Cracking a skill-specific interview, like one for Bridge Plug Setting and Retrieval, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Bridge Plug Setting and Retrieval Interview

Q 1. Describe the different types of bridge plugs and their applications.

Bridge plugs are essential tools in well intervention, used to isolate sections of a wellbore. They come in various types, each suited for specific applications. The choice depends on factors like well conditions, pressure, temperature, and the intended operation.

- Hydraulic Bridge Plugs: These are the most common type, set by pumping a fluid that expands a packer element, creating a seal against the wellbore wall. They are versatile and suitable for a wide range of applications, including zonal isolation during testing, stimulation, or completion operations.

- Mechanical Bridge Plugs: These plugs use mechanical means, such as expanding mandrels or inflatable packers, to achieve a seal. They offer greater reliability in challenging conditions, such as high-pressure, high-temperature wells, or where a hydraulic seal may be difficult to achieve.

- Composite Bridge Plugs: Combining aspects of both hydraulic and mechanical plugs, these offer a balance of reliability and ease of setting. They may use a combination of hydraulic pressure and a mechanical locking mechanism.

- Expandable Bridge Plugs: These use a material that expands upon activation (e.g., due to temperature or pressure changes) to create the seal. Useful in situations where hydraulic pressure is limited.

For example, a hydraulic bridge plug might be used to isolate a specific zone during a formation test, ensuring accurate pressure readings. A mechanical bridge plug might be preferred in a high-pressure well where a hydraulic seal could be compromised.

Q 2. Explain the process of setting a hydraulic bridge plug.

Setting a hydraulic bridge plug is a precise operation requiring careful planning and execution. It involves several key steps:

- Preparation: Ensure the well is properly cleaned and the desired setting depth is confirmed. The correct type and size of bridge plug must be selected for the well conditions.

- Running the Plug: The bridge plug is lowered into the wellbore on a wireline or tubing string.

- Setting the Plug: Once the plug reaches the target depth, a hydraulic fluid (usually a compatible oil-based fluid) is pumped into the plug. This fluid expands the packer element, creating a tight seal against the wellbore.

- Verification: After setting, pressure tests are conducted to verify the integrity of the seal. This confirms that the plug is successfully isolating the wellbore section.

Think of it like inflating a balloon inside a pipe – the expanding balloon (packer) seals the pipe (wellbore).

Q 3. What are the safety precautions involved in bridge plug setting?

Safety is paramount during bridge plug setting operations. Several precautions are crucial:

- Rig-site Safety Procedures: Strict adherence to company and regulatory safety rules is mandatory, including proper PPE (Personal Protective Equipment).

- Pressure Control: Maintaining control of well pressure is critical throughout the operation. Blowout preventers (BOPs) must be properly tested and operational.

- Well Integrity: Thorough pre-operation well surveys and analysis are crucial to assess the well’s condition and identify potential risks. Ensuring the wellbore is clean and free from debris before setting the plug minimizes issues.

- Emergency Response Planning: A well-defined emergency response plan should be in place, addressing potential scenarios like a pressure surge or equipment failure.

- Proper Training and Supervision: All personnel involved must be adequately trained and supervised by experienced professionals.

Failure to follow these precautions can lead to serious accidents, including well control incidents.

Q 4. How do you ensure proper sealing during bridge plug setting?

Ensuring proper sealing is crucial for the success of any bridge plug operation. Several factors contribute to a successful seal:

- Proper Plug Selection: Choosing the right size and type of plug for the well conditions is fundamental. This includes accounting for wellbore diameter, pressure, and temperature.

- Wellbore Condition: A clean, smooth wellbore is essential for a good seal. Any debris or irregularities can prevent the packer from achieving a full seal.

- Setting Pressure: The hydraulic pressure used to set the plug should be carefully controlled to ensure the packer expands adequately, creating a tight seal without damaging the wellbore.

- Fluid Compatibility: The setting fluid should be compatible with both the plug and the wellbore fluids. Incompatible fluids can cause swelling or damage to the seal.

- Post-Set Verification: Post-set pressure testing is the best way to verify a successful seal. This involves pressurizing the wellbore section to check for leaks.

Think of it like using the right size and type of sealant for a window – an improperly sized or incompatible sealant won’t create a proper seal.

Q 5. What are the common causes of bridge plug setting failures?

Bridge plug setting failures can have various causes, often related to improper planning or execution:

- Incorrect Plug Selection: Using a bridge plug that’s too small, too large, or unsuitable for the well conditions is a common cause of failure.

- Insufficient Setting Pressure: Failure to apply sufficient hydraulic pressure can prevent the packer from expanding adequately.

- Wellbore Irregularities: Deformation, corrosion, or debris in the wellbore can interfere with the seal.

- Fluid Incompatibility: Using incompatible setting fluids can cause the seal to fail.

- Equipment Malfunction: Issues with the pumping equipment or the bridge plug itself can lead to failure.

A thorough pre-job planning phase, including wellbore analysis and equipment inspection, helps mitigate many of these risks.

Q 6. Describe the process of retrieving a bridge plug.

Retrieving a bridge plug is often a more challenging operation than setting it. It typically involves these steps:

- Preparation: A thorough understanding of the plug’s type, setting method, and well conditions is necessary. The appropriate retrieval tools must be selected.

- Running the Retrieval Tool: The chosen tool, which may involve a specialized milling or pulling device, is run into the wellbore.

- Engaging the Plug: The retrieval tool is engaged with the bridge plug. This may involve mechanical gripping, hydraulic disengagement, or milling out the plug.

- Retrieving the Plug: Once engaged, the plug is carefully pulled out of the wellbore. This often requires controlled pressure and speed.

- Post-Retrieval Inspection: After retrieval, the plug should be inspected for any damage or indication of failure.

Imagine it as carefully removing a stuck bottle cap – you need the right tool and technique to avoid damage.

Q 7. What are the different methods for retrieving bridge plugs?

Several methods exist for retrieving bridge plugs, depending on the plug type and well conditions:

- Pulling (with a specialized tool): For some plugs, a direct pull with a retrieval tool that grips the plug is possible. This relies on the plug’s integrity.

- Milling: If the plug is damaged or stuck, it might need to be milled out using a specialized milling tool. This method grinds away the plug, allowing for its removal.

- Hydraulic Release: Some plugs are designed with a hydraulic release mechanism. Applying pressure to this mechanism allows for easier removal.

- Combination Methods: Often a combination of techniques is needed, for example, partially milling the plug to facilitate its extraction.

The choice of retrieval method is crucial for the successful and safe removal of the plug, and requires professional judgment based on the situation.

Q 8. How do you select the appropriate bridge plug retrieval technique?

Selecting the appropriate bridge plug retrieval technique hinges on several crucial factors: the type of bridge plug deployed (e.g., inflatable, hydraulic, mechanical), its setting depth and condition, the wellbore environment (temperature, pressure, fluid type), and the available equipment. Think of it like choosing the right tool for a specific job – you wouldn’t use a hammer to screw in a screw.

- Inflatable bridge plugs are typically retrieved by deflating them using a specialized tool that reduces the plug’s diameter, allowing it to be pulled back up the wellbore. The choice here might depend on the pressure control needed during deflation.

- Hydraulic bridge plugs, which are set and released using hydraulic pressure, require careful monitoring of the pressure during retrieval to ensure smooth operation and prevent damage. The choice involves considering the pressure capabilities of the retrieval equipment and the well’s pressure profile.

- Mechanical bridge plugs often require specialized tools like a fishing neck or jar to dislodge and retrieve them. The selection depends on the specific design of the mechanical plug and potential obstructions.

A thorough pre-job planning phase, involving review of well logs, previous operations data, and available equipment specifications, is crucial for a successful retrieval.

Q 9. What are the potential risks associated with bridge plug retrieval?

Bridge plug retrieval carries inherent risks, many stemming from the high-pressure, high-temperature environments of oil and gas wells. These risks can be broadly categorized as:

- Wellbore damage: Improper techniques can lead to damage to the casing, tubing, or formation, resulting in costly repairs or even well abandonment. Imagine trying to remove a stubborn bolt with the wrong tool – you risk stripping the bolt or damaging the surrounding material.

- Equipment failure: The retrieval tools themselves can fail under pressure, potentially causing a well control incident or compromising the integrity of the well.

- Stuck bridge plug: The plug might become stuck in the wellbore due to unexpected formations or cement bridging, requiring specialized fishing techniques to recover it. This can dramatically increase the cost and time of the operation.

- Environmental hazards: Leaks during retrieval could lead to hydrocarbon releases, posing environmental and safety risks. This underscores the importance of using proper equipment and careful procedures.

Mitigation of these risks requires meticulous planning, experienced personnel, and the use of appropriate equipment and safety protocols.

Q 10. How do you troubleshoot problems encountered during bridge plug retrieval?

Troubleshooting during bridge plug retrieval often involves systematic analysis and a methodical approach. Imagine a detective solving a case – you need to gather clues and proceed step-by-step.

- Pressure anomalies: Unexpected pressure changes during retrieval might indicate a stuck plug, damaged equipment, or a leak. Careful monitoring of pressure is essential and may require adjustments to the retrieval procedure.

- Stuck plug: If the plug becomes stuck, we might employ specialized fishing tools, such as jarring tools, or try to dislodge the plug by using controlled pressure pulses or by milling around the plug.

- Equipment malfunction: Equipment failure requires immediate assessment of the problem, which might involve replacing damaged components or adjusting operational parameters.

Thorough documentation of all steps, pressures, and observations is crucial for effective troubleshooting and future operational improvements. A well-defined emergency response plan is also essential to handle unforeseen complications.

Q 11. Explain the importance of wellbore integrity during bridge plug operations.

Wellbore integrity is paramount during bridge plug operations. The wellbore is essentially a pressurized vessel, and maintaining its structural soundness prevents leaks, uncontrolled fluid flow, and potential environmental damage. Think of it as the foundation of a building – if it’s compromised, the entire structure is at risk.

Bridge plug setting and retrieval can impact wellbore integrity. Improper setting techniques can cause casing or cement damage, while aggressive retrieval methods can weaken the wellbore. Therefore, maintaining pressure control, utilizing appropriate equipment and techniques, and employing thorough inspections before and after operations are crucial for preserving wellbore integrity.

Q 12. What are the environmental considerations during bridge plug operations?

Environmental considerations are critical during bridge plug operations, primarily focusing on preventing hydrocarbon leaks and waste disposal. Any accidental release of oil or gas can have severe environmental consequences.

- Spill prevention: Procedures must be in place to prevent and rapidly respond to any potential spills. This includes using specialized equipment designed to contain and clean up any leaked fluids.

- Waste management: Drilling fluids and other wastes generated during bridge plug operations should be managed responsibly and in accordance with regulations. This might involve using specialized waste disposal techniques or employing environmentally friendly drilling fluids.

- Air quality: Fugitive emissions during the operation must be minimized to protect the atmosphere.

Environmental impact assessments should be conducted before operations commence, and proper regulatory permits must be obtained. Environmental monitoring during and after the operation helps ensure compliance and identify potential issues early on.

Q 13. Describe your experience with different bridge plug setting tools and equipment.

Throughout my career, I’ve gained extensive hands-on experience with a range of bridge plug setting tools and equipment. This includes various types of bridge plugs (inflatable, hydraulic, mechanical) and their associated setting and retrieval tools, including hydraulic pumps, specialized running tools, and wireline equipment. I’ve worked with both conventional and advanced technologies, such as remotely operated vehicles (ROVs) for subsea operations.

For example, I’ve been involved in setting and retrieving inflatable bridge plugs using high-pressure pumps and specialized packers. In another project, we utilized a wireline system for the deployment and retrieval of a mechanical bridge plug in a deviated well. Each operation required detailed planning and careful execution to ensure safety and efficiency.

Q 14. How do you calculate the necessary pressure for setting a bridge plug?

Calculating the necessary pressure for setting a bridge plug is a complex process that involves considering several factors. There’s no single formula, as it’s highly dependent on the specific bridge plug design, the wellbore geometry, and the fluid properties.

The pressure required depends on the bridge plug’s sealing mechanism and the well’s pressure profile. For instance, inflatable bridge plugs need sufficient pressure to expand and create a seal against the wellbore. The pressure calculation often involves using empirical correlations or specialized software that accounts for the wellbore diameter, the bridge plug’s dimensions, the fluid viscosity, and the frictional forces involved. In practice, the setting pressure is determined through careful calculations and may be adjusted based on real-time monitoring during the operation. It’s often done through a combination of engineering calculation and using experience-based safety factors.

Safety margins are crucial, ensuring the set pressure sufficiently exceeds the anticipated wellbore pressure to maintain a secure seal. The process often requires iterative calculations, and any doubt is usually resolved by erring on the side of caution.

Q 15. Explain the role of pressure monitoring during bridge plug operations.

Pressure monitoring is absolutely crucial during bridge plug operations; it’s our primary way of ensuring successful setting and retrieval. Think of it as the vital signs of the operation. We monitor pressure changes both above and below the plug to verify its proper seating and integrity.

During setting: We’ll see a gradual pressure increase as the plug is inflated or mechanically expanded, sealing the wellbore. A sudden, significant pressure drop could indicate a leak or failure. Consistent pressure maintenance after setting confirms a secure seal.

During retrieval: We’ll monitor pressure as we deflate or release the plug. A controlled pressure decrease is expected. Any unusual pressure spikes or fluctuations might suggest problems with the plug’s release mechanism or potential wellbore damage.

For example, during a recent operation, a slight pressure drop during setting initially caused concern. However, by carefully analyzing the rate of pressure decrease and cross-referencing it with the setting depth, we concluded it was caused by a small void within the wellbore that was being filled and not indicative of a malfunctioning plug.

Career Expert Tips:

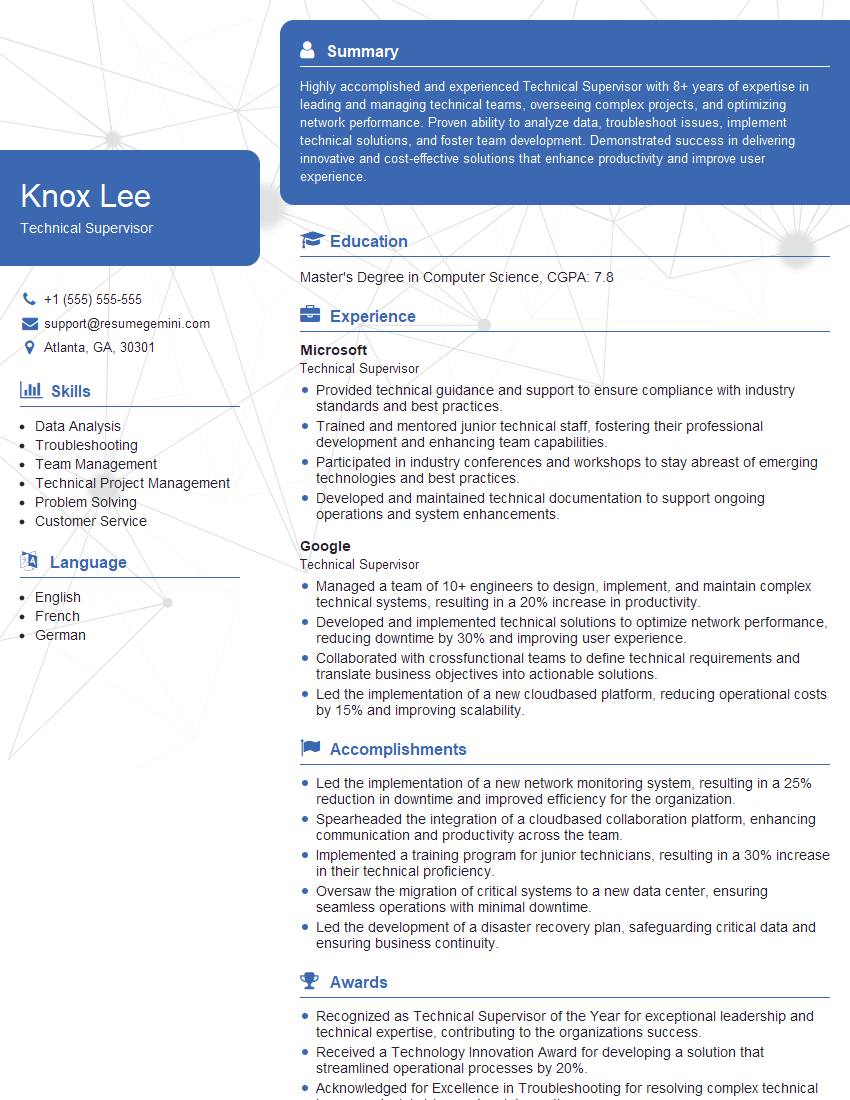

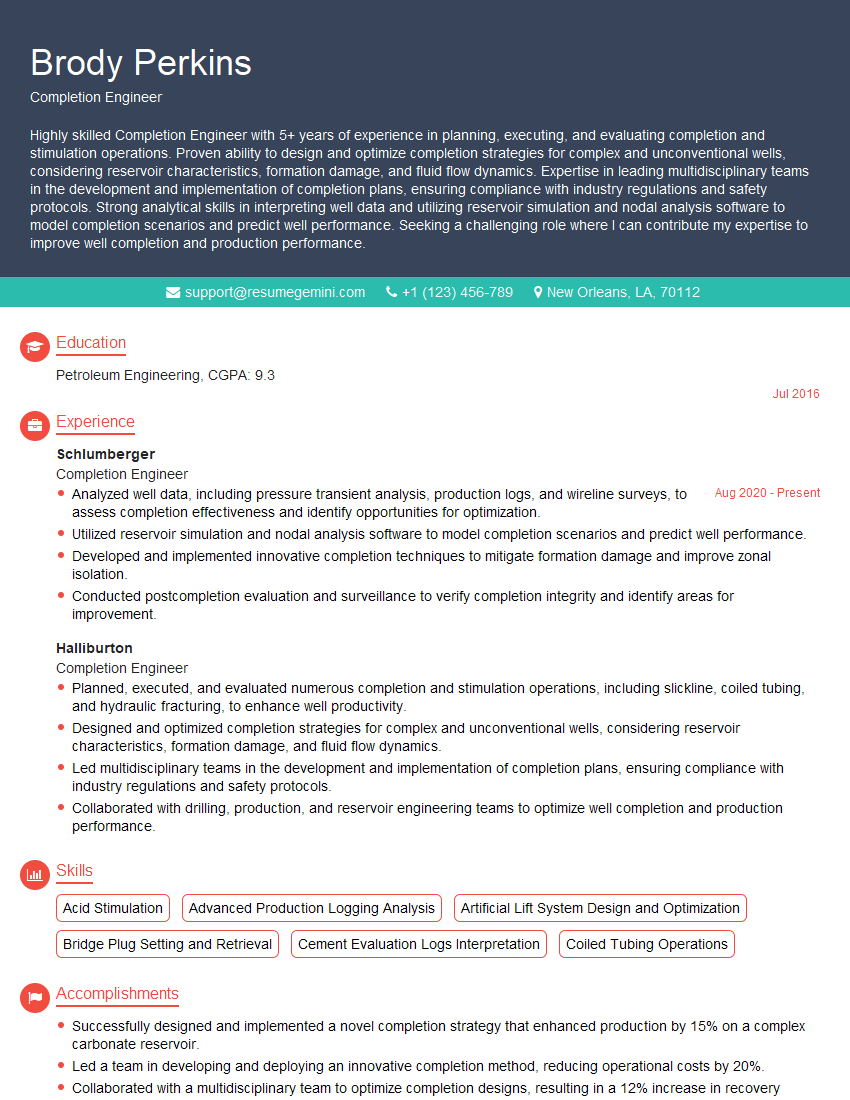

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the limitations of different bridge plug types?

Different bridge plug types have their own sets of limitations. It’s like choosing the right tool for a specific job – there’s no one-size-fits-all solution.

- Inflatable Bridge Plugs: Their limitations include the need for a reliable pressure source, potential for over-inflation damage, and susceptibility to leaks if the elastomer seal is compromised. They are also less suitable for highly deviated wells or wells with complex formations.

- Mechanical Bridge Plugs: These can struggle in narrow or irregular wellbore sections. Setting and retrieving them might require more force, increasing the risk of damage to the wellbore or the plug itself. They can also be more challenging to deploy in wells with significant debris.

- Hydraulic Bridge Plugs: While robust, hydraulic plugs can be difficult to retrieve if the hydraulic system fails. They also require precise pressure control to avoid damaging the plug or the formation.

For instance, in a well with known debris, an inflatable plug might be a risky choice due to the potential for the debris to hinder the expansion of the sealing element. A mechanical bridge plug, with its relatively simpler design and less sensitive sealing mechanism, would be a more suitable option.

Q 17. How do you handle unexpected situations during bridge plug operations?

Unexpected situations are part of the job, and a structured approach is vital. My strategy involves:

- Immediate assessment: Identify the nature of the problem – pressure spike, plug failure, equipment malfunction etc. Accurate assessment requires careful pressure and flow data monitoring, along with an understanding of the well’s characteristics.

- Safety protocols: Prioritize the safety of personnel and equipment. Initiate emergency shutdown procedures if needed.

- Problem analysis: This step requires considering various factors including the wellbore conditions, the type of bridge plug, and any changes to the operational plan since the start. Careful review of pressure and flow data will often reveal clues.

- Corrective actions: Depending on the problem, we could attempt to rectify the situation (e.g., restarting the setting/retrieval process, adjusting the pressure), or we might need to initiate a contingency plan which includes well logging and re-evaluation.

- Post-incident review: After the situation is resolved, conducting a thorough review is critical to understand the root cause, implement preventative measures, and improve future operations.

For example, during one operation, a mechanical bridge plug failed to set correctly. After reviewing pressure data and well logs, we identified a previously unknown constriction in the wellbore which was impacting the plug’s expansion. We then deployed a different plug with a more robust expansion mechanism, successfully completing the operation.

Q 18. What is your experience with different types of bridge plug packers?

My experience encompasses a wide range of bridge plug packers, including:

- Elastomeric packers: These are commonly used for their flexibility and sealing capabilities. Their effectiveness depends heavily on the wellbore pressure and temperature. I’ve worked with various elastomers, each with different temperature and pressure tolerances. Proper selection requires careful consideration of the downhole conditions.

- Metal packers: These provide greater strength and durability but are less adaptable to irregular wellbore geometries. They’re preferred in challenging environments with high pressures and temperatures.

- Hydraulic packers: The expansion/contraction mechanism in these relies on hydraulic pressure. Careful monitoring of this pressure during setting and retrieval is essential to prevent damage. I’ve personally used these in multiple deep-well operations where reliable sealing was crucial.

Each packer type has unique strengths and weaknesses, and selecting the right one requires a thorough understanding of the well’s characteristics and the operation’s objectives. Improper selection can lead to failure, time delays, and even significant costs.

Q 19. Describe your understanding of wellhead equipment relevant to bridge plug operations.

Wellhead equipment plays a vital role, acting as the interface between the surface and the wellbore. Understanding its functionality is key for successful bridge plug operations. Key components include:

- Wellhead casing hangers: These secure the casing strings and maintain wellbore integrity.

- BOP (Blowout Preventer): Essential for safety, it prevents uncontrolled well flow.

- Manifolds and valves: These direct and control the flow of fluids during the operation.

- Pressure gauges and sensors: Used to monitor pressure during bridge plug operations.

For example, a malfunctioning valve in the wellhead manifold could severely compromise the operation, potentially resulting in pressure loss or fluid leakage. Regular inspection and maintenance of this equipment is paramount to prevent such issues and ensure the safety of personnel.

Q 20. How do you interpret pressure and flow data during bridge plug setting and retrieval?

Interpreting pressure and flow data is a crucial skill. It’s like reading a story – the data points tell a tale of what’s happening downhole.

Pressure data: Steady pressure build-up during setting indicates successful expansion of the bridge plug; fluctuations could suggest a leak or irregular wellbore geometry. A slow pressure drop during retrieval indicates controlled release. Rapid changes, however, could indicate problems.

Flow data: Zero flow after setting is confirmation of a complete seal. Any flow after setting indicates a failure to seal the wellbore. Monitoring flow during retrieval helps assess the completeness of the plug’s removal from the wellbore.

Software and data analysis tools help visualize this data and correlate it with other operational parameters, allowing us to make informed decisions and mitigate risks. For example, a sudden pressure increase during retrieval might suggest that the plug has dislodged something, and this would require more cautious retrieval.

Q 21. What are the key differences between inflatable and mechanical bridge plugs?

Inflatable and mechanical bridge plugs differ significantly in their design and operation:

| Feature | Inflatable Bridge Plug | Mechanical Bridge Plug |

|---|---|---|

| Setting Mechanism | Expansion via internal pressure | Mechanical expansion (e.g., using slips or wedges) |

| Sealing Element | Elastomeric seal | Metal components (e.g., slips, cones) |

| Retrieval Mechanism | Deflation | Release of mechanical components |

| Suitability | Suitable for a wider range of wellbore diameters; simpler setting. | More robust for high pressure/temperature conditions and irregular wellbores; requires more force. |

| Limitations | Susceptible to damage from overinflation or temperature extremes | More complex to set and retrieve; limited adaptability. |

The choice between the two depends on various factors including wellbore geometry, pressure and temperature conditions, and the specific operational requirements. For instance, in a well with potential high temperatures, a mechanical bridge plug might be a safer choice than an inflatable plug, where the elastomer could be degraded by high heat.

Q 22. Explain your experience with zonal isolation techniques related to bridge plug setting.

Zonal isolation, crucial in well operations, involves sealing off specific sections of a wellbore. In bridge plug setting, this means preventing fluid flow between different zones. My experience encompasses a wide range of techniques, from using inflatable packers for temporary isolation to setting permanent bridge plugs made of various materials like metal or elastomers. I’ve worked with both single and multiple bridge plugs to achieve complex zonal isolation, for instance, isolating a specific reservoir interval during a multi-stage fracturing operation or sealing off a damaged zone to allow for remedial work. The selection of the appropriate technique depends heavily on the well’s specific conditions, such as pressure, temperature, and the type of fluid present. For example, in a high-pressure, high-temperature (HPHT) well, specialized high-strength metal bridge plugs would be necessary, while in a lower-pressure well, a simpler, less expensive inflatable packer might suffice. I’m proficient in pre-job planning to ensure the chosen method is optimal for the conditions.

- Example: In one project, we used multiple bridge plugs to isolate different perforated intervals in a horizontal well during a multi-stage hydraulic fracturing process. This ensured that the fracturing fluid was directed to the desired zones, maximizing the efficiency of the stimulation treatment.

Q 23. How do you ensure the compatibility of bridge plugs with wellbore conditions?

Ensuring compatibility between bridge plugs and wellbore conditions is paramount to prevent failure and ensure operational safety. This involves a thorough assessment of the well’s characteristics, including pressure, temperature, fluid composition (including potential corrosive elements), and the wellbore diameter. Material selection is key; for instance, high-temperature wells necessitate bridge plugs made of materials like high-alloy steel or specialized elastomers capable of withstanding extreme heat. Similarly, the presence of corrosive fluids would require plugs made of corrosion-resistant alloys. Beyond material selection, the design of the bridge plug itself needs to account for the specific wellbore geometry. I always ensure we have the right pressure rating for the plug to handle anticipated pressures. We also use specialized software to simulate setting and retrieval procedures to mitigate any potential issues.

- Example: In a well containing highly corrosive hydrogen sulfide (H2S), we selected bridge plugs made from a specialized corrosion-resistant alloy to prevent premature failure and potential environmental hazards.

Q 24. What is your experience with the use of logging tools in conjunction with bridge plugs?

Logging tools provide essential information regarding the wellbore conditions and the success of bridge plug setting. We routinely use various logging tools, such as pressure-temperature gauges, caliper logs, and acoustic tools, both before and after bridge plug setting. Pre-setting logs help us to confirm wellbore conditions and choose the right type of bridge plug. Post-setting logs verify the integrity of the seal and the location of the bridge plug. For example, acoustic logs help identify potential fluid leaks around the plug. Pressure-temperature logs confirm successful zonal isolation by showing pressure differentials across the bridge plug. I’m experienced in interpreting log data to identify and resolve potential issues, ensuring the operation’s overall success.

- Example: After setting a bridge plug, we used a pressure-temperature log to confirm a successful seal, showing no pressure communication between the isolated zone and the rest of the wellbore.

Q 25. Describe your understanding of relevant industry regulations and safety standards.

Safety and regulatory compliance are paramount in bridge plug operations. I possess a thorough understanding of relevant regulations such as those set by OSHA (Occupational Safety and Health Administration), API (American Petroleum Institute) standards related to well control and pressure testing procedures, and any other specific regulations pertinent to the geographic location of the operation. These regulations guide us in aspects like well control procedures, risk assessment, emergency response planning, and ensuring the proper use of personal protective equipment (PPE). Adhering to these standards is not just a requirement; it’s integral to ensuring the safety of personnel and the environment.

- Example: Before every operation, we conduct a thorough Job Safety Analysis (JSA) to identify potential hazards and establish preventative measures, always adhering to API standards.

Q 26. How do you manage risks associated with high-pressure and high-temperature environments?

High-pressure and high-temperature (HPHT) environments pose significant challenges. Managing these risks involves careful planning and using specialized equipment and procedures. This starts with selecting the right bridge plug materials, as mentioned earlier. We also use specialized high-pressure hydraulic equipment and rigorous pressure testing protocols to ensure the integrity of the bridge plug and the entire well system. Redundancy is crucial; we often utilize backup systems and procedures to handle potential equipment failure. Thorough pre-job risk assessments are critical in identifying and mitigating potential hazards. Finally, regular monitoring of the wellbore parameters during the operation helps us identify any deviations from expected behavior, allowing for timely intervention.

- Example: In a HPHT well, we used a specialized high-pressure testing system to verify the bridge plug’s integrity before and after setting, ensuring a secure seal at the elevated temperatures and pressures present.

Q 27. Explain your experience with different types of fluids used during bridge plug operations.

Various fluids are used during bridge plug operations. The selection depends on factors such as wellbore conditions, the type of bridge plug, and the overall operation’s objective. Common fluids include drilling muds, completion fluids, and specialized bridge plug setting fluids. Drilling muds are often used during the initial setting process to lubricate the plug and ensure smooth placement. Completion fluids may be used to displace drilling muds and prepare the well for production. Specialized bridge plug setting fluids are designed to provide a clean seal and to prevent damage to the plug or the wellbore. These fluids have specific properties like minimal fluid loss or compatibility with formation fluids. I have experience selecting and managing fluids for optimal results and avoiding compatibility issues.

- Example: In one operation, we used a specialized low-viscosity fluid to set a bridge plug in a highly deviated well to ensure smooth placement and prevent formation damage.

Q 28. Describe a challenging bridge plug operation you have encountered and how you resolved it.

During a deepwater well intervention, we encountered a situation where a bridge plug became stuck during retrieval. Initial attempts to retrieve the plug using standard procedures failed. The preliminary analysis suggested the plug might have been cemented in place. To resolve the issue, we employed a multi-pronged approach. First, we used logging tools to confirm the plug’s location and condition and evaluate the extent of cement bonding around it. Then, we employed a specialized milling tool to carefully remove the cement around the plug, creating enough space for retrieval. Finally, we successfully retrieved the plug using a different retrieval method optimized for the conditions we had discovered. The successful resolution demonstrates my ability to adapt to unexpected challenges and employ innovative solutions while adhering to safety and operational efficiency.

Key Topics to Learn for Bridge Plug Setting and Retrieval Interview

- Wellhead Equipment & Procedures: Understanding the various types of bridge plugs, their functionalities, and the standard operating procedures for setting and retrieving them. This includes pre-job planning and risk assessments.

- Hydraulics and Pressure Management: Mastering the principles of hydraulics as they relate to bridge plug deployment and retrieval. This involves calculations, pressure limitations, and safety protocols for pressure control.

- Tubular Handling and Running Procedures: Familiarize yourself with the techniques and equipment involved in running and retrieving tubing, casing, and other tubular goods in relation to bridge plug operations.

- Troubleshooting and Problem Solving: Develop your ability to identify and troubleshoot common issues encountered during bridge plug setting and retrieval operations, such as stuck plugs or equipment malfunctions. Be prepared to discuss your approach to problem-solving in a high-pressure environment.

- Safety and Regulations: Deep understanding of relevant safety regulations, best practices, and emergency procedures related to well intervention and bridge plug operations. This includes well control and emergency response protocols.

- Materials Science and Compatibility: Knowledge of the materials used in bridge plug construction and their compatibility with different wellbore fluids and environments.

- Wellbore Geometry and Completion Design: Understanding how wellbore geometry and completion design impact bridge plug setting and retrieval operations.

Next Steps

Mastering Bridge Plug Setting and Retrieval is crucial for advancing your career in the oil and gas industry, opening doors to more challenging and rewarding roles. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume significantly increases your chances of getting your application noticed by recruiters. To build a compelling and effective resume that showcases your skills and experience, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform to craft a professional document that highlights your expertise. Examples of resumes tailored specifically to Bridge Plug Setting and Retrieval are available through ResumeGemini to help guide your creation process. Invest in your future – invest in your resume.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good