The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Pattern Drafting and Measurement interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Pattern Drafting and Measurement Interview

Q 1. Explain the difference between slopers and blocks.

Both slopers and blocks are foundational pattern pieces, but they serve different purposes. Think of them as the base templates for garment construction. A sloper, also known as a basic bodice or skirt block, is a two-dimensional representation of a body’s basic shape, usually made with minimal seam allowances. It’s a highly customized, precise pattern that fits very closely to the individual’s measurements. It’s like a detailed blueprint tailored to one person. In contrast, a block is a more standardized base pattern, often available in a range of sizes. It’s created from a set of standard measurements and typically includes seam allowances. It’s like a ready-to-use template that can be adapted further.

The key difference lies in the level of customization. Slopers are highly individualized, while blocks are more generic. You’d create a sloper from specific body measurements, whereas you’d purchase or find a block already sized to various body types.

Q 2. Describe your experience with various pattern drafting methods (e.g., draping, flat pattern making).

My experience encompasses both draping and flat pattern making methods. Draping is a three-dimensional process where fabric is manipulated directly on a dress form to create the desired garment shape. This method allows for superior fit and creative exploration of fabric drape, particularly useful for complex silhouettes or unusual fabrics. I’ve used draping extensively to create intricate evening gowns and unique structured pieces. For example, I draped a silk chiffon gown, carefully shaping the fabric to achieve the desired flow and movement.

Flat pattern making involves constructing a pattern from two-dimensional measurements and calculations. This method offers more control and precision, especially when replicating designs or producing large quantities. I frequently employ this method for ready-to-wear patterns, ensuring accuracy and consistency. For instance, I recently used flat pattern making to create a collection of tailored trousers, meticulously calculating grainlines and ease allowances.

Q 3. How do you adjust a pattern for different body types and sizes?

Adjusting patterns for different body types and sizes requires a thorough understanding of body proportions. This involves manipulating key pattern measurements and shapes. For example, to adjust for a larger bust, I would widen the bust area and adjust the shoulder and armhole shaping to accommodate the increased volume. For broader shoulders, I would lengthen the shoulder slope and possibly adjust the armhole depth to prevent binding. For a fuller hip, I would increase the hip circumference and adjust the shaping of the lower garment to ensure a smooth fit. I would also make adjustments to the length of the garment, accounting for variations in torso length, and adjust the overall grading strategy to maintain the same design integrity across size ranges.

Often, this involves making adjustments to the grading lines and using techniques like adding or removing darts, shifting seams, and making ease adjustments to allow for comfort and movement. I also consider the specific design style, as some styles are inherently more forgiving to body shape variations than others.

Q 4. What software are you proficient in for pattern making (e.g., Gerber, Lectra, OptiTex)?

My proficiency extends to several industry-standard pattern-making software packages. I am highly skilled in Gerber Accumark, known for its powerful grading and marker-making capabilities. I also have extensive experience using Lectra Modaris, which excels in 3D visualization and its advanced features for complex design. My experience with these programs enables me to seamlessly create patterns, grade them for different sizes, and generate efficient marker plans for optimal fabric utilization.

Q 5. Explain the process of grading a pattern.

Grading a pattern involves systematically increasing or decreasing its dimensions to create a range of sizes. This process involves proportionally scaling the pattern pieces, ensuring that the garment’s design and proportions remain consistent across all sizes. It’s a critical step in mass production, allowing manufacturers to offer a wide size range. The process usually starts with the base size (typically a size medium). I would use specialized software (like Gerber Accumark) to automate the grading process, inputting grading rules and specifications. These rules determine how much each measurement will increase or decrease for each size increment. It’s crucial to verify the graded patterns with physical checks for proper fit and proportions to ensure accuracy and quality. Manually grading each piece is also possible, but highly time-consuming for larger size ranges.

Q 6. How do you ensure accurate measurements when creating a pattern?

Accurate measurements are paramount in pattern making. I use a combination of techniques to guarantee precision. For example, I use flexible measuring tapes, taking measurements directly on the body and always considering posture. I carefully record the measurements, noting any discrepancies or unique body characteristics. This process includes multiple measurements in key areas to minimize errors. Additionally, I make sure to use appropriate tools, maintaining them in good condition and applying consistent measuring techniques across all patterns.

Moreover, I always double-check the measurements, comparing them to standard size charts for reference. For intricate areas, I take multiple measurements from different angles. For instance, I take three measurements for the bust — full bust, high bust, and under bust — to capture the nuances of the bust curve and ensure a proper fit. I also cross-reference my measurements with industry standards and check with the customer to clarify any discrepancies. This approach reduces potential errors and ensures the pattern accurately reflects the required measurements.

Q 7. Describe your experience with different types of fabrics and how they impact pattern making.

Different fabrics have unique properties that significantly impact pattern making. For instance, stretchy fabrics, like knits, require different ease allowances compared to woven fabrics. Knits generally have more give, so I would use less ease to avoid baggy garments. Wovens don’t stretch as much so accurate measurements are critical to avoid pulling or tightness. The drape and weight of the fabric also play a role. A heavy fabric, such as wool, will hang differently than a lightweight fabric, such as silk chiffon. This necessitates adjustments in the pattern’s shaping and design, to ensure that the finished garment hangs and drapes appropriately for the chosen fabric.

For instance, when working with a sheer fabric like silk chiffon, I would pay attention to the fabric’s transparency and add interfacings or linings where necessary. With stable fabrics such as linen, I would account for less stretch. Understanding these properties ensures that the finished garment reflects the intended design and hangs well on the body, enhancing the overall aesthetic and ensuring a successful outcome.

Q 8. How do you troubleshoot fit issues in a garment?

Troubleshooting fit issues requires a systematic approach. It’s like detective work, carefully examining the garment on the wearer to pinpoint the problem areas. I start by identifying the specific areas of ill-fit – is it too tight across the bust, too loose in the waist, or pulling in the shoulders? Then, I analyze the discrepancy between the body measurements and the finished garment.

- Ease: I check if the pattern includes the correct amount of ease (extra fabric for comfort and movement). Insufficient ease often leads to tightness, while excessive ease results in bagginess.

- Grainline: I verify that the grainline (the direction of the fabric threads) is aligned correctly, as deviations can drastically affect the fit. Misaligned grainline can cause unwanted stretching or distortion.

- Pattern Adjustments: Based on the identified issues, I make targeted adjustments to the pattern. For example, if the garment is too tight across the bust, I might add width to the bust area of the pattern by making adjustments to the front and back bodice pieces.

- Fabric Stretch and Drape: The choice of fabric significantly influences fit. Highly stretchy fabrics require different ease allowances compared to stiffer materials. Fabrics with drape that differ from that in my test garment can influence the fit significantly.

- Construction Errors: I also check for potential construction errors – improper seam allowances, uneven stitching, or incorrect seam placement – all of which can impact fit.

For instance, I once worked on a dress that was consistently too tight across the bust for several samples. After checking ease and grainline, I realized I hadn’t accounted for the significant stretch of the chosen jersey fabric. By adding more ease and carefully grading the pattern piece, the fit was corrected.

Q 9. What are your strategies for managing multiple projects and deadlines?

Managing multiple projects and deadlines effectively hinges on organization and prioritization. I employ a project management system using a combination of digital tools (like Trello or Asana) and a physical to-do list. This allows for a visual overview of all projects, their deadlines, and their progress.

- Prioritization: I rank projects according to urgency and importance, focusing on high-priority tasks first using methods such as the Eisenhower Matrix (urgent/important). This ensures that the most critical deadlines are met.

- Time Blocking: I dedicate specific time slots to each project, minimizing distractions and maximizing efficiency. This approach provides focused time for each part of a pattern design project.

- Communication: Open communication with clients and team members is essential. Regular updates keep everyone informed, allowing for proactive problem-solving and avoiding potential delays.

- Delegation: Where possible, I delegate tasks to others, freeing up my time to concentrate on the most complex or demanding aspects of the projects.

- Contingency Planning: I build buffer time into my schedule to account for unexpected delays or complications. This helps mitigate potential setbacks and keeps projects on track.

For example, during a busy season, I might have three dress projects and two pant projects all with tight deadlines. My system allows me to allocate specific days for each project’s cutting, sewing, fitting, and finishing stages, ensuring that I meet all deadlines. If an unforeseen problem arises with one project, the buffer time allows me to adjust my schedule without significantly impacting the other projects.

Q 10. Explain your experience with marker making and efficient fabric utilization.

Marker making is crucial for efficient fabric utilization in garment production. It’s the art of arranging pattern pieces on a fabric layout to minimize waste. My experience encompasses both manual and computer-aided marker making.

- Manual Marker Making: I’m proficient in laying out pattern pieces manually, optimizing placement and orientation to reduce fabric consumption. This requires a strong understanding of pattern shapes and fabric grainlines.

- Computer-Aided Marker Making (CAM): I utilize specialized software to create markers digitally, which allows for greater precision, speed, and efficiency. This software calculates the optimal arrangement of pieces, resulting in significant fabric savings compared to manual methods.

- Fabric Considerations: I always take into account the fabric’s width, grain direction, and pattern repeat when creating markers to optimize layout and minimise waste, this is essential for patterned or directional fabrics.

- Nesting: Mastering efficient nesting techniques – arranging pieces to minimise the spaces between them – is essential for maximizing fabric utilization. Different nesting techniques are appropriate for different patterns and fabric types.

For instance, when working with a highly patterned fabric, I use CAM software to create a marker that carefully aligns the pattern repeat across all garment pieces, ensuring a consistent aesthetic across multiple garments. In another instance, when using a wide, plain fabric, my manual skills allowed me to create a marker that reduced fabric waste by approximately 15% compared to a less experienced marker maker’s efforts.

Q 11. Describe your process for creating a pattern from a sketch or design.

Creating a pattern from a sketch or design involves translating a 2D visual representation into a 3D functional garment. It’s a multi-step process requiring both artistic and technical skills.

- Measurements and Analysis: I start by analyzing the design sketch to understand its key features: silhouette, neckline, sleeve style, and other details. I then develop the necessary measurements needed to create the basic block.

- Block Construction: Next, I construct a basic block—a foundation pattern that’s tailored to the specific size and body shape. This involves creating drafting a sloper, and using standard measurement tables and formulas to ensure accurate proportions.

- Design Application: I then adapt this block to incorporate the design details from the sketch. This could involve adding darts, shaping seams, or modifying the neckline, sleeves, and other components.

- Pattern Grading: Once the base pattern is complete, I grade it to create multiple sizes. This entails systematically adjusting the pattern pieces to accommodate different body measurements.

- Pattern Testing and Refinement: Finally, I test the pattern by creating a toile (a test garment) to check the fit and make any necessary adjustments.

As an example, if a client provides a sketch of a fitted A-line dress with a boat neck, I would begin by creating a basic bodice block, incorporating appropriate shaping in the bodice and skirt to achieve the A-line silhouette. I would then adjust the neckline to form the desired boat neck, using my knowledge of neckline construction techniques.

Q 12. How do you handle pattern adjustments based on sample fit sessions?

Pattern adjustments based on sample fit sessions are iterative and crucial for achieving a perfect fit. I approach this stage with methodical precision.

- Detailed Analysis: I begin by meticulously documenting the fit issues observed during the sample fit session. This includes pin-fitting and noting measurements of areas needing adjustment, such as the shoulder width, sleeve length, bust circumference, and waist.

- Targeted Adjustments: Based on the fit notes, I make localized adjustments to the pattern pieces, avoiding large-scale changes that can disrupt the garment’s overall balance. Small adjustments, for example, a 1/4 inch change can have a large impact.

- Multiple Iterations: This is often an iterative process requiring several rounds of pattern adjustments and sample making. Every adjustment is carefully considered before being implemented and documented.

- Documentation: I maintain meticulous records of all adjustments, keeping track of each change made. This enables me to track progress, repeat successful adjustments, and quickly identify solutions to recurring issues.

- Grading Considerations: Any adjustments must be considered across multiple sizes to avoid fit issues in graded sizes. This might require re-grading the entire pattern after making the adjustment.

For example, if a jacket’s shoulders were drooping in the first sample, I’d raise the shoulder seam line on the pattern by a certain amount, and then create a second sample to check. I’d carefully document the amount adjusted and repeat on the other side and size.

Q 13. How familiar are you with different types of closures (e.g., zippers, buttons, hooks)?

I possess extensive experience with various types of closures, understanding their strengths and limitations for different garment types.

- Zippers: I’m skilled in using various zipper types – center-back zippers, invisible zippers, side zippers, and lapped zippers – and adapting their insertion techniques to different fabrics and garment styles.

- Buttons: I understand button placement, sizing, and attachment methods, including shank buttons, self-covered buttons, and decorative buttons.

- Hooks and Eyes: I’m experienced in using hooks and eyes for closures, including their placement for effective fastening and durability.

- Other Closures: My expertise also extends to other closure options, such as snaps, toggles, and buckles, each best suited to specific garment applications and styling.

- Functionality and Aesthetics: My approach considers not only the functionality but also the aesthetic integration of the closure into the overall garment design. The choice of closure should complement the style and not detract from the finished product.

For instance, for a formal gown, I might choose an invisible zipper for a clean, seamless finish, while a casual shirt might use buttons for a more relaxed look. I would select and use the appropriate closure based on several factors, including the design, fabric, and desired aesthetic of the garment.

Q 14. Describe your experience with creating patterns for different garment types (e.g., dresses, pants, jackets).

My experience in pattern drafting spans a wide range of garment types, allowing me to adapt my skills and techniques to different designs and complexities.

- Dresses: I’m comfortable drafting patterns for various dress styles – A-line, sheath, fit-and-flare, wrap, and more – considering elements such as darts, waistlines, necklines, and sleeves.

- Pants: My expertise includes drafting patterns for various pant styles – jeans, trousers, leggings – and understanding the intricacies of pant construction, including fly fronts, pockets, and waistbands.

- Jackets: I’m experienced in drafting patterns for jackets, including tailored jackets, blazers, and coats, accounting for features like collars, lapels, and closures.

- Other Garments: My pattern drafting skills also extend to other garments, such as skirts, blouses, and outerwear.

- Understanding Garment Construction: My approach to pattern drafting always considers the construction process of each garment. The pattern needs to facilitate the construction process, allowing for seams and shaping of the garment. I understand which types of seams work best for different fabrics and garment types.

For instance, when drafting a tailored jacket pattern, I pay meticulous attention to the details of the collar and lapel construction to ensure a professional finish. For pants, I design the pattern to accommodate the fly front and pocket placement, ensuring a seamless and functional final product. My experience allows me to adapt my pattern drafting techniques to meet the needs of any specific garment type.

Q 15. How do you incorporate ease and seam allowance into your patterns?

Ease and seam allowance are crucial for garment comfort and construction. Ease is the extra fabric added to the pattern’s measurements to allow for comfort and movement. Seam allowance is the extra fabric added to the pattern’s edges to allow for stitching. They are added at different stages of pattern making.

Ease: I typically add ease to the basic block (the foundation pattern) based on the garment type and desired fit. For example, a snug-fitting dress might have minimal ease (1/2 inch to 1 inch), while a looser-fitting shirt could have more (1-2 inches or more depending on the style and fabric). This ease is usually added to the body measurements before creating the base pattern. I calculate this incrementally across body measurements, considering factors like intended drape and fabric stretch.

Seam Allowance: Seam allowance is added after the base pattern is complete. I typically use a standard seam allowance of 5/8 inch (1.5cm) for most garments, but I will adjust this based on the garment’s construction. For example, a curved seam like a neckline might use a smaller seam allowance, like 1/4 inch (6mm), for better fit, whilst heavier fabrics might benefit from a slightly larger allowance to avoid bulk.

Adding both is a critical step in pattern making; omitting ease leads to ill-fitting garments, whereas ignoring seam allowance results in construction issues and a finished garment that’s too small.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of grainlines and their importance in pattern making.

Grainline refers to the direction of the warp and weft yarns in a woven fabric. It’s crucial for pattern making because the fabric’s drape and stability are strongly influenced by the grain.

- Warp: The lengthwise yarns, usually stronger and less stretchy.

- Weft: The crosswise yarns.

- Bias: The diagonal direction, highly stretchable and drapes differently.

Using the correct grainline is essential for garment stability, drape, and overall fit. Cutting a garment piece on the bias (45-degree angle to the warp) will dramatically change how it hangs. Cutting on the warp makes the garment less prone to stretching in one direction, as seen with garments like trousers which need stability. Conversely, cutting on the weft can produce a softer drape.

I always ensure that my patterns have clearly marked grainline arrows. These arrows indicate the direction the warp yarns should run on the fabric. Misaligned grainline results in distortions that significantly affect the fit and appearance of the final garment. For example, a skirt cut on the wrong grain may hang unevenly or stretch excessively.

Q 17. How do you work with different types of pattern paper and tools?

Selecting the appropriate pattern paper and tools significantly impacts pattern quality and efficiency.

Pattern Paper: I use various types depending on the project’s complexity and scale.

- Lightweight Tracing Paper: Ideal for creating initial sketches and transferring patterns, as it’s transparent and easy to manipulate.

- Medium-weight Pattern Paper: My go-to choice for most patterns. It’s durable enough to withstand repeated handling but still lightweight enough to be easily cut and manipulated.

- Heavyweight Pattern Paper: Best suited for creating large patterns or those intended for industrial usage where sturdiness is paramount, and multiple pattern pieces might need stacking.

Tools: My toolkit includes:

- Pattern shears: Sharp, long shears for clean, precise cuts.

- Rotary cutter and mat: For rapid and accurate cutting of large pattern pieces.

- French curve: To create smooth, curved lines.

- Hip curve: Specifically for creating curvy lines that precisely align with the body’s curves.

- Ruler: For accurate measurement and marking.

- Measuring tape: Flexible, accurate measuring.

- Tailor’s chalk and pencils: For marking and transferring pattern pieces onto fabric.

- Weights or clips: To secure pattern pieces in place during cutting.

The use of correct tools and paper reduces the chance of error and ensures that the pattern accurately reflects the design intent, leading to a far better-fitting and well-made garment.

Q 18. What is your experience with digital pattern making and 3D design software?

I have significant experience with digital pattern making software and 3D design tools. I’m proficient in programs such as CLO 3D, Optitex, and Pattern Design.

Digital Pattern Making Advantages:

- Increased Efficiency: Digital tools drastically reduce the time spent on manual pattern making, allowing for quicker prototyping and iteration.

- Precise Measurements and Grading: Digital tools ensure accuracy and consistency across various sizes, simplifying the grading process (adapting the pattern to different sizes).

- 3D Visualization: 3D design software allows for visualization of the garment on an avatar, identifying potential fit issues before cutting fabric, saving materials and time.

- Collaboration: Digital patterns can be easily shared and collaboratively edited, streamlining the design process, especially in team environments.

However, proficiency in manual techniques is still necessary. Understanding the underlying principles of pattern making, including ease, seam allowance, and grainline, is fundamental and will enhance digital skills. Digital pattern making is a powerful tool; I see it as complementary to, rather than a replacement for, traditional methods.

Q 19. How do you create a balanced pattern for symmetry and correct drape?

Creating balanced patterns for symmetry and correct drape involves several key steps.

Symmetry: I ensure symmetry by:

- Accurate Measurements: Taking precise body measurements is fundamental to creating a balanced base pattern.

- Consistent Marking: Marking all points and lines accurately on the pattern prevents asymmetry in the final garment.

- Mirroring: Using the software or by manually folding the pattern, I accurately mirror the front and back pattern pieces. This ensures the final garment is balanced from left to right.

Correct Drape: Achieving this involves:

- Grainlines: Correct placement of grainline arrows is crucial. Incorrect placement will significantly affect the drape and make the garment hang unevenly.

- Ease: Appropriate ease is vital to ensure that the garment hangs naturally and drapes properly, and avoids pulling or bunching.

- Fabric Choice: The fabric’s weight, texture, and drape properties influence the overall fit. Heavy fabrics might require modifications to the pattern’s design or ease to avoid it being too weighty.

- Testing and Fitting: Making a muslin (test garment) is crucial. This helps to identify and correct any fit or drape issues early on before cutting expensive fabric.

Creating a well-balanced pattern is an iterative process that may require several adjustments to achieve the desired outcome.

Q 20. Describe your knowledge of different fit models and their influence on pattern construction.

Different fit models influence pattern construction significantly. A fit model is a person whose body measurements represent the target audience for a particular garment or design. Using a fit model allows designers to assess how a pattern drapes on a real body.

Types of Fit Models and their Influence:

- Standard or Average Fit Model: This model has measurements within a standard size range. Patterns drafted for a standard fit model will typically fit a larger portion of the target population. However, this may mean it may need adjustments for people outside that average range.

- Specific Fit Model: Patterns can be drafted to fit a specific client or target market. This requires precise measurements and may involve considerable customization during the pattern making process. For example, it might be used for designing patterns for athletic body types with specific muscle definition or designing clothes for plus sizes.

- Ideal Fit Model: Often used in high fashion design, this model embodies the ideal body shape for a specific design. This approach often results in garments that are highly stylized but may not fit a broader range of body types.

The fit model’s body shape influences the design decisions I make in pattern construction. For example, a model with a large bust might require adjustments to the bodice pattern to avoid pulling or gaping, whereas a person with a more slender figure requires different adjustments. The fit model serves as a real-world reference for assessing and refining the pattern’s fit and drape.

Q 21. Explain the importance of consistent pattern measurements and tolerances.

Consistent pattern measurements and tolerances are essential for achieving accurate and repeatable results in pattern making. Inconsistent measurements lead to poorly fitting garments.

Importance of Consistent Measurements:

- Accuracy: Precise measurements are critical for creating patterns that fit the intended body shape and size. Even small errors can significantly affect the final garment’s fit.

- Repeatability: Consistent measurements ensure the pattern can be reproduced accurately, allowing for easy replication of the same style in different sizes and fabrics.

- Grading: Accurate measurements are paramount for seamless grading of patterns to different sizes.

Tolerances: Tolerances acknowledge the minor variations that may occur in the manufacturing process, such as slight inconsistencies in fabric cutting or stitching. I incorporate small allowances for tolerances to prevent issues. For example, a 1/8-inch tolerance might be built into the seam allowance.

Maintaining consistent measurements and implementing tolerances are integral to efficient and error-free pattern-making. Without attention to this detail, the patterns won’t yield consistently fitting garments.

Q 22. How familiar are you with different types of seam finishes?

Seam finishes are crucial for garment durability and a professional look. They prevent raw edges from fraying and add a clean, polished finish. The choice of finish depends on the fabric type, garment style, and desired aesthetic.

- Serging/Overlocking: Uses a serger machine to stitch and enclose raw edges simultaneously. Ideal for knit fabrics and seams needing stretch. Example: A T-shirt neckline.

- Zigzag Stitch: A simple machine stitch that prevents fraying. Works well for woven fabrics but may not be as durable as other methods. Example: A simple cotton blouse seam.

- French Seam: A very neat finish, particularly for sheer fabrics, where raw edges are completely enclosed. It involves two stitching steps. Example: A delicate silk dress.

- Hong Kong Finish: A clean, professional finish where bias binding is used to encase the raw edge. Excellent for curved seams and more luxurious garments. Example: A high-end tailored jacket.

- Bound Seam: Similar to Hong Kong finish, but uses fabric strips cut on the straight grain instead of bias. Example: A children’s garment where durability is key.

Selecting the appropriate seam finish is a key decision in pattern making, impacting both the garment’s longevity and overall appearance.

Q 23. Describe your approach to working with complex or unusual design elements.

Complex design elements require a methodical approach. I start by meticulously studying the design, breaking it down into manageable sections. I’ll create individual pattern pieces for each section, ensuring smooth transitions between them. For instance, if the design incorporates intricate draping, I’ll create a muslin toile first, adjusting the pattern until the drape is perfect. Unusual shapes might involve using innovative techniques such as adding darts or shaping seams creatively, and then I would test fit and refine accordingly. I use digital pattern design software to create complex curves and shapes, allowing for adjustments and modifications seamlessly.

For example, working on a garment with a complex asymmetrical neckline, I would start by creating a basic neckline pattern. Then I’d use a series of curves and adjustments, guided by the design sketch, to form the asymmetrical shape. This would likely involve a combination of computer-aided design and manual adjustments to a toile.

Q 24. How do you maintain accuracy while working on large-scale production patterns?

Maintaining accuracy in large-scale production is paramount. I rely on a combination of precise measurements, digital pattern making software, and rigorous quality control checks. Starting with accurate measurements taken from a representative sample size is key. This ensures that the pattern accurately reflects the target body measurements. Using CAD software like Gerber or Lectra allows for precise grading (sizing) and pattern adjustments and minimizes errors while keeping track of all changes. I also incorporate detailed specifications and production tolerances into the pattern package. Finally, I conduct thorough checks at different stages—initial pattern creation, grading, and sample production—to catch and correct any errors before mass production begins.

For example, if grading a pattern from a size 6 to a size 16, I will carefully adjust each part of the pattern proportionately using software, and I will check calculations against manual calculations. The slightest inconsistency can lead to significant issues during production, leading to cost and time issues.

Q 25. Explain your experience with pattern alterations and adjustments for mass production.

Pattern alterations for mass production require a systematic approach. I begin by understanding the specific adjustments needed—whether it’s a change in fit, style, or fabric type. Alterations are then implemented carefully using digital tools that allow for precise changes to the base pattern. I meticulously document every alteration to maintain consistency across different sizes and to ensure that the changes can be easily replicated. This documentation is incredibly important because these adjustments form the basis for future pattern iterations and scale-up.

For example, if customer feedback indicates the need to widen the sleeve opening on a jacket, I use the CAD software to make the adjustments, making sure the grading is recalculated to maintain the balance and fit throughout the size range. I’ll then create a test garment to verify the alterations before implementing them across the entire production run.

Q 26. How do you prioritize accuracy and speed in pattern making?

Balancing accuracy and speed requires a strategic workflow. I leverage digital pattern-making tools to expedite the process while maintaining precision. Automation of tasks such as grading, and using templates, minimizes errors and saves significant time. I also prioritize efficient methods—like using pre-made blocks as a base—to build patterns quickly. However, I would never compromise accuracy for speed. Quality control checks are integrated into every step, catching potential issues early. Through experience, one learns to quickly identify areas that need attention while not cutting corners.

Think of it like assembling a complex machine. While speed is important, each part must be precisely fitted to ensure a functional end product. Cutting corners could result in the machine not functioning correctly.

Q 27. Describe a challenging pattern-making project you faced and how you overcame it.

One challenging project involved creating a pattern for a highly structured, intricately draped evening gown with multiple layers of different fabrics. The initial patterns didn’t drape correctly, creating uneven gathers and awkward folds. To overcome this, I started by using a muslin toile. I experimented with various techniques like manipulating the seam lines, adding darts, and changing the fabric cuts to achieve the desired drape. I also collaborated with the designer to adjust the design details, slightly simplifying some elements to make them more feasible for production. Through multiple iterations, careful adjustments, and meticulous attention to detail, the final pattern achieved the desired effect—a beautifully draped gown without sacrificing accuracy or structural integrity. This process highlighted the importance of flexibility, collaboration, and persistent refinement.

Q 28. How do you stay updated with the latest trends and technologies in pattern making?

Staying updated in this field is essential. I achieve this through several avenues: attending industry conferences and workshops to learn about new technologies and techniques. I actively participate in online forums and communities of pattern makers, allowing for the exchange of knowledge and insights. Reading trade publications and following industry blogs helps stay abreast of the latest trends in design and technology. Continuous learning is crucial, ensuring that my skills and knowledge remain current and relevant. I would also pursue further training on new software and techniques to keep my skillset updated to ensure I remain competitive.

Key Topics to Learn for Pattern Drafting and Measurement Interview

- Basic Pattern Construction: Understanding the fundamental principles of drafting basic bodice, sleeve, and skirt blocks. This includes accurate measurements and adjustments for various body types.

- Advanced Pattern Alterations: Practical application of pattern adjustments for fit improvements, including dart manipulation, ease additions, and sleeve cap adjustments. Be prepared to discuss how you would approach correcting common fitting issues.

- Measurement Techniques: Mastering accurate body measurement techniques, understanding standard measurement charts, and interpreting measurement discrepancies. Discuss the importance of consistent and precise measurements.

- Software Applications: Familiarity with industry-standard CAD software for pattern making (e.g., Optitex, Gerber). Highlight your proficiency in using these tools for efficient pattern creation and modification.

- Draping Techniques: Understanding the principles of draping fabric on a dress form to create patterns directly from fabric. Discuss the benefits and limitations of draping compared to drafting.

- Gradings & Sizing: Knowledge of grading patterns to create multiple sizes from a base pattern. Explain the process and its importance in apparel production.

- Fabric Selection & Properties: Understanding how fabric properties (drape, stretch, weight) influence pattern design and construction. Be ready to discuss appropriate pattern adjustments for different fabrics.

- Problem-Solving & Troubleshooting: Demonstrate your ability to identify and solve common pattern-making problems, such as fitting discrepancies and production challenges.

Next Steps

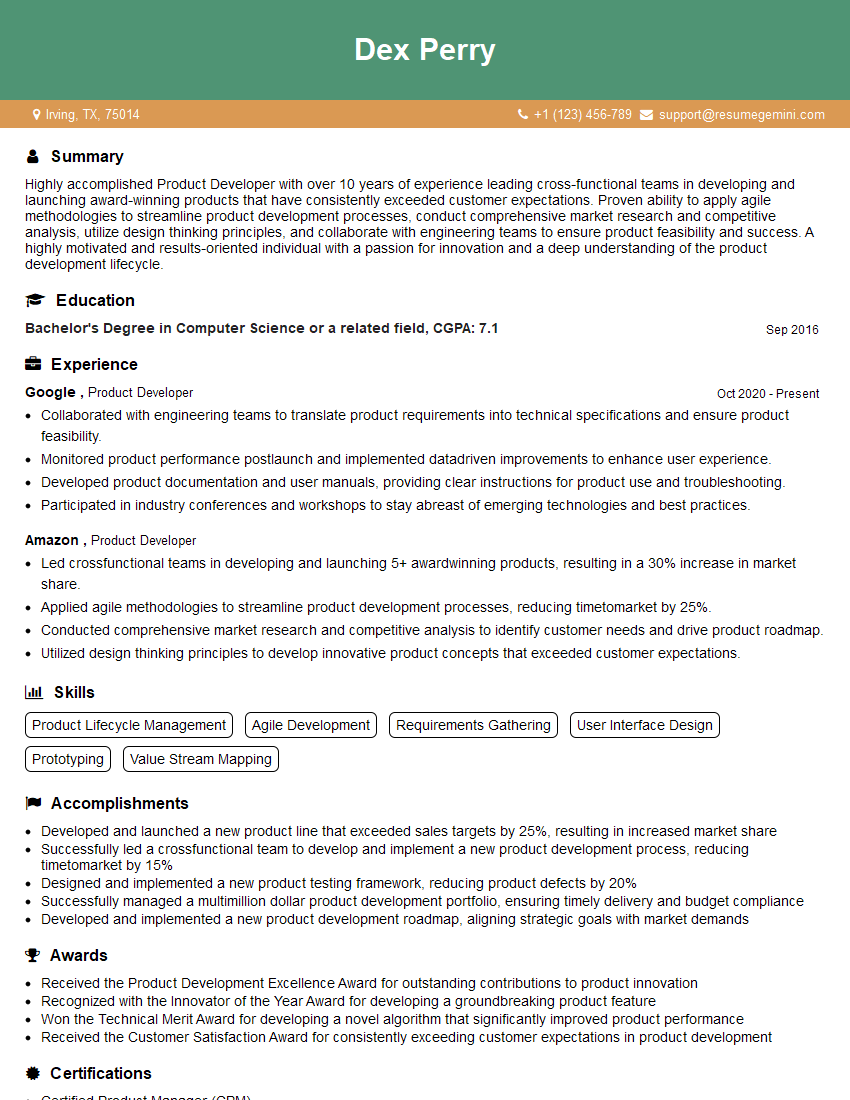

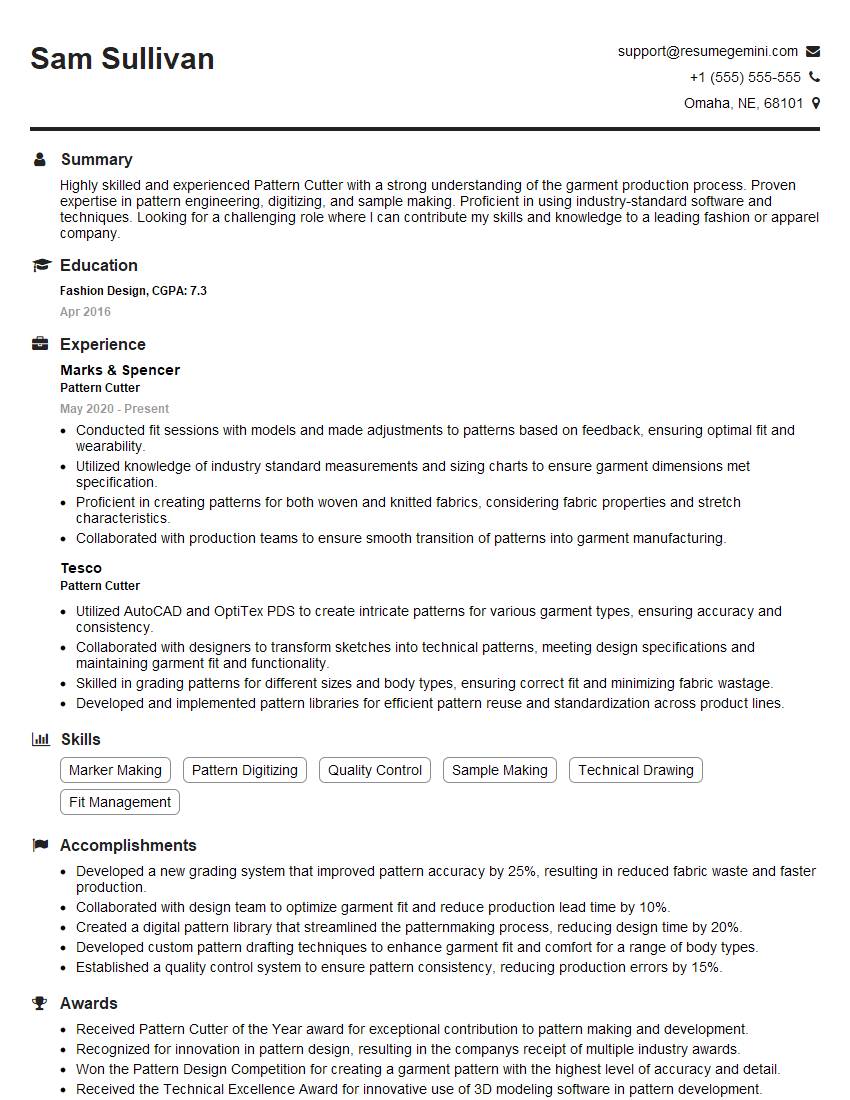

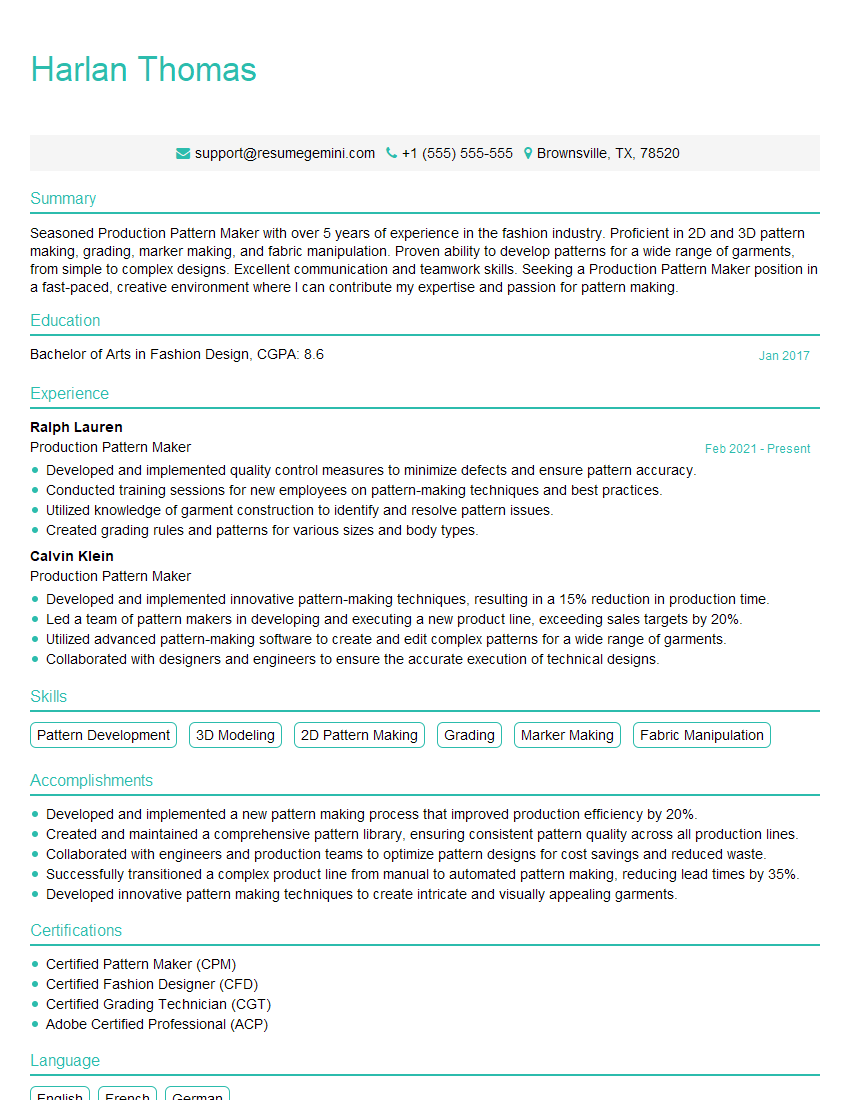

Mastering Pattern Drafting and Measurement is crucial for career advancement in the fashion and apparel industry, opening doors to exciting roles and increased earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of landing interviews. We recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume that showcases your skills and experience. ResumeGemini offers examples of resumes tailored to Pattern Drafting and Measurement professionals, providing you with a template for success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good