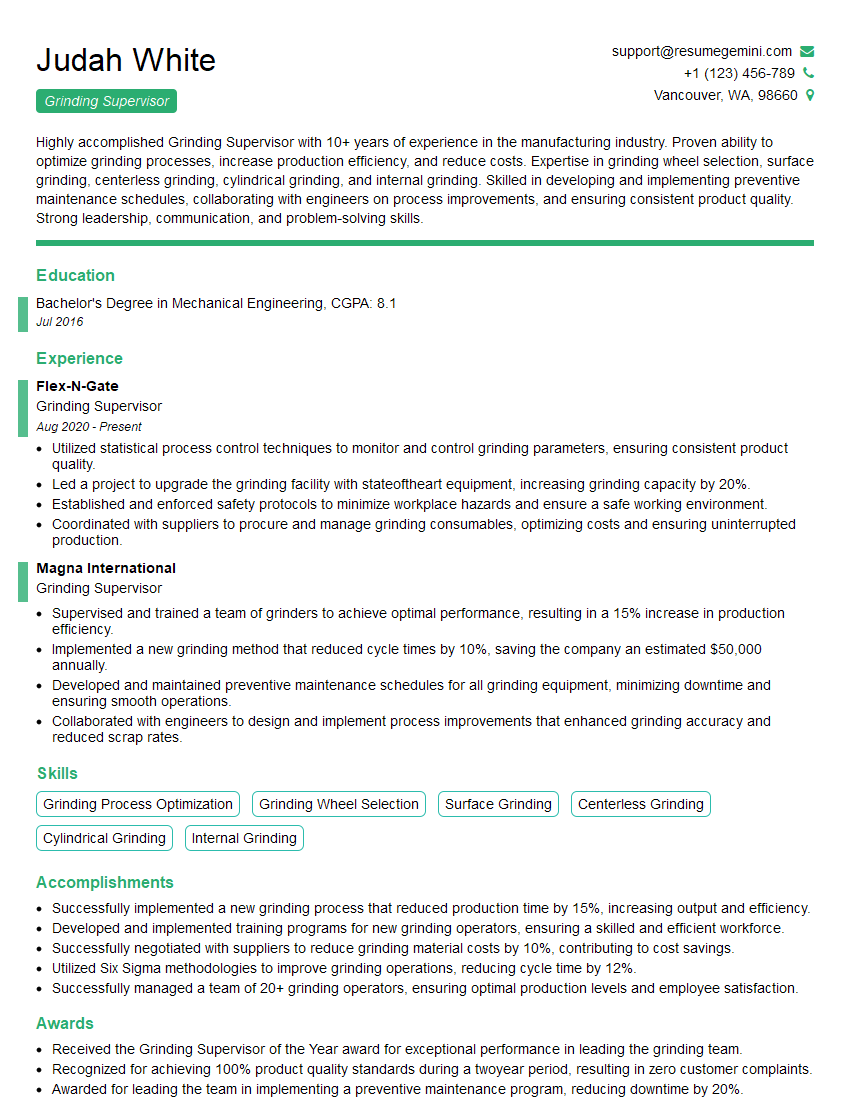

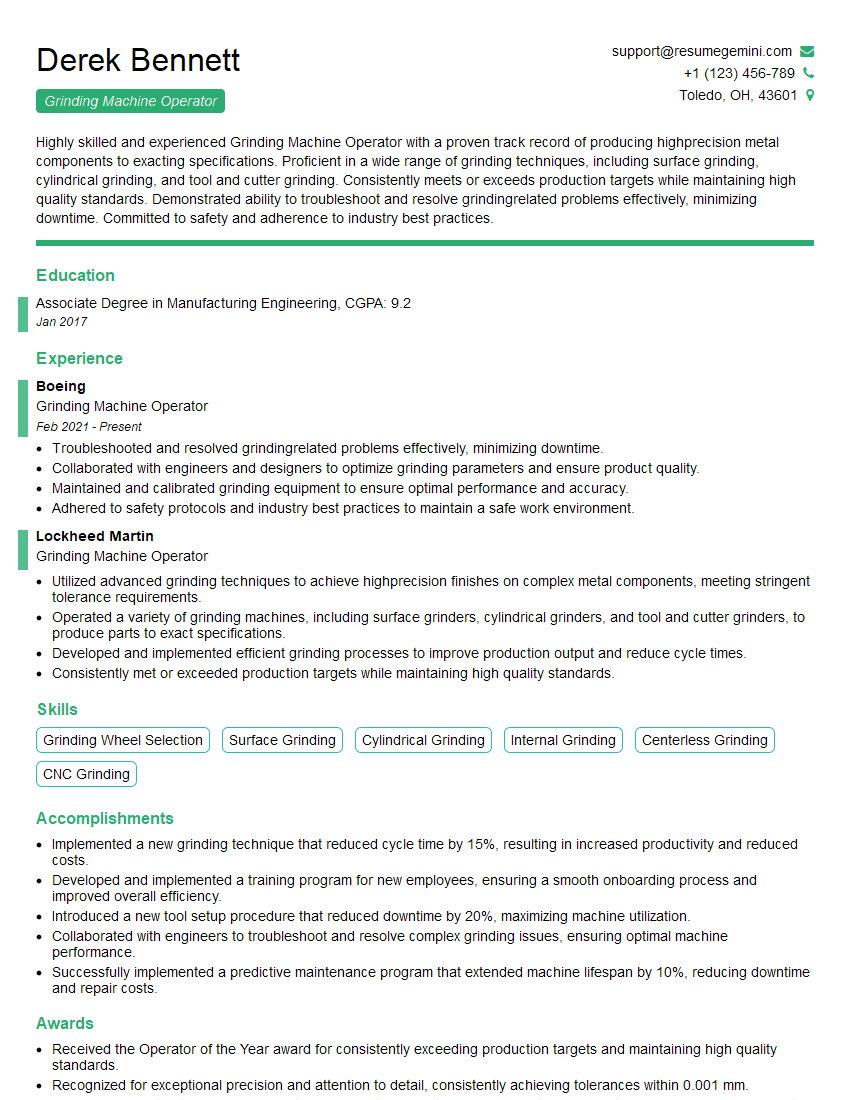

Mastering Grinding Technology opens doors to exciting career opportunities in manufacturing, automotive, aerospace, and many other high-precision industries. A strong understanding of these concepts will significantly boost your interview performance and career prospects. To maximize your chances, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that stands out to recruiters. We provide examples of resumes tailored to the Grinding Technology field to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good