Are you ready to stand out in your next interview? Understanding and preparing for Precision Machine Setup interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Precision Machine Setup Interview

Q 1. Explain the process of setting up a CNC milling machine for a specific job.

Setting up a CNC milling machine involves a meticulous process to ensure accuracy and efficiency. Think of it like preparing a complex recipe – each step is crucial for the final outcome. It begins with interpreting the engineering drawing to understand the part’s geometry and tolerances. Next, we select the appropriate cutting tools based on material properties and desired surface finish. Then, we program the CNC machine using CAM software (Computer-Aided Manufacturing), translating the design into a set of instructions for the machine. This involves defining toolpaths, feed rates, and spindle speeds. The workpiece is then securely clamped onto the machine’s worktable, ensuring proper alignment and stability. Before starting the machining process, we perform a tool length offset (TLO) measurement to accurately position the cutting tools relative to the workpiece. This is crucial for achieving the desired dimensions. Finally, a test cut is often performed to verify the program and machine setup before commencing the full production run. Any necessary adjustments are made at this stage. For example, if I’m milling a complex aluminum part, I might begin with a roughing pass to remove most of the material, followed by a finishing pass with a smaller cutter for a precise surface finish. Each pass requires careful adjustment of cutting parameters like feed rate and depth of cut.

Q 2. Describe your experience with different types of precision measuring tools.

My experience encompasses a wide range of precision measuring tools, each with its own strengths and limitations. I’m proficient with dial indicators for checking runout and parallelism, micrometers for precise linear measurements, and calipers for quick measurements of external and internal dimensions. I also regularly use coordinate measuring machines (CMMs) for detailed three-dimensional measurements, crucial for complex parts. In addition, I use optical comparators for precise inspection of intricate shapes. Choosing the right tool is critical; for example, when checking the flatness of a surface plate, a dial indicator is more suitable than a micrometer. The use of CMMs allows for verifying the overall accuracy of a part after milling, ensuring tolerances are maintained throughout.

Q 3. How do you ensure the accuracy of machine setup and alignment?

Ensuring accuracy starts with meticulous machine alignment and calibration. We use precision levels and squares to check the machine’s perpendicularity and parallelism. Regular maintenance, including lubrication and cleaning, is vital. Tool length compensation is verified using a precision probe. I frequently use a test workpiece, machining a simple feature to check dimensional accuracy and compare it to the blueprint specifications. Any discrepancies indicate a problem with the setup. During setup, we systematically check all axes for squareness and proper zeroing. We also monitor and adjust the machine’s thermal stability because even minor temperature fluctuations can affect accuracy. For instance, I once encountered a slight misalignment in a CNC lathe resulting in inconsistent diameters. By systematically checking the alignment using dial indicators and making minute adjustments, I resolved the issue.

Q 4. What are the common causes of machine inaccuracies, and how do you troubleshoot them?

Inaccuracies can stem from various sources. Tool wear is a major culprit, leading to dimensional inaccuracies and poor surface finish. Improper tool clamping can cause vibration and chatter, affecting precision. Machine wear, such as worn bearings or guides, can also lead to inaccuracies. Incorrect programming is a common human error resulting in unexpected results. Environmental factors like temperature fluctuations or vibrations can also impact accuracy. Troubleshooting involves a systematic approach; we start by checking the obvious – tool condition, clamping, and program verification. Then we investigate machine elements, like checking bearings for play, measuring lead screws, and verifying axis alignment. Environmental factors are investigated by analyzing the shop environment for unusual vibrations or temperature gradients. For example, I once diagnosed chatter during machining as originating from a slightly loose chuck – a simple fix resulted in a significant improvement in accuracy.

Q 5. How do you interpret engineering drawings and blueprints for machine setup?

Interpreting engineering drawings is paramount. We need to understand all dimensions, tolerances, surface finishes, and material specifications. This includes identifying critical features, datum points (reference points), and any specific requirements. We also need to understand the manufacturing processes specified to choose the right machine setup and tools. For instance, a drawing might specify a surface finish of Ra 0.8 µm, requiring a specific cutter and cutting strategy. Another common challenge is dealing with ambiguous or incomplete drawings, where clarifications from the design engineer are needed. We have to be completely sure about the tolerances and specifications before we proceed to avoid mistakes. Drawings are the roadmap for the entire process.

Q 6. Describe your experience with different types of cutting tools and their applications.

My experience spans various cutting tools, including end mills (for milling slots and pockets), drills (for creating holes), reamers (for enlarging and finishing holes), and face mills (for planar surfaces). Each has specific applications depending on material, geometry, and surface finish. For example, high-speed steel (HSS) tools are suitable for most materials, while carbide tools are preferred for harder materials and higher cutting speeds. I also have experience with specialized tools like ball-nose end mills for complex 3D shapes and form tools for generating precise curves. Choosing the right tool is crucial for efficiency and accuracy; using a wrong tool type could lead to broken tools, poor surface quality, or outright failure. I often use cutting tool catalogs that list the tool’s specifications for material suitability. For example, milling titanium alloy requires the use of sharp, wear-resistant carbide tools and appropriate cutting fluids.

Q 7. How do you select the appropriate cutting parameters (speed, feed, depth of cut)?

Selecting appropriate cutting parameters is a balancing act between productivity and tool life. Spindle speed (RPM) determines the cutting speed, while feed rate (in/min or mm/min) dictates the material removal rate. Depth of cut defines how much material is removed with each pass. These parameters are interrelated and influenced by several factors: material hardness, tool geometry, and desired surface finish. Higher speeds generally lead to faster machining but may also reduce tool life. If the parameters are not properly chosen, it can lead to broken tools, bad surface finish or poor part quality. There are many commercially available resources for determining optimal parameters based on these factors. Often, I start with recommended values from the tool manufacturer and then fine-tune them based on trial cuts and feedback from the machine. Experience is key here as each material and cutter combination require an optimized cutting parameter configuration.

Q 8. How do you perform a tool change on a CNC machine?

A CNC machine tool change is a critical process demanding precision and safety. It involves removing a worn or unsuitable tool from the spindle and replacing it with a new one, ensuring proper alignment and clamping.

- Machine Power Down: First, always power down the CNC machine and ensure the spindle is completely stopped.

- Tool Removal: Carefully unlock the tool holder, typically using a lever or pneumatic mechanism. Then, gently remove the tool, noting its position in the magazine for accurate replacement.

- Tool Selection and Installation: Select the appropriate tool from the magazine based on the CNC program. Insert the new tool into the holder, ensuring it’s fully seated and securely clamped. Some machines will have a visual indicator or sensor to confirm correct installation.

- Tool Length Offset Setting (if necessary): Often, a tool length offset needs to be set using a tool setting probe. This ensures that the cutting edge is accurately positioned relative to the workpiece. Failure to set this correctly can result in inaccurate cuts.

- Machine Power Up and Verification: Power the CNC machine back on. Verify the tool change through a manual tool change function within the control interface. The machine will typically allow you to rotate the spindle and visually inspect the tool to confirm its secure placement.

For example, on a Haas machine, the tool change process involves utilizing the M6 T# command in the G-code program, where ‘#’ represents the tool number. Incorrectly sequenced tool changes can cause crashes or inaccurate machining.

Q 9. Explain the importance of proper workholding in precision machining.

Proper workholding is paramount in precision machining as it directly impacts the accuracy, surface finish, and overall quality of the finished part. Without secure and stable workholding, the workpiece can shift during machining, resulting in dimensional inaccuracies, poor surface quality, and potentially damaging the cutting tool or the machine itself.

- Rigidity: The workholding system must be rigid enough to resist the cutting forces generated during machining. Vibration or deflection will cause inaccuracies.

- Accuracy: The workpiece must be accurately positioned and held to maintain dimensional tolerances. Misalignment leads to inconsistent results.

- Accessibility: The workholding system should allow easy access for the cutting tools to reach all required areas of the workpiece.

- Safety: A secure workholding system protects the operator from potential hazards during machining.

Imagine trying to carve a delicate piece of wood without a vise. The wood would move, the carving would be uneven, and potentially dangerous. Similarly, a poorly designed fixture in precision machining will lead to a substandard product and potentially a machine accident.

Different workholding methods exist such as vises, chucks, fixtures, vacuum chucks, and magnetic chucks—each suited to different workpiece materials and geometries. The selection depends on factors like material, size, shape, and required accuracy.

Q 10. How do you ensure the safety of yourself and others during machine setup and operation?

Safety is the absolute top priority in machine setup and operation. A proactive safety mindset and adherence to strict protocols are essential.

- Lockout/Tagout Procedures: Always follow lockout/tagout procedures before working on or near any machine, preventing accidental power-ups.

- Personal Protective Equipment (PPE): Consistent use of PPE, including safety glasses, hearing protection, and appropriate clothing, is mandatory.

- Machine Guarding: Ensure all machine guards are in place and functioning correctly. This protects against flying debris and accidental contact with moving parts.

- Regular Inspections: Regularly inspect the machine for any signs of damage or malfunction before starting operation.

- Emergency Stop Procedures: Thorough understanding of emergency stop procedures and knowing the location of the emergency stop button is critical.

- Training and Certification: Operators should receive adequate training and certification before operating any CNC machine.

For instance, before performing any work on a CNC mill, I always lock out and tag out the power supply. Then, I conduct a visual inspection of the machine, tools and workpiece before initiating the process.

Q 11. Describe your experience with different CNC control systems.

My experience encompasses a range of CNC control systems, including Fanuc, Siemens, Heidenhain, and Haas. Each system has its own unique programming language and user interface, but the fundamental principles of CNC machining remain consistent.

- Fanuc: I’m proficient in using Fanuc’s conversational programming and its macro capabilities for complex part programming. I’m familiar with troubleshooting and diagnostics using its alarm codes.

- Siemens: Siemens 840D systems are known for their robust features. I have experience programming and operating machines with this system, especially its advanced functions for multi-axis machining.

- Heidenhain: Heidenhain’s control systems are frequently found in high-precision applications. I am knowledgeable in its user-friendly interface and precision measurement capabilities.

- Haas: I’m well-versed in the intuitive design of Haas controls. I use their conversational programming features frequently and am familiar with their troubleshooting methods.

My experience across these platforms allows me to adapt quickly to new systems and efficiently program and operate machines with varied control systems. I frequently utilize the specific manuals for each machine and control system to ensure accurate and safe operation.

Q 12. How do you handle unexpected problems during machine setup?

Handling unexpected problems during machine setup requires a systematic and analytical approach. Panicking only exacerbates the situation.

- Identify the Problem: First, carefully identify the nature of the problem. Is it a tooling issue, a programming error, a machine malfunction, or something else?

- Check the Obvious: Start with simple checks such as verifying power connections, tool clamping, and the workpiece’s securement.

- Review the Program: If a programming error is suspected, examine the G-code for mistakes like incorrect coordinates, tool selection, or feed rates.

- Diagnostics: Utilize the machine’s diagnostic tools and error messages to pinpoint the source of the problem. Many controls provide detailed logs that can help in troubleshooting.

- Seek Assistance: If the problem is beyond my capabilities, I don’t hesitate to seek help from more experienced colleagues or the machine’s manufacturer.

- Documentation: After resolving the issue, I meticulously document the problem, the troubleshooting steps, and the solution to avoid repeating the same mistake in the future.

For example, if I encounter a tool breakage, I would first ensure the machine is safely shut down. Then, I would check for tool path issues in the program, replace the broken tool, reset the machine, and carefully re-check my work. Detailed documentation of the incident would help prevent similar failures in future jobs.

Q 13. What is your experience with G-code programming and interpretation?

G-code programming and interpretation are fundamental aspects of my expertise. G-code is the language CNC machines understand, dictating the machine’s movements and operations. Proficiency in both programming and interpreting is crucial for accurate and efficient machining.

- Programming: I can write G-code programs for various machining operations, including milling, turning, and drilling, using both manual and CAM (Computer-Aided Manufacturing) software. I understand the various G and M codes and their functions.

- Interpretation: I am capable of interpreting existing G-code programs to understand the intended machining processes, identify potential errors, and make necessary modifications.

- CAM Software: I have experience with various CAM software packages, such as Mastercam and Fusion 360, which allow me to generate optimized G-code from 3D CAD models.

- Troubleshooting: My ability extends to identifying and resolving errors within the G-code, ensuring smooth and accurate machine operation.

For instance, understanding the difference between a G00 (rapid traverse) and a G01 (linear interpolation) command is crucial for ensuring that the machine moves at the appropriate speed during different phases of machining. Similarly, the correct application of M codes (miscellaneous functions) is critical in achieving specific operations like tool changes and coolant control.

G01 X10.0 Y20.0 F100 ;Example of linear interpolation

Q 14. Explain your process for verifying machine setup accuracy.

Verifying machine setup accuracy is a multi-step process that ensures the final product meets the required specifications. This involves a combination of pre-machining checks and post-machining verification.

- Pre-Machining Checks: Before starting a machining operation, I verify the following: Correct workpiece clamping, tool length offset settings, the program’s accuracy by simulating the run on the control interface, machine coordinate system alignment, and checking the machine’s zero points.

- Test Cuts: I often perform test cuts on scrap material to confirm that the toolpaths are correct and the machine is functioning as expected. These test cuts allow me to make adjustments before machining the actual workpiece.

- Post-Machining Verification: After machining, I meticulously inspect the workpiece using precision measuring instruments like calipers, micrometers, and coordinate measuring machines (CMMs) to ensure it meets the specified dimensions and tolerances. This involves checking critical features and comparing them to the design specifications.

- Statistical Process Control (SPC): For high-volume production, SPC charts help track and monitor the consistency and accuracy of the machining process, identifying any potential drift or deviations from expected values.

For example, before machining a precise part, I conduct a test cut on a similar material and check the dimensions using a CMM. This confirms the accuracy of the toolpaths and tooling before committing to the final part. Any discrepancies are addressed before proceeding with the main machining process.

Q 15. Describe your experience with different types of materials used in precision machining.

My experience encompasses a wide range of materials commonly used in precision machining. Understanding a material’s properties – machinability, hardness, thermal conductivity, etc. – is crucial for optimal setup and results. For instance, I’ve worked extensively with various steels, including stainless steels (known for their corrosion resistance but challenging to machine), tool steels (exceptionally hard and durable, requiring specialized tooling), and aluminum alloys (lightweight and readily machinable but prone to work hardening). I’m also proficient in machining titanium alloys (high strength-to-weight ratio but difficult to cut due to its tendency to gall), and plastics like polymers (requiring different cutting parameters to avoid melting or tearing). Each material necessitates a tailored approach, including selecting the appropriate cutting tools, speeds, feeds, and coolants to achieve the desired precision and surface finish.

For example, when machining stainless steel, I’d use a high-speed steel (HSS) or carbide tool with a sharp cutting edge and ample coolant to manage heat generation and prevent tool wear. Conversely, for plastics, I’d employ lower speeds and feeds to minimize heat build-up and avoid material deformation. My experience allows me to quickly assess the material and select the optimal machining strategy to ensure accuracy and efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform regular maintenance on precision machinery?

Regular maintenance is paramount for ensuring the accuracy and longevity of precision machinery. My maintenance routine is both preventative and reactive, encompassing daily, weekly, and monthly checks. Daily checks typically include verifying coolant levels, inspecting for loose components, and cleaning debris from the machine bed and tooling. Weekly maintenance involves more thorough cleaning, lubricating moving parts according to the manufacturer’s specifications, and checking for any signs of wear on critical components like spindle bearings and ways. Monthly maintenance might include more involved tasks such as checking and adjusting the machine’s alignment, performing a thorough inspection of electrical connections, and verifying the accuracy of the machine’s measuring systems using precision gauges. I meticulously document all maintenance activities, ensuring compliance with safety regulations and the machine’s operating manual. Proactive maintenance prevents unexpected downtime and prolongs the machine’s lifespan.

Imagine it like maintaining a high-performance car: regular oil changes, tire rotations, and fluid checks keep it running smoothly and prevent costly repairs down the line. Similarly, a consistent maintenance schedule for precision machinery prevents costly repairs and ensures consistent, high-quality output.

Q 17. Explain your experience with machine diagnostics and troubleshooting.

Machine diagnostics and troubleshooting are integral parts of my skill set. I approach problem-solving systematically, starting with a thorough assessment of the issue. This often involves reviewing error messages displayed on the machine’s control panel, listening to the machine’s operational sounds to identify unusual noises, visually inspecting the components for signs of damage or wear, and checking the tooling for any defects. I’m proficient in using various diagnostic tools, including vibration analyzers, temperature sensors, and precision measuring instruments, to pinpoint the root cause of the problem. My experience spans various types of issues, from minor adjustments like tool offsets to more complex problems such as hydraulic system leaks or control system malfunctions.

For example, I once encountered a situation where a CNC lathe produced parts with inconsistent dimensions. Through systematic diagnostics, I discovered a slight misalignment in the machine’s turret. After precise adjustment using a laser alignment system, the problem was resolved, demonstrating my ability to troubleshoot complex machine issues efficiently.

Q 18. Describe a time you had to adjust your setup due to unexpected issues.

During a high-precision milling operation on a particularly challenging aerospace component, we encountered a significant problem. The material, a high-strength titanium alloy, exhibited unexpected work hardening, leading to tool breakage and inconsistent surface finishes. Initially, our setup was optimized for standard machining parameters, but the work hardening demanded a change in strategy. Instead of persisting with the initial approach, I immediately halted the operation. I then collaborated with the engineering team to analyze the problem. We decided to implement cryogenic treatment of the titanium before machining to reduce its hardness and improve its machinability. We also adjusted cutting parameters such as feed rate and depth of cut to mitigate the work hardening effect. This revised approach involved recalibrating the machine’s settings and choosing suitable cutting tools that were better suited to the changed material properties. We successfully completed the project, delivering the required precision within the designated timeframe. This experience highlighted the importance of adaptability and collaboration in overcoming unexpected challenges in precision machining.

Q 19. What are some common errors in precision machine setup, and how to avoid them?

Common errors in precision machine setup often stem from inadequate preparation or overlooking crucial details. These can include improper tool selection, incorrect tool clamping, insufficient workholding, inaccurate workpiece alignment, and neglecting to account for thermal expansion.

- Improper Tool Selection: Using a dull or incorrect tool can lead to poor surface finish, dimensional inaccuracies, and tool breakage. Always select a tool appropriate for the material and operation.

- Incorrect Tool Clamping: Loose or improperly clamped tools can cause vibrations, leading to inaccurate machining. Ensure that tools are firmly clamped and properly aligned.

- Insufficient Workholding: Inadequate workholding can lead to workpiece movement during machining, causing dimensional errors and potentially damaging the workpiece or machine. Use robust fixtures and appropriate clamping forces.

- Inaccurate Workpiece Alignment: Misaligned workpieces will result in parts that do not meet specifications. Carefully align workpieces using precision measuring instruments before starting the machining operation.

- Neglecting Thermal Expansion: Changes in temperature can affect the dimensions of both the workpiece and the machine. Account for thermal expansion to maintain accuracy, especially during long machining cycles.

Avoiding these errors requires meticulous planning and execution. This includes a thorough review of the machining process, careful selection of tools and fixtures, precise alignment of workpieces, and regular monitoring of the machining process to detect and correct any deviations from the plan.

Q 20. How do you manage your time effectively during machine setup?

Effective time management during machine setup is crucial for maximizing productivity. I employ a structured approach, beginning with a thorough review of the engineering drawings and machining instructions. This helps me identify potential challenges and plan the setup accordingly. I then systematically gather and prepare all necessary tools, fixtures, and materials. This includes pre-setting cutting tools to the correct dimensions and checking their condition. I prioritize tasks based on their criticality and sequence, focusing on those that require the most time or attention first. I also utilize machine simulation software where appropriate to optimize tool paths and reduce setup time. Finally, I conduct thorough checks at each stage to ensure accuracy and prevent errors. This systematic approach not only reduces setup time but also minimizes the likelihood of errors and rework.

Think of it like building with LEGOs. You wouldn’t just start throwing pieces together; you’d carefully examine the instructions, gather the necessary bricks, and follow a structured sequence to construct the model efficiently and accurately. Similarly, a well-structured approach to precision machine setup optimizes both time and quality.

Q 21. What is your experience with different types of fixturing and workholding?

My experience with fixturing and workholding is extensive, encompassing various types of fixtures designed for different applications and workpiece geometries. I’m familiar with common fixtures such as vises, chucks (3-jaw, 4-jaw, and power chucks), magnetic fixtures, and specialized workholding devices like hydraulic or pneumatic clamps. Selection of the appropriate fixture depends on factors like workpiece material, size, shape, and the machining operation being performed. For example, a 3-jaw chuck is suitable for cylindrical workpieces, while a 4-jaw chuck offers greater flexibility for irregularly shaped parts. I’m also experienced in designing and fabricating custom fixtures when commercially available options are inadequate. This requires an understanding of material properties, clamping forces, and structural integrity to ensure safe and accurate workpiece holding during machining. Proper workholding is essential for maintaining dimensional accuracy and preventing workpiece damage.

Consider it like holding a delicate piece of artwork: you need the right kind of support to keep it stable and prevent damage. Similarly, selecting the correct fixture for the workpiece ensures stability and prevents inaccuracies during machining.

Q 22. How do you ensure the quality of machined parts?

Ensuring the quality of machined parts is paramount in precision machining. It’s a multifaceted process that begins even before the machine is powered on. It involves meticulous planning, precise execution, and rigorous inspection.

- Proper Tooling and Setup: Selecting the right cutting tools for the material and ensuring they are properly sharpened and securely mounted is crucial. A poorly set tool will lead to inaccurate cuts and surface finish problems. For example, using a dull end mill on aluminum will result in a rough surface finish and potentially broken tools.

- Precise Measurement: Consistent and accurate measurements throughout the process are vital. This includes using calibrated measuring tools like micrometers and calipers, and regularly checking the machine’s accuracy through periodic calibrations. Imagine building a house without precise measurements – the structure would be unstable and likely collapse!

- Process Monitoring and Control: Constantly monitoring the machining process is key. This includes checking the machine’s parameters (speed, feed rate, depth of cut) and visually inspecting the workpiece for any irregularities. For instance, observing the chip formation can indicate whether the cutting parameters are optimal.

- Post-Machining Inspection: A thorough inspection after the machining process is critical. This involves using various measuring instruments like CMMs (Coordinate Measuring Machines) to check for dimensional accuracy and surface finish. Any deviations from the specifications need to be carefully analyzed to identify root causes and corrective actions.

A combination of these techniques, along with a well-maintained machine and a skilled operator, are essential to consistently produce high-quality machined parts.

Q 23. Describe your experience with using CAD/CAM software in relation to machine setup.

CAD/CAM software is indispensable in modern precision machining. My experience involves using software like Mastercam and Fusion 360 extensively. These tools allow us to create detailed 3D models of parts, generate toolpaths for CNC machines, and simulate the machining process before actually running it on the machine.

In my previous role, I used Mastercam to program complex parts with multiple features, requiring intricate toolpaths and precise control over cutting parameters. The software’s simulation capabilities allowed me to identify and resolve potential collisions or machining errors before they occurred on the actual machine, saving valuable time and material.

For example, when machining a delicate impeller with thin blades, the simulation feature in Fusion 360 helped me optimize the cutting strategy to avoid vibration and tool chatter, resulting in a smoother, more accurate part. This is crucial for ensuring the part meets the required specifications and tolerances.

The ability to seamlessly transfer the toolpaths from CAD/CAM software directly to the CNC machine minimizes errors and speeds up the setup process considerably, streamlining the overall workflow and improving efficiency.

Q 24. What is your experience with automated machine loading and unloading?

My experience with automated machine loading and unloading is extensive. I’ve worked with various systems, from simple robotic arms to more complex automated cell setups. These systems significantly improve efficiency and reduce human error in repetitive tasks.

In one project, I integrated a robotic arm with a CNC lathe. The robot would automatically load and unload parts from a conveyor system, significantly increasing production output and reducing the time the machine was idle. We also incorporated a vision system to inspect the parts before and after machining, ensuring only acceptable parts were processed.

The benefits of automated loading and unloading extend beyond increased production. It enhances workplace safety by minimizing operator interaction with the machine during operation, and it ensures consistent part handling, leading to higher quality parts. The implementation required careful planning to ensure the robot’s reach and movements were compatible with the machine and the part handling system. This involved close coordination with robotics specialists and the programming of the robot’s control system.

Q 25. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a crucial tool for monitoring and improving the consistency and quality of a machining process. It involves collecting and analyzing data from the machining process to identify trends and variations. This allows for early detection of potential problems before they lead to significant defects.

I’ve used SPC techniques like control charts (X-bar and R charts, for example) to monitor critical dimensions of machined parts. By plotting the data on control charts, we can identify whether the process is in control (stable and predictable) or out of control (exhibiting unexpected variations). Any points falling outside the control limits require immediate investigation to identify and rectify the root cause.

For instance, while machining a batch of shafts, if I observe an increasing trend in diameter on a control chart, I’d investigate factors such as tool wear, machine settings, or material inconsistencies to bring the process back into control. SPC ensures not just individual part quality but a consistent, high-quality outcome for the entire batch.

Q 26. How do you maintain clean and organized work area during machine setup?

Maintaining a clean and organized work area during machine setup is not just about aesthetics; it’s essential for safety and efficiency. A cluttered workspace increases the risk of accidents, delays, and errors. My approach is based on a few key principles:

- 5S Methodology: I apply the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize my workspace. This involves sorting out unnecessary items, arranging tools and materials in a logical order, regularly cleaning the area, standardizing the arrangement, and maintaining the cleanliness consistently.

- Designated Storage: Tools, materials, and work-in-progress are stored in designated locations using standardized containers and labels. This helps prevent clutter and makes it easy to find what is needed.

- Regular Cleaning: I regularly clean the machine and surrounding area, removing chips, oil, and debris. This prevents potential hazards like slip-and-falls and keeps the machine in optimal working condition. A clean machine is a more accurate machine.

- Preventative Maintenance: Regularly checking and maintaining the machine and its components are crucial for minimizing downtime. Following the manufacturer’s maintenance schedules is standard procedure.

A well-organized workspace contributes to a smoother workflow, reducing setup time and improving overall efficiency. It also significantly minimizes the chance of errors and potential safety incidents. Think of a surgeon’s operating room – meticulous organization is crucial for success, and precision machining is no different.

Q 27. Describe your understanding of tolerances and specifications in precision machining.

Understanding tolerances and specifications is fundamental to precision machining. Tolerances define the permissible variations in dimensions and other characteristics of a machined part. Specifications outline the required properties of the part, including dimensions, surface finish, material, and other relevant attributes.

For example, a drawing might specify a shaft diameter of 10mm ± 0.05mm. This means the acceptable diameter range is between 9.95mm and 10.05mm. Anything outside this range is considered a defect. Different types of tolerances (e.g., bilateral, unilateral) exist, and their implications need to be carefully understood.

Similarly, surface finish specifications define the roughness of the part’s surface, often expressed in Ra (average roughness) values. The required surface finish depends on the part’s function and application. A highly polished surface might be needed for a bearing, whereas a rougher surface might be acceptable for a structural component. Failing to meet these tolerances and specifications can lead to part failure and render the part unusable.

Proper understanding of Geometric Dimensioning and Tolerancing (GD&T) is also essential to communicate and control the geometric characteristics of parts accurately. GD&T symbols provide clear and unambiguous information on tolerances, which are critical for proper manufacturing and assembly.

Q 28. How do you stay updated with the latest technologies and best practices in precision machine setup?

Staying updated in the rapidly evolving field of precision machining is crucial. I employ several strategies to stay current with the latest technologies and best practices:

- Industry Publications and Journals: I regularly read industry magazines and journals, such as those published by SME (Society of Manufacturing Engineers) to learn about new technologies and techniques.

- Professional Organizations: Membership in professional organizations like SME provides access to conferences, workshops, and networking opportunities where I can learn from experts and exchange knowledge.

- Online Resources and Webinars: I utilize online resources, including manufacturers’ websites and online courses, to keep abreast of advancements in machining technologies and software.

- Manufacturer Training: Participating in training courses provided by machine manufacturers is another effective way to learn about the latest features and capabilities of specific machines.

- Hands-on Experience: Actively seeking opportunities to work with new machines and technologies provides invaluable practical experience.

Continuous learning is vital in this field. New materials, cutting tools, and software are constantly being developed, and staying informed is necessary to maintain a competitive edge and deliver high-quality results.

Key Topics to Learn for Precision Machine Setup Interview

- Machine Tool Knowledge: Understanding the operation and capabilities of various precision machine tools (e.g., CNC lathes, milling machines, grinders). This includes familiarity with different control systems (CNC, manual).

- Setup Procedures: Mastering the practical steps involved in setting up a machine for a specific job, including tool selection, workpiece fixturing, and program loading/verification. This also includes understanding safety protocols.

- Measurement and Inspection: Proficiency in using precision measuring instruments (e.g., micrometers, calipers, dial indicators) to ensure accuracy and quality control throughout the setup process. Understanding tolerance specifications and GD&T (Geometric Dimensioning and Tolerancing) is crucial.

- Blueprint Reading and Interpretation: Ability to accurately interpret engineering drawings and specifications to determine the correct machine settings and tolerances for a given part. This includes understanding different views and annotations.

- Troubleshooting and Problem-Solving: Developing skills to identify and resolve common setup issues, including tool wear, machine malfunctions, and dimensional inaccuracies. This includes a methodical approach to diagnostics and repair.

- Programming (if applicable): Depending on the role, familiarity with CNC programming (G-code, CAM software) may be essential. Understanding the logic and structure of CNC programs is key.

- Safety Regulations and Procedures: Demonstrating a strong understanding of workplace safety practices and regulations related to operating and maintaining precision machine tools. This includes lockout/tagout procedures and personal protective equipment (PPE).

Next Steps

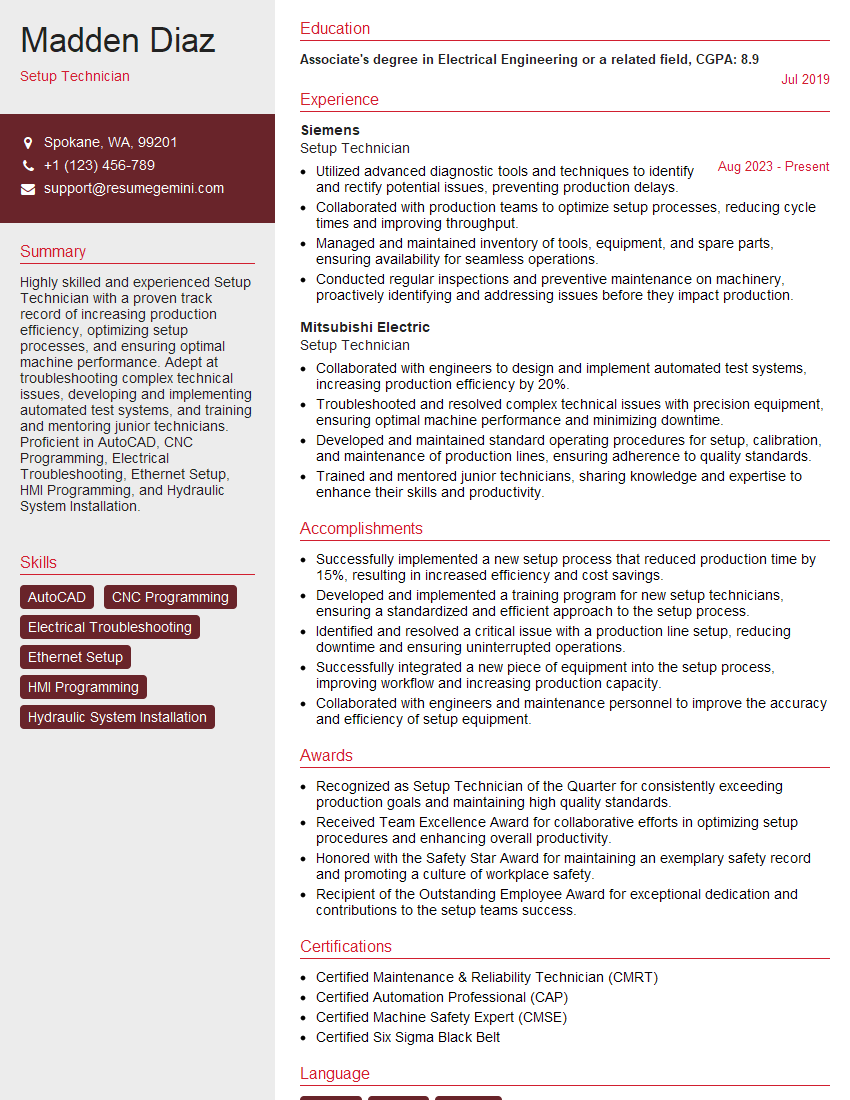

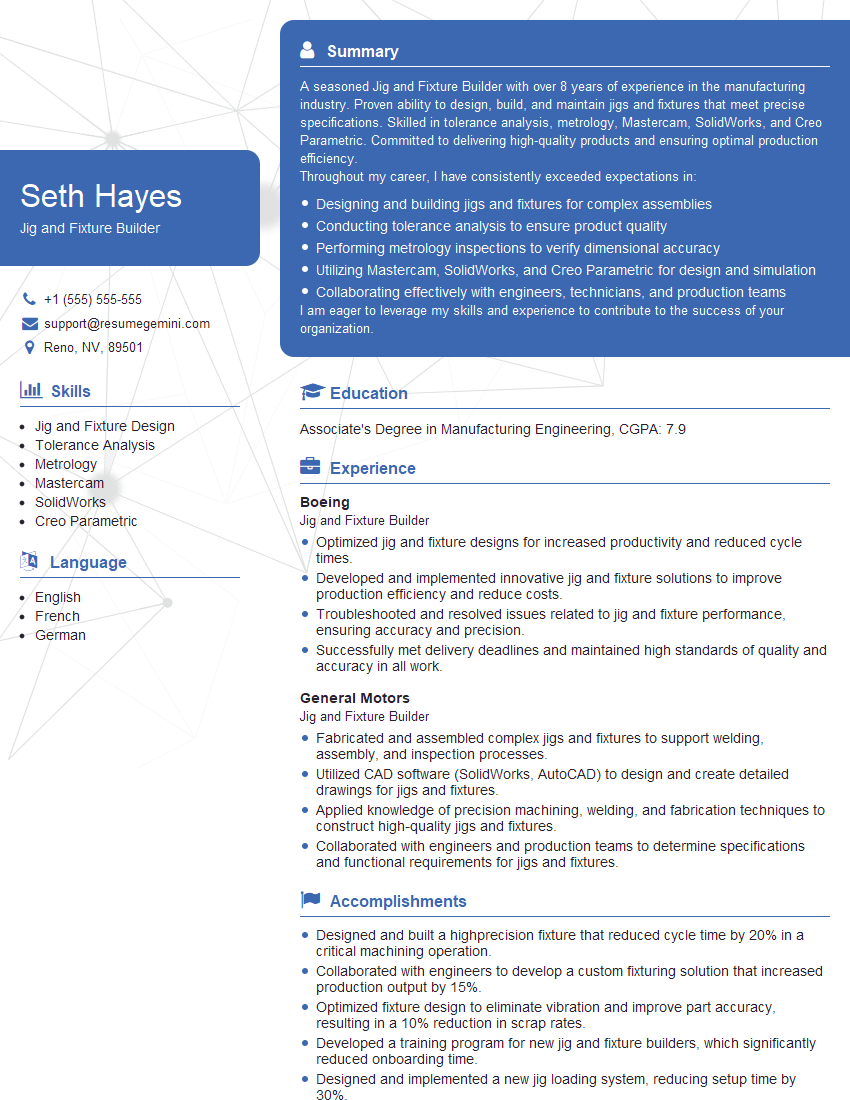

Mastering precision machine setup opens doors to a rewarding career with excellent growth potential in manufacturing and related industries. Your expertise in this area is highly valued, and demonstrating your skills effectively is critical for landing your dream job. To maximize your chances, create an ATS-friendly resume that highlights your abilities and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed by recruiters. Examples of resumes tailored to Precision Machine Setup are available, providing you with the best chance for interview success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good