The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Ability to identify and correct defects in garments interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Ability to identify and correct defects in garments Interview

Q 1. Describe your experience identifying different types of fabric defects.

Identifying fabric defects requires a keen eye and a deep understanding of textile properties. My experience encompasses a wide range of defects, categorized broadly into yarn faults, fabric construction flaws, and finishing issues.

- Yarn faults: These include things like slubs (thickened areas), neps (small entangled fibers), broken or weak yarns, and uneven dyeing. I’ve learned to distinguish between these by examining the yarn’s structure under magnification, often using a magnifying glass or even a microscope for intricate details.

- Fabric construction flaws: This area covers defects stemming from the weaving or knitting process. Examples include mispicks (missed interlacings in woven fabric), holes, laddering (runs in knitted fabric), and fabric inconsistency in weight or density. I often use a fabric testing device to objectively measure these inconsistencies.

- Finishing issues: These are defects that occur after the fabric is woven or knitted, such as creases, wrinkles, stains, color variations (off-shade), and uneven shrinkage. Identifying these often involves comparing the finished product to a standard sample to assess deviations from the desired quality.

For example, in one instance, I identified a significant number of slubs in a batch of cotton fabric intended for high-end shirts. This required immediate action to address the source of the problem with the yarn supplier.

Q 2. How do you assess the severity of a garment defect?

Assessing the severity of a garment defect is crucial for determining the appropriate course of action. I use a multi-faceted approach involving visual inspection, measurement, and consideration of the garment’s intended use and price point.

- Visual inspection: This helps identify the type and location of the defect. Is it a small imperfection or a large, noticeable flaw?

- Measurement: For certain defects, precise measurements are needed. For example, the length of a seam slippage or the size of a hole.

- Contextual assessment: This considers the garment’s purpose. A small imperfection might be acceptable in a low-cost item, but unacceptable in a luxury garment.

I typically classify defects into categories like critical (unacceptable, requiring immediate action), major (significant, affecting functionality or appearance), minor (small imperfections, possibly acceptable depending on the context), and negligible (extremely minor, insignificant). This systematic approach ensures consistent defect evaluation.

Q 3. Explain your process for documenting and reporting garment defects.

My documentation and reporting process is meticulous and follows a standardized format to ensure clarity and efficiency. I use a combination of visual aids and written records.

- Visual documentation: I take clear photographs or videos of the defects, highlighting their location and severity. This helps provide visual evidence during the investigation.

- Written reports: These reports include detailed descriptions of the defects, their location on the garment (e.g., ‘left sleeve, 5cm below the cuff’), the type of defect (e.g., ‘seam slippage’), the severity rating, the number of affected garments, and any suggested corrective actions. I often use a standardized defect reporting form.

- Data entry: All this information is then entered into a database, enabling efficient tracking and analysis of defects over time. This data is essential for identifying recurring problems and implementing preventative measures.

For instance, I’ve created Excel spreadsheets specifically designed to log details of each defect and correlate them with production batches. This has proven invaluable in pinpointing the root cause of recurring issues.

Q 4. What are the common causes of stitching defects?

Stitching defects are a common concern in garment manufacturing and can arise from various factors. Understanding these root causes is essential for prevention.

- Machine malfunction: Problems with the sewing machine’s needles, tension, or feed dogs can lead to skipped stitches, uneven stitching, broken threads, or puckering.

- Operator error: Improper machine settings, incorrect needle selection for the fabric type, or lack of operator skill can cause similar defects.

- Fabric-related issues: Working with damaged or weakened fabric, overly thick or thin material, or fabric with unusual texture can create challenges for the sewing machine and cause stitching defects.

- Thread issues: Using poor quality thread, incorrect thread tension, or knots in the thread will all affect the quality of stitching.

For example, I once traced a consistent pattern of skipped stitches to a faulty needle on a particular sewing machine. Replacing the needle immediately resolved the problem and prevented further defects.

Q 5. How do you handle a situation where a significant defect is found in a large batch of garments?

Discovering a significant defect in a large batch requires a swift and decisive response. My approach involves a structured plan of action.

- Immediate halt to production: Prevent further production of defective garments.

- Thorough investigation: Determine the root cause of the defect. This might involve examining the raw materials, the sewing process, or the quality control procedures.

- Defect analysis and categorization: Assess the severity and prevalence of the defect. This helps to determine the extent of the corrective action needed.

- Corrective action implementation: Depending on the severity, this might involve repairing the defects, discarding the affected garments, or revising the production process.

- Communication and reporting: Clearly communicate the situation to the relevant stakeholders (management, suppliers) and document the entire process, including corrective measures implemented.

In one instance, a significant fabric flaw was discovered in a large shipment of dresses. We immediately halted production, initiated a full quality audit of the fabric supplier, and worked with them to replace the flawed material. This prevented a major financial and reputational loss.

Q 6. Describe your experience with using quality control tools and equipment.

My experience includes utilizing a range of quality control tools and equipment, enhancing accuracy and efficiency.

- Measuring tools: Calipers, rulers, and measuring tapes for accurate assessment of dimensions and tolerances.

- Magnifying glasses and microscopes: For detailed examination of yarn and fabric structures, as well as stitching quality.

- Fabric testing equipment: Instruments that measure fabric properties like tensile strength, bursting strength, and abrasion resistance. This helps identify underlying issues in the fabric itself that might contribute to garment defects.

- Seam strength testers: Devices that measure the strength of seams and stitch integrity.

- Colorimeters: Used to ensure color consistency throughout production runs, preventing off-shade defects.

Proficiency in using these tools allows for objective assessment of garment quality, leading to more informed decision-making and reduced waste.

Q 7. What are some common fabric flaws and how are they corrected?

Numerous fabric flaws can occur during production, requiring specific corrective measures. Here are some common examples:

- Holes and tears: These can be repaired by patching or darning, depending on the size and location of the defect. In high-end garments, these might necessitate replacement of the entire fabric panel.

- Stains: Depending on the stain’s nature and the fabric type, stain removal techniques range from simple pre-treatment and laundering to more specialized dry-cleaning methods.

- Wrinkles and creases: These are often addressed through pressing and steaming during the finishing process. However, severe wrinkles may indicate a problem with the fabric itself or the finishing process.

- Uneven dyeing: This can sometimes be addressed through re-dyeing or by strategically using the fabric to minimize the visibility of the defect. However, severely uneven dye lots may necessitate discarding the fabric.

- Shrinkage problems: Pre-shrinking fabrics before cutting and sewing helps prevent this, but if shrinkage occurs after processing, correcting this is very difficult and often means discarding the garment.

The choice of corrective action always depends on the nature of the defect, its severity, and the garment’s value. Repair is always attempted if economically and aesthetically viable.

Q 8. How do you prioritize different types of garment defects?

Prioritizing garment defects involves a multi-faceted approach, considering factors like the severity of the defect, its impact on garment functionality and aesthetics, and the cost of rectification. I typically use a system that combines criticality and frequency.

- Critical Defects: These are defects that render the garment unwearable or unsafe (e.g., major rips, missing closures, hazardous stitching). These are always addressed first.

- Major Defects: These significantly affect the garment’s appearance or functionality, though not rendering it unusable (e.g., large stains, mismatched patterns, significant shrinkage). These are prioritized after critical defects.

- Minor Defects: These are small imperfections that do not significantly affect the garment’s functionality or appearance (e.g., small loose threads, slight color variations). These are addressed last, often as part of a final quality check.

For example, a large hole in a shirt (critical defect) takes precedence over a slightly crooked hem (minor defect). This prioritization ensures resources are allocated effectively to address the most pressing quality issues. I regularly review this prioritization system to ensure it aligns with current production needs and customer expectations.

Q 9. What is your experience with different types of sewing machines and their potential defect points?

My experience encompasses various sewing machine types, including single-needle, double-needle, overlock (serger), coverstitch, and industrial button-sewing machines. Understanding each machine’s strengths and weaknesses is crucial for defect identification.

- Single-needle machines: Common defects include skipped stitches, inconsistent stitch length, needle breakage leading to fabric damage, and uneven seam allowance.

- Double-needle machines: Problems often involve inconsistent spacing between the two needle lines, uneven stitch lengths on both sides, and difficulties with delicate fabrics.

- Overlock (serger) machines: Defects typically include uneven trimming, broken threads, incorrect tension leading to loose or tight seams, and failure to properly finish the seam.

- Coverstitch machines: These machines often have issues with uneven stitch coverage, stitch inconsistencies due to tension issues, and problems with fabric feeding.

For instance, a consistently uneven seam allowance on multiple garments might indicate a machine’s needle needs adjustment or the presser foot needs servicing. Recognizing such patterns enables preventative maintenance and timely repairs, minimizing production delays and defects.

Q 10. How do you ensure consistency in defect identification across different team members?

Maintaining consistent defect identification across the team is achieved through comprehensive training, standardized checklists, regular calibration sessions, and clear visual aids.

- Detailed Training: All team members receive in-depth training on identifying various garment defects using clear examples and images. This training covers common defects and their causes.

- Standardized Checklists: A detailed checklist with images and descriptions of acceptable and unacceptable quality levels is provided to every inspector. This ensures consistent evaluation criteria.

- Regular Calibration Sessions: Periodic calibration sessions with visual aids are conducted to ensure consistent interpretations across team members. This includes blind testing to identify any discrepancies in perception.

- Visual Aids: Large-scale, high-quality photos and samples showcasing various defects are used as reference points, ensuring consistent judgment. This reduces any ambiguity in determining defect severity.

This multi-pronged approach creates a shared understanding of quality standards, minimizes subjective judgment, and improves overall accuracy in defect identification.

Q 11. Describe your experience in using quality control checklists and procedures.

Quality control checklists and procedures are integral to my workflow. I’ve used various checklists tailored to specific garment types and production stages. A typical checklist might include sections on:

- Fabric Inspection: Checking for flaws in fabric before cutting (e.g., holes, stains, inconsistencies in weave).

- Cutting Inspection: Verifying the accuracy of cut pieces against the pattern.

- Sewing Inspection: Checking for stitching quality, seam allowance, and correct placement of components.

- Finishing Inspection: Examining the final garment for flaws in closures, hems, and overall appearance.

These checklists are often accompanied by detailed procedures for each inspection stage, which might include specific measurement tolerances and acceptable deviation limits. For example, a procedure might specify that seam allowances must be within ± 2mm of the designated size. Through rigorous application of these checklists and procedures, I significantly reduce the incidence of defects.

Q 12. What is your experience with different types of quality control standards (e.g., ISO 9001)?

My experience includes working within quality control standards like ISO 9001. Understanding and implementing ISO 9001 principles involves focusing on continuous improvement, customer satisfaction, and the establishment of a robust quality management system.

- Documented Procedures: ISO 9001 emphasizes the importance of documented procedures for all aspects of garment production, ensuring consistency and traceability.

- Internal Audits: Regular internal audits are conducted to assess compliance with the standard and identify areas for improvement. This helps maintain quality standards.

- Corrective Actions: A robust system is in place for implementing corrective actions when non-conformances are identified. This ensures defects are not repeated.

- Preventive Actions: Proactive measures are taken to prevent potential quality issues, focusing on root cause analysis to avoid recurrence.

For instance, understanding ISO 9001’s requirements for record-keeping allowed me to implement a system for tracking defects, their causes, and corrective actions taken. This data is used to identify trends and implement improvements to reduce defect frequency. This systematic approach builds quality into the entire process.

Q 13. How do you identify and address dimensional inconsistencies in garments?

Addressing dimensional inconsistencies starts with preventative measures, including careful pattern making, accurate cutting, and consistent sewing techniques. However, inconsistencies can still occur. My approach is a combination of detection and correction.

- Measurement tools: Utilizing precise measuring tools like rulers, measuring tapes, and calipers ensures accurate measurements at each stage of production.

- Sampling and analysis: I randomly sample garments at various production stages to check for size deviations from specifications. This data is analyzed to identify trends and potential issues.

- Correction techniques: Depending on the nature of the inconsistency, correction methods can range from minor adjustments to complete reworking of garments. Techniques may involve steaming, pressing, or restitching to adjust sizing.

- Root cause analysis: Once inconsistencies are identified, a root cause analysis is performed to pinpoint the source (e.g., incorrect pattern, machine malfunction, inaccurate measurements).

For example, if consistently large size discrepancies appear in a specific batch, I would investigate the cutting process and compare the cut pieces to the original pattern to identify any errors.

Q 14. What are your methods for preventing defects during the garment production process?

Preventing garment defects is a proactive strategy that encompasses multiple stages of the production process.

- Raw Material Inspection: Thoroughly inspecting fabrics for flaws before cutting is crucial in eliminating defects at their source. This might involve checking for color consistency, weave quality, and any pre-existing damage.

- Pattern Accuracy: Ensuring patterns are accurately drafted and graded minimizes errors during cutting and sewing. This involves using appropriate tools and techniques to develop precise patterns.

- Operator Training: Well-trained operators, experienced in various sewing techniques, use the correct machine settings and ensure consistent stitch quality and seam allowance. Proper training minimizes human error.

- Machine Maintenance: Regular maintenance of sewing machines and other equipment is essential to ensure smooth operation and prevent machine-related defects. Scheduled servicing and necessary repairs prevent costly downtime and quality issues.

- Quality Checks at each Stage: Implementing in-line quality checks at each stage of production—cutting, sewing, finishing—allows for early detection and correction of defects, preventing them from propagating to the next stage. This minimizes waste and increases efficiency.

By systematically addressing potential issues at every stage, we proactively minimize defects and create a higher quality product.

Q 15. Describe your experience with root cause analysis for garment defects.

Root cause analysis (RCA) for garment defects is crucial for preventing recurrence. It’s a systematic process of identifying the underlying causes of a problem, not just the symptoms. My approach involves a multi-step process, often utilizing tools like the ‘5 Whys’ technique and fishbone diagrams.

- Define the Problem: Clearly describe the defect, including its location, type, and frequency. For example, ‘consistent misalignment of the collar on 20% of shirts produced on Line 3’.

- Gather Data: Collect information on the production process, materials used, and operator techniques. This may involve inspecting samples, reviewing production records, and interviewing operators.

- Identify Potential Causes: Brainstorm potential causes using techniques like the fishbone diagram (Ishikawa diagram), categorizing causes into categories like materials, machinery, methods, manpower, and environment.

- Analyze Root Causes: This is where the ‘5 Whys’ comes in. Repeatedly asking ‘why’ helps to drill down to the fundamental cause. For instance: Why is the collar misaligned? Because the stitching machine is miscalibrated. Why is it miscalibrated? Because the operator didn’t perform regular calibration checks. Why weren’t checks performed? Because the training on calibration wasn’t thorough. Why was the training inadequate? Because the training materials were outdated.

- Develop Solutions: Based on the root cause, implement corrective actions, such as retraining operators, updating machinery, improving material quality, or refining processes.

- Verify Effectiveness: Monitor the defect rate after implementing the solutions to confirm their effectiveness.

For example, I once identified consistent fraying on a particular seam as being caused by using a dull needle. By replacing the needles regularly according to a newly implemented schedule, we eliminated the defect entirely.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate defect information effectively to other team members?

Effective communication is vital in defect resolution. I prioritize clarity, accuracy, and timeliness. My methods include:

- Clear and Concise Reporting: I use standardized defect reports, including details like defect type, location, severity, quantity affected, and proposed solutions. Photographs and diagrams are crucial, especially for visual defects.

- Visual Aids: I use clear visual aids such as photos, videos, and diagrams to illustrate the defect and its location. This prevents misunderstandings and enhances understanding across teams with different levels of garment-making expertise.

- Team Meetings: I actively participate in team meetings to present findings, discuss potential solutions, and ensure everyone is aligned on the next steps. This fosters a collaborative environment and promotes shared responsibility in finding solutions.

- Collaboration Tools: I use collaborative software to share information efficiently, allowing for real-time updates and feedback from different stakeholders.

For instance, when dealing with a complex defect involving multiple production stages, I’ve used a collaborative online document to track the progression of our investigation and solutions, enabling all team members to participate in real-time and access the latest information.

Q 17. How do you handle disagreements about the severity of a defect?

Disagreements on defect severity are common. My approach is to use objective criteria and data-driven decision making. I’ll follow these steps:

- Clearly Define Severity Criteria: We’ll start by establishing a clear, agreed-upon scale for defect severity (e.g., critical, major, minor) based on factors like impact on functionality, aesthetics, safety, and customer satisfaction.

- Present Evidence: I’ll provide objective evidence such as photos, measurements, and data on defect frequency to support my assessment.

- Collaborative Discussion: We’ll have a structured discussion involving all relevant stakeholders. Each person will share their perspective, supported by evidence.

- Escalation Process: If a consensus isn’t reached, we’ll escalate the decision to a senior manager who can act as a neutral arbitrator.

- Documentation: The final decision on severity, along with the rationale, will be clearly documented and shared with all involved parties.

For instance, in a disagreement about whether a slight color variation was a ‘major’ or ‘minor’ defect, we reviewed customer feedback on similar variations in the past, and concluded it was a minor defect based on a lack of customer complaints.

Q 18. Explain your experience in using statistical process control techniques.

Statistical Process Control (SPC) techniques are invaluable in garment manufacturing for identifying trends and preventing defects. My experience includes applying control charts (like X-bar and R charts) to monitor key quality characteristics.

- Control Chart Implementation: I’ve used control charts to monitor metrics like stitch count per inch, fabric width variation, and seam strength. This allows us to visualize the process stability and identify when it deviates from acceptable limits.

- Data Collection and Analysis: I have experience collecting data on various quality characteristics during the production process, inputting this data into SPC software, and then analyzing the control charts for patterns and anomalies. For example, consistently high or low values, or points outside the control limits, indicate potential problems.

- Process Capability Analysis: I’ve used Cp and Cpk calculations to assess the process’ ability to meet specification limits. This helps identify areas where process improvement is needed to reduce defect rates.

- Root Cause Analysis Integration: I integrate SPC data into root cause analysis to pin point the source of variation and develop effective corrective actions.

In one instance, by implementing X-bar and R charts to monitor the tension of the stitching machine, we identified a cyclical variation in stitch strength, which we traced to regular maintenance that wasn’t consistently performed. Adjusting the maintenance schedule solved this problem.

Q 19. How do you ensure the accuracy of defect reporting?

Ensuring accurate defect reporting is paramount. My strategy includes:

- Standardized Reporting Forms: Utilizing consistent forms with clearly defined fields for defect type, location, quantity, severity, and other relevant information ensures consistency and minimizes errors.

- Data Validation: Implementing checks and balances to verify reported data, either through a second review or using automated systems, minimizes errors and omissions.

- Training and Calibration: Providing thorough training to all inspectors and ensuring consistent calibration of inspection tools (e.g., measuring devices) helps maintain accuracy.

- Regular Audits: Conducting regular audits of defect reporting procedures to identify and correct any inconsistencies or deviations from established processes.

- Defect Tracking System: Using a well-organized defect tracking system, such as a database or software, allows for efficient tracking, analysis, and reporting of defects.

To maintain accuracy, we implemented a double-checking system where a second inspector verifies a percentage of defects reported by the first inspector before the data is entered into our central database.

Q 20. Describe your experience in working with different types of fabrics.

My experience encompasses a wide range of fabrics, including natural fibers (cotton, silk, wool, linen), synthetic fibers (polyester, nylon, rayon), and blends. Understanding fabric properties is vital for identifying and correcting defects.

- Fiber Identification: I can identify different fiber types and their properties, which impacts how defects might appear and how they should be addressed. For instance, a snag is more easily repaired on a tightly woven cotton than on a loosely knit wool.

- Fabric Construction: Understanding weave structures (plain, twill, satin), knit structures (single jersey, double knit), and fabric finishes (dyeing, printing, coating) is crucial to understanding how defects arise. A defect in a tightly woven fabric might be very different from a defect in a loosely woven fabric.

- Fabric Handling: I’m skilled in handling different fabric types to avoid damage during inspection and repair. Delicate fabrics require different handling techniques than more durable ones.

- Defect Specifics: Each fabric type has its own susceptibility to specific defects. For example, silk is prone to snags, while linen can wrinkle easily.

Working with a high-end silk garment required a significantly different approach to defect detection and repair compared to working with a heavy-duty cotton canvas, highlighting the importance of understanding material properties.

Q 21. How do you handle defects that are difficult to correct?

Handling difficult-to-correct defects requires a systematic approach:

- Assess the Feasibility of Repair: First, I’ll assess if the defect can be repaired economically. Sometimes, discarding the garment might be the most cost-effective solution.

- Explore Repair Techniques: If repair is feasible, I’ll explore various techniques, potentially consulting with specialized repair personnel. This might involve advanced stitching, patching, or other specialized methods.

- Test Different Solutions: I’ll test various repair techniques on samples to determine the best approach without damaging the garment further.

- Document Repair Process: I’ll document the chosen repair method, along with any challenges encountered, to prevent similar issues in the future.

- Quality Control: After repair, the garment will undergo a thorough quality check to ensure the repair is effective and doesn’t cause new issues.

- Cost-Benefit Analysis: In cases of high-value garments or those involving complex defects, the cost-benefit of repair will be carefully considered, weighing the cost of repair against the value of the garment.

For example, I once encountered a complex dye transfer on a high-end leather jacket. After experimenting with different cleaning techniques, we developed a method that removed most of the stain without damaging the leather. This repair process was carefully documented to be utilized in similar future scenarios.

Q 22. What is your experience with different types of garment construction?

My experience encompasses a wide range of garment construction techniques, from basic flat-pattern construction to more complex methods like draping and pattern grading. I’m proficient in various stitching methods, including lockstitching, chainstitching, and overlocking, and I understand the nuances of different seam finishes like French seams and Hong Kong finishes. I have worked extensively with various fabrics, including woven fabrics like cotton, silk, and wool, and knit fabrics like jersey and rib knit, understanding how each fabric behaves and requires different construction techniques. For example, working with delicate silk requires a gentler hand and specific needle types to prevent damage, while sturdy denim necessitates stronger stitching and more robust seam finishes. My experience also includes working with different garment types, from simple t-shirts and blouses to more complex structured pieces like jackets and coats, which involve more intricate pattern pieces and construction steps.

- Flat Pattern Construction: Creating patterns from scratch using measurements and drafting tools.

- Draping: Creating patterns directly on a dress form using fabric.

- Pattern Grading: Adjusting patterns to different sizes.

- Various Seam Finishes: Using different techniques to create professional and durable seams.

Q 23. Describe your experience in using different types of measuring tools.

Throughout my career, I’ve utilized a variety of measuring tools essential for accurate garment construction and defect detection. My proficiency extends beyond basic rulers and tape measures to include more specialized tools. Accuracy is paramount, and selecting the right tool for the job ensures precision. For instance, a flexible tape measure is ideal for body measurements, while a steel ruler provides accuracy when working with patterns. I’m also skilled in using calipers for precise measurements, and I understand the importance of proper calibration and maintenance for all tools.

- Tape Measures: For measuring body measurements and garment parts.

- Steel Rulers: For accurate pattern measurements and grading.

- Calipers: For precise measurements of small components.

- Seam Gauge: For measuring seam allowances.

Q 24. How do you identify and correct defects related to patterns?

Pattern defects can significantly impact the final garment. Identifying these defects requires a keen eye for detail and a thorough understanding of pattern construction. Common pattern defects include incorrect sizing, inaccurate seam allowances, missing or misplaced markings, and incorrect grainlines. I approach correcting these defects systematically. First, I carefully examine the pattern for discrepancies against the original specifications or design. Then, I use my knowledge of pattern making and grading to make the necessary corrections. For instance, if seam allowances are inconsistent, I adjust them using a ruler and other tools. If there’s an issue with grainlines, I realign the pattern pieces to ensure proper fabric drape and prevent distortion. Minor adjustments are usually done directly on the pattern, while more significant issues might necessitate redrawing parts or even generating a new pattern piece.

- Incorrect Sizing: Adjusting pattern pieces to fit correctly.

- Inaccurate Seam Allowances: Correcting inconsistent or incorrect seam allowances.

- Missing or Misplaced Markings: Adding or relocating notches, darts, and other markings.

- Incorrect Grainline: Realigning pattern pieces to ensure proper fabric direction.

Q 25. What are some common color and printing defects?

Color and printing defects are frequently encountered in garment production and can significantly affect the final product’s appearance and market value. Common color defects include variations in shade (off-shade), uneven color distribution (mottling), and color bleeding (dye migration). Printing defects can range from misalignment (registration errors) and blurred images (poor print resolution) to missing or faded print (ink problems). Identifying these requires careful visual inspection under consistent lighting. Sometimes, measuring color variations with a spectrophotometer offers quantitative data for consistent quality checks. To troubleshoot, it’s crucial to analyze the source: Was the dye bath inconsistent? Was the printing press misaligned? Was the fabric pre-treated appropriately?

- Off-shade: Color variations compared to the standard.

- Mottling: Uneven color distribution.

- Color Bleeding: Dye migration from one area to another.

- Registration Errors: Misalignment of multiple print colors.

- Blurred Images: Poor print resolution.

- Faded Prints: Insufficient ink or poor ink adhesion.

Q 26. How do you stay up-to-date with best practices in garment quality control?

Staying current with best practices in garment quality control is vital. I achieve this through a combination of continuous learning and professional networking. I regularly read industry publications, attend conferences and workshops, and actively participate in online forums and communities focused on garment manufacturing and quality control. This allows me to stay informed about emerging technologies, new standards, and innovative quality control methods. I also maintain strong relationships with suppliers and manufacturers, learning from their experiences and sharing best practices. Additionally, I regularly review and update my knowledge of relevant standards and certifications such as ISO 9001 (quality management) to ensure I’m always applying the latest and most effective techniques.

Q 27. What is your experience with implementing corrective actions to prevent future defects?

Implementing corrective actions to prevent future defects is a crucial aspect of my role. My approach involves a systematic process. First, I thoroughly analyze the root cause of the defect, going beyond simply addressing the immediate problem. This often requires investigating the entire production process to pinpoint where things went wrong, whether it’s a faulty machine, a mistake in the pattern, or inadequate training for operators. Once identified, I work collaboratively with the production team to develop a clear and effective corrective action plan. This might involve adjusting machine settings, modifying production procedures, providing additional training, or upgrading equipment. The plan always includes measures to monitor its effectiveness and prevent similar issues from arising in the future.

Q 28. Describe a time you had to troubleshoot a complex garment defect.

I once encountered a complex defect involving inconsistent stitching on a batch of tailored jackets. The problem wasn’t simply missed stitches; it was a pattern of inconsistent tension leading to some seams being too tight and others too loose. Initial investigations pointed towards a faulty sewing machine needle, but replacing it didn’t resolve the issue entirely. Through systematic troubleshooting, I discovered the problem wasn’t solely with the needle. The bobbin tension was also inconsistent due to a small piece of lint jamming the mechanism. This required a deep clean and recalibration of the machine. Further investigation revealed that insufficient maintenance and inadequate operator training had contributed to the problem. We implemented a daily maintenance schedule for all sewing machines and a more rigorous training program for operators, resulting in significantly improved consistency and a reduction in stitching defects.

Key Topics to Learn for Ability to Identify and Correct Defects in Garments Interview

- Fabric Knowledge: Understanding different fabric types, their properties (e.g., weave, weight, drape), and common defects associated with each.

- Defect Identification: Mastering the ability to recognize various types of garment defects, including stitching flaws, fabric imperfections (holes, stains, discoloration), and construction errors.

- Quality Control Standards: Familiarizing yourself with industry-standard quality control procedures and grading systems for assessing garment quality.

- Repair Techniques: Developing practical skills in repairing common defects using appropriate tools and techniques (e.g., hand-stitching, machine stitching, patching).

- Problem-Solving & Troubleshooting: Analyzing the root cause of defects, suggesting preventative measures, and implementing effective solutions to minimize future occurrences.

- Safety Procedures: Understanding and adhering to relevant safety regulations and best practices when handling sewing machines and other equipment.

- Industry Terminology: Becoming fluent in industry-specific terminology related to garment construction and defects.

- Documentation and Reporting: Accurately documenting identified defects and reporting findings effectively to relevant personnel.

Next Steps

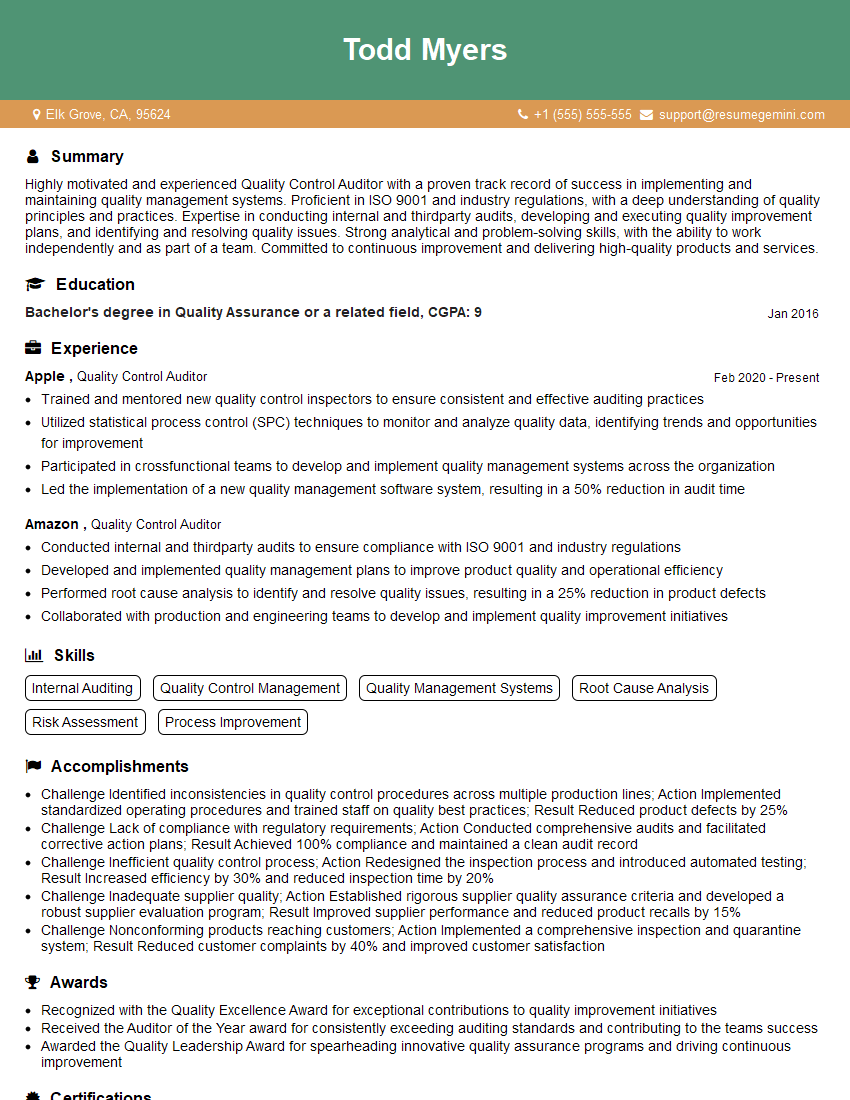

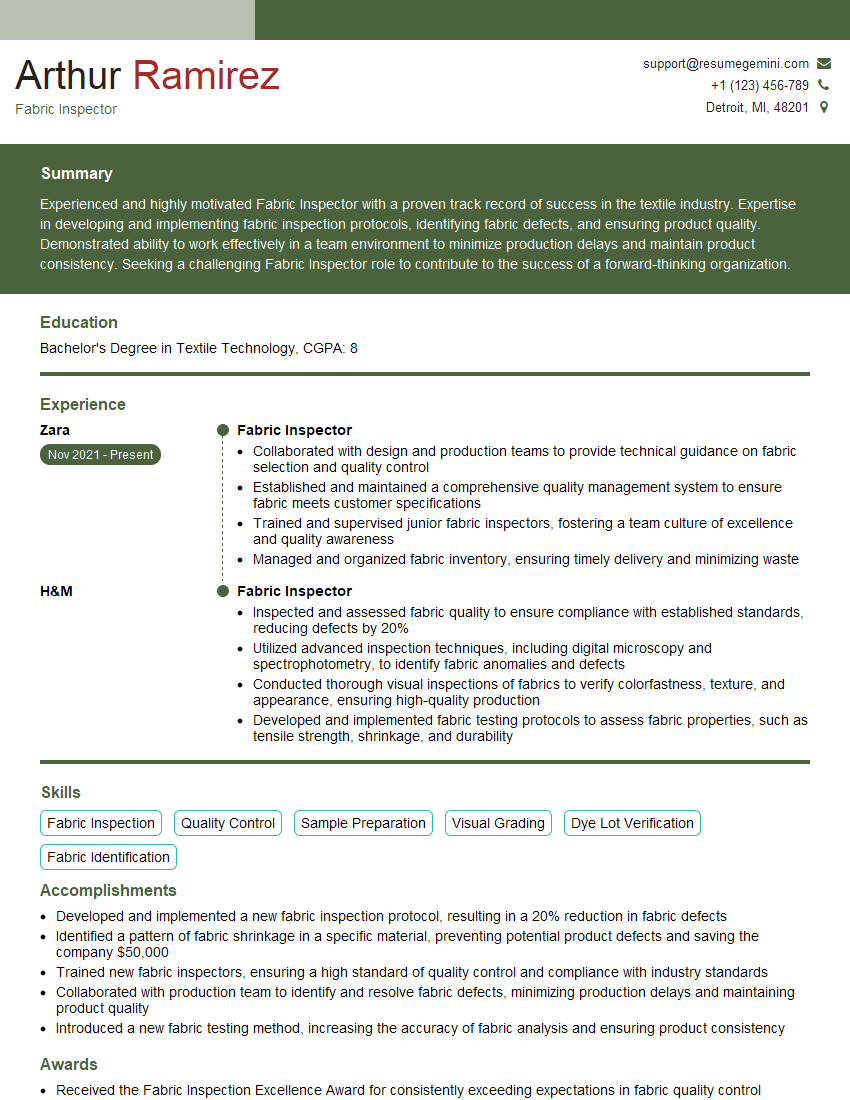

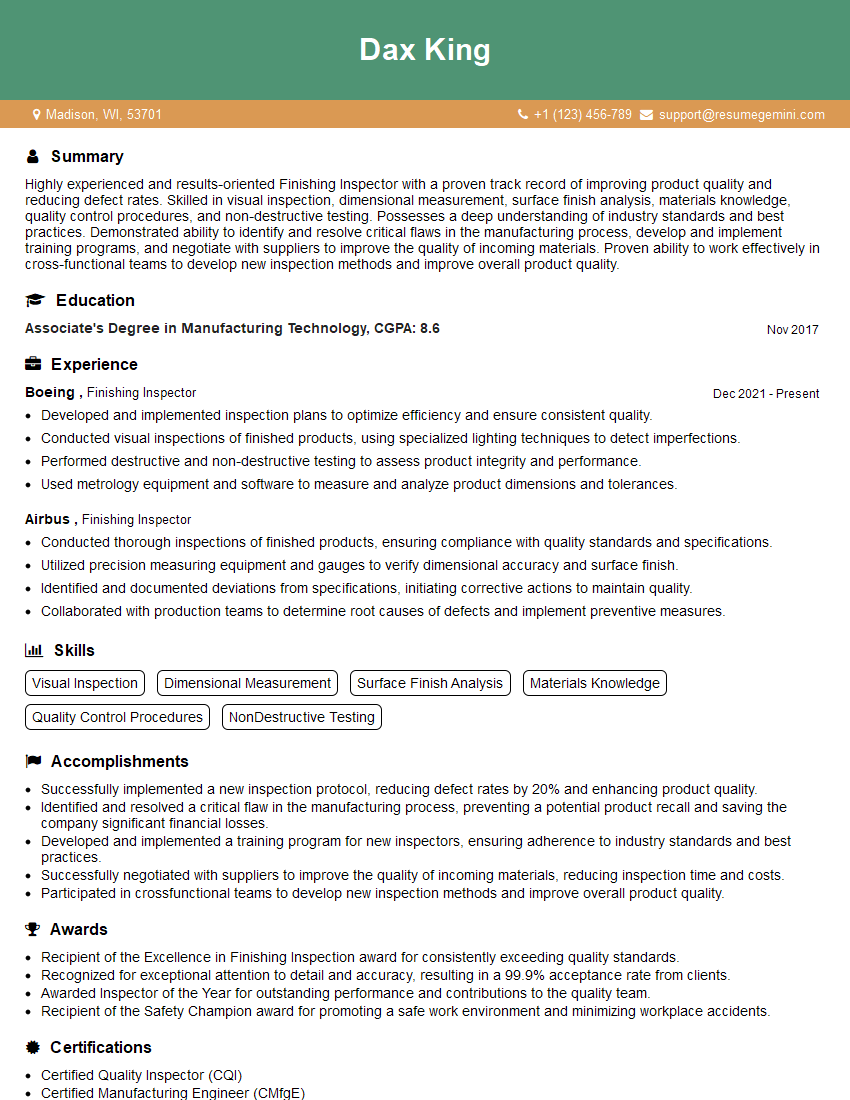

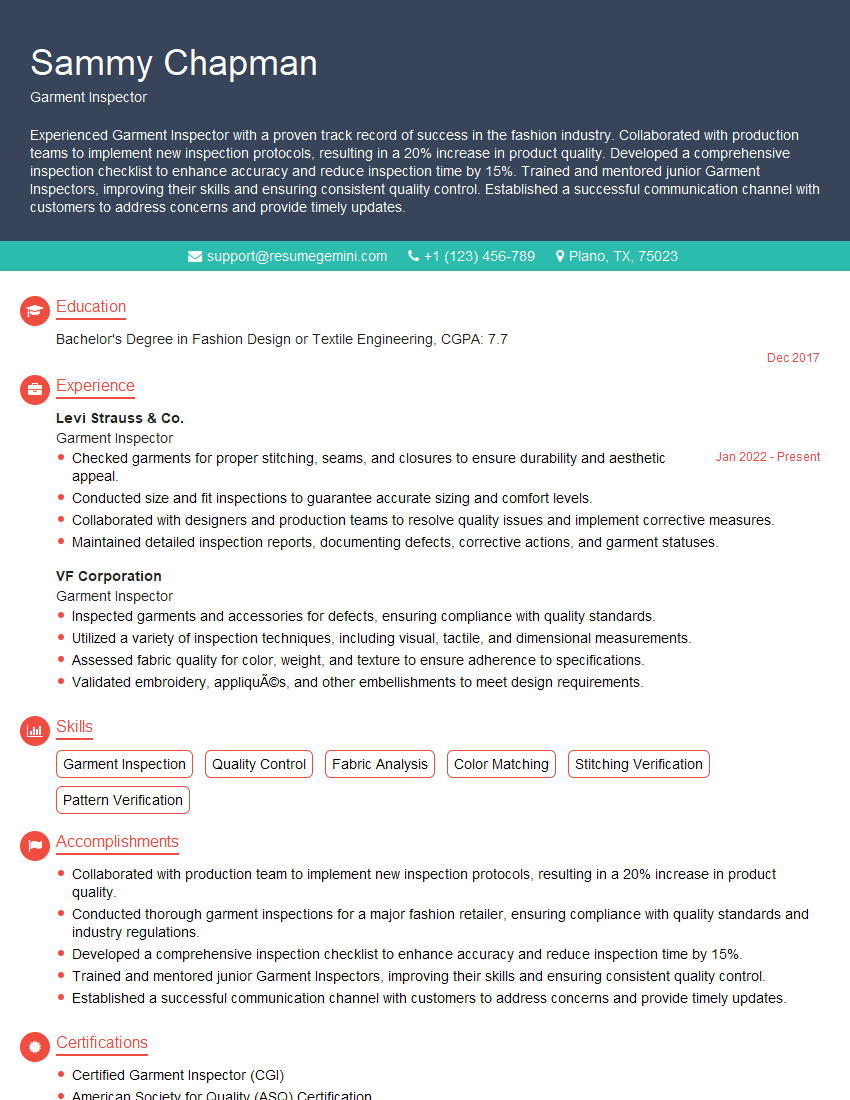

Mastering the ability to identify and correct garment defects is crucial for career advancement in the apparel industry. Proficiency in this area demonstrates attention to detail, problem-solving skills, and a commitment to quality – all highly valued attributes by employers. To increase your chances of landing your dream job, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of your target roles. We offer examples of resumes tailored to highlight expertise in identifying and correcting garment defects, providing you with a valuable head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good