Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Bioreactor Scale-Up interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Bioreactor Scale-Up Interview

Q 1. Explain the principles of bioreactor scale-up.

Bioreactor scale-up involves transitioning a cell culture process from a small-scale laboratory bioreactor to a larger-scale production bioreactor. The goal is to maintain consistent process performance and product quality while increasing production volume. This requires careful consideration of numerous factors to ensure the larger bioreactor achieves the same cell growth, product yield, and quality as the smaller one. It’s like baking a cake – you can’t just multiply the ingredients and expect the same result; you need to adjust baking time and oven temperature to achieve the desired outcome.

The core principle is to maintain key process parameters – such as oxygen transfer rate (OTR), mixing time, shear stress, and nutrient delivery – within a range that supports optimal cell growth and product formation at each scale. Failing to do so can lead to reduced productivity, lower product quality, and even cell death.

Q 2. Describe different scale-up strategies (e.g., constant impeller tip speed, constant power input).

Several scale-up strategies exist, each with advantages and disadvantages. The choice depends on the specific cell culture process and product. Common strategies include:

- Constant Impeller Tip Speed: This strategy maintains a constant impeller tip speed during scale-up. It aims to maintain a similar mixing intensity across different scales. However, power consumption increases significantly with scale. It might be suitable for processes less sensitive to shear stress.

- Constant Power Input per Unit Volume (P/V): This approach maintains a constant power input per unit volume. It ensures similar mixing intensity relative to the bioreactor volume, resulting in a more consistent energy dissipation rate. This method generally leads to a lower impeller tip speed in larger reactors and can reduce shear stress. However, it may not perfectly maintain all other process parameters.

- Constant Shear Stress: This strategy directly controls shear stress, which is crucial for sensitive cell lines. It can be complex to implement and requires detailed modeling and measurement of shear stress profiles. It is critical in processes where shear forces significantly affect cell viability and productivity.

- Geometric Similarity: This involves maintaining the same geometric ratios between bioreactor dimensions and impeller parameters across scales. While this simplifies scale-up, it doesn’t guarantee consistent process performance and might not always be achievable.

Often, a combination of these strategies is employed, fine-tuned based on experimental data and process understanding.

Q 3. What are the challenges associated with scaling up cell culture processes?

Scaling up cell culture processes presents several significant challenges:

- Increased Oxygen Transfer Limitations: As bioreactor size increases, the surface area-to-volume ratio decreases, making oxygen transfer more challenging. This can lead to oxygen limitation and reduced cell growth.

- Maintaining Consistent Mixing: Achieving uniform mixing becomes more difficult in larger bioreactors. Dead zones can develop, leading to variations in nutrient concentration, pH, and dissolved oxygen, which negatively impact cell growth and product quality.

- Shear Stress Effects: Increased impeller speed in larger bioreactors can lead to higher shear stress, potentially damaging delicate cells. This is particularly important for mammalian cell cultures.

- Heat Transfer: Larger bioreactors generate more heat, necessitating effective cooling systems to prevent overheating and maintain optimal temperature for cell growth.

- Scale-Dependent Variability: Unpredictable and hard-to-control variations, such as subtle differences in cell seeding density, can introduce significant differences across scales.

- Increased Cost and Complexity: Larger-scale bioreactors require more significant investments in equipment, infrastructure, and operational expertise.

Q 4. How do you maintain consistent mixing and oxygen transfer during scale-up?

Maintaining consistent mixing and oxygen transfer during scale-up requires a multi-faceted approach:

- Impeller Design and Optimization: Choosing appropriate impeller types and configurations (e.g., Rushton turbine, marine impeller) is crucial. Computational Fluid Dynamics (CFD) modeling can help optimize impeller design for effective mixing and oxygen transfer in different-sized bioreactors.

- Sparger Design: Efficient sparger design (e.g., ring sparger, nozzle sparger) is essential for effective gas dispersion. The sparger design should be optimized for the specific scale and gas flow rate.

- Gas Flow Rate Control: Carefully controlling the gas flow rate ensures sufficient oxygen supply. This often involves online monitoring of dissolved oxygen (DO) levels.

- Impeller Speed Control: Adjusting impeller speed helps control mixing intensity and shear stress. This requires a sophisticated control system that maintains consistent mixing while preventing excessive shear stress.

- Bioreactor Geometry: Maintaining geometric similarity can aid in consistent mixing and oxygen transfer. However, this approach is not always the optimal solution.

Careful consideration of all these factors, possibly aided by CFD modeling, is essential to minimize scale-up challenges related to mixing and oxygen transfer.

Q 5. Discuss the importance of geometric similarity in bioreactor scale-up.

Geometric similarity in bioreactor scale-up refers to maintaining the same ratios of key dimensions and parameters between different bioreactor sizes. For example, maintaining the same ratio of height to diameter (H/D) and impeller diameter to tank diameter (Di/Dt) across scales. While this simplifies scale-up by reducing the number of variables to consider, it does not guarantee that all process parameters will scale linearly. Geometric similarity is useful as a starting point but often needs refinement through additional strategies and monitoring.

Imagine scaling up a model airplane. You can’t just enlarge the plans proportionally; you need to adjust the wingspan and other aspects to maintain aerodynamic properties. Similarly, while geometric similarity offers a baseline, further optimization is often necessary in bioreactor scale-up to ensure consistent performance.

Q 6. Explain how to scale up a bioreactor while maintaining consistent shear stress.

Maintaining consistent shear stress during scale-up requires a detailed understanding of the forces affecting cells. This often involves a combination of strategies:

- Power Input per Unit Volume (P/V): Maintaining a constant P/V is a common approach to maintain relatively constant shear stress. This approach helps to ensure that the energy dissipated per unit volume is relatively consistent across scales. However, it is crucial to be aware of its limitations and consider other contributing factors.

- Impeller Design: Choosing impellers with lower shear stress generation capabilities is crucial for sensitive cell lines. For example, using pitched-blade impellers instead of Rushton turbines might be beneficial.

- CFD Modeling: Advanced computational fluid dynamics modeling can help predict shear stress profiles at different scales and guide impeller design and operating parameters to minimize excessive shear.

- Experimental Validation: Monitoring shear stress directly in the bioreactor during the scale-up process is crucial for verifying predictions and making adjustments as needed. This may involve using specialized sensors or techniques to measure shear stress.

The approach should be tailored to the specific cell type and process. For highly shear-sensitive cells, maintaining constant shear stress may be the primary scale-up criterion, potentially overriding other scale-up criteria.

Q 7. What are the key parameters to monitor during bioreactor scale-up?

Monitoring numerous key parameters is critical during bioreactor scale-up to ensure consistent process performance and product quality. These parameters include:

- Dissolved Oxygen (DO): Continuous monitoring ensures adequate oxygen supply for cell growth.

- pH: Maintaining optimal pH is essential for cell viability and product quality.

- Temperature: Consistent temperature control is critical for optimal cell growth and product formation.

- Cell Density: Monitoring cell density provides insights into cell growth and viability.

- Nutrient Concentrations: Monitoring nutrient levels ensures sufficient substrate availability for cell growth.

- Metabolic Byproducts: Monitoring the accumulation of metabolic byproducts (e.g., lactate, ammonia) helps detect potential inhibitory effects.

- Mixing Time: Monitoring mixing time ensures adequate mixing throughout the bioreactor.

- Power Consumption: Monitoring power consumption provides information on mixing intensity and energy dissipation.

- Shear Stress: If possible and relevant, direct monitoring of shear stress helps to verify the selected scale-up strategy.

- Product Concentration and Quality: Continuous monitoring of product concentration and quality attributes is essential to verify process consistency.

Data from these parameters should be used to refine scale-up strategies and optimize the process for the larger bioreactor.

Q 8. Describe your experience with different bioreactor types (e.g., stirred tank, airlift, photobioreactor).

My experience encompasses a wide range of bioreactor types, each with its own strengths and weaknesses. I’ve extensively worked with stirred tank reactors (STRs), which are the workhorses of the industry due to their excellent mixing capabilities and relatively simple design. I’ve used them for various applications, from mammalian cell culture to microbial fermentations. For oxygen-sensitive cultures, I’ve utilized airlift bioreactors, leveraging their gentle mixing and high oxygen transfer rates. Finally, my experience extends to photobioreactors, crucial for cultivating photosynthetic microorganisms. These require careful design to optimize light penetration and distribution throughout the culture, a challenge I’ve successfully addressed in several projects. For example, in one project involving algal cultivation, we experimented with different photobioreactor designs (flat panel, tubular) to find the optimal configuration for biomass productivity. We found that a tubular design, with its enhanced surface area to volume ratio, provided significantly better light distribution and a higher algal density than the flat panel design.

- Stirred Tank Reactors (STRs): Excellent mixing, versatile, widely used.

- Airlift Bioreactors: Gentle mixing, high oxygen transfer, suitable for shear-sensitive cells.

- Photobioreactors: Specialized for photosynthetic organisms, focus on light distribution.

Q 9. How do you address potential issues like foaming or contamination during scale-up?

Foaming and contamination are significant hurdles in bioreactor scale-up. Foaming can lead to operational issues like sensor malfunction, loss of culture volume, and even bioreactor overflow. We address this using anti-foaming agents, carefully selecting the type and concentration based on the culture and process. For example, silicone-based antifoams are often preferred for their inertness but require careful monitoring to prevent excessive accumulation. Real-time monitoring of foam height using sensors is crucial for timely intervention. Contamination, on the other hand, is combatted through stringent sterile techniques – from media preparation and sterilization to equipment design and aseptic operation. We employ techniques like steam-in-place (SIP) sterilization, HEPA filtration of incoming air, and regular integrity testing of seals and connections. In one instance, we identified a recurring contamination issue stemming from a faulty air filter. Replacing it eliminated the contamination, highlighting the importance of rigorous quality control.

Q 10. Explain the role of process analytical technology (PAT) in bioreactor scale-up.

Process Analytical Technology (PAT) is indispensable for successful bioreactor scale-up. It enables real-time monitoring and control of critical process parameters (CPPs) like pH, dissolved oxygen (DO), temperature, and substrate concentration. By implementing PAT, we gain a deeper understanding of the process dynamics and can adjust operating parameters accordingly to maintain consistent product quality. This includes using online sensors, in-line spectroscopy (e.g., NIR), and advanced data analytics. PAT helps identify and mitigate deviations early on, leading to improved yield, reduced variability, and accelerated process development. In a recent project, using real-time glucose monitoring via an inline sensor enabled us to optimize the feeding strategy, resulting in a 15% increase in product titer.

Q 11. Describe your experience with model-based scale-up approaches.

Model-based scale-up approaches offer a more scientific and predictable way to transition from small-scale to large-scale bioreactors, compared to traditional empirical methods. These approaches leverage mathematical models to simulate the bioprocess, incorporating factors like mass transfer, heat transfer, and mixing characteristics. This allows for the prediction of process performance at different scales. I have extensive experience using Computational Fluid Dynamics (CFD) models to simulate mixing in various bioreactor designs. By simulating different impeller configurations and agitation speeds, we can optimize mixing efficiency in the larger reactor. Furthermore, we use population balance models to understand cell growth dynamics and predict product formation under varied conditions. These models allow us to design the scale-up strategy to maintain consistent cell viability and productivity in larger systems. For example, by using a CFD model, we successfully predicted and avoided dead zones in a large-scale bioreactor, which would have otherwise negatively impacted cell growth and product formation.

Q 12. How do you validate a scaled-up bioreactor process?

Validating a scaled-up bioreactor process is critical to ensure its consistency and reliability. This involves demonstrating that the scaled-up process performs comparably to the smaller-scale process and meets predetermined quality attributes. We typically conduct extensive testing, including multiple runs at the larger scale, to assess process parameters, product quality, and reproducibility. This may involve rigorous statistical analysis to demonstrate the equivalence of the two scales. Furthermore, we perform thorough risk assessment to identify and mitigate any potential deviations from the smaller-scale process. Documentation of all aspects of the validation process, including methods, results, and conclusions, is essential for regulatory compliance. We use a validation plan that clearly defines acceptance criteria and outlines the steps for demonstrating process consistency and robustness. In one case, we had to adjust the gas sparger design during validation to maintain consistent dissolved oxygen levels in the larger bioreactor, showcasing the iterative nature of the validation process.

Q 13. What are the regulatory considerations for bioreactor scale-up?

Regulatory considerations for bioreactor scale-up are significant, particularly in the pharmaceutical and biopharmaceutical industries. These regulations aim to ensure product safety, efficacy, and consistency. Compliance with guidelines like Good Manufacturing Practices (GMP) is paramount throughout the scale-up process. This includes detailed documentation, robust quality control procedures, and thorough investigation of any deviations. Specific regulatory requirements vary depending on the product and intended use, but generally involve stringent validation protocols, comprehensive risk assessments, and detailed process characterization. We work closely with regulatory agencies throughout the process to ensure our scale-up procedures meet the required standards. This involves submitting comprehensive documentation and potentially responding to inquiries from regulatory bodies.

Q 14. How do you ensure the reproducibility of results during scale-up?

Reproducibility is crucial for successful bioreactor scale-up. We achieve this through meticulous control of all process parameters, starting with the raw materials. This includes using standardized procedures for media preparation, inoculum development, and reactor operation. Calibration and maintenance of all instruments are rigorously performed according to defined schedules. Detailed Standard Operating Procedures (SOPs) are developed and strictly followed to ensure consistency across different batches and scales. We also employ statistical process control (SPC) techniques to monitor and track process parameters over time, allowing early detection of any deviations from the target range. Further, we implement robust data management systems to track all aspects of the process, ensuring traceability and providing valuable information for continuous improvement. A well-defined quality management system is the bedrock of maintaining reproducibility.

Q 15. Explain your experience with designing experiments for bioreactor scale-up.

Designing experiments for bioreactor scale-up is a critical process requiring a structured approach. It’s not simply about increasing the volume; it’s about maintaining consistent product quality and yield across different scales. My approach involves a combination of statistical experimental design and a deep understanding of the biological system. I typically begin by defining the critical process parameters (CPPs) – those factors that significantly impact the final product. These could include factors like temperature, pH, dissolved oxygen, agitation speed, and nutrient feed rates.

Then, I employ experimental designs like Design of Experiments (DOE), specifically fractional factorial designs or central composite designs, to efficiently investigate the impact of multiple CPPs simultaneously. This allows me to identify the most influential factors and their optimal ranges, minimizing the number of experiments needed. For example, in scaling up a mammalian cell culture, I might use a 2k-p fractional factorial design to investigate the effects of temperature, pH, and dissolved oxygen concentration. Following this initial screening, I would employ a response surface methodology (RSM) to optimize the identified critical factors, building a predictive model to guide further scale-up.

Finally, I meticulously document all experimental conditions and results, ensuring traceability and reproducibility across different scales. This documentation also allows for robust data analysis and interpretation later.

Career Expert Tips:

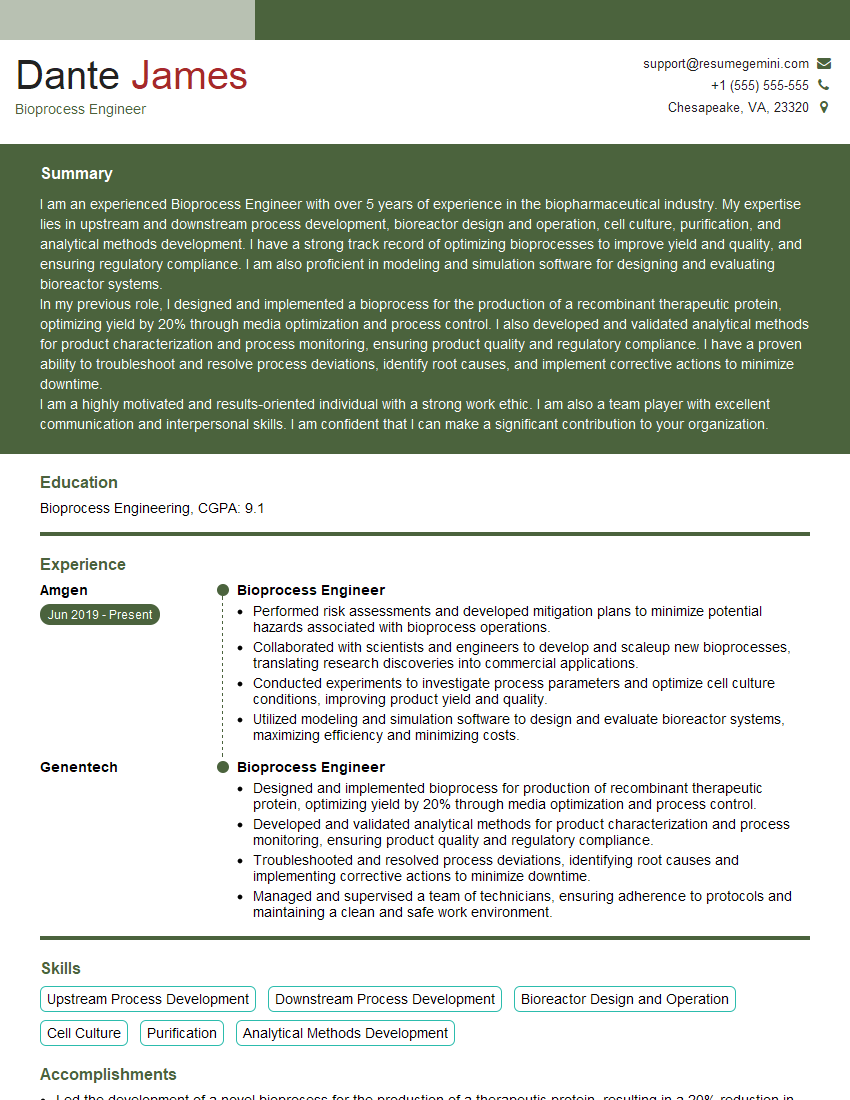

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected deviations during bioreactor scale-up?

Unexpected deviations during bioreactor scale-up are inevitable. My approach to handling these deviations prioritizes quick identification of the root cause, followed by implementation of corrective actions and preventative measures. I begin by systematically reviewing all process parameters and monitoring data, looking for any anomalies. This includes visual inspection of the bioreactor, cell viability checks, and analysis of metabolites. Sophisticated monitoring systems with automated alarms are vital for immediate alerts.

For instance, if I notice a sudden drop in dissolved oxygen (DO) during scale-up, I would first check the aeration and agitation rates. If those are within the expected range, I’d investigate potential problems like foam build-up or a decrease in cell viability. Data logging helps enormously; the deviation could be a trend suggesting a problem, or a sudden shift indicating a fault in the system itself. Depending on the situation, corrective actions might involve adjusting parameters (e.g., increasing aeration), implementing a corrective feed strategy, or even temporarily halting the process to address the issue.

After resolving the immediate problem, a thorough root cause analysis (RCA) is conducted to prevent similar deviations in future runs. This RCA often involves collaboration with other engineers and scientists.

Q 17. Describe your experience with data analysis and interpretation in bioreactor scale-up.

Data analysis and interpretation are crucial for successful bioreactor scale-up. I have extensive experience using various statistical software packages such as JMP, Minitab, and R to analyze data collected during bioreactor runs. This data often includes time-series data on critical process parameters (CPPs) like pH, temperature, DO, nutrient concentrations, and cell density. It also includes product quality attributes such as protein titer, purity, and glycosylation profile. My analysis goes beyond simple descriptive statistics.

I use advanced techniques like regression analysis to develop predictive models that link CPPs to product quality. For example, I might use multiple linear regression to determine the relationship between temperature, pH, and agitation rate on the final product yield. Principal component analysis (PCA) is particularly useful for visualizing high-dimensional data and identifying trends. This is crucial for understanding the interactions between different parameters and for identifying potential process bottlenecks.

Finally, rigorous data interpretation is vital. The key is to avoid overfitting the model and to ensure that conclusions drawn from the analysis are relevant and applicable to the larger scale. Visualizations like graphs and charts are vital for effective communication and presentation of findings.

Q 18. Explain your understanding of critical quality attributes (CQAs) in bioreactor processes.

Critical Quality Attributes (CQAs) are the physical, chemical, biological, or microbiological properties or characteristics that should be within an appropriate limit, range, or distribution to ensure the desired product quality. In bioreactor processes, CQAs can vary depending on the product. For a therapeutic protein, CQAs might include things like protein concentration, purity (absence of aggregates or degradation products), post-translational modifications (e.g., glycosylation), and the presence of host cell proteins (HCPs). For a microbial fermentation producing a metabolite, the CQAs may be related to the metabolite concentration, its purity, and the absence of undesirable byproducts.

Understanding and controlling CQAs is paramount for ensuring the safety and efficacy of the final product. Throughout the scale-up process, meticulous monitoring and control of parameters impacting CQAs are crucial. This often involves implementing real-time monitoring systems and appropriate analytical methods such as HPLC, mass spectrometry, and various immunoassays.

Deviations from established CQA ranges often trigger investigations and necessitate corrective actions, emphasizing the importance of robust quality control measures throughout the scale-up process.

Q 19. How do you optimize bioreactor parameters for maximum yield and productivity?

Optimizing bioreactor parameters for maximum yield and productivity is a multi-faceted challenge. It requires a systematic approach that combines careful experimental design, data analysis, and process understanding. My approach typically involves a combination of techniques:

- Feed Optimization: Designing feeding strategies that deliver nutrients at optimal rates throughout the culture period is essential. This often involves employing fed-batch or perfusion strategies to avoid nutrient limitations and maintain high cell densities.

- Environmental Control: Precise control of parameters like temperature, pH, and dissolved oxygen is crucial. Optimal ranges for these parameters can vary significantly depending on the cell line and product. For instance, maintaining optimal dissolved oxygen (DO) is key to avoid cellular stress and maintain high metabolic activity. Continuous monitoring and automated control systems are essential here.

- Agitation and Aeration: Optimization of agitation and aeration to ensure uniform mixing and adequate oxygen transfer throughout the bioreactor is vital, especially in large-scale bioreactors.

- Process Modeling: Building mathematical models to describe the bioprocess can help predict optimal operating conditions. These models often incorporate mechanistic equations and empirical relationships derived from experimental data.

By systematically optimizing these parameters, we can enhance cellular growth, increase product formation, and improve overall bioreactor productivity. This iterative optimization process usually involves several experimental runs and careful data analysis.

Q 20. Discuss the importance of media optimization during bioreactor scale-up.

Media optimization is a critical aspect of bioreactor scale-up. The growth medium provides the essential nutrients for cell growth and product formation. However, the optimal composition of the medium can vary considerably depending on the cell line and the desired product. Simply scaling up the recipe from small-scale cultures can lead to suboptimal results. Inconsistent medium quality can significantly impact yield and product quality across different scales.

During scale-up, I typically focus on several key aspects of media optimization:

- Nutrient Composition: Careful selection of carbon sources, nitrogen sources, vitamins, and trace elements is crucial. The requirements for these nutrients often change as the cell culture progresses, so designing a tailored feed strategy is frequently necessary.

- Osmolarity: Maintaining optimal osmolarity is crucial for cell health and viability, particularly during scale-up where the effects of changes in osmolarity can be amplified.

- pH Control: Choosing buffers that maintain pH within the optimal range for the cell line is essential. The buffering capacity of the medium can change with scale, requiring adjustments in the buffer concentration.

- Cost-Effectiveness: While optimizing for performance, it’s important to evaluate the cost-effectiveness of different media formulations.

I often employ statistical experimental designs, such as Design of Experiments (DOE), to efficiently optimize media components, reducing the number of experiments required. The optimized medium must be thoroughly tested at different scales to ensure consistent performance across different bioreactors.

Q 21. What are your experiences with different types of cell lines and their specific scale-up requirements?

My experience encompasses various cell lines, including microbial cells (bacteria, yeast), insect cells, and mammalian cells. Each cell line has unique scale-up requirements, necessitating a tailored approach.

For example, scaling up E. coli fermentations for the production of recombinant proteins usually focuses on maintaining optimal oxygen transfer and controlling temperature to avoid overheating. In contrast, mammalian cell cultures are significantly more sensitive to shear stress and require careful control of agitation and aeration to prevent cell damage. Insect cell cultures often require specific media formulations and temperature conditions.

Furthermore, different cell lines have different growth characteristics and metabolic requirements. Some cell lines might be more sensitive to nutrient limitations, while others might be more susceptible to environmental stress. This requires careful consideration of factors such as media formulation, feeding strategies, and environmental control parameters.

In each case, thorough understanding of the cell line’s specific requirements and the development of tailored strategies are crucial for successful and cost-effective scale-up. This often involves rigorous characterization of the cell line, optimization of culture parameters, and careful monitoring of critical quality attributes throughout the scale-up process.

Q 22. Explain your understanding of single-use bioreactors and their advantages/disadvantages for scale-up.

Single-use bioreactors (SUBs) are disposable bioreactors made from materials like films and bags, eliminating the need for extensive cleaning and sterilization between batches. This contrasts with traditional stainless steel bioreactors that require intensive cleaning validation (CIP) and sterilization (SIP) processes.

Advantages for Scale-up:

- Reduced cleaning and sterilization costs and time: Eliminates the need for CIP/SIP, accelerating turnaround times and minimizing operational costs.

- Reduced risk of contamination: The disposable nature significantly reduces the risk of cross-contamination between batches, crucial for sensitive products.

- Increased flexibility and scalability: SUBs are readily available in various sizes, making scale-up and process optimization more straightforward. Moving from a 1L benchtop scale to a 1000L production scale is significantly simplified.

- Suitable for smaller batches and clinical trials: Economically viable for smaller scale productions where the cost of cleaning a traditional bioreactor would be disproportionately high.

Disadvantages for Scale-up:

- Higher upfront material costs: The cost of disposable bags can be substantial, particularly for larger scales. This needs to be carefully factored into the cost-benefit analysis.

- Material compatibility: Choosing the right material is crucial for cell growth and product integrity. Certain materials may leach substances that negatively impact cell culture or product quality.

- Waste disposal: Proper disposal of single-use components is essential for environmental compliance and requires a robust waste management plan.

- Limited process monitoring capabilities: In some cases, certain sensors and in-situ monitoring techniques may be less readily adaptable to SUBs compared to traditional bioreactors.

For example, in a recent project scaling up a mammalian cell culture, we switched from stainless steel to a single-use system. Although initial material costs increased, the savings in labor, time, and cleaning validation more than offset the added expense, improving our overall timeline and product cost.

Q 23. How do you assess the economic feasibility of a scaled-up bioreactor process?

Assessing the economic feasibility of a scaled-up bioreactor process requires a detailed cost-benefit analysis. This involves comparing the projected costs of the scaled-up operation with the expected revenue generated from increased production.

Key Factors to Consider:

- Capital Expenditures (CAPEX): Costs associated with purchasing or leasing larger bioreactors, auxiliary equipment (e.g., pumps, sensors, control systems), and facility modifications.

- Operating Expenditures (OPEX): Ongoing costs including media, utilities (electricity, water, steam), labor, waste disposal, maintenance, and consumables like single-use components.

- Production Capacity and Yield: Evaluating the increase in production volume and yield achieved through scale-up. Improved yield can significantly impact profitability.

- Product Price and Market Demand: Analyzing the market price for the biopharmaceutical product and the expected demand at the larger production scale.

- Risk Assessment: Considering potential risks such as process failures, regulatory delays, and market fluctuations.

Methods for Analysis:

- Discounted Cash Flow (DCF) analysis: This technique accounts for the time value of money, providing a more accurate evaluation of long-term profitability.

- Payback period calculations: Determining how long it takes for the initial investment to be recouped.

- Return on Investment (ROI) analysis: Measuring the profitability of the investment relative to its cost.

For instance, a thorough economic model would incorporate detailed cost estimates for each component, using historical data and industry benchmarks for accurate forecasting. Sensitivity analysis is crucial to understand the impact of variable factors like product price fluctuations or unexpected downtime.

Q 24. Describe your experience with troubleshooting bioreactor scale-up problems.

Troubleshooting bioreactor scale-up problems requires a systematic approach, combining process understanding, data analysis, and experimental design. The challenges often arise from differences in mixing, oxygen transfer, heat transfer, and shear stress as the scale changes.

Common Problems and Solutions:

- Lower cell viability at larger scale: This could be due to inadequate mixing leading to nutrient limitations or the accumulation of toxic byproducts in certain regions. Solution: Optimize impeller design and speed, investigate alternative mixing strategies, implement better dissolved oxygen control.

- Reduced product yield at larger scale: This may stem from issues with oxygen transfer, limiting substrate supply, or increased shear stress damaging cells. Solution: Improve aeration and agitation strategies, employ dissolved oxygen control systems, adjust cell seeding density or media composition.

- Inconsistent product quality at larger scale: This might be caused by variations in temperature, pH, or dissolved oxygen across the bioreactor. Solution: Enhance temperature and pH control systems, improve online monitoring and control strategies, implement better process automation.

- Scale-dependent metabolic shifts: Cells might exhibit altered metabolic behavior at larger scales due to changed environmental factors. Solution: Adapt cell lines or media formulation to optimize performance at larger scales, employ fed-batch strategies to control nutrient supply.

I once encountered a scale-up issue where we observed significant cell aggregation at larger scales, leading to reduced viability. After careful investigation, we found the shear stress at the impeller was too high. By modifying impeller design and reducing agitation speed, we resolved the aggregation problem, improving cell viability and product yield.

Q 25. What software and tools do you have experience with for modeling and simulation in bioreactor scale-up?

Modeling and simulation are essential for successful bioreactor scale-up. They enable the prediction of process behavior at larger scales, minimizing the need for extensive and costly experimentation. I’m proficient in several software tools, including:

- Aspen Plus: A powerful process simulator widely used in chemical engineering and can be adapted to model bioprocesses.

- COMSOL Multiphysics: A finite element analysis software capable of simulating fluid dynamics, heat transfer, and mass transfer within the bioreactor.

- MATLAB with Simulink: A versatile platform for developing custom models and simulations, often used to incorporate biological kinetics.

- Specialized Bioprocess Simulation Software: Several commercial software packages are specifically designed for bioprocess simulation, incorporating advanced models for cell growth, metabolism, and product formation.

In a recent project, we used COMSOL to simulate the fluid dynamics in our bioreactor, optimizing impeller design to achieve uniform mixing and oxygen transfer across the vessel. The simulation data provided critical insights that informed our scale-up strategy, leading to a more efficient and successful transition.

Example MATLAB code snippet (Simplified):

% Define parametersk = 0.1; % growth rateX0 = 1; % initial cell densityt = linspace(0, 100); % time vector% Solve ODEdXdt = @ (t,X) k*X;[t,X] = ode45(dXdt, t, X0);% Plot resultsplot(t, X);

Q 26. Discuss your experience with different types of sensors and their applications in bioreactor scale-up.

Various sensors are crucial for monitoring and controlling parameters within a bioreactor during scale-up, ensuring optimal cell growth and product formation.

Types of Sensors and Applications:

- Dissolved Oxygen (DO) sensors: Monitor the oxygen concentration in the culture media, crucial for aerobic cell cultures. Critical for automated control of aeration and agitation.

- pH sensors: Measure the acidity or alkalinity of the culture medium, influencing cell growth and product quality. Maintaining optimal pH is critical for cell viability.

- Temperature sensors: Monitor and regulate the temperature of the bioreactor, essential for maintaining optimal growth conditions for cells and preventing product degradation.

- Optical sensors: Employ various optical techniques (e.g., turbidity, fluorescence) to monitor cell density, viability, or product concentration. Provides real-time information about culture progress.

- Flow sensors: Measure the flow rate of gases and liquids in and out of the bioreactor, essential for controlling aeration, feeding strategies, and harvest processes.

- Mass spectrometers: Used for real-time monitoring and analysis of volatile metabolites, offering deeper insights into cell metabolism.

The selection of sensors is dictated by the specific process and product. For example, while optical sensors provide a non-invasive way to monitor cell density, other methods like cell counting might be needed for absolute quantification. During scale-up, it is crucial to ensure the sensor signals are accurately scaled to ensure proper control at larger reactor volumes.

Q 27. Explain your understanding of Design of Experiments (DOE) in the context of bioreactor scale-up.

Design of Experiments (DOE) is a statistical approach for efficiently planning and analyzing experiments, minimizing the number of runs while maximizing the information obtained. In bioreactor scale-up, DOE is crucial for identifying the optimal operating parameters (e.g., agitation, aeration, temperature) across different scales.

Applying DOE in Bioreactor Scale-up:

- Factorial designs: Investigating the effect of multiple factors and their interactions on cell growth and product formation. This helps determine which factors have the largest impact.

- Response surface methodology (RSM): Developing empirical models to understand the relationship between the factors and the responses (e.g., cell density, product yield). This aids in optimization.

- Central composite design (CCD): A type of RSM that allows for the estimation of quadratic effects and the optimal setting of parameters.

Using DOE ensures the scale-up is systematic and data-driven, rather than relying on a trial-and-error approach. For example, in a recent scale-up, we used a factorial design to investigate the effects of agitation speed, aeration rate, and temperature on cell growth. This allowed us to identify the optimal parameter combinations at different scales efficiently.

Q 28. How do you ensure compliance with GMP regulations during bioreactor scale-up?

Ensuring compliance with Good Manufacturing Practices (GMP) during bioreactor scale-up is paramount for producing safe and effective biopharmaceuticals. This requires adherence to strict regulations and guidelines throughout the process.

Key GMP Aspects for Bioreactor Scale-up:

- Documentation: Maintaining meticulous records of all aspects of the scale-up process, including experimental designs, data acquisition, and deviations.

- Validation: Ensuring that equipment, processes, and methods are validated to meet the required specifications and consistently produce the desired results.

- Quality Control (QC): Implementing rigorous QC measures at each stage of the process, including raw materials, intermediates, and final products, to ensure quality.

- Calibration and Maintenance: Regularly calibrating and maintaining all equipment, including bioreactors, sensors, and control systems, to ensure accuracy and reliability.

- Personnel Training: Ensuring that all personnel involved in the scale-up process are adequately trained and understand GMP principles.

- Traceability: Establishing a robust system for tracing materials and processes, ensuring complete accountability.

- Change Control: Implementing procedures for managing and documenting changes to the process or equipment during scale-up.

We always follow strict SOPs (Standard Operating Procedures) and adhere to regulatory requirements like those from the FDA. Regular audits and inspections are critical for maintaining GMP compliance and ensuring product safety and quality throughout the entire bioreactor scale-up and manufacturing process.

Key Topics to Learn for Bioreactor Scale-Up Interview

- Geometric Similarity and its Limitations: Understand the principles of scaling up bioreactors while considering limitations imposed by changes in surface area to volume ratio and mass transfer limitations.

- Mass Transfer Considerations: Analyze oxygen transfer rate (OTR), kLa values, and their impact on cell growth and productivity at different scales. Discuss strategies for improving oxygen transfer in larger bioreactors.

- Power Input and Mixing: Explain the relationship between impeller design, power input, and mixing efficiency. Discuss the challenges of maintaining homogenous mixing in larger bioreactors and strategies to address them.

- Heat Transfer and Temperature Control: Understand the importance of maintaining optimal temperature during scale-up. Discuss different heat transfer mechanisms and strategies for efficient temperature control in large-scale bioreactors.

- Scale-Down Models: Explore the use of smaller-scale bioreactors to predict and optimize performance in larger systems. Understand the challenges and limitations associated with scale-down modeling.

- Process Validation and Scale-Up Strategies: Discuss different approaches to bioreactor scale-up, including linear, geometric, and empirical methods. Understand the importance of process validation and quality control during scale-up.

- Troubleshooting and Problem-Solving: Be prepared to discuss common challenges encountered during bioreactor scale-up, such as foaming, contamination, and process instability, and how to troubleshoot these issues.

- Economic Considerations: Understand the economic implications of different scale-up strategies, considering factors such as capital costs, operating costs, and production yield.

Next Steps

Mastering bioreactor scale-up is crucial for advancing your career in bioprocess engineering, opening doors to leadership roles and exciting research opportunities. A well-crafted resume is your first step to showcasing your expertise. Creating an ATS-friendly resume is essential to ensure your application gets noticed. To significantly enhance your resume and increase your chances of landing your dream job, leverage the power of ResumeGemini. ResumeGemini offers a streamlined and user-friendly platform to build professional, impactful resumes. We provide examples of resumes tailored specifically to Bioreactor Scale-Up to help guide you. Take the next step towards a successful career – build your winning resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good