The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Hardware and Fixture Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Hardware and Fixture Installation Interview

Q 1. Explain your experience with different types of fasteners.

My experience with fasteners is extensive, encompassing a wide range of types for various applications. I’m proficient with screws (machine screws, wood screws, self-tapping screws), bolts (carriage bolts, machine bolts, anchor bolts), rivets, nails, and various specialized fasteners like expansion anchors and toggle bolts. The choice of fastener depends critically on the material being joined (wood, metal, concrete, etc.), the load it needs to bear, and the aesthetic requirements of the installation. For example, when installing a heavy fixture on a concrete wall, I’d choose expansion anchors for their superior holding power compared to a simple nail. Conversely, for a lightweight picture frame on drywall, a simple nail or picture hook would suffice. I’m also familiar with different head types (Phillips, flathead, hex) and drive systems, enabling me to select the most efficient tool for the job.

- Machine Screws: Used for precision applications requiring high strength and reusability.

- Wood Screws: Designed for use in wood, featuring threads designed for self-cutting and holding power.

- Expansion Anchors: Ideal for fixing items to hollow walls or masonry.

Q 2. Describe your process for reading and interpreting installation blueprints.

Reading and interpreting installation blueprints is a fundamental part of my work. I start by reviewing the title block for project details, revisions, and the scale. I then systematically analyze the different views (plan, elevation, section) to understand the fixture’s location, dimensions, and relationships to other elements. I pay close attention to details like elevations to ensure proper leveling, dimension notations for precise placement, and material specifications to select appropriate fasteners. Symbols and callouts are carefully examined to understand specialized details like conduit routing or bracing requirements. If there’s anything unclear, I always consult with the project engineer or supervisor for clarification before proceeding. Think of it like reading a detailed map – each line and symbol tells a story, and I need to understand the entire narrative to successfully complete the installation.

For example, a detail drawing might show the exact spacing and type of fasteners required for a specific structural connection, which is crucial for ensuring the strength and safety of the installation.

Q 3. How do you ensure the proper alignment and leveling of fixtures?

Ensuring proper alignment and leveling is paramount for both functionality and aesthetics. I use a variety of tools to achieve this, including levels (spirit levels, laser levels), plumb bobs, and measuring tapes. Before fixing a fixture, I pre-drill pilot holes (if necessary) to prevent cracking or splitting, then carefully position it according to the blueprints. I use shims – small pieces of wood or metal – to adjust for minor imperfections in the surface. Laser levels are particularly helpful for aligning multiple fixtures or ensuring a straight line for linear installations. I regularly check alignment and leveling during the installation process, making small adjustments as needed. Once the fixture is secured, I perform a final check to verify that it meets the specified tolerances.

For instance, installing a row of recessed lighting requires precise alignment to create a visually appealing and evenly lit space. Using a laser level ensures each light fixture is perfectly positioned relative to the others and the ceiling plane.

Q 4. What safety precautions do you follow during installations?

Safety is my top priority. I always begin by assessing the work area for potential hazards like exposed wiring, sharp edges, or unstable structures. I wear appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and steel-toed boots. When working at heights, I use fall protection equipment like harnesses and safety lines. I properly ground power tools to prevent electrical shock and use lockout/tagout procedures to isolate power sources before working on energized equipment. I’m also mindful of the location of others in the workspace, ensuring clear communication and avoiding obstructions. I regularly inspect my tools and equipment for damage or wear before each use. Safety isn’t just a checklist; it’s a mindset that permeates every aspect of my work.

For example, before using a power drill near live electrical wires, I’d always ensure the power is turned off and locked out to prevent any accidental electrical contact.

Q 5. How do you troubleshoot common installation problems?

Troubleshooting is a key skill. Common problems include misaligned fixtures, incorrect fastener selection, and damaged materials. My approach involves systematic investigation. First, I carefully review the blueprints and installation instructions to ensure I’m following the correct procedures. Then, I visually inspect the affected area for obvious issues. I use measuring tools to verify alignment and dimensions. If the problem is related to fasteners, I might switch to a different type or size. If materials are damaged, they need to be replaced. If the problem persists, I consult with the project supervisor or engineer for further guidance. Documenting the issue and the steps taken towards resolution is essential for future reference and quality control.

For instance, if a fixture is not level, I would first check my leveling tools, then ensure the mounting surface is even. If these checks are good, I’d investigate whether the issue might be due to an underlying structural problem.

Q 6. Describe your experience with various hand and power tools.

I’m proficient in using a wide range of hand and power tools. Hand tools include screwdrivers (various types and sizes), wrenches, pliers, hammers, levels, measuring tapes, and chisels. My power tool experience encompasses drills (impact drivers, cordless drills), saws (circular saws, reciprocating saws), and other specialized tools such as stud finders and hole saws. I understand the safe and efficient operation of each tool, including proper techniques for minimizing vibration and fatigue. Regular maintenance of these tools is crucial for their longevity and safety. I also understand the importance of selecting the right tool for the specific task. Using the wrong tool can lead to damage, injury, or an inefficient workflow.

For example, using an impact driver for fastening screws in a delicate material might cause damage, while using a regular screwdriver might be excessively time-consuming for large volume work. Choosing the correct tool is key for efficiency and quality.

Q 7. Explain your understanding of building codes and regulations related to installations.

Understanding building codes and regulations is critical for ensuring the safety and compliance of my work. I’m familiar with relevant codes like the International Building Code (IBC) and local ordinances. These codes cover aspects like electrical wiring, structural integrity, fire safety, and accessibility. Before starting any installation, I carefully review the applicable codes to ensure the work adheres to all requirements. This includes ensuring proper grounding of electrical fixtures, using appropriate fasteners for load-bearing applications, and maintaining proper clearances for ventilation and accessibility. Staying updated on code changes is also essential, as regulations evolve to reflect advancements in technology and safety practices. Non-compliance can result in significant penalties and safety risks. This knowledge extends to understanding the requirements for working with different materials, ensuring installations are structurally sound and meet the specific needs of the building.

For example, installing a smoke detector requires adherence to specific height and spacing requirements outlined in the building codes to ensure optimal coverage.

Q 8. How do you manage your time and prioritize tasks during an installation project?

Effective time management and task prioritization are crucial for successful hardware and fixture installations. I employ a multi-step approach. First, I meticulously review the project blueprints and specifications to fully understand the scope of work, identifying all tasks and dependencies. Then, I create a detailed schedule, breaking down the project into manageable phases with realistic timelines. This includes allocating specific time slots for each task, considering potential delays and factoring in buffer time. I utilize project management tools, often digital checklists and calendars, to track progress and ensure I stay on schedule. Prioritization involves focusing on critical path tasks – those that directly impact the project completion – first. For example, if installing plumbing is a prerequisite for appliance installation, I’ll prioritize the plumbing work. Regularly reviewing and adjusting the schedule as needed is key, as unforeseen issues may arise.

For instance, on a recent commercial kitchen renovation, I prioritized the installation of the main gas line and ventilation system before tackling the individual appliance hookups. This ensured the kitchen’s core infrastructure was in place, preventing delays and facilitating a smooth workflow.

Q 9. Describe your experience working with different materials (wood, metal, plastic).

My experience spans a wide range of materials, including wood, metal, and plastic. I’m adept at working with various wood types, understanding their unique properties – from the strength of hardwoods like oak to the flexibility of softwoods like pine. This understanding informs my choice of fasteners and cutting techniques. With metals, I’m proficient in working with steel, aluminum, and brass, utilizing appropriate tools and safety measures for cutting, drilling, and fastening. I understand the importance of corrosion protection and selecting the right fasteners for different metal types. Similarly, I’m experienced with different plastics, understanding their varying strengths and weaknesses, and choosing appropriate joining methods, considering factors like heat sensitivity.

For example, when building a custom wooden cabinet, I’d use dowels and wood glue for strong joints, while constructing a metal shelving unit might involve welding or using high-strength bolts. When working with plastic pipes, I’d use solvent welding techniques for robust, leak-proof connections.

Q 10. How do you handle unexpected challenges or changes during an installation?

Unexpected challenges are inevitable in any installation project. My approach involves a combination of preparedness, problem-solving skills, and clear communication. Firstly, thorough planning helps mitigate unforeseen issues. However, if problems arise – such as discovering faulty materials or encountering unanticipated structural limitations – I maintain a calm and methodical approach. I assess the situation, identifying the root cause of the problem. I then develop several potential solutions, weighing their pros and cons in terms of time, cost, and safety. Once a solution is chosen, I clearly communicate the change to the client, explaining the impact on the timeline or budget, if any.

In one instance, while installing lighting fixtures, I discovered incorrect wiring in the existing electrical system. Instead of proceeding, I immediately alerted the client, documenting the issue and providing a detailed explanation of the necessary rectification. We worked together to determine the best solution – calling an electrician to fix the wiring before I continued with the lighting installation – ensuring a safe and compliant outcome.

Q 11. What are your methods for quality control during and after installation?

Quality control is integrated into every stage of my work, starting with careful material selection and inspection. During installation, I consistently check for accuracy, ensuring fixtures are level, plumb, and securely fastened. Regular visual inspections are crucial, checking for any defects or inconsistencies. After completion, a thorough final inspection verifies functionality and aesthetics. This involves testing all fixtures, checking for leaks (in plumbing installations), ensuring proper electrical connections, and verifying alignment and finish. Documentation, including photographs and detailed notes, serves as a record of the work and aids in troubleshooting any future issues. Client feedback is also integral, ensuring their satisfaction with the completed installation.

For example, after installing a new kitchen faucet, I’d meticulously check for leaks by running water at full pressure for several minutes. I’d also inspect the faucet’s operation, ensuring smooth handle movement and proper water flow.

Q 12. Describe your experience with different types of fixtures (lighting, plumbing, HVAC).

I have extensive experience installing various types of fixtures, including lighting, plumbing, and HVAC. My lighting experience encompasses a wide range of styles and technologies – from simple recessed lights to complex chandelier installations. I understand the nuances of different lighting circuits and safety regulations. Plumbing experience includes installing sinks, toilets, faucets, and shower systems, with expertise in handling various piping materials and connection techniques. In HVAC, I’ve worked with various systems, from installing simple exhaust fans to working on more complex HVAC units, understanding airflow principles and safety protocols.

For instance, installing a complex chandelier requires careful planning and execution, considering weight distribution, electrical connections, and aesthetic alignment. Similarly, installing a new toilet involves understanding water pressure, drain connections, and ensuring a leak-proof seal.

Q 13. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is paramount for efficiency and safety. I start by organizing materials and tools before commencing the project, grouping similar items and keeping them readily accessible. I use appropriate storage containers to keep small parts organized and prevent loss. As I work, I regularly dispose of debris and keep the immediate work area clear of clutter. Protective coverings, like drop cloths, are used to safeguard surfaces. At the end of each workday, I thoroughly clean the area, ensuring all tools are stored properly and materials are secured.

This organized approach not only enhances efficiency but also minimizes the risk of accidents caused by tripping hazards or misplaced tools.

Q 14. Explain your understanding of electrical wiring and safety procedures.

I have a thorough understanding of electrical wiring and safety procedures. I am familiar with different wiring types, including Romex, BX cable, and conduit systems. I understand electrical codes and regulations, ensuring all installations are compliant. Before starting any electrical work, I always ensure the power is shut off at the breaker box and use a voltage tester to confirm the absence of power. I follow proper wire stripping and connection techniques, using appropriate connectors and ensuring secure connections to avoid shorts or other hazards. I’m also proficient in using various electrical testing equipment to ensure the safety and integrity of the installation.

Safety is my top priority. I never work on live wires and always follow the established safety protocols, including using proper personal protective equipment (PPE) such as safety glasses and insulated gloves.

Q 15. Describe your experience with working at heights or in confined spaces.

Safety is paramount when working at heights or in confined spaces. My experience includes extensive training and practical application of safety protocols, including the proper use of harnesses, fall arrest systems, and confined space entry procedures. I’ve worked on projects involving installing fixtures on tall buildings, requiring the use of scaffolding and rope access techniques. In confined spaces, like crawl spaces or attics, I’ve always prioritized proper ventilation and the use of gas detectors to mitigate risks. For example, during a recent project installing lighting fixtures in a cathedral ceiling, I meticulously followed all fall protection protocols, ensuring my harness was properly secured to a robust anchor point at all times. In a separate instance, while installing ductwork in a cramped basement, I used a gas detector before entering and maintained constant communication with a colleague outside to ensure my safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate with customers or supervisors regarding installation progress?

Clear and consistent communication is essential. I use a multi-pronged approach, employing various methods depending on the situation. I start by scheduling regular check-in meetings with customers to review the progress, discuss any challenges, and address concerns. For supervisors, I provide daily or weekly progress reports detailing completed tasks, outstanding issues, and any potential delays. I frequently utilize email and project management software to provide updates, share photos and videos of installations, and ensure transparency. For example, when faced with an unexpected material delay on a recent kitchen remodel project, I immediately notified both the customer and my supervisor, outlining the problem and proposing alternative solutions to minimize disruption. The proactive communication helped manage expectations and maintain trust.

Q 17. Describe a time you had to adapt to a change in installation plans.

Adaptability is crucial in this field. On a recent project installing bathroom fixtures in a historic home, the original plans called for a specific type of faucet that proved unavailable due to supply chain issues. I quickly researched suitable alternatives, presented them to the customer with their pros and cons, and obtained their approval for a change. This involved adjusting the installation schedule slightly, but it prevented significant project delays. We carefully considered the historical context and selected a replacement faucet that preserved the home’s aesthetic while meeting the customer’s functionality requirements. This experience highlighted the importance of proactive problem-solving and clear communication during unexpected changes.

Q 18. How do you ensure the proper sealing and waterproofing of fixtures?

Proper sealing and waterproofing are critical for preventing leaks and damage. My process begins with careful preparation of the surfaces, ensuring they are clean, dry, and free of any debris. I then select appropriate sealants and waterproof membranes, based on the specific material and application. This often includes using high-quality silicone caulk for joints and applying waterproof membranes around showers and bathtubs. After installation, I thoroughly inspect all seals and connections, paying close attention to details. This includes using specialized tools for testing and verifying the integrity of the seals. For example, during a recent shower installation, I utilized a waterproof membrane system and ensured all seams were sealed meticulously with a compatible sealant to ensure long-term leak prevention. Following manufacturer’s instructions on sealant application is also crucial.

Q 19. What software or tools do you use to plan or manage installations?

I utilize several software and tools for effective project management and planning. I am proficient in using project management software like Asana and Trello for task assignments, scheduling, and tracking progress. I also utilize CAD software for visualizing and planning complex installations, ensuring accurate measurements and material estimations. Moreover, I use mobile apps for communication and real-time updates on the job site. These tools allow for better organization, streamlined communication, and ultimately efficient project execution. For instance, during a large-scale office renovation, I used CAD software to create a detailed 3D model of the space, facilitating efficient planning and preventing costly errors during the fixture installation phase. The use of the project management software also allowed for smooth team coordination and task management throughout the project.

Q 20. Describe your experience with troubleshooting electrical or plumbing issues.

Troubleshooting electrical and plumbing issues requires a systematic approach and a good understanding of building codes. I have experience identifying and resolving various problems, such as faulty wiring, leaky pipes, and low water pressure. I always prioritize safety and will not proceed if unsure of a solution. When encountering an issue, I first assess the situation, identifying the likely cause. I then test my hypothesis using appropriate tools (multimeter for electrical, pressure gauge for plumbing). Once the problem is identified, I carefully implement the necessary repairs or replacements, ensuring all work adheres to safety regulations and building codes. For example, on one occasion, I discovered a short circuit in a lighting fixture causing a tripping breaker. By systematically checking the wiring, I isolated the faulty wire, repaired the connection, and tested the fixture before restoring power.

Q 21. How do you dispose of waste materials responsibly during installations?

Responsible waste disposal is a priority. I meticulously separate materials into appropriate categories (metal, plastic, wood, etc.) to facilitate recycling or proper disposal. I utilize local recycling centers and waste management facilities in accordance with regulations. I always ensure that hazardous materials, such as chemicals and broken glass, are handled and disposed of according to safety guidelines and local regulations. For example, on a recent demolition project, I diligently sorted the debris, ensuring that recyclable materials like metal and wood were properly separated for recycling and that hazardous waste like asbestos-containing materials were handled and disposed of according to all environmental regulations.

Q 22. What is your experience with different types of installation methods (e.g., surface mount, recessed)?

Installation methods vary widely depending on the fixture and the substrate. Surface mount installations are the simplest, attaching directly to the surface with screws or adhesive. Think of a picture hung on a wall with a nail and hook – that’s a surface mount. Recessed installations, on the other hand, require cutting into the surface to embed the fixture, offering a cleaner, more integrated look. This is common with recessed lighting where the fixture sits flush with the ceiling. I’ve extensive experience with both, including other methods like flush mounting (where the fixture sits flat against the surface but isn’t recessed), and even semi-recessed options. My experience encompasses various materials like drywall, concrete, wood, and metal, each requiring tailored approaches. For example, installing a surface mount light on concrete requires different anchors and techniques compared to drywall.

- Surface Mount: Simple, quick installation, suitable for lighter fixtures. Requires less expertise.

- Recessed Mount: More complex, requiring precise cutting and potentially specialized tools. Offers a cleaner aesthetic and is suitable for heavier fixtures.

- Flush Mount: A compromise between surface and recessed, often used for clean aesthetics without the complexity of recessed installations.

Q 23. Describe your familiarity with various types of anchors and their appropriate applications.

Choosing the right anchor is crucial for a secure and safe installation. My experience covers a wide range, including:

- Drywall anchors: These are commonly used in drywall, and the type depends on the weight of the fixture. Plastic expansion anchors are suitable for lighter fixtures, while molly bolts or toggle bolts are better for heavier ones. I always assess the drywall’s thickness and the fixture’s weight before selecting the appropriate anchor.

- Concrete anchors: Concrete requires different anchors due to its density. I’m proficient with various types, including sleeve anchors, wedge anchors, and chemical anchors, each with specific application requirements.

- Masonry anchors: For brick or stone, masonry anchors offer secure fixing. The choice depends on the material’s composition and the fixture’s weight.

Selecting the wrong anchor can lead to fixture failure and potential damage. I carefully evaluate the substrate material, the weight of the fixture, and the anticipated load before making a choice. For example, using a plastic anchor for a heavy fixture in drywall would be a mistake, potentially leading to the fixture falling.

Q 24. How do you ensure the structural integrity of the installation?

Structural integrity is paramount. I meticulously assess the load-bearing capacity of the substrate before installation. This involves considering factors such as:

- Fixture weight: Heavier fixtures require stronger anchors and possibly additional support.

- Substrate material: Different materials have varying strength characteristics.

- Environmental conditions: Exposure to moisture or temperature fluctuations can affect structural integrity.

For critical installations, I may even consult structural drawings or conduct load calculations to ensure the installation can withstand the expected stresses. I always use appropriate tools and techniques to ensure the anchors are properly set, preventing premature failure. In cases of doubt, I will always recommend a more robust anchoring system or consult with an engineer.

Q 25. What is your experience with installing fixtures in different environments (e.g., residential, commercial)?

My experience spans both residential and commercial settings. Residential installations often involve smaller-scale projects with a focus on aesthetics and ease of use. Commercial installations, however, tend to involve larger projects with higher safety and code compliance requirements. For example, a residential job might involve installing a few light fixtures, whereas a commercial job could involve a complete lighting system for a large office building, requiring a more rigorous approach to safety and compliance with building codes. I’m familiar with the specific needs of each environment, including appropriate fixtures and installation techniques.

For example, in a commercial setting, I would be more concerned about ensuring that the wiring is properly grounded and that the fixtures are installed to meet all relevant safety standards. In a residential setting, the focus might be more on aesthetics and making sure that the fixtures match the overall design of the home.

Q 26. Describe a time you had to solve a complex installation problem.

During a commercial renovation, I encountered a situation where we needed to install a heavy, custom-designed light fixture in a high-ceiling space with exposed ductwork. The original plan used standard anchors, but the ceiling was unusually weak. Simply using heavier anchors wasn’t sufficient due to the weight and the ceiling’s condition. My solution involved a three-step approach:

- Assessment: I carefully inspected the ceiling, identified the weak points, and assessed the fixture’s weight and center of gravity.

- Reinforcement: I proposed and implemented a solution using strategically placed metal plates bolted to the supporting structure above the ceiling, effectively distributing the weight across a wider area.

- Secure Installation: Once the reinforcement was in place, we used high-strength anchors to attach the fixture to the metal plates, ensuring a secure and stable installation.

This approach prevented potential damage and ensured the fixture’s safety and longevity. It highlights the importance of careful assessment and creative problem-solving in complex installations.

Q 27. How do you stay current with the latest installation techniques and technologies?

Staying current is crucial in this field. I regularly attend industry workshops and conferences to learn about new products, techniques, and safety standards. I also subscribe to relevant trade publications and online resources, keeping abreast of technological advancements. I actively participate in professional organizations, networking with other professionals and sharing best practices. Moreover, I consistently review and update my knowledge on building codes and safety regulations, which are essential for maintaining a high standard of work and ensuring client safety. Continuous learning is vital to maintaining expertise in this ever-evolving field.

Key Topics to Learn for Hardware and Fixture Installation Interview

- Tools and Equipment: Understanding the proper use and maintenance of various hand tools, power tools, and measuring instruments crucial for efficient and safe installation.

- Reading and Interpreting Blueprints/Schematics: Practical application involves accurately interpreting technical drawings to understand fixture placement, wiring diagrams, and structural considerations.

- Installation Techniques: Mastering techniques for various fixtures (e.g., lighting, plumbing, cabinetry) including proper anchoring, securing, and connection methods.

- Safety Procedures and Regulations: Understanding and adhering to relevant safety standards, including OSHA guidelines, to ensure a safe work environment and prevent accidents.

- Troubleshooting and Problem-Solving: Developing skills to identify and resolve common installation problems, such as misaligned fixtures, faulty wiring, or material defects. This includes practical experience in diagnosing issues and implementing effective solutions.

- Material Selection and Handling: Understanding the properties of different materials used in installations and choosing the appropriate materials based on project requirements. This involves knowledge of material compatibility and best practices for handling and storage.

- Code Compliance: Familiarity with relevant building codes and regulations to ensure all installations meet legal and safety requirements. This includes understanding how local codes may impact installation procedures.

- Project Management Fundamentals: Basic understanding of project timelines, budgeting, and resource allocation relevant to installation projects. This helps demonstrate an ability to manage time and materials effectively.

Next Steps

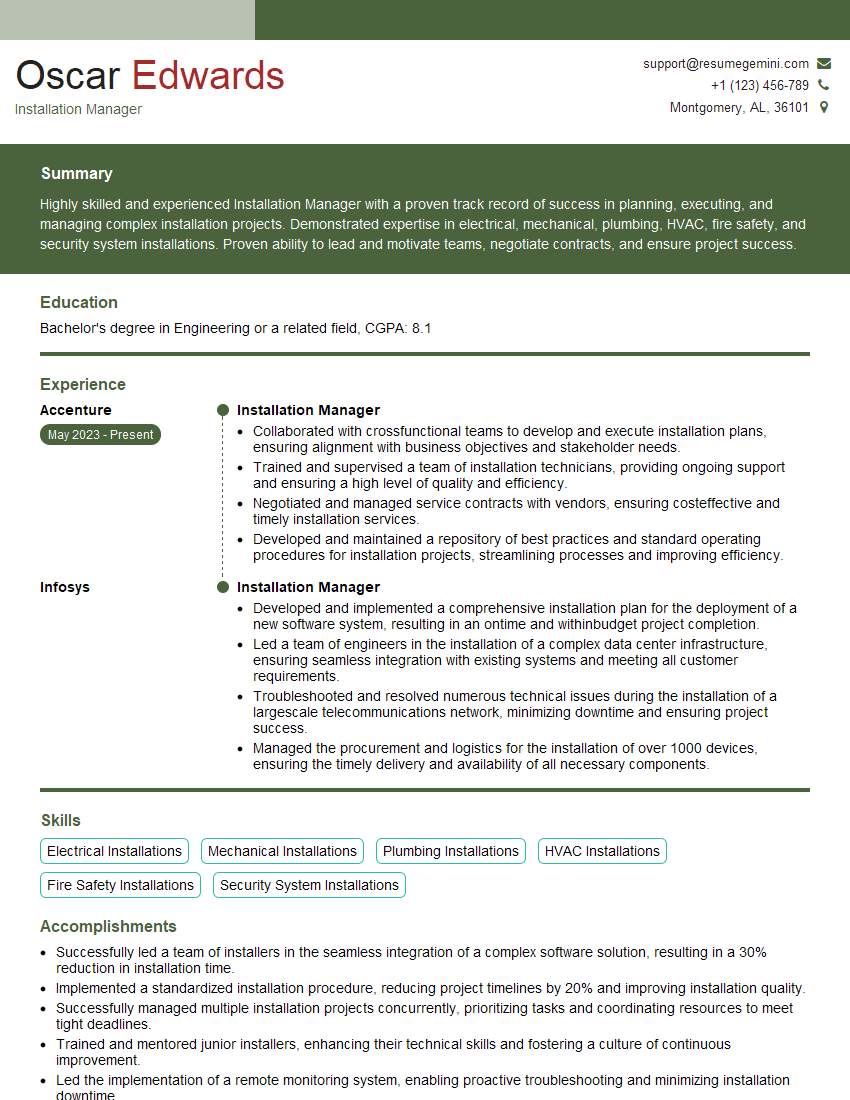

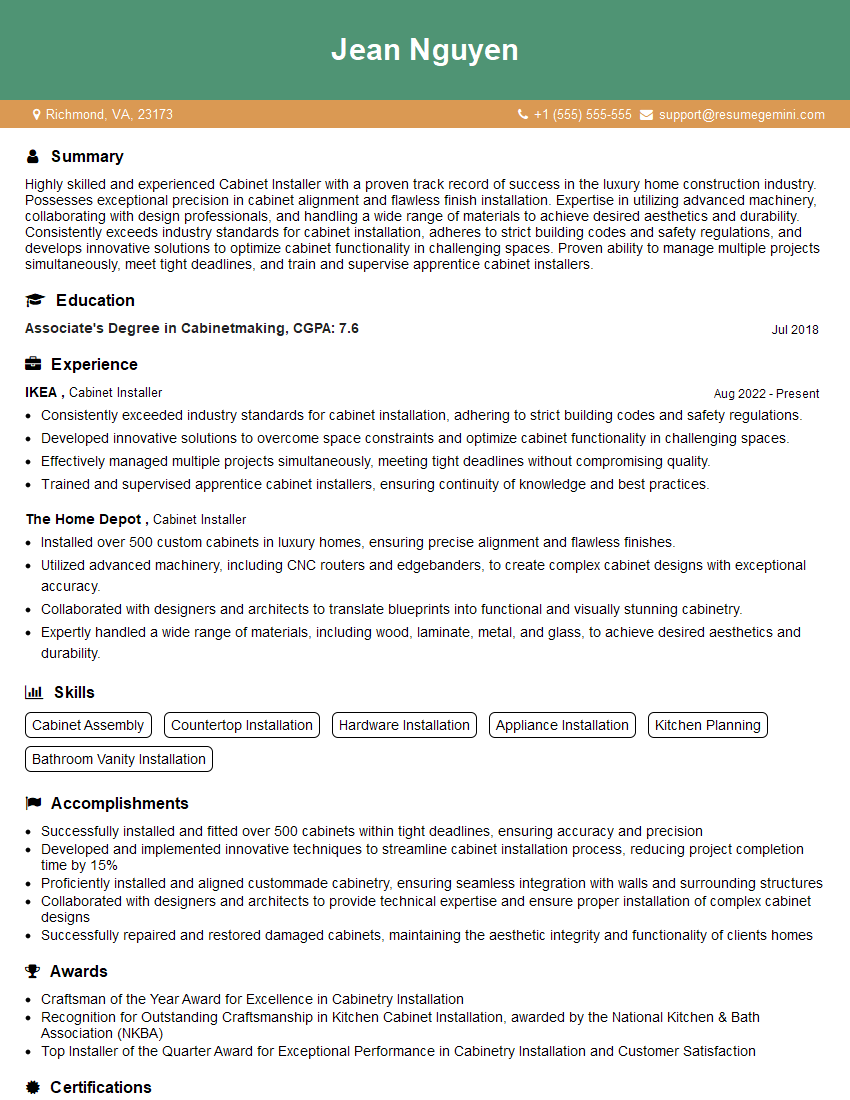

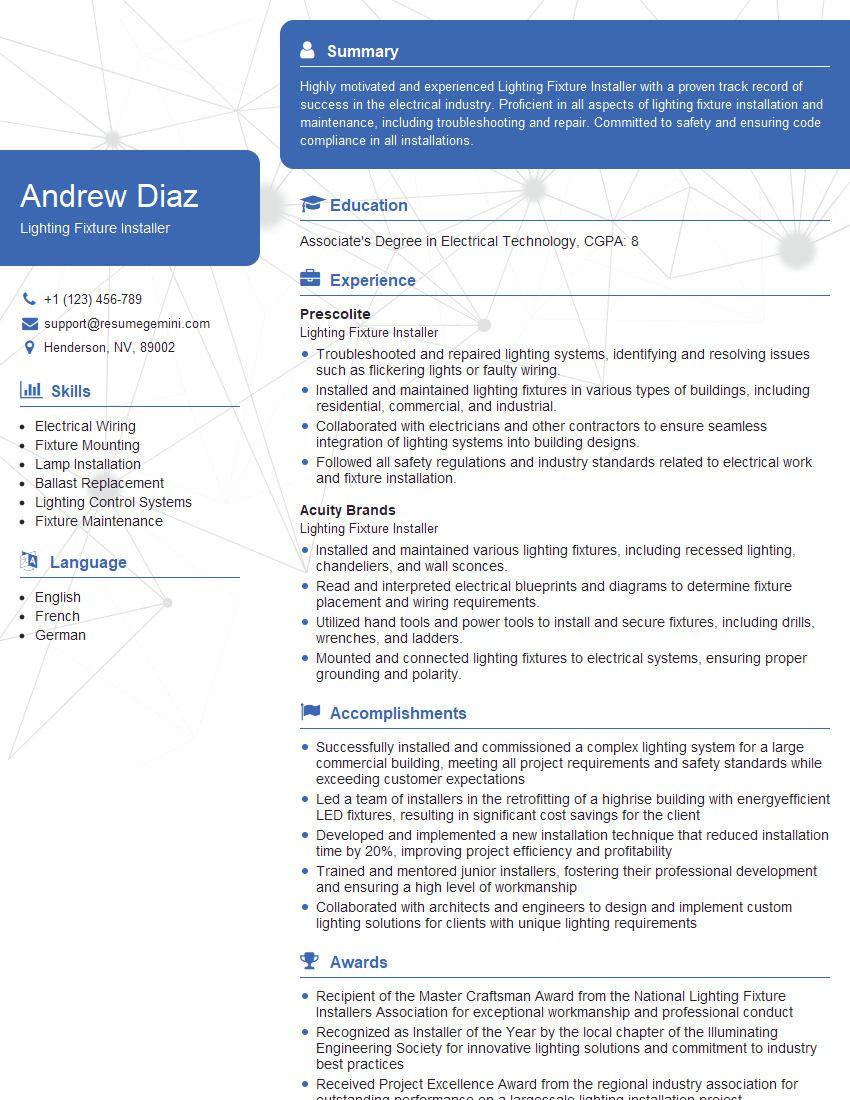

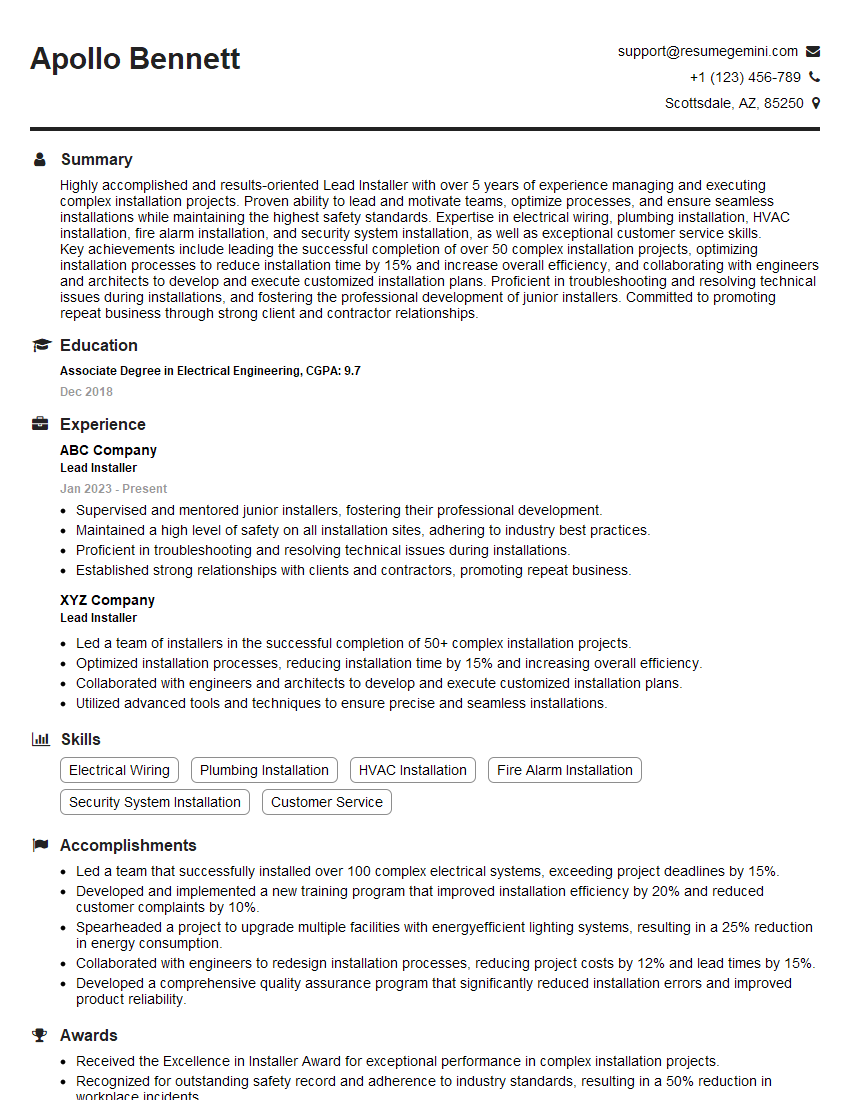

Mastering Hardware and Fixture Installation opens doors to a rewarding career with excellent growth potential. As the demand for skilled tradespeople continues to rise, proficiency in this area ensures a competitive edge in the job market. To maximize your chances of landing your dream role, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Hardware and Fixture Installation are provided to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good