Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Warehouse and Operations Management interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Warehouse and Operations Management Interview

Q 1. Describe your experience with Warehouse Management Systems (WMS).

Warehouse Management Systems (WMS) are the backbone of efficient warehouse operations. I’ve extensively used WMS software from various vendors, including Oracle, SAP, and Manhattan Associates. My experience spans implementing, configuring, and optimizing these systems to streamline processes like receiving, putaway, picking, packing, and shipping. For example, in a previous role, we implemented a new WMS to replace an outdated system. This resulted in a 20% reduction in order fulfillment time and a 15% decrease in picking errors. I’m proficient in configuring different modules within a WMS, including inventory management, labor management, and reporting and analytics. I also have experience integrating WMS with other enterprise systems such as ERP and TMS to create a seamless flow of information across the supply chain.

A key aspect of my WMS expertise is understanding how to tailor the system to the specific needs of the warehouse and its operations. This involves careful analysis of current processes, identifying areas for improvement, and configuring the WMS to support those improvements. I’m not just a user; I actively participate in system upgrades and customization to ensure it remains an effective tool for ongoing efficiency.

Q 2. How do you optimize warehouse layout for maximum efficiency?

Optimizing warehouse layout is crucial for efficiency. It’s about minimizing travel time, maximizing storage capacity, and ensuring smooth workflow. My approach involves a detailed analysis of product velocity (how quickly items move), storage requirements (size, weight, temperature sensitivity), and order picking patterns. I utilize various techniques, including slotting optimization, where fast-moving items are placed in easily accessible locations, and zone picking, where different areas of the warehouse are assigned to specific picking tasks. Imagine a grocery store: high-demand items like milk and bread are placed near the entrance for quick access, while less frequently purchased items are further back. The same principle applies to warehouse design.

Furthermore, I consider the use of automation like conveyor belts and automated guided vehicles (AGVs) to further enhance efficiency. Safety is paramount, so the layout also needs to account for adequate aisle widths, clear signage, and designated areas for receiving and shipping. I’ve successfully implemented several warehouse redesigns, resulting in significant improvements in productivity and space utilization. For instance, at one company, a strategic warehouse re-layout led to a 10% increase in order picking throughput and a 5% reduction in storage space requirements.

Q 3. Explain your process for inventory control and cycle counting.

Inventory control and cycle counting are essential for accurate inventory management. My process begins with implementing a robust system for tracking inventory movements—from receiving to shipping. This usually involves using barcodes or RFID tags for precise identification. Cycle counting is a crucial part of this process. Instead of a full inventory count, which can be disruptive, I employ a systematic approach of counting a small portion of the inventory regularly. This allows us to identify discrepancies early on and prevent larger problems later. For example, we might count a specific aisle every week, rotating through all aisles over several weeks. This method ensures accuracy without halting operations.

I leverage WMS features to automate parts of this process, such as generating cycle counting schedules and tracking discrepancies. Data analysis helps identify slow-moving or obsolete items, enabling us to take appropriate action, such as implementing discounts or removing them from inventory. Regular reconciliation with our ERP system ensures that the inventory data in our WMS is always accurate and up to date.

Q 4. What metrics do you use to measure warehouse performance?

Several key metrics are used to measure warehouse performance. These include:

- Order fulfillment rate: The percentage of orders processed and shipped on time and accurately.

- Inventory accuracy: The percentage of inventory records that accurately reflect the actual stock levels.

- Order cycle time: The time it takes to receive, process, and ship an order.

- Storage capacity utilization: The percentage of available storage space being used efficiently.

- Picking accuracy: The percentage of orders picked without errors.

- Labor productivity: The number of units picked or orders processed per labor hour.

- Inventory turnover rate: How many times inventory is sold or used in a period.

By tracking these metrics, we can identify areas of strength and weakness in our warehouse operations and make data-driven improvements. Regular reporting and analysis are key to continuous improvement. I regularly use dashboards and reports generated by the WMS to monitor performance and identify trends.

Q 5. How do you handle peak season demands in a warehouse?

Handling peak season demands requires proactive planning and execution. My approach involves several key strategies:

- Forecasting demand: Accurate forecasting is crucial to anticipate peak volumes and ensure sufficient resources are available.

- Capacity planning: This includes evaluating current storage capacity, labor availability, and equipment capabilities to determine if adjustments are needed (e.g., temporary staffing, renting additional space).

- Process optimization: Streamlining processes, such as order picking and shipping, to maximize throughput during peak periods. This could involve adjusting picking strategies or optimizing routes.

- Inventory management: Ensuring sufficient inventory levels of high-demand items while managing storage space effectively.

- Communication and collaboration: Effective communication with all stakeholders, including suppliers, carriers, and internal teams, is vital for smooth operations.

In a previous role, we successfully managed a 50% increase in order volume during peak season by implementing a combination of these strategies. This involved hiring temporary staff, optimizing our picking process, and utilizing overtime effectively. Careful monitoring of key metrics throughout the peak season allows us to make necessary adjustments in real-time.

Q 6. Describe your experience with different inventory management techniques (FIFO, LIFO, etc.).

I have extensive experience with various inventory management techniques, including FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and FEFO (First-Expiring, First-Out). FIFO is ideal for perishable goods, ensuring that the oldest items are used first to minimize waste. LIFO is often used for non-perishable items, and can have tax advantages in some circumstances. FEFO is critical for products with expiration dates, such as food or pharmaceuticals. The choice of method depends on the specific characteristics of the inventory and the business goals.

For example, in managing a warehouse for a food distributor, FEFO was paramount. The WMS was configured to prioritize picking items with the closest expiration dates. This minimized waste and ensured that customers received fresh products. In managing a warehouse storing non-perishable parts, the FIFO method might be sufficient, ensuring older parts are used first to reduce potential obsolescence. The right method is always chosen based on a risk/reward assessment, accounting for possible storage and obsolescence costs.

Q 7. How do you ensure workplace safety in a warehouse environment?

Workplace safety is a top priority in any warehouse environment. My approach to ensuring safety involves a multi-faceted strategy:

- Regular safety training: Employees receive comprehensive training on safe operating procedures, including the proper use of equipment, handling of materials, and emergency response protocols.

- Hazard identification and risk assessment: Regular inspections are conducted to identify potential hazards, such as uneven flooring, blocked aisles, or faulty equipment. Risk assessments help determine the severity of these hazards and appropriate mitigation strategies.

- Implementation of safety measures: This involves implementing measures to address identified hazards, such as installing safety guards on machinery, implementing proper lighting, and providing personal protective equipment (PPE) to employees.

- Enforcement of safety rules: Strict enforcement of safety rules and regulations, including disciplinary action for violations, is crucial to maintaining a safe work environment.

- Incident reporting and investigation: A clear process for reporting and investigating accidents or near misses allows for identifying root causes and implementing preventative measures.

Beyond these steps, fostering a strong safety culture is essential. This involves open communication, employee involvement in safety initiatives, and recognition of safe work practices. A safe warehouse is a productive warehouse. I’ve been instrumental in reducing workplace accidents in several warehouses by implementing these strategies. A focus on safety not only protects employees but also improves efficiency by reducing downtime and lost productivity.

Q 8. What is your experience with implementing and managing KPIs?

Key Performance Indicators (KPIs) are crucial for measuring warehouse efficiency and identifying areas for improvement. My experience encompasses selecting, implementing, and regularly reviewing a range of KPIs, tailored to specific warehouse goals and operational contexts. For instance, in a previous role focused on e-commerce fulfillment, we prioritized KPIs like order fulfillment rate, picking accuracy, and on-time shipping. In a different role managing a distribution center for a manufacturing company, we focused on inventory turnover rate, storage utilization, and damage rate. My approach involves:

- Identifying Relevant KPIs: Starting with a thorough understanding of business objectives and translating them into measurable metrics. This requires close collaboration with stakeholders across departments.

- Data Collection and Analysis: Implementing robust data collection systems – often involving Warehouse Management Systems (WMS) – and utilizing data analytics tools to track KPIs and identify trends.

- Reporting and Communication: Regularly reporting KPI performance to management, highlighting successes and areas needing attention. This includes creating visually appealing dashboards and presentations that clearly communicate complex data.

- Continuous Improvement: Using KPI data to drive process improvements and optimize warehouse operations. This is an iterative process involving identifying root causes of performance gaps, implementing solutions, and measuring the impact.

For example, when we noticed a consistently low inventory turnover rate, we implemented a new inventory management system and adjusted our forecasting methods, resulting in a 15% improvement within six months.

Q 9. How do you handle warehouse staff scheduling and resource allocation?

Efficient staff scheduling and resource allocation are paramount to warehouse productivity. My approach involves a combination of forecasting, optimization software, and hands-on management. I begin by analyzing historical data on order volume, peak seasons, and employee availability to predict staffing needs. This forecasting informs the creation of optimized schedules using scheduling software that considers employee skills, breaks, and labor regulations. Beyond software, I also factor in:

- Cross-training: Equipping staff with multiple skills ensures flexibility and resilience during unexpected absences or surges in demand. This is akin to having a versatile team of players in a sports match, adapting to different roles as needed.

- Real-time adjustments: Regularly monitoring warehouse activity to identify bottlenecks and adjust resource allocation dynamically. This might involve temporarily reassigning staff to support areas experiencing high volumes.

- Employee input: Incorporating employee preferences and feedback into the scheduling process fosters a positive work environment and improves morale, leading to better productivity.

For instance, during peak holiday seasons, we use predictive modeling to anticipate demand fluctuations and proactively adjust our staffing levels, avoiding costly overtime and ensuring smooth order fulfillment.

Q 10. Explain your approach to resolving conflicts among warehouse staff.

Conflict resolution is crucial for maintaining a positive and productive warehouse environment. My approach is based on proactive communication, fair investigation, and a focus on finding mutually acceptable solutions. I believe in addressing conflicts promptly and directly, avoiding escalation. My steps typically include:

- Active Listening: Patiently listening to all parties involved to understand their perspectives and concerns. This is essential to ensure everyone feels heard and valued.

- Neutral Facilitation: Guiding the discussion towards a constructive resolution, ensuring all parties participate fairly and respectfully.

- Identifying the Root Cause: Delving beneath the surface to pinpoint the underlying reasons for the conflict, addressing systemic issues as necessary.

- Mediation and Compromise: Facilitating a discussion that leads to a mutually acceptable solution, emphasizing cooperation and shared goals.

- Documentation: Maintaining records of the conflict and the resolution reached, both for future reference and to protect all parties involved.

In one instance, a conflict arose between two teams due to unclear responsibilities. By facilitating a joint meeting and clearly defining roles and processes, I was able to resolve the conflict and improve inter-team collaboration significantly.

Q 11. Describe your experience with different types of warehouse equipment.

My experience spans a variety of warehouse equipment, from basic hand-held scanners and forklifts to advanced automated guided vehicles (AGVs) and conveyor systems. I’m familiar with the operational aspects of each, including maintenance, safety procedures, and best practices for efficient utilization. This includes:

- Forklifts (various types): Sit-down, stand-up, reach trucks – proficient in safe operation, maintenance schedules, and operator training.

- Conveyors: Roller, belt, and sorters – understanding system design, troubleshooting malfunctions, and maximizing throughput.

- Automated Guided Vehicles (AGVs): Experience with programming, routing, and maintenance of automated systems, understanding the benefits and limitations.

- Warehouse Management Systems (WMS) integration: Familiarity with integrating equipment with WMS for real-time tracking and control.

- Safety procedures and regulations: Adherence to OSHA and other relevant safety regulations, ensuring operator training and equipment maintenance meet safety standards.

For example, in a previous role, we implemented a new AGV system to optimize material handling, resulting in a 20% reduction in transportation time and a significant increase in efficiency.

Q 12. How do you manage warehouse receiving and shipping processes?

Efficient receiving and shipping processes are crucial for maintaining smooth warehouse operations. My approach focuses on streamlining workflows, optimizing space, and utilizing technology to enhance accuracy and speed. This involves:

- Receiving: Implementing a system for verifying incoming shipments against purchase orders, checking for damage, and accurately recording inventory. This often involves using barcode scanners and WMS integration.

- Put-away: Developing efficient put-away strategies based on product characteristics and demand, maximizing storage space and minimizing travel time.

- Shipping: Optimizing order picking and packing processes, utilizing appropriate shipping methods, and generating accurate shipping labels. This includes integrating with shipping carriers for real-time tracking and cost optimization.

- Inventory Management: Maintaining accurate inventory records, performing cycle counts, and addressing discrepancies promptly. This ensures that the warehouse always has the right items available for shipment.

- Dock scheduling: Coordination of inbound and outbound shipments to minimize congestion and maximize dock utilization.

For example, by implementing a new dock scheduling system and optimizing our receiving process, we reduced shipping delays by 10% and improved on-time delivery rates.

Q 13. How do you minimize warehouse damage and loss?

Minimizing warehouse damage and loss requires a multi-faceted approach combining preventative measures, robust tracking systems, and efficient investigation procedures. This includes:

- Proper Storage and Handling: Implementing appropriate storage methods based on product characteristics, utilizing protective packaging, and training staff on safe handling techniques. This is about treating inventory with care, considering factors like weight, fragility, and environmental sensitivity.

- Inventory Control Systems: Using a WMS with robust tracking capabilities to monitor inventory levels, track movements, and identify discrepancies. This involves regular cycle counting and reconciliation to ensure accuracy.

- Damage Reporting and Investigation: Establishing clear procedures for reporting damage, thoroughly investigating incidents to determine root causes, and implementing corrective actions to prevent recurrence. This might involve analyzing common causes, such as poor stacking techniques or equipment malfunctions.

- Security Measures: Implementing security protocols like access control, surveillance systems, and regular security audits to deter theft and vandalism. This is about protecting the entire operation, not just the goods themselves.

- Regular Audits and Inspections: Conducting regular inspections of the warehouse to identify potential hazards and address safety concerns proactively.

For example, by implementing a new damage reporting system and conducting regular safety training, we were able to reduce warehouse damage by 15% in a year.

Q 14. Explain your experience with order fulfillment and order picking strategies.

Order fulfillment and order picking strategies are critical for meeting customer expectations. My experience includes implementing and optimizing various strategies based on warehouse layout, order volume, and product characteristics. This includes:

- Order Picking Strategies: Familiar with various picking methods, including batch picking, zone picking, wave picking, and piece picking. The choice depends on the order profile, warehouse layout, and technological capabilities.

- Technology Integration: Utilizing WMS and other technologies like voice-picking systems and mobile scanners to improve picking accuracy and efficiency. This allows for real-time tracking and optimization.

- Process Optimization: Analyzing order picking processes to identify bottlenecks and implement improvements such as optimizing travel routes, improving picking station layouts, and implementing efficient packing methods. This often requires detailed process mapping and data analysis.

- Inventory Optimization: Strategic placement of fast-moving items to minimize travel time and improve overall efficiency. This also includes considering factors like product size and weight.

- Metrics and Performance Management: Tracking key metrics such as picking accuracy, order fulfillment time, and picking productivity to monitor performance and identify areas for improvement. This data-driven approach allows for continuous refinement of strategies.

In one project, by implementing a zone picking strategy and integrating a voice-picking system, we improved picking efficiency by 30% and reduced picking errors significantly.

Q 15. How do you manage returns and damaged goods in a warehouse?

Managing returns and damaged goods requires a robust system that ensures efficient processing while minimizing losses. It starts with clear guidelines for receiving returns – a designated area, standardized forms for documenting the reason for return (e.g., damaged, defective, wrong item), and clear instructions on inspection procedures.

For damaged goods, we implement a multi-step process:

- Inspection and Classification: Each returned item undergoes a thorough inspection to determine the extent of the damage. This categorization helps in deciding whether the item can be repaired, salvaged for parts, or needs to be disposed of.

- Documentation: Detailed documentation is crucial. We use a system that records the date of return, the reason for return, the condition of the item, and the disposition (repair, salvage, disposal).

- Segregation: Damaged goods are segregated from sellable inventory to prevent accidental shipment. Different areas are designated for repairable, salvageable, and disposal items.

- Repair or Salvage: If economically feasible, we repair damaged items or salvage usable parts. This reduces waste and potentially recovers some value.

- Disposal: Proper disposal of unsalvageable items must follow environmental regulations. We partner with responsible recycling or waste management companies.

- Credit or Refund Processing: The returns process seamlessly integrates with the accounting department to ensure timely credits or refunds to customers.

For example, in a previous role, we implemented a barcode scanning system for returns, which significantly sped up the process and reduced errors in tracking returned items. The system automatically updated inventory records upon successful processing of the return.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure accurate and timely order processing?

Accurate and timely order processing is the backbone of efficient warehouse operations. It requires a well-defined workflow, integrated systems, and a committed team. We achieve this through a combination of:

- Order Management System (OMS): A robust OMS is key. It automates order receiving, prioritization, picking, packing, and shipping. This minimizes manual intervention, reduces errors, and ensures consistent processing.

- Warehouse Management System (WMS): A WMS integrates seamlessly with the OMS and provides real-time visibility into inventory levels, order status, and warehouse activity. Features like directed picking (guiding pickers to the optimal location) significantly improve picking efficiency.

- Process Optimization: We regularly review and optimize processes to identify bottlenecks and inefficiencies. Lean methodologies, such as eliminating unnecessary steps and reducing waiting times, are crucial.

- Real-time Tracking: Tracking orders from placement to delivery provides transparency and helps resolve any delays quickly. Real-time dashboards display key metrics like order fulfillment rates and delivery times.

- Quality Control Checks: Multiple quality control checks are built into the process to ensure accurate picking, packing, and shipping. These range from visual checks to weight verification.

For instance, in a past project, we implemented a pick-to-light system which guided pickers to the correct locations, drastically reducing picking errors by 15% and improving overall order fulfillment time by 10%.

Q 17. What is your experience with using barcode scanners and RFID technology?

Barcode scanners and RFID technology are indispensable tools in modern warehouse management. Both offer significant improvements over manual processes, but they have distinct advantages:

- Barcode Scanners: These are widely used for tracking individual items. They are cost-effective and readily integrated with existing WMS systems. They provide accurate item identification during receiving, putaway, picking, and shipping.

- RFID (Radio-Frequency Identification): RFID tags allow for tracking multiple items simultaneously without line-of-sight. This is especially useful for tracking pallets or larger quantities of goods. RFID offers greater efficiency in inventory management and real-time tracking capabilities, but the initial investment is typically higher.

My experience includes extensive use of both technologies. In one project, we transitioned from a manual inventory system to an RFID-based system, resulting in a 20% reduction in inventory discrepancies and a 10% increase in picking efficiency. The barcode system has been my reliable tool for many years, proving to be an extremely valuable tool in ensuring accurate tracking and minimizing manual errors in operations where RFID was not economically viable.

Q 18. How do you maintain accurate inventory records?

Maintaining accurate inventory records is crucial for efficient warehouse operations and financial reporting. Inaccuracies lead to stockouts, overstocking, and ultimately, lost revenue. We achieve accuracy through:

- Cycle Counting: Regular cycle counting involves counting a small portion of inventory frequently, rather than a full inventory count annually. This helps identify discrepancies early on.

- WMS Integration: Our WMS is the central repository for inventory data. All inventory transactions (receipts, shipments, adjustments) are recorded in the system, providing a real-time view of inventory levels.

- Barcode/RFID Technology: As mentioned earlier, barcode and RFID systems automate data capture, reducing manual entry errors.

- Regular Reconciliation: We periodically reconcile physical inventory counts with the WMS data to identify and correct any discrepancies.

- Inventory Control Procedures: Clear procedures for receiving, putaway, picking, and shipping minimize errors. We also have protocols for handling damaged or obsolete inventory.

For example, in a previous role, we implemented a cycle counting program that reduced inventory discrepancies by 30% within six months. This improved inventory accuracy, leading to better order fulfillment rates and reduced stockouts.

Q 19. Describe your experience with warehouse space optimization strategies.

Warehouse space optimization is critical for maximizing efficiency and minimizing costs. Strategies include:

- Slotting Optimization: Strategic placement of inventory based on factors like frequency of picking, item size, and weight. Fast-moving items are placed in easily accessible locations.

- Vertical Space Utilization: Utilizing vertical space with high-bay racking, mezzanine floors, or other vertical storage solutions.

- Lean Warehouse Layout: Designing a warehouse layout that minimizes travel distances and reduces unnecessary movement of materials and people. This often involves using a U-shaped or other optimized layout.

- Improved Storage Density: Using narrow aisle racking, mobile shelving, or other high-density storage systems to maximize the storage capacity of available space.

- Cross-Docking: Directly transferring goods from incoming shipments to outgoing shipments, eliminating the need for intermediate storage.

In one engagement, we redesigned a warehouse layout using lean principles, resulting in a 15% reduction in travel time for pickers and a 10% increase in order fulfillment capacity without increasing the warehouse footprint.

Q 20. How do you manage relationships with carriers and 3PL providers?

Managing relationships with carriers and 3PL providers is vital for efficient and cost-effective transportation. This involves:

- Strategic Partnerships: Establishing strong relationships with reliable carriers and 3PL providers who understand our business needs and offer competitive rates.

- Negotiation and Contracts: Negotiating favorable rates and service level agreements (SLAs) that define performance expectations.

- Performance Monitoring: Regularly monitoring carrier and 3PL performance against SLAs using key performance indicators (KPIs) such as on-time delivery rates and damage rates.

- Communication and Collaboration: Maintaining open communication channels to address issues quickly and proactively. Regular meetings and feedback sessions are essential.

- Technology Integration: Using technology to streamline communication and data exchange with carriers and 3PLs. This includes electronic data interchange (EDI) and transportation management systems (TMS).

I have experience negotiating contracts with multiple carriers and managing relationships with 3PL providers. In one instance, by consolidating shipments and leveraging volume discounts, we were able to reduce our transportation costs by 12%.

Q 21. What is your experience with Lean manufacturing and Six Sigma methodologies?

Lean manufacturing and Six Sigma methodologies are invaluable for continuous improvement in warehouse operations.

- Lean Manufacturing: Focuses on eliminating waste (muda) in all aspects of operations. This includes reducing inventory, optimizing workflows, and improving efficiency. Lean tools like 5S (sort, set in order, shine, standardize, sustain) and value stream mapping are frequently used.

- Six Sigma: A data-driven methodology aimed at reducing defects and variability in processes. It uses statistical tools to identify and eliminate root causes of errors. Six Sigma techniques, like DMAIC (define, measure, analyze, improve, control) are powerful in improving quality and consistency.

I have practical experience applying both methodologies. In a past project, we used Six Sigma’s DMAIC methodology to reduce order picking errors by 40%. We identified the root cause of errors (lack of clear labeling) and implemented a solution (improved labeling system) that drastically reduced defects. Lean principles helped us optimize warehouse layout and streamline processes to reduce lead times and improve overall efficiency.

Q 22. How do you improve warehouse efficiency and productivity?

Improving warehouse efficiency and productivity involves a multifaceted approach focusing on optimizing processes, technology, and personnel. It’s like conducting an orchestra – each section needs to play in harmony for a beautiful performance.

Process Optimization: This involves streamlining workflows. For example, implementing lean methodologies like 5S (Sort, Set in Order, Shine, Standardize, Sustain) can eliminate waste and improve flow. Analyzing picking routes using software can significantly reduce travel time. Cross-docking, where goods are transferred directly from receiving to shipping without storage, can drastically speed up the process.

Technology Integration: Warehouse Management Systems (WMS) are crucial. A good WMS optimizes inventory management, tracks shipments, and automates tasks like order picking and putaway. Radio Frequency Identification (RFID) technology can provide real-time visibility of inventory location, improving accuracy and speeding up processes.

Personnel Management: Investing in training for staff is vital. Well-trained employees are more efficient and make fewer errors. Empowering employees to identify and suggest improvements through Kaizen events (continuous improvement initiatives) fosters a culture of efficiency. Clear communication and performance metrics further contribute to enhanced productivity.

Layout Optimization: The physical layout of the warehouse significantly impacts efficiency. Strategically placing high-demand items closer to shipping docks and utilizing vertical space maximizes throughput. This is like strategically placing ingredients in a kitchen to minimize movement during meal preparation.

Q 23. How do you address challenges related to warehouse automation?

Challenges in warehouse automation are often related to implementation, integration, and return on investment. It’s not simply a matter of buying robots; it requires careful planning and execution.

High Initial Investment: Automated systems, such as automated guided vehicles (AGVs) or automated storage and retrieval systems (AS/RS), are expensive. A thorough cost-benefit analysis is essential to justify the investment and ensure a reasonable return.

Integration Complexity: Integrating new automated systems with existing infrastructure and software can be challenging and require specialized expertise. This might involve custom software development or extensive system modifications.

Maintenance and Downtime: Automated systems require regular maintenance, and any downtime can significantly impact warehouse operations. Planning for maintenance and having backup systems is crucial.

Reskilling of Workforce: Automation may require retraining existing employees to operate and maintain the new systems. A well-structured training program is crucial for a smooth transition.

Scalability and Flexibility: The chosen automation solution should be scalable to accommodate future growth and flexible enough to adapt to changing business needs. Investing in a rigid system can become a bottleneck.

Q 24. Explain your experience with different types of warehouse storage systems.

My experience encompasses various storage systems, each suited to different needs and product types. Choosing the right system is like selecting the right tool for a job – a hammer is unsuitable for screwing in a screw.

Racking Systems: These include selective pallet racking (most common), drive-in/drive-through racking (high-density storage), cantilever racking (for long or bulky items), and push-back racking (FIFO or LIFO storage).

Shelving Systems: These are suitable for smaller items and offer easy access. Different types exist, including light-duty, medium-duty, and heavy-duty shelving, depending on weight capacity.

Bulk Storage: This is used for large quantities of homogenous items and typically involves floor stacking or bulk bins. This is often less efficient in terms of access but can be cost-effective for low-value, high-volume items.

AS/RS (Automated Storage and Retrieval Systems): These systems utilize automated cranes or robots to move pallets or individual items in and out of high-bay storage. They are highly efficient but require a substantial initial investment.

In my previous role, I successfully implemented a drive-in racking system which increased storage capacity by 30% in a space-constrained warehouse, optimizing the existing footprint.

Q 25. How do you manage and mitigate warehouse security risks?

Warehouse security is paramount, protecting assets and ensuring compliance. A multi-layered approach is necessary, like a castle with multiple defenses.

Access Control: Implementing a robust access control system with keycard or biometric entry limits access to authorized personnel only. Regular audits of access logs are crucial.

Surveillance Systems: CCTV cameras, strategically positioned throughout the warehouse, provide visual monitoring and act as a deterrent. Integration with alarm systems enhances security.

Inventory Control: Accurate inventory tracking minimizes the risk of theft or loss. Regular stock checks and reconciliation help identify discrepancies promptly.

Employee Training: Educating employees on security procedures and protocols is essential. This includes reporting suspicious activities and following proper handling procedures for sensitive items.

Physical Security: Securing entrances, exits, and loading docks with appropriate measures like fences, gates, and security lighting enhances physical protection.

Cybersecurity: Protecting the WMS and other warehouse systems from cyber threats is crucial. This includes regular software updates, strong passwords, and firewalls.

Q 26. What are your strengths and weaknesses in Warehouse Operations Management?

My strengths lie in my analytical abilities, problem-solving skills, and my ability to effectively manage teams. I excel at identifying process bottlenecks, implementing improvements, and fostering a collaborative work environment. I am also adept at leveraging technology to enhance warehouse efficiency.

One area for development is my experience with specific emerging technologies, such as AI-powered robotics. While I understand the concepts, hands-on experience would further enhance my capabilities in this rapidly evolving field. I am actively seeking opportunities to expand my knowledge in this area through professional development courses and industry networking.

Q 27. Describe a time you had to solve a complex logistical problem.

In a previous role, we experienced a major supplier delay impacting a critical product launch. This threatened to disrupt our production schedule and damage our reputation. The challenge was to find an alternative supply source quickly without compromising quality.

My approach involved several steps: first, I assessed the impact of the delay, quantifying the potential losses. Second, I mobilized a team to research alternative suppliers, considering factors like lead times, pricing, and quality certifications. Third, we conducted due diligence on potential suppliers, evaluating their capabilities and reliability. Fourth, we negotiated contracts and expedited shipping to minimize disruptions. We successfully secured an alternative supplier within a week, preventing significant production delays and reputational damage.

This experience highlighted the importance of proactive risk management, having contingency plans, and building strong relationships with suppliers. It also showcased my ability to lead a team under pressure and find creative solutions to complex logistical challenges.

Q 28. How do you stay up-to-date with best practices in warehouse management?

Staying current with best practices is crucial in this dynamic field. I utilize a combination of methods to keep my knowledge sharp.

Industry Publications and Journals: I regularly read publications like Modern Materials Handling and other relevant industry journals to stay abreast of new technologies and best practices.

Professional Organizations: Membership in professional organizations like the Material Handling Industry of America (MHIA) provides access to webinars, conferences, and networking opportunities.

Online Courses and Webinars: Platforms like Coursera and edX offer valuable courses on warehouse management, supply chain optimization, and related topics.

Industry Conferences and Trade Shows: Attending industry events allows me to learn about new technologies and network with other professionals.

Networking: Maintaining connections with colleagues and industry experts through professional networks like LinkedIn provides invaluable insights and knowledge sharing.

Key Topics to Learn for Warehouse and Operations Management Interview

- Inventory Management: Understanding inventory control techniques like FIFO, LIFO, and JIT. Practical application includes optimizing stock levels to minimize storage costs and prevent stockouts.

- Warehouse Layout and Design: Analyzing the efficiency of warehouse layouts and the impact of slotting optimization. Practical application involves improving workflow and minimizing travel time for picking and packing.

- Supply Chain Management: Understanding the flow of goods from origin to consumer, including procurement, logistics, and distribution. Practical application includes identifying bottlenecks and improving overall supply chain efficiency.

- Warehouse Safety and Security: Implementing safety protocols and security measures to protect personnel and assets. Practical application includes risk assessment and implementing preventative measures.

- Warehouse Technology and Automation: Familiarity with WMS (Warehouse Management Systems), RFID, and automated guided vehicles (AGVs). Practical application includes evaluating the ROI of implementing new technologies.

- Performance Measurement and KPIs: Understanding key performance indicators (KPIs) like order fulfillment rate, inventory turnover, and warehouse operating costs. Practical application includes using data to identify areas for improvement.

- Team Management and Leadership: Effective communication, motivation, and delegation within a warehouse environment. Practical application includes conflict resolution and fostering a positive team dynamic.

- Process Improvement Methodologies: Knowledge of Lean principles, Six Sigma, and Kaizen for continuous improvement. Practical application includes identifying and eliminating waste in warehouse operations.

- Budgeting and Cost Control: Understanding warehouse operating budgets and developing strategies for cost reduction. Practical application includes forecasting and managing expenses effectively.

- Logistics and Transportation: Understanding different transportation modes and their impact on delivery times and costs. Practical application includes route optimization and carrier selection.

Next Steps

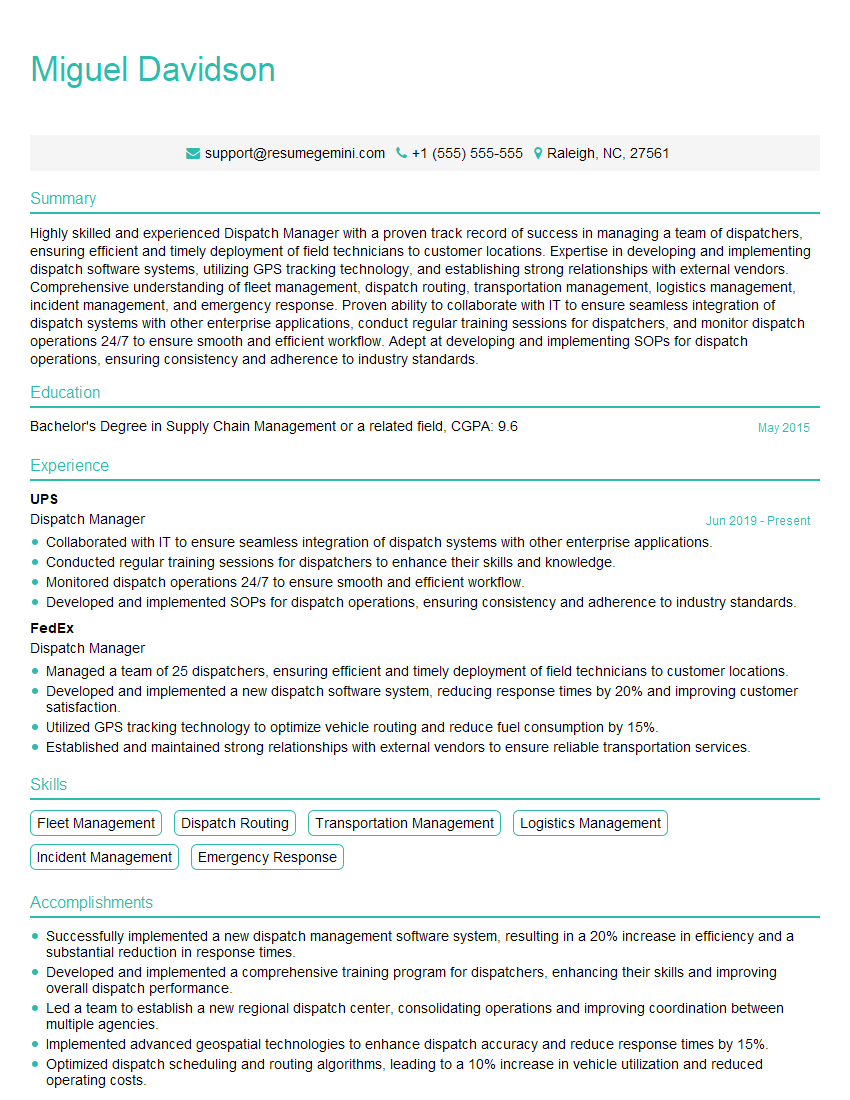

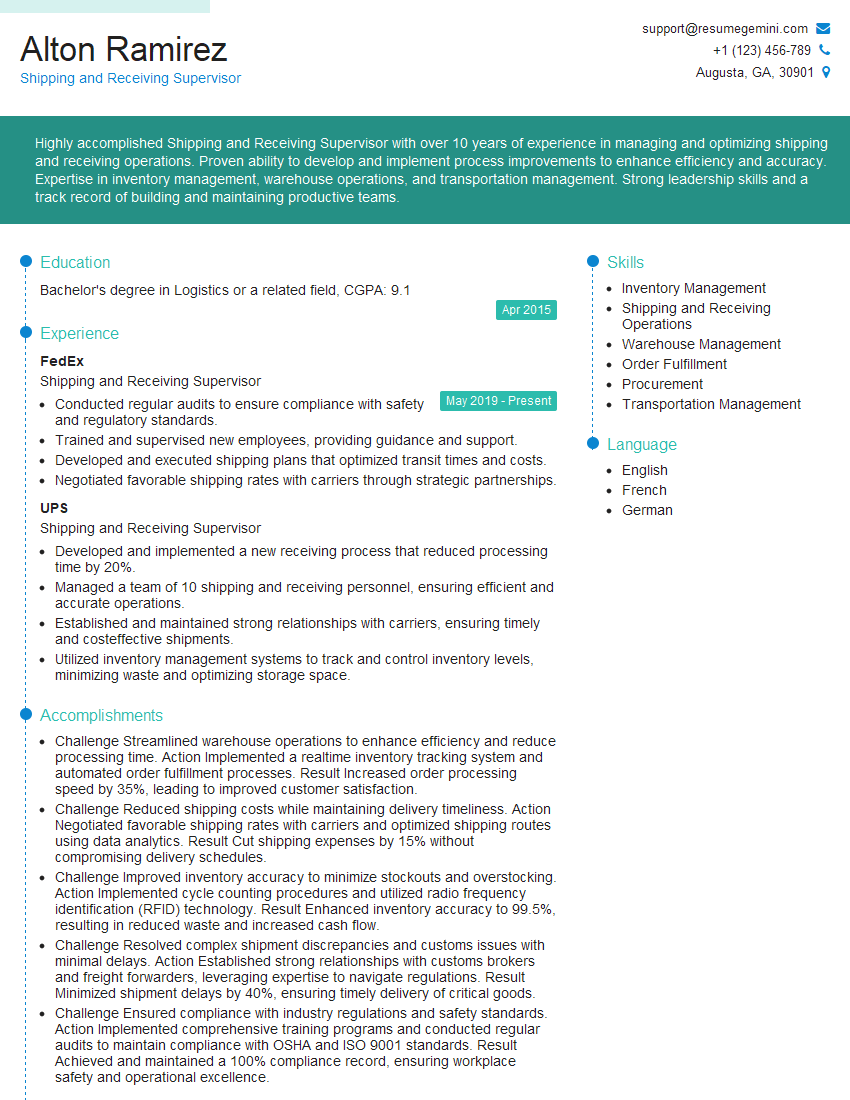

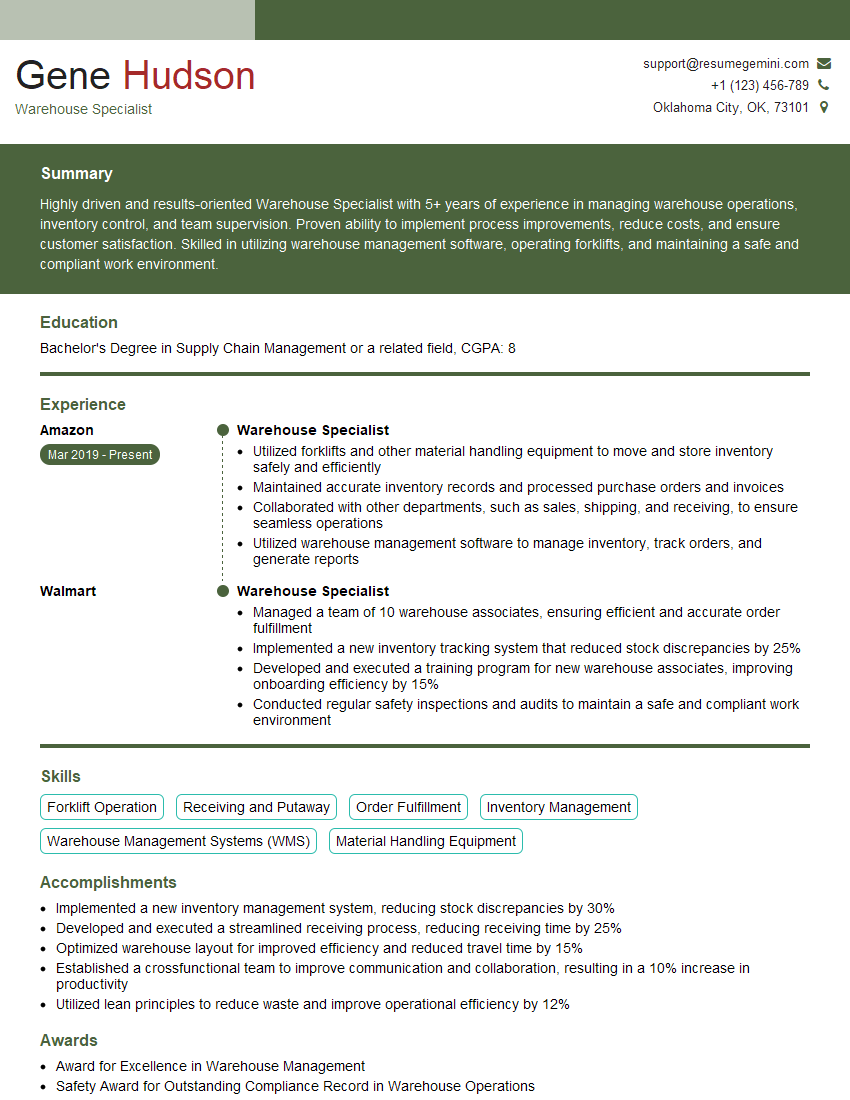

Mastering Warehouse and Operations Management opens doors to exciting career opportunities with significant growth potential. To maximize your chances of landing your dream role, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume designed to get noticed. We provide examples of resumes tailored specifically to Warehouse and Operations Management to help you get started. Invest in your future – invest in a compelling resume.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good