Preparation is the key to success in any interview. In this post, we’ll explore crucial Ability to Achieve High Production Targets and Maintain Quality Standards interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Ability to Achieve High Production Targets and Maintain Quality Standards Interview

Q 1. Describe your experience in setting and achieving ambitious production targets.

Setting and achieving ambitious production targets requires a strategic approach that blends meticulous planning with adaptable execution. It’s not just about setting a high number; it’s about understanding the feasibility and implementing processes to ensure success.

In my previous role at Acme Manufacturing, we aimed to increase production by 25% within a six-month timeframe. This wasn’t simply a top-down directive; we engaged in a thorough analysis of current capacity, identifying potential bottlenecks, and establishing clear, measurable, achievable, relevant, and time-bound (SMART) goals. We broke down the overall target into smaller, manageable milestones, allowing for regular progress checks and adjustments as needed. This iterative process, coupled with regular team meetings and open communication, allowed us to surpass the target by 5%, exceeding expectations.

Another example involved streamlining the assembly line. By implementing a new workflow leveraging lean manufacturing principles, we reduced processing time per unit, which directly translated to a significant increase in overall output without compromising quality.

Q 2. How do you balance the need for high production with maintaining quality standards?

Balancing high production with maintaining quality is a delicate act, akin to walking a tightrope. It requires a commitment to both efficiency and precision. The key is not to view them as opposing forces, but as complementary aspects of a successful operation.

My approach involves proactive quality control measures integrated throughout the production process, not just at the end. This includes rigorous quality checks at each stage of production, employee training emphasizing quality over speed, and regular equipment maintenance to prevent defects. Utilizing statistical process control (SPC) helps us to monitor production processes and identify areas for improvement in real-time, thereby preventing quality issues from escalating.

For instance, at Beta Technologies, we implemented a system of ‘quality circles’ where team members collectively brainstorm solutions to quality issues, fostering a shared responsibility for maintaining standards. This participatory approach not only boosted quality but also improved team morale and efficiency.

Q 3. Explain a time you identified a bottleneck in a production process and how you resolved it.

During my time at Gamma Industries, we identified a significant bottleneck in our packaging department. The existing packaging machine was outdated and prone to frequent breakdowns, creating a backlog of finished products. This directly impacted our ability to meet production targets.

To resolve this, I initiated a three-step process: First, we analyzed the problem thoroughly, documenting downtime, repair costs, and production losses. Second, we evaluated several solutions, including repairing the existing machine, leasing a temporary machine, or investing in a new, more efficient model. Finally, after a cost-benefit analysis, we opted to invest in a new automated packaging machine. The result was a 30% increase in packaging efficiency, eliminating the bottleneck and significantly boosting overall production.

Q 4. What metrics do you use to measure production efficiency and quality?

Measuring production efficiency and quality requires a multi-faceted approach that goes beyond simply looking at the number of units produced. I utilize a range of key performance indicators (KPIs) to obtain a comprehensive view.

- Production Efficiency: Units produced per hour, Overall Equipment Effectiveness (OEE), lead time, cycle time, and manufacturing cost per unit.

- Quality: Defect rate, customer returns, rework percentage, yield rate, and adherence to quality standards (e.g., ISO 9001).

By tracking these metrics regularly and analyzing trends, we can identify areas for improvement and proactively address potential issues before they impact production or quality significantly. Data visualization tools are crucial in this process, allowing for clear and concise representation of the data.

Q 5. How do you prioritize tasks to ensure both high production and quality are met?

Prioritizing tasks to achieve both high production and quality necessitates a structured approach. I typically employ a combination of techniques, including the Eisenhower Matrix (urgent/important), and lean principles like Kanban to manage workflow.

For example, tasks that directly impact quality (e.g., equipment calibration, staff training) are always prioritized, even if it means slightly delaying other tasks. We utilize a Kanban board to visually track workflow, identify bottlenecks, and ensure tasks are completed in a timely manner while adhering to quality standards. This visual representation makes it easier to balance high-volume production and quality control measures, ensuring neither is compromised.

Q 6. Describe your experience with implementing quality control measures.

Implementing effective quality control measures involves a systematic approach covering various aspects of the production process. This includes establishing clear quality standards, documenting processes, regularly auditing procedures, and training employees on quality control best practices.

At Delta Corporation, I was instrumental in implementing a Six Sigma methodology, significantly reducing defects and improving overall product quality. This involved training employees in statistical process control (SPC) and implementing robust data collection and analysis techniques to pinpoint and resolve root causes of defects. Regular internal audits and external certifications further reinforce our commitment to quality. We also utilize Total Quality Management (TQM) principles to ensure a culture of quality permeates all levels of the organization.

Q 7. How do you handle situations where production targets conflict with quality standards?

Conflicts between production targets and quality standards are inevitable, but they should never be resolved by compromising quality. Instead, the focus should be on finding creative solutions that allow for both to be met.

In such situations, I advocate for a collaborative approach, involving all stakeholders to find a common ground. This may involve re-evaluating the production target, identifying areas where efficiencies can be gained without sacrificing quality, or exploring innovative solutions to streamline the production process. Open communication and transparent decision-making are crucial to ensure a fair and effective resolution that prioritizes long-term success over short-term gains. For instance, instead of rushing production to meet a deadline and sacrificing quality, we might explore options like overtime or adjusting the project scope to align with realistic production capabilities while maintaining quality standards.

Q 8. How do you motivate your team to achieve high production targets without compromising quality?

Motivating a team to achieve high production targets without sacrificing quality requires a multifaceted approach that focuses on empowerment, clear communication, and a shared understanding of goals. It’s not about pushing people harder; it’s about creating an environment where everyone feels invested in success.

Clear Goals and Expectations: Start by setting SMART (Specific, Measurable, Achievable, Relevant, Time-bound) goals. Everyone needs to understand not only the production target but also the quality standards. Use visual management tools like dashboards to track progress transparently.

Empowerment and Ownership: Instead of dictating tasks, involve the team in setting processes and finding solutions. Give them the autonomy to make decisions within defined parameters. This fosters a sense of ownership and responsibility.

Recognition and Reward: Celebrate successes, both large and small. Acknowledge individual and team contributions. Reward systems don’t have to be monetary; public praise, extra time off, or opportunities for professional development can be highly effective.

Continuous Feedback and Training: Regular feedback sessions allow for addressing concerns, identifying roadblocks, and providing support. Investing in training programs ensures the team has the skills and knowledge necessary to meet both quality and quantity targets. This also boosts morale and shows a commitment to their growth.

Open Communication: Create a safe space for team members to voice concerns or suggest improvements without fear of retribution. Active listening and addressing feedback are critical.

For example, in my previous role, we implemented a suggestion box system combined with regular team meetings. This led to a 15% increase in productivity while maintaining our defect rate below 1%.

Q 9. What is your experience with lean manufacturing principles?

Lean manufacturing principles are fundamental to achieving high production with superior quality. My experience encompasses implementing several lean tools and techniques to streamline processes and eliminate waste.

Value Stream Mapping: I’ve extensively used value stream mapping to visualize the entire production process, identify bottlenecks, and eliminate non-value-added activities (muda). This leads to improved flow and reduced lead times.

5S Methodology: Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) in various work areas has significantly improved workplace organization and efficiency, reducing search times and errors.

Kaizen Events: I’ve participated in and led several Kaizen events, which are focused improvement projects involving cross-functional teams. These events have resulted in substantial improvements in process efficiency and quality.

Kanban: Implementing Kanban systems for managing workflow has improved visibility, reduced work-in-progress, and helped us better respond to changing demands.

In a previous project, implementing lean principles in our assembly line reduced cycle time by 20% and improved overall equipment effectiveness (OEE) by 15%.

Q 10. Describe your experience with Six Sigma or other quality improvement methodologies.

I have extensive experience with Six Sigma methodologies, specifically DMAIC (Define, Measure, Analyze, Improve, Control). This structured approach to problem-solving has been invaluable in identifying and eliminating defects, reducing variation, and improving overall process capability.

DMAIC Methodology: I have led several DMAIC projects to address critical quality issues. This involves systematically defining the problem, measuring key metrics, analyzing root causes using statistical tools, implementing solutions, and controlling the improved process to prevent regression.

Control Charts: I’m proficient in using control charts (e.g., X-bar and R charts) to monitor process stability and identify potential shifts in performance.

Statistical Process Control (SPC): Applying SPC techniques ensures that processes remain within acceptable limits of variation, minimizing defects and improving consistency.

For instance, in one project, using DMAIC to address a recurring defect in a critical component reduced the defect rate from 5% to less than 0.5%, resulting in significant cost savings and improved customer satisfaction.

Q 11. How do you identify and address quality issues in a timely manner?

Addressing quality issues requires a proactive and systematic approach. It’s not enough to simply react to problems; we need to prevent them from happening in the first place.

Real-time Monitoring: Employing real-time monitoring systems, like automated quality checks and dashboards, allows for immediate identification of deviations from standards.

Root Cause Analysis: When issues arise, I utilize tools like the 5 Whys or fishbone diagrams to delve into the root cause, not just treating the symptoms. This ensures lasting solutions.

Corrective Actions: Once the root cause is identified, we implement corrective actions, which may involve process improvements, equipment adjustments, or employee retraining.

Preventative Measures: After addressing the issue, we implement preventative measures to avoid recurrence. This might involve updating standard operating procedures, improving training, or investing in new equipment.

Documentation and Tracking: Meticulous record-keeping of quality issues, corrective actions, and preventative measures is crucial for continuous improvement and accountability.

For example, we recently implemented a new automated inspection system that immediately flags defects, allowing us to address them before they reach the customer. This reduced our customer returns by 20%.

Q 12. What is your approach to continuous improvement in production processes?

Continuous improvement is the cornerstone of high-performance manufacturing. My approach relies on a data-driven methodology coupled with team engagement.

Data Analysis: Regularly analyzing production data, defect rates, and customer feedback provides insights into areas needing improvement. Key Performance Indicators (KPIs) are crucial here.

Process Optimization: Identifying bottlenecks and inefficiencies through techniques like value stream mapping and process mapping allows for targeted improvements.

Team Involvement: Encouraging employee suggestions and participation in improvement initiatives is vital. They often possess valuable insights into areas for enhancement.

Benchmarking: Comparing our processes and performance against industry best practices allows us to identify opportunities for improvement.

Regular Reviews: Conducting periodic reviews of our improvement efforts helps to assess progress, identify roadblocks, and adjust strategies as needed.

We regularly hold Kaizen events to focus on specific areas for improvement. This collaborative approach fosters a culture of continuous learning and improvement within the team. For example, a recent Kaizen event streamlined our packaging process, reducing waste by 10%.

Q 13. How do you handle pressure and deadlines when striving for high production?

Handling pressure and deadlines while maintaining quality requires a structured approach focusing on prioritization, resource allocation, and effective communication.

Prioritization: Clearly defining priorities and focusing on the most critical tasks first is essential. This involves understanding the impact of each task on both production targets and quality.

Resource Allocation: Effectively allocating resources (personnel, equipment, materials) based on priorities ensures that critical tasks receive the necessary attention.

Effective Communication: Maintaining open communication with the team, management, and stakeholders keeps everyone informed of progress, challenges, and any necessary adjustments to the plan.

Contingency Planning: Developing contingency plans for potential setbacks helps to mitigate risks and ensure that delays are minimized.

Stress Management: Promoting a healthy work-life balance and providing access to stress management resources (e.g., employee assistance programs) are critical for team well-being and sustained performance.

In one instance, facing a tight deadline for a large order, we prioritized tasks, reallocated resources, and worked extended hours while still maintaining our quality standards. We successfully met the deadline without compromising quality, thanks to effective communication and team collaboration.

Q 14. Describe a time you had to make a difficult decision to improve quality even if it impacted production targets.

In a past project, we were facing pressure to meet a very aggressive production target. However, a new batch of raw materials exhibited inconsistencies that could compromise the final product’s quality. The decision to halt production and thoroughly investigate the issue, even if it impacted our production schedule, was difficult. It meant potentially missing a critical deadline and facing potential penalties.

However, I believed that prioritizing quality over short-term production goals was crucial for long-term success. We investigated the root cause of the material inconsistency, implemented corrective actions with our supplier, and then resumed production with the correct materials. While we experienced a temporary delay, this proactive approach prevented a far more significant issue: a large batch of defective products reaching our customers. This ultimately preserved our reputation, maintained customer trust, and demonstrated our commitment to quality. The long-term benefits far outweighed the short-term setback.

Q 15. How do you measure the effectiveness of your quality control measures?

Measuring the effectiveness of quality control hinges on establishing clear Key Performance Indicators (KPIs) and consistently monitoring them. We don’t just look at the final product; we track metrics throughout the entire production process.

Defect Rate: This is the percentage of defective units produced. A lower defect rate indicates better quality control. For example, if we aim for a defect rate below 1%, consistent monitoring allows us to identify trends and take corrective action if it rises above that threshold.

Yield Rate: This represents the percentage of good units produced compared to the total units produced. A high yield rate signifies efficient production and effective quality control. Let’s say our target yield rate is 98%. Tracking this allows us to quickly spot bottlenecks or issues impacting production efficiency and quality.

Customer Returns: Analyzing customer returns helps identify recurring defects that might not be immediately apparent during internal quality checks. For instance, a spike in returns related to a specific component might indicate a problem in that area of the production line.

Process Capability: We use statistical process control (SPC) charts to assess the consistency of our processes and identify variations that could lead to defects. This helps in proactively preventing problems before they escalate.

By combining these metrics and analyzing trends, we can pinpoint areas for improvement and assess the overall effectiveness of our quality control measures. Regular reviews of these KPIs are crucial for continuous improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure your team understands and adheres to quality standards?

Ensuring team understanding and adherence to quality standards requires a multi-faceted approach that emphasizes training, communication, and accountability.

Comprehensive Training: We provide initial and ongoing training on quality standards, procedures, and the use of quality control tools. This includes hands-on training and simulations to reinforce learning.

Clear Communication: We utilize various communication channels, including regular meetings, visual aids (like flowcharts and checklists), and readily available documentation to ensure everyone is on the same page. We also encourage open communication, creating a safe space for team members to raise concerns or suggest improvements.

Visual Management: Visual aids, such as scoreboards displaying key quality metrics, can foster a culture of accountability and transparency. This makes it clear to everyone how we’re performing against targets.

Regular Audits and Feedback: We conduct regular internal audits to assess compliance with quality standards and provide constructive feedback. This helps identify areas needing improvement and reinforce good practices.

Empowerment and Ownership: We empower our team members to take ownership of quality by giving them the authority to stop the line if they identify a potential quality issue. This fosters a proactive approach to quality control.

By implementing these strategies, we cultivate a quality-focused culture where everyone understands and embraces their role in maintaining high standards.

Q 17. Explain your experience with using technology to improve production efficiency and quality control.

Technology plays a vital role in enhancing both production efficiency and quality control. In my previous role, we implemented several technological solutions to improve our processes.

Automated Inspection Systems: We integrated automated optical inspection (AOI) systems into our production lines. These systems automatically detect defects during manufacturing, significantly improving detection rates and reducing human error.

Example: AOI systems identified a subtle variation in component placement that human inspectors consistently missed, leading to a significant reduction in defects.Data Acquisition and Analysis: We utilize sensors and data acquisition systems to collect real-time data on production parameters, such as temperature, pressure, and speed. This data is then analyzed using statistical process control (SPC) software to identify trends and potential problems before they lead to defects.

For instance, using SPC charts we identified a correlation between temperature fluctuations and increased defect rates, allowing us to adjust the process parameters and prevent further issues.MES (Manufacturing Execution System): Our MES system provides real-time visibility into the entire production process, allowing us to track progress, identify bottlenecks, and manage resources effectively. It also integrates with our quality control systems, providing a comprehensive view of production performance and quality.

These technologies not only improve efficiency but also help us proactively prevent defects and continuously improve our processes. The data-driven approach allows for informed decision-making and optimization of resources.

Q 18. How do you prevent defects from reaching the customer?

Preventing defects from reaching the customer requires a robust multi-layered approach that encompasses prevention, detection, and correction.

Proactive Prevention: This involves rigorously implementing preventative measures throughout the production process. This includes robust training, preventative maintenance on equipment, and thorough inspections of raw materials.

Multiple Inspection Points: Implementing quality checks at various stages of production, not just at the end, ensures that defects are caught early, minimizing waste and rework.

Statistical Process Control (SPC): Using SPC charts allows us to monitor processes for variations and identify potential problems before they result in defects. This proactive approach allows for timely corrections and prevents mass production of faulty goods.

100% Final Inspection: In certain critical applications, a 100% final inspection is essential to guarantee zero defects. This may involve manual or automated inspection, depending on the complexity and nature of the product.

Corrective Actions: Implementing a robust system for identifying the root cause of defects and implementing corrective actions to prevent recurrence is essential.

By combining these strategies, we create a robust system to minimize defects and ensure customer satisfaction.

Q 19. Describe your experience with root cause analysis for production issues.

Root cause analysis (RCA) is a critical skill for identifying the underlying reasons for production issues. I’ve used various RCA techniques, including the 5 Whys and Fishbone diagrams.

Example using the 5 Whys: Let’s say we experienced a sudden increase in product rejects. We might ask:

- Why are we seeing more rejects?

- Because the welding process is producing inconsistent welds.

- Because the welding machine is not calibrated correctly.

- Because the calibration procedure wasn’t followed.

- Because the operators weren’t adequately trained on the new calibration procedure.

This reveals the root cause: insufficient operator training. Addressing this through retraining would prevent future issues. Fishbone diagrams are used similarly but allow for a broader brainstorming of potential causes, categorized into categories like machinery, materials, methods, and manpower.

After identifying the root cause, implementing corrective actions, and verifying their effectiveness is crucial. This often involves documenting the RCA process, the corrective actions taken, and the results to prevent similar issues in the future. This helps maintain a continuous improvement mindset within the production environment.

Q 20. How do you communicate production progress and quality metrics to stakeholders?

Communicating production progress and quality metrics effectively is crucial for stakeholder alignment and informed decision-making. My approach involves a combination of methods to ensure transparency and clarity.

Regular Reporting: I prepare regular reports (weekly or monthly, depending on stakeholder needs) that summarize key performance indicators (KPIs), including production volume, defect rates, yield rates, and on-time delivery. These reports are presented in a clear and concise manner, using charts and graphs to illustrate trends.

Visual Management Dashboards: Real-time dashboards displaying key metrics are accessible to all stakeholders. These provide up-to-the-minute insights into production progress and quality performance.

Meetings and Presentations: Regular meetings and presentations are held to discuss progress, address challenges, and share relevant information with stakeholders. This allows for open dialogue and collaborative problem-solving.

Customized Communication: I tailor my communication style and content to the audience. For example, technical details might be shared with production managers, while a summary of key achievements is shared with executives.

By using multiple communication channels and customizing my approach, I ensure that stakeholders are kept informed and can make informed decisions based on accurate and timely data.

Q 21. What strategies do you use to reduce production costs while maintaining quality?

Reducing production costs while maintaining quality requires a strategic approach that balances efficiency improvements with quality assurance. Here are some strategies I have successfully used:

Lean Manufacturing Principles: Implementing lean principles, such as eliminating waste, optimizing workflows, and improving process efficiency, can significantly reduce costs without compromising quality. For example, implementing 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) creates a more efficient and organized workspace.

Process Optimization: Analyzing production processes to identify bottlenecks and areas for improvement is crucial. This could involve streamlining workflows, automating repetitive tasks, or improving material handling. For example, re-engineering a process to reduce the number of steps can drastically lower costs.

Preventive Maintenance: Implementing a robust preventive maintenance program reduces downtime and unexpected repairs, ultimately saving costs and improving product quality. By minimizing equipment downtime, production efficiency increases while reducing the risk of defects.

Supplier Relationship Management: Building strong relationships with reliable suppliers can lead to cost savings through better pricing, on-time delivery, and high-quality raw materials. Negotiating favorable contracts and implementing vendor scorecards helps ensure supplier performance.

Employee Training and Empowerment: Investing in employee training improves their skills and efficiency, reducing errors and waste. When employees are empowered to identify and solve problems proactively, it leads to a more cost-effective and quality-focused production environment.

By focusing on continuous improvement and data-driven decision-making, it’s possible to simultaneously reduce costs and maintain high-quality standards.

Q 22. How do you manage and resolve conflicts between different departments regarding production targets and quality standards?

Resolving inter-departmental conflicts regarding production targets and quality hinges on effective communication, clear expectations, and a collaborative approach. I’ve found that proactively scheduling regular meetings between departments, involving representatives from each, is crucial. These meetings serve as a platform to discuss potential bottlenecks, share progress updates, and address emerging conflicts before they escalate.

For instance, in a previous role, the marketing team requested a significant increase in production volume for a new product launch, while the manufacturing team voiced concerns about maintaining quality standards at that accelerated pace. To resolve this, we collaboratively established a phased production rollout, increasing volume gradually. We also implemented rigorous quality checks at each phase, using a data-driven approach to monitor production metrics and adjust our strategy as needed. This transparent, collaborative process prevented a major conflict and ensured both high production and high-quality output.

A key element of conflict resolution is understanding the root cause. This requires active listening to all involved parties. Often, perceived conflicts stem from a lack of information or misaligned expectations. Clearly defined roles, responsibilities, and communication channels minimize such misunderstandings.

Q 23. How do you handle unexpected issues that may affect production or quality?

Handling unexpected issues requires a swift, decisive, and systematic response. My approach involves a three-step process: Identify, Assess, and Act.

- Identify: The first step is quickly identifying the nature and scope of the issue. Is it a machine malfunction, a supply chain disruption, a quality defect, or something else?

- Assess: Once identified, the issue needs thorough assessment. What’s the impact on production? What are the potential risks to quality and safety? Are there immediate safety concerns that need addressing first?

- Act: Based on the assessment, a plan of action needs to be developed and implemented. This often involves mobilizing the relevant team members, exploring alternative solutions, and communicating the situation to stakeholders. Documentation of the entire process is vital for future reference and preventing recurrence.

For example, during a major storm, we experienced a power outage that halted production. Following my three-step process, we quickly assessed the situation, prioritized safety measures (securing machinery and ensuring employee safety), and then identified a backup generator solution. While the outage caused a temporary slowdown, our proactive response minimized the overall impact on production schedules and quality.

Q 24. What is your experience with different quality management systems (e.g., ISO 9001)?

I possess extensive experience with various quality management systems, most notably ISO 9001. I’ve been involved in implementing, maintaining, and auditing this standard in several organizations. Understanding ISO 9001’s principles – customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management – is crucial for creating a robust quality management framework.

My experience includes developing and implementing quality control procedures, conducting internal audits, and participating in management reviews. I understand the importance of documentation, record-keeping, and continuous improvement in maintaining ISO 9001 compliance. I’ve witnessed firsthand how the structured approach of ISO 9001 can lead to improved efficiency, reduced errors, and increased customer satisfaction.

Beyond ISO 9001, I’m familiar with other quality management principles and methodologies, such as Six Sigma and Lean manufacturing. I believe in adopting the most suitable approach based on specific organizational needs and contexts.

Q 25. Describe your experience with process optimization techniques.

Process optimization is at the heart of maximizing production efficiency and maintaining quality. I’ve utilized several techniques, including Lean manufacturing and Six Sigma, to streamline processes and eliminate waste. Lean focuses on eliminating non-value-added activities, improving workflow, and reducing inventory. Six Sigma employs statistical methods to identify and eliminate defects, improving process consistency and quality.

In a previous role, we applied Lean principles to our assembly line. By analyzing the workflow, we identified several bottlenecks and redundant steps. We rearranged the workstation layout, implemented a ‘5S’ system (sort, set in order, shine, standardize, sustain) for workplace organization and implemented Kaizen events – continuous improvement workshops – to optimize each step. This resulted in a 15% increase in production efficiency with no reduction in quality.

Similarly, using Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, Control) methodology, we tackled a specific quality issue related to product defects. By systematically analyzing the process, we identified the root causes of the defects and implemented targeted improvements, leading to a significant reduction in the defect rate.

Q 26. How do you ensure compliance with safety regulations during high-production periods?

Maintaining compliance with safety regulations during high-production periods is non-negotiable. My approach involves a proactive, multi-layered strategy focusing on training, monitoring, and continuous improvement.

- Comprehensive Training: Regular safety training is essential for all employees, emphasizing safe work practices specific to high-production environments. This training needs to be reinforced periodically and adapted as needed.

- Rigorous Monitoring: Implementing a robust system for monitoring workplace safety is crucial. This can include regular safety inspections, use of safety checklists, and observation of employee work practices. Data from these inspections can inform any necessary improvements.

- Incident Reporting and Investigation: Establishing a clear process for reporting and investigating safety incidents is vital. This helps identify root causes, prevent recurrence, and continually improve safety procedures.

- Emergency Preparedness: Developing and regularly practicing emergency response plans is essential to ensure preparedness for unexpected events.

For example, during a period of peak production, we implemented a ‘buddy system’ where each employee had a partner to monitor their safety practices. We also increased the frequency of safety inspections and emphasized the importance of reporting any potential hazards, immediately. This proactive approach ensured we maintained a safe working environment despite the increased pressure.

Q 27. How do you utilize data analysis to improve production and quality?

Data analysis is fundamental to improving production and quality. I leverage various analytical tools and techniques to gain insights from production data, quality metrics, and other relevant sources. This data-driven approach helps to identify trends, predict potential problems, and make informed decisions.

I frequently use tools like statistical process control (SPC) charts to monitor production processes and identify variations that could lead to quality issues. I also utilize data visualization techniques to present complex data in a clear and understandable manner. This allows for effective communication of insights to relevant stakeholders and facilitates informed decision-making.

For example, by analyzing historical production data, we identified a correlation between machine downtime and specific environmental factors. This insight led us to implement changes in the production environment, reducing downtime and improving overall efficiency. Similarly, analyzing quality control data allowed us to identify the root causes of certain defects, leading to targeted process improvements and a reduction in the defect rate.

Q 28. Describe a time you had to delegate tasks effectively to achieve high production while maintaining quality.

In a previous role, we faced a critical deadline for a large order. To meet the deadline while maintaining quality, effective delegation was essential. I began by clearly defining the tasks, responsibilities, and expected timelines for each team member, based on their individual skills and experience. I also held a team meeting to communicate the overall goals, expectations and the individual roles and responsibilities. This was critical in getting buy-in from the team.

I ensured each team member had the necessary resources and support to complete their tasks. This included providing access to necessary tools, materials, and training if needed. Regular check-ins were crucial; I provided support and addressed challenges promptly, adjusting tasks where necessary. Open communication was key, preventing misunderstandings and maintaining morale. This approach not only met the production deadline, but we exceeded quality expectations.

Delegation isn’t just about assigning tasks; it’s about empowering individuals, fostering teamwork, and creating a shared sense of ownership towards achieving the collective goal. This experience highlighted that successful delegation requires careful planning, clear communication, and consistent monitoring and support.

Key Topics to Learn for Ability to Achieve High Production Targets and Maintain Quality Standards Interview

- Understanding Production Goals: Defining and interpreting production targets, aligning personal goals with organizational objectives, and identifying key performance indicators (KPIs).

- Time Management & Prioritization: Effective scheduling, task delegation (if applicable), prioritizing tasks based on urgency and importance, and utilizing productivity tools.

- Quality Control Processes: Implementing and adhering to quality control measures, identifying and addressing potential quality issues proactively, and understanding relevant quality standards (e.g., ISO).

- Process Optimization: Identifying bottlenecks in workflows, suggesting and implementing improvements to increase efficiency and reduce waste, and using data analysis to inform process changes.

- Problem-Solving & Adaptability: Responding effectively to unexpected challenges, adapting to changing priorities and deadlines, and employing structured problem-solving methodologies.

- Teamwork & Collaboration (if applicable): Working effectively within a team environment, contributing to a positive team dynamic, and coordinating efforts to achieve shared goals.

- Data Analysis & Reporting: Tracking progress against targets, interpreting data to identify trends and areas for improvement, and presenting findings clearly and concisely.

- Continuous Improvement Mindset: Demonstrating a commitment to ongoing learning and development, proactively seeking opportunities for improvement, and sharing best practices with colleagues.

Next Steps

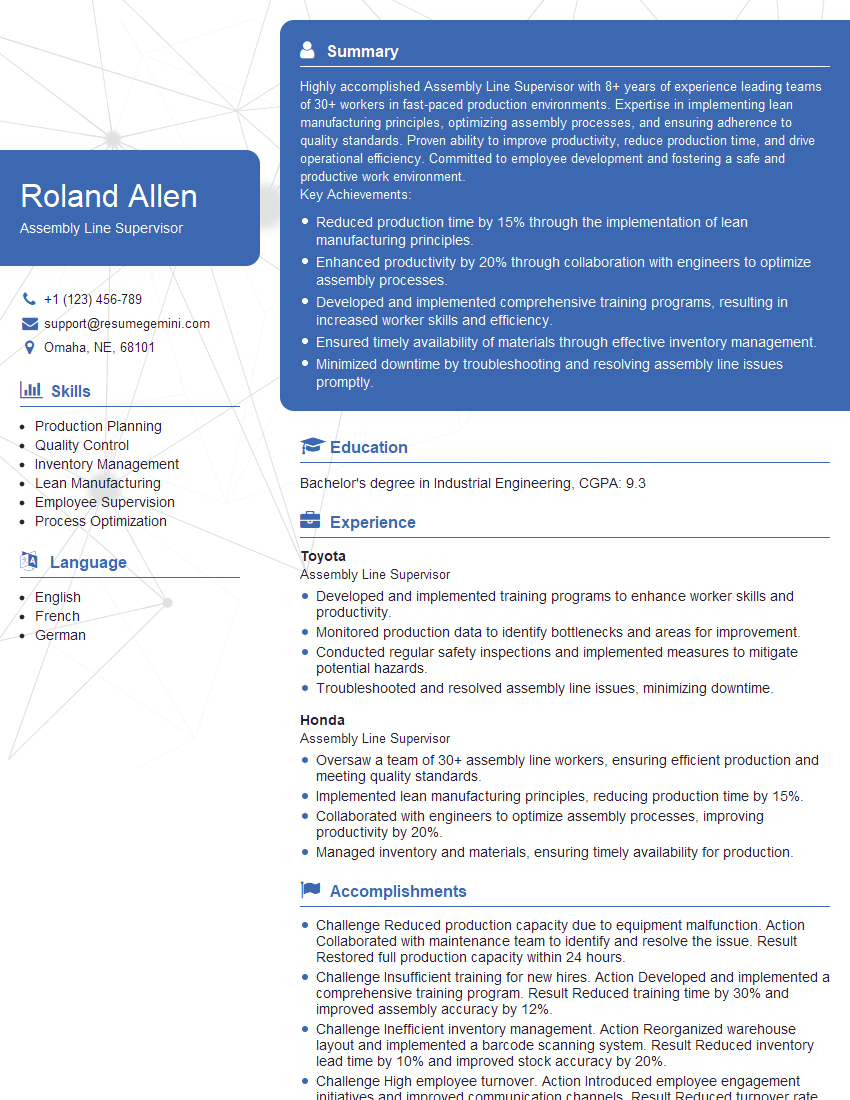

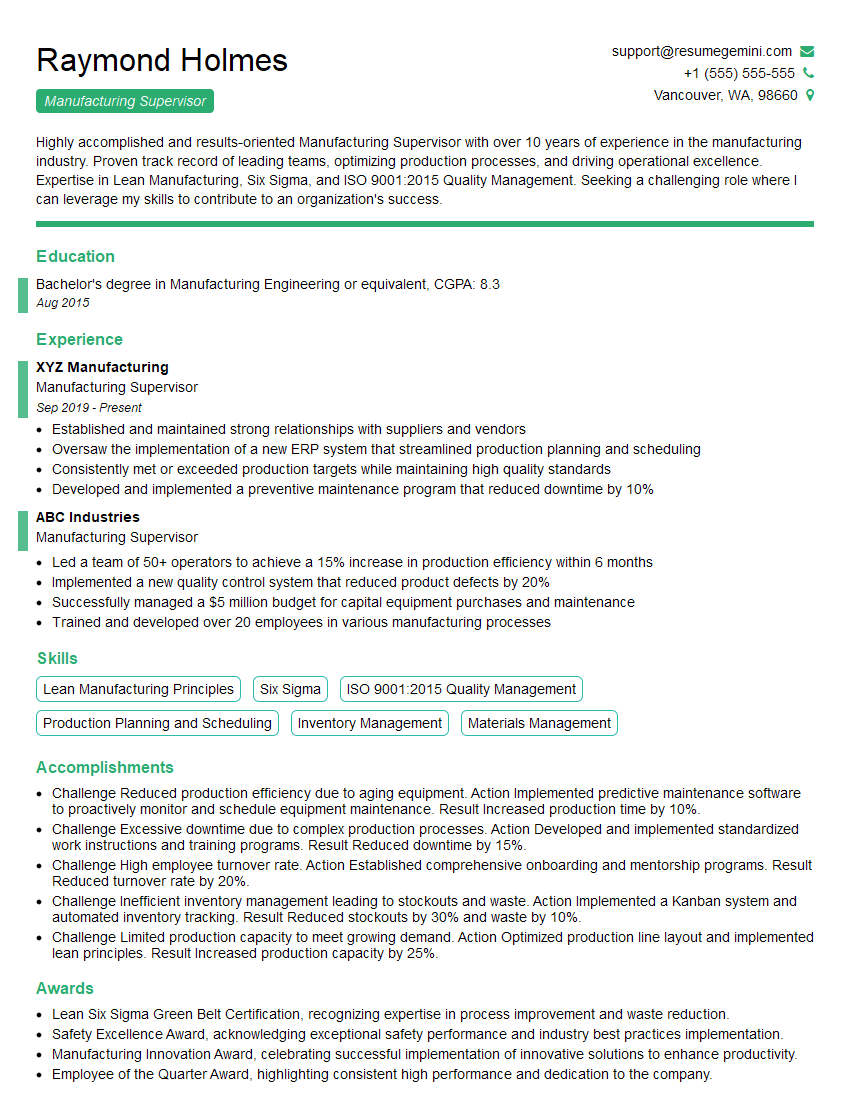

Mastering the ability to achieve high production targets while maintaining quality standards is crucial for career advancement. It demonstrates your efficiency, reliability, and commitment to excellence – qualities highly valued by employers. To significantly boost your job prospects, it’s vital to present these skills effectively on your resume. Create an ATS-friendly resume that highlights your accomplishments and quantifies your contributions. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your abilities. Examples of resumes tailored to highlight “Ability to Achieve High Production Targets and Maintain Quality Standards” are available, providing you with valuable templates and inspiration.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good