Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Asphalt Paving and Repair interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Asphalt Paving and Repair Interview

Q 1. Describe your experience with different asphalt types (e.g., hot mix asphalt, cold mix asphalt).

My experience encompasses a wide range of asphalt types, primarily hot mix asphalt (HMA) and cold mix asphalt (CMA). HMA, produced at high temperatures, offers superior strength, durability, and longevity. It’s ideal for high-volume roadways and areas demanding exceptional performance. I’ve extensively worked with various HMA designs, adjusting aggregate gradations and binder content to meet specific project needs. For instance, I’ve used dense-graded HMA for heavily trafficked interstates and open-graded mixes for porous pavements designed to manage stormwater runoff. CMA, on the other hand, is mixed at lower temperatures and is often used for temporary repairs or patching smaller areas. Its ease of application makes it suitable for quick fixes, but its performance is generally lower compared to HMA in terms of strength and lifespan. I’ve used CMA effectively for pothole repairs and temporary surface treatments, understanding its limitations and choosing it appropriately.

Q 2. Explain the process of asphalt pavement design.

Asphalt pavement design is a multi-faceted process, balancing structural integrity, cost-effectiveness, and environmental considerations. It starts with a thorough site assessment, including traffic volume and type, soil conditions, and climate. Next, I use sophisticated software and engineering principles to determine the necessary pavement structure. This involves calculating the thickness of each layer – subgrade, base, and asphalt surface – based on factors like traffic loading, soil strength, and the desired pavement life. For example, a high-traffic highway would require thicker asphalt layers than a residential street. Material selection is crucial; we choose aggregates, binders, and additives optimized for local conditions. Finally, we develop detailed construction plans, ensuring the project aligns with industry best practices and relevant specifications.

Q 3. What are the common causes of asphalt pavement failures?

Asphalt pavement failures can stem from various causes. Inadequate design is a primary culprit, leading to insufficient structural capacity to handle traffic loads. Poor construction practices, such as inadequate compaction or improper material handling, can also significantly reduce pavement life. Environmental factors, including freeze-thaw cycles, moisture ingress, and ultraviolet radiation, contribute to deterioration. Traffic loading, exceeding the design capacity, causes rutting, cracking, and other distress manifestations. Lastly, the aging process itself, with the oxidation and hardening of the binder, affects pavement performance. For example, I’ve encountered projects where insufficient compaction caused premature cracking, while others showed rutting due to overloading. Identifying the root cause is critical for effective repair and future prevention.

Q 4. How do you ensure proper compaction of asphalt during paving?

Proper compaction is vital for asphalt’s strength and longevity. It ensures the asphalt mix achieves its designed density, eliminating voids and maximizing its resistance to deformation. We achieve this using a combination of rollers, carefully selected based on the layer thickness and mix type. I typically begin with smaller, pneumatic-tired rollers for initial breakdown, followed by heavier, steel-wheeled rollers for final compaction. Compaction levels are constantly monitored using nuclear density gauges or other testing methods. The goal is to achieve specified density targets, typically expressed as a percentage of the maximum theoretical density. The number of roller passes and the speed and weight of the rollers are adjusted based on the temperature of the mix and the moisture content of the base layers. I always insist on achieving these compaction goals to prevent future issues.

Q 5. Describe your experience with different asphalt paving equipment.

My experience includes operating and overseeing a variety of asphalt paving equipment. This includes asphalt pavers, which accurately spread and shape the asphalt mix; different types of rollers, from pneumatic-tired to steel-wheeled, for compaction; material transfer vehicles to efficiently transport the hot mix; and support equipment like excavators and graders for earthworks and subgrade preparation. I’m also proficient with modern technologies, including GPS-guided pavers and compaction monitoring systems that enhance accuracy and efficiency. For example, using a GPS-guided paver ensures precise placement and minimizes material waste. Each piece of equipment requires regular maintenance and careful operation to ensure optimal performance and worker safety.

Q 6. What safety precautions do you follow during asphalt paving operations?

Safety is paramount in asphalt paving. We adhere to strict safety protocols, including regular safety meetings, personal protective equipment (PPE) use for all workers (e.g., hard hats, safety glasses, high-visibility clothing), and adherence to traffic control plans. We establish well-defined work zones, utilizing barricades, cones, and flaggers to protect workers and the public. Equipment is regularly inspected to prevent malfunctions and accidents. Workers receive training on safe operating procedures, including hot asphalt handling, equipment operation, and hazard recognition. We meticulously monitor environmental conditions, especially temperature and weather, to prevent heat stress and ensure worker safety. Our accident prevention record is excellent thanks to a commitment to a strong safety culture.

Q 7. How do you determine the required thickness of an asphalt layer?

Determining asphalt layer thickness is crucial for pavement design and involves several factors. It’s based on structural design considerations, including the anticipated traffic load, the strength of the underlying base and subgrade, and the desired pavement lifespan. I utilize pavement design software and established design methodologies like AASHTO’s design guide to calculate the required thickness of each layer. This often involves layered design, incorporating multiple layers of varying materials and thicknesses to optimize performance and cost-effectiveness. For example, a higher traffic volume or weaker subgrade would necessitate thicker asphalt layers compared to a low-traffic situation with a strong subgrade. The ultimate goal is to achieve a pavement that provides adequate structural support, meets design life, and is economically viable.

Q 8. Explain your experience with asphalt repair techniques (e.g., pothole patching, crack sealing).

Asphalt repair is crucial for extending pavement lifespan and maintaining road safety. My experience encompasses a wide range of techniques, primarily focusing on pothole patching and crack sealing. Pothole patching involves removing loose material, cleaning the cavity, and filling it with hot-mix asphalt or a cold-mix patching material, carefully compacted to ensure a smooth, level surface. This process requires selecting the right patching material based on the size and depth of the pothole, as well as considering factors like weather and traffic conditions. For instance, a large pothole in a high-traffic area might need a hot-mix asphalt patch for superior durability. Crack sealing, on the other hand, focuses on preventing water infiltration into the pavement structure. This involves cleaning the cracks, applying a sealant, and ensuring proper adhesion to prevent water damage which can lead to further deterioration and potholes. I’ve utilized different sealant types, like rubberized crack sealants, depending on the crack’s size and type. I always prioritize using materials appropriate for the climate and traffic volume.

For instance, I once managed a project where we were facing a significant number of potholes after an unusually harsh winter. We developed a rapid response team, using a combination of cold-mix patching for immediate repairs, and scheduling a larger hot-mix patching operation after the weather improved, ensuring long-term durability. This allowed for continuous traffic flow while ensuring the repairs were ultimately durable and effective.

Q 9. What are the key factors influencing the lifespan of an asphalt pavement?

The lifespan of asphalt pavement depends on a complex interplay of factors. Think of it like a living organism; it needs the right conditions to thrive. Key factors include the quality of the base materials – a weak foundation will always lead to a shorter lifespan, regardless of the top layer’s quality. The type of asphalt binder used – some binders are more resilient to temperature fluctuations and oxidation than others – is critical. The design of the pavement structure, including the thickness and layering, impacts its ability to withstand traffic loads and environmental stress. Climate plays a huge role; freeze-thaw cycles, heavy rainfall, and extreme temperatures all contribute to pavement deterioration. Traffic volume and load – heavier traffic causes faster wear and tear, similar to how a heavily used rug wears out faster than one that isn’t. Lastly, proper maintenance and timely repairs are vital. Neglecting cracks and potholes will accelerate the deterioration process.

For example, a pavement designed for a light residential area will likely have a shorter lifespan if subjected to the heavy loads of commercial trucks. Similarly, a pavement in a region with frequent freeze-thaw cycles will require a more robust design and potentially more frequent maintenance than one in a milder climate. I always emphasize a holistic approach in my project design, considering all these interconnected factors.

Q 10. How do you handle unexpected weather conditions during asphalt paving?

Unexpected weather can significantly impact asphalt paving operations. Rain, for instance, can wash away aggregate and prevent proper compaction, resulting in weak pavement. Freezing temperatures can halt the process entirely as the asphalt won’t be workable. High winds can also affect the placement of asphalt and increase the risk of dust and debris contamination. My approach to managing these challenges involves close weather monitoring throughout the project. We utilize weather forecasts to plan work schedules, ensuring we have contingency plans in place. For example, we might prioritize areas that are less vulnerable to rain damage in case of an unexpected shower. Protecting the newly laid asphalt with coverings is sometimes necessary, and we have specialized equipment to quickly cover large areas if rain threatens. If extreme weather conditions arise, we safely halt operations and resume work once the weather permits, ensuring the quality and integrity of the paving are not compromised. In short, flexibility and proactive planning are essential for navigating weather-related challenges during asphalt paving.

Q 11. Describe your experience with quality control procedures in asphalt paving.

Quality control is paramount in asphalt paving. It’s not just about aesthetics; it’s about ensuring a safe and durable road surface. My quality control procedures begin with material selection; we use reputable suppliers and strictly adhere to specified material properties. During the paving process, we continuously monitor the compaction levels using sophisticated equipment such as nuclear gauges to ensure density meets specifications. We also regularly check asphalt temperature and mix consistency to maintain the quality of the product. Sampling and testing are performed at various stages to verify the compliance with design standards. We document everything meticulously – from material testing reports to compaction data – using digital records to ensure traceability and compliance. Finally, a thorough post-construction inspection identifies any deficiencies to ensure the project meets or surpasses the required specifications. Regular visual inspections, as well as specialized tests like rut depth measurements, are employed to evaluate the long-term quality of the work.

For example, I once identified a slight variation in asphalt temperature during a large project. This could have led to inconsistent compaction. By promptly addressing the issue, we prevented a significant quality problem, avoiding costly repairs down the line. This highlights the importance of continuous monitoring and proactive adjustments.

Q 12. How do you manage a paving crew and ensure efficient workflow?

Managing a paving crew requires strong leadership and organizational skills. Clear communication is key. I use daily briefings to outline the day’s tasks, assign responsibilities, and ensure everyone understands their roles and expectations. Safety is always my top priority; regular safety talks and enforcement of safety protocols are fundamental. I foster teamwork and collaboration, empowering crew members to contribute their ideas and expertise. Efficient workflow management involves scheduling tasks logically to minimize downtime and optimize resource utilization. I frequently review work progress and make necessary adjustments to ensure project completion on schedule and within budget. Motivating the crew is also crucial. Recognizing good work and addressing concerns promptly contributes to a positive and productive work environment.

For instance, during one particularly challenging project involving a tight deadline, I organized the crew into smaller, specialized teams, each responsible for a specific task. This modular approach facilitated better organization and allowed for more efficient parallel processing, leading to timely completion despite the complexities of the project.

Q 13. Explain your experience with asphalt emulsion applications.

Asphalt emulsions are a versatile binder commonly used in pavement construction and maintenance. My experience involves various applications, including surface treatments, prime coats, and tack coats. Surface treatments, such as seal coats, improve the surface’s durability and extend the pavement’s life. Prime coats prepare the base for subsequent asphalt layers, enhancing adhesion. Tack coats provide bonding between different asphalt layers. The application process requires precise control of emulsion type and application rate to ensure proper coverage and penetration. Different emulsion types are selected based on project requirements; for instance, cationic emulsions are often preferred for applications on aggregate bases. Understanding the emulsion’s break characteristics and proper mixing techniques is crucial for optimum performance. During application, the weather conditions, such as temperature and humidity, need to be carefully considered, as these can significantly affect the emulsion’s performance.

For example, while working on a highway resurfacing project, we used a specific slow-setting cationic emulsion for the prime coat to ensure adequate penetration and bonding with the existing base. This careful selection and precise application prevented potential issues with stripping and detachment of the overlay, leading to a more durable and longer-lasting pavement.

Q 14. What is your experience with different types of asphalt binders?

Different asphalt binders exhibit varying properties, influencing the pavement’s performance characteristics. I have experience working with various types, including PG (Performance Graded) binders, which are the most common type nowadays. PG binders are classified based on their performance grades, reflecting their ability to withstand temperature variations. For instance, a PG 64-22 binder is suitable for areas experiencing high summer temperatures and moderate winter temperatures. Other types include polymer-modified binders, which enhance the pavement’s durability, fatigue resistance, and rutting resistance. These are often used in high-traffic areas or regions with harsh climate conditions. I also have experience with rubberized asphalt binders, which incorporate recycled tire rubber. These are environmentally friendly options that improve the binder’s flexibility and crack resistance. The choice of binder depends on several factors, including the climate, traffic loading, and project requirements. Understanding the properties of each type is crucial for selecting the optimal binder to meet the specific needs of a project.

I recently used a polymer-modified asphalt binder on a major thoroughfare in an area with heavy traffic and extreme temperature swings. The enhanced performance of this binder ensured a durable and long-lasting pavement, significantly reducing maintenance costs over its lifespan. Proper binder selection is a cornerstone of successful asphalt paving projects.

Q 15. Describe your experience with the use of GPS and surveying equipment in asphalt paving.

GPS and surveying equipment are indispensable for accurate and efficient asphalt paving. We use GPS systems, typically RTK (Real-Time Kinematic) GPS, for precise positioning and grade control. This ensures the asphalt layer is laid to the exact design specifications, avoiding costly rework. Survey equipment, including total stations and levels, are used to establish benchmarks and control points, providing the framework for the GPS system. For example, on a recent highway project, RTK GPS guided our pavers, maintaining consistent grade within a tolerance of ±5mm, resulting in a smooth, even surface. The data collected is also invaluable for as-built documentation.

Imagine trying to pave a road perfectly without precise measurements; it would be like trying to paint a straight line without a ruler! GPS and surveying provide that ‘ruler’ ensuring accuracy and efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with asphalt recycling and reclamation techniques?

Asphalt recycling and reclamation are crucial for sustainability and cost-effectiveness. I have extensive experience with both cold in-place recycling (CIR) and hot in-place recycling (HIR). CIR involves milling the existing asphalt pavement, mixing it with rejuvenating agents and new aggregate, and then repaving it. HIR involves heating the existing pavement in place, mixing in new binder, and then compacting it. The choice between CIR and HIR depends on factors such as the condition of the existing pavement, project budget, and environmental considerations. For example, on a project with an aged but structurally sound pavement, CIR proved to be a cost-effective and environmentally friendly solution, saving both material costs and reducing waste sent to landfills. HIR is better suited for pavements with more significant structural deficiencies where a more thorough rejuvenation is required.

Q 17. How do you calculate the quantities of asphalt materials needed for a project?

Calculating asphalt quantities requires meticulous planning and accurate measurements. It starts with detailed surveying to determine the area and volume of the pavement to be constructed. We then use the design specifications, which include the thickness of each asphalt layer and the density of the asphalt mix, to calculate the total volume of asphalt needed. This volume is then converted to weight using the asphalt mix design’s density. For instance, if we need to pave an area of 1000 square meters with a 150mm thick layer and the asphalt density is 2.3 tonnes per cubic meter, the calculation would be: (1000 m² * 0.15 m) * 2.3 tonnes/m³ = 345 tonnes of asphalt. This calculation needs to account for additional factors such as waste, compaction, and potential variations in thickness to avoid shortages or overages.

Q 18. What are the common challenges you face in asphalt paving projects?

Asphalt paving projects present numerous challenges. Weather is a major factor; rain can delay work and affect the quality of the asphalt. Traffic control and managing the flow of traffic around the project site are also critical, requiring careful planning and coordination with local authorities. Maintaining the required compaction levels, ensuring proper mix design, and managing the logistics of material delivery and disposal all add to the complexities of the project. Finally, dealing with unexpected site conditions, such as subsurface issues or variations in the existing pavement, can necessitate adjustments to the project plan and potentially increase costs.

Q 19. How do you address issues related to asphalt segregation and stripping?

Asphalt segregation (separation of aggregates from binder) and stripping (loss of adhesion between aggregates and binder) are major concerns that can significantly compromise the pavement’s performance. We address segregation through proper mix design, including the use of appropriate aggregate gradation and binders. Careful control during mixing and paving is equally important. To minimize stripping, we use anti-stripping additives in the asphalt mix design, these additives improve the bond between aggregates and the binder. Regular quality control testing throughout the project ensures the mix properties are within the specified limits, and addressing any issues promptly.

Q 20. How do you maintain the accuracy of measurements and documentation throughout a project?

Accuracy in measurements and documentation is paramount. We use calibrated equipment and established procedures to ensure the data’s reliability. All measurements are recorded digitally and stored securely, creating a comprehensive audit trail. Regular quality control checks are implemented throughout the project, comparing the as-built data with the design specifications. Detailed daily reports document progress, challenges, and any deviations from the plan, enabling effective project management and problem-solving. This detailed record-keeping is also crucial for meeting regulatory requirements and avoiding disputes.

Q 21. What is your experience with estimating the cost of asphalt paving projects?

Estimating asphalt paving project costs involves a detailed breakdown of all expenses. This includes materials (asphalt, aggregates, additives), labor, equipment rental or ownership costs, transportation, permits, and contingency allowances for unforeseen events. We use historical data, current market prices, and detailed quantity calculations to arrive at a realistic cost estimate. For example, we might use unit cost rates for asphalt laying (cost per square meter) and then multiply it by the total area to get a preliminary estimate. However, this is refined with a more detailed breakdown to encompass all anticipated costs. Detailed risk assessment forms an important part of this estimation to account for any potential cost overruns.

Q 22. Describe your problem-solving skills related to asphalt paving issues.

My problem-solving approach to asphalt paving issues is systematic and data-driven. I start by thoroughly assessing the problem, which involves visual inspection, material testing, and reviewing historical data if available. For instance, if I encounter premature cracking in a newly paved road, I wouldn’t just patch it. I’d investigate the cause. Was the subgrade properly compacted? Was the asphalt mix designed for the expected traffic load and climate? Were there any issues with the aggregate quality or the paving process itself? I use this information to develop a solution, often involving multiple steps. This might include subgrade remediation, employing different mixes, adjusting compaction parameters, or even implementing preventative measures for the future. I document all steps and findings, allowing for continuous improvement and better decision-making in future projects.

For example, I once encountered extensive rutting on a highway section. Initial inspection suggested poor compaction. Further investigation revealed inconsistent aggregate gradation in the asphalt mix, weakening the structural integrity. The solution involved milling out the affected sections, re-grading the subgrade with proper compaction testing, using a revised asphalt mix with improved aggregate gradation, and finally repaving the area. Regular monitoring of the repaired section confirmed the efficacy of the solution.

Q 23. How do you ensure compliance with safety regulations during paving operations?

Safety is paramount in asphalt paving. Compliance begins with pre-planning, encompassing thorough risk assessments and the development of site-specific safety plans. This involves identifying potential hazards like heavy machinery, high temperatures, and working near traffic. We implement measures such as clear signage, barricades, and traffic control plans. Our team receives comprehensive safety training covering operating machinery safely, wearing appropriate PPE (Personal Protective Equipment) like hard hats, high-visibility vests, and safety footwear, and recognizing and responding to emergencies. Regular toolbox talks reinforce safety protocols and address any emerging issues. We maintain detailed safety records, including incident reports and near-miss analyses, to continuously refine our safety program and prevent future accidents. We also ensure that all our subcontractors are equally committed to safety standards.

For instance, on a recent project near a busy intersection, we implemented a phased traffic management plan using temporary lane closures and flag persons to guide traffic safely around the construction area. This minimized disruption to traffic flow while ensuring the safety of our workers.

Q 24. Explain your experience working with different types of aggregates in asphalt mixes.

My experience encompasses working with a wide array of aggregates, including crushed stone, gravel, slag, and recycled materials. The choice of aggregate depends on factors such as its gradation, durability, strength, and availability. Each aggregate type impacts the asphalt mix’s properties, such as its stiffness, stability, and resistance to cracking. For example, crushed stone with a well-graded particle size distribution generally provides good stability and strength. Slag, a byproduct of steel manufacturing, can be a cost-effective and environmentally friendly alternative but requires careful quality control to ensure consistent performance. Recycled materials, like reclaimed asphalt pavement (RAP), offer sustainability benefits by reducing the need for virgin materials; however, their incorporation requires careful consideration of their properties and potential impact on the mix design. Understanding the characteristics of different aggregates allows me to optimize mix designs for specific project needs and environmental conditions.

I’ve worked on projects where using a specific type of locally sourced gravel proved cost-effective and environmentally sustainable, leading to faster project completion and reduced carbon footprint compared to using imported aggregates.

Q 25. What is your experience with soil stabilization techniques before asphalt paving?

Soil stabilization is crucial for providing a stable base for asphalt paving, preventing future issues like settlement and cracking. I have extensive experience employing various soil stabilization techniques, including lime stabilization, cement stabilization, and using geotextiles. Lime stabilization improves the strength and bearing capacity of cohesive soils, while cement stabilization provides even greater strength and is suitable for a wider range of soil types. Geotextiles act as a separation layer between the subgrade and the base course, preventing mixing and improving drainage. The choice of technique depends on the soil type, project requirements, and budget constraints. Before applying any technique, we conduct thorough soil testing to determine the best approach. This testing provides data on soil properties like plasticity, strength, and moisture content. This helps in designing the appropriate stabilization mix and determining the required quantities of stabilizing agents.

In one project, we used lime stabilization on a highly expansive clay subgrade. The soil tests indicated significant swelling potential. By incorporating lime, we effectively reduced the soil’s plasticity and improved its stability, preventing future pavement distress due to soil movement.

Q 26. How do you manage material delivery and storage in an asphalt paving project?

Efficient material management is vital for successful asphalt paving. This begins with accurate material quantity estimations based on project plans and specifications. We schedule material deliveries to coincide with paving operations to minimize storage needs and reduce potential material degradation or theft. Storage areas are selected carefully to ensure accessibility for construction equipment and to prevent material contamination. We utilize stockpiles with appropriate drainage to prevent water damage. We maintain detailed records of all materials received, stored, and used, including quantity, source, and quality test results. Regular inventory checks ensure that sufficient materials are available to meet the project schedule, and any discrepancies are investigated and resolved promptly. We strive for just-in-time delivery to minimize storage costs and risk of spoilage.

A recent project successfully utilized a just-in-time delivery system for asphalt, ensuring minimal stockpile size and eliminating storage-related problems. This system improved efficiency and saved on storage costs.

Q 27. Describe your experience with different types of pavement markings and their applications.

My experience covers various pavement markings, including thermoplastic, paint, and preformed markings. Thermoplastic markings, known for their durability and longevity, are ideal for high-traffic areas and provide excellent visibility. Paint markings are a cost-effective solution for temporary or low-traffic areas, but their lifespan is shorter. Preformed markings are applied in sections and offer good durability. The choice of marking depends on the location, traffic volume, and expected lifespan. Application techniques vary; thermoplastic markings are applied hot and require specialized equipment, while paint is sprayed or rolled on. We ensure that markings meet regulatory standards regarding color, reflectivity, and dimensions to ensure traffic safety. We also account for the local climate and environmental factors when selecting and applying markings to ensure their long-term effectiveness.

For example, on a highway project, we used thermoplastic markings for lanes and crosswalks due to the high traffic volume. For less trafficked side streets, we chose paint markings for cost-effectiveness.

Q 28. Explain your understanding of sustainable paving practices.

Sustainable paving practices are crucial for minimizing the environmental impact of our projects. This involves incorporating recycled materials like RAP (Reclaimed Asphalt Pavement) in asphalt mixes, reducing the need for virgin aggregates. We optimize mix designs to minimize energy consumption during production and transportation. We employ techniques that reduce waste generation, such as precise material quantity estimations and efficient construction methods. We also prioritize environmentally friendly construction equipment that reduces emissions and noise pollution. Proper compaction techniques minimize the use of energy and ensure pavement longevity, reducing the need for future repairs. Water management strategies, such as effective drainage systems, prevent erosion and runoff contamination. We also actively seek opportunities to collaborate with local communities and environmental agencies to integrate sustainability initiatives into our projects.

A recent project successfully incorporated a high percentage of RAP, significantly reducing the environmental impact and achieving cost savings compared to using virgin materials exclusively.

Key Topics to Learn for Asphalt Paving and Repair Interview

- Asphalt Composition and Properties: Understanding the different types of asphalt, their binder properties, and how they affect pavement performance is crucial. Consider the impact of aggregate type and gradation.

- Paving Techniques and Equipment: Familiarize yourself with various paving methods (e.g., hot-mix, cold-mix), the operation of relevant machinery (pavers, rollers, etc.), and quality control procedures during the paving process.

- Asphalt Repair and Maintenance: Learn about different repair techniques for potholes, cracks, and other pavement distresses. Understand preventative maintenance strategies and their long-term cost benefits.

- Safety Regulations and Best Practices: Demonstrate knowledge of OSHA regulations and industry best practices for safety on asphalt paving and repair projects. This includes personal protective equipment (PPE) and site safety procedures.

- Project Management and Estimation: Understand the basics of project planning, scheduling, cost estimation, and resource allocation in asphalt projects. This includes understanding project timelines and potential challenges.

- Problem-Solving and Troubleshooting: Be prepared to discuss common problems encountered in asphalt paving and repair and how you would approach solving them. This includes understanding the root causes of pavement failures.

- Environmental Considerations: Demonstrate awareness of environmental regulations and sustainable practices related to asphalt paving and repair, such as minimizing waste and using recycled materials.

Next Steps

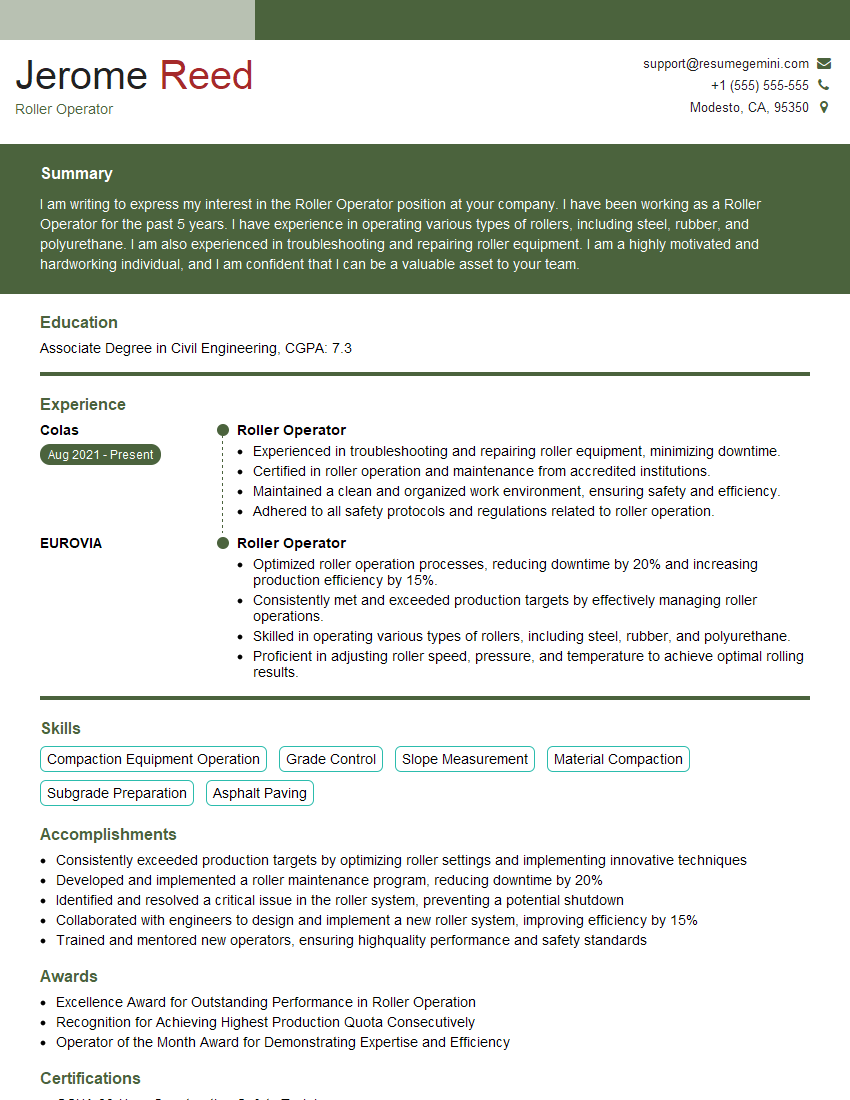

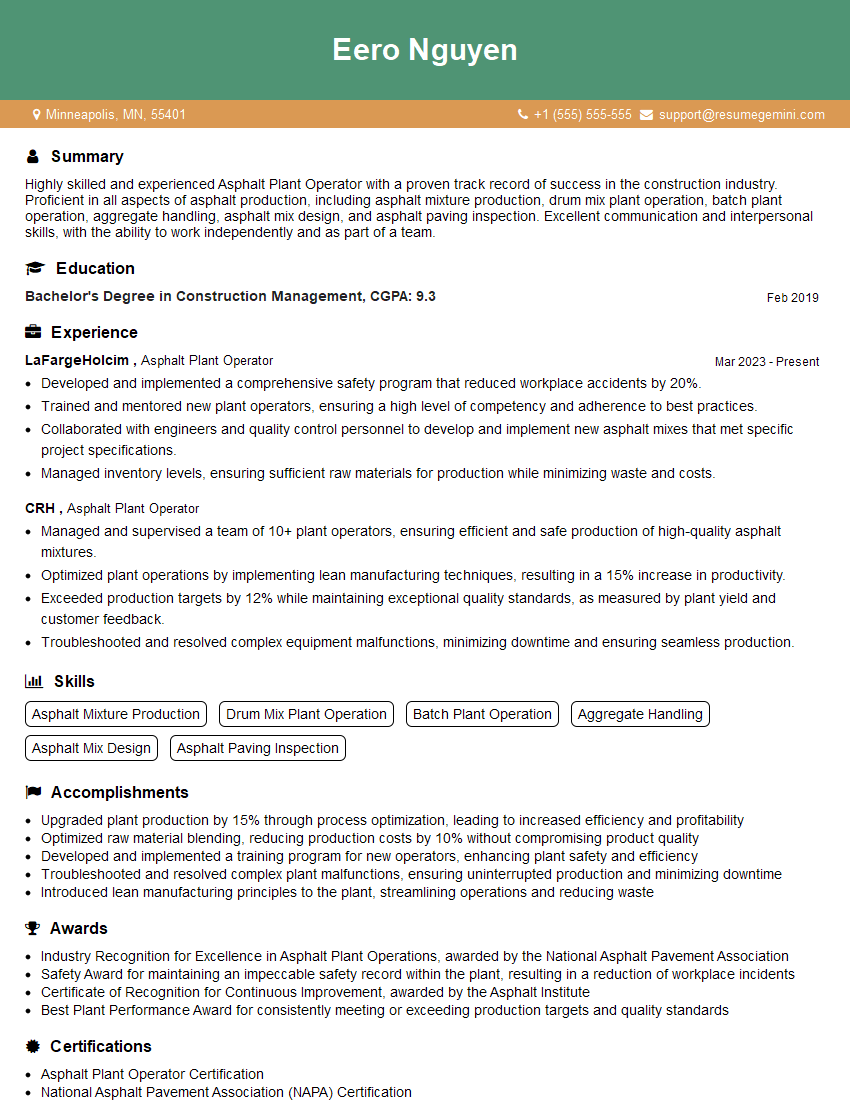

Mastering asphalt paving and repair skills opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization and advancement into project management or supervisory roles. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional, impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to the Asphalt Paving and Repair industry are available to guide you through the process. Take the next step toward your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good