The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Meter Installation and Maintenance interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Meter Installation and Maintenance Interview

Q 1. Describe your experience with different types of meters (gas, electric, water).

My experience spans a wide range of meter types, encompassing gas, electric, and water meters. Each type presents unique installation and maintenance challenges. For instance, gas meters require meticulous attention to safety due to the flammable nature of the gas, involving leak checks and specialized tools. Electric meters necessitate a thorough understanding of electrical safety regulations and procedures, including lockout/tagout protocols. Water meters, while seemingly simpler, demand precision during installation to ensure accurate readings and prevent leaks. I’ve worked with various meter technologies, from older electromechanical meters to advanced smart meters, gaining proficiency in their respective functionalities and maintenance needs.

- Gas Meters: I’ve installed and maintained both diaphragm and rotary gas meters, understanding the importance of regular leak checks and proper connection to gas lines. I’m familiar with the different pressure ratings and the implications for safety.

- Electric Meters: My experience includes installing both single-phase and three-phase electric meters, encompassing both electromechanical and solid-state electronic meters. I’m proficient in metering configurations for different voltage levels and load requirements.

- Water Meters: I have extensive experience installing and maintaining various water meter types, including positive displacement and turbine meters. I’m adept at handling different pipe sizes and addressing issues like leakage and low flow accuracy.

Q 2. Explain the process of installing a smart meter.

Smart meter installation is a multi-step process demanding precision and adherence to safety protocols. It begins with a thorough site survey to assess the existing infrastructure and determine the optimal location for the meter. This includes checking for adequate space, accessibility for future maintenance, and proximity to the power supply (for communication). Next, the old meter is safely disconnected and removed, following all relevant safety procedures for the specific meter type (gas, electric, or water). The new smart meter is then carefully connected, ensuring all wiring and connections are secure and meet specifications. This involves testing the connections for proper voltage and amperage (for electric meters), gas leaks (for gas meters), and water tightness (for water meters). Finally, the meter is activated, registered on the utility company’s network, and its functionality is verified. Data communication is tested, and the installation is completed with a final inspection and customer briefing.

Think of it like replacing a phone: first you disconnect the old one, then install the new one, making sure all the connections are right, then you test to make sure everything works (making calls, sending texts), finally you confirm it’s working correctly.

Q 3. What safety precautions do you take when working with electrical meters?

Safety is paramount when working with electrical meters. I always follow a strict lockout/tagout procedure to prevent accidental energization. This involves visually inspecting the meter and its surrounding equipment to ensure no unexpected power sources are present. I use appropriate personal protective equipment (PPE), including insulated gloves, safety glasses, and arc flash protection if necessary. Before beginning any work, I verify that the power is disconnected at the main service panel and use a non-contact voltage tester to confirm the absence of voltage. I also adhere to all relevant electrical codes and safety regulations. Each step is meticulously documented to ensure accountability and traceability.

Ignoring safety protocols when working with electricity can lead to severe injury or even death. Safety is non-negotiable.

Q 4. How do you troubleshoot a malfunctioning meter?

Troubleshooting a malfunctioning meter involves a systematic approach. I first visually inspect the meter for any obvious damage or loose connections. Then, I check the meter’s readings against expected values based on the customer’s usage patterns. For example, a consistently high reading compared to historical data might indicate a fault within the meter or a leak (for water meters). If a visual inspection reveals no obvious issues, I’ll use specialized testing equipment to measure voltage, current, or flow rate, depending on the meter type. Testing methods vary with the meter’s technology and could involve using digital multimeters, clamp meters, or specific meter testing tools. If the problem is internal to the meter, a replacement is usually necessary after documenting the findings. Proper documentation throughout the troubleshooting process is crucial for efficient repair and future reference.

Q 5. What are the common causes of meter inaccuracy?

Meter inaccuracy can stem from various factors. Mechanical wear and tear, particularly in older electromechanical meters, can lead to inaccurate readings. Environmental factors, such as extreme temperatures or humidity, can also affect meter performance. For instance, freezing temperatures can damage water meters. Corrosion or damage to internal components can significantly compromise accuracy. External factors like magnetic fields interfering with the operation of certain meter types are also a possibility. Calibration drift over time is another significant contributor to inaccuracy. For smart meters, communication issues or software glitches can affect readings. It is important to perform regular checks and maintenance to detect and rectify issues before they escalate.

Q 6. Describe your experience with meter calibration and testing procedures.

I have extensive experience with meter calibration and testing procedures, using specialized equipment and following standardized protocols. The calibration process typically involves comparing the meter’s readings to a known standard, adjusting the meter (if possible) to minimize any deviation. For example, water meters often undergo flow calibration using calibrated flow test benches, ensuring accuracy across various flow rates. Similarly, electric meters are calibrated using precision instruments to verify their accuracy in measuring voltage, current, and power. These calibrations are performed according to industry standards and documented meticulously. Testing procedures might also involve functional tests to check the integrity of the meter’s internal components and ensure proper operation.

Q 7. How do you handle meter repairs and replacements?

Meter repairs range from simple fixes like tightening loose connections to more complex repairs involving internal component replacement. If a repair is feasible and cost-effective, I’ll proceed with the necessary steps, always ensuring safety precautions are followed. However, if the meter is beyond economical repair or the damage is substantial, a replacement is the preferred solution. Replacement involves obtaining a new meter with matching specifications, safely removing the old meter, and installing and testing the new one, following the same rigorous procedures used during the initial installation. All work is documented, and any removed parts are disposed of appropriately. Customer notification and scheduling are a key aspect of the process, minimizing disruption to their service.

Q 8. What software or tools do you use for meter installation and maintenance?

For meter installation and maintenance, we utilize a variety of software and tools, depending on the specific task and meter type. This often includes:

- Meter Data Management Systems (MDMS): These software packages allow us to manage meter data, track installations, schedule maintenance, and generate reports. Examples include [Name of MDMS Software 1] and [Name of MDMS Software 2]. These systems often integrate with mobile devices for field technicians.

- Geographic Information Systems (GIS) Software: GIS software, such as ArcGIS or QGIS, helps us locate meters, plan routes for installations, and visualize network infrastructure. This is crucial for efficient work scheduling and minimizing travel time.

- Handheld Devices: We use ruggedized tablets or smartphones with specialized apps for meter reading, data logging, and communication with the MDMS. These devices often have GPS capabilities for accurate location tracking.

- Testing Equipment: This includes various tools for testing meter accuracy, such as precision multimeters, calibration equipment, and specialized test sets designed to conform to industry standards. We use these tools to ensure meters are functioning correctly and meeting accuracy requirements.

- Installation Tools: Basic hand tools like screwdrivers, wrenches, and cable cutters are essential, along with more specialized equipment depending on the type of meter and installation requirements (e.g., conduit benders, drilling equipment).

The specific tools and software used often depend on the client’s infrastructure and the type of meters being installed and maintained.

Q 9. Explain your understanding of meter reading and data collection methods.

Meter reading and data collection methods have evolved significantly. Traditionally, this involved manual reading using handheld devices and recording the readings on paper forms. Now, there’s a shift towards automated systems:

- Manual Meter Reading: This is still relevant in certain situations, particularly for older meters or in areas with limited infrastructure. It involves physically going to each meter and recording the reading.

- Automated Meter Reading (AMR): AMR systems use various technologies, such as radio frequency (RF) communication or power line carrier (PLC) communication, to transmit meter readings wirelessly to a central system. This significantly reduces the need for manual reading and improves efficiency.

- Advanced Metering Infrastructure (AMI): AMI is an even more advanced system which utilizes two-way communication between the meter and the utility. This allows for real-time data monitoring, remote disconnection/reconnection, and more detailed information on energy consumption patterns. AMI often incorporates smart meters with advanced functionalities.

- Data Collection Software: This is crucial to consolidate the data from various sources (manual readings, AMR, AMI). The collected data is then analyzed to generate reports, bill customers, and monitor energy usage trends.

Choosing the right method depends on factors such as budget, geographical location, existing infrastructure, and the needs of the utility company. For example, a large urban utility might opt for AMI, while a smaller rural utility might rely more on AMR or a combination of manual and AMR.

Q 10. How do you ensure the accuracy of meter readings?

Ensuring the accuracy of meter readings is paramount. We use a multi-pronged approach:

- Regular Calibration: Meters are calibrated at regular intervals using certified equipment to verify their accuracy. This involves comparing the meter reading to a known standard to detect any deviations.

- Quality Control Checks: We perform rigorous quality checks during installation to ensure the meters are correctly connected and functioning properly. This includes checking for leaks, loose connections, and proper grounding.

- Data Validation: We analyze the collected data to identify any inconsistencies or anomalies. For instance, unusually high or low readings might indicate a problem with the meter or the customer’s equipment, prompting further investigation.

- Cross-Referencing: If there are doubts about a particular meter reading, we might cross-reference it with readings from neighboring meters or use historical data to identify any significant variations.

- Meter Testing: We utilize specialized test equipment to measure the accuracy of the meter, verifying its conformity with industry standards.

In cases of discrepancies, we perform thorough investigations to identify the cause, whether it’s a faulty meter, a problem with the customer’s equipment, or even an error in the data collection process. Accuracy is our highest priority, as it directly affects customer billing and the overall efficiency of the energy distribution network.

Q 11. What is your experience with different types of meter connections?

I have extensive experience with various meter connections, including:

- Direct Wiring: This involves connecting the meter directly to the service wires, usually within a meter socket or enclosure. This is common for residential and smaller commercial installations.

- Meter Socket Connections: Meter sockets provide a standardized interface for connecting meters, facilitating easier installation and replacement. Different types of sockets exist depending on the voltage and amperage rating.

- Current Transformer (CT) Connections: CTs are used for metering high-current applications, such as industrial installations. They measure the current indirectly by measuring the magnetic field around the conductor.

- Potential Transformer (PT) Connections: PTs are used for metering high-voltage applications, stepping down the voltage to a safer level for the meter. These are commonly used in substation metering.

- Wireless Connections: As mentioned earlier, wireless connections (RF, PLC) are becoming increasingly prevalent in AMR and AMI systems. These eliminate the need for physical wiring in some cases, improving installation flexibility.

My experience encompasses working with different types of meters—mechanical, electromechanical, and electronic—and adapting the connection methods accordingly. I understand the safety protocols and regulations that govern each connection type and ensure all installations meet the required standards.

Q 12. Describe your experience with working at heights or in confined spaces.

Safety is my top priority. I possess extensive experience working at heights and in confined spaces. This includes:

- Height Safety: I’m certified and experienced in using fall protection equipment, including harnesses, lanyards, and safety lines. I adhere strictly to safety protocols when working on elevated structures, such as utility poles or rooftops. This involves using proper access equipment, conducting thorough inspections, and ensuring appropriate safety measures are in place.

- Confined Space Entry: I’m familiar with the hazards associated with confined spaces, such as underground vaults or meter pits. I’m trained in proper entry procedures, including atmospheric testing, ventilation, and using appropriate respiratory protection equipment. I always work with a partner and adhere to strict confined space entry protocols.

- Risk Assessment: Before any work commences, I thoroughly assess the risks involved and develop a detailed safety plan to mitigate those risks. This includes identifying potential hazards, selecting appropriate safety equipment, and outlining emergency procedures.

I believe that a proactive approach to safety is the best way to prevent accidents and ensure the well-being of myself and my colleagues. I regularly participate in safety training and stay updated on best practices.

Q 13. How do you handle difficult or challenging installations?

Difficult installations require a systematic approach. I start by:

- Thorough Site Assessment: I carefully assess the site conditions, identifying any potential obstacles or challenges, such as difficult terrain, limited access, or unusual infrastructure.

- Developing a Detailed Plan: Based on the site assessment, I develop a detailed plan that outlines the steps required for the installation, including the tools and equipment needed and any safety precautions.

- Problem Solving & Adaptability: I’m adept at problem-solving and adapting to unforeseen challenges. This might involve finding creative solutions to overcome obstacles, such as using specialized equipment or modifying the installation method.

- Seeking Guidance & Support: If I encounter a particularly difficult installation, I’m not afraid to seek guidance from senior colleagues or specialists. Teamwork is crucial in handling complex situations.

- Documentation: I thoroughly document the installation process, including any challenges encountered and the solutions implemented. This is valuable for future reference and helps to improve our processes.

For example, I once encountered an installation where access to the meter location was extremely limited due to dense vegetation. I coordinated with the landscaping team to temporarily clear the area, ensuring both the installation’s success and the safety of the landscaping crew.

Q 14. Explain your knowledge of relevant safety regulations and codes.

I possess a thorough understanding of all relevant safety regulations and codes concerning meter installation and maintenance. These vary depending on location and governing bodies, but typically include:

- Occupational Safety and Health Administration (OSHA) Regulations (or equivalent local regulations): I adhere to all OSHA standards regarding fall protection, confined space entry, lockout/tagout procedures, and personal protective equipment (PPE).

- National Electrical Code (NEC) (or equivalent local codes): I’m proficient in the NEC and understand the requirements for safe electrical installations, including grounding, wiring, and overcurrent protection.

- Utility-Specific Safety Rules: Each utility company has its own safety guidelines and procedures that I follow meticulously.

- Manufacturer’s Instructions: I always consult the manufacturer’s instructions for the specific meters and equipment being installed or maintained.

Safety is not just a set of rules, it’s a mindset. I regularly attend safety training, stay informed about updates to regulations and codes, and promote a safety-conscious culture in my work environment. I firmly believe that safety should be prioritized above all else.

Q 15. How do you maintain accurate records of meter installations and maintenance?

Maintaining accurate records in meter installation and maintenance is crucial for operational efficiency and regulatory compliance. We utilize a comprehensive, integrated system, typically a computerized maintenance management system (CMMS), to track every aspect of a meter’s lifecycle.

Installation Records: Each installation is meticulously documented, including the meter’s serial number, location (using GPS coordinates if available), date of installation, installer’s ID, type of meter, and any relevant site-specific notes (e.g., soil type for grounding). Digital photos are also included.

Maintenance Records: All maintenance activities, from routine inspections to repairs, are logged with similar detail. This includes the date, time, performed tasks, parts replaced (with serial numbers if applicable), and the technician’s ID. Before and after photos are common to assess condition.

Calibration Records: Regular calibration data is stored, ensuring accuracy and compliance. This includes the calibration date, results, and the equipment used.

Reporting and Analytics: The CMMS provides powerful reporting capabilities, allowing us to generate reports on meter performance, maintenance schedules, and overall system health. This aids in proactive maintenance planning and identifying potential problems.

For example, if a meter malfunctions, we can quickly access its entire history to diagnose the issue and plan repairs. This systematic approach minimizes downtime and ensures accurate billing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with communication systems related to meter data transmission?

My experience encompasses a range of communication systems used for meter data transmission. These range from traditional methods to sophisticated smart grid technologies.

Traditional Methods: I’m proficient in handling manual meter readings and data transfer via phone lines or dedicated data lines. This includes understanding data formats and troubleshooting connectivity issues.

Advanced Metering Infrastructure (AMI): I have extensive experience with AMI systems, including cellular, power-line, and radio frequency (RF) communication technologies. This involves installing, configuring, and troubleshooting these systems, ensuring reliable and secure data transmission.

Data Management Systems: I’m familiar with various software platforms used to collect, store, and analyze data from smart meters. This includes understanding data protocols and working with data visualization tools.

For instance, I once successfully resolved a widespread communication outage by identifying a faulty cellular repeater in a remote area. This was done using diagnostic tools and working closely with the communications team. In addition, I’m adept at handling the security concerns associated with wireless data transmission to prevent unauthorized access.

Q 17. Describe your experience with working independently and as part of a team.

I thrive both independently and as part of a team. Independent work requires self-motivation and problem-solving skills, which I’ve honed through years of experience troubleshooting complex meter issues in remote locations. Teamwork involves effective collaboration and communication to ensure projects are completed efficiently and accurately.

Independent Work: I’m comfortable working on individual tasks, prioritizing my workload, and managing my time to meet deadlines. An example would be conducting a scheduled meter inspection and repair in a remote area, requiring self-sufficiency in problem-solving and decision-making.

Teamwork: I actively participate in team discussions, sharing my expertise and contributing to shared goals. One example was coordinating a large-scale meter upgrade project with a team of engineers, technicians, and project managers. This necessitated effective communication and collaboration to manage logistics and deadlines.

My strength lies in effectively balancing both independent work and teamwork to maximize efficiency and effectiveness. I can work independently to troubleshoot intricate problems then share my solutions with the team to ensure consistent processes and knowledge sharing.

Q 18. How do you prioritize tasks and manage your time effectively?

Effective task prioritization and time management are essential in my role. I utilize a combination of techniques to optimize my workflow.

Prioritization: I employ methods such as the Eisenhower Matrix (urgent/important), prioritizing tasks based on their impact and urgency. This ensures that critical tasks are addressed promptly. For example, urgent repairs take precedence over routine maintenance.

Time Management: I utilize scheduling tools and techniques, such as time blocking, to allocate specific time slots for different tasks. This helps to maintain focus and avoid disruptions.

Planning: I carefully plan my daily and weekly activities, taking into account travel time, potential delays, and unexpected issues. This proactive approach helps to avoid unnecessary delays.

For instance, during peak installation season, I carefully prioritize installation based on customer needs and deadlines, ensuring timely completion while maintaining accuracy. This strategic approach minimizes delays and ensures customer satisfaction.

Q 19. What are your problem-solving skills when dealing with complex meter issues?

Problem-solving is a cornerstone of my work. When facing complex meter issues, I follow a structured approach:

Identify the Problem: I begin by gathering information, conducting thorough inspections, and analyzing data to pinpoint the root cause of the problem. This often involves checking meter readings, examining wiring, and testing connections.

Develop Solutions: Once the problem is identified, I brainstorm potential solutions, considering factors like cost, safety, and the impact on service.

Implement and Test: I implement the chosen solution, carefully documenting each step. After implementation, I conduct rigorous testing to ensure the problem is resolved and the meter is functioning correctly.

Document and Report: Finally, I meticulously document the entire process, including the problem, solution, and test results. This information is critical for future reference and troubleshooting.

For example, I recently resolved a complex issue involving intermittent meter readings by systematically checking the wiring, identifying a loose connection, and subsequently repairing it. This systematic approach prevented further downtime and ensured accurate meter readings.

Q 20. Describe your experience with customer interaction and communication.

Effective customer interaction is vital. I strive to provide exceptional service through clear communication, empathy, and professionalism.

Clear Communication: I explain technical issues in a simple, understandable manner, avoiding jargon. I actively listen to customer concerns and answer questions patiently and thoroughly.

Empathy: I understand that meter issues can be frustrating, and I approach each interaction with empathy and a desire to resolve the problem quickly and efficiently.

Professionalism: I maintain a professional demeanor at all times, representing my company positively. I keep customers informed of progress and proactively address any concerns.

I recall a situation where a customer was experiencing unusually high electricity bills. Through clear and patient communication, I discovered a faulty appliance was responsible, saving the customer both money and stress. This positive interaction reinforced the importance of effective customer communication.

Q 21. How familiar are you with different types of meter enclosures and their installation?

I’m familiar with a wide variety of meter enclosures and their installation requirements, ensuring proper protection and safe operation of meters.

Pad-Mounted Enclosures: These are common for larger meters, requiring knowledge of grounding, bonding, and proper placement for accessibility and environmental protection.

Wall-Mounted Enclosures: These are more common in residential settings and require attention to proper mounting techniques, weatherproofing, and compliance with building codes.

Underground Enclosures: These require specialized knowledge of excavation, conduit installation, and ensuring proper sealing and waterproofing to prevent water damage.

Specialized Enclosures: I have experience with specialized enclosures for hazardous locations, requiring knowledge of safety regulations and appropriate materials.

For example, when installing a meter in a flood-prone area, I would select a waterproof enclosure and use appropriate sealing techniques to prevent damage. Knowledge of diverse enclosure types and installation practices allows me to ensure meters are adequately protected and operate reliably in various environments.

Q 22. What is your experience with preventative maintenance on various types of meters?

Preventative maintenance on meters is crucial for ensuring accuracy, reliability, and longevity. My experience encompasses a wide range of meter types, including electromechanical, electronic, smart meters (both AMI and AMR), and water meters. A comprehensive preventative maintenance program typically includes:

Regular Inspections: Visual checks for damage, corrosion, tampering, and loose connections. I’d check for things like broken seals, unusual readings, or signs of external interference.

Calibration and Testing: Using specialized equipment, I’d verify the meter’s accuracy against known standards. This involves comparing the meter’s readings to a known calibrated source, ensuring it’s functioning within acceptable tolerances. For example, a slight drift in an electronic meter’s reading over time would be identified and addressed.

Cleaning: Removing dirt, debris, or insects that might obstruct operation, especially important for mechanical meters.

Software Updates (for smart meters): Keeping the firmware up-to-date ensures optimal performance, security patches, and new features. This often involves remote updates, but sometimes requires on-site work.

Data Logging Review: Analyzing historical data from the meter to identify patterns or anomalies that might indicate impending failure. A sudden jump in energy consumption, for instance, could flag a problem.

For example, in one project, preventative maintenance on a large bank of old electromechanical meters prevented a significant outage by identifying and replacing several meters nearing the end of their lifespan before they failed completely.

Q 23. How do you identify and address potential hazards during meter installations?

Safety is paramount during meter installations. My approach involves a multi-step process to identify and mitigate potential hazards:

Site Assessment: Before commencing any work, I conduct a thorough site survey to identify potential risks, including overhead power lines, underground utilities, hazardous materials, and environmental factors (e.g., weather conditions). This often involves using utility locators to pinpoint buried cables and pipes.

Lockout/Tagout Procedures: Following strict lockout/tagout procedures to de-energize circuits and prevent accidental electrical shocks. This is especially crucial when working with electrical meters.

Personal Protective Equipment (PPE): Utilizing appropriate PPE, including safety glasses, gloves, hard hats, and high-visibility clothing, as per the specific requirements of the job and safety regulations.

Traffic Control (if necessary): Implementing traffic control measures to ensure the safety of both the installation crew and the public, especially in busy areas.

Emergency Response Plan: Having a pre-planned emergency response strategy in place to handle unforeseen incidents, including emergency contacts and procedures.

For instance, during a recent installation near a busy highway, we implemented a traffic management plan to ensure the safety of our team and the motorists. This involved flaggers, warning signs, and temporary lane closures.

Q 24. What is your understanding of the lifecycle of a meter, from installation to decommissioning?

The lifecycle of a meter begins with its design and manufacturing, followed by installation, operation, maintenance, and ultimately, decommissioning.

Installation: This involves carefully connecting the meter to the service line, ensuring proper grounding, and testing for correct operation. The location should be easily accessible for maintenance and readings.

Operation: This is the active phase where the meter records consumption data. Regular monitoring and preventative maintenance are key to ensure accurate readings.

Maintenance: This phase includes regular inspections, calibrations, repairs, and replacements as needed. This extends the operational life of the meter.

Decommissioning: When a meter reaches the end of its lifespan or is replaced, it needs to be decommissioned safely and properly disposed of, adhering to environmental regulations. This may include removing the meter from service, securely disabling it, and properly disposing of any hazardous components.

Understanding each stage is critical for cost-effective management. For example, prioritizing preventative maintenance during the operational phase can significantly extend a meter’s lifespan, delaying the need for costly replacements.

Q 25. How do you ensure compliance with all relevant regulations and standards?

Compliance is a top priority. My work always adheres to relevant regulations and standards, including but not limited to:

National Electrical Code (NEC): For electrical meter installations, ensuring all wiring and connections meet NEC standards for safety.

Local Building Codes: Adhering to any local regulations governing meter installations and locations.

Manufacturer’s Specifications: Following the manufacturer’s guidelines for installation, maintenance, and operation of specific meter types.

Occupational Safety and Health Administration (OSHA) Regulations: Complying with all relevant OSHA regulations to ensure a safe working environment.

Environmental Regulations: Proper handling and disposal of any hazardous materials associated with meter installation and decommissioning.

Regular training and updates on relevant standards are crucial to maintaining compliance. For example, we recently completed training on the latest NEC updates impacting smart meter installations.

Q 26. Describe your experience troubleshooting meter communication issues.

Troubleshooting meter communication issues requires a systematic approach. My experience includes working with various communication protocols (e.g., cellular, RF, power line communication) used in smart metering systems.

Signal Strength Check: Measuring the signal strength at the meter to identify weak signals. This might involve using a signal analyzer or dedicated communication testing equipment.

Network Connectivity: Verifying network connectivity using ping tests or other network diagnostic tools to determine if the problem lies within the meter or the network infrastructure.

Data Log Analysis: Examining the meter’s data logs for error messages or events that might indicate communication problems.

Hardware Inspection: Physically inspecting the meter’s communication hardware, such as antennas and connections, for damage or faults.

Software Diagnostics: Running diagnostic software on the meter to identify and resolve any software-related communication issues. This may involve remote access or on-site intervention.

For example, I recently resolved a communication issue with a smart meter by identifying a loose antenna connection. A simple fix, but it highlighted the importance of thorough inspection.

Q 27. How do you handle emergency repairs and meter failures?

Emergency repairs and meter failures demand immediate action. My process involves:

Prioritization: Quickly assess the urgency of the situation, prioritizing critical failures affecting service to customers.

Safety First: Ensuring the safety of personnel and the public before starting any repair work.

Rapid Response: Deploying resources quickly to address the issue, possibly involving dispatching a specialized team.

Temporary Solutions: If a full repair isn’t immediately feasible, implementing temporary solutions to restore service while awaiting parts or specialized equipment.

Root Cause Analysis: After resolving the immediate issue, conducting a thorough root cause analysis to prevent future occurrences.

Documentation: Meticulously documenting all emergency repair activities, including the problem, the solution, and any preventative measures taken.

In one instance, we had a sudden, widespread outage due to a faulty transformer affecting multiple meters. Our quick response, prioritizing safety and using temporary power solutions, minimized the impact on our customers.

Q 28. What is your experience with using diagnostic tools for meters?

I have extensive experience with various diagnostic tools used for meters. These tools are critical for troubleshooting, preventative maintenance, and data analysis. Examples include:

Multimeters: For basic electrical measurements, such as voltage, current, and resistance.

Clamp Meters: To measure current without breaking the circuit.

Communication Testers: To test the communication signals between the meter and the central system, often used for smart meters.

Specialized Meter Test Equipment: Manufacturer-specific tools for testing various aspects of meter performance, including accuracy and functionality.

Data Acquisition Systems: To collect and analyze data from multiple meters simultaneously.

Using these tools allows for efficient diagnosis and targeted repairs. For instance, a communication tester can quickly pinpoint a problem with a smart meter’s communication module, reducing downtime and repair costs.

Key Topics to Learn for Meter Installation and Maintenance Interview

- Meter Types and Technologies: Understanding different meter types (e.g., electric, gas, water) and their underlying technologies (e.g., smart meters, AMR systems) is crucial. Be prepared to discuss their functionalities and limitations.

- Installation Procedures and Safety Regulations: This includes knowledge of proper installation techniques, adherence to safety protocols (e.g., lockout/tagout procedures), and compliance with relevant codes and standards. Think about explaining a typical installation process step-by-step.

- Troubleshooting and Repair: Discuss common meter malfunctions, diagnostic techniques, and repair procedures. Be ready to explain your problem-solving approach in a practical scenario.

- Calibration and Testing: Understand the importance of accurate meter calibration and testing methods to ensure precise readings. Consider the different tools and equipment used in this process.

- Data Management and Reporting: Familiarize yourself with data logging procedures, reporting requirements, and how meter data is used for billing and analysis. This might involve discussing software or systems used in this process.

- Preventive Maintenance and Scheduling: Discuss the importance of routine maintenance, identifying potential issues before they become major problems, and creating efficient maintenance schedules.

- Health and Safety: Demonstrate a strong understanding of relevant safety regulations, personal protective equipment (PPE), and risk assessment procedures related to meter installation and maintenance.

Next Steps

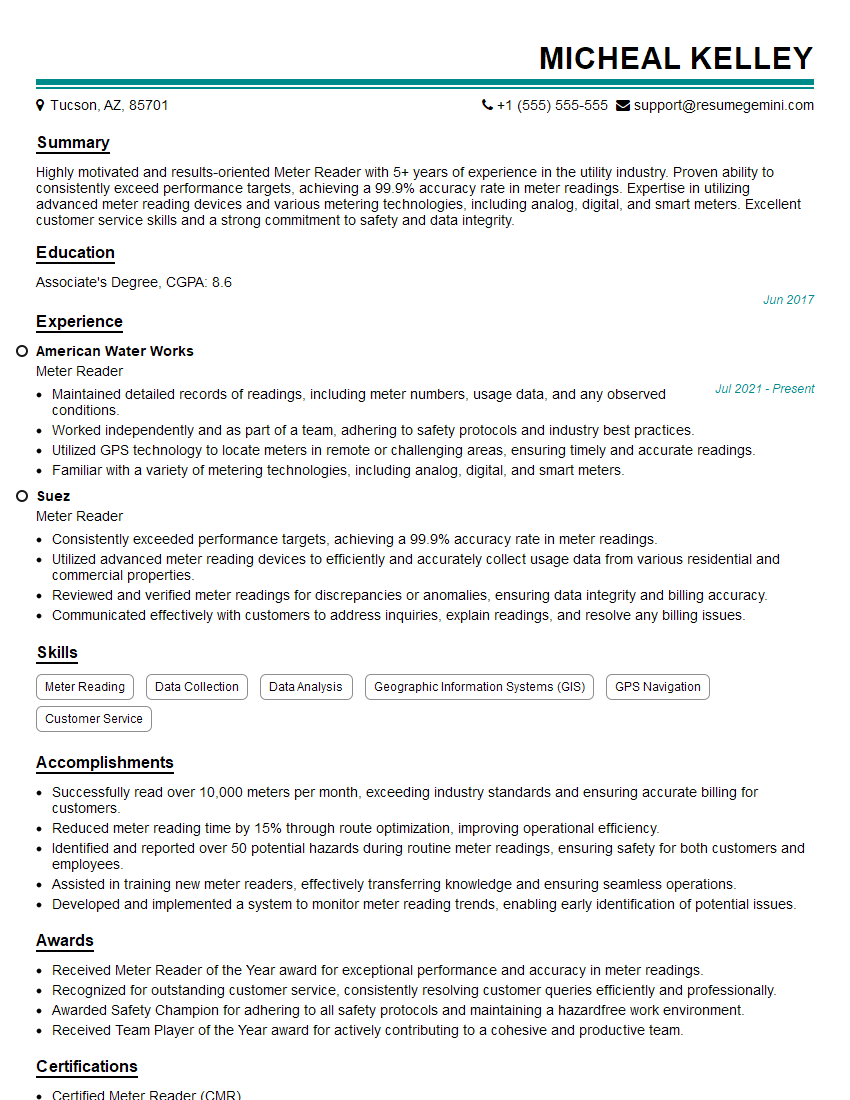

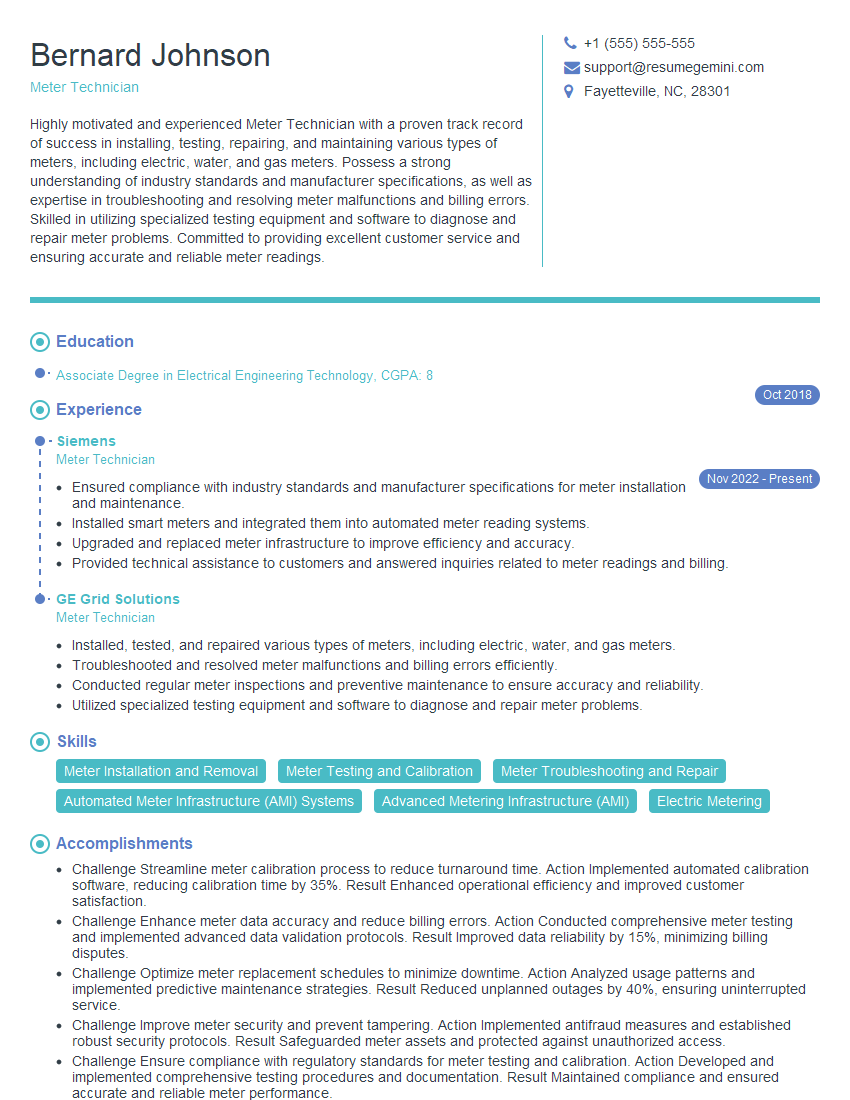

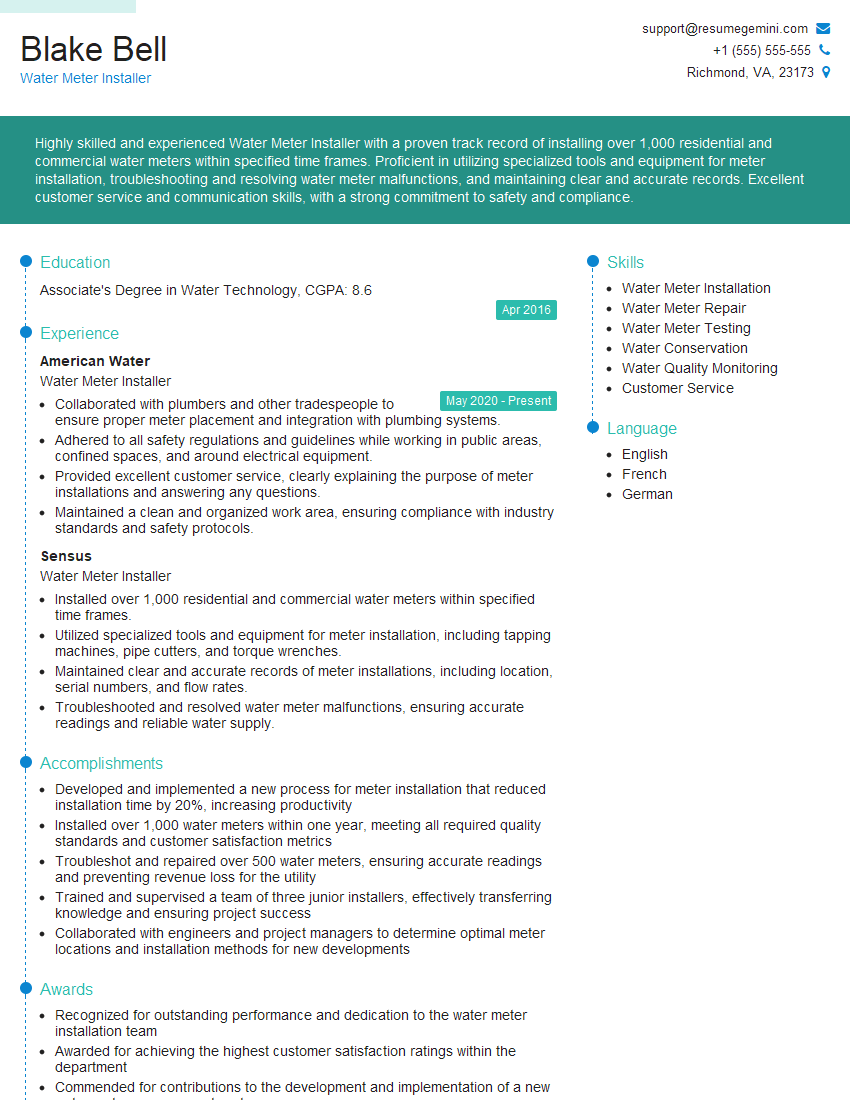

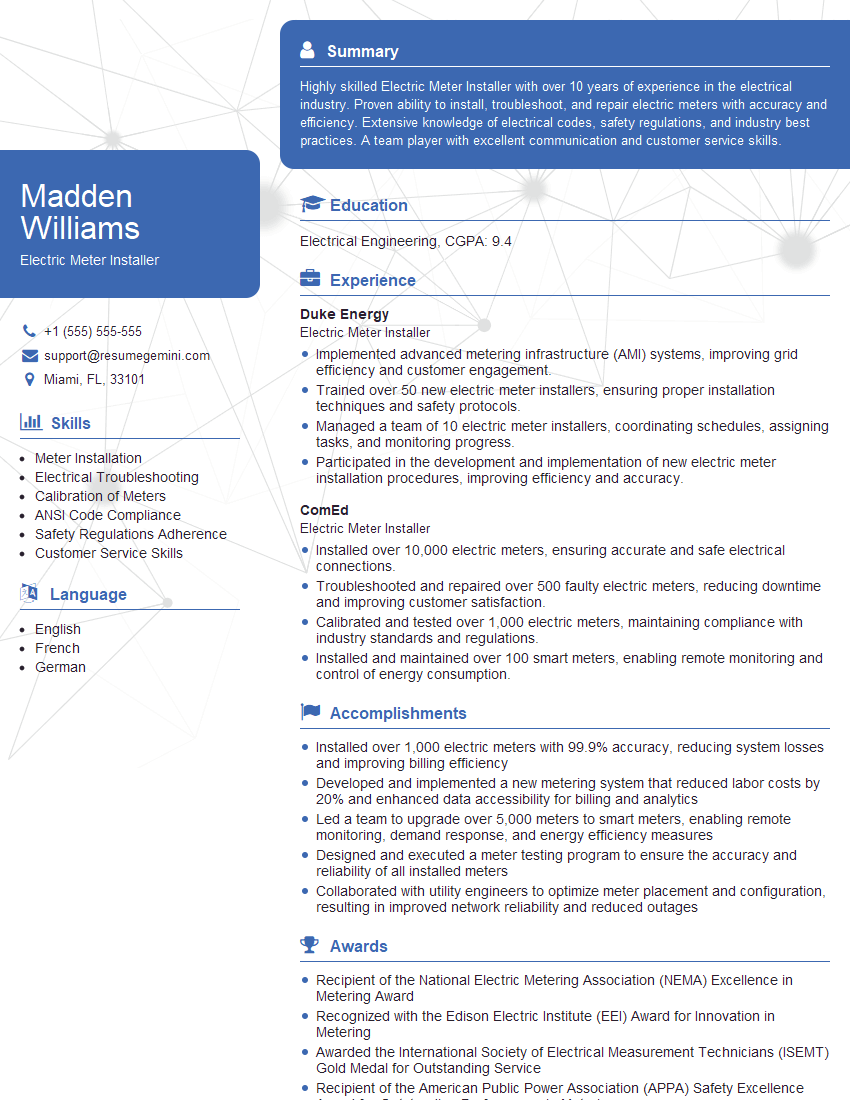

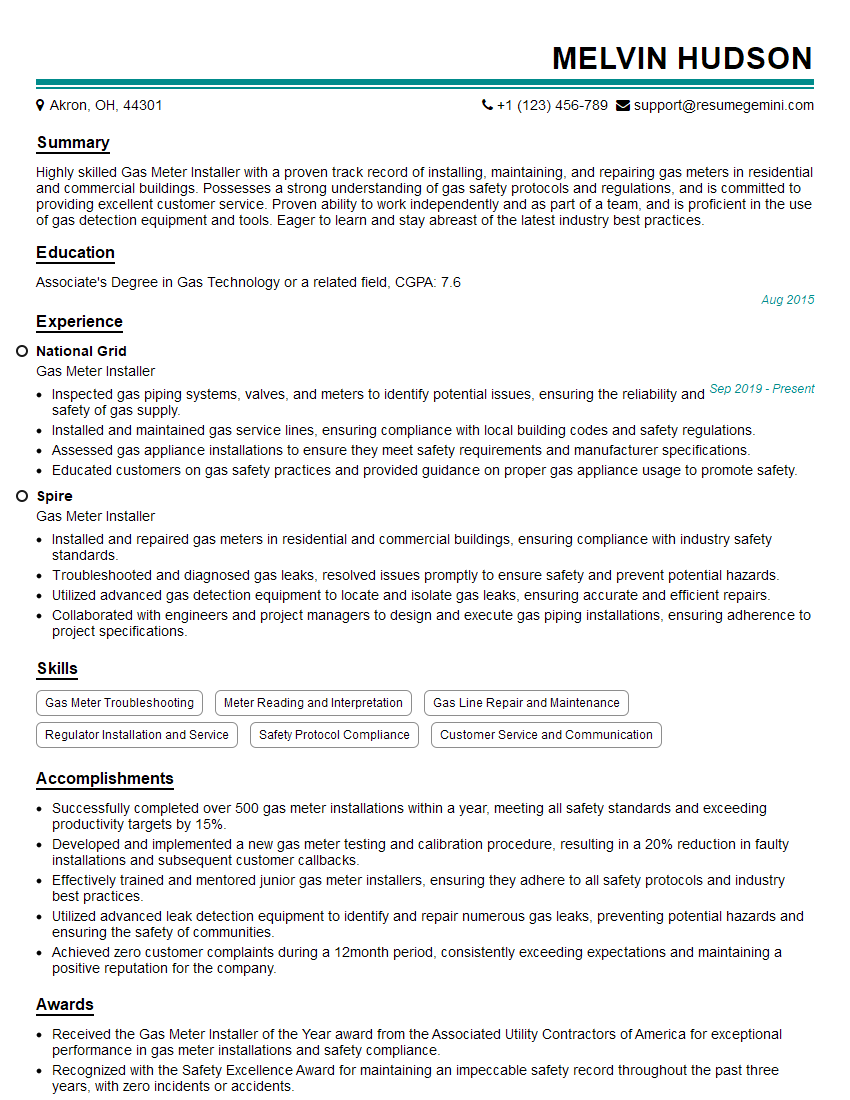

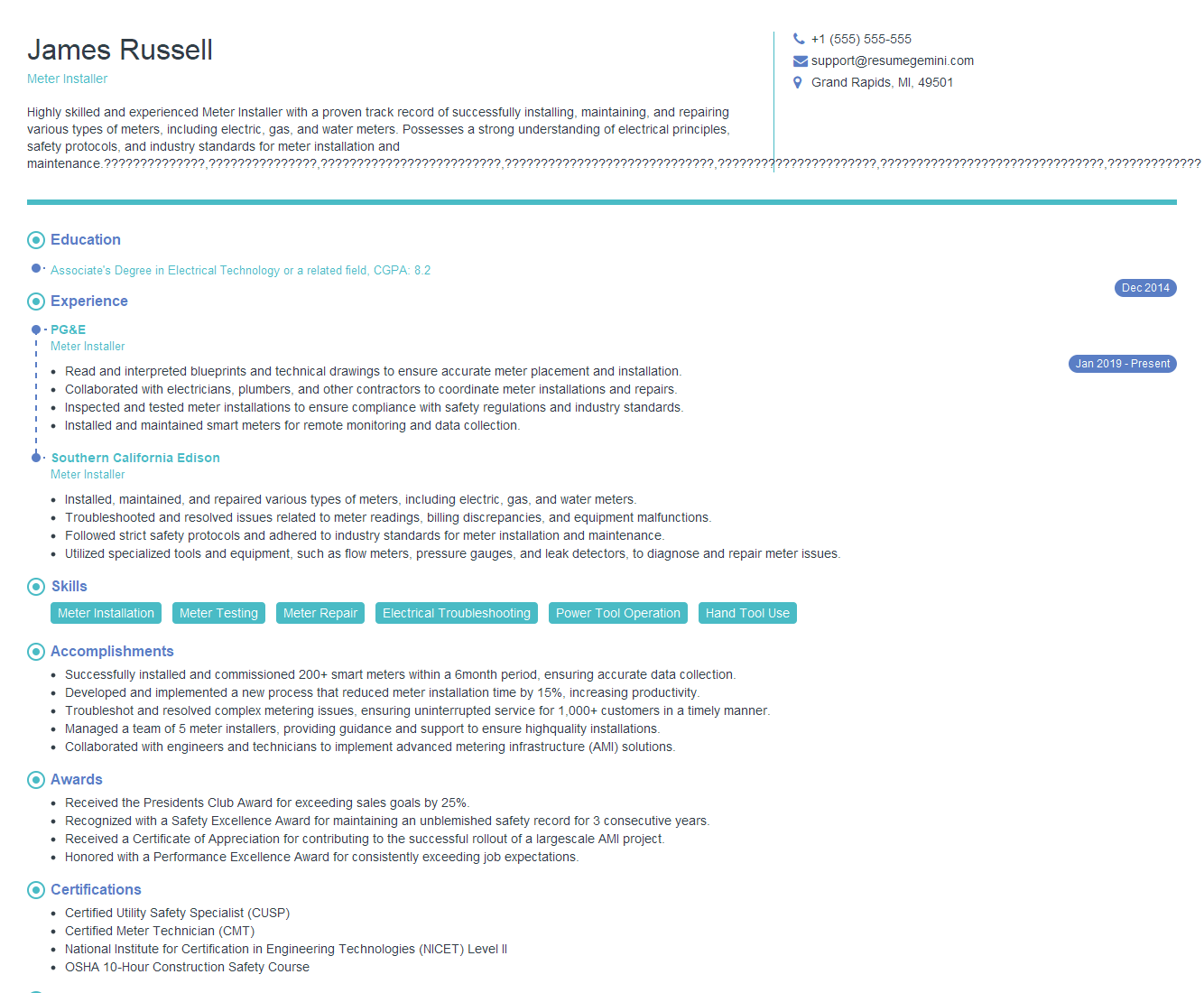

Mastering Meter Installation and Maintenance opens doors to a rewarding career with excellent growth potential. Demand for skilled technicians is high, offering opportunities for advancement and specialization. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Meter Installation and Maintenance are available to guide you, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good