Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Horizontal Completion Techniques interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Horizontal Completion Techniques Interview

Q 1. Explain the advantages of horizontal completion techniques over vertical completions.

Horizontal completion techniques offer significant advantages over vertical completions, primarily by increasing the contact area with the reservoir. Imagine trying to drink from a straw versus a wide cup – the cup allows for much greater intake. Similarly, a horizontal wellbore intersects a much larger volume of the reservoir than a vertical one, leading to increased production.

- Increased Reservoir Contact: Horizontal wells extend through the reservoir’s most productive zones, maximizing hydrocarbon extraction.

- Improved Drainage Area: They drain a larger area compared to vertical wells, significantly increasing the well’s productivity.

- Enhanced Sweep Efficiency: Horizontal wells allow for more efficient displacement of hydrocarbons, reducing the amount left behind.

- Better Conformance Control: In heterogeneous reservoirs (where the rock properties vary widely), horizontal wells can selectively target the most permeable zones, improving production.

- Reduced Water and Gas Coning: In reservoirs with water or gas below or above the oil zone, horizontal wells can help minimize their encroachment into the producing zone.

For example, in a thin, layered reservoir, a vertical well might only intersect a small portion of the productive layer. A horizontal well, however, can fully traverse this layer, greatly increasing its production capacity.

Q 2. Describe the different types of horizontal well completions.

Horizontal well completions are categorized based on several factors, including the type of reservoir, the well trajectory, and the completion strategy. Some common types include:

- Openhole completions: The simplest type, where the wellbore is left uncased in the productive zone, allowing for direct contact with the reservoir. This is suitable for strong, consolidated formations.

- Cased-hole completions: The wellbore is cased (lined with steel pipe) and perforated to allow fluid flow into the wellbore. This is preferred for weaker formations to provide stability.

- Gravel-pack completions: A gravel pack is placed around the perforated casing to prevent sand production, maintaining wellbore permeability.

- Multi-lateral completions: These involve branching off additional horizontal sections from the main horizontal wellbore, further increasing reservoir contact.

- Sleeved completions: These involve placing packers or sleeves within the casing to isolate different zones, allowing for independent production control.

The choice depends on reservoir conditions and production objectives. A gravel pack might be necessary in a reservoir prone to sand production, while a multi-lateral completion would be suitable for a large, heterogeneous reservoir.

Q 3. What are the key considerations for designing a horizontal completion?

Designing a horizontal completion requires careful consideration of several critical factors:

- Reservoir characteristics: Understanding reservoir properties such as permeability, porosity, thickness, and pressure is crucial for optimizing well placement and completion design. A detailed geological model is essential.

- Well trajectory: The path of the horizontal section must be carefully planned to maximize contact with the most productive zones. This often involves using advanced logging and imaging tools.

- Completion type: The choice of completion type (openhole, cased-hole, etc.) will depend on reservoir strength and the risk of sand production.

- Fracture stimulation design: Hydraulic fracturing is often necessary to enhance permeability in the reservoir, and the design should be tailored to the specific reservoir characteristics.

- Completion equipment: Selection of appropriate casing, tubing, packers, and other completion equipment is critical for ensuring well integrity and efficient production.

- Production forecasting: Models should be used to predict the well’s likely production rate based on the planned completion design.

For instance, in a fractured reservoir, the completion design might focus on intersecting the most conductive fractures. In a low-permeability reservoir, the design would emphasize maximizing fracture stimulation to enhance permeability.

Q 4. How do you optimize well placement for horizontal completions?

Optimizing well placement for horizontal completions involves integrating geological data with engineering expertise to maximize the well’s productivity. This process usually involves:

- Seismic interpretation: Seismic data helps identify potential reservoir zones and structures.

- Geological modeling: A detailed 3D geological model is built to integrate all available data (seismic, well logs, core data) to predict reservoir properties.

- Reservoir simulation: Numerical models are used to simulate the flow of hydrocarbons in the reservoir and predict the impact of different well placement strategies.

- Advanced well logging: Logging tools provide real-time data on formation properties during drilling, allowing for adjustments to the well trajectory.

- Geosteering: This technology uses real-time data to steer the drill bit along a predetermined path, optimizing the well’s placement within the reservoir.

For example, if a reservoir shows significant lateral variations in permeability, the horizontal well would be placed to maximize contact with the most permeable zones. Geosteering allows for dynamic adjustments to the wellbore path as the drilling progresses, ensuring optimal placement even in complex geological settings.

Q 5. What are the challenges associated with horizontal well drilling and completion?

Horizontal well drilling and completion present several challenges:

- High costs: Horizontal drilling is significantly more expensive than vertical drilling due to the extended drilling time and specialized equipment.

- Technical complexity: Drilling horizontal wells requires advanced drilling technology and expertise to navigate complex geological formations.

- Wellbore instability: Horizontal sections are more susceptible to wellbore instability, which can lead to drilling problems and reduced production.

- Increased risk of formation damage: The extended contact with the reservoir during drilling and completion increases the risk of formation damage.

- Difficulty in completion operations: Deploying and retrieving completion equipment in horizontal wells can be challenging.

- Environmental concerns: Careful environmental management is necessary to minimize the environmental impact of drilling and completion operations.

One example is the difficulty in accurately predicting the behavior of hydraulic fractures in complex geological formations. Unexpected fracture propagation can lead to reduced production efficiency.

Q 6. Explain the role of hydraulic fracturing in horizontal well completions.

Hydraulic fracturing (fracking) plays a crucial role in horizontal well completions by creating artificial fractures in the reservoir rock to enhance permeability. Imagine trying to suck liquid through a tightly packed sponge versus one with many channels – the channels allow for much easier passage. Similarly, fracking creates these channels (fractures) in the rock, allowing for easier flow of hydrocarbons to the wellbore. It’s particularly important for low-permeability reservoirs where natural fractures are insufficient to allow for economical production.

The process involves pumping a high-pressure fluid mixture (water, sand, and chemicals) down the wellbore, creating fractures in the reservoir rock. Proppants, such as sand or ceramic beads, are included in the fluid to keep the fractures open after the pressure is released, ensuring long-term permeability enhancement.

Q 7. Describe different types of proppants used in hydraulic fracturing.

Several types of proppants are used in hydraulic fracturing, each with its own strengths and limitations. The selection depends on the reservoir conditions and the desired fracture conductivity.

- Sand: The most commonly used proppant, relatively inexpensive and readily available. However, it can be prone to crushing under high stress conditions.

- Ceramic proppants: These are manufactured proppants made from materials like bauxite or ceramics. They are stronger and more resistant to crushing than sand, making them suitable for high-pressure reservoirs. They come in various shapes and sizes for optimized performance.

- Resin-coated proppants: These are sand or ceramic proppants coated with a resin to improve their strength and reduce their tendency to crush.

The choice of proppant is critical for maintaining fracture conductivity and maximizing long-term production. For example, in a high-pressure, deep reservoir, ceramic proppants might be preferred over sand due to their superior strength. In lower-pressure scenarios, a cost-effective sand might suffice. The selection involves a careful evaluation of the reservoir conditions and proppant properties.

Q 8. How do you evaluate the success of a horizontal completion?

Evaluating the success of a horizontal completion involves a multifaceted approach, going beyond simply achieving high initial production rates. We need to consider the long-term performance and the overall efficiency of the well. Key performance indicators (KPIs) include:

- Cumulative Production: The total amount of hydrocarbons produced over time is the ultimate measure of success. A consistently high production rate over the well’s lifespan indicates a successful completion.

- Production Decline Rate: A slower decline rate signifies better reservoir contact and less rapid depletion. We analyze the decline curve to predict future production and optimize well management.

- Water Cut: The percentage of water in the produced fluid. A low and stable water cut indicates effective zonal isolation and efficient production from the target reservoir.

- Pressure Maintenance: Monitoring reservoir pressure helps assess the effectiveness of the completion in maintaining reservoir energy and sustaining production.

- Costs and ROI: Ultimately, the success is also judged by the economic viability. We assess the return on investment (ROI) considering the completion cost, operational expenses, and revenue generated.

For example, a horizontal well initially producing high volumes but exhibiting a rapid decline rate and high water cut might be deemed less successful than a well with a more moderate initial production but a significantly slower decline and low water cut over a longer period. It’s about the entire lifecycle, not just the initial burst.

Q 9. What are the common completion fluids used in horizontal wells?

The choice of completion fluid depends heavily on the specific reservoir conditions, including temperature, pressure, and the type of formation. The primary goals are to prevent formation damage, ensure wellbore stability, and facilitate the placement of other completion components. Common fluids include:

- Water-based fluids: These are often the most cost-effective and environmentally friendly. However, they can be prone to causing formation damage if not carefully formulated and managed.

- Oil-based fluids: Offer excellent lubricity and reduce friction during drilling and completion, minimizing formation damage. However, they are more expensive and have greater environmental concerns.

- Synthetic-based fluids: Designed to balance the benefits of oil-based fluids with reduced environmental impact. They often offer better lubricity and minimal formation damage compared to water-based fluids.

- Gelled fluids: Provide effective temporary wellbore support and can be easily removed. Useful for situations where wellbore stability is particularly challenging.

The selection process involves careful consideration of potential environmental impact, cost, and the specific needs of the well. Laboratory testing is crucial to ensure compatibility with the reservoir rock and formation fluids.

Q 10. Explain the concept of wellbore stability in horizontal wells.

Wellbore stability in horizontal wells is significantly more challenging than in vertical wells due to the extended lateral reach and increased exposure to different stress regimes within the formation. Instability can lead to wellbore collapse, stuck pipe, and ultimately, a failed completion. Key factors affecting stability include:

- In-situ stresses: The natural stresses acting on the formation can cause wellbore collapse or fracturing.

- Formation strength: The rock’s mechanical properties determine its ability to withstand the stresses imposed by the wellbore.

- Fluid pressure: The pressure exerted by the completion fluids on the wellbore wall can induce instability.

- Temperature: Temperature changes affect formation properties and fluid behavior, impacting wellbore stability.

Maintaining stability often involves using specialized completion fluids, employing casing design optimization (including heavier-weight casings), and implementing real-time monitoring of wellbore conditions to anticipate and mitigate potential instabilities. Failure to address wellbore stability can lead to significant cost overruns and project delays.

Q 11. What are the different types of completion packers used?

Completion packers are essential for isolating different zones within a wellbore, allowing for selective production or injection. Several types exist:

- Single packers: Isolate a single zone above or below the packer.

- Multiple packers: Isolate multiple zones simultaneously, enabling independent control of different intervals.

- Retrievable packers: Can be removed and replaced, offering flexibility for future operations.

- Permanent packers: Remain in place permanently, providing a more robust long-term isolation.

- Hydraulic packers: Set and released using hydraulic pressure.

- Mechanical packers: Set and released mechanically, typically using a wireline tool.

The choice depends on factors like the number of zones to be isolated, the need for future intervention, and the specific operational requirements. Improper packer selection or deployment can lead to zonal communication and production issues.

Q 12. Describe the process of perforating a horizontal well.

Perforating a horizontal well involves creating controlled openings in the casing and cement to allow hydrocarbons to flow into the wellbore. This is typically done using shaped charges or other perforation tools that are deployed via wireline or coiled tubing. The process involves:

- Selecting perforation intervals: Determining the precise locations within the horizontal section to create perforations based on reservoir characteristics and log data.

- Deploying perforating guns: Lowering the guns into the wellbore to the desired depth.

- Firing the guns: Initiating the charges, which create small, precisely placed holes in the casing and cement.

- Cleaning perforations: Removing any debris generated during the perforation process to ensure free flow of hydrocarbons.

Proper perforation design is crucial to maximize reservoir contact and optimize production. Factors such as perforation density, phasing, and orientation all influence the efficiency of the completion.

Q 13. How do you manage sand production in horizontal wells?

Sand production in horizontal wells is a common challenge, as the extended lateral reach exposes a larger surface area to the formation. Excessive sand production can lead to equipment damage, reduced production rates, and environmental issues. Management strategies include:

- Gravel packing: Placing a layer of gravel around the wellbore to act as a filter and prevent sand migration.

- Screen completion: Using specialized screens to allow fluid flow while retaining sand particles.

- Sand control completion: Utilizing specialized completion techniques like resin-coated sand or other sand control technologies to mitigate sand production.

- Production optimization: Adjusting production rates to minimize stress on the formation and reduce the likelihood of sand production.

The choice of sand control strategy depends on factors such as formation properties, reservoir pressure, and the expected production rate. Ignoring sand production can have severe consequences for the well’s long-term performance and safety.

Q 14. What are the different methods for zonal isolation in horizontal wells?

Zonal isolation in horizontal wells is critical for controlling fluid flow from different reservoir zones. This is especially important in multi-layered reservoirs or when dealing with water or gas coning. Methods include:

- Packers: As described earlier, packers provide mechanical isolation between zones.

- Cementing: Placing cement between different zones to create a permanent barrier.

- Squeeze cementing: Injecting cement under pressure to seal off unwanted zones.

- Selective perforation: Precisely perforating only the desired zones, avoiding communication with other layers.

Effective zonal isolation is vital for maximizing production from the target zones while preventing unwanted fluid influx. The chosen method depends on the specific geological conditions, the complexity of the reservoir, and the required level of isolation.

Q 15. Explain the role of reservoir simulation in horizontal well completion design.

Reservoir simulation plays a crucial role in optimizing horizontal well completion design by providing a predictive model of reservoir behavior under various completion scenarios. Before a single bit of steel touches the ground, we use reservoir simulation to understand fluid flow, pressure distribution, and production performance. Think of it as a virtual test lab. We input geological data (porosity, permeability, fluid saturations), well parameters (length, trajectory, perforation density), and completion design elements (proppant type and volume, completion fluids). The simulator then predicts how the well will perform over its lifetime – crucial for maximizing hydrocarbon recovery and minimizing operational costs. For example, by simulating different perforation cluster spacing, we can determine the optimal configuration to maximize contact with the most productive reservoir zones, leading to higher flow rates.

This allows us to assess the impact of various completion strategies before implementation. We can compare different completion designs, evaluate the sensitivity of production to various parameters (like proppant placement), and make informed decisions about completion equipment and procedures. Without reservoir simulation, we’d be essentially flying blind, relying on guesswork and potentially missing out on significant production gains.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the different types of logging tools used for evaluating horizontal wells.

Evaluating horizontal wells requires a suite of specialized logging tools. These tools are run downhole after drilling and completion, providing crucial data about the reservoir and the wellbore itself. Some key types include:

- Resistivity Logs: These logs measure the electrical resistance of the formation, helping us identify hydrocarbon-bearing zones (hydrocarbons are less conductive than water).

- Porosity Logs: These logs determine the pore space within the rock, indicating the reservoir’s ability to store hydrocarbons. Neutron porosity and density porosity logs are commonly used.

- Density Logs: Measure the bulk density of the formation, used in conjunction with porosity logs to determine lithology and pore fluid type.

- Nuclear Magnetic Resonance (NMR) Logs: These provide detailed information on pore size distribution and fluid properties, which is particularly helpful in understanding the efficiency of hydraulic fracturing.

- Production Logs: These tools measure flow rates and pressure within the wellbore, identifying zones contributing the most to production and pinpointing any flow restrictions.

- Image Logs: These create detailed images of the borehole wall, allowing visualization of fractures, bedding planes, and other geological features that affect production.

The selection of logging tools depends on the specific reservoir characteristics and the objectives of the evaluation. For instance, in a fractured reservoir, image logs are crucial for understanding fracture geometry and connectivity. In a tight gas reservoir, NMR logs provide invaluable information on pore size distribution to aid in hydraulic fracture design.

Q 17. How do you optimize the number and placement of perforations?

Optimizing perforation placement and density is crucial for maximizing production in horizontal wells. Simply perforating the entire wellbore isn’t optimal; it can lead to uneven fluid flow and reduced efficiency. The goal is to create a balanced flow profile along the wellbore, maximizing contact with the most productive reservoir zones. Several factors guide this process:

- Reservoir Heterogeneity: Perforations should be concentrated in the most permeable zones identified through logging and seismic data. Imagine a sponge: You want to poke holes where the sponge is most absorbent, not in the dense, less-porous areas.

- Fracture Network: In fractured reservoirs, perforation clusters are strategically positioned to intersect and stimulate the most conductive fractures. This requires detailed analysis of fracture orientation and spacing.

- Wellbore Trajectory: Perforation placement needs to account for the well’s trajectory to ensure efficient drainage of the reservoir. Perforations might be denser in sections of the well that intersect more productive zones.

- Simulation Results: Reservoir simulation plays a critical role in optimizing perforation design. By modeling various perforation configurations, we can predict the flow profile and identify the optimal number and placement to achieve maximum production.

In practice, perforation optimization involves iterative processes involving data analysis, simulation, and field testing. We might start with a base case design, then use simulation to refine perforation density and placement until we achieve the desired production targets. We might even use different perforation cluster sizes along the well to adapt to variable reservoir properties.

Q 18. What are the factors influencing the selection of completion equipment?

The selection of completion equipment for a horizontal well is a complex process influenced by several factors:

- Reservoir Properties: The type of reservoir (sandstone, carbonate, shale), its permeability, pressure, and fluid properties all dictate the choice of completion equipment. For instance, a high-pressure reservoir might require specialized high-strength casing and tubing.

- Wellbore Geometry: The length and trajectory of the horizontal section influence equipment choices. Long horizontal reaches might necessitate specialized tools for running and setting the completion string.

- Production Strategy: The planned production method (e.g., primary production, enhanced oil recovery) impacts the selection of completion equipment. For example, if water injection is planned, specialized packers and valves are needed.

- Environmental Conditions: The geographic location and environmental conditions, like temperature and pressure, influence the materials and design of the equipment. High-temperature reservoirs might require specialized high-temperature-tolerant materials.

- Cost Considerations: The cost of various equipment options is always a factor, balancing cost-effectiveness with the desired performance and reliability. Different materials and designs come at varying price points.

For example, a shale gas well might require a cemented liner to prevent sand production, a multi-stage fracturing system for creating multiple flow paths, and advanced downhole tools for monitoring well performance. Contrast this with a conventional sandstone reservoir that might require a simpler completion design with fewer stages.

Q 19. Describe the process of running and setting a completion string.

Running and setting a completion string in a horizontal well is a complex operation requiring precision and careful coordination. The process typically involves these steps:

- Preparation: The completion string, consisting of casing, tubing, packers, valves, and other components, is assembled and inspected before running.

- Running the String: The completion string is carefully lowered into the wellbore using a drilling rig. Horizontal wells require specialized techniques to guide the string along the trajectory and minimize friction.

- Cementing: Casing is cemented in place to provide wellbore stability and zonal isolation. This is crucial to prevent fluid leakage and maintain pressure integrity.

- Setting Packers: Packers are inflatable devices that create a seal between different zones of the wellbore. They are set in place to isolate zones that will be stimulated individually during hydraulic fracturing.

- Installing Downhole Tools: Monitoring and control equipment, such as pressure gauges, flow meters, and valves, are installed within the completion string.

- Testing: After the completion string is set, rigorous testing is conducted to ensure zonal isolation and verify that everything is functioning as designed.

This process demands precision and expertise. Deviations from the planned trajectory or improper setting of packers can significantly impact production and well integrity. Sophisticated equipment and experienced personnel are necessary to successfully execute this critical phase.

Q 20. How do you handle complications during horizontal well completion?

Complications during horizontal well completion are common, requiring prompt and decisive action. Some common complications include:

- Stuck Pipe: The completion string can become stuck in the wellbore due to friction, differential sticking, or other reasons. This requires specialized tools and techniques to free the stuck equipment.

- Lost Circulation: Completion fluids can be lost into the formation, requiring remedial measures to restore wellbore integrity and prevent environmental damage. This often involves changing the completion fluid to a higher viscosity fluid or plugging the leak points.

- Formation Fracturing: Excessive pressure during completion operations can cause unintended fracturing of the formation, leading to lost circulation or reduced wellbore stability. Careful pressure control is vital.

- Equipment Malfunction: Downhole tools or surface equipment can malfunction, requiring repairs or replacements. A backup plan for such situations is crucial.

Handling complications requires a systematic approach. First, the problem needs to be properly diagnosed using downhole tools and logging data. Then, a solution is developed based on the nature and severity of the complication. This often involves consultation with experts, reviewing contingency plans, and deploying specialized equipment or techniques.

Q 21. What are the key safety considerations during horizontal well completion operations?

Safety is paramount during horizontal well completion operations. The high-pressure, high-temperature environment, complex equipment, and hazardous materials involved demand rigorous safety protocols. Key considerations include:

- Well Control: Maintaining well control is the most critical safety aspect. Procedures and equipment must be in place to prevent uncontrolled releases of hydrocarbons or formation fluids.

- Hydrogen Sulfide (H2S) Management: H2S is a toxic gas that can be present in some reservoirs. Safety procedures and monitoring equipment must be in place to detect and mitigate H2S risks.

- Personnel Safety: Rigorous safety training and adherence to safety procedures are essential to protect personnel from hazards associated with high pressures, heavy equipment, and hazardous chemicals.

- Emergency Response Planning: Well-defined emergency response plans must be in place to handle various scenarios, such as well control incidents or equipment failures. This includes evacuation procedures, communication protocols, and access to emergency medical services.

- Environmental Protection: Precautions must be taken to prevent spills or leaks of fluids into the environment. This involves careful handling of completion fluids, proper disposal of waste materials, and monitoring for environmental impacts.

Regular safety audits, thorough training, and adherence to strict safety protocols are vital to minimize risks and ensure a safe working environment for all personnel involved in horizontal well completion operations.

Q 22. Explain the concept of multilateral wells and their advantages.

Multilateral wells are highly advanced horizontal wells that branch off into multiple laterals from a single wellbore. Imagine a tree; the main trunk is the initial wellbore, and the branches are the laterals extending into different sections of the reservoir. This allows for increased contact with the reservoir rock, leading to enhanced hydrocarbon production.

- Advantages:

- Increased Reservoir Contact: Dramatically increases the surface area in contact with the producing formation, resulting in higher production rates.

- Improved Sweep Efficiency: The multiple laterals can access different parts of the reservoir, improving the efficiency of fluid extraction and reducing bypassed hydrocarbon reserves.

- Reduced Well Count: Fewer wells are needed to drain the same reservoir volume compared to a traditional well pattern, leading to cost savings in drilling and completion.

- Enhanced Reservoir Management: Allows for more targeted stimulation and production optimization in specific reservoir zones.

For example, in a fractured reservoir, a multilateral well could target multiple fracture systems, maximizing production from each.

Q 23. How do you monitor the performance of a horizontal well after completion?

Monitoring a horizontal well’s performance post-completion is crucial for maximizing its lifespan and profitability. This is accomplished through a combination of techniques:

- Production Data Analysis: Regular monitoring of oil, gas, and water production rates, pressure, and temperature allows for tracking of decline curves and identifying potential issues.

- Downhole Pressure Gauges: These permanently installed sensors provide real-time data on pressure changes in different sections of the wellbore, indicating flow distribution and reservoir pressure depletion.

- Production Logging Tools: These tools are run down the wellbore to measure flow profiles and identify zones with reduced productivity or water influx. This allows for targeted interventions.

- Seismic Monitoring: Seismic surveys can track changes in reservoir pressure and fluid saturation over time, providing a broader picture of reservoir performance.

- Chemical Tracer Surveys: Injecting tracers into the wellbore helps to map flow paths and identify zones of preferential flow.

Analyzing this data helps engineers to optimize production strategies, identify and address wellbore issues, and predict future performance.

Q 24. What are the environmental considerations associated with horizontal well completion?

Horizontal well completion carries environmental risks, primarily related to:

- Drilling Fluids: The potential for spills and leaks of drilling muds, which can contain harmful chemicals, into the environment must be minimized through strict well control practices and waste management.

- Produced Water: Horizontal wells often produce large volumes of water alongside hydrocarbons. Proper treatment and disposal of this produced water are crucial to prevent water contamination.

- Greenhouse Gas Emissions: Methane leakage during drilling and production is a significant contributor to greenhouse gas emissions. Mitigation strategies are essential to reduce the environmental footprint.

- Waste Management: Careful planning and disposal of drilling cuttings, contaminated soil, and other waste materials are crucial to prevent environmental damage.

- Induced Seismicity: In some cases, high-pressure injection of fluids during stimulation can induce minor earthquakes. Careful monitoring and risk mitigation measures are necessary.

Environmental regulations and best practices are crucial to mitigate these risks and ensure sustainable operations.

Q 25. Describe the impact of formation heterogeneity on horizontal well performance.

Formation heterogeneity, meaning the variation in rock properties (permeability, porosity, etc.) within a reservoir, significantly impacts horizontal well performance. Uniform reservoirs are ideal, but in reality, reservoirs often exhibit considerable variations.

- Reduced Sweep Efficiency: Highly heterogeneous formations can lead to preferential flow paths, resulting in bypassed oil and reduced overall recovery.

- Uneven Pressure Distribution: Variations in permeability create uneven pressure distribution along the lateral, leading to inefficient drainage.

- Water or Gas Coning: Heterogeneity can exacerbate water or gas coning, where unwanted fluids migrate towards the wellbore, reducing hydrocarbon production.

- Challenges in Stimulation Design: Heterogeneity makes it difficult to design effective stimulation treatments, as the effectiveness of hydraulic fracturing will vary across the reservoir.

Advanced reservoir characterization techniques and simulation models are vital to understand and mitigate the impact of formation heterogeneity on horizontal well performance.

Q 26. How do you optimize production from a horizontal well?

Optimizing production from a horizontal well involves a multi-faceted approach:

- Smart Well Technologies: Employing downhole sensors and control systems to monitor and adjust production parameters in real-time, maximizing recovery from different zones.

- Hydraulic Fracturing Optimization: Tailoring the hydraulic fracturing design to the specific reservoir properties to enhance permeability and improve flow.

- Water Management: Implementing strategies to minimize water production and efficiently manage produced water.

- Artificial Lift Systems: Employing technologies such as ESPs (Electrical Submersible Pumps) or gas lift to maintain production from low-pressure zones.

- Reservoir Simulation and Modeling: Using advanced simulation techniques to predict future performance and optimize production strategies.

A systematic approach involving continuous monitoring, data analysis, and adaptive strategies is crucial for optimal production.

Q 27. Compare and contrast different types of completion strategies for different reservoir types.

Completion strategies vary significantly depending on the reservoir type. Here’s a comparison:

- Conventional Reservoirs (High Permeability): These reservoirs may only require simple perforations to allow hydrocarbons to flow into the wellbore. Gravel packing might be used to prevent sand production.

- Tight Reservoirs (Low Permeability): These require extensive hydraulic fracturing to create flow paths and increase productivity. Multi-stage fracturing with different proppant types and fluids is often implemented.

- Fractured Reservoirs: Completion strategies focus on intersecting and stimulating existing fractures to improve flow. This might involve oriented perforations and selective stimulation.

- Heavy Oil Reservoirs: These often require thermal recovery methods (steam injection) in conjunction with horizontal wells to reduce viscosity and improve flow. Completion may involve techniques to minimize heat loss.

- Unconventional Reservoirs (Shale): These rely heavily on massive hydraulic fracturing to create a complex fracture network. The design incorporates multiple stages, complex fluid systems, and advanced proppant technologies.

The choice of completion strategy is a critical decision, requiring detailed reservoir characterization and analysis to optimize production.

Q 28. Discuss the economic considerations in designing a horizontal completion.

Economic considerations are paramount in horizontal well completion design. Key factors include:

- Drilling Costs: Horizontal wells are more expensive to drill than vertical wells due to increased drilling time and specialized equipment.

- Completion Costs: Completion costs can be substantial, especially for complex completions involving hydraulic fracturing and other advanced technologies.

- Production Costs: Ongoing operational costs such as artificial lift, water handling, and chemical treatments must be factored into the economic analysis.

- Reservoir Size and Productivity: The size and productivity of the reservoir dictates the economic viability of a horizontal well. Detailed reservoir simulation is essential.

- Oil and Gas Prices: Fluctuations in commodity prices significantly impact the profitability of a horizontal well project.

- Regulatory Costs and Environmental Considerations: Compliance with environmental regulations and permitting adds to the overall cost.

A comprehensive economic analysis is critical to ensure a project’s financial viability, comparing potential profits against the investment required.

Key Topics to Learn for Horizontal Completion Techniques Interview

- Wellbore Trajectory Design: Understanding the principles behind designing optimal horizontal well paths, considering factors like reservoir geology, drilling limitations, and target placement. This includes analyzing survey data and evaluating different trajectory planning software.

- Hydraulic Fracturing Optimization: Mastering the principles of hydraulic fracturing in horizontal wells, including understanding fracture geometry, proppant selection, fluid design, and pressure monitoring techniques to maximize production.

- Completion Techniques and Equipment: Gaining familiarity with various completion methods (e.g., cemented liners, gravel packs, slotted liners), their applications, advantages, and disadvantages in different reservoir conditions. Understanding the associated equipment and their functionalities is crucial.

- Reservoir Simulation and Modeling: Developing a strong understanding of how reservoir simulators are used to predict the performance of horizontal wells, including the impact of different completion designs and stimulation techniques. This involves interpreting simulation results and making informed decisions based on the data.

- Production Optimization and Monitoring: Learning how to monitor and optimize production from horizontal wells. This involves analyzing production data (pressure, flow rates, etc.), identifying potential problems, and implementing solutions to maximize well productivity.

- Challenges and Problem Solving: Preparing to discuss common challenges encountered in horizontal completion projects, such as sand production, water influx, and wellbore instability, and developing effective problem-solving strategies to mitigate these issues.

- Health, Safety, and Environmental (HSE) Considerations: Understanding and applying HSE regulations and best practices throughout the horizontal completion lifecycle.

Next Steps

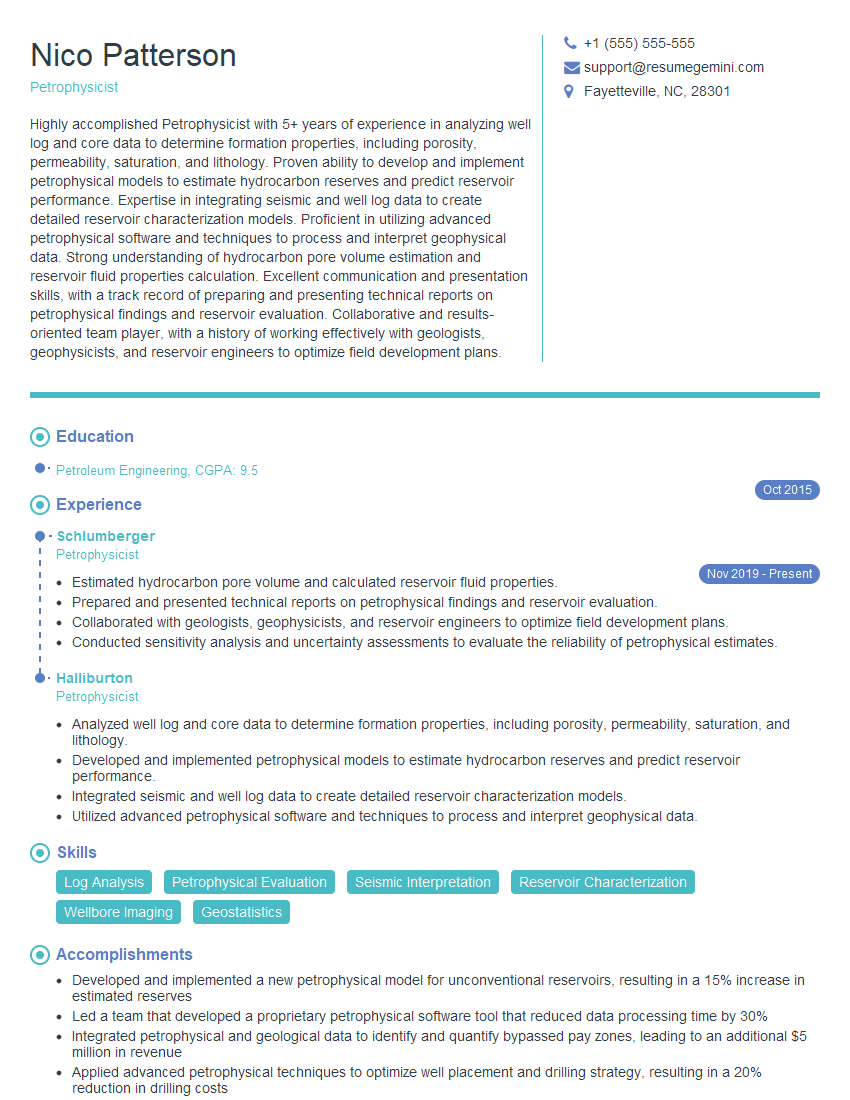

Mastering Horizontal Completion Techniques is paramount for career advancement in the energy sector, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Crafting an ATS-friendly resume is essential to ensure your application reaches the right hands. To significantly boost your chances, we highly recommend using ResumeGemini, a trusted resource for building professional and impactful resumes. Examples of resumes tailored specifically to highlight expertise in Horizontal Completion Techniques are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good