Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Proficient in Sewing Techniques for Different Buttonhole Styles interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Proficient in Sewing Techniques for Different Buttonhole Styles Interview

Q 1. Describe the different types of buttonholes you are proficient in creating.

I’m proficient in creating a variety of buttonholes, each suited to different fabrics and garment styles. My expertise encompasses:

- Standard Buttonholes: These are the most common, usually created with a straight stitch and a reinforcing bar tack at each end. They are versatile and work well on most fabrics.

- Keyhole Buttonholes: These feature a small slit at one end that allows for a wider opening, ideal for thicker fabrics or where a wider button is required.

- Bound Buttonholes: A decorative option where a strip of fabric is folded and stitched around the buttonhole opening, providing a neat, professional finish. Perfect for adding a touch of elegance to garments.

- Worked Buttonholes: Created entirely by hand, these buttonholes offer maximum control and allow for intricate decorative stitching. This is a great technique for showcasing couture-level skill.

- Satin Buttonholes: These buttonholes are characterized by a continuous, decorative stitch, creating a sleek, polished look, often used for finer fabrics.

My experience allows me to select the optimal buttonhole type based on the project requirements, ensuring both functionality and aesthetic appeal.

Q 2. Explain the process of creating a keyhole buttonhole using a sewing machine.

Creating a keyhole buttonhole on a sewing machine involves several steps. First, I’d mark the buttonhole’s position precisely on the fabric, ensuring it’s perfectly aligned.

Next, I would utilize my sewing machine’s built-in buttonhole stitch function. Most machines offer automatic buttonhole options – I’d select this and follow the machine’s instructions (adjusting width and length according to button size). The machine typically creates the buttonhole in one continuous stitch.

Once the machine completes the stitch, I’d carefully cut the slit between the two rows of stitching, stopping just short of the stitching itself to prevent fraying. If the machine doesn’t have an automatic cutting feature, you’d need a sharp, fine-bladed seam ripper for precise cutting.

Finally, I would reinforce the slit ends with small, careful hand stitches (or by using my machine’s reinforcing tacks) to prevent any further fraying. The overall finish should be smooth and professional. It is important to carefully choose the correct stitch length and tension for the fabric used.

Q 3. How do you adjust your sewing machine settings for different fabric weights when creating buttonholes?

Adjusting sewing machine settings for different fabric weights is crucial for creating perfect buttonholes. Heavier fabrics require different needle types, stitch length settings, and pressure foot configurations compared to lightweight fabrics.

- Heavier Fabrics (e.g., denim, canvas): I would use a stronger needle, such as a denim needle, and increase the stitch length slightly. Also, I might adjust the pressure foot pressure to ensure that the fabric feeds evenly and doesn’t bunch.

- Lightweight Fabrics (e.g., silk, chiffon): A finer needle, such as a microtex needle, is essential to prevent snags and damage. The stitch length should be reduced and a lighter pressure foot pressure setting is generally recommended. I would also select a buttonhole stitch that’s delicate enough for the material.

Experimentation and careful observation are key to finding the optimal settings for each fabric type. I often test settings on a scrap piece of the same fabric before proceeding with the actual garment.

Q 4. What are the common problems encountered when creating buttonholes, and how do you troubleshoot them?

Common buttonhole problems include uneven stitching, broken needles, skipped stitches, and the buttonhole being too tight or too loose. I troubleshoot these issues by:

- Uneven Stitching: Check the tension on the machine, ensuring it’s balanced. Inspect the bobbin case for any lint or damage. Incorrectly aligned presser foot could also be the cause.

- Broken Needles: Using an incorrect needle type for the fabric is a common cause; I make sure to use the right needle for the specific fabric weight and type.

- Skipped Stitches: Check the bobbin for winding issues or lint build-up. I’d also verify that the needle is properly inserted and in good condition.

- Buttonhole Too Tight/Loose: Adjust the stitch length accordingly. If the machine has width settings, that can be altered too. Re-evaluating the tension is important here.

If the problem persists, I’ll always consult the sewing machine manual for specific troubleshooting steps, or seek assistance from an experienced sewing machine technician.

Q 5. Compare and contrast the advantages and disadvantages of using different buttonhole techniques.

Each buttonhole method offers unique advantages and disadvantages:

- Machine-made buttonholes: Advantages include speed and consistency. Disadvantages can be a lack of customization and difficulty with very thick or delicate fabrics.

- Hand-worked buttonholes: Advantages are unparalleled control over size, shape, and design. Disadvantages are slower speed and requires significant skill.

- Bound buttonholes: Advantages include durability and a polished finish. Disadvantages are more time-consuming than machine-made buttonholes and may not be suitable for all fabrics.

The best technique depends entirely on the project and desired outcome. For a high-volume production, machine stitching is preferred. For a bespoke garment, hand-worked buttonholes could be a superior choice.

Q 6. How do you ensure consistent buttonhole size and placement?

Consistency in buttonhole size and placement is achieved through precise marking and careful attention to detail. I use a variety of methods to achieve this:

- Precise Marking: I begin by using a pattern’s markings for buttonhole placement and sizing. I use tailor’s chalk or a fabric marker for clear, easily removable markings.

- Templates and Guides: I often use buttonhole templates to guide my cutting and stitching. I also utilize adjustable buttonhole feet which help maintain a precise size.

- Measuring and Double-Checking: Before sewing, I measure and double-check the buttonhole dimensions against the button itself to ensure a perfect fit. This is particularly important for high-quality hand-worked buttonholes.

- Practice and Experience: Consistent results come with lots of practice and a steady hand. Through years of experience I’ve developed a keen eye for precise placement and sizing.

Q 7. Explain the importance of proper tension and stitch length when making buttonholes.

Proper tension and stitch length are fundamental to creating strong, durable, and aesthetically pleasing buttonholes. The right balance prevents skipped stitches, puckering, or loose buttonholes.

- Tension: Incorrect tension leads to uneven stitching or stitches that are easily broken. Too much upper tension causes puckering, while too little can lead to skipped stitches and loose threads. The correct balance ensures clean and secure stitching.

- Stitch Length: The stitch length influences both the durability and the look of the buttonhole. Shorter stitches are more durable but can create a stiff or bulky buttonhole, particularly on lightweight fabrics. Longer stitches are gentler but may not be as strong.

I always adjust both tension and stitch length according to fabric weight, type, and buttonhole style, ensuring the most appropriate settings to achieve the best results.

Q 8. Describe your experience with hand-sewing buttonholes.

Hand-sewing buttonholes is a skill requiring precision and patience. It allows for intricate control and is particularly valuable when working with delicate fabrics or complex designs that a machine might struggle with. My experience encompasses a wide range of buttonhole styles, from the simple blanket stitch to more elaborate techniques like bound buttonholes. I’ve created hand-sewn buttonholes on everything from tailored jackets to heirloom quilts, adapting my technique to the specific fabric and desired aesthetic. For instance, on a finely woven silk shirt, I might use a very fine needle and thread, opting for an almost invisible technique, whereas on a heavier linen garment, a more robust stitch would be appropriate.

I find that the process of hand-sewing buttonholes is a meditative one, allowing me to focus on the quality of each stitch and create a truly bespoke finish. It’s a skill that enhances my appreciation for the artistry involved in garment construction.

Q 9. What types of needles and thread are best suited for creating buttonholes in various fabrics?

Needle and thread selection is crucial for successful buttonhole creation. The ideal choice depends heavily on the fabric type. For delicate fabrics like silk or chiffon, use a very fine sharp needle (size 70/10 or smaller) and a high-quality, fine thread like 60/2 cotton or silk thread. These prevent damage to the fabric and create a near-invisible buttonhole. For medium-weight fabrics such as cotton or linen, a size 80/12 needle and a stronger thread like 50/3 cotton are suitable. Heavier fabrics like denim or leather demand a heavier needle (size 100/16 or larger) and a strong thread like polyester or upholstery thread to withstand stress. It’s important to always use a needle that’s appropriate for the thread weight to avoid breaking the thread or damaging the needle.

Q 10. How do you adapt your buttonhole technique for different fabric types (e.g., knit, woven, leather)?

Adapting buttonhole techniques to different fabric types requires understanding their properties. Woven fabrics, with their distinct warp and weft threads, allow for clean, precise buttonholes. Knits, however, are more stretchy and require techniques that account for this. I might use a slightly looser stitch on a knit to accommodate stretch and prevent the buttonhole from being pulled out of shape. Leather, with its thickness and density, necessitates the use of heavier needles and threads, and techniques may involve additional reinforcement to prevent tearing. For example, I might use a reinforced stitch or add a backing fabric to reinforce the buttonhole on leather. Each fabric presents unique challenges, and the choice of needle, thread, stitch, and even the buttonhole style itself should be tailored accordingly. A bound buttonhole, for example, is incredibly durable and suits many types of fabric.

Q 11. How do you prevent skipped stitches or broken threads when creating buttonholes?

Skipped stitches and broken threads are common frustrations. To prevent them, ensure your needle is sharp and correctly threaded. Using the appropriate needle and thread size for your fabric is critical. Maintain consistent tension on the thread, avoid pulling it too tightly, and keep your stitches even and regular. Regularly inspect the needle for bends or damage. If using a machine, check the tension settings and the bobbin for proper winding. A slow, steady pace ensures quality over speed. Sometimes, the fabric itself might be the problem; pre-treating the fabric with a stabilizer can help prevent skipped stitches on particularly flimsy materials.

Q 12. How do you finish a buttonhole to prevent fraying and enhance its durability?

Finishing a buttonhole to prevent fraying and enhance durability is key. For hand-sewn buttonholes, a whip stitch or blanket stitch is effective. These stitches not only finish the raw edges neatly but also provide reinforcement. For machine-made buttonholes, reinforcing with interfacing before stitching adds significant durability. After stitching, I often use a small amount of fabric glue to secure the edges, though this step is often unnecessary when using a strong and secure stitch. Applying a thin coat of fabric sealant can also help protect against fraying and prolong the life of the buttonhole. The choice of finishing method depends on the fabric type and the desired aesthetic, but reinforcement is always key.

Q 13. Describe your experience with using different types of sewing machine feet for buttonholes.

My experience with machine buttonhole feet is extensive. Different feet are designed for various buttonhole styles and fabric thicknesses. I’m proficient in using the standard buttonhole foot, the adjustable buttonhole foot, and various specialized feet for specific tasks. The adjustable foot offers the most control, allowing precise adjustments to the buttonhole length and width. The ability to customize the settings allows for adaptation to the specifics of each project and ensures consistent results. Using the correct foot is crucial; the wrong foot can lead to uneven stitching, skipped stitches, and damaged fabric. Understanding the nuances of each foot type and its capabilities is a significant part of my sewing machine expertise.

Q 14. How do you measure and mark the placement of buttonholes accurately?

Accurate buttonhole placement is vital for a professional finish. I typically use a combination of techniques. Firstly, I assess the garment and the intended placement in relation to other design elements like pockets or seams. Then, I use tailor’s chalk or a marking pen to make accurate markings. For consistent placement, I utilize buttonhole templates or rulers designed for this purpose. Measuring from a consistent point (like a seam) allows for symmetry. Often, I’ll create a small test buttonhole on a scrap of the same fabric to check stitch density and settings before applying it to the final garment. This ensures a flawless, perfectly symmetrical, and precisely placed buttonhole every time.

Q 15. Explain the process of reinforcing a buttonhole to improve its strength.

Reinforcing a buttonhole significantly extends its lifespan, preventing tears and ensuring a secure closure. Think of it like adding extra support to a bridge – it makes the whole structure stronger. There are several key techniques:

Using a reinforcing fabric: Before stitching the buttonhole, place a small piece of fusible interfacing or a lightweight fabric like silk organza behind the area where the buttonhole will be. This adds extra strength and prevents the fabric from stretching or tearing.

Stitching techniques: Employing a dense, secure stitch like a zig-zag or a satin stitch, particularly when using a sewing machine, provides excellent reinforcement. Multiple rows of stitching are even better. Hand-stitching with a strong thread like embroidery floss can also provide exceptional reinforcement. The key is to completely cover the buttonhole’s edges.

Using a buttonhole foot: A buttonhole foot, a specialized sewing machine attachment, guides the stitching for a perfectly formed and reinforced buttonhole.

Bar tacks: At either end of the buttonhole, secure it with bar tacks—short, dense stitches that prevent fraying. These are like little anchors that stop the buttonhole from unraveling.

For example, when working with delicate fabrics like silk, using a fusible interfacing and two rows of tightly spaced zig-zag stitches is particularly effective.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some techniques for creating decorative buttonholes?

Beyond functionality, buttonholes offer a wonderful opportunity for creative expression. There are many ways to create stunning decorative buttonholes:

Embroidery: Surround the buttonhole with intricate embroidery patterns, using a variety of stitches and colors to add visual interest. This works beautifully on garments and other projects.

Beading: Attach beads to the buttonhole’s edges or use them to create a decorative border. This technique adds sparkle and texture.

Braiding: Weave a decorative braid around the edges of the buttonhole. The braid can match or contrast with the fabric for a striking effect.

Appliqué: Add small fabric shapes or decorative elements (like felt flowers) to the buttonhole area to create a three-dimensional effect.

Fancy Stitches: Use decorative machine stitches or hand stitches, such as blanket stitch, to embellish the buttonhole’s edges.

For instance, I recently enhanced a tailored jacket by stitching a delicate floral pattern around each buttonhole using a combination of satin stitch and French knots. The result was quite elegant.

Q 17. How do you repair a damaged buttonhole?

Repairing a damaged buttonhole requires patience and precision. The method depends on the extent of the damage:

Small tears or loose stitches: Carefully reinforce the area with hand stitching using matching thread, focusing on securing any loose threads and strengthening weakened areas.

Larger tears or missing sections: Carefully cut away the damaged section, ensuring a clean edge. Apply a small piece of matching fabric underneath for support and then re-stitch the buttonhole, mimicking the original shape and size. This may require a bit of fabric patching behind.

Completely destroyed buttonhole: This situation requires creating a completely new buttonhole. Consider using a buttonhole template or guide for accuracy and consistency.

It’s crucial to choose a strong thread and use appropriate stitching techniques for the fabric type. In one instance, I rescued a beloved heirloom blouse by painstakingly repairing a severely damaged buttonhole with a nearly invisible hand-stitched repair.

Q 18. What safety precautions do you take when working with sewing machines and needles?

Safety is paramount when working with sewing machines and needles. My routine includes:

Always unplug the machine before cleaning, changing needles, or making adjustments.

Use the appropriate needle for the fabric type. Using the wrong needle can lead to broken needles and injury.

Keep fingers clear of the needle and presser foot. Never reach under the needle while the machine is running.

Use a needle threader. This minimizes the risk of pricking your fingers.

Regularly inspect and replace worn needles. A blunt needle increases the risk of the needle breaking.

Keep the work area well-lit and organized. This reduces the likelihood of accidents.

If using a hand needle, always use a thimble to protect your finger

These precautions might seem obvious, but they are essential to prevent accidents and injuries.

Q 19. How do you handle a buttonhole that is too large or too small?

Addressing buttonholes that are too large or too small requires different approaches:

Too large: If the buttonhole is only slightly too large, you can try to reduce the opening by carefully hand-stitching additional layers of fabric to the edges. For larger discrepancies, it’s best to create a new buttonhole. Consider using a piece of interfacing for support to prevent stretching.

Too small: For a buttonhole that’s too small, carefully unstitch the entire buttonhole. If the fabric is undamaged, you can re-stitch the buttonhole using a wider setting on your machine or creating a larger template.

It’s important to be patient and precise in these adjustments. One time, I had to painstakingly reshape a buttonhole that was slightly too small by carefully unstitching and restitching it using a hand-sewing technique. The final result looked flawless.

Q 20. Describe your experience with using buttonhole templates or guides.

Buttonhole templates and guides are invaluable tools that improve accuracy and consistency. I’ve used both paper templates and the built-in guides on my sewing machine. Paper templates are versatile, allowing customization for different buttonhole styles and sizes. They’re particularly useful for hand-stitching. On the other hand, the machine-based guides ensure consistent buttonhole size and shape and can enhance speed in production.

In a recent project, I used a paper template to create perfectly uniform buttonholes on a custom-made shirt. The templates allowed me to have uniform buttonhole sizes and spacing, which created a very professional finish.

Q 21. Explain the importance of using a stabilizer when making buttonholes on certain fabrics.

Using a stabilizer, such as interfacing, is essential when creating buttonholes on certain fabrics, especially those that are lightweight, stretchy, or prone to fraying. The stabilizer provides a stable base for the stitching, preventing the fabric from stretching or distorting during the buttonhole creation process. Think of it as giving the fabric a strong, supportive foundation.

For example, when making buttonholes on silk or chiffon, a tear-away stabilizer is perfect. It provides the necessary support during stitching, then easily removes once completed. On knits, a sew-in interfacing or a lightweight fusible interfacing offers additional support and prevents the buttonhole from stretching out of shape. Without a stabilizer, the buttonholes can become distorted or easily tear due to the inherent properties of these fabric types.

Q 22. How do you choose the appropriate stitch density for buttonholes?

Stitch density for buttonholes is crucial; it directly impacts the buttonhole’s durability and appearance. Too loose, and the buttonhole will easily unravel; too tight, and the fabric may pucker or the stitches break. The ideal density depends on the fabric’s weight and type.

For lightweight fabrics like silk or chiffon, a lower stitch density (e.g., 12-15 stitches per inch) is recommended to prevent puckering. Heavier fabrics like denim or canvas will need a higher stitch density (e.g., 18-22 stitches per inch) for strength and to prevent the buttonhole from stretching out of shape. I always test a sample before working on the final piece to fine-tune the stitch density for optimal results. Think of it like building a house – a lightweight structure needs fewer bricks, while a sturdy building requires more.

- Lightweight fabrics: Lower stitch density (12-15 stitches per inch)

- Medium-weight fabrics: Medium stitch density (15-18 stitches per inch)

- Heavyweight fabrics: Higher stitch density (18-22 stitches per inch)

Q 23. What is your experience with industrial sewing machines used for buttonhole creation?

My experience with industrial sewing machines for buttonhole creation is extensive. I’ve worked with various models, from single-needle machines with specialized buttonhole attachments to advanced computerized machines capable of creating intricate and customized buttonholes. Industrial machines offer superior speed and consistency compared to domestic machines, crucial for high-volume production. The key is understanding the specific functionality of each machine – learning to adjust the stitch length, width, and feed mechanisms is critical to achieve consistent, high-quality buttonholes.

I’m proficient in programming stitch patterns on computerized machines, allowing for precise control over the buttonhole’s design and dimensions. This allows me to create unique buttonholes that match specific design needs, even incorporating decorative elements like eyelets or embroidery stitches.

Q 24. How do you maintain and clean your sewing machine to ensure optimal buttonhole performance?

Regular maintenance is paramount for optimal buttonhole performance. My routine includes daily cleaning of the bobbin case, feed dogs, and needle plate. I remove lint and thread buildup using a small brush and compressed air. I also lubricate moving parts according to the manufacturer’s instructions. This prevents friction, extends the machine’s lifespan, and ensures smooth operation. Regular cleaning prevents thread breakage, skipped stitches, and ensures consistent stitch formation, crucial for perfect buttonholes.

Beyond daily cleaning, I conduct a more thorough monthly maintenance, checking and cleaning the hook assembly. This is a more involved process but vital for keeping the machine functioning at its peak. I also replace the needle regularly, as a bent or damaged needle is a frequent cause of buttonhole problems.

Q 25. Describe your experience working with different buttonhole attachments for sewing machines.

I have extensive experience using various buttonhole attachments, from the basic single-needle zigzag stitch attachments to more advanced, automatic buttonhole foot attachments. Each type has its own advantages and disadvantages. Single-needle attachments are versatile but require more manual skill and precision, while automatic attachments are faster but less adaptable. I’m familiar with both styles and select the appropriate attachment based on the design, the fabric type, and production demands.

For instance, a keyhole buttonhole might require a single-needle attachment for greater control over the shaping, whereas a standard buttonhole on a mass-produced garment is ideally suited for an automatic foot. I’ve worked with attachments from various manufacturers (such as Brother, Singer, and industrial brands) and am comfortable adapting to new technologies.

Q 26. How do you diagnose and fix common sewing machine problems related to buttonhole creation?

Diagnosing and fixing buttonhole problems requires a systematic approach. I start by visually inspecting the stitches for inconsistencies, such as skipped stitches, broken threads, or uneven stitching. Then, I check the needle for damage, ensure the thread is properly tensioned, and verify the correct stitch length and width settings. Often, the problem is as simple as a slightly bent needle or a tangled thread. I then check the bobbin case for any issues and clean or replace it as needed.

More complex problems might involve the buttonhole foot or the machine’s timing. If the buttonhole is consistently too short or long, this suggests a timing issue that might require professional attention. I always document the steps taken and the solutions found to help me quickly resolve similar issues in the future. Remember to always consult your machine’s manual for troubleshooting.

Q 27. What are some common mistakes to avoid when making buttonholes?

Common mistakes to avoid include using the wrong needle for the fabric, improper thread tension, incorrect stitch settings, and neglecting to reinforce the buttonhole ends. Using the wrong needle can lead to broken needles or damaged fabric, while incorrect tension creates uneven stitches or a weak buttonhole. Incorrect stitch settings can result in buttonholes that are too large or small, too loose or too tight. Failing to reinforce the ends of the buttonhole leaves it vulnerable to unraveling.

Another frequent error is neglecting to pre-test the buttonhole on a scrap piece of fabric before working on the garment. This crucial step ensures the settings are correct and avoids costly mistakes on the final piece. A little extra preparation goes a long way in achieving perfect buttonholes every time.

Q 28. How do you adapt buttonhole techniques to accommodate unusual design elements?

Adapting buttonhole techniques to unusual design elements requires creativity and problem-solving. For example, creating a buttonhole on a curved seam or around a decorative element requires careful planning and execution. I might use a smaller stitch length, a different buttonhole attachment, or even hand-stitch sections of the buttonhole for intricate designs. The key is to consider the limitations of the machine and find creative solutions that achieve the desired result.

For instance, if working with a heavily embellished fabric, I’d carefully consider the placement of the buttonhole to avoid covering any important details. I’d also use techniques like hand-stitching or appliqué to integrate the buttonhole seamlessly with the design. Adapting to unusual elements is where the true expertise lies – it’s about understanding the properties of the fabric, the functionality of the machine, and using both to create something beautiful and functional.

Key Topics to Learn for Proficient in Sewing Techniques for Different Buttonhole Styles Interview

- Understanding Buttonhole Types: Familiarize yourself with various buttonhole styles (e.g., keyhole, bound, welt, machine-made) and their unique characteristics.

- Fabric Selection and Preparation: Learn how fabric type influences buttonhole construction and appropriate pre-sewing preparations (e.g., interfacing, stabilizers).

- Machine Operation and Settings: Master the settings and techniques for creating different buttonhole styles on various sewing machines (both industrial and domestic).

- Hand-Sewn Buttonholes: Develop proficiency in hand-sewing techniques for buttonholes, including different stitches and finishing methods.

- Troubleshooting Common Issues: Understand and be prepared to address common problems encountered during buttonhole creation, such as puckering, uneven stitching, and broken needles.

- Quality Control and Finishing: Learn techniques to ensure professional-looking buttonholes with clean finishes and consistent sizing.

- Adapting Techniques: Practice adapting your buttonhole techniques to various garment types and designs (e.g., tailored clothing, casual wear).

- Efficiency and Production: Discuss strategies for efficient buttonhole creation, especially relevant for production-oriented roles.

Next Steps

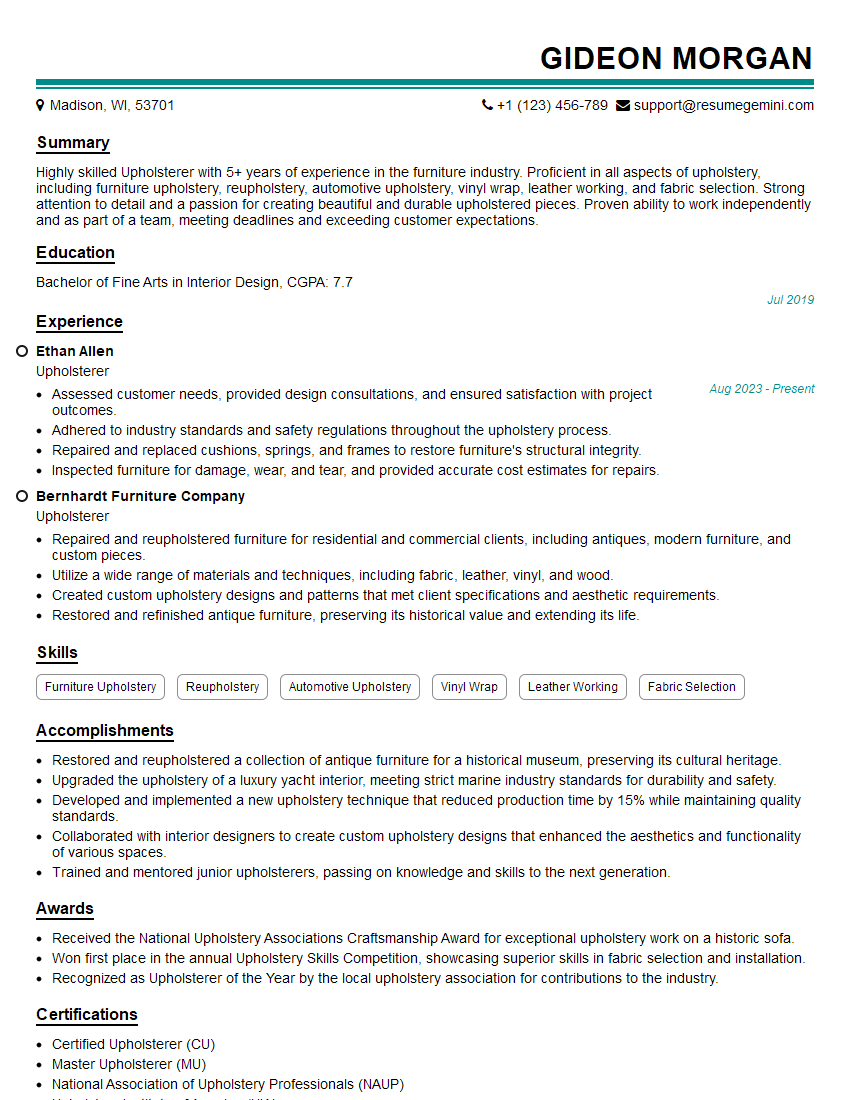

Mastering proficient sewing techniques for different buttonhole styles is crucial for career advancement in the garment industry, opening doors to higher-paying positions and specialized roles. A well-crafted resume is your first impression – ensure yours is ATS-friendly to maximize your chances of landing an interview. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to highlight your skills. Examples of resumes specifically designed for candidates proficient in various buttonhole sewing techniques are available to help you craft the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good