Cracking a skill-specific interview, like one for Lift Operations, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Lift Operations Interview

Q 1. Describe your experience with different types of lift systems (hydraulic, traction, etc.).

My experience encompasses a wide range of lift systems, primarily hydraulic and traction lifts. Hydraulic lifts, which use a hydraulic cylinder to move the car, are commonly found in low-rise buildings due to their simpler design and lower initial cost. I’ve worked extensively on maintaining and repairing these systems, including troubleshooting issues with pumps, valves, and cylinders. I’m proficient in identifying leaks, replacing seals, and calibrating pressure systems. Traction lifts, on the other hand, utilize counterweights and a motor to operate the lift car, making them ideal for high-rise buildings. My experience with traction lifts includes working with gearless and geared systems, diagnosing motor issues, and understanding the intricacies of control systems, including VVVF (Variable Voltage Variable Frequency) drives. I’ve also had some exposure to machine-room-less (MRL) traction lifts, which offer space-saving advantages. In each case, my approach focuses on thorough understanding of the system’s mechanics and electrical components.

For example, in one instance, a hydraulic lift experienced frequent stops due to inconsistent pressure. Through methodical checks, I identified a faulty pressure relief valve, which I promptly replaced, restoring the lift’s functionality. In another instance, I diagnosed a problem with a traction lift’s VVVF drive through detailed analysis of the error codes and eventually replaced faulty IGBTs to resolve the issue.

Q 2. Explain the process of conducting a lift safety inspection.

A lift safety inspection is a crucial process that ensures the safe and reliable operation of the lift. It involves a systematic examination of all critical components and safety features. The process typically begins with a thorough visual inspection of the lift car, hoistway, and machinery room, checking for any signs of damage, wear, or corrosion. This includes checking cables for fraying or broken strands, examining the safety gear, such as governors and buffers, and verifying the proper functioning of the emergency stop buttons. Next, I perform operational checks, testing the lift’s smooth operation at various speeds and load capacities. I also verify the proper functioning of safety devices, like the overspeed governor and safety brakes. Documentation is key, and I carefully record all observations and findings, including any necessary repairs or replacements. This process adheres strictly to relevant safety regulations and standards.

For instance, I recently identified a severely corroded cable during a visual inspection – a potential safety hazard that was immediately addressed. Regular inspections like this prevent catastrophic failures and ensure passenger safety.

Q 3. How do you troubleshoot common lift malfunctions?

Troubleshooting lift malfunctions requires a systematic approach. I begin by carefully listening to the sounds the lift is making; unusual noises often indicate specific problems. I then systematically check each component based on the symptoms. For example, if the lift fails to start, I will check the power supply, control circuits, and the motor itself. If the lift is jerky or hesitant, this could indicate issues with the braking system or drive mechanisms. For hydraulic lifts, I’d look for leaks, examine the pump pressure, and verify the proper functioning of valves. For traction lifts, I might inspect the motor, brakes, and cables. Using diagnostic tools, such as multimeters and specialized lift diagnostic equipment, helps to pinpoint the exact problem. I meticulously document my findings and the steps I take to resolve the issue.

A recent case involved a lift that wouldn’t move beyond a certain floor. After thorough checks, I isolated the problem to a faulty floor-level sensor. After replacing the sensor, the lift worked perfectly.

Q 4. What are the key safety regulations and standards you adhere to?

My work adheres strictly to relevant safety regulations and standards, including [mention specific standards relevant to the location, e.g., ASME A17.1 in the US, EN 81 in Europe, etc.]. These standards provide a framework for safe lift design, installation, operation, and maintenance. They address aspects such as emergency stops, safety brakes, overspeed governors, and regular inspections. Adherence to these regulations is non-negotiable; passenger safety is paramount. I am also familiar with local building codes and regulations that may apply.

Q 5. Describe your experience with preventative maintenance on lifts.

Preventative maintenance is crucial for ensuring the longevity and safety of lift systems. My approach involves scheduled inspections and servicing according to the manufacturer’s recommendations and applicable safety standards. This includes lubrication of moving parts, visual inspections for wear and tear, cleaning, and testing of safety mechanisms. Regular maintenance prevents breakdowns, prolongs the lift’s lifespan, and minimizes costly repairs. I meticulously maintain detailed records of all maintenance activities, ensuring traceability and compliance with regulations.

A well-maintained preventative maintenance schedule greatly reduces the likelihood of unexpected breakdowns and ensures the lift remains in optimal operational condition, minimizing downtime and maximizing passenger safety.

Q 6. How do you handle emergency situations involving lift breakdowns?

Handling emergency situations involving lift breakdowns requires quick thinking and decisive action. My first priority is ensuring passenger safety. I follow established emergency procedures, immediately contacting emergency services if necessary. Depending on the nature of the breakdown, I may attempt to safely rescue passengers using appropriate procedures, such as using the emergency power supply or manual lowering mechanisms. I’ll also secure the lift to prevent further movement and inform building occupants of the situation. Post-incident investigation is crucial; I’ll conduct a thorough analysis of the cause of the breakdown and implement corrective measures to prevent future occurrences.

Safety is paramount in these scenarios. Following established emergency protocols ensures the safety of passengers and minimises the risk of accidents.

Q 7. What are your skills in diagnosing electrical and mechanical problems in lifts?

I possess strong skills in diagnosing both electrical and mechanical problems in lifts. My electrical diagnostics involve the use of multimeters, oscilloscopes, and specialized lift diagnostic tools to identify faults in control circuits, motor windings, and other electrical components. I can interpret error codes and schematics to troubleshoot complex electrical issues. Mechanically, I can identify problems with cables, gears, pulleys, brakes, and hydraulic systems through visual inspection, sound analysis, and operational testing. My experience allows me to quickly isolate the problem area and develop effective repair strategies. This includes understanding the interaction between the electrical and mechanical components in the lift system. I routinely identify and fix problems using both preventative and reactive strategies.

For example, my understanding of electrical systems and schematics allowed me to troubleshoot a short circuit in a complex control system, quickly identifying and resolving an issue that would have caused significant downtime.

Q 8. Explain the process of repairing a faulty lift door mechanism.

Repairing a faulty lift door mechanism requires a systematic approach, prioritizing safety and adherence to regulations. First, we must isolate the lift to prevent accidental operation. This usually involves switching off the power supply and applying appropriate lockout/tagout procedures. Then, a thorough visual inspection is crucial to pinpoint the exact cause of the malfunction. This might involve checking the door sensors, the locking mechanism, the hinges, and the operating cables for wear, damage, or misalignment. Common problems include faulty sensors (leading to door reopening unexpectedly), broken or worn rollers, and damaged cables.

The repair process itself will vary based on the specific problem. For instance, a faulty sensor might simply require replacement, while damaged rollers might need lubrication or replacement. More complex issues, like a damaged locking mechanism, might require more specialized tools and expertise. Throughout the process, we meticulously follow the manufacturer’s guidelines and relevant safety standards. Once the repair is complete, we conduct rigorous testing to ensure the door operates smoothly and safely, meeting all safety criteria before returning the lift to service. For example, we would test the door’s opening and closing mechanisms multiple times, ensuring that the safety features, such as the photocells, work correctly and prevent accidents. A final safety inspection is always performed before releasing the lift back into operation.

Q 9. How familiar are you with different lift control systems?

My experience encompasses a broad range of lift control systems, including traditional relay logic systems, microprocessor-based systems, and modern programmable logic controller (PLC) systems. I’m proficient in understanding the schematics and operating principles of each type. I’m familiar with the advantages and disadvantages of each: Relay logic systems, while simpler, require more wiring and maintenance; microprocessor-based systems offer improved diagnostics and flexibility; and PLC systems provide highly sophisticated control and monitoring capabilities, often integrated with building management systems (BMS). Furthermore, I understand the safety protocols and emergency shutdown mechanisms inherent in each system. For example, I’ve worked with systems incorporating fire service interfaces, ensuring safe evacuation during emergencies. My experience also extends to various communication protocols used in modern lift systems, including fieldbus systems and network technologies for remote monitoring and diagnostics.

Q 10. Describe your experience with lift modernization projects.

I’ve been involved in numerous lift modernization projects, ranging from small-scale upgrades to complete overhauls. My experience includes replacing obsolete components with modern, energy-efficient alternatives. This involves careful planning and execution, ensuring minimal disruption to building occupants. I’ve successfully upgraded control systems, improved safety features (such as adding emergency call buttons and improved lighting), and implemented modern destination dispatch systems to optimize efficiency. One notable project involved upgrading a bank of aging hydraulic lifts to a more efficient and environmentally friendly traction system. This required meticulous planning, careful coordination with contractors, and close communication with building management to minimize downtime. The project resulted in significant improvements in energy efficiency, operational reliability, and passenger comfort.

Q 11. What is your experience with hydraulic lift systems?

I have extensive experience with hydraulic lift systems, understanding their operation, maintenance, and troubleshooting. I’m familiar with various types of hydraulic systems, including those using direct-acting or indirect-acting hydraulic cylinders. My knowledge includes the maintenance procedures specific to these systems, such as checking oil levels, filter changes, and hydraulic pump inspections. Troubleshooting issues like leaks, low pressure, and slow operation is a routine part of my work. I understand the importance of regular maintenance in hydraulic systems to prevent catastrophic failures and ensure the safety and longevity of the equipment. For example, I’ve dealt with situations involving damaged hydraulic seals, where quick identification and repair prevented significant downtime and potential safety hazards.

Q 12. What is your experience with traction lift systems?

Traction lift systems represent a significant portion of my expertise. I’m well-versed in the intricacies of motor and gearbox maintenance, rope inspection and replacement (including the use of various rope inspection techniques), and the operation of safety devices like governors and brakes. I’m comfortable working with various traction machine designs, and I understand the importance of regular inspections to ensure the longevity and safety of the system. My experience also includes working with different types of traction sheaves and their associated maintenance requirements. One particular project involved diagnosing and repairing a traction system with a faulty governor, preventing a potentially dangerous situation. The repair involved carefully inspecting and replacing the faulty components, followed by thorough testing to ensure the system’s compliance with safety regulations.

Q 13. How do you handle a situation where a lift is stuck between floors?

A lift stuck between floors requires a calm and methodical response, prioritizing passenger safety. The first step is to assess the situation—check for any injuries, and reassure the trapped passengers. Next, I would contact emergency services and building management to inform them of the situation. Then, I would attempt to determine the cause of the malfunction through the lift’s control panel or any available communication systems. I would then use appropriate procedures to safely release the lift, which typically involves using the lift’s manual override system or external access to reset the system. Once the lift is freed, a thorough inspection is conducted to identify the root cause of the failure and prevent recurrence. Passenger safety and communication are paramount throughout the entire process. Documentation of the incident and the subsequent repair is crucial.

Q 14. What safety measures would you implement during a lift repair?

Safety is paramount during any lift repair. Before commencing work, we always implement a thorough lockout/tagout procedure to isolate the power supply, preventing accidental activation. This is accompanied by clearly visible signage warning others of the ongoing maintenance. We use appropriate personal protective equipment (PPE), such as safety harnesses, gloves, and eye protection, as needed for specific tasks. If working at heights, fall protection measures are mandatory. Regular risk assessments are conducted to identify and mitigate potential hazards. Furthermore, we strictly adhere to all manufacturer guidelines and relevant safety regulations. Proper handling and disposal of hazardous materials, such as oil and other chemicals, are also critical aspects of our safety procedures. Communication with building occupants and the maintenance team is maintained throughout the process, providing clear updates and addressing any concerns.

Q 15. Explain your understanding of the relevant codes and standards for lift safety.

Lift safety relies heavily on adherence to a comprehensive set of codes and standards. These vary by region but generally cover design, installation, testing, maintenance, and operation. Key standards often include those published by organizations like ASME (American Society of Mechanical Engineers) in the US, EN (European Norm) in Europe, and similar national or regional bodies. These standards dictate safety features like emergency stops, overspeed governors, buffer systems, and regular inspection procedures. For instance, ASME A17.1 covers the design and construction of elevators, while A17.3 covers the installation and maintenance aspects. Understanding these standards is crucial to ensuring the safe and reliable operation of lifts, preventing accidents, and complying with legal requirements. Failure to comply can result in severe penalties and legal action.

I’m proficient in interpreting and applying these standards, having personally ensured compliance in numerous projects. For example, on a recent project involving the modernization of a high-rise building’s lift system, I meticulously reviewed and implemented the latest ASME A17.1/CSA B44 standards to guarantee that all new components and modifications met the strictest safety requirements. This involved detailed documentation and rigorous testing at every stage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting control system issues.

Troubleshooting lift control system issues requires a systematic approach combining electrical and mechanical knowledge. My experience involves diagnosing problems ranging from simple sensor failures to complex software glitches. I typically start with a visual inspection, checking for loose connections, damaged wiring, or obvious mechanical problems. Then, I utilize diagnostic tools such as multimeters, oscilloscopes, and specialized lift control system software to pinpoint the source of the malfunction. This often involves analyzing error codes, checking sensor readings, and tracing signals through the control circuit.

For instance, I once encountered a situation where a lift was repeatedly getting stuck between floors. After a thorough inspection, I discovered a faulty encoder on the hoisting machine that was providing inaccurate position feedback to the control system. Replacing the encoder immediately resolved the issue. In another instance, a seemingly intermittent fault led me to discover a loose connection in the control cabinet, affecting the communication between the controller and the door operating system. Addressing such details is part of ensuring safe lift operation.

Q 17. How familiar are you with the different types of lift governors?

Lift governors are critical safety devices that prevent overspeeding. There are several types, each with its own operating mechanism. The most common are:

- Mechanical Governors: These rely on centrifugal force; as the lift car exceeds its safe speed, a rotating mechanism activates a braking system.

- Electronic Governors: These utilize sensors to monitor speed and employ electronic circuitry to initiate braking when the speed limit is breached. They often offer more precise control and diagnostics.

- Hydraulic Governors: These use hydraulic pressure to activate the braking system, particularly suitable for hydraulic lifts.

My experience encompasses working with all these types. The choice of governor depends on the type of lift, its speed, and specific safety requirements. Understanding their operational principles and maintenance needs is essential for preventing accidents caused by overspeeding, a potentially catastrophic event. Regular inspections and testing are crucial to ensuring they function correctly.

Q 18. How do you ensure the regular testing and maintenance of safety devices on lifts?

Regular testing and maintenance of lift safety devices are paramount. This involves a planned and systematic approach with detailed records kept for compliance and traceability. The schedule depends on local regulations and lift usage but typically includes:

- Daily Inspections: Visual checks of safety devices for any visible damage or wear.

- Periodic Testing: Regular functional testing of safety devices like emergency stops, limit switches, and governors, usually performed by qualified technicians following manufacturer’s instructions and relevant standards.

- Routine Maintenance: Lubrication, cleaning, and replacement of worn components as needed.

For example, I’ve implemented a comprehensive maintenance program that employs a computerized maintenance management system (CMMS) to track all tests and maintenance activities. This system generates automated alerts for upcoming inspections and allows for easy retrieval of maintenance history for audits and regulatory compliance.

Q 19. Explain the process of replacing worn or damaged lift components.

Replacing worn or damaged lift components requires careful planning and execution to ensure safety and compliance. The process involves several steps:

- Assessment: Identifying the faulty component and determining its cause of failure.

- Planning: Obtaining the correct replacement part, ensuring it meets the original specifications and safety standards. This might involve liaising with the lift manufacturer or a certified supplier.

- Isolation: Securing the lift from operation, disabling power, and taking necessary precautions.

- Removal: Carefully removing the damaged component, following the manufacturer’s instructions and any safety procedures.

- Installation: Installing the replacement component, ensuring correct alignment and secure fastening. This often requires specialized tools and equipment.

- Testing: Thoroughly testing the lift to ensure its safe and proper operation after the replacement.

- Documentation: Recording all work performed, including the date, parts used, and test results.

A real-world example involved replacing a worn-out brake system in an older lift. The entire process, from initial assessment to final testing, was meticulously documented and followed established safety protocols. We used only certified replacement parts and rigorous testing confirmed its safe operation before returning the lift to service.

Q 20. How do you maintain accurate records of lift maintenance and repairs?

Maintaining accurate lift maintenance and repair records is crucial for safety, compliance, and efficient management. This is typically achieved through a combination of physical and digital records. A comprehensive system includes:

- Logbooks: Physical logbooks documenting daily inspections, maintenance activities, and repairs.

- Computerized Maintenance Management Systems (CMMS): Software programs storing digital records of maintenance schedules, work orders, repair histories, and parts inventory.

- Inspection Reports: Detailed reports from periodic inspections by qualified personnel.

- Repair Orders: Documents outlining repair work, including parts used, labor costs, and any relevant observations.

I always ensure all records are accurate, complete, and readily accessible. In addition to fulfilling regulatory requirements, maintaining these records allows for effective trend analysis, enabling proactive maintenance and minimizing downtime.

Q 21. How do you communicate technical information clearly to non-technical personnel?

Communicating technical information clearly to non-technical personnel requires a shift in approach. It’s about translating complex technical jargon into simple, understandable language. Key strategies include:

- Using plain language: Avoiding technical terms unless absolutely necessary, and defining them clearly when used.

- Visual aids: Employing diagrams, charts, and illustrations to support explanations.

- Analogies and metaphors: Using relatable comparisons to simplify complex concepts.

- Active listening: Ensuring understanding by actively engaging the audience and addressing any questions or concerns.

For instance, when explaining a complex lift malfunction to a building manager, I would avoid technical terms like ‘encoder malfunction’. Instead, I might say ‘a sensor that tells the lift where it is was not working properly, causing it to get stuck’. This approach fosters better understanding and ensures everyone is on the same page, ultimately enhancing safety and cooperation.

Q 22. What are your experience with various types of lift doors and their mechanisms?

My experience encompasses a wide range of lift door types and their mechanisms. This includes manual sliding doors, automatic sliding doors (often employing various drive systems like geared motors or belt drives), telescopic doors (saving space in limited lobbies), and centre-opening doors. I’m familiar with the safety features integral to each type, such as interlocks preventing movement with doors open, and emergency release mechanisms. I understand the importance of regular lubrication, adjustments to ensure smooth operation, and the replacement of worn components to maintain safety and efficiency. For instance, I’ve worked extensively with the troubleshooting and repair of automatic sliding doors using infrared sensors for safety, addressing issues ranging from misaligned tracks to faulty sensor detection. Understanding the different door mechanisms, from the simple to the complex, is critical for effective maintenance and repair.

- Manual Sliding Doors: Simple, reliable, but require regular inspection for track alignment and smooth operation.

- Automatic Sliding Doors: Employ sensors, motors, and control systems requiring regular maintenance and diagnostic checks.

- Telescopic Doors: Space-saving, but complex mechanisms with multiple moving parts needing careful attention.

- Centre-Opening Doors: Often used in high-traffic areas; require robust construction and reliable mechanisms.

Q 23. Describe your experience with lift modernization projects. Include specific examples.

I’ve been involved in numerous lift modernization projects, significantly enhancing the safety, efficiency, and longevity of existing systems. One notable project involved upgrading a series of hydraulic lifts in a high-rise building to a more energy-efficient traction system. This included replacing the hydraulic pump and accumulator, installing a new machine room-less (MRL) traction system with a smaller footprint, and integrating a modern control system with improved diagnostics and safety features. The result was a noticeable reduction in energy consumption, improved ride quality, and an enhanced safety profile. Another project focused on replacing outdated control panels with modern microprocessor-based systems. These systems allowed for remote monitoring, predictive maintenance, and faster response times to faults, minimizing downtime and improving overall system reliability. In both cases, meticulous planning and phased implementation were crucial to minimizing disruption during the upgrade process.

A third project involved replacing an older, inefficient door system with modern, energy-efficient automatic doors. This included installing new door operators, sensors, and safety systems. This improvement not only enhanced the aesthetic appeal of the lift but also improved energy efficiency and passenger safety.

Q 24. How familiar are you with the use of diagnostic tools for lift systems?

I’m highly proficient in using diagnostic tools for lift systems. This includes both handheld diagnostic devices and sophisticated computer-based systems. Handheld tools allow for quick checks of electrical circuits, sensor outputs, and motor performance, often isolating the problem to a specific component. Computer-based systems provide more comprehensive data logging and analysis, allowing for trend identification and predictive maintenance. I’m familiar with various diagnostic software packages, enabling me to interpret fault codes, analyze system parameters, and identify potential issues before they escalate into major malfunctions. For example, I regularly use diagnostic software to track the performance of lift motors, identifying potential wear and tear or impending failures, allowing for proactive maintenance and preventing unexpected downtime.

Understanding the limitations of each tool and how to best utilize them is key to efficient troubleshooting. For instance, while handheld meters are great for basic checks, a computer-based diagnostic system may be necessary for complex issues involving the lift’s control system.

Q 25. Describe your understanding of load capacity and weight distribution in lifts.

Load capacity and weight distribution are critical aspects of lift safety and operation. Each lift has a clearly defined maximum load capacity, which must never be exceeded. Overloading can lead to serious safety hazards, including structural damage, malfunctioning components, and potential accidents. I carefully review the specifications for each lift I work on and ensure that the load capacity is clearly displayed and adhered to. Moreover, weight distribution within the lift car is important; uneven loading can lead to instability and potentially dangerous swaying during operation. It’s important to ensure that heavier items are distributed evenly to avoid any imbalances.

For example, I’ve had to address situations where overloading was a concern, implementing measures such as stricter enforcement of load limits and the use of load sensors to monitor weight and prevent exceeding the capacity. In situations where uneven weight distribution caused problems, I addressed the issues through improved communication and signage, providing clear guidelines for passengers.

Q 26. How do you identify and address potential safety hazards related to lift operation?

Identifying and addressing potential safety hazards is paramount in lift operation. My approach involves a multi-faceted strategy, incorporating regular inspections, proactive maintenance, and thorough risk assessments. Regular inspections include visual checks for wear and tear, testing safety devices (such as emergency stops and safety brakes), and verifying the functionality of all components. Proactive maintenance helps prevent many potential hazards by addressing issues before they become critical. Risk assessments are used to proactively identify potential hazards and to implement corrective measures.

For example, during an inspection, I discovered a frayed cable near a lift motor, potentially leading to a short circuit or fire. Immediate action was taken to replace the cable, eliminating a significant safety hazard. Similarly, during a risk assessment, I noticed a lack of emergency lighting in a certain section of the lift shaft; I recommended and implemented an upgrade to address this deficiency.

Q 27. What is your experience working under pressure in time-sensitive lift repair situations?

Working under pressure in time-sensitive lift repair situations is a common occurrence. I’ve successfully managed numerous instances requiring rapid problem-solving and efficient execution. My approach relies on a structured methodology: prioritizing critical issues, swiftly diagnosing the problem, and implementing effective solutions. Communication is key: I keep stakeholders informed of the progress, manage their expectations, and maintain transparency throughout the repair process. A recent example involved a lift malfunction in a busy hospital during peak hours. I immediately prioritized restoring service, effectively diagnosing the fault as a faulty motor control circuit. Efficiently replacing the faulty component quickly restored service, minimizing disruption to hospital operations.

My experience has taught me the importance of staying calm under pressure, maintaining focus, and drawing on my problem-solving skills to address time-critical issues.

Q 28. How do you manage multiple priorities and tasks during a busy maintenance schedule?

Managing multiple priorities and tasks during a busy maintenance schedule requires efficient organization and prioritization. I utilize various tools and techniques, including scheduling software, detailed checklists, and prioritization matrices. Scheduling software helps me manage appointments, allocate resources, and track progress efficiently. Checklists ensure I don’t miss critical maintenance steps, and prioritization matrices assist in identifying the most critical tasks and ensuring that they are addressed first. I also practice effective communication with my team and clients, ensuring that everyone is aware of my schedule and priorities.

For example, on a particularly busy week, I used a project management tool to coordinate multiple lift maintenance tasks, prioritizing emergency repairs and routine inspections accordingly. Clear communication with clients ensured that all parties were aware of the schedule and any potential delays.

Key Topics to Learn for Lift Operations Interview

- Lift Mechanics and Hydraulics: Understanding the fundamental principles governing lift operation, including hydraulic systems, counterweights, and safety mechanisms. Practical application includes troubleshooting malfunctions based on mechanical understanding.

- Safety Regulations and Procedures: Thorough knowledge of all relevant safety standards, emergency procedures, and preventative maintenance protocols. Practical application involves demonstrating your ability to identify and address potential hazards.

- Electrical Systems and Controls: Familiarity with the electrical components of lifts, control systems, and their interaction with other mechanical parts. Practical application includes explaining the diagnostic process for electrical faults.

- Maintenance and Repair: Understanding preventative maintenance schedules, troubleshooting common issues, and performing basic repairs. Practical application involves outlining your experience with different maintenance tasks and repair methodologies.

- Modernization and Upgrades: Knowledge of current trends in lift technology, including modernization projects and the integration of new technologies. Practical application involves discussing your understanding of improving efficiency and safety in existing systems.

- Code Compliance and Inspections: Understanding relevant building codes and regulations, as well as the inspection process. Practical application includes explaining your role in ensuring compliance and your experience with inspections.

Next Steps

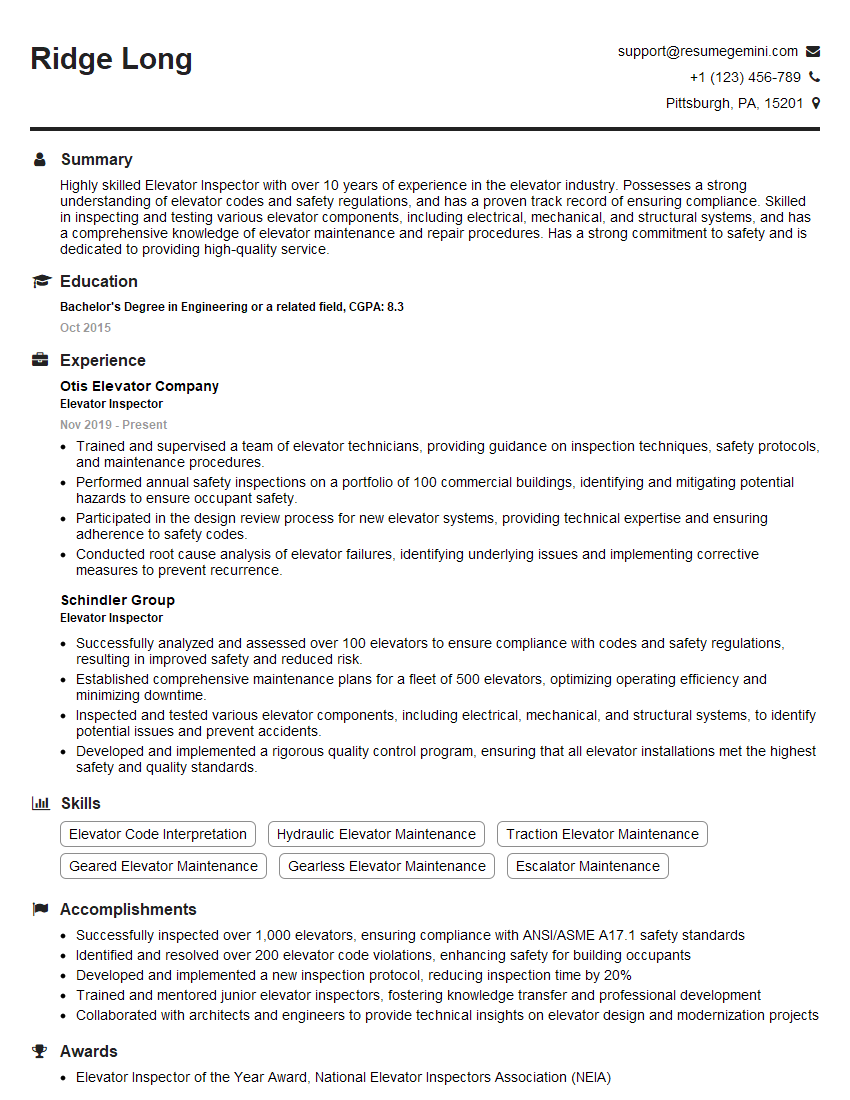

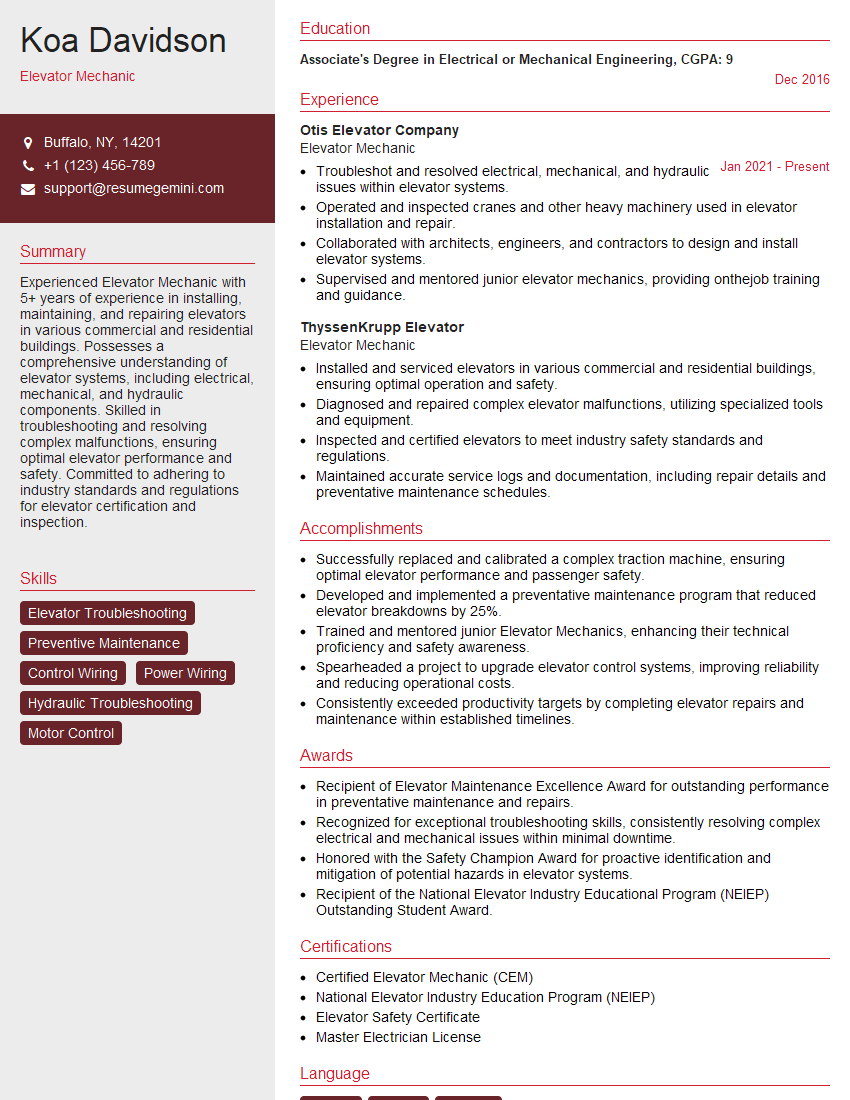

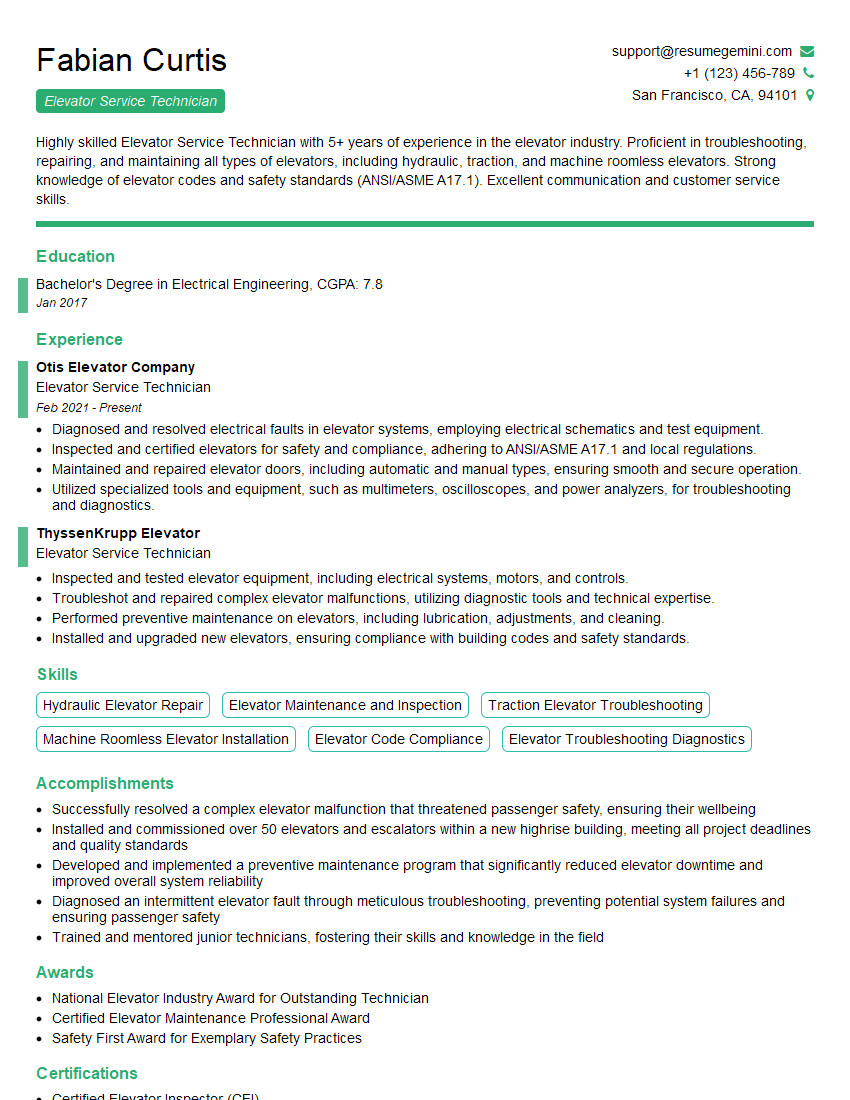

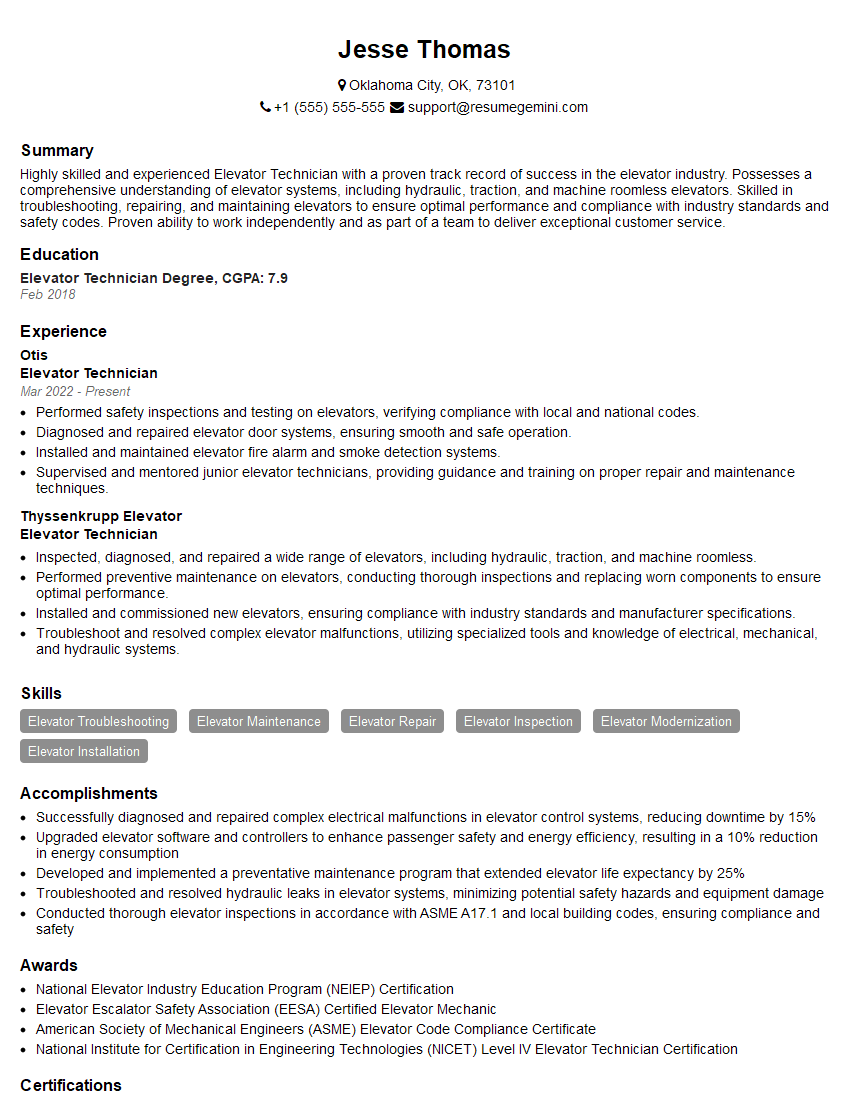

Mastering Lift Operations opens doors to a rewarding career with excellent growth potential. The industry constantly evolves, demanding skilled professionals who can ensure safe and efficient operation. To significantly improve your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your skills and experience shine. We provide examples of resumes tailored to Lift Operations to guide you in creating a winning application. Take the next step towards your dream career – build your best resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good