Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Proficient in Operating Industrial Sewing Machines interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Proficient in Operating Industrial Sewing Machines Interview

Q 1. What types of industrial sewing machines have you operated?

Throughout my career, I’ve gained extensive experience operating a variety of industrial sewing machines. This includes high-speed single-needle machines for straight stitching and precise work, like on tailored garments. I’m also proficient with double-needle machines for creating parallel seams, often used in denim or sportswear production. My experience extends to coverstitch machines, which produce a very neat and professional-looking finish, ideal for hems and necklines. I’m also comfortable with overlock (serger) machines for finishing raw edges quickly and efficiently, preventing fraying. Finally, I’m adept at using specialized machines like button-attaching machines and bar-tacking machines for specific tasks.

Q 2. Describe your experience with different stitch types and their applications.

Different stitch types are crucial for achieving specific functionalities and aesthetics. A simple straight stitch (000), for instance, is versatile and used for basic seams, while a zigzag stitch (001) is excellent for stretching fabrics like knits, preventing seam breakage. A blind stitch (002) is nearly invisible, perfect for hemming. The overlock stitch, created by a serger, secures and finishes seams simultaneously, preventing fraying. A lockstitch, the most common, is highly durable and used in many applications. The choice depends entirely on the fabric and the desired outcome – a delicate silk blouse requires vastly different stitches from a heavy-duty work jacket. I’ve developed a keen eye for selecting the appropriate stitch type based on the project requirements.

Q 3. How do you troubleshoot common sewing machine malfunctions?

Troubleshooting is a key skill. My systematic approach starts with identifying the issue. Is the machine not stitching? Is the stitch inconsistent? Is there a noise problem? I then systematically check the most common culprits: First, I check the needle – is it the correct type for the fabric, is it bent or broken? Then, I examine the thread – is it the correct type, is it properly threaded, and is the tension correctly adjusted? I check the bobbin – is it correctly wound and inserted? Then I will look at the presser foot – is it raised or lowered appropriately and is the fabric feeding correctly? If the problem persists, I might check the timing of the machine or consult the manual to identify the specific problem. For example, a skipped stitch often points to a tension problem, whereas a broken needle likely indicates a material or speed issue. Experience has taught me to isolate the problem quickly and efficiently, minimizing downtime.

Q 4. What safety precautions do you follow while operating industrial sewing machines?

Safety is paramount. Before operating any machine, I ensure all guards are in place and functioning correctly. I never reach into the moving parts of the machine while it’s running. Long hair must be tied back, and loose clothing must be secured to prevent entanglement. I maintain a clean and organized workspace, free of clutter to prevent tripping hazards. I always use the correct safety glasses to protect my eyes from flying debris or needle breakage. Proper maintenance, including regular lubrication and cleaning, also contributes to preventing malfunctions that could cause injury. Safety isn’t just a protocol; it’s a habit ingrained through years of experience.

Q 5. Explain your process for setting up a sewing machine for a specific project.

Setting up for a project involves several steps. First, I carefully read the design specifications to understand the fabric, stitch type, and desired outcome. Based on this, I select the correct needle, thread (considering color and strength), and stitch settings. Then, I thread the machine correctly, ensuring proper tension. I test the stitch on a scrap piece of fabric, adjusting the machine settings as necessary until I achieve the desired look. Once the settings are perfected, I can begin sewing the actual project. For example, if working with a delicate silk, I will choose a fine needle, thinner thread, and lower stitch tension to prevent the fabric from tearing. Preparation is key to efficient and high-quality work.

Q 6. How do you maintain the efficiency and accuracy of your sewing work?

Maintaining efficiency and accuracy involves meticulous attention to detail and preventative maintenance. Regular cleaning and lubrication prevent wear and tear, ensuring smooth operation. I inspect my work frequently, correcting any minor inconsistencies promptly. I keep a well-stocked supply of needles, thread, and other consumables to avoid interruptions. Using consistent tension and stitch length enhances the quality and evenness of my work. I also continually refine my techniques through practice and observation, striving for improvement and efficiency in every task. A well-maintained machine and consistent technique are essential for consistent, high-quality output.

Q 7. How do you handle large production runs and meet deadlines?

Handling large production runs requires careful planning and organization. I start with a thorough review of the specifications and production targets. I then break down the work into manageable steps, tracking progress and identifying potential bottlenecks. I prioritize efficient workflows, maintaining consistent speed and accuracy while staying focused on quality. Communication is vital; I keep my supervisor updated on progress and any issues encountered. In some cases, prioritizing certain sections of the project might help meet the deadlines more efficiently. For instance, completing all the button attachments at the end could help streamline the production process.

Q 8. Describe your experience with different sewing machine needles and threads.

My experience with sewing machine needles and threads is extensive. Needle selection is crucial for achieving the desired stitch quality and preventing damage to the fabric. I’m familiar with a wide range of needle types, including:

- System needles: These are the most common type, identified by a number indicating size and type (e.g., 14/80 for medium-weight fabrics).

- Ballpoint needles: Designed for knit fabrics to prevent snagging or skipped stitches. I often use these for jersey or stretch fabrics.

- Sharp needles: Ideal for woven fabrics like cotton, linen, or silk. They pierce the fibers cleanly.

- Embroidery needles: Specifically designed for creating embroidery, these have a larger eye and a more rounded point for delicate work.

Thread selection is equally important. I consider factors such as fiber content (cotton, polyester, silk), ply (single, double), and weight (tex number). For example, a heavier thread is needed for a durable seam on a heavy denim jacket, whereas a finer thread might be suitable for a delicate silk blouse. I’ve worked extensively with various thread types, learning to match them appropriately to the fabric and needle type to prevent breakage and ensure consistent stitch quality. I often pre-wind my bobbins to maintain consistent tension throughout the project.

Q 9. How do you identify and correct fabric defects or inconsistencies during sewing?

Identifying and correcting fabric defects during sewing requires a keen eye and practical experience. I regularly check for:

- Fabric flaws: This includes holes, weak areas, uneven weaving, or inconsistencies in the fabric’s structure. I meticulously examine the fabric *before* beginning to sew to minimize issues.

- Tension problems: Uneven tension can lead to puckering, skipped stitches, or broken threads. I adjust the machine tension accordingly (both needle and bobbin) and check for proper threading.

- Needle issues: A bent, dull, or incorrectly sized needle can cause skipped stitches, fabric damage, or broken threads. Regular needle changes are essential.

- Stitch inconsistencies: Uneven stitch length or spacing can be caused by speed adjustments or other machine settings. I carefully monitor stitch quality throughout the process.

My approach to correction varies depending on the nature of the defect. A small hole might be mended by hand stitching before machine sewing. If the fabric is consistently flawed, I might need to adjust the pattern or use a different piece. For tension issues, I meticulously check and readjust the top and bottom tensions, often testing on a scrap fabric until I get the right tension balance before moving to the main fabric.

Q 10. How familiar are you with different sewing machine attachments and their uses?

I’m very familiar with various sewing machine attachments and their uses. My experience includes:

- Zipper foot: Used for applying zippers cleanly and accurately. I’ve utilized different types for different zipper styles (invisible, metal, coil).

- Buttonhole foot: Enables precise and consistent buttonhole stitching. I have experience with various buttonhole types and settings.

- Walking foot: Essential for sewing multiple layers of fabric or slippery materials, ensuring even feed. This is particularly useful for quilting or sewing leather.

- Blind hem foot: Creates almost invisible hems on various fabrics. I’ve practiced this on various weights and types of fabric to achieve a professional finish.

- Gathering foot: Used to create gathers or ruffles. This attachment simplifies this often-complex sewing task.

I understand the importance of selecting the appropriate attachment for the task at hand and understand how to correctly install and use each one efficiently.

Q 11. What is your experience with pattern interpretation and following specifications?

Pattern interpretation and adhering to specifications are fundamental to my work. I’m proficient in reading and understanding sewing patterns, including:

- Understanding pattern markings: I’m adept at interpreting notches, grainlines, seam allowances, and other markings to ensure accurate garment construction.

- Adjusting patterns: I can make adjustments to patterns based on individual measurements or design preferences while maintaining the integrity of the pattern design.

- Following instructions: I meticulously follow the provided instructions, ensuring I understand each step before proceeding. I often make test samples before working on the final product.

For example, I recently worked on a project where the client provided specific measurements and fabric choices. I accurately interpreted the pattern, made the necessary adjustments for the client’s body type, and ensured the final garment met their exacting specifications in terms of fit and finish. I always prioritize precision and accuracy in every aspect of the project, from pattern cutting to final stitching.

Q 12. Describe your experience with different sewing machine tension adjustments.

Sewing machine tension adjustments are critical for achieving quality stitches. I have extensive experience adjusting both the upper (needle) and lower (bobbin) tension. I understand that:

- Upper tension: Controls the tension of the thread from the top spool. Too tight can cause puckering, while too loose results in loose stitches.

- Lower tension: Controls the tension of the thread from the bobbin. Similar to upper tension, incorrect settings lead to stitch issues.

I usually adjust tension by making slight adjustments – a quarter or half turn at a time – and testing on a scrap of fabric. It is crucial to check the stitch on both the front and back side of the fabric. A balanced tension will result in a consistent stitch with minimal thread show on either side. I often encounter situations requiring fine-tuning the tension depending on the fabric type and weight, even using different thread types depending on the project. My experience allows me to troubleshoot and resolve tension issues quickly and efficiently.

Q 13. How do you ensure consistent stitch quality throughout a garment or project?

Consistent stitch quality is paramount. I achieve this through a combination of techniques:

- Proper machine maintenance: Regular cleaning and lubrication of the machine are crucial for preventing malfunctions and ensuring smooth operation.

- Consistent speed and pressure: Maintaining a steady sewing speed and even pressure on the foot pedal prevents inconsistencies in stitch length and tension.

- Proper needle and thread selection: Choosing the correct needle and thread for the fabric prevents skipped stitches, breakage, and poor stitch quality.

- Regular tension checks: Frequent checks of the stitch quality and adjustments of the upper and lower tensions are essential.

I often utilize test pieces to check settings before working on the actual garment. For instance, before sewing a seam on an expensive fabric, I always test the stitch setting on a similar scrap to ensure I am happy with the result. This allows me to catch problems before the actual work, saving time and material.

Q 14. What is your experience with quality control procedures in sewing?

My experience with quality control in sewing encompasses several key areas:

- Pre-sewing inspection: Thoroughly inspecting the fabric for flaws, checking the pattern pieces for accuracy, and ensuring the correct needle and thread are selected.

- In-process checks: Regularly monitoring stitch quality, tension, and seam alignment during the sewing process to catch any issues early.

- Post-sewing inspection: A thorough examination of the finished garment for any defects, such as loose threads, uneven seams, or inconsistencies in stitching.

- Measuring and fitting: Precisely measuring and fitting garments to ensure they meet the required specifications.

I follow a structured approach to quality control. If I find defects, I immediately address them and document the issues. My aim is to produce high-quality garments that meet the highest standards. It’s not just about creating something beautiful, it’s about constructing something durable and functional.

Q 15. How do you maintain a clean and organized sewing workstation?

Maintaining a clean and organized sewing workstation is paramount for efficiency and safety. Think of it like a chef’s kitchen – a messy workspace leads to mistakes and accidents. My approach involves several key steps:

- Regular Cleaning: I clean my machine and surrounding area at the beginning and end of each shift. This includes removing fabric scraps, lint, and dust using a brush and compressed air. I also wipe down the machine surface with a damp cloth.

- Organized Supplies: I keep my threads, needles, bobbins, and other supplies neatly organized in labeled containers. This allows me to quickly find what I need without wasting time searching.

- Ergonomic Setup: My workstation is arranged ergonomically to minimize strain. This includes proper lighting, comfortable seating, and a well-positioned machine to prevent awkward postures. Think of it as setting up for a marathon, not a sprint – comfort prevents fatigue and mistakes.

- Preventative Maintenance: Regularly lubricating moving parts and checking tension settings prevents future problems. It’s like servicing a car – small steps prevent larger breakdowns.

A clean and organized workspace not only boosts efficiency but also fosters a safer environment, reducing the risk of accidents and improving overall productivity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle a machine malfunction during peak production time?

Machine malfunctions during peak production are a serious challenge, demanding quick thinking and problem-solving skills. My approach is a systematic one:

- Assess the Problem: First, I carefully identify the nature of the malfunction. Is the needle breaking? Is the stitch quality inconsistent? Is the machine making unusual noises?

- Basic Troubleshooting: I then attempt basic troubleshooting steps, such as checking the needle, bobbin, and thread tension. Many issues can be solved with simple adjustments.

- Seek Assistance: If the problem persists, I immediately report it to my supervisor or maintenance personnel. Time is crucial during peak production, so collaboration is key. I provide detailed information about the malfunction to help them diagnose the issue quickly.

- Alternative Solutions: While waiting for the machine to be repaired, I might explore alternative solutions, such as re-prioritizing tasks or assisting other team members to maintain overall productivity. It’s about adapting to the situation and maximizing efficiency.

My experience has taught me that proactive maintenance and prompt communication are critical in minimizing downtime and maximizing output during peak production times.

Q 17. How do you work effectively within a team environment in a sewing operation?

Effective teamwork in a sewing operation is essential for meeting production goals and maintaining a positive work environment. My approach centers around communication, collaboration, and mutual support:

- Clear Communication: I ensure clear and timely communication with my team members regarding tasks, challenges, and progress. This includes actively listening and offering constructive feedback.

- Collaboration: I actively participate in team discussions, offering my expertise and assisting colleagues where needed. A team is only as strong as its weakest link, so support is crucial.

- Mutual Respect: I maintain a respectful and supportive attitude towards my colleagues, recognizing their individual contributions to the team’s success. A positive atmosphere is more productive.

- Shared Goals: I understand and contribute to our team’s shared goals, recognizing that individual success contributes to the team’s overall success. This promotes a sense of unity and shared purpose.

In a previous role, I was part of a team that successfully completed a large order ahead of schedule by effectively collaborating and sharing workloads. This demonstrates my ability to thrive in team environments.

Q 18. Describe your experience with various fabric types and their sewing characteristics.

Experience with diverse fabric types is crucial in industrial sewing. Each fabric possesses unique characteristics that influence sewing techniques. Here are a few examples:

- Cotton: A common, versatile fabric that’s relatively easy to sew. However, it can fray easily, requiring attention to seam finishing.

- Silk: A delicate, luxurious fabric requiring specialized needles and slow, careful stitching to avoid snagging or tearing.

- Leather: A durable, thick material that requires strong needles, specialized machine settings, and potentially walking foot attachments to prevent slippage.

- Synthetics (Polyester, Nylon): Often very smooth and slippery, these require careful attention to needle choice and tension to prevent skipped stitches or puckering.

- Woven vs. Knit: Woven fabrics have distinct warp and weft threads, creating a stable structure. Knit fabrics, however, are flexible and can stretch, requiring different needle and stitch types to prevent distortion.

My experience encompasses working with a wide array of fabrics, allowing me to adapt my sewing techniques to achieve optimal results for each material.

Q 19. How do you adapt your sewing technique for different fabric weights and textures?

Adapting sewing techniques to different fabric weights and textures is fundamental to successful sewing. The key is understanding how fabric properties impact stitch formation and machine settings.

- Needle Selection: Heavier fabrics require stronger needles to penetrate the material without bending or breaking. Lighter fabrics need finer needles to avoid creating holes.

- Stitch Length: Longer stitches are generally used for heavier fabrics, while shorter stitches are preferred for finer fabrics. This ensures adequate strength while maintaining aesthetic appeal.

- Presser Foot Pressure: Heavier fabrics require greater presser foot pressure to feed the material smoothly. Lighter fabrics may need reduced pressure to prevent puckering.

- Feed Dogs: Adjusting the feed dog settings can help control the fabric feed rate, particularly important for stretchy or slippery materials.

- Stitch Type: Certain stitch types are better suited for specific fabric weights. For example, a zigzag stitch provides better elasticity for knit fabrics than a straight stitch.

For instance, sewing denim (heavy) requires a stronger needle and longer stitches compared to sewing chiffon (light), which necessitates a finer needle and shorter stitches with reduced presser foot pressure.

Q 20. What is your experience with computerized sewing machines or CAD systems?

While my primary experience lies with traditional industrial sewing machines, I possess familiarity with computerized sewing machines and have some experience with CAD systems. This exposure has broadened my understanding of the industry and its technological advancements.

Computerized sewing machines offer features such as programmable stitch patterns and automated tension adjustments, improving efficiency and consistency. I have used such machines to produce intricate designs and complex patterns with great precision. The automation reduces human error.

My CAD experience includes using software to create digital patterns and design layouts. This experience has enhanced my understanding of pattern making and design principles. While not directly involved in the sewing process itself, it helps in creating more efficient workflows and understanding how designs are translated into finished products. This allows me to work seamlessly with designers and pattern makers.

Q 21. How do you handle challenging or complex sewing projects?

Approaching challenging or complex sewing projects requires a methodical approach that blends technical skill with problem-solving abilities. My approach follows these steps:

- Thorough Analysis: I begin by carefully examining the project specifications, identifying any unique challenges or complexities. This includes understanding the fabric, design details, and construction methods.

- Planning and Preparation: Based on the analysis, I develop a detailed plan, outlining the steps involved, materials needed, and potential obstacles. This includes creating a sample if necessary.

- Testing and Adjustment: I frequently test different techniques and make adjustments as needed during the process. I consider alternative methods to overcome difficulties and ensure quality. This iterative process is crucial.

- Attention to Detail: Precision and attention to detail are crucial throughout the project. Small errors can have significant impacts on the final result.

- Continuous Improvement: I regularly reflect on my approach to identify areas for improvement and learn from any challenges encountered. Every project offers a learning opportunity.

For example, I once worked on a project involving intricate leatherwork and embroidery. Through careful planning, testing, and attention to detail, I successfully completed the project, meeting the demanding specifications and exceeding expectations.

Q 22. What are your methods for improving speed and efficiency in your sewing work?

Improving speed and efficiency in industrial sewing relies on a combination of technique, machine knowledge, and workflow optimization. Think of it like an assembly line – each step needs to be smooth and efficient to maximize output.

Ergonomics and Posture: Maintaining correct posture minimizes fatigue and maximizes sewing speed. Poor posture leads to strain and errors.

Machine Proficiency: A thorough understanding of my machine’s capabilities, including stitch length, tension, and feed dog adjustments, allows me to tailor settings for optimal speed and stitch quality. For example, I can adjust the presser foot pressure for different fabric weights to prevent skipped stitches or fabric puckering.

Efficient Threading and Needle Changes: I’ve developed quick and efficient methods for threading and changing needles, minimizing downtime. Practicing these skills repeatedly makes them second nature.

Pre-Cutting and Preparation: Efficient pre-cutting and accurate pattern marking drastically reduce sewing time. Proper organization of materials is essential to avoid searching for the right fabric or pattern piece.

Batching Similar Tasks: Grouping similar sewing tasks together, such as sewing all the seams on one batch of garments before moving on to another task, streamlines the workflow and improves speed and consistency.

Q 23. How do you stay updated on the latest trends and technologies in industrial sewing?

Staying current in industrial sewing requires proactive engagement with industry resources. I regularly attend industry trade shows and workshops, where I see demonstrations of new equipment and techniques. I also subscribe to relevant trade publications and online forums which offer insights into new technologies and best practices. Furthermore, I actively seek out online training courses focusing on new sewing machine models and software integrations used for pattern design and production management.

Q 24. How do you assess the quality of your work and make improvements?

Quality assessment is a critical part of my process. I use a multi-faceted approach to ensure the highest quality output.

Regular Inspections: I visually inspect my work throughout the sewing process, looking for inconsistencies in stitch quality, seam alignment, and fabric integrity.

Stitch Quality Check: I regularly check stitch length and tension to ensure they meet the project specifications. For example, a consistent, even stitch length indicates proper machine settings and prevents weak seams.

Measurement and Comparison: I frequently measure completed pieces against the pattern specifications to ensure accuracy and identify any potential issues early on. If there are variances, I analyze the cause and adjust my technique or machine settings accordingly.

Feedback and Improvement: Constructive feedback from supervisors or quality control personnel is invaluable for identifying areas where improvement is needed.

Q 25. What are your strengths and weaknesses in regards to industrial sewing?

My strengths lie in my adaptability to various sewing machines and projects, my dedication to maintaining high-quality standards, and my efficient problem-solving skills. I’m also a quick learner and can readily adapt to new techniques and technologies. However, like anyone, I have areas for improvement. While proficient in most machine types, gaining expertise in specialized machines like bar tacking machines could enhance my skillset. Furthermore, I’m continually refining my time management skills for optimal workflow efficiency.

Q 26. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, aligned with industry standards for experienced industrial sewing machine operators in this region. I’m open to discussing this further based on the specifics of the role and company benefits package.

Q 27. Describe your experience working with different types of industrial sewing equipment.

My experience encompasses a wide range of industrial sewing equipment. I’m proficient in operating single-needle and double-needle machines, overlock machines (sergers), coverstitch machines, and button-sewing machines. I have experience with both high-speed machines for mass production and more specialized machines used in intricate garment construction. My experience extends to working with various types of fabrics, from lightweight silks to heavy-duty denim. I am also familiar with operating computerized sewing machines and their integrated software systems for pattern design and production management.

Q 28. What is your approach to problem-solving when encountering a sewing machine issue?

My approach to troubleshooting sewing machine issues is systematic and methodical. I follow a step-by-step process:

Identify the Problem: Carefully observe the machine’s behavior, note the specific issue (e.g., skipped stitches, broken needle, inconsistent tension).

Basic Checks: Begin with the simplest checks: ensure the machine is properly threaded, the needle is correctly inserted, and the bobbin is properly wound and inserted.

Systematic Troubleshooting: If the issue persists, I systematically check each component, starting with the needle and thread, then moving to the tension settings, feed dog, and finally more complex components like the timing belt or motor.

Consult Manuals and Resources: If I can’t identify the problem, I consult the machine’s manual or online resources for troubleshooting guidance.

Seek Assistance if Needed: If the problem remains unresolved, I seek assistance from a qualified technician.

Key Topics to Learn for Proficient in Operating Industrial Sewing Machines Interview

- Machine Operation & Maintenance: Understanding the mechanics of various industrial sewing machines (e.g., single-needle, double-needle, overlock), their functionalities, and routine maintenance procedures (lubrication, needle changes, tension adjustments).

- Seam Types & Applications: Knowledge of different seam types (e.g., straight stitch, zigzag stitch, overlock stitch) and their appropriate applications based on fabric type and garment construction. Be prepared to discuss the strengths and weaknesses of each.

- Fabric Handling & Selection: Understanding different fabric types (e.g., knits, wovens, leathers) and their specific sewing requirements, including needle and thread selection, stitch density, and appropriate sewing speeds.

- Troubleshooting & Problem-Solving: Ability to identify and resolve common sewing machine issues (e.g., skipped stitches, broken needles, thread jams) and demonstrate a systematic approach to troubleshooting.

- Safety Procedures & Regulations: Familiarity with workplace safety protocols related to industrial sewing machines, including proper machine operation, preventative maintenance and the use of safety equipment.

- Production Efficiency & Quality Control: Understanding the importance of maintaining consistent stitch quality, adhering to production deadlines, and minimizing waste. Be ready to discuss your methods for achieving efficiency and quality.

- Pattern Reading & Interpretation: Ability to interpret sewing patterns and understand technical specifications related to seam allowances, stitch lengths, and other construction details.

Next Steps

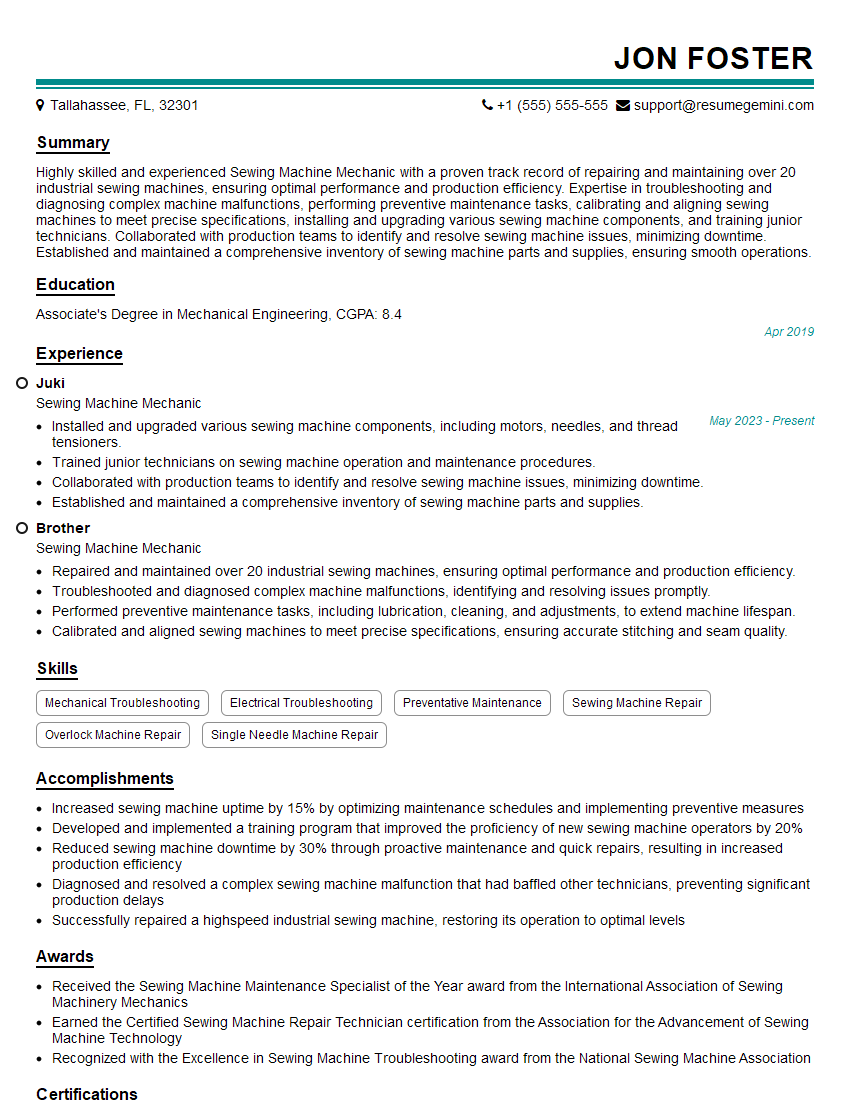

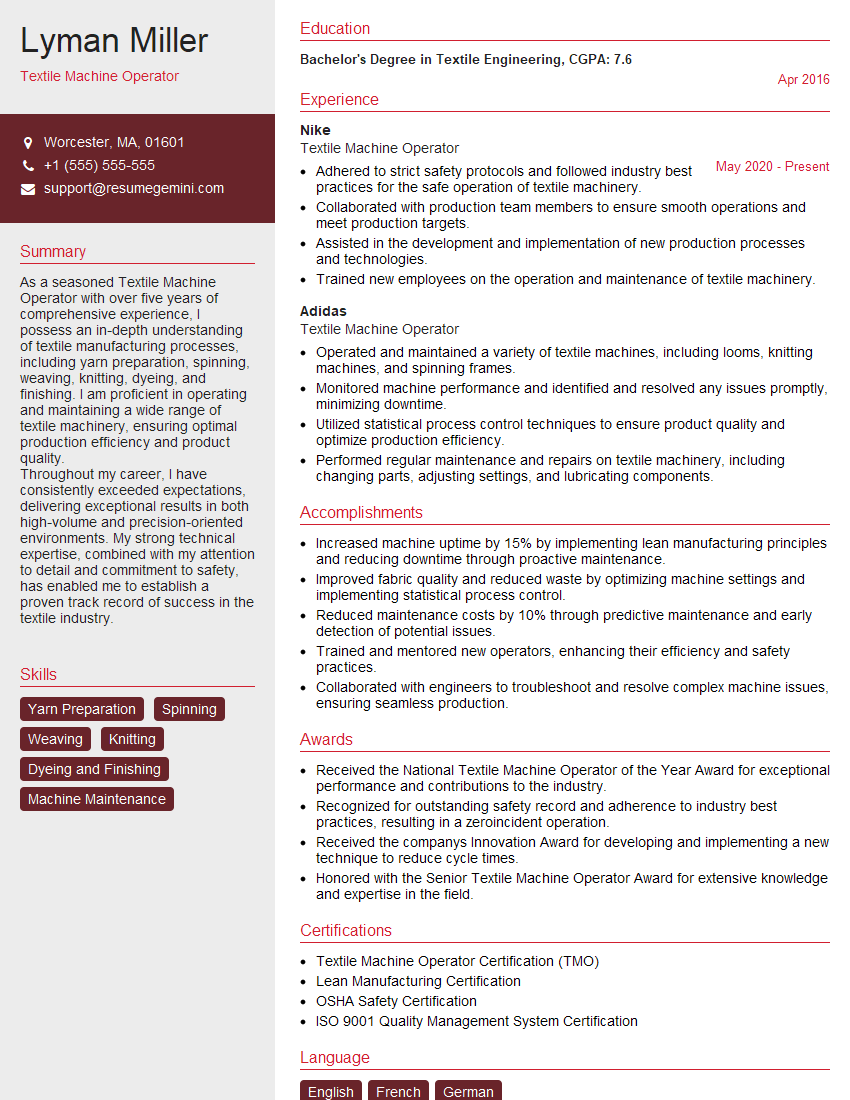

Mastering the operation of industrial sewing machines opens doors to diverse and rewarding career opportunities in the apparel and textile industries. From entry-level positions to more specialized roles, proficiency in this area is highly valued. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, showcasing your skills and experience effectively. Examples of resumes tailored to highlight proficiency in operating industrial sewing machines are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good