Preparation is the key to success in any interview. In this post, we’ll explore crucial Custom Pressing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Custom Pressing Interview

Q 1. Describe your experience with different types of pressing equipment.

My experience with pressing equipment spans a wide range, from basic steam irons and hand-held garment steamers to industrial-grade pressing machines like professional steam presses, vacuum presses, and sleeve presses. I’m proficient in using both analog and digitally controlled models, understanding the nuances of each type. For example, a steam press is excellent for achieving a crisp, flat finish on larger garments like shirts and jackets, while a vacuum press is ideal for delicate fabrics or those requiring a truly wrinkle-free finish by removing excess moisture. Sleeve presses are specialized tools designed for achieving that perfect crease on sleeves and trouser legs. My familiarity extends to understanding the different pressure settings, steam output adjustments, and temperature controls on each machine, crucial for achieving consistent results across various fabrics.

Q 2. What are the common fabrics you’ve worked with and their specific pressing requirements?

I’ve worked extensively with a diverse range of fabrics, each with unique pressing needs. For instance, linen, a naturally crisp fabric, requires a high temperature and plenty of steam to smooth wrinkles and remove creases. Cotton, on the other hand, is more forgiving and can tolerate various pressing temperatures depending on its weight and weave. Silk, a delicate fabric, necessitates lower temperatures and a pressing cloth to protect it from scorching. Wool is best pressed with a light touch, usually with steam, and often requires a press cloth to prevent shiny marks. Synthetics can vary widely; some are heat-resistant while others can melt or scorch easily. I always perform a test press on a hidden seam allowance before starting to ensure I’ve selected the correct temperature and approach for the specific fabric.

Q 3. Explain your process for pressing delicate fabrics.

Pressing delicate fabrics requires extra care and precision. My process typically involves using a low to medium temperature setting, always utilizing a pressing cloth between the iron or press and the garment. This prevents direct heat contact and potential damage. I also prefer to work on the wrong side of the fabric whenever possible. For highly delicate items like lace or silk chiffon, I might even opt for a hand-held steamer, holding it several inches away and gently steaming the fabric to lift wrinkles without direct contact. Patience is key—slow, even movements are vital to avoid stretching or damaging the fabric. I often work in small sections, constantly checking for any signs of scorching or damage. If a garment calls for specific pressing instructions, I always follow those diligently.

Q 4. How do you identify and address pressing-related defects in garments?

Identifying pressing defects involves careful inspection of the garment after pressing. Common issues include scorch marks (shiny spots or discoloration), creases in the wrong places, puckers or wrinkles, and uneven finishes. Addressing these defects depends on their severity and the fabric. Minor wrinkles can usually be corrected with a quick touch-up using a steam iron. Scorch marks, however, are generally irreversible and may necessitate re-pressing with a pressing cloth or, in severe cases, repair. Uneven pressing often points to inconsistent technique, requiring re-pressing with more attention to detail. Pucker formation may indicate pressing too harshly or using the incorrect temperature, necessitating a gentler approach or temperature adjustment for subsequent presses.

Q 5. What safety procedures do you follow when operating pressing equipment?

Safety is paramount when operating pressing equipment. I always ensure the equipment is unplugged when not in use and the iron or press is completely cool before handling. I never leave hot irons or presses unattended and always use caution when handling hot surfaces. I wear heat-resistant gloves when needed, especially when working with heavy-duty industrial presses. Appropriate ventilation is essential to avoid inhaling excess steam. Regular inspections of the equipment for any signs of damage or malfunction are performed. Lastly, I always follow the manufacturer’s safety instructions and guidelines.

Q 6. How do you maintain pressing equipment to ensure optimal performance?

Maintaining pressing equipment is crucial for optimal performance and longevity. This includes regular cleaning of the soleplate or pressing surface, removing any build-up of starch, lint, or other residues. I also regularly descale and clean the water reservoir to prevent mineral deposits that can clog steam jets and reduce efficiency. For industrial presses, I perform periodic checks on pressure gauges, steam generators, and safety mechanisms. Lubricating moving parts, as per the manufacturer’s instructions, and checking electrical connections are also part of routine maintenance. Addressing any issues promptly is crucial to prevent larger problems and ensure that the equipment functions optimally for years to come.

Q 7. Describe your experience with different pressing techniques (e.g., blocking, pleating).

My experience encompasses a variety of pressing techniques. Blocking, for instance, is used to create crisp, structured shapes, particularly useful with structured garments or those with stiff fabrics. It involves applying pressure and steam to specific areas to create a defined form. Pleating is another specialized technique, usually requiring a specialized pleating machine or board to create precise, consistent folds. This may involve pressing the pleats individually or using a press to create multiple pleats simultaneously. I’m skilled at tailoring my pressing techniques to the garment’s design, fabric, and desired outcome, always employing the most appropriate method to achieve a flawless finish.

Q 8. How do you ensure consistent pressing quality across multiple garments?

Maintaining consistent pressing quality across multiple garments hinges on standardization and meticulous attention to detail. Think of it like baking a cake – you need the same recipe and oven temperature each time to get the same result. In pressing, this means establishing consistent pressing parameters for each fabric type and garment style.

- Pre-Pressing Preparation: Always start with clean, pre-treated garments. Any stains or wrinkles should be addressed before pressing to avoid setting them.

- Consistent Temperature and Pressure: Use a calibrated press with consistent temperature and pressure settings for each fabric type. This is crucial; using too much heat can scorch delicate fabrics, while insufficient heat won’t remove wrinkles effectively. I always have a temperature chart tailored to various fabrics.

- Proper Pressing Techniques: Follow a standardized pressing sequence for each garment type. For example, pressing seams open first ensures a flat, smooth finish. This sequence should be documented and followed diligently by all pressers.

- Regular Machine Maintenance: Regular cleaning and maintenance of the pressing equipment, including cleaning the press head and checking steam pressure, is vital for maintaining consistent performance. A poorly maintained machine can lead to inconsistent heat distribution.

- Quality Control Checks: Implement regular quality checks at various stages of the process. This includes visually inspecting garments after pressing for any imperfections and establishing clear criteria for acceptable quality.

For example, when pressing a batch of cotton shirts, I’d start by setting the press to a specific temperature and pressure based on the fabric weight. I’d then press each shirt using the same technique—ensuring the seams are open, and the collar and cuffs receive appropriate attention.

Q 9. Explain your understanding of fabric shrinkage and how to mitigate it during pressing.

Fabric shrinkage is the reduction in fabric dimensions due to the relaxation of fibers after being subjected to heat and moisture. Imagine a tightly wound spring—when heated and wet, the fibers loosen and the fabric shrinks. This can lead to significant problems with garment fit and dimensions.

- Pre-Shrinking: The most effective method is pre-shrinking the fabric before cutting and sewing. This involves washing the fabric in the appropriate manner (according to its care label), drying, and then pressing it. This pre-emptive measure ensures that any shrinkage occurs before garment construction.

- Careful Steam Application: When pressing finished garments, avoid excessive steam and heat, especially with fabrics prone to shrinkage like wool or silk. Use a lower temperature and less steam and always press from the wrong side of the garment.

- Controlled Drying: Ensure proper drying after washing to minimize shrinkage. Avoid using high heat in dryers and opt for air drying or low-heat settings whenever possible.

- Fabric Selection: Selecting pre-shrunk or low-shrinkage fabrics can greatly reduce shrinkage issues.

I once encountered a batch of wool trousers that shrunk significantly after pressing. We found out that the pre-shrinking step had been skipped. That experience reinforced the importance of adhering to all the steps, especially for delicate or high-risk fabrics.

Q 10. How do you handle pressing garments with intricate details or embellishments?

Pressing garments with intricate details or embellishments requires a delicate touch and specialized techniques. It’s like working with a masterpiece; you need to handle it with care to preserve its beauty.

- Protective Materials: Always use protective materials such as press cloths and tailor’s ham (a specialized pressing tool) to protect delicate embellishments and prevent scorching or damage.

- Low Pressure and Temperature: Use lower heat and pressure settings to prevent damage to the embellishments. This protects delicate beads, sequins, and embroidery.

- Targeted Pressing: Focus on pressing around the embellishments instead of directly on them. You may need to use a smaller press or even a hand iron to reach those areas precisely.

- Blocking Techniques: Blocking techniques can be useful to shape the area around embellishments, helping them stay in place.

- Testing on a Scrap: Before working on the garment itself, always test your pressing techniques on a scrap piece of fabric to avoid causing damage to the garment.

For instance, when pressing a dress with delicate lace trim, I would use a press cloth and tailor’s ham to support the fabric while pressing carefully around the lace, never directly on it. I would also use a lower temperature and pressure than I would for the main fabric.

Q 11. Describe your experience with steam pressing vs. dry pressing.

Both steam pressing and dry pressing have their applications, and the choice depends on the fabric type and desired outcome. Steam pressing uses moisture to relax fibers and remove wrinkles, while dry pressing relies solely on heat and pressure.

- Steam Pressing: Ideal for most fabrics, particularly those that are prone to wrinkles or require shaping. Steam helps relax fibers making pressing more efficient. However, steam is unsuitable for fabrics that are water-sensitive (like silk or wool), as it can cause shrinking or discoloration.

- Dry Pressing: Best for delicate fabrics like silk or acetate that shouldn’t be exposed to moisture. Dry pressing is also used for fabrics prone to water marks. However, it might not be as effective for removing stubborn wrinkles as steam pressing.

I usually prefer steam pressing for its efficiency, but I always switch to dry pressing when working with delicate or water-sensitive fabrics. It’s a versatile skill to have.

Q 12. What are the common causes of pressing-related quality issues and how do you prevent them?

Common pressing-related quality issues stem from several causes, many of which are preventable with careful attention to detail and regular maintenance.

- Scorch Marks: Caused by excessive heat or pressure; prevent by using the correct temperature settings for the fabric and avoiding prolonged contact with the pressing surface.

- Wrinkles and Creases: Often caused by insufficient heat, pressure, or improper pressing techniques; prevent with thorough pre-pressing and correct techniques.

- Water Marks: Result from using too much steam on sensitive fabrics or improper use of press cloths; prevent through careful steam application and the proper use of protective cloths.

- Shine: Excessive pressure can cause shine, especially on delicate fabrics; prevent by using lower pressure and appropriate press cloths.

- Uneven Pressing: Happens due to inconsistent pressure or technique; prevent through practice and standardized procedures.

To illustrate, scorch marks on a silk blouse are typically caused by applying too much heat, hence the importance of understanding fabric types and using appropriate temperatures.

Q 13. How do you adapt your pressing techniques to different garment styles?

Adapting pressing techniques to different garment styles involves understanding the unique construction and fabric properties of each garment. Think of it as tailoring your approach to each unique piece of art.

- Seams: Pressing seams open or to one side varies depending on the style. For example, pressing darts flat contributes to a smooth silhouette.

- Collars: Different collar types require specific pressing methods; a shirt collar needs a crisp edge, while a more relaxed style might require a softer press.

- Cuffs: The technique will differ if it’s a simple cuff or a more elaborate design. The goal is always to maintain the structural integrity of the garment.

- Pleats: Pressing pleats requires precise folding and pressing to create a sharp, clean finish.

- Hemlines: Whether it’s a simple hem or a more elaborate one, appropriate techniques must be followed to ensure a clean and professional finish.

For example, pressing a tailored suit jacket requires different techniques from pressing a casual cotton shirt. The suit jacket necessitates attention to shoulder pads, lapels, and darts to maintain a structured silhouette.

Q 14. What are your methods for troubleshooting common pressing machine malfunctions?

Troubleshooting pressing machine malfunctions requires a systematic approach and a good understanding of the machine’s mechanics. It’s similar to diagnosing a car problem—you need to systematically identify the root cause.

- Check the Power Supply: Begin by verifying that the machine is correctly plugged in and receiving power.

- Inspect the Heating Element: Check if the heating element is functioning correctly. If there’s an issue with heat generation, it may need professional repair.

- Examine the Steam System: If the machine uses steam, inspect the water reservoir and check the steam output. There may be blockages or a lack of water.

- Inspect the Pressure System: Problems with the pressure mechanism could involve faulty parts that need repair or replacement.

- Check for Mechanical Issues: Look for any signs of physical damage or loose components, such as loose screws or damaged hoses.

- Seek Professional Help: If the problem persists after basic troubleshooting, it is best to contact a qualified technician for professional repair.

For example, a sudden drop in steam pressure may indicate a problem with the boiler or a clogged steam vent. I would first check the water level and try cleaning the steam vent before calling a technician.

Q 15. How do you manage your workload and prioritize tasks efficiently during peak production?

During peak production, efficient workload management is crucial. I employ a multi-pronged approach. Firstly, I prioritize tasks based on urgency and deadline. This often involves using a Kanban-style system, either physically with a whiteboard or digitally, to visualize the workflow and identify bottlenecks. Secondly, I break down large tasks into smaller, manageable sub-tasks. This makes the overall workload less daunting and allows for better tracking of progress. Finally, I leverage any available resources – if possible, collaborating with colleagues on tasks where we can share the workload or seeking assistance with particularly time-sensitive jobs. For example, during a recent rush order for a high-end wedding dress collection, I prioritized the most intricate beading and lace work first, delegating simpler pressing tasks to a junior team member while maintaining oversight.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working under pressure and meeting deadlines.

Working under pressure and meeting deadlines is an integral part of this profession. I thrive in fast-paced environments, as my experience has honed my ability to remain calm and focused under pressure. For instance, when faced with a sudden influx of orders requiring urgent turnaround, I maintain a clear head by focusing on one task at a time, systematically working through the queue. I also proactively communicate any potential delays to relevant parties, keeping everyone informed. My methodical approach and attention to detail ensure that the quality of my work remains consistently high, even under pressure. I once successfully completed a large order for a fashion show only 24 hours before the event, demonstrating my ability to handle high-pressure situations effectively.

Q 17. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is not just about aesthetics; it’s about efficiency and safety. I follow a consistent cleaning routine at the end of each day, wiping down all surfaces, cleaning the pressing irons, and organizing pressing boards and other equipment. I also regularly maintain the iron’s cleaning and de-scaling process, following manufacturer recommendations. This helps prevent build-up that could damage garments or cause malfunctions. My organizational system involves strategically placing pressing boards and cloths within easy reach and using labeled containers to store smaller tools and accessories. This organized approach minimizes wasted time searching for equipment and prevents accidents.

Q 18. Explain your understanding of different pressing board types and their uses.

Different pressing boards cater to various fabric types and garment construction. For instance,

- Foam-padded boards: Ideal for general-purpose pressing, offering a soft surface that prevents harsh creases on delicate fabrics like silk or lace.

- Hard pressing boards: These provide a firm, flat surface, essential for sharp creases in heavier fabrics like linen or cotton. They are also great for pressing seams that require a crisp finish.

- Sleeve boards: Specifically designed for pressing sleeves and curved areas of garments, ensuring a smooth, even finish without creating creases in unwanted areas.

- Tailor’s ham: A curved, padded form used to shape and press curved garment sections like collars, lapels, and darts, producing a professional finish.

Q 19. What are the common types of pressing irons and their applications?

The choice of pressing iron depends on the job’s specifics.

- Dry irons: Most common for general-purpose pressing, these are versatile and suitable for various fabric types, provided the correct temperature is used.

- Steam irons: Offer steam functionality, excellent for removing wrinkles and relaxing fabrics. Steam is particularly useful for delicate fabrics and to smooth out pleats and creases without excessive pressure.

- Industrial Pressing Irons: Much larger and more powerful than household irons, these are often used in professional settings and provide consistent high heat and pressure ideal for high-volume pressing.

Q 20. How do you determine the appropriate temperature and pressure settings for various fabrics?

Determining the correct temperature and pressure is paramount to prevent fabric damage and achieve optimal pressing results. Fabric labels usually provide guidance, but experience is key. I always start with a lower temperature and apply light pressure, gradually increasing as needed. Heavier fabrics like denim or canvas require higher temperatures and firmer pressure compared to delicate fabrics like chiffon or silk. Testing on a scrap piece of the same fabric beforehand can be incredibly helpful – especially with unknown materials – as it allows for adjustments before applying the iron to the garment itself. For example, wool requires a medium temperature and light pressure to avoid shrinkage or shine, while linen requires a higher temperature and slightly more pressure for a crisp finish.

Q 21. Describe your experience using pressing aids like pressing cloths and seam rolls.

Pressing aids are crucial for achieving a professional finish and protecting delicate fabrics.

- Pressing cloths: Protect fabric surfaces from direct heat and prevent shine, especially useful with delicate fabrics and dark colours. I use a variety of cloths, including cotton, silk, and muslin, depending on the fabric being pressed.

- Seam rolls: Provide a firm, rounded surface for pressing seams and curved areas, ensuring a smooth and even finish without creating unwanted creases or ridges. They are indispensable when working with tailored garments.

Q 22. How do you ensure the longevity of pressed garments?

Ensuring the longevity of pressed garments hinges on understanding the fabric and applying the correct pressing techniques. Think of pressing like sculpting – you want to shape the garment without damaging the ‘clay’.

- Choosing the Right Temperature and Pressure: Using too high a temperature can scorch or melt delicate fabrics, while insufficient heat won’t set the creases properly. Different fabrics require different settings on the pressing equipment; silk needs a lower temperature than linen, for example.

- Using Pressing Cloths: Pressing cloths act as a buffer between the iron and the garment, preventing shine and protecting delicate fibers. A clean, damp press cloth is your best friend for most fabrics.

- Proper Technique: Pressing should involve gliding the iron smoothly, avoiding harsh pressure or lingering in one place. For instance, when pressing a seam, use a back-and-forth motion, ensuring even heat distribution.

- Appropriate Equipment Maintenance: A clean iron and well-maintained pressing equipment are crucial. Regular cleaning of the iron’s soleplate removes residue that can cause discoloration or damage.

- Correct Garment Handling: After pressing, garments should be hung or folded properly to prevent creasing. Avoiding harsh folding or crumpling is especially important for structured pieces.

By meticulously following these steps, we ensure garments maintain their shape and quality for a much longer time, extending the life of the garment beyond its initial wear.

Q 23. How do you handle customer requests or special instructions related to pressing?

Handling customer requests requires clear communication and a flexible approach. I always begin by carefully reviewing the instructions, asking clarifying questions if anything is unclear. It’s like interpreting a recipe – even a minor detail can drastically alter the final outcome.

- Clarification: If a client requests a ‘crisp’ finish on a cotton shirt but doesn’t specify the type of crispness, I would confirm if they want a very sharp crease or a slightly softer pressed look.

- Feasibility: I openly communicate if a request is not feasible, perhaps due to the fabric type or the complexity of the design. It’s better to manage expectations upfront than to risk producing subpar results.

- Collaboration: Often, customers are open to suggestions. If they request a specific finish that might damage the fabric, I offer alternatives that achieve a similar visual effect without compromising the garment’s integrity. For instance, I’d steer away from hard pressing a garment with delicate beading.

- Documentation: I maintain detailed records of all special instructions to ensure consistent execution and easy reference for future orders.

Effective communication and a proactive approach ensure that the finished garment perfectly matches the customer’s expectations, strengthening client relationships.

Q 24. What are your strategies for improving pressing efficiency and productivity?

Improving pressing efficiency and productivity requires a combination of optimized processes and skilled execution. It’s like running a well-oiled machine – every component needs to work in harmony.

- Workflow Optimization: I streamline my workflow by organizing garments according to fabric type and pressing requirements. This eliminates unnecessary switching of iron temperatures and prevents delays.

- Equipment Upgrade: Investing in high-quality, ergonomic pressing equipment significantly reduces fatigue and enhances speed. A professional-grade iron, for instance, with a larger soleplate and better temperature control, saves valuable time and effort.

- Skill Enhancement: Continuous training and practice refine techniques and increase speed. Mastering shortcuts and efficient pressing methods, like using tailor’s ham and sleeve boards effectively, minimizes time and improves output.

- Quality Control Measures: Implementing a systematic quality check before packaging prevents rework and ensures client satisfaction. This is an ongoing process of refining quality control processes.

By implementing these strategies, we can maximize output without sacrificing the quality of our work, achieving both efficiency and excellence.

Q 25. Explain your understanding of different types of pressing finishes (e.g., sharp crease, soft drape).

Different pressing finishes create distinct looks. Think of it as a painter using different brushstrokes to achieve different textures.

- Sharp Crease: This requires high heat and firm pressure, resulting in a crisp, defined crease. This is ideal for garments that need strong structure, like tailored trousers or crisp shirts.

- Soft Drape: This is achieved using lower heat and lighter pressure, creating a gentler, more fluid appearance. This technique suits flowing fabrics like silk or rayon, where a sharp crease would appear harsh.

- Pleats: These need precise folding and application of heat to ensure even, uniform folds. The choice of pressing equipment matters significantly for proper pleat creation.

- Rounded Edges: This technique focuses on softening edges and corners to prevent a boxy appearance. Rounded edges are often preferred for garments that need a softer look and feel.

Understanding these distinctions allows us to tailor the pressing method to the garment’s design and fabric, producing the desired aesthetic effect.

Q 26. How do you handle pressing garments with various types of interfacing?

Pressing garments with various interfacings requires careful attention to avoid damaging the interfacing or the garment itself. Different interfacings react differently to heat and pressure.

- Fusible Interfacing: These interfacings can be easily damaged by too much heat, potentially causing them to melt or separate from the fabric. Low heat and a press cloth are essential.

- Non-Fusible Interfacing: These interfacings generally tolerate higher heat, but still, a press cloth is recommended to avoid scorching.

- Specific Interfacing Types: Some interfacings, like those containing wool or other natural fibers, are more sensitive to heat and may require more gentle pressing techniques.

- Testing: Whenever working with a new type of interfacing, it’s crucial to test the heat settings on a hidden area of the garment before pressing the entire piece.

By understanding the properties of different interfacings and adjusting our techniques accordingly, we prevent damage and ensure a professional finish. It’s all about recognizing and adapting to the unique characteristics of each material.

Q 27. Describe a time you had to solve a pressing-related problem creatively.

Once, I received a heavily beaded evening gown that had been severely creased during shipping. The beads were delicate and the fabric was silk, making traditional pressing methods risky. Simply ironing could damage the beads or leave shiny marks on the silk.

My solution involved using a low-heat steam setting combined with a light-weight pressing cloth, then gently lifting the creases using my fingers. I worked slowly and carefully, section by section. The use of a low-temperature steam worked to hydrate and relax the fibres, encouraging them to fall naturally into place. It was slower than using a regular iron and pressing cloth but it produced excellent results, successfully removing the wrinkles without damaging the delicate beads or the silk.

This experience highlighted the importance of thinking outside the box and tailoring my approach to the garment’s unique requirements. This creative problem-solving approach minimizes damage and produces perfect results in challenging situations.

Q 28. What are your career goals related to custom pressing?

My career goals focus on continuous growth and excellence in the field of custom pressing. I want to continue honing my skills and refine my techniques, becoming a master of my craft.

- Advanced Training: I plan to pursue advanced training in specialized pressing techniques, perhaps focusing on high-end couture or historical garment pressing.

- Mentorship: I aspire to mentor and train other professionals, sharing my knowledge and passion for quality craftsmanship.

- Innovation: I am interested in exploring the intersection of technology and pressing, researching new tools and techniques to enhance efficiency and precision.

- Industry Recognition: Ultimately, I want to become a recognized authority in the field, contributing to the advancement of custom pressing practices.

I believe in lifelong learning and continuous improvement, aiming to achieve mastery and make a lasting contribution to the profession.

Key Topics to Learn for Custom Pressing Interview

- Understanding Pressing Techniques: Explore various pressing methods, including steam pressing, dry pressing, and the appropriate selection based on fabric type and garment construction.

- Fabric Knowledge: Develop a strong understanding of different fabrics and their responses to heat and pressure. This includes identifying potential issues like shrinking, scorching, or unwanted sheen.

- Equipment Operation and Maintenance: Familiarize yourself with the operation and maintenance of industrial pressing equipment, including troubleshooting common malfunctions and ensuring safe operation.

- Quality Control and Inspection: Learn how to identify and correct pressing defects, ensuring high-quality finished garments. Understand industry standards for pressing quality.

- Production Processes and Workflow: Understand the role of pressing within the broader garment manufacturing process, including efficient workflow management and optimizing pressing techniques for speed and quality.

- Health and Safety Procedures: Understand and adhere to all relevant health and safety regulations related to operating pressing equipment and handling potentially hazardous materials.

- Problem-Solving and Adaptability: Be prepared to discuss your approach to problem-solving in pressing related scenarios, such as addressing inconsistent pressing results or adapting to new garment styles.

Next Steps

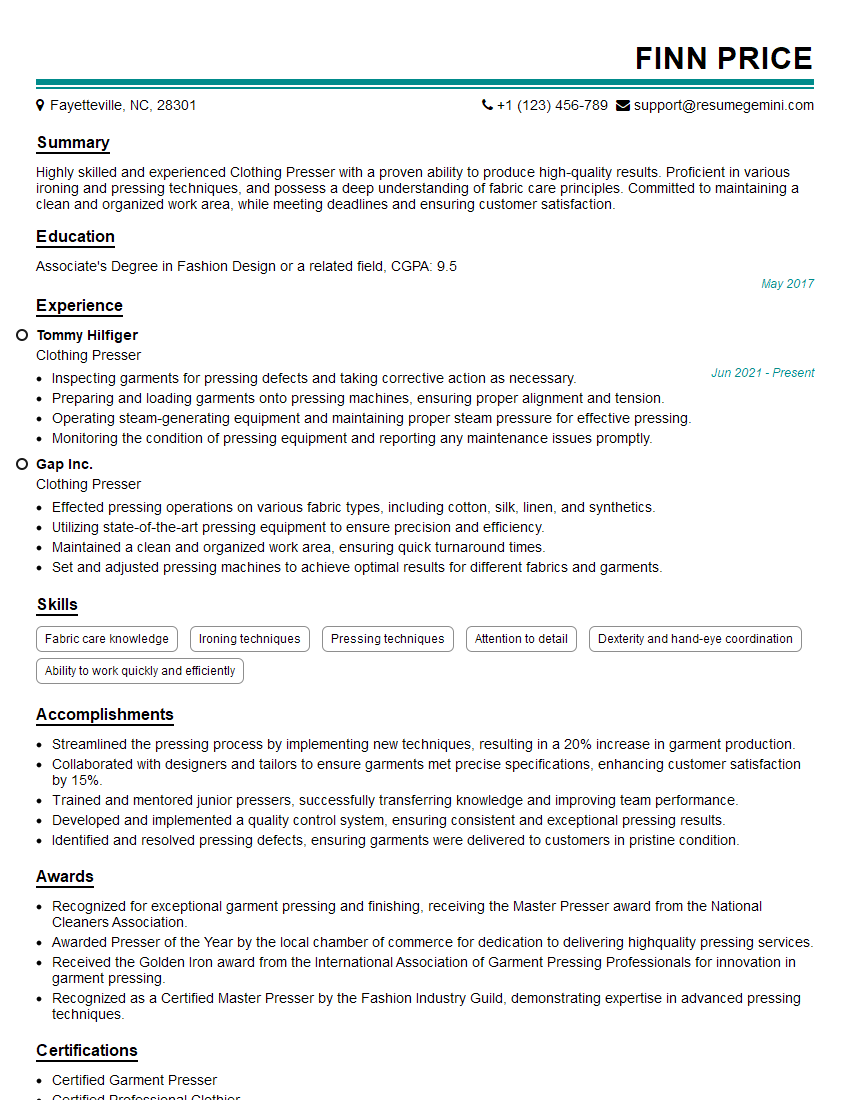

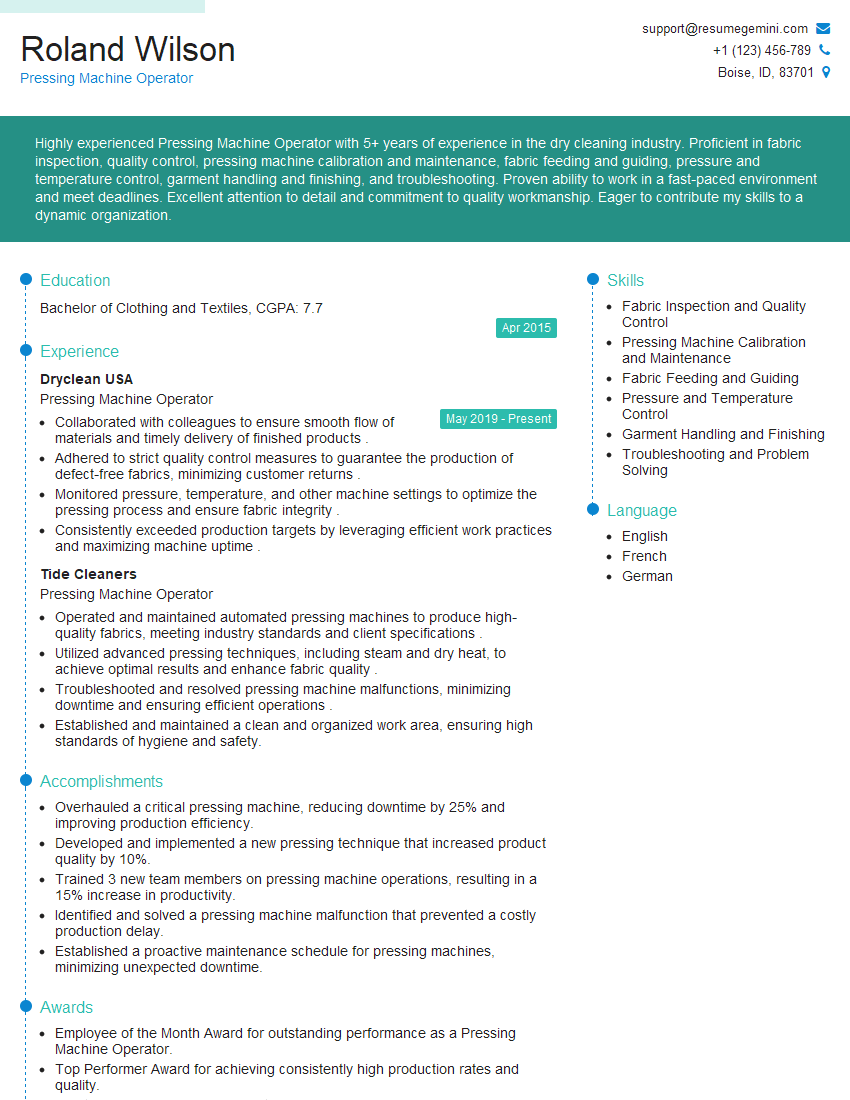

Mastering custom pressing techniques opens doors to exciting opportunities in the apparel industry, offering diverse roles with excellent growth potential. A strong understanding of this crucial skillset significantly enhances your marketability. To maximize your job prospects, it’s vital to create an ATS-friendly resume that highlights your abilities effectively. We highly recommend leveraging ResumeGemini to build a professional and compelling resume. ResumeGemini provides a streamlined process and offers examples of resumes tailored to the Custom Pressing field to help you present your skills in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good