Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Concrete Forming and Finishing interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Concrete Forming and Finishing Interview

Q 1. Describe your experience with different types of concrete forms (wood, steel, aluminum).

My experience encompasses a wide range of concrete formwork materials, each with its own strengths and weaknesses. Wood forms, while cost-effective and readily available, require skilled craftsmanship for precise construction and are susceptible to warping and damage. I’ve worked extensively with plywood forms, using them for projects ranging from simple footings to complex curved walls. Steel forms, on the other hand, offer superior strength, durability, and reusability, making them ideal for large-scale projects and intricate designs. I’ve used steel forms in high-rise construction and projects demanding precise dimensions. Finally, aluminum forms provide a lightweight yet robust option, particularly beneficial in situations requiring frequent form stripping or handling. I’ve found them useful on projects where ease of maneuverability was crucial.

Choosing the right form material depends on factors such as project size, complexity, budget, and required concrete finish. Each demands slightly different techniques for assembly and maintenance.

Q 2. Explain the process of preparing a concrete form for pouring.

Preparing concrete forms for pouring is a critical step that directly impacts the final concrete structure’s quality and integrity. It’s a multi-step process I always follow meticulously. First, the forms must be thoroughly cleaned of any debris, ensuring a smooth, clean surface contact with the concrete. Next, I apply a release agent, typically a specialized oil-based product or silicone-based mold release, to prevent the concrete from adhering to the forms and facilitate easy stripping. The amount and type of release agent are carefully chosen depending on the form material. After applying the release agent, I check the formwork for any gaps or leaks. These imperfections can lead to concrete leakage, weakening the structure and causing uneven surfaces. These are addressed by caulking, sealing, or reinforcing as needed. Finally, I thoroughly inspect the form alignment, bracing, and overall stability to ensure it can withstand the weight of the wet concrete.

Q 3. How do you ensure proper alignment and bracing of concrete forms?

Proper alignment and bracing are paramount to prevent formwork collapse and ensure the concrete structure meets the design specifications. I use a combination of techniques. Accurate alignment starts with establishing a strong and level base. This often involves using laser levels or transit levels to establish precise elevations and benchmarks. String lines and plumb bobs are invaluable for ensuring verticality and accurate positioning. Bracing is equally crucial. I use a combination of walers (horizontal supports), shores (vertical supports), and bracing struts to distribute the weight of the wet concrete and prevent formwork deflection. The spacing and strength of bracing are determined by the height and complexity of the formwork, along with the anticipated concrete pressure. For example, in tall walls, additional bracing might be required at intervals to prevent buckling. Regular inspections during the pouring process are critical to ensure that the bracing remains effective and no shifting or deformation occurs. I always document the bracing layout for future reference.

Q 4. What are the common problems encountered during concrete forming and how do you address them?

Several common problems can arise during concrete forming. One frequent issue is formwork leakage, which can lead to voids or honeycombing in the concrete. This is usually addressed by carefully sealing gaps and cracks with appropriate materials before pouring. Another challenge is formwork deflection or bulging under the pressure of wet concrete. This necessitates careful bracing and possibly reinforcement of the formwork during the pour. Inconsistent formwork alignment can result in uneven concrete surfaces. Careful planning, precise measurements, and the use of proper alignment tools are crucial to mitigate this. Lastly, improper form stripping (removing the forms) can damage the concrete’s surface. This is avoided by allowing sufficient curing time and using proper stripping techniques. Experience allows me to anticipate potential issues and implement preventative measures to ensure smooth operation.

Q 5. Describe your experience with different concrete finishing techniques (troweling, floating, etc.).

My concrete finishing experience covers a range of techniques, each suited for different applications and desired finishes. Troweling is a common method for achieving a smooth, level surface. It involves using a steel trowel to work the concrete surface, removing irregularities and creating a consistent texture. Floating is employed earlier in the finishing process, using a bull float to create a level and even surface before troweling. I also have experience with power finishing techniques, using power trowels for large areas, which greatly increases efficiency. Choosing the right technique depends on the project requirements. For example, broom finishing is preferred for creating a slip-resistant surface, such as in driveways, and I often choose this approach for outdoor projects. Each technique requires specific timing and attention to detail to achieve the desired aesthetic and functional characteristics.

Q 6. How do you achieve a smooth and level concrete surface?

Achieving a smooth and level concrete surface involves a combination of careful formwork preparation, proper concrete placement, and skilled finishing techniques. Precise formwork alignment and a consistent concrete mix design are fundamental. After the initial concrete pour, I use a bull float to level the surface. Then, I use hand floats to smooth out minor inconsistencies. Finally, I employ steel trowels to create a consistently smooth surface, removing any residual irregularities. This process typically involves multiple passes, with the concrete’s moisture content playing a crucial role in determining how and when each tool is applied. Maintaining the right level of moisture is crucial; too dry, and the surface won’t smooth properly; too wet, and the trowel may create pits and imperfections. This experience helps me to judge the appropriate time for each stage of finishing to get the best results.

Q 7. What are the key factors influencing concrete curing?

Concrete curing is a critical process that significantly impacts the concrete’s strength, durability, and overall performance. Key factors influencing curing are moisture retention, temperature, and time. Maintaining adequate moisture during the curing period is essential to allow the hydration process to complete properly. This can be achieved through various methods including water curing (regular sprinkling), membrane curing (applying a curing compound), or using insulated blankets or curing mats. Temperature also plays a significant role. Ideally, a consistent temperature range (between 50°F and 75°F or 10°C and 24°C) promotes optimal hydration. Extreme temperatures can either accelerate or retard the curing process, negatively impacting the concrete’s final properties. Finally, sufficient curing time is necessary for the cement to fully hydrate, typically at least 7 days but often longer depending on the concrete mix design and project requirements. I always carefully monitor these factors throughout the curing period to ensure optimal strength development in the concrete.

Q 8. Explain your understanding of concrete slump and its importance.

Concrete slump is a measure of the consistency or workability of fresh concrete. It’s essentially a test that tells us how easily the concrete can be poured and placed into forms. We measure slump by filling a standard slump cone with concrete, removing the cone, and measuring how much the concrete settles. A higher slump indicates wetter, more workable concrete, while a lower slump indicates a stiffer, less workable mix.

Its importance lies in ensuring proper placement and consolidation. If the slump is too low, the concrete will be difficult to place and may not fully fill the formwork, leading to voids and weaknesses. Conversely, if the slump is too high, the concrete may segregate (the heavier components settling separately from the lighter ones), leading to reduced strength and durability. Imagine trying to build a sandcastle with either extremely dry or extremely wet sand – neither works well! The ideal slump depends on the application; for example, a vertical pour might need a lower slump than a horizontal placement.

Q 9. How do you control the water-cement ratio in concrete mixes?

Controlling the water-cement ratio is crucial for achieving the desired strength and durability in concrete. The water-cement ratio is simply the ratio of the weight of water to the weight of cement in a concrete mix. A lower water-cement ratio generally results in higher strength and durability because there’s less water to weaken the cement paste.

We control this ratio primarily through precise measurement of both water and cement during batching. This is usually done using calibrated equipment like weigh-batching plants, ensuring accurate weights of each ingredient. Experienced concrete technicians understand how different aggregates (sand and gravel) absorb varying amounts of water, so we adjust water content accordingly. In cases of unexpected changes in aggregate moisture, we’ll adjust the water-cement ratio to maintain the target workability (slump). We also use admixtures (discussed in the next question) to fine-tune the workability while minimizing changes to the water-cement ratio.

Q 10. Describe your experience with different types of concrete admixtures and their uses.

I have extensive experience with various concrete admixtures, each serving a specific purpose. These are chemical additives that modify the properties of concrete.

- Water reducers: These decrease the amount of water needed for a given slump, allowing us to maintain workability while lowering the water-cement ratio and increasing strength. I’ve used them extensively on projects with demanding strength requirements.

- Superplasticizers: A more powerful type of water reducer, these allow us to produce very high-slump concrete that is still strong. They are invaluable for pumping concrete into complex forms or for placing concrete in congested areas.

- Accelerators: These speed up the setting time of concrete, which is helpful in cold weather or when rapid completion is needed. I recall using them once when we had a significant weather front approaching a large pour.

- Retarders: These slow down the setting time, useful for hot weather or large pours where setting too quickly is a problem. These were particularly helpful in a large commercial project during a heatwave.

- Air-entraining admixtures: These incorporate tiny air bubbles into the concrete, improving its durability and resistance to freeze-thaw cycles. Essential for outdoor projects in colder climates.

Choosing the right admixture and dosage is critical, always following manufacturer’s instructions and adjusting based on site conditions and specific concrete properties.

Q 11. How do you ensure the proper consolidation of concrete in forms?

Proper consolidation of concrete is essential for eliminating air pockets and ensuring a dense, strong, and uniform structure. It involves removing trapped air and ensuring complete filling of the formwork.

Methods we employ include:

- Vibration: Using internal vibrators (immersion vibrators) is the most common method. These are inserted into the fresh concrete and vibrate it to release trapped air and ensure good consolidation. It’s crucial to vibrate correctly; excessive vibration can cause segregation, while insufficient vibration can lead to voids.

- Rodding: For smaller pours or areas inaccessible to vibrators, we use a long rod to carefully poke and work the concrete into the corners and around reinforcement bars.

- Formwork Design: Proper formwork design contributes significantly to consolidation. Well-designed formwork, with adequately spaced ties and proper bracing, ensures that the concrete can flow freely into all areas.

After consolidation, we carefully inspect the surface to check for any visible voids or honeycombing (a porous surface). We correct these issues immediately. This is a critical step to meet quality standards.

Q 12. What safety precautions do you take when working with concrete?

Safety is paramount when working with concrete. We always adhere to strict safety protocols:

- Personal Protective Equipment (PPE): This includes safety boots, hard hats, safety glasses, gloves, and high-visibility clothing. We ensure everyone on site wears the appropriate PPE.

- Respiratory Protection: When handling cement dust, we use respirators to prevent inhalation of harmful particles.

- Fall Protection: On elevated pours, we use harnesses and safety lines to prevent falls. Proper scaffolding and access points are crucial.

- Chemical Safety: When using admixtures, we follow the manufacturer’s safety data sheets (SDS) carefully and handle them accordingly.

- Emergency Preparedness: We have a well-defined emergency response plan in place in case of accidents, including access to first aid and clear communication procedures. This involves clearly designated emergency contact numbers and well-marked emergency exits.

- Proper Handling: We utilize proper lifting techniques for heavy materials and equipment, avoiding manual handling whenever possible.

Safety briefings are mandatory before each pour, ensuring everyone is aware of the hazards and safety procedures.

Q 13. Explain your experience with reading and interpreting concrete plans and specifications.

Reading and interpreting concrete plans and specifications is a core competency for me. I’m proficient in understanding drawings that show formwork layouts, reinforcement details, concrete mix designs, and quality control requirements.

My experience involves extracting key information such as concrete quantities, required strength (measured in compressive strength – usually expressed in psi or MPa), slump requirements, and placement tolerances. I also understand the symbols and notations used on structural drawings to accurately locate reinforcement bars, embedded items, and formwork locations. I frequently check these plans against relevant industry standards (like ACI codes in the US or BS codes in the UK) to ensure compliance.

For example, on a recent high-rise project, I carefully reviewed plans detailing the placement of high-strength concrete for the core columns, ensuring that the specified slump, strength, and curing methods were meticulously followed to meet the project’s structural requirements.

Q 14. How do you handle unexpected challenges or delays during a concrete pour?

Unexpected challenges are a reality on any concrete pour. My approach involves a combination of preparedness, problem-solving, and clear communication.

For example, if we encounter a sudden equipment malfunction (e.g., a concrete pump breakdown), my immediate actions would be:

- Assess the situation: Determine the extent of the problem and its impact on the pour schedule.

- Communicate effectively: Inform the project manager, engineers, and other relevant parties immediately.

- Implement contingency plans: We have backup plans in place, such as using alternative equipment or adjusting the pour sequence if necessary.

- Problem-solve collaboratively: Work with the team to identify and implement the best solution to minimize downtime and maintain the project schedule.

- Document everything: Maintain a detailed record of the event, actions taken, and any impact on the project schedule or budget.

Similarly, if we encounter unexpected changes in weather (like a sudden downpour), we immediately cover the fresh concrete to protect it from damage. We use tarps and other protective measures and adjust the work schedule as needed. Through proactive planning and a flexible approach, we can effectively manage and mitigate unexpected issues to ensure project success.

Q 15. What is your experience with different types of concrete reinforcement (rebar, fiber reinforcement)?

My experience encompasses a wide range of concrete reinforcement techniques, primarily focusing on rebar and fiber reinforcement. Rebar, or reinforcing steel bars, are the traditional method, providing tensile strength to counteract concrete’s inherent weakness in tension. I’m proficient in selecting appropriate rebar sizes and spacing based on structural design specifications, ensuring proper placement and cover to protect against corrosion. This includes working with various bar shapes and sizes, understanding lap splicing techniques, and ensuring proper anchorage.

Fiber reinforcement, on the other hand, involves incorporating synthetic fibers (steel, polypropylene, glass) directly into the concrete mix. This improves the concrete’s tensile strength, crack resistance, and impact resistance. I have experience with various fiber types and their applications, understanding how fiber length, type, and dosage influence the final concrete properties. For instance, I’ve used steel fibers in high-impact areas like industrial floors and polypropylene fibers in applications where shrinkage cracking is a concern. The choice between rebar and fiber reinforcement often depends on the project’s scale, budget, and specific requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with quality control procedures for concrete work.

Quality control is paramount in concrete work. My approach involves a multi-stage process starting with material testing. This includes verifying the compressive strength of the concrete by obtaining and testing cylinder samples at regular intervals, ensuring it meets the specified design strength. We also meticulously check the aggregate grading and cement content to maintain consistency.

During placement, I ensure proper consolidation using vibration methods to eliminate air pockets and achieve a uniform, dense structure. Proper curing is crucial; this involves maintaining adequate moisture and temperature to allow for proper hydration of the cement. I meticulously monitor the curing process and ensure the concrete is protected from excessive drying or freezing. Finally, after the concrete has hardened, we perform visual inspections to check for surface imperfections, cracks, or other defects. Detailed documentation of all these steps is maintained throughout the project.

Q 17. How do you calculate the amount of concrete needed for a project?

Calculating concrete quantity involves determining the volume of the structure and adding a waste factor. The volume is typically calculated based on the dimensions of the formwork. For simple shapes like rectangular slabs or walls, this is straightforward: Length x Width x Height. However, more complex shapes require breaking them down into smaller, simpler volumes and summing them up.

For example, to calculate the concrete needed for a rectangular footing, you’d measure its length, width, and depth. Let’s say it’s 10ft x 4ft x 1ft. The volume is 40 cubic feet. However, you must account for waste, typically 5-10% depending on the complexity of the pour and material handling. So, for a 10% waste factor, you’d need 40 cubic feet + (40 cubic feet * 0.10) = 44 cubic feet of concrete. Remember to always convert cubic feet to cubic yards (1 cubic yard = 27 cubic feet) as concrete is usually ordered in cubic yards.

Q 18. Explain your understanding of different concrete surface treatments (sealers, stains, etc.).

Concrete surface treatments enhance both aesthetics and durability. Sealers prevent water damage and staining, increasing the lifespan of the concrete. They come in various types – penetrating sealers soak into the concrete, while topical sealers form a film on the surface. The choice depends on the desired look and level of protection. Penetrating sealers are generally preferred for porous concrete, providing longer-lasting protection. Topical sealers offer quicker application but may need reapplication over time.

Stains add color and enhance the visual appeal of concrete. Acid stains react chemically with the concrete, producing unique patterns, while water-based stains offer a more uniform color. I’ve used both in numerous projects, carefully considering the porosity of the concrete and the desired aesthetic result. Other treatments include polishing to create a high-gloss finish and densifiers to harden the surface and make it more resistant to wear.

Q 19. How do you ensure the longevity and durability of concrete structures?

Ensuring the longevity and durability of concrete structures involves a holistic approach encompassing several key aspects. Proper design and detailing are crucial, considering factors such as anticipated loads, environmental conditions, and potential shrinkage. We must select appropriate concrete mixes with sufficient strength and durability to withstand these conditions. Careful placement and consolidation procedures, as discussed earlier, prevent defects that weaken the structure.

Equally important is proper curing. This allows the concrete to hydrate fully, developing its design strength and minimizing shrinkage cracking. Regular maintenance is also vital. This could involve cleaning to remove stains and debris, resealing to protect against water damage, and prompt repair of any cracks or damage. Regular inspections can help to identify and address issues before they become major problems, significantly extending the lifespan of the structure.

Q 20. What are the common causes of concrete cracking and how can they be prevented?

Concrete cracking can stem from various causes. Shrinkage cracking, caused by moisture loss during curing, is common, especially in hot, dry conditions. Plastic shrinkage cracking occurs before the concrete has fully hardened, often due to rapid water evaporation. This can be mitigated by proper curing techniques, using shrinkage-reducing admixtures, and minimizing surface area exposed to sun and wind.

Another cause is thermal cracking, resulting from temperature changes that cause the concrete to expand and contract. This is often seen in large slabs or structures with inadequate expansion joints. These joints allow for controlled movement, preventing stress buildup that leads to cracking. Load-related cracking happens when the concrete is subjected to excessive loads exceeding its design capacity. Proper design and reinforcement are essential to prevent this. Finally, Alkali-Aggregate Reaction (AAR) is a chemical reaction that can lead to cracking over time. Using appropriate aggregates and controlling the alkali content of the cement can mitigate this.

Q 21. What is your experience with using different types of concrete saws and cutting equipment?

My experience includes using various concrete saws and cutting equipment, ranging from handheld saws for smaller cuts to larger, more powerful equipment for extensive work. Handheld saws, such as diamond blade saws, are suitable for cutting smaller sections or making precise cuts. I’ve used these extensively for cutting expansion joints or creating decorative patterns.

For larger projects, I’m proficient with walk-behind saws and specialized concrete cutting equipment like ring saws and wire saws. Ring saws are incredibly powerful and efficient for making deep cuts, while wire saws are useful for cutting very large or irregularly shaped sections. Safety is paramount when operating this equipment. I always follow safety protocols, including using appropriate personal protective equipment (PPE), such as eye protection, hearing protection, and dust masks. Proper blade selection is also critical, choosing the right blade for the type of concrete and the desired cut.

Q 22. How do you maintain concrete formwork equipment?

Maintaining concrete formwork equipment is crucial for project success and safety. It involves a multi-pronged approach focusing on cleanliness, repair, and storage.

- Cleaning: After each use, thoroughly clean all formwork components, removing any residual concrete, debris, or release agent. Power washing is often effective, but be mindful not to damage the material. For intricate details, manual cleaning with brushes and scrapers might be necessary.

- Repair and Maintenance: Regularly inspect for damage such as cracks, warping, or loose fasteners. Minor repairs, like tightening bolts or patching small cracks, can be handled on-site. More significant damage requires professional repair or replacement to ensure structural integrity.

- Proper Storage: Store formwork in a dry, protected area to prevent rust, rot, or warping. Stacking should be done carefully to avoid damage, and larger components may require specialized storage racks or supports.

- Lubrication: Moving parts, such as hinges and mechanisms, should be lubricated regularly to prevent seizing and ensure smooth operation. Using appropriate lubricants, designed for outdoor use and compatible with the formwork material, is vital.

Think of it like caring for your car: regular maintenance prevents major breakdowns and extends the life of your equipment, saving you time and money in the long run.

Q 23. Describe your experience with working in diverse weather conditions.

Working in diverse weather conditions is a significant part of concrete work. My experience spans a wide range, from scorching summer heat to freezing winter temperatures. Extreme heat can accelerate concrete setting time, requiring adjustments to the mix design and placement strategies. We often need to use methods like pre-wetting forms and using cold-added water to prevent rapid drying and cracking. Conversely, freezing temperatures can delay or halt the curing process, necessitating the use of insulation, curing blankets, or even heated enclosures to maintain adequate temperature for proper strength development.

Safety is paramount. In extreme heat, we implement heat stress protocols including frequent breaks, hydration strategies and using appropriate PPE. In cold weather, frostbite prevention and ensuring equipment functions properly in sub-zero temperatures are top priorities. I’ve developed a keen awareness of how different weather conditions affect the concrete’s properties and have adapted my techniques accordingly to deliver consistently high-quality results, regardless of the weather.

Q 24. How do you manage a team of concrete workers effectively?

Effective team management in concrete work requires a blend of leadership, communication, and technical expertise. I believe in fostering a collaborative environment where everyone feels valued and understands their role. This begins with clear communication of project goals and expectations. I use daily briefings to coordinate tasks, address concerns, and ensure everyone is on the same page.

- Delegation: I delegate tasks based on individual skills and experience, ensuring that each team member has responsibilities that challenge and engage them.

- Training and Development: I invest time in training and mentoring team members, helping them develop their skills and advance their careers. This includes both hands-on training and safety procedures.

- Motivation and Recognition: I recognize and reward good work to boost morale and encourage continued high performance.

- Safety First: Safety is my top priority. I ensure all team members are properly trained in safety procedures and wear appropriate PPE. Regular safety checks and incident reporting are part of my standard operating procedure.

Building a strong team is akin to building a strong structure – a solid foundation, clear communication, and collaborative effort are essential to achieving a high-quality outcome.

Q 25. Explain your understanding of concrete testing methods.

Concrete testing methods are critical to ensure the final product meets the required specifications. These tests evaluate various properties, including strength, workability, and durability.

- Slump Test: This measures the workability of fresh concrete, indicating its consistency and ability to be placed and consolidated. A slump cone is filled with concrete, then removed, and the slump or settlement is measured.

- Compressive Strength Test: This determines the concrete’s strength by applying a compressive load to a standard-sized cylinder or cube cured under controlled conditions. The load at failure indicates the compressive strength.

- Air Content Test: This measures the amount of entrained air in the concrete, which affects its durability and resistance to freeze-thaw cycles. Methods include the pressure method or the volumetric method.

- Flexural Strength Test: This assesses the strength of concrete under bending loads, important for structural members like beams and slabs.

Understanding these tests allows me to troubleshoot problems during construction, such as adjusting the mix design to achieve the desired strength or workability, and ensuring that the final concrete meets the project specifications and building codes.

Q 26. What software or tools do you use for concrete design or estimation?

For concrete design and estimation, I utilize a combination of software and tools.

- Autodesk AutoCAD: I use AutoCAD for creating detailed drawings and plans, including formwork design and reinforcement detailing. This allows for precise visualization and accurate quantity takeoffs.

- Revit: For larger or more complex projects, Revit’s BIM capabilities facilitate better collaboration and coordination among different disciplines, enhancing design accuracy and minimizing errors. It’s incredibly helpful for visualizing the entire project and managing changes effectively.

- Spreadsheets (Excel, Google Sheets): These are essential for cost estimation, material quantity calculations, and project scheduling. I use formulas to automate calculations and track progress.

- Specialized Concrete Design Software: Some projects require specialized software that allows for detailed concrete mix design calculations based on specific material properties and performance requirements. These programs often include modules for analysis of structural elements.

The choice of software depends on project complexity and client requirements. My proficiency across various tools allows me to adapt my approach to diverse project needs.

Q 27. How do you ensure compliance with building codes and regulations for concrete work?

Compliance with building codes and regulations is paramount in concrete work. My approach involves a thorough understanding of local, state, and national codes, along with regular updates to stay current on any changes. I start by reviewing the project’s specifications to identify applicable codes and standards.

- Material Specifications: I ensure all concrete materials meet the specified requirements for strength, durability, and other relevant properties, using certified materials and obtaining accompanying test reports.

- Formwork Design and Construction: Formwork design must adhere to code requirements for load-bearing capacity, stability, and dimensional accuracy. Regular inspections during construction are critical to ensure compliance.

- Reinforcement Detailing and Placement: Reinforcement must be placed accurately according to design drawings and code requirements to ensure the structural integrity of the concrete element. This includes proper spacing, cover depth, and lapping.

- Inspection and Documentation: I maintain detailed records of all inspections, tests, and material certifications, along with any deviations from specifications or code requirements. This documentation serves as evidence of compliance during audits or inspections by building authorities.

Ignoring building codes can lead to serious consequences, including structural failures, project delays, and legal liabilities. My commitment to compliance ensures that projects are safe, durable, and meet all regulatory requirements.

Q 28. Describe a time you had to troubleshoot a problem during a concrete project. What was the solution?

During a large foundation pour, we experienced significant slump loss in the concrete after it had been mixed and transported to the site. The concrete was becoming too stiff to place properly, threatening project timelines and potentially affecting the structural integrity of the foundation. Initially, we suspected issues with the mix design, but tests showed that the mix itself was within specifications.

After careful investigation, we discovered that the high ambient temperature combined with the extended transit time in the mixer truck was causing the rapid evaporation of water, leading to the slump loss. The solution was twofold: First, we adjusted the water-cement ratio in the mix, slightly increasing the amount of water to compensate for the anticipated evaporation. Second, we significantly reduced the transportation time by coordinating the delivery of smaller batches from a closer mixing plant. We also shaded the concrete during transportation. By implementing these changes, we were able to ensure that the concrete remained workable, completing the pour without compromising quality.

This experience underscored the importance of carefully considering environmental factors and adjusting our processes accordingly. It also highlighted the value of a systematic approach to troubleshooting, starting with thorough data collection and analysis before implementing any solution.

Key Topics to Learn for Concrete Forming and Finishing Interview

- Formwork Design and Construction: Understanding different formwork systems (e.g., plywood, steel, aluminum), their applications, and proper assembly techniques for various concrete structures. Consider the impact of formwork design on concrete placement and finishing.

- Concrete Mix Design and Properties: Knowledge of different concrete mixes (strength, slump, water-cement ratio), their suitability for various applications, and the impact of mix design on workability and durability. Be prepared to discuss how these properties affect the finishing process.

- Concrete Placement and Consolidation: Mastering techniques for efficient and effective concrete placement, including methods for minimizing segregation and ensuring proper consolidation to prevent voids and honeycombing. Understand the use of vibrators and other consolidation tools.

- Finishing Techniques: Thorough understanding of various finishing techniques (e.g., screeding, floating, troweling, brooming) and their application based on the desired surface finish (e.g., smooth, textured). Be ready to discuss different tools and their appropriate use.

- Quality Control and Inspection: Knowledge of quality control procedures, including concrete testing methods, identifying defects (e.g., cracks, honeycombing, surface imperfections), and implementing corrective actions. Understand safety protocols and best practices.

- Safety Regulations and Procedures: Demonstrate a strong understanding of OSHA regulations and safety procedures related to concrete forming and finishing, including personal protective equipment (PPE) and hazard prevention.

- Problem-Solving and Troubleshooting: Prepare examples demonstrating your ability to identify and resolve common issues encountered during concrete forming and finishing, such as formwork failures, concrete defects, and finishing problems. Highlight your analytical and problem-solving skills.

Next Steps

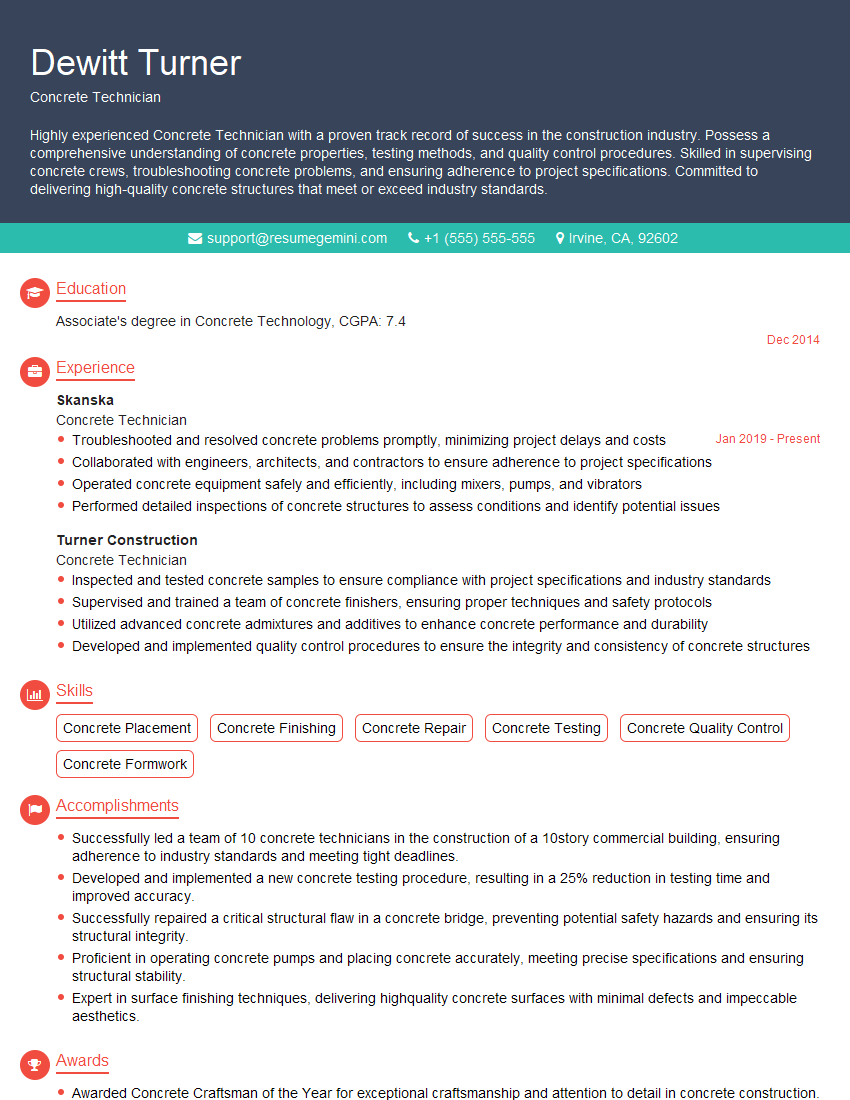

Mastering Concrete Forming and Finishing opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization and advancement. To maximize your job prospects, it’s crucial to create a professional and ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a compelling resume that stands out. They provide examples of resumes tailored to the Concrete Forming and Finishing field to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good