The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Load Securement and Distribution interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Load Securement and Distribution Interview

Q 1. Explain the different types of load securement methods.

Load securement methods are crucial for safe transportation and depend heavily on the type of cargo being moved. They can broadly be categorized into:

- Strapping: This involves using strong webbing straps, often with ratchet buckles or cam buckles, to secure the load. Think of it like tightly wrapping a present – the straps provide tension and hold the load in place. Different strap types exist, offering varied breaking strengths and suitability for different cargo types.

- Chaining: Chains offer exceptional strength but require more careful handling to avoid damage. They are often used for heavy and bulky goods and require proper attachment points and tensioning.

- Rope/Webbing: While less common for primary securement in heavy-duty transport, ropes and webbing can be used for supplementary securing, tying down smaller items or providing extra support.

- Wedging/Blocking: This method involves using blocks of wood or other materials to prevent shifting and stabilize the load, particularly useful for oddly-shaped objects.

- Netting: Nets are ideal for securing smaller, loose items, preventing them from scattering during transit. Imagine securing a load of smaller parts in a container.

- Load Restraint Devices: These are specialized devices designed to prevent load movement, offering various configurations for different needs. They often involve a system of bars, clamps, and winches working together to tightly contain the cargo.

The best method depends on the cargo’s weight, dimensions, fragility, and the type of vehicle used. Often, a combination of methods is employed for optimal security.

Q 2. Describe the importance of proper load securement.

Proper load securement is paramount for several reasons:

- Safety: Improperly secured loads can shift during transit, leading to accidents. This can cause damage to the vehicle, injury to the driver and other road users, or even fatalities. Imagine a heavy object dislodging and hitting another vehicle.

- Legal Compliance: Most jurisdictions have strict regulations regarding load securement, and failure to comply can result in hefty fines, legal action, and damage to reputation.

- Cargo Protection: Securement prevents damage to the goods themselves. Think of fragile items like electronics or glassware that would be destroyed without adequate protection.

- Efficiency: Properly secured loads minimize delays caused by accidents or inspections. A smooth delivery means a productive business.

- Insurance: Insurance companies typically require proof of proper load securement to process claims in case of accidents or damage.

In short, proper securement is a matter of safety, legality, efficiency, and economic responsibility.

Q 3. What are the legal requirements for load securement in your region?

Legal requirements for load securement vary by region. In [Insert your region/country here], the primary legislation governing this is [Insert relevant legislation/regulation here, e.g., specific transport codes, safety standards]. These regulations typically specify:

- Maximum load weights and dimensions: Restrictions exist on how much and what size cargo a vehicle can carry safely.

- Securement methods: Regulations often specify appropriate methods and equipment, like the type and strength of straps or chains required for different loads.

- Inspection procedures: Regular inspections of the load before and during transport are usually mandated.

- Documentation: Proper documentation, including load securement plans, may be required.

- Penalties for non-compliance: Significant fines and potential legal consequences are typically in place.

It is crucial to be thoroughly familiar with the specific regulations in your area. Ignoring these regulations can have severe consequences.

Q 4. How do you calculate the appropriate number of straps or chains for a load?

Calculating the appropriate number of straps or chains isn’t a simple formula; it’s a risk assessment that considers several factors:

- Load weight and distribution: Heavier loads require more securement points. Uneven weight distribution needs extra attention.

- Cargo dimensions and shape: Larger or oddly shaped loads may need more straps to prevent shifting.

- Vehicle type and characteristics: The vehicle’s suspension, braking system, and available tie-down points influence securement requirements.

- Road conditions: Rough terrain requires stronger and more numerous securement points.

- Weather conditions: Wind and rain can affect load stability, necessitating more robust securement.

While there are no universal formulas, the key is to always err on the side of caution. Using more securement points than initially estimated is far safer than underestimating.

Many professional load securement guides and calculation tools can help you in this process. Remember to consult with experienced professionals when dealing with complex or heavy loads.

Q 5. What are the common causes of load shifting during transit?

Load shifting during transit is often caused by several factors:

- Insufficient securement: This is the most common cause. Using too few straps, chains, or improper securing techniques allows movement.

- Improper load distribution: Uneven weight distribution puts extra stress on one part of the load, increasing chances of shifting.

- Sudden braking or acceleration: These actions can cause loads to slide or shift, especially if not properly secured.

- Road conditions: Rough roads, potholes, or curves put extra stress on the load and securement system.

- Weather conditions: Strong winds or heavy rain can increase the risk of shifting.

- Cargo movement: Loads containing loose items may shift due to their internal movement.

Preventing load shifting requires careful planning, proper securement techniques, and vigilance during transit.

Q 6. How do you identify potential hazards associated with load securement?

Identifying potential hazards related to load securement involves a thorough risk assessment. This involves considering:

- Condition of the securement equipment: Inspect straps, chains, and other equipment for wear, tear, or damage. Replace any worn or damaged components.

- Suitability of the securement method: Ensure the chosen method is appropriate for the type of cargo and vehicle used.

- Load stability: Check if the load is evenly distributed and stable, considering its shape, weight, and center of gravity.

- Vehicle condition: Inspect the vehicle’s tie-down points and ensure they are in good condition and properly used.

- Environmental factors: Assess the impact of weather conditions (wind, rain, snow) and road conditions (curves, hills, uneven surfaces) on load stability.

A thorough pre-trip inspection is crucial to identify and mitigate potential hazards. Ignoring even minor issues can lead to significant problems down the line.

Q 7. Explain the process of inspecting a load before and after transit.

Load inspection is a critical part of safe transport. The process involves:

Before Transit:

- Visual Inspection: Carefully examine the load for any damage, loose items, or potential hazards.

- Securement Check: Verify that all straps, chains, or other securement devices are properly attached and tensioned.

- Stability Assessment: Ensure the load is stable and evenly distributed.

- Documentation: Record all relevant details, including weight, dimensions, securement methods, and any potential issues.

After Transit:

- Visual Inspection: Check for any damage to the load, vehicle, or securement equipment.

- Securement Check: Inspect the securement system for any signs of wear, tear, or damage.

- Load Stability: Assess if the load has shifted or been damaged during transport.

- Documentation: Record the post-transit condition of the load and any observed issues.

Thorough inspections minimize risks, protect cargo and property, and ensure compliance with regulations.

Q 8. What are the best practices for securing different types of cargo?

Securing cargo effectively depends heavily on its type and the mode of transportation. The overarching principle is to prevent shifting, overturning, or falling during transit. This involves understanding the cargo’s weight, dimensions, and center of gravity. We use different techniques and equipment for different cargo types.

- Pallettized Goods: These are relatively easy to secure using straps, stretch wrap, and dunnage (material used to fill gaps). We ensure the pallets are stacked evenly, with heavier items on the bottom, and that straps are tensioned correctly to prevent movement. Think of it like building a sturdy brick wall – each layer supports the one above.

- Loose Cargo: This requires more meticulous planning. We might use netting, bulkheads, or even specialized containers to contain the cargo and prevent shifting. Imagine transporting sand – without proper containment, it would shift and potentially damage the vehicle.

- Oversized or Heavy Cargo: These often require specialized equipment like chains, winches, and heavy-duty straps. Careful planning and calculations are essential to distribute weight evenly and prevent stress on the vehicle or tie-down points. Think of securing a large piece of machinery – you need robust and reliable methods to prevent it from moving.

- Liquid Cargo: This needs appropriate tank securement, checking for leaks and ensuring proper ventilation. A spill could be disastrous, so it’s crucial to maintain integrity and prevent shifting.

In all cases, proper documentation of securement methods is crucial for safety and liability purposes.

Q 9. How do you handle damaged or compromised load securement?

Discovering damaged or compromised load securement is a serious situation demanding immediate action. Safety is paramount. We follow a clear protocol:

- Immediate Assessment: We carefully inspect the damage, assessing the extent and potential risks. Is the cargo still stable? Are there any potential hazards (e.g., sharp edges, leaking materials)?

- Secure the Load: We take immediate steps to re-secure the load, if possible, using additional tie-downs or other methods to prevent further movement or damage. If re-securing is impossible or unsafe, we immediately halt the shipment.

- Documentation: Thorough documentation is vital. We meticulously record the nature and extent of the damage, the steps taken to secure the load (or the reason it couldn’t be re-secured), and the condition of the cargo. Photos and videos are extremely helpful.

- Reporting: We immediately report the incident to the relevant parties, including our supervisors, clients, and possibly regulatory bodies depending on the severity. This ensures appropriate action is taken and prevents future incidents.

- Investigation: We thoroughly investigate the cause of the damage to understand why the securement failed and prevent similar occurrences in the future.

The key is to prioritize safety and thoroughly document every step of the process.

Q 10. Describe your experience with various load securement devices.

My experience encompasses a wide range of load securement devices, including:

- Straps: I’m proficient in using various types, from ratchet straps (which offer high tensioning capabilities) to webbing straps (more flexible). I understand the importance of choosing the right strap for the cargo and securing it correctly to designated tie-down points.

- Chains: I have experience using chains for heavy and oversized loads, understanding the need for proper chain tension, and the use of binders for securing the chain. Safety is paramount with chains; regular inspection is crucial.

- Winches: I’m skilled in the operation and maintenance of winches, ensuring they are properly used and regularly inspected to maintain optimal functionality. This is particularly important for securing heavy or awkward loads.

- Netting: I know how to effectively use various types of netting to contain loose cargo and prevent shifting. The type of netting depends on the cargo and securing methods. A strong and appropriate netting is key.

- Dunnage: I understand how to effectively utilize dunnage (wood blocks, air bags etc.) to create a stable base for palletized goods and to fill gaps in order to prevent shifting.

I’m always learning about new and improved devices and techniques to enhance safety and efficiency.

Q 11. What is your experience with load securement software or technology?

My experience with load securement software and technology involves using systems to plan and document load securing arrangements. These systems often include:

- 3D Modeling Software: This allows us to visualize the load and plan securement strategies virtually, optimizing placement and ensuring stability before loading.

- Load Securement Calculation Software: This software calculates the necessary tie-down forces and ensures compliance with regulations based on cargo weight, dimensions, and transport conditions.

- Mobile Apps: Many applications help document inspections, record securement details, and capture images of the secured load. This provides a digital record for auditing purposes and enhances accountability.

These technologies improve efficiency, reduce risks, and enhance compliance by providing detailed, reliable records and precise calculations.

Q 12. How do you ensure compliance with load securement regulations?

Ensuring compliance with load securement regulations is a core part of my responsibility. This involves:

- Understanding Regulations: I stay updated on all relevant local, national, and international regulations regarding load securement. These regulations differ based on location and mode of transportation.

- Regular Training: I undergo regular training on load securement best practices and regulatory updates to ensure I’m always up to date and competent.

- Pre-Trip Inspections: I perform thorough pre-trip inspections to verify that the load is secured according to regulations and that all equipment is in good working order.

- Documentation: I meticulously document all aspects of load securement, including the securement methods used, equipment details, and any potential issues encountered. This documentation serves as proof of compliance.

- Audits: I actively participate in internal and external audits to ensure our load securement procedures align with regulations and best practices.

Non-compliance can lead to significant fines, accidents, and reputational damage, making adherence to regulations crucial.

Q 13. How do you communicate load securement procedures to your team?

Communicating load securement procedures effectively is vital for team safety and operational efficiency. My approach involves:

- Clear and Concise Training: I provide comprehensive training sessions using a mix of theoretical instruction, practical demonstrations, and hands-on exercises. I use visual aids and real-world examples to ensure understanding.

- Regular Refresher Training: I conduct regular refresher courses to reinforce knowledge and address any new regulations or best practices. This ensures everyone remains informed.

- Written Procedures: I ensure clear, concise, and readily available written procedures are in place. These procedures serve as a reference for every member of the team.

- Open Communication: I foster an open communication environment where team members feel comfortable asking questions and raising concerns without fear of reprisal.

- Regular Audits and Feedback: I conduct regular inspections and provide constructive feedback to team members on their securement techniques. This allows for improvement and identifies areas for further training.

Effective communication ensures everyone is on the same page, maximizing safety and productivity.

Q 14. How do you manage and resolve conflicts related to load securement?

Conflicts related to load securement can arise due to various reasons, such as differing opinions on securement methods, time constraints, or equipment availability. My approach to resolving these conflicts is:

- Open Dialogue: I encourage open and respectful dialogue between the conflicting parties. The goal is to understand each perspective and identify the root cause of the disagreement.

- Focus on Safety: I emphasize that safety is paramount. All decisions related to load securement should prioritize safety over speed or convenience.

- Data-Driven Decisions: I encourage data-driven decision-making by referring to regulations, best practices, and relevant documentation to guide resolution.

- Collaboration and Compromise: I facilitate collaboration between the parties to reach a mutually agreeable solution. This may involve compromising on certain aspects to ensure the load is securely and safely transported.

- Documentation: I thoroughly document the conflict, the discussions held, the solutions agreed upon, and the rationale behind those solutions. This creates a record for future reference.

The key is to create a safe and respectful environment where everyone feels comfortable expressing their concerns and working together towards a safe and compliant solution.

Q 15. What is your experience with different types of transport vehicles?

My experience encompasses a wide range of transport vehicles, from standard semi-trailers and box trucks to specialized vehicles like refrigerated units (reefers) for temperature-sensitive goods, flatbed trailers for oversized cargo, and even articulated lorries for bulk transportation. I’m familiar with their weight capacities, dimensional limitations, and operational characteristics. For instance, understanding the nuances of loading a reefer requires knowledge of pre-trip temperature checks, maintaining the cold chain, and ensuring proper ventilation to prevent spoilage. Similarly, securing oversized loads on a flatbed requires specialized techniques and adherence to strict regulations to prevent accidents.

I’ve worked with various carriers, each with its own fleet and operating procedures, which has broadened my understanding of the practical challenges in different modes of transportation. This includes working with logistics companies that utilize air freight, ocean freight, and rail transport, allowing me to oversee the entire supply chain.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you plan and optimize load distribution for efficient delivery?

Planning and optimizing load distribution is crucial for efficient delivery. It’s like a three-dimensional Tetris puzzle, but with real-world consequences. My approach involves a systematic process: First, I analyze the order details—weight, volume, fragility, and delivery location. Then, I use specialized software and my experience to create a load plan that maximizes space utilization while ensuring stability and preventing damage. This frequently involves considering the center of gravity to maintain balance during transit.

For example, heavier items are placed lower and towards the center of the vehicle, while lighter, more fragile items are placed on top, cushioned appropriately. I always prioritize safety and compliance with load securement regulations. Optimization also involves route planning to minimize travel time and fuel consumption, considering factors like traffic patterns and delivery windows. The aim is to deliver the goods safely, on time, and at the lowest possible cost.

Q 17. What are the factors you consider when planning load distribution?

Several factors significantly impact load distribution planning. These include:

- Weight and dimensions of cargo: Accurate weight and volume measurements are essential for proper load balancing and space optimization.

- Fragility and handling requirements: Delicate items necessitate special handling and protection, including cushioning and securement methods. This is where understanding the nature of the product is critical. Perishable goods need specialized conditions that would need to be taken into consideration.

- Destination and delivery routes: Route planning affects the duration of transit and the potential for shifting during transport. A longer route may require more robust securement techniques.

- Vehicle type and capacity: The dimensions and weight limits of the transport vehicle dictate the load configuration.

- Legal regulations and safety standards: Adhering to all applicable regulations on load securement is paramount to ensure safe transportation and avoid penalties.

- Environmental conditions: Extreme temperatures or weather conditions can impact load stability and require specific handling procedures.

Ignoring any of these factors can lead to accidents, damage to goods, delays, and even legal repercussions.

Q 18. How do you manage inventory levels to optimize distribution?

Managing inventory levels for optimized distribution is a delicate balancing act. Holding too much inventory ties up capital and increases storage costs, while insufficient inventory leads to stockouts and lost sales. My approach leverages data analysis and forecasting techniques to predict demand accurately. I use sophisticated inventory management systems that track stock levels in real-time and integrate with our distribution network.

This involves using techniques like Just-in-Time (JIT) inventory management for frequently demanded items to reduce storage costs while ensuring availability. For less frequently demanded items, a more traditional inventory strategy might be employed. Regular stock audits and cycle counting ensure the accuracy of inventory records. Furthermore, effective communication with suppliers allows for timely replenishment of stock, preventing disruptions to the distribution process.

Q 19. Describe your experience with warehouse management systems.

I have extensive experience with various Warehouse Management Systems (WMS). I’m proficient in using WMS software to manage inventory, track shipments, optimize warehouse layout, and control workflows. My expertise extends to different systems, from cloud-based solutions to on-premise systems. I understand the importance of integrating the WMS with other enterprise systems like Enterprise Resource Planning (ERP) systems to achieve seamless data flow.

For instance, I’ve worked with systems that optimize picking routes for improved efficiency, manage warehouse space effectively, and provide real-time visibility into inventory levels. My experience also covers the implementation, configuration, and troubleshooting of WMS solutions, including data migration and user training. A key aspect of WMS usage is ensuring data integrity, which is paramount for accurate inventory control and efficient order fulfillment.

Q 20. How do you track and trace shipments throughout the distribution process?

Tracking and tracing shipments is crucial for maintaining transparency and accountability throughout the distribution process. We leverage a combination of technologies to achieve this, including GPS tracking devices on vehicles, barcode scanning at various stages of handling, and sophisticated tracking software that provides real-time visibility into shipment location and status. This data allows us to proactively identify potential issues and make informed decisions to mitigate delays.

For example, if a shipment is delayed, the tracking system alerts us immediately, allowing us to investigate the cause and notify customers. We also use electronic proof of delivery (ePOD) systems to confirm successful delivery and streamline the documentation process. This holistic approach ensures that all stakeholders have access to real-time information, improving efficiency and communication throughout the distribution process.

Q 21. How do you handle unexpected delays or disruptions in the distribution process?

Unexpected delays and disruptions are inevitable in distribution. My approach to handling such situations involves a proactive and flexible strategy. First, we identify the cause of the disruption – whether it’s traffic congestion, inclement weather, mechanical failure, or unforeseen circumstances. Then, we assess the impact on the delivery schedule and communicate with customers promptly to manage expectations.

To mitigate the impact, we might implement alternative routing, utilize backup transportation, or re-allocate resources as needed. We maintain strong relationships with our carriers and other stakeholders to ensure quick responses to emergencies. Regular contingency planning and risk assessment help us prepare for potential disruptions and implement effective mitigation strategies. Documentation of these events, including the cause and resolution, is critical for continuous improvement and avoiding future occurrences.

Q 22. What is your experience with different distribution channels?

My experience spans a variety of distribution channels, from direct-to-consumer (DTC) deliveries using our own fleet and independent contractors, to working with third-party logistics providers (3PLs) for larger-scale distribution, and leveraging e-commerce platforms for online sales. Each channel presents unique challenges and advantages in terms of cost, speed, and control. For instance, DTC offers greater control over the customer experience and branding, but it’s more capital intensive. Conversely, using 3PLs is cost-effective for large volumes but requires meticulous management of contracts and performance metrics. E-commerce offers broad market reach but demands efficient order fulfillment processes and robust inventory management.

- Direct-to-Consumer (DTC): I’ve overseen the optimization of our company’s own delivery fleet, resulting in a 15% reduction in delivery times and a 10% decrease in fuel costs through route optimization and driver training programs.

- Third-Party Logistics (3PLs): I’ve successfully negotiated contracts with multiple 3PLs, ensuring competitive pricing and service level agreements (SLAs) that meet our stringent delivery requirements. This included key performance indicators (KPIs) such as on-time delivery rates and damage claims.

- E-commerce Platforms: I’ve integrated our distribution processes with major e-commerce platforms, automating order fulfillment and tracking, thus significantly reducing manual effort and enhancing customer satisfaction.

Q 23. How do you ensure timely and efficient delivery of goods?

Ensuring timely and efficient delivery relies on a multi-faceted approach. It begins with accurate forecasting of demand, enabling proactive inventory management and optimized resource allocation. This is coupled with robust order management systems that track orders from placement to delivery, flagging potential delays early on. Efficient route planning, utilizing software and real-time traffic data, minimizes transit times. Finally, a well-trained and motivated workforce is crucial for handling unexpected challenges and maintaining high service standards.

For example, we utilize a Transportation Management System (TMS) that automatically generates routes, taking into account factors like traffic, delivery windows, and vehicle capacity. This system also provides real-time tracking and alerts us to potential delays, allowing for proactive communication with customers and adjustments to the delivery schedule.

Q 24. Describe your experience with route optimization software or techniques.

My experience with route optimization software includes working with both proprietary and third-party solutions, such as the popular Route4Me and OptimoRoute. These tools allow us to input delivery addresses, vehicle constraints (e.g., capacity, weight limits), and time windows, to generate the most efficient delivery routes. Beyond software, I also apply manual optimization techniques, particularly for smaller-scale deliveries or those with unique constraints that software might not fully account for. This can involve using mapping software to visually assess routes and identifying potential shortcuts or alternative routes to avoid congestion.

For instance, we recently faced a challenge delivering to a remote area with limited road access. The software initially generated a route that would have significantly exceeded the expected delivery time. By manually adjusting the route based on local knowledge and using satellite imagery to identify alternative paths, we managed to cut delivery time by 20%.

Q 25. How do you measure the effectiveness of your load securement and distribution strategies?

Measuring the effectiveness of load securement and distribution strategies involves tracking a range of Key Performance Indicators (KPIs). These include on-time delivery rates, damage rates, fuel efficiency, and overall transportation costs. We also assess customer satisfaction through feedback surveys and reviews. Specifically, for load securement, we monitor the number of incidents involving cargo shifting or damage during transit. A reduction in these incidents directly reflects the effectiveness of our securement procedures and training programs.

We use data dashboards to visualize these KPIs, allowing for regular performance monitoring and identification of areas for improvement. For example, a sudden increase in damage rates might indicate a need for retraining on securement techniques or a review of our packaging materials.

Q 26. How do you stay updated on changes in load securement regulations and best practices?

Staying updated on load securement regulations and best practices requires a multi-pronged approach. I actively participate in industry conferences and workshops, subscribe to relevant publications and newsletters (such as those from industry associations), and regularly review updates from regulatory bodies like the Department of Transportation (DOT). I also engage in professional development courses and maintain a network of contacts within the industry to share information and best practices.

Furthermore, we maintain a comprehensive internal document that tracks all relevant regulations and updates, making sure our team is well-informed and adheres to the latest standards. We even conduct regular internal audits to ensure compliance with all applicable regulations.

Q 27. Explain a time when you had to troubleshoot a problem related to load securement.

During a large-scale distribution project, we experienced an unusually high number of damaged goods. Initial investigations pointed towards inadequate load securement. We conducted a thorough review of our procedures, inspecting the securement equipment, and interviewing drivers and warehouse staff. This revealed that a recent change in packaging materials had compromised the effectiveness of our standard securement techniques. We quickly implemented corrective actions, including retraining staff on proper securement using the new packaging, and updating our securement guidelines to accommodate the change. This resulted in a significant reduction in damage rates within the following weeks.

Q 28. Describe your experience with managing a team responsible for load securement and distribution.

Managing a team responsible for load securement and distribution requires strong leadership, communication, and organizational skills. I focus on clear goal setting, empowering team members, and fostering a collaborative work environment. Regular performance reviews and feedback sessions ensure that everyone is performing at their best and that their contributions are recognized. I also prioritize training and development to enhance their skills and knowledge, especially in areas such as safe load securement techniques, route planning software, and customer service.

One key aspect of my management style is open communication. I maintain regular team meetings to discuss challenges, share successes, and brainstorm solutions. I also encourage open feedback and actively listen to my team’s concerns and suggestions, ensuring everyone feels heard and valued. This collaborative approach has significantly improved team morale and overall operational efficiency.

Key Topics to Learn for Load Securement and Distribution Interview

- Understanding Load Securement Principles: Explore the fundamental physics behind load stability, weight distribution, and center of gravity. Consider different types of loads and their unique securing requirements.

- Practical Application of Securement Techniques: Learn about various securing methods, including strapping, chaining, netting, and blocking. Understand the importance of proper tensioning and the use of appropriate equipment.

- Regulations and Compliance: Familiarize yourself with relevant safety regulations and industry standards (e.g., Department of Transportation regulations). Understand the implications of non-compliance.

- Risk Assessment and Mitigation: Practice identifying potential hazards associated with load securement and distribution. Develop strategies for mitigating risks and ensuring safe handling procedures.

- Load Distribution Planning: Understand the process of planning load distribution to optimize space utilization, weight balance, and efficient transport. Consider different vehicle types and their limitations.

- Emergency Procedures: Learn about proper procedures to follow in case of load shifting, accidents, or other emergencies. This includes knowing how to assess the situation and respond safely and effectively.

- Documentation and Record Keeping: Understand the importance of maintaining accurate records related to load securement, including inspection reports and securing procedures followed.

- Types of Cargo and Their Specific Needs: Learn about the unique securement requirements for different types of cargo, such as hazardous materials, oversized loads, and fragile goods.

- Technology and Load Securement: Explore the role of technology in improving load securement, such as load monitoring systems and software for planning and optimization.

Next Steps

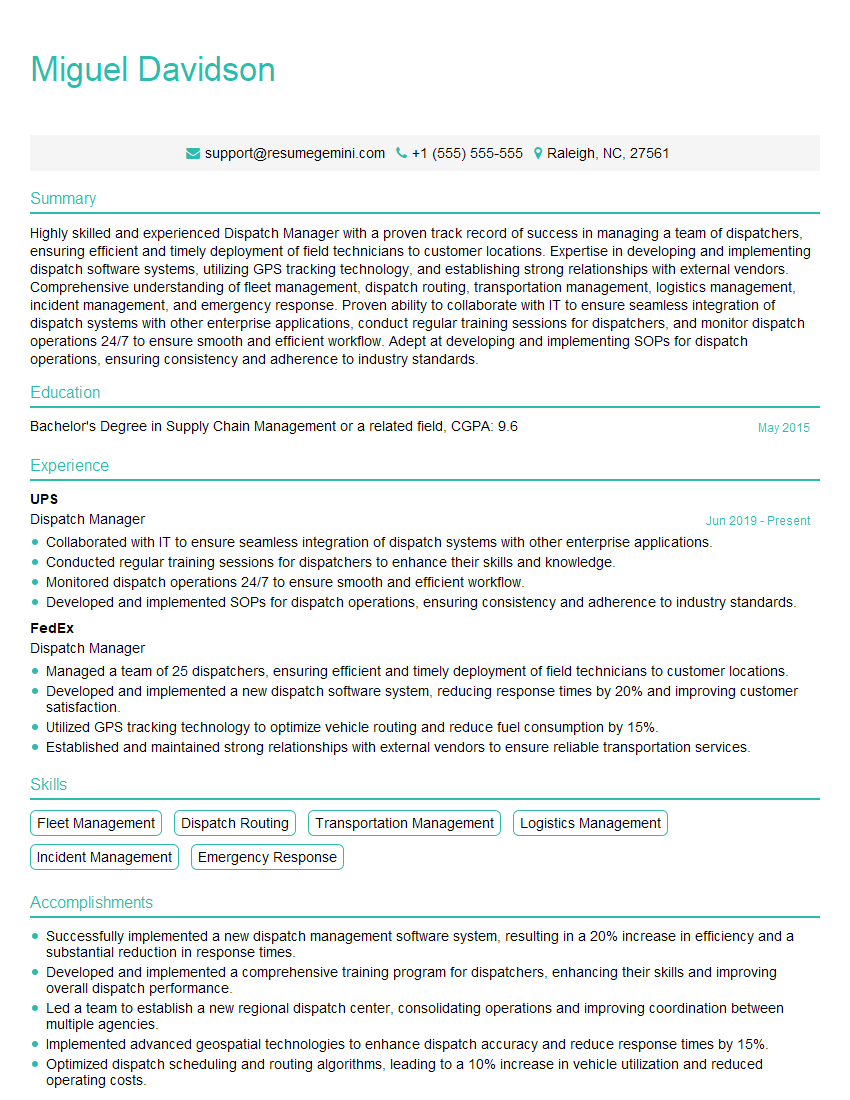

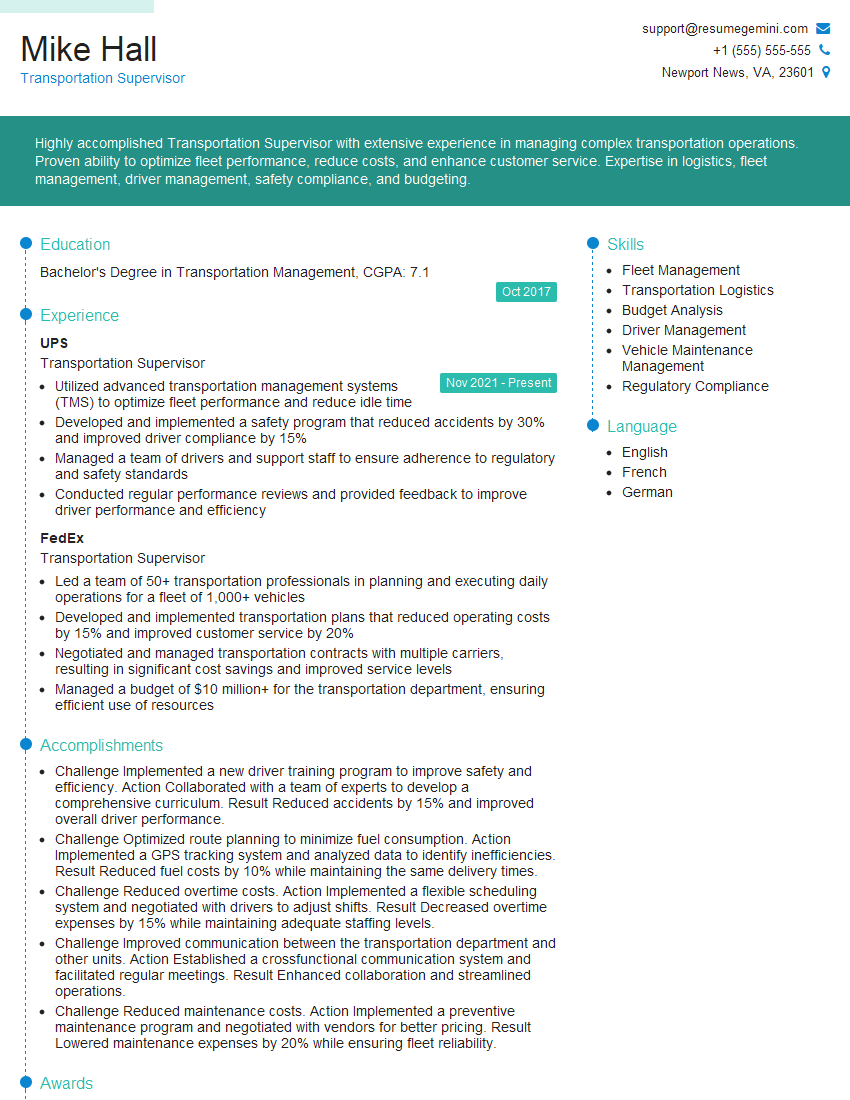

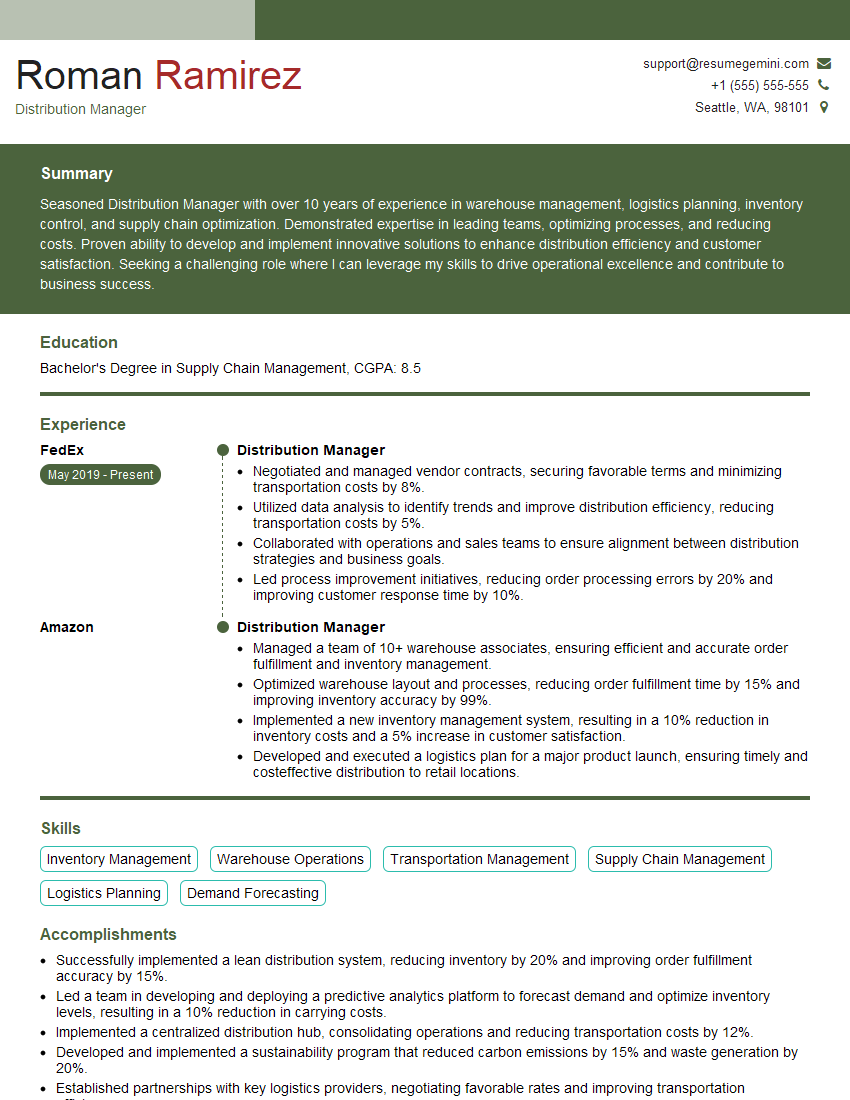

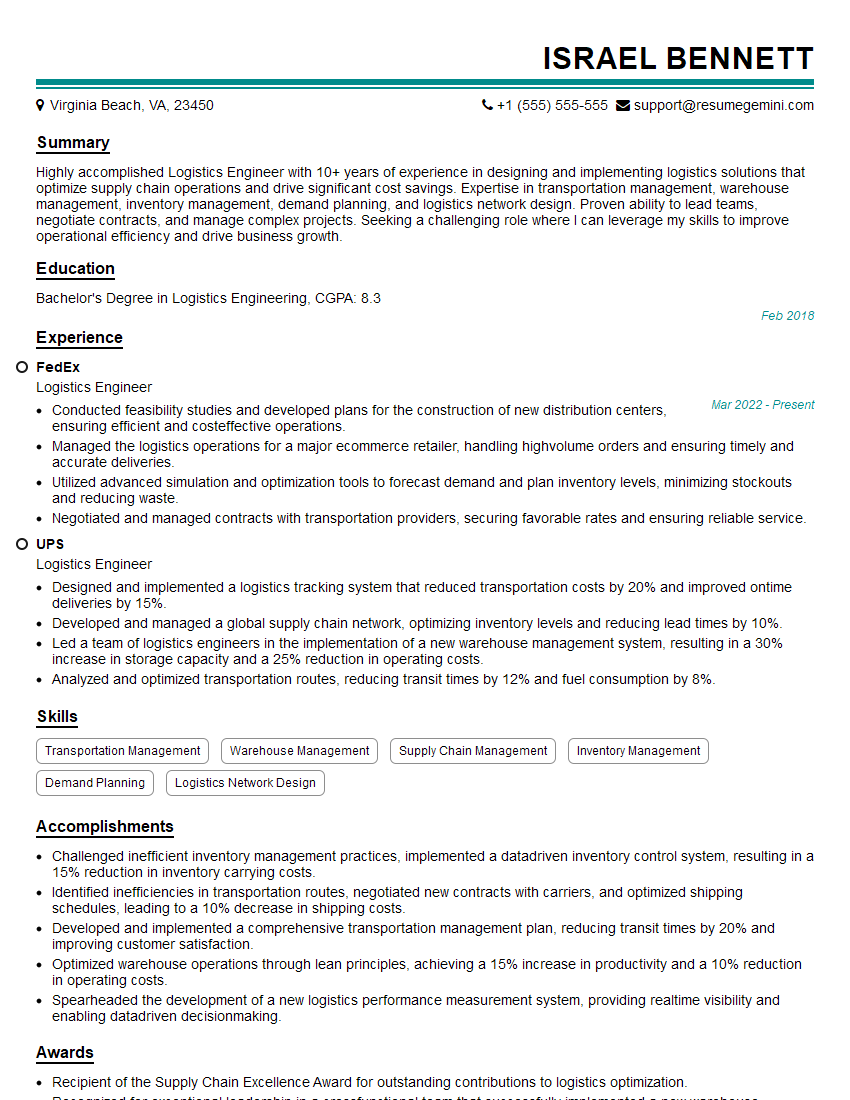

Mastering Load Securement and Distribution is crucial for career advancement in the logistics and transportation industries. It demonstrates a commitment to safety, efficiency, and regulatory compliance – highly valued attributes by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Load Securement and Distribution to guide you. Invest time in crafting a strong resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good