Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Drainage Installation and Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Drainage Installation and Maintenance Interview

Q 1. Explain the different types of drainage systems.

Drainage systems are broadly categorized into surface drainage and subsurface drainage. Surface drainage systems manage water runoff from the surface, preventing flooding and erosion. These systems typically involve features like swales, ditches, gutters, and storm drains. Subsurface drainage systems, on the other hand, collect and remove water from beneath the ground’s surface. This is crucial for preventing waterlogging, foundation damage, and basement flooding. Subsurface systems utilize a network of pipes and other components, often incorporating features like perforated pipes, gravel filters, and collection chambers.

- Surface Drainage: Think of the drainage system along a roadway – the gutters collect water and direct it to storm drains, which eventually lead to larger water bodies.

- Subsurface Drainage: Imagine a building’s foundation; a subsurface drainage system, often involving French drains, intercepts groundwater to prevent it from accumulating around the structure.

Each system’s design depends heavily on factors like the site’s topography, soil type, rainfall patterns, and the specific needs of the property.

Q 2. Describe your experience with trenchless drainage installation techniques.

I have extensive experience with trenchless drainage installation techniques, primarily using horizontal directional drilling (HDD) and pipe bursting. HDD allows for the precise placement of new pipes underground without the need for extensive trenching. This is particularly advantageous in areas with existing infrastructure, minimizing disruption. I’ve successfully used HDD to install drainage pipes under roads, driveways, and even established landscaping. Pipe bursting, another trenchless method, involves breaking up the existing pipe and simultaneously pulling a new one into its place. This is especially useful for replacing damaged or deteriorated pipes without the need for excavation.

One memorable project involved installing a new drainage line under a busy city street using HDD. The traditional trenching method would have caused significant traffic disruption and cost delays. By using HDD, we minimized disruption, completed the project on schedule, and delivered significant cost savings to the client.

Q 3. How do you identify and resolve drainage system blockages?

Identifying drainage blockages typically starts with visual inspection. Looking for pooling water, slow drainage, or overflowing drains helps pinpoint the problem area. Then, we use a combination of techniques:

- Drain Snaking: A flexible auger is inserted into the drain to break up and remove clogs.

- High-Pressure Water Jetting: This powerful technique uses high-pressure water to clear away stubborn blockages.

- CCTV Drain Inspection: A small camera on a flexible rod is used to visually inspect the drain line, identifying the exact location and nature of the blockage. This is invaluable for complex issues.

Once the blockage is identified, the appropriate method – whether snaking, jetting, or even excavation in severe cases – is employed to clear it. Afterward, a thorough inspection ensures the drain is flowing freely.

For example, a slow-draining kitchen sink might be cleared easily with a drain snake, but a complete sewer line blockage usually requires a CCTV inspection to pinpoint the location before deciding on the best method for clearing the obstruction.

Q 4. What are the common causes of drainage system failures?

Drainage system failures stem from various factors. Root intrusion is a very common culprit, where tree roots grow into pipes, causing blockages and cracks. Improper installation, such as insufficient slope or incorrect pipe sizing, frequently contributes to problems. Over time, pipes deteriorate due to corrosion, ground shifting, or wear and tear. External factors like heavy rainfall or ground saturation can overwhelm the system’s capacity, causing backups and failures. Lastly, improper maintenance, such as neglecting regular cleaning and inspections, significantly increases the likelihood of failures.

For instance, neglecting regular maintenance on a storm drain can lead to sediment buildup, reducing its capacity and eventually leading to overflows during heavy rain.

Q 5. What safety precautions do you take during drainage installation and maintenance?

Safety is paramount. Before any work begins, we conduct thorough site assessments to identify potential hazards. We utilize appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and high-visibility clothing. When working in confined spaces or trenches, we use confined space entry procedures and trench shoring to prevent collapses. We always follow OSHA guidelines and local safety regulations. Proper signage and traffic control measures are implemented to protect workers and the public during installation and maintenance activities.

For example, when working near traffic, we ensure appropriate signage, traffic cones, and flaggers are in place to prevent accidents.

Q 6. How do you ensure proper slope and grading for effective drainage?

Proper slope and grading are fundamental for effective drainage. The goal is to ensure a consistent flow of water away from structures and towards designated discharge points. This typically involves a minimum slope of 1% to 2%, depending on the pipe diameter and type of soil. We use laser levels and surveying equipment to accurately determine and establish the correct grades before installation. Grading the surrounding land to direct water towards the drainage system is also critical. Incorrect grading can lead to ponding, erosion, and ultimately, drainage system failure.

Imagine building a house on a hill – proper grading directs rainwater away from the foundation, preventing potential basement flooding. Failure to do so could lead to water damage and costly repairs.

Q 7. Explain your experience with different types of drainage pipes (PVC, HDPE, clay).

I have extensive experience with PVC, HDPE, and clay pipes. PVC (polyvinyl chloride) pipes are widely used due to their affordability, durability, and ease of installation. They are well-suited for many drainage applications but are susceptible to damage from heavy loads or extreme temperatures. HDPE (high-density polyethylene) pipes offer excellent strength, flexibility, and resistance to corrosion, making them ideal for challenging conditions or situations requiring long spans. Clay pipes, while less common now, are still found in older systems. They’re durable but can be brittle and prone to cracking, especially when subjected to ground movement.

The choice of pipe material depends on several factors, including the project’s budget, soil conditions, the depth of the installation, and the required lifespan of the system. For example, HDPE pipes are often preferred for large diameter applications and areas with challenging soil conditions because of their strength and flexibility.

Q 8. Describe your experience with drainage system inspections and reporting.

Drainage system inspections are crucial for preventative maintenance and identifying potential problems before they escalate into costly repairs. My process begins with a thorough visual inspection, checking for signs of blockage, erosion, cracks in pipes or structures, and evidence of water ponding. I use specialized equipment like CCTV cameras to inspect underground pipes, providing a detailed view of their internal condition. I then carefully document all findings, including the location of any issues, their severity, and photographic evidence. This information is compiled into a comprehensive report that clearly outlines the current state of the drainage system, recommends necessary repairs or maintenance, and estimates the costs involved. For example, I once discovered a significant root intrusion in a main drainage line during a routine inspection, preventing a future catastrophic failure.

My reports are always structured consistently, following a standardized format to improve clarity and facilitate easy comparison over time. This format generally includes a site overview, detailed descriptions of any problems encountered, photographic evidence, recommendations for remediation, and cost estimates. This ensures clients fully understand the situation and can make informed decisions.

Q 9. How do you handle emergency drainage repairs?

Emergency drainage repairs demand immediate action and a rapid response. My priority is always to mitigate the immediate problem and prevent further damage. This usually involves assessing the situation quickly, identifying the source of the problem, and implementing temporary solutions to control water flow. For example, this might include using pumps to remove excess water or deploying temporary dams to redirect flow. Once the immediate threat is addressed, I proceed to diagnose the root cause and develop a more permanent repair strategy. This could involve anything from clearing blockages to replacing damaged sections of pipe. Open communication with the client throughout the entire process is key, keeping them updated on progress and outlining the next steps.

I’ve handled numerous emergency situations, such as burst pipes during heavy rainfall or sewer backups causing significant flooding. In each case, swift action, coupled with a systematic approach, ensures minimal disruption and prevents further damage.

Q 10. What are your skills in using surveying equipment for drainage installation?

Proficient use of surveying equipment is essential for accurate drainage installation. I am skilled in using Total Stations, GPS receivers, and laser levels to establish accurate grades, elevations, and alignments. This ensures that the drainage system functions optimally and prevents issues like ponding or insufficient drainage. For instance, using a Total Station, I can precisely determine the required slope of a drainage pipe to ensure efficient water flow. Laser levels help me establish consistent elevations for various components of the drainage system, ensuring proper installation and minimizing potential problems down the line. My experience also includes the use of digital level and other surveying software which improve speed and accuracy.

Accuracy is paramount in surveying for drainage installation; even small errors can lead to significant problems. I rigorously check my measurements and use various techniques to ensure the precision required for a long-lasting and efficient drainage system.

Q 11. What is your experience with the use of Computer-Aided Design (CAD) in drainage design?

I’m highly proficient in using Computer-Aided Design (CAD) software, specifically AutoCAD and Civil 3D, for drainage design. These tools allow me to create detailed and accurate plans, cross-sections, and 3D models of drainage systems. This is crucial for efficient design, cost estimation, and communication with clients and contractors. For example, I use CAD to model complex drainage networks, simulating flow patterns to ensure optimal design. The software also allows me to generate detailed construction drawings, including specifications and material lists, which simplifies the construction process.

My experience with CAD extends to incorporating surveyed data, integrating various design elements, and preparing detailed construction documents. I also utilize CAD software to generate quantity take-offs for accurate material estimation and cost projections. The use of CAD ensures that all parties involved have a complete and accurate understanding of the project scope and design.

Q 12. Explain the process of installing a drainage system in challenging terrain.

Installing a drainage system in challenging terrain requires careful planning and the use of specialized techniques. This might involve working on steep slopes, rocky areas, or areas with limited access. A thorough site assessment is the first step, carefully analyzing the terrain, soil conditions, and any potential obstacles. This assessment informs the design process, guiding the selection of appropriate materials and construction methods. For instance, in steep areas, we might use specialized trenching techniques or employ retaining structures to prevent erosion. In rocky areas, rock excavation and specialized equipment might be necessary. We may also need to utilize different pipe materials or adapt the drainage system design to suit the unique challenges presented by the terrain.

My experience includes projects in various challenging environments, where I successfully adapted drainage system designs and installation methods to ensure effective and long-lasting results. Careful planning, meticulous execution, and adapting to site-specific challenges are critical for success in these projects.

Q 13. How do you maintain accurate records and documentation of drainage work?

Maintaining accurate records is essential for effective drainage management. I use a combination of digital and physical methods to ensure all work is meticulously documented. This includes creating detailed site reports, utilizing project management software to track progress, maintain comprehensive as-built drawings, and storing all relevant paperwork, including material certificates, inspection reports, and client correspondence. Every aspect of a project, from the initial survey to final inspection, is documented, making it easy to access project history and manage ongoing maintenance. For example, using a GPS-enabled device allows me to accurately record the locations of drainage components, creating a precise digital record of the drainage network.

The use of a well-organized, centralized system simplifies future inspections and maintenance operations, while also providing a valuable record for compliance purposes and potential future projects. This detailed documentation ensures consistency and transparency throughout the entire project lifecycle.

Q 14. Describe your experience with working with different types of soil conditions.

Experience with diverse soil conditions is critical for successful drainage installation. Different soil types have varying permeabilities, bearing capacities, and erosion characteristics, all affecting drainage system design and construction. For example, clay soils require different drainage strategies compared to sandy soils. Clay soils tend to be less permeable, potentially causing water to pond, requiring more extensive drainage systems or the use of perforated pipes with gravel backfill to enhance drainage. Sandy soils, on the other hand, drain readily but are prone to erosion, necessitating careful trenching and installation techniques to avoid collapse. In rocky soil, specialized excavation methods are employed.

I have extensive experience working across diverse soil conditions, allowing me to tailor the drainage system design and installation methods to optimize performance and longevity. Soil testing and analysis, coupled with a deep understanding of soil mechanics, are fundamental in this process to ensure a durable and effective drainage system.

Q 15. How familiar are you with local drainage codes and regulations?

I possess a thorough understanding of local drainage codes and regulations. My experience includes staying updated on all relevant municipal, county, and state ordinances pertaining to drainage installation and maintenance. This includes regulations concerning pipe sizing, slope requirements, backflow prevention, and permitted materials. For example, I’m intimately familiar with the specific requirements for installing drainage systems in areas prone to flooding or those with sensitive environmental concerns, like wetlands. I regularly consult these codes throughout the entire project lifecycle – from initial design to final inspection – ensuring complete compliance and avoiding costly delays or legal issues. I also maintain a library of current codes and regularly attend industry seminars to stay abreast of any changes or updates.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper drainage around foundations?

Proper drainage around foundations is crucial to prevent water damage and structural issues. My approach involves creating a system that directs water away from the foundation using a combination of techniques. This typically starts with grading the soil around the foundation to create a slight slope (minimum 2%) away from the building. We’ll then install a perimeter drain, often a perforated pipe encased in gravel, to intercept subsurface water and channel it to a designated discharge point. A swale (a shallow, vegetated ditch) can be added for larger areas to further manage surface runoff. Finally, we ensure proper downspout extension, directing rainwater away from the foundation and into a storm drain or dry well. For example, in a recent project on a hillside property, we implemented a combination of grading, perimeter drains, and a French drain to effectively manage heavy rainfall and prevent water from seeping into the basement.

Q 17. Explain your experience with using various excavation equipment.

My experience with excavation equipment is extensive, covering a wide range of machines, from small excavators for precise trenching to larger machines for large-scale earthmoving. I am proficient in operating and maintaining excavators (both mini and full-size), backhoes, trenchers, and loaders. I understand the limitations and capabilities of each piece of equipment and select the appropriate tool for the job based on soil conditions, project scope, and site accessibility. Safety is paramount, and I always adhere to strict safety protocols, ensuring all equipment is properly maintained and operated by certified personnel. For instance, on a recent project involving the installation of a large drainage network, I utilized a large excavator for the initial earthmoving and a smaller excavator with a specialized trenching attachment for the precise placement of the drainage pipes, ensuring minimal disturbance to surrounding utilities.

Q 18. Describe your understanding of water flow dynamics in drainage systems.

Understanding water flow dynamics is essential for effective drainage system design. This involves considering factors like gravity, friction, pipe diameter, slope, and the volume of water to be handled. We use principles of fluid mechanics to calculate the appropriate pipe size and slope to ensure efficient water movement. We also consider factors such as infiltration, where water seeps into the ground, and the potential for clogging due to sediment buildup. Think of it like a river system; a larger river can handle a higher flow rate than a small stream. Similarly, larger diameter pipes with appropriate slope allow for greater water flow without backup or overflow. I use specialized software to model water flow and optimize drainage system design for efficiency and reliability.

Q 19. What is your approach to troubleshooting complex drainage problems?

My approach to troubleshooting complex drainage problems is systematic and methodical. I begin with a thorough site assessment, carefully observing the problem areas and gathering information from the client. I then utilize tools like cameras to inspect pipes for blockages, and soil testing to evaluate drainage capabilities. Based on this data, I develop a hypothesis about the cause of the problem, and formulate a testing plan to validate my theory. This might involve temporarily rerouting water flow, or using dye tests to identify the source of a leak. Once the problem is identified, I devise a targeted solution, addressing the root cause rather than simply treating the symptoms. For example, I recently solved a persistent basement flooding issue by discovering a collapsed section of the main drain line several feet from the house, requiring excavation and pipe replacement rather than simply addressing the surface water.

Q 20. How do you manage drainage projects within budget and schedule?

Managing drainage projects within budget and schedule requires careful planning and execution. This starts with accurate cost estimation, factoring in material costs, labor, equipment rental, and potential unforeseen challenges. I develop detailed project schedules with clearly defined milestones and utilize project management software to track progress and identify potential delays. Regular communication with clients keeps them informed of project status and any necessary adjustments. I am adept at finding cost-effective solutions without compromising quality, by exploring alternative materials or construction methods, for example, utilizing recycled materials where appropriate. Proactive risk management identifies and mitigates potential issues before they impact the project schedule or budget. Throughout, meticulous record-keeping ensures accurate cost accounting and efficient resource allocation.

Q 21. Explain your experience working with subcontractors and suppliers.

I have extensive experience collaborating with subcontractors and suppliers. I build strong, collaborative relationships based on trust, clear communication, and mutual respect. I select subcontractors based on their qualifications, experience, and reputation. Detailed contracts outline scope of work, payment terms, and timelines. Regular communication ensures smooth coordination of work, resolving issues promptly and preventing delays. With suppliers, I maintain relationships with multiple vendors to ensure competitive pricing and timely material delivery. I meticulously track deliveries and ensure materials meet project specifications. Successful project completion relies heavily on these collaborative relationships, ensuring high-quality workmanship delivered efficiently and on time.

Q 22. How do you ensure the longevity and efficiency of installed drainage systems?

Ensuring the longevity and efficiency of a drainage system relies on a multifaceted approach encompassing careful design, quality materials, and diligent maintenance. Think of it like building a sturdy house – you need a solid foundation (proper design and installation) and regular upkeep (maintenance) to prevent issues.

- Proper Design and Installation: This includes using appropriate pipe materials (PVC, HDPE, clay) for the specific soil conditions and anticipated flow rates. Incorrect sizing or unsuitable materials can lead to blockages, leaks, and premature failure. For example, using undersized pipes in high-traffic areas is a recipe for disaster.

- Regular Inspection and Cleaning: Scheduling routine inspections – ideally annually – allows for the early detection of problems like root intrusion, blockages, or pipe deterioration. This proactive approach is far cheaper than emergency repairs. Imagine regularly checking your home’s plumbing to avoid a major leak.

- Material Selection: Opting for high-quality, durable materials is crucial. While the initial cost might be higher, the long-term savings in repairs and replacements significantly outweigh it. Think of it like investing in high-quality tools that last longer than cheap alternatives.

- Proper Slope and Grading: Ensuring the drainage system is installed with the correct slope and gradient is essential for efficient water flow. Poor grading leads to stagnant water, which can cause blockages and damage.

- Effective Protection from External Factors: Protecting the pipes from damage from tree roots, heavy machinery, or extreme weather conditions is vital. This might involve using root barriers or protective casings.

Q 23. Describe your familiarity with different types of drainage pumps and their applications.

My experience encompasses a wide range of drainage pumps, each with its own strengths and applications. Choosing the right pump is crucial for effective drainage.

- Submersible Pumps: These pumps are fully submerged in the water being pumped and are ideal for sump pits, basements, and other areas with standing water. They’re relatively low-maintenance and effective for handling large volumes of water.

- Self-Priming Pumps: These pumps can draw water from a dry well and are suitable for applications where the water level fluctuates or is not always submerged. They are often used in drainage systems for shallow depths.

- Centrifugal Pumps: These pumps use centrifugal force to move water and are frequently used in larger drainage systems or wastewater treatment plants. They can handle high flow rates but often require a priming system.

- Sewage Pumps: Specifically designed to handle wastewater containing solids, these pumps are crucial for sewage treatment and lift stations. They are robust and built to withstand abrasive materials.

The selection of the pump depends on factors such as flow rate, head pressure (the vertical distance the water needs to be lifted), the type of fluid being pumped, and the overall system design. For instance, a sump pump in a basement would require a submersible pump, whereas a lift station may require a more powerful centrifugal pump.

Q 24. What is your experience with the maintenance of drainage pumps?

Maintenance of drainage pumps is critical for ensuring their longevity and efficient operation. Neglecting this can lead to costly breakdowns and potential flooding.

- Regular Inspections: Visual inspections should be conducted regularly to check for leaks, corrosion, or damage to the pump housing and motor. Listen for unusual noises; these could signal a problem.

- Oil Changes (for oil-lubricated pumps): Changing the oil according to the manufacturer’s recommendations is essential for keeping the pump lubricated and preventing wear. Failing to do this will shorten the life of the pump significantly.

- Impeller Checks: Inspecting the impeller for wear and tear is important. A worn impeller reduces the pump’s efficiency and can lead to blockages.

- Cleaning: Regularly cleaning the pump, particularly the suction strainer, prevents debris from clogging the system and affecting the pump’s performance. This is analogous to cleaning a filter in a home air conditioning unit.

- Testing: Periodically testing the pump’s performance, checking its flow rate and pressure, ensures it’s operating within the specified parameters.

I’ve had situations where neglecting regular oil changes led to a catastrophic failure of a submersible sewage pump, causing a significant backup of wastewater. This highlights the importance of proactive maintenance.

Q 25. How do you conduct a thorough drainage system inspection?

A thorough drainage system inspection is a systematic process that starts with a visual assessment and progresses to more advanced techniques where needed. Think of it as a detective investigating a crime scene, looking for clues to the problem.

- Visual Inspection: This involves checking for obvious signs of problems such as cracks in the pipes, pooling water, signs of root intrusion, or excessive debris.

- Flow Assessment: Observing the flow of water through the system helps identify areas of reduced flow or blockages. I often use dye tests to pinpoint infiltration or leakage points.

- Manhole Inspections: Inspecting manholes allows for a closer look at the condition of the pipes, connections, and the presence of blockages. I document everything using photographs and detailed notes.

- CCTV Inspection: For more in-depth assessments, CCTV camera inspection is invaluable in detecting issues that are not visible from the surface. This allows for detailed internal inspection of pipe condition.

- Flow Metering: For larger systems, measuring flow rates at various points helps to identify bottlenecks and assess the overall efficiency of the drainage network.

A recent inspection revealed a significant root intrusion problem that wasn’t apparent during a surface-level inspection. Only through CCTV inspection did we identify the extent of the damage and plan appropriate remediation.

Q 26. What are the different methods for cleaning and maintaining drainage pipes?

Cleaning and maintaining drainage pipes requires various techniques depending on the severity and type of blockage. The goal is to restore efficient flow without damaging the pipes.

- High-Pressure Water Jetting: This is a highly effective method for clearing blockages caused by grease, sediment, or debris. The high pressure of the water jet dislodges the material and flushes it downstream. This is like using a power washer to clean a sidewalk.

- Mechanical Cleaning: Using specialized tools such as drain augers or snaking tools is suitable for removing more stubborn blockages that are less responsive to water jetting. This is similar to using a plumbing snake to clear a clogged sink.

- Chemical Cleaning: Specific chemicals can be used to break down grease and organic matter, improving the flow. This is usually a secondary method following mechanical or water jetting methods.

- Root Cutting: For blockages caused by tree roots, specialized root cutting tools are used to remove the intruding roots. This is usually coupled with root barriers for future prevention.

I’ve found that a combination of methods often provides the best results. For example, in one instance we used high-pressure water jetting to dislodge a significant amount of sediment before using a drain auger to clear a stubborn blockage caused by a collapsed section of pipe.

Q 27. Describe your experience with using CCTV cameras for drainage pipe inspection.

CCTV cameras are indispensable for thorough drainage pipe inspections, providing a detailed visual record of the pipe’s internal condition. This is far superior to relying on guesswork.

My experience involves using various CCTV inspection equipment, including push cameras (smaller cameras for smaller pipes) and self-propelled cameras (for longer runs or difficult access). The cameras transmit real-time video to a monitor, allowing for immediate identification of problems like cracks, blockages, root intrusion, or pipe collapses. The video footage provides irrefutable evidence for repairs or replacements.

The data collected provides crucial information for planning repairs. For example, I’ve used CCTV footage to precisely locate the source of a leak or to determine the best approach for clearing a blockage without causing further damage. The digital recording also acts as a historical record.

Q 28. How do you handle customer complaints related to drainage issues?

Handling customer complaints about drainage issues requires a professional, empathetic, and solution-oriented approach. Prompt and effective communication is key.

- Active Listening: Firstly, I listen carefully to the customer’s concerns, allowing them to explain the issue in detail without interruption. This shows respect and helps me understand the full scope of the problem.

- Thorough Inspection: I then conduct a thorough inspection of the drainage system to identify the root cause of the problem, ensuring accuracy in diagnosis.

- Clear and Honest Communication: I communicate my findings clearly and honestly to the customer, explaining the cause of the problem and the proposed solutions in a way that they can understand.

- Realistic Solutions: I propose realistic and cost-effective solutions, taking into consideration the customer’s budget and expectations. If necessary, I provide multiple options.

- Follow-up: After completing the repairs, I follow up with the customer to ensure they’re satisfied with the outcome and that the problem is resolved. This builds trust and reinforces a commitment to customer service.

One instance involved a customer who was experiencing chronic basement flooding. By carefully listening to their description of the problem, I discovered an issue with their sump pump that was overlooked by previous contractors. This highlighted the importance of understanding the bigger picture.

Key Topics to Learn for Drainage Installation and Maintenance Interview

- Drainage System Design: Understanding different types of drainage systems (e.g., gravity, pumped), their components, and design considerations based on site conditions and regulations.

- Pipe Installation Techniques: Mastering various pipe laying methods, including trenchless techniques, and ensuring proper slope and alignment for efficient drainage.

- Material Selection and Properties: Knowledge of different pipe materials (PVC, HDPE, clay), their strengths, weaknesses, and appropriate applications in various scenarios.

- Joint and Connection Methods: Proficiency in various jointing techniques, ensuring watertight seals and preventing leaks. Understanding the implications of different joint types on system performance.

- Troubleshooting and Repair: Diagnosing common drainage problems (e.g., blockages, leaks, collapses), identifying their root causes, and implementing effective repair strategies.

- Maintenance and Inspection: Understanding routine maintenance procedures, including cleaning, inspection, and preventative measures to extend the lifespan of drainage systems. Knowledge of CCTV inspection techniques and interpretation of results.

- Health and Safety Regulations: Familiarity with relevant health and safety regulations and best practices for working in confined spaces and with potentially hazardous materials.

- Sustainable Drainage Systems (SuDS): Understanding the principles of SuDS and their role in managing stormwater runoff and minimizing environmental impact.

- Working with Plans and Specifications: Ability to interpret engineering drawings, specifications, and other technical documents related to drainage installation and maintenance projects.

- Problem-solving and Decision-Making: Demonstrating the ability to analyze complex situations, identify potential problems, and develop effective solutions under pressure.

Next Steps

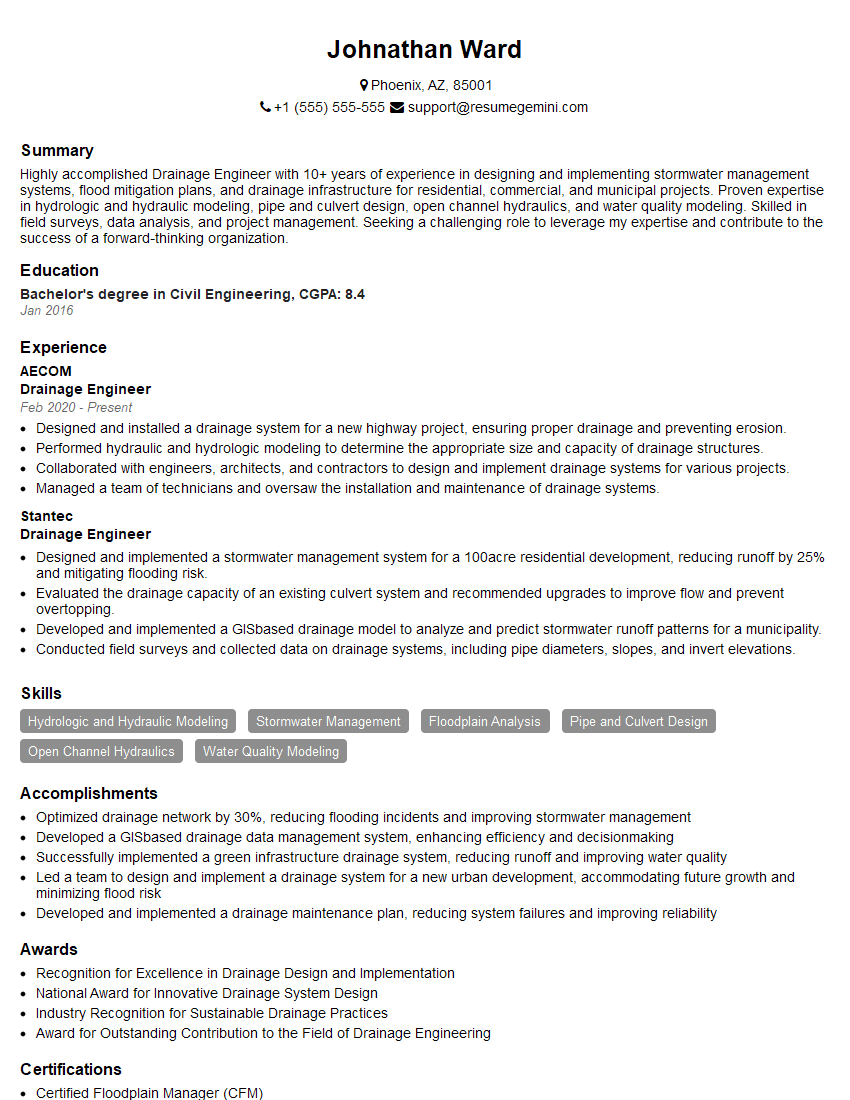

Mastering Drainage Installation and Maintenance opens doors to a rewarding career with excellent growth potential. From entry-level positions to specialized roles, your expertise in this critical infrastructure area is highly sought after. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that gets noticed by recruiters. We provide examples of resumes tailored specifically to Drainage Installation and Maintenance to help guide you. Invest time in crafting a compelling resume – it’s your first impression and a crucial step towards your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good